LENZING™ has established the use of its Lyocell bers in various lter media ranging from automotive and industrial lter papers to heavyweight depth lter media for liquid and pharmaceutical ltration.

LENZING™ has established the use of its Lyocell bers in various lter media ranging from automotive and industrial lter papers to heavyweight depth lter media for liquid and pharmaceutical ltration.

you are invited to explore more at booth 2040

Caryn Smith

Chief Content Officer & Publisher, INDA Media csmith@inda.org

Adrian Wilson International Correspondent adawilson@gmail.com +44 7897.913134

Dr. Iyad Al-Attar Global Correspondent, Technology & Innovation, Visiting Academic Fellow Cranfield University i@driyadalattar.com

Dr. Tanya Shirman

Co-founder & VP of Materials, Metalmark Innovations, PBC tanya@metalmark.xyz

Sissi Liu

Co-founder and CEO, Metalmark Innovations, PBC sissi@metalmark.xyz

International Filtration News is actively seeking viewpoints from qualified industry professionals and those allied to the filtration industry for insightful columns on topics such as trends, innovation, equipment, processes, etc.

Email Caryn Smith, csmith@inda.org with column ideas.

CSMITH@INDA.ORG +1 239.225.6137

“Individually we are one drop, but together we are an ocean.” — Ryunosuke Satoro

The day-to-day publishing of an issue of International Filtration News takes the hard work and effort of a team of contributors of varying expertise. We always aim to bring you the best trending ‘news’ through inspirational, educational, and informational content. From editors, writers, graphic designers, proofreaders and production coordinators, and more, we work tirelessly with the hope that you – the reader, and active participant in this process – will dedicate some of your valuable time to reading IFN

To complete our team, I must acknowledge our Most Valuable Players – our Loyal Advertisers – without whom we would not be successful.

Recently, I was reminded by a longstanding and valuable advertiser that sometimes, in all our best efforts, we fall short. We make mistakes. I am glad that they brought the error to my attention because it matters

that we get the facts right! We cannot be the best at what we do without the faithful and loyal advertisers who support our endeavors. We sincerely value you. As readers, I hope that you take note of the companies that support your industry news in IFN and other publications! In this issue, you will find a list on page 56.

CORRECTION: “Filtration on Display” Issue 1, 2025, page 46 incorrectly listed the machine on display in the A2Z Filtration Specialists stand at FILTECH. The machine on display was the A2Z Intelligent Blade Pleater with hotmelt Pitching system (pictured above). We truly regret the error. Thank you to all our advertisers; we value your support! We will continue to work hard to earn your confidence and trust in IFN.

Caryn Smith Chief Content Officer & Publisher, INDA Media, IFN

R. Vijayakumar, Ph.D., Chair

AERFIL

Tel: +1 315-506-6883

Email: vijay@aerfil.com

Tom Justice, CAFS, NCT

ZENE, LLC Filtration

Tel: +1 757-378-3857

Email: justfilter@yahoo.com

James J. Joseph

Joseph Marketing

Tel/Fax: +1 757-565-1549

Email: josephmarketing120@gmail.com

Wenping Li, Ph.D.

Agriltech Research Company

Tel: +1 337-421-6345

Email: wenpingl@agrilectric.com

Rishit R. Merchant

Parker Hannifin

Tel: +1 805-604-3519

Email:rishit.merchant@parker.com

Thad Ptak, Ph.D.

TJ Ptak & Associates

Tel: +1 414-514-8937

Email: thadptak@hotmail.com

If you would like to utilize your expertise to help shape the content in the IFN , consider applying for the IFN Editorial Advisory Board. We welcome participation through input on trends and innovations, new story ideas and overall thought leadership. This is a collaborative board that meets quarterly to discuss the state of the industry. Send an email to Caryn Smith at csmith@inda.org for consideration.

In an era where air quality and public health have taken center stage, the need for advanced filtration solutions has never been more critical. While traditional air filtration systems can trap airborne microbes, they often fail at eliminating these harmful pathogens, leaving the potential for self-contamination and further spread. Applied Nanoscience Inc. (ANI) has developed a breakthrough solution to this long-standing problem – NanoFense™, an innovative antimicrobial filter media coating designed to eradicate, rather than simply capture, harmful airborne pathogens.

The deficiencies of conventional air filtration systems became apparent through extensive industry research and real-world observations. At the heart of NanoFense is a deceptively simple idea: Why stop at capturing microbes when you can eradicate them entirely? Protected by U.S. Patent No. 7,807,199, this antimicrobial filter media ‘coating’ transforms any existing filtration system into a proactive defender. Applied as a suspension material, NanoFense uniformly coats filter media with a formulation that acts as a “destructive adsorbent” – a scientific mouthful that translates to a microscopic killing machine. Think of it as a shield that doesn’t just block the enemy – it is obliterated. NanoFense is a proprietary antimicrobial suspension that can be seamlessly applied to virtually any filtration media, transforming conventional air filters into active defense mechanisms against viruses and bacteria. Unlike traditional filters that may become a breeding ground for pathogens, NanoFense ensures that collected microbes are neutralized on contact, preventing bacterial colonization and viral persistence.

Protected under U.S. Patent No. 7,807,199, this technology is poised to enhance air filtration products across multiple industries, including disposable facemasks, room air purifiers, and airline cabin air systems. With verified scalability in production, ANI is positioning NanoFense as a vital enhancement for companies seeking to elevate their air filtration performance.

The research and development of NanoFense has spanned over a decade, from initial research and formulation refinement to realworld application trials. ANI methodically evolved the validation of its formulation from suspension time-kill studies to aerosolized pathogen testing on aged, coated filter media samples. This ensured that the solution remained effective over time and in real-use conditions.

Comprehensive independent laboratory testing was exclusively conducted at Microbiotest, Inc., a BSL-3 level facility in Sterling, Virginia. This division of Microbac Laboratories, Inc. specializes in microbiology and virology, offering antimicrobial efficacy testing and viral clearance services globally. The studies provided conclusive validation that NanoFense not only kills but eradicates a broad spectrum of viruses and bacteria.

• Avian Influenza virus (H9N2)

• Human Influenza A virus

• Haemophilus Influenzae (H-flu)

• Rhinovirus

• Swine Influenza virus (H1N1)

• Staphylococcus aureus (including MRSA strain)

• Streptococcus pneumoniae

While NanoFense has wide-ranging applications, initial interest has been strongest in the disposable facemask and air purifier segments, where consumer and regulatory demands for enhanced filtration performance are at an all-time high. Additionally, industries such as aviation, healthcare, and HVAC manufacturers are recognizing the potential for NanoFense to add value to their existing filtration systems. These sectors offer the most viable paths for large-scale production and integration due to the critical need for improved air quality in enclosed spaces.

As air filtration companies face increasing demands for more effective protective solutions, ANI is positioned as a key partner in advancing public safety. “The ever-growing demand for air filtration companies to provide genuinely protective solutions necessitates ANI’s position as an attractive partner for the introduction of pragmatic value-added products. Public safety is non-negotiable, and air quality is a frontline defense,” says Thomas Allen, President and CEO of ANI.

Bringing NanoFense to market on a global scale requires collaboration with industry leaders who possess extensive distribution capabilities. ANI envisions a future where NanoFenseenhanced filtration becomes the new standard in air quality protection, safeguarding public health in homes, workplaces, transportation systems, and medical environments worldwide. Contact Applied Nanoscience at jointventure@appliednanoscience.com. www.appliednanoscience.com

t Dr. Jordan Poler’s PFAS removal consists of a resin jar reactor filled with natural zeolite that, when combined with other materials, removes PFAS from water.

Poler Research Group

Professor Jordan Poler at the University of North Carolina at Charlotte (UNCC) has been working for eight years to develop new technology to help strip PFAS or forever chemicals and other contaminants from drinking water. PFAS have been linked to health problems – including an increased risk for cancer and can be found in non-stick cookware that contains Teflon, firefighting foam and some makeup.

“They bioaccumulate in your body until they reach a toxic level,” said Poler. “Then you have health concerns including cancer, fetal early childbirth and things like that.”

Poler’s technology could help make those “forever chemicals” disappear. Last year, the chemistry professor received one of eight inaugural grants from the NC Innovation Grant Project. The grant will help Poler scale up his research to partner with a manufacturer that could sell it to the public.

His research involves a process called ion exchange, which works by trading an atom or group of atoms (ions) with ones that do not degrade the quality of drinking water. The chemistry developed in Poler’s lab is all water-based. Poler showed how his technology filters those harmful chemicals out by pouring colored water to represent the PFAS into a tube with the zeolite. After gently shaking for 30 seconds the color/chemicals disappeared.

“As the water’s going through, the molecules are seeing these brushes and they just grab onto them, the brushes grab onto the molecules right away,” he explained in interviews.

Traditional filters like those in refrigerators or under the sink remove PFAS, but Poler says the chemicals are not really gone. “What you’ve done is you’ve concentrated all the impurities onto that filter and then you put it into the landfill and all those impurities leach back out.”

Poler’s research shows his method not only removes the PFAS but it can also be regenerated.

Poler hopes with the grant investment they will be able to sell the filter materials to the public within a year. Since the materials can be regenerated, customers would be able to send in their filter to be cleaned and then replaced without causing any harm to the environment. pages.charlotte.edu/poler-research/research

Bacterial contamination remains a critical concern across industries, particularly in hospitals, where infections pose significant risks to patient safety. LAM-X initially developed a safer, more effective, and environmentally friendly solution for patients. The result was the LAM-X Solution – an innovative antimicrobial nanomembrane that was successfully tested on hospitalized patients reducing the infections rates. Since, the company has successfully adapted that nanomembrane to deal with bacterial contamination in other sectors such as water and air filtration. Existing filtration solutions in these fields often compromise environmental safety, damage equipment, or pose risks to consumers. The LAM-X Solution addresses these challenges head-on.

At the core of LAM-X’s breakthrough is a patented three-step process that delivers superior antimicrobial performance:

1. Trap: Optimized fiber sizing creates a dense nanofiber network capable of efficiently trapping microbes.

2. Prime: Embedded organic photosensitizers, activated by safe blue light (avoiding harmful UV exposure), prime the fibers for antimicrobial action.

3. Kill: Activated nanofibers interact with surrounding oxygen to eliminate microbes in their immediate vicinity, achieving 99.999% bacterial reduction while preventing biofilm formation.

Available in both biodegradable and synthetic versions, LAM-X’s nanofibers meet diverse industry requirements without compromising on environmental responsibility.

LAM-X provide solutions tailored to the evolving demands of the filtration market and their approach centers on three key pillars:

• Innovation

• Flexibility

• Environmental Responsibility www.lamxnano.com

LG

LG Electronics has introduced the LG PuriCare™ AeroHit, an advanced air care solution designed to seamlessly integrate into any living space while delivering superb indoor air quality. Boasting advanced purification capabilities, convenient features and a modern, minimalist aesthetic, the AeroHit brings both comfort and style at home.

The LG PuriCare AeroHit delivers fresher, safer air at home with its Aero Series H Filter –a multi-layer “360-degress” filtration system that effectively reduces dust particles, odors, viruses and allergens while also absorbing various airborne pollutants. In addition, its Particulate Matter (PM) 1.0 sensor detects ultrafine dust as small as 0.01 micrometers, enabling real-time air quality monitoring. The AeroHit automatically adjusts its purification performance to maintain optimal indoor conditions.

Setting itself apart from conventional air purifiers, the AeroHit features an ultra-slim, space-saving design that would fit effortlessly into even the smallest rooms. Its muted matte finish complements a variety of interior styles, while the integrated LED display provides intuitive control and air-quality updates. Along with the standard model, LG is launching the PuriCare AeroHit Pet, designed specifically for pet-friendly households. www.lgnewsroom.com

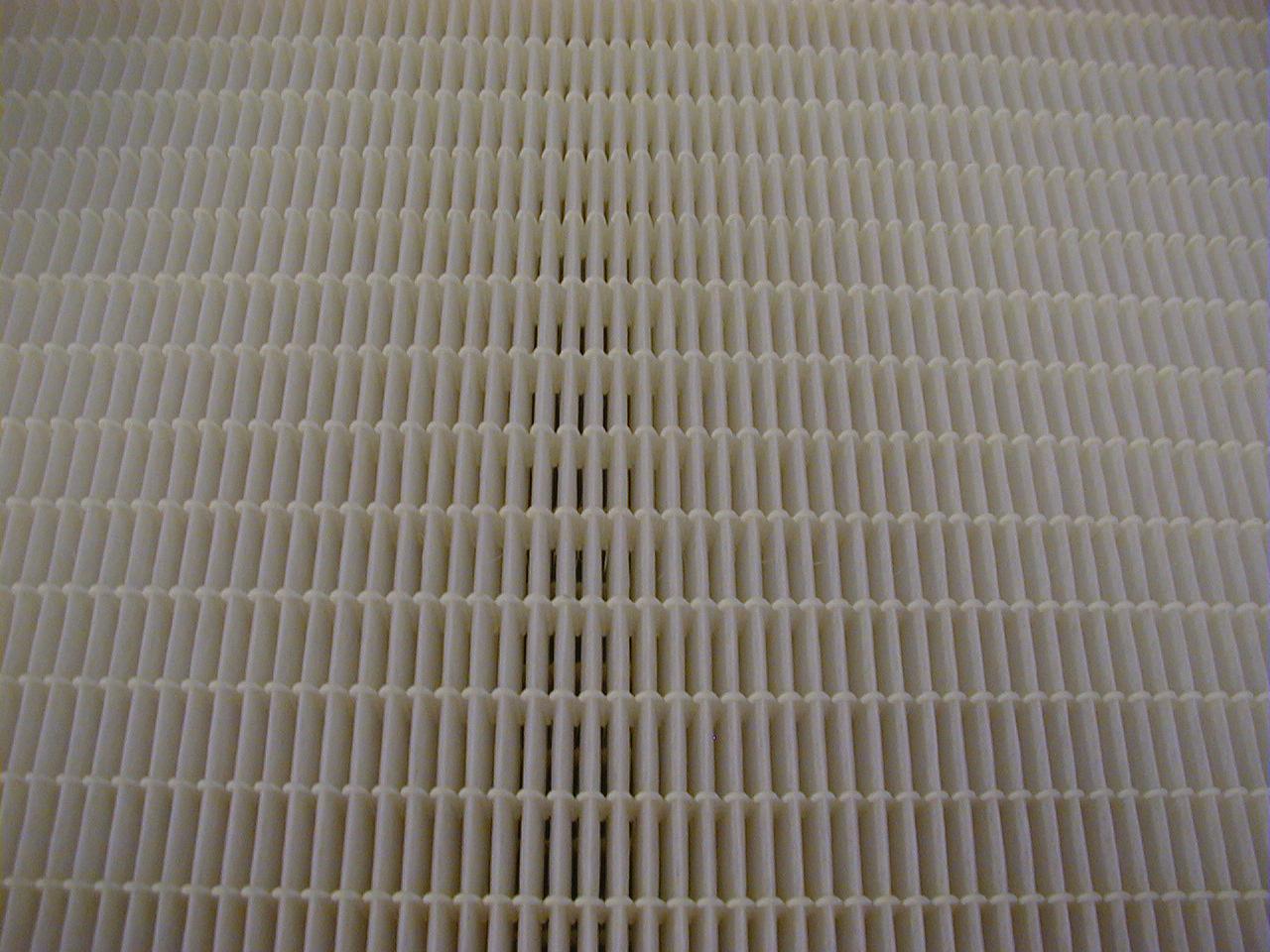

Camfil, a global leader in clean air solutions, announced the launch of the Opakfil ES+, the latest innovation in compact V-Bank air filters. Designed to meet the growing demand for energy-efficient and sustainable HVAC solutions, the Opakfil ES+ offers superior performance, extended operational life, and significant environmental benefits.

Building upon the success of the original Opakfil ES, the Opakfil ES+ features an increased filter depth, resulting in a larger amount of filtration media. This enhancement leads to a higher dust holding capacity, allowing the filter to last up to 50% longer in HVAC systems. The extended lifespan not only reduces maintenance frequency but also minimizes waste and labor costs, contributing to a lower total cost of ownership.

Energy efficiency is at the core of the Opakfil ES+ design. The filter achieves a 62% reduction in energy consumption compared to the industry average and a 24% reduction compared to other A/A+ rated compact filters. This remarkable performance is attributed to its low pressure drop and aerodynamic radial design, which optimize airflow and reduce energy usage.

The Opakfil ES+ is available in ePM1 and ePM2.5 efficiencies, in accordance with ISO 16890 standards, ensuring high indoor air quality across various applications. Its molded frame, constructed from recycled plastic, underscores Camfil’s commitment to sustainable manufacturing practices. www.camfil.com

Great Lakes Filters, a leader in industrial filtration solutions, announced the offering of patented Electrocoagulation (EC) technology that destroys PFAS “forever chemicals” in industrial wastewater and landfill leachate streams immediately and on-site. This groundbreaking technology is the most cost-effective solution to meet strict U.S. EPA and Michigan EGLE discharge limits.

PFAS compounds, notorious for their resistance to degradation, pose a significant environmental and health risk due to their stability and bioaccumulative properties. Michigan currently enforces a 12ppt limit. Compliance with these stringent regulations has previously required expensive and complex treatment methods, including pre-filtration and off-site disposal. Great Lakes Filters’ new EC technology destroys PFAS compounds at their molecular level, eliminating the need for secondary processing and reducing liability by preventing the transportation and disposal of hazardous materials.

Unlike existing PFAS capture technologies such as dissolved air flotation, ion exchange resin (IXR), granular activated carbon (GAC), nanofiltration (NF), and reverse osmosis (RO), which only separate or adsorb PFAS without fully eliminating them, EC technology breaks the fluorine-carbon bond within the PFAS structure, rendering the chemicals harmless. This process also removes both dissolved and suspended solids, kills pathogens and viruses, and consistently meets water standards, all while significantly lowering operational and capital expenses. www.acmemills.com/greatlakesfilters

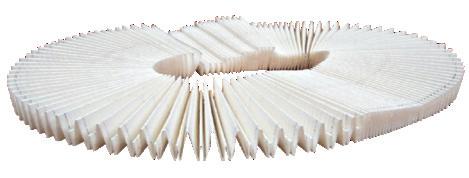

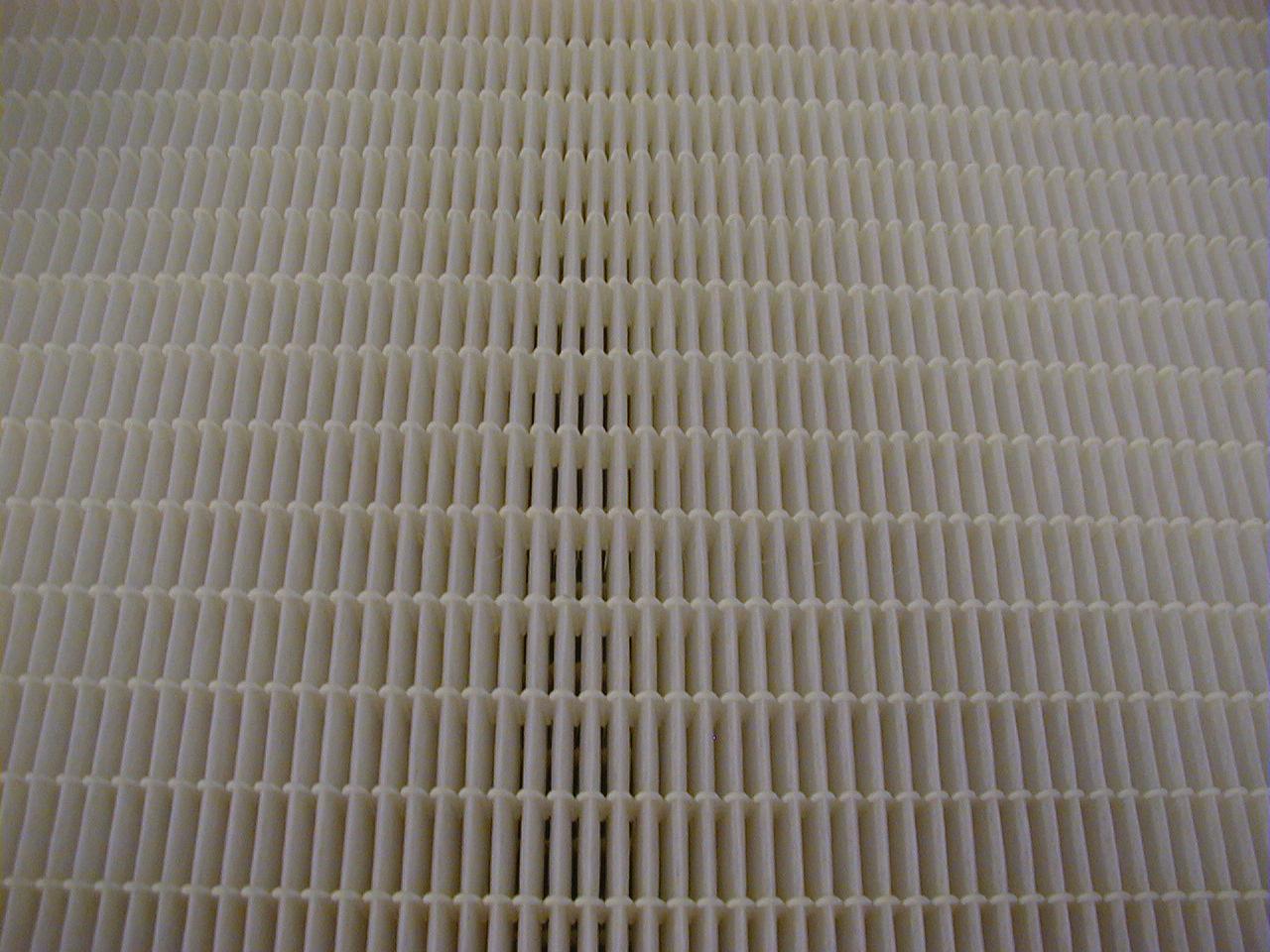

p Separation membrane module structure.

Toray Industries, Inc., announced that it has developed a high-efficiency separation membrane module for biopharmaceutical manufacturing processes. This module delivers more than double the filtration performance of conventional counterparts by reducing clogging. It should also lift biopharmaceutical yields to more than 90% and enhance purification. The company will initially supply prototypes to diverse customers to evaluate in purification processes for producing gene therapy drugs with a view to swift commercialization.

Recent years have seen the pharmaceutical market shift from conventional small-molecule drugs to biopharmaceuticals. Gene therapies and other treatment modalities are also coming to market in what seems to be an ongoing trend. A prime downside is the high manufacturing costs for these biopharmaceuticals, which are driving up medical expenses.

Gene therapy drugs are made with cultured cells. Purification entails using a depth filter to remove cell fragments from the culture medium, after which an ultrafiltration membrane removes impurities like proteins. Depth filter clogging or gene therapy drug adhesion to the ultrafiltration membrane can cause active ingredient losses, leading to higher costs.

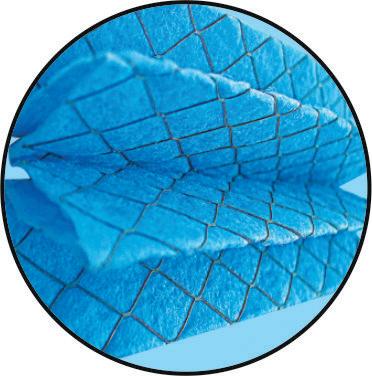

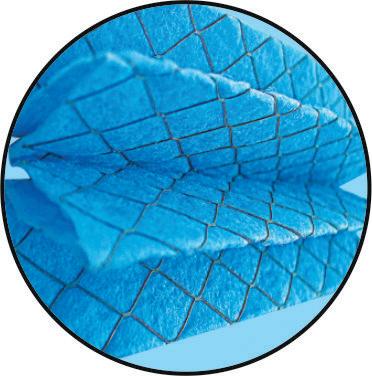

The module comprises a depth filter incorporating multiple types of non-woven fabric and a hollow fiber ultrafiltration membrane. www.toray.com

The Shaw Institute, a nonprofit science research organization, has tested CLEANR’s external microplastic filter for washing machines and certified it to be over 90% efficient at capturing microplastics as small as 50-microns. CLEANR for Washing Machines will be available for purchase in the U.S. later this year.

CLEANR’s technology, VORTX, is unique among microplastic filtering solutions for washing machines. CLEANR’s design was inspired by manta rays and basking sharks whose unique gill structures allow them to glide through the water and feed passively without clogging their gills. Instead of forcing particles against a filtering surface like conventional filters, VORTX creates vortices which suspend and isolate microplastic particles from washing machine wastewater and channel them into the CLEANR Pod, a microplastic capture unit, which ensures proper disposal of the microplastics.

The Shaw Institute tested the effectiveness of CLEANR for Washing Machines by running a mix of tap water and plastic flock fibers (10 microns in diameter and 300 microns in length) through the filter at various concentration levels to simulate real world laundry conditions. The test was repeated three times in January and February and resulted in 90%, 97%, and 98% microplastic fiber removal rates. www.shawinstitute.org

Pall Corporation, a leading provider of filtration, separation and purification solutions, and MTR Carbon Capture (MTR) have entered a collaboration focused on providing innovative solutions for carbon capture to diverse industry verticals dedicated to decarbonization. This partnership aims to promote a highly modular, scalable and costeffective integrated solution leveraging MTR’s pioneering Polaris™ membrane system for carbon capture and Pall’s advanced filtration solutions for flue gas pre-treatment as well as innovative coalescer and filter technologies that safeguard critical assets throughout the carbon capture workflow.

The collaboration will help customers make informed decisions about investments in carbon capture, help accelerate deployment and achieve their net zero ambitions. A key objective of the collaboration is to effectively identify, pilot and drive adoption of decarbonization solutions with customers in emissionintensive industries such as cement production, refineries, steel manufacturing, and waste-to-energy facilities. This initiative will also involve engaging with other industry stakeholders, including Engineering, Procurement and Construction (EPC) firms, equipment suppliers, project developers and regulatory agencies across the carbon capture value chain.

“Filtration systems play a pivotal role in carbon capture by effectively removing contaminants,” said Greg Sears, VP/GM of the Energy+ business unit of Pall. “As part of the flue gas pre-treatment system, and throughout the entire workflow, Pall’s technology ensures that only clean gases pass through the carbon capture system, maximizing membrane lifetime, safeguarding critical carbon capture equipment from contaminants, and optimizing the performance of carbon capture systems.”

The collaboration is well aligned with Pall’s mission to harness the power of science to deliver innovative solutions to customers and MTR Carbon Capture’s mission to deliver highly modular, scalable and costeffective carbon capture solutions. www.pall.com

Compiled by Caryn Smith, IFN Chief Content Officer

International Filtration News Explores Trending Innovation

IFN highlights significant research from universities and institutions around the world. If you are a part of a project you would like to highlight, email csmith@inda.org. Please write “IFN Emerging Research Submission” in your subject line in order to apply. Please send a completed press release and/or summary of the research as you would want it to be printed, a link to the university online story (if applicable), and all high resolution photographs/charts/graphs, short researcher bio(s). All selections could be edited for length.

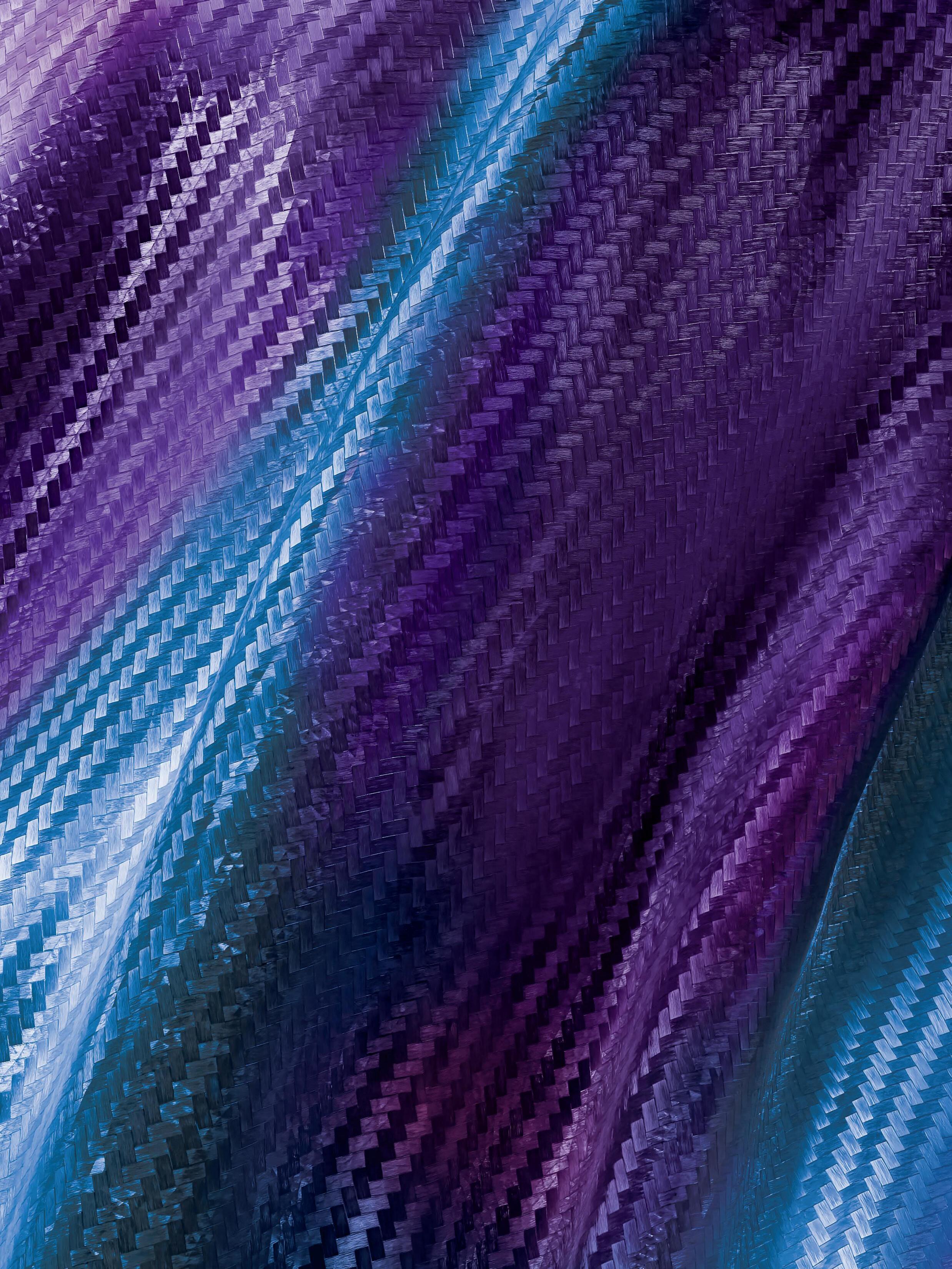

The method can upcycle carbon fibers to restore 90% of the strength of original fibers. By

UYashna Dodrajka

SC researchers have developed a study that promises complete upcycling of high-performance composite materials, according to Travis Williams, a professor of chemistry at Dornsife College of Letters, Arts and Sciences and the leader of the study.

Carbon fibers are expensive, highperformance materials largely used in the construction of aircrafts and automobiles. The substance that keeps airplanes together is made up of eight layers of woven carbon fiber held together with a strong type of epoxy resin. Williams said as an aircraft reaches the end of its life, it will turn into waste because there is currently no technology to separate the carbon fibers from the epoxy.

“Trying to un-thermoset a thermoset, un-epoxy an epoxy, is like trying to unboil an egg,” Williams said. “We started inventing reactions to do that for the different kinds of epoxies and different kinds of thermosets that they use in aviation. It worked in a number of cases … you can get it back, still woven as fabric, and nobody else has been able to do that. So this got people’s attention.”

Williams said 99.1% of the composite materials end up in landfills due to the “expensive” process of recycling. He said 1% of the composite that is recycled is subjected to high heat, which damages

p Carbon fibers are expensive, high-performance materials largely used in the construction of aircrafts and automobiles. USC research shows promise to fully recycle these fibers to restore 90% of the strength of the original fibers. Caryn Smith

the fibers, such as polymer. The study has pioneered a method that transforms polymer, one of the cheapest fibers in the composite space, into high-cost, valuable substances, Williams said.

“Nobody had ever asked that about taking aircraft epoxy apart, so we were the first to report if you do it oxidatively, these are the molecular events that happen,” Williams said. “Now, all sorts of people are making all sorts of creative contributions to this [because] we taught them how to think about it like molecules, not like the material … A lot of molecular people are coming up with great ideas to handle all sorts of composites. It’s really cool to watch.”

Williams said in the study, researchers have focused on breaking down the mechanism behind different chemical

reactions. Despite initially being published in lesser-known journals, according to Williams, the study has quickly gained the attention of many.

“I would argue that our method is superior to other methods out there in the literature today,” said Justin Lim, a doctoral student studying chemistry. “Our group is advantageous because we aim to make our methods sustainable.”

Ding-Yuan Lim, a graduate student studying chemistry, said another factor that sets USC’s approach apart is their effort to incorporate common chemical reagents, which helps in cost reduction, ensures safety and makes large-scale application feasible, while most of the studies out there focus on using super critical conditions like high pressure and high temperatures.

The researcher’s process of upcycling carbon fibers from composite material consumes 10.8 to 36 megajoules of energy per kilogram, while the production of new carbon fibers consumes 198 to 594 megajoules per kilogram, said Madison Fette, a graduate student studying chemistry. Fette said the cost of upcycling the carbon fibers is also only a fifth of producing original fibers.

Williams said the carbon fibers upcycled through this method are lighter, stronger and stiffer than aluminum. As a result, they benefit the aviation industry tremendously. Due to their light weight, aircrafts made from recycled carbon fibers require 20% less fuel which also leads to a significant reduction in CO2 emissions, Williams said.

Lim said the study also ensures that carbon fibers recycled through their process would maintain nearly the same mechanical properties as original fibers and are at least within 90% or higher of carbon fibers’ original strength, which has been tested by USC researchers through single fiber tensile tests.

MIT engineers designed a nanofiltration process that could make aluminum production more efficient while reducing hazardous waste.

By Jennifer Chu | MIT News

than 99 percent of aluminum ions in these solutions.

If scaled up and implemented in existing production facilities, the membrane technology could reduce the amount of wasted aluminum and improve the environmental quality of the waste that plants generate.

U“The thing that’s going to break us are the people who buy these materials philosophically believe that the recycled fiber is inferior,” Williams said. “What’s going to kill us is … the manufacturing community who seem to believe that recycled [fiber] is lower quality.”

Williams said he believes the situation might change as President Donald Trump’s administration shifts national priorities in energy.

“Policy wise, whilst there’s a lot that you can say that’s not real flattering about our current president, I think he might help us as we try to change manufacturing through energy transition, through the transition from traditional metals to composite and modern materials,” Williams said.

© University of Southern California/Daily Trojan. All rights reserved.

Read: https://dailytrojan.com/2025/02/13/ usc-researchers-discover-method-to-fullyrecycle-carbon-fibers/

sed in everything from soda cans and foil wrap to circuit boards and rocket boosters, aluminum is the secondmost-produced metal in the world after steel. By the end of this decade, demand is projected to drive up aluminum production by 40 percent worldwide. This steep rise will magnify aluminum’s environmental impacts, including any pollutants that are released with its manufacturing waste.

MIT engineers have developed a new nanofiltration process to curb the hazardous waste generated from aluminum production. Nanofiltration could potentially be used to process the waste from an aluminum plant and retrieve any aluminum ions that would otherwise have escaped in the effluent stream. The captured aluminum could then be upcycled and added to the bulk of the produced aluminum, increasing yield while simultaneously reducing waste.

The researchers demonstrated the membrane’s performance in lab-scale experiments using a novel membrane to filter various solutions that were similar in content to the waste streams produced by aluminum plants. They found that the membrane selectively captured more

“This membrane technology not only cuts down on hazardous waste but also enables a circular economy for aluminum by reducing the need for new mining,” says John Lienhard, the Abdul Latif Jameel Professor of Water in the Department of Mechanical Engineering, and director of the Abdul Latif Jameel Water and Food Systems Lab (J-WAFS) at MIT. “This offers a promising solution to address environmental concerns while meeting the growing demand for aluminum.”

Trent Lee

Lienhard and his colleagues report their results in a study appearing today in the journal ACS Sustainable Chemistry and Engineering. The study’s co-authors include MIT mechanical engineering undergraduates Trent Lee and Vinn Nguyen, and Zi Hao Foo SM ’21, PhD ’24, who is a postdoc at the University of California at Berkeley.

Lienhard’s group at MIT develops membrane and filtration technologies for desalinating seawater and remediating various sources of wastewater. In looking for new areas to apply their work, the team found an unexplored opportunity in aluminum and, in particular, the wastewater generated from the metal’s production.

As part of aluminum’s production, metal-rich ore, called bauxite, is first mined from open pits, then put through a series of chemical reactions to separate the aluminum from the rest of the mined rock. These reactions ultimately produce aluminum oxide, in a powdery form called alumina. Much of this alumina is then shipped to refineries, where the powder is poured into electrolysis vats

containing a molten mineral called cryolite. When a strong electric current is applied, cryolite breaks alumina’s chemical bonds, separating aluminum and oxygen atoms. The pure aluminum then settles in liquid form to the bottom of the vat, where it can be collected and cast into various forms.

Cryolite electrolyte acts as a solvent, facilitating the separation of alumina during the molten salt electrolysis process. Over time, the cryolite accumulates impurities such as sodium, lithium, and potassium ions – gradually reducing its effectiveness in dissolving alumina. At a certain point, the concentration of these impurities reaches a critical level, at which the electrolyte must be replaced with fresh cryolite to main process efficiency. The spent cryolite, a viscous sludge containing residual aluminum ions and impurities, is then transported away for disposal.

“We learned that for a traditional aluminum plant, something like 2,800 tons of aluminum are wasted per year,” says lead author Trent Lee, who carried out the new work as part of the MITEI Energy UROP program. “We were looking at ways that the industry can be more efficient, and we found cryolite waste hadn’t been well-researched in terms of recycling some of its waste products.”

In their new work, the researchers aimed to develop a membrane process to filter cryolite waste and recover aluminum ions that inevitably make it into the waste stream. Specifically, the team looked to capture aluminum while letting through all other ions, especially sodium, which builds up significantly in the cryolite over time.

The team reasoned that if they could selectively capture aluminum from cryolite waste, the aluminum could be poured back into the electrolysis vat without adding excessive sodium that would further slow the electrolysis process.

The researchers’ new design is an adaptation of membranes used in conventional water treatment plants. These membranes are typically made from a thin sheet of polymer material that is

perforated by tiny, nanometer-scale pores, the size of which is tuned to let through specific ions and molecules.

The surface of conventional membranes carries a natural, negative charge. As a result, the membranes repel any ions that carry the same negative charge, while they attract positively charged ions to flow through.

In collaboration with the Japanese membrane company Nitto Denko, the MIT team sought to examine the efficacy of commercially available membranes that could filter through most positively charged ions in cryolite wastewater while repelling and capturing aluminum ions. However, aluminum ions also carry a positive charge, of +3, where sodium and the other cations carry a lesser positive charge of +1.

Motivated by the group’s recent work investigating membranes for recovering lithium from salt lakes and spent batteries, the team tested a novel Nitto Denko membrane with a thin, positively charged coating covering the membrane. The coating’s charge is just positive enough to strongly repel and retain aluminum while allowing less positively charged ions to flow through.

“The aluminum is the most positively charged of the ions, so most of it is kicked away from the membrane,” Foo explains.

The team tested the membrane’s performance by passing through solutions with various balances of ions, similar to what can be found in cryolite waste. They observed that the membrane consistently captured 99.5 percent of aluminum ions while allowing through sodium and the other cations. They also varied the pH of the solutions, and found the membrane maintained its performance even after sitting in highly acidic solution for several weeks.

“A lot of this cryolite waste stream comes at different levels of acidity,” Foo says. “And we found the membrane works really well, even within the harsh conditions that we would expect.”

The new experimental membrane is about the size of a playing card. To treat cryolite waste in an industrialscale aluminum production plant, the

researchers envision a scaled-up version of the membrane, similar to what is used in many desalination plants, where a long membrane is rolled up in a spiral configuration, through which water flows.

“This paper shows the viability of membranes for innovations in circular economies,” Lee says. “This membrane provides the dual benefit of upcycling aluminum while reducing hazardous waste.”

© MIT News Office, part of the Institute Office of Communications. Read: https://news.mit.edu/2025/new-filter-capturesand-recycles-manufacturing-waste-aluminum-0107

By Juliana Fischer

About 12% of drinking water in Germany comes from lakes and reservoirs. Their water quality is significantly influenced by the organisms living within them. However, climate change, environmental pollution, and invasive species such as blue-green algae threaten biodiversity –and thus the quality of drinking water. In the research project IQ Wasser,* an interdisciplinary team at the University of Duisburg-Essen is examining microbial biodiversity using environmental DNA analyses. The goal is to develop an AIbased early warning system that detects changes in water quality.

“Many organisms contribute to water quality in drinking water reservoirs,” explains Dr. Julia Nuy from Environmental Metagenomics at the Research Centre

One Health. “Mussels filter particles out of the water, freshwater amphipods break down organic matter, and certain bacteria metabolize nitrogen or carbon.” A key principle is: the greater the diversity of species, the more stable ecosystem services such as water filtration remain. However, the role of biodiversity – particularly microbial diversity – has so far been largely overlooked when assessing water quality. Microorganisms like bacteria play essential roles in the ecosystem but also pose risks, search as cyanobacteria (blue-green algae), which proliferate as temperatures rise.

Over the next three years, the interdisciplinary team will collect samples four times a year from the Wahnbach Reservoir and the Kleine Kinzig Reservoir. “After filtration, we extract and fully sequence the DNA,” says Dr. Julia Nuy, who leads the subproject on microbial ecology and biodiversity. “By working genome-

resolved, we can reconstruct nearly complete genomes from small fragments, providing precise insights into microbial diversity and the ecosystem’s services,” she explains. “From the genomes, we can identify whether bacteria metabolize nitrogen or carbon – a core function for the ecosystem.”

Another area of focus is the potential for pathogenicity. “We are examining how antibiotic resistance develops over time, whether specific resistance genes are only found in certain bacteria or across a wide range of microorganisms. Additionally, we analyze whether current trends in antibiotic use are detectable in the bacteria we study,” says Dr. Nuy.

The data collected feeds into AI models that predict environmental changes and their impact on biodiversity. “Our aim is to create an early warning system for drinking water suppliers,” emphasizes Nuy. “This will enable the early detection

• Rigid plastic cores

• Flexible tubular sleeves

• Flow channel spacers

• Media, pleat support

• Welded tube overwraps

• You design it, we create it!

of potential hazards, such as algal blooms or antibiotic-resistant pathogens, allowing targeted countermeasures to be implemented.”

Juliana Fischer, Editor, University of DuisburgEssen, can be reached at +49 203/37 9-1488, juliana.fischer-uni-due.de.

*The IQ Wasser project is funded by the Federal Ministry of Education and Research with approximately two million euros and coordinated by the TZW: DVGW Water Technology Center under Prof. Dr. Andreas Tiehm. At the University of Duisburg-Essen (UDE), Prof. Dr. Alexander Probst is a consortium partner. Other partners include the Fraunhofer Institute IOSB (Dr. Christian Kühnert), the Museum für Naturkunde Berlin (Dr. Sabrina Kirschke), Moldaenke GmbH (Christian Moldaenke), and Ident Me GmbH (Anne Findeisen).

More information: https://tzw.de/projekte/ project details/projects/iq-water-ki-bioiversitate

Contact: Dr. Julia Nuy, Environmental Department, Research Centre One Health, Tel. +49 201/18 3-4109, mail julia.nuy.uni-due.de

Read: https://www.uni-due.de/2025-01-14-iqwasser-ai-based-early-warning-system-for-drinkingwater-suppliers

By Juliana Fischer

Europe’s water bodies are in poor condition: more than half of them are heavily polluted with chemicals. This is hardly surprising – every day, up to 70,000 different chemicals are used in Europe’s industries and agriculture. Researchers at the University of Duisburg-Essen have now

developed a new method for purifying polluted water. Their recent study demonstrates* that the fossil remains of diatoms (a type of algae) can efficiently remove contaminants from water after being chemically modified.

Researchers have identified more than 500 chemicals in Europe’s rivers, originating from industrial and agricultural sources, threatening aquatic habitats. The team led by Junior Professor Dr. Anzhela Galstyan aims to remove these chemicals using algae. “Diatoms are microscopic single-celled organisms that live in water and possess a cell wall made of silica (silicon dioxide). Thanks to its porous structure, it can absorb a wide variety of pollutants,” Galstyan explains.

•Unwinds / Rewinds

•Pocket filter machines

•Slitters (Ultrasonic, Laser or Conventional)

•Laminators (Ultrasonic, Thermal and Adhesive)

•Traverse and Spiral winders

•Membrane / Hollow fiber lines

•Festooners

•Accumulators

•Ultrasonic sewing machines

•Pleat welders

•Ring Welders

•Custom assembly machines

We employ our 70 years of web handling experience to benefit our customers. Contact Chase Machine today for your equipment needs!

The researchers tested diatom shells on two exemplary

Manufacturing high-performance air, liquid, and

Consumer Products

Medical & Mask

Specialty Media

Value- Added Serv ices

pollutants commonly found in rivers and groundwater due to the textile industry: methylene blue and methyl orange. To enhance the adsorption capacity, the diatomaceous earth was chemically modified by adding specific functional groups to its surface. “This could easily be implemented on an industrial scale,” emphasizes the junior professor for nanomaterials in aquatic systems.

The diatomaceous earth was tested in the lab under various conditions, such as different salt concentrations and pH levels. The results are promising: regardless of the conditions, the material consistently removed pollutants effectively. For comparison, the researchers evaluated silica, a material already established in water purification. Diatomaceous earth performed significantly better: within an hour, up to 100 per cent of methylene blue was removed, whereas silica removed only 88 percent of the dye in the same period. For methyl orange, both silica and diatomaceous earth absorbed about 70 percent of the pollutant.

“We see diatomaceous earth as an ecofriendly and cost-effective solution for water treatment,” Galstyan concludes. The significant advantage is that algae are a renewable resource and can be cultivated with minimal energy input –unlike the commonly used filter material, activated carbon.

The researchers are now examining how diatomaceous earth can be used in membranes for water purification. Thanks to the world’s largest algae collection, housed at the University of Duisburg-Essen, the conditions for developing this environmentally friendly technology are ideal. Juliana Fischer, Editor, University of DuisburgEssen, can be reached at +49 203/37 9-1488, juliana.fischer-uni-due.de.

*C. A. Ojike, V. Hagen, B. Beszteri, A. Galstyan, Surface-Functionalized Diatoms as Green NanoAdsorbents for the Removal of Methylene Blue and Methyl Orange as Model Dyes from Aqueous Solution. Adv. Sustainable Syst. 2025, 2400776.

More information: https://doi.org/10.1002/ adsu.202400776.

Contact: Prof. Dr. Anzhela Galstyan, Analytische Chemie, Tel. +49 201/18 3-3963, anzhela.galstyan@ uni-due.de

Read: https://www.uni-due.de/2025-01-24-waterpurification-with-algae

q Analytical determination of PFAS samples by liquid chromatography with mass spectrometry coupling after filtering.

Removing hazardous PFAS chemicals from drinking water.

The chemicals known as PFAS are considered a severe threat to human health. Among other things, they can cause liver damage, cancer, and hormonal disorders. Researchers at the Technical University of Munich (TUM) have now developed a new, efficient method of filtering these substances out of drinking water. They rely on so-called metal-organic framework compounds, which work much better than the materials commonly used to date. Even extremely low concentrations of PFAS in the water can still be captured.

Per- and polyfluoroalkyl substances (PFAS) are considered “forever chemicals:” they generally do not decompose on their own even after centuries and, therefore, pose a long-term threat to humans and animals. PFAS have been used in numerous products such as textiles, firefighting foams, and food packaging, and have thus been released into the environment. The substances can accumulate in the body via food and drinking water, and thus cause serious health issues.

The team led by Nebojša Ilić from the TUM Chair of Urban Water Systems

Engineering and Prof. Soumya Mukherjee, a former Alexander von Humboldt postdoctoral researcher at the TUM Chair of Inorganic and Organometallic Chemistry during the study period and now Assistant Professor of Materials Chemistry at the University of Limerick, identified water-stable metal-organic framework compounds made of zirconium carboxylate as particularly effective PFAS filters. The bespoke class of materials is characterized by the adaptable pore sizes and surface chemistry. The materials are water-resistant and highly electrostatically charged. By specifically designing the structures and combining them with polymers, the filter capacity has been significantly improved compared to materials already in use, such as activated carbon and special resins.

Prof. Jörg Drewes, Chair of Urban Water Systems Engineering, emphasizes the great social significance of the research results: “PFAS pose a constant threat to public health. For too long, the negative effects of the chemicals, which, among other things, ensure that rain jackets are waterproof and breathable, have been underestimated. The industry has now started to rethink this, but the legacy of PFAS will continue to affect us for several generations to come.”

Researchers from the TUM School of Natural Sciences worked together with colleagues from the TUM School of

Engineering and Design and simulation experts from the TUM School of Computation, Information, and Technology to develop and research the new filters. Prof. Roland Fischer, Chair of Inorganic and Organometallic Chemistry, emphasizes: “When solving such major challenges, experts from a wide range of disciplines have to work together. You simply can't get anywhere on your own. I am delighted that this approach has again proved its worth here.”

However, it will be some time before this new filter material is adopted at large scale in waterworks. The newly discovered principle would have to be implemented with sustainably available, inexpensive materials that are safe in every respect. This will require considerable further research and engineering solutions.

© Technical University of Munich

Read: https://www.tum.de/en/news-and-events/all-news/press-releases/details/ removing-hazardous-pfas-chemicals-from-drinking-water

SINGAPORE INSTITUTE OF TECHNOLOGY

Memsift Innovations Pte Ltd has announced a pioneering research collaboration with the Singapore Institute of Technology (SIT) to develop innovative chemical-resistant hollow fiber nanofiltration (NF) membranes. These advanced membranes are designed to recover valuable chemicals from spent acids and bases in liquidwaste produced by the microelectronics and semiconductor industries, offering a sustainable alternative to existing practices.

The semiconductor industry, a cornerstone of modern technology, faces significant environmental challenges due to its intensive use of water and chemicals. Wastewater generated from semiconductor manufacturing processes is often laden with high concentrations of spent acids, bases, and heavy metals, making treatment both technically complex and financially burdensome. Current solutions, such as neutralization and incineration, are energy-intensive and environmentally damaging, creating an urgent need for more sustainable alternatives, especially as global regulations tighten.

“The collaboration between Memsift and SIT addresses the urgent need for innovative liquid-waste treatment solutions that prioritize sustainability and circular economy principles,” said Dr. J Antony Prince, the founder and CEO of Memsift Innovations.

This partnership focuses on developing a new generation of NF membranes with enhanced chemical resistance, selective permeability, and robust performance. Advanced materials such as functionalized graphene and hybrid organic-inorganic nanomaterials will be utilized to ensure the membranes can withstand the harsh chemical environments found in semiconductor wastewater. The membranes are tailored to recover over 90% of valuable chemicals, such as those used in stripping baths for removing photoresist and organic residues from wafers. The performance of these membranes will be optimized through cutting-edge characterization techniques and tested rigorously with real industrial wastewater. The technology will also undergo an onsite demonstration at a global microelectronics manufacturing facility in Singapore by the end of 2025.

The adoption of these NF membranes is expected to significantly reduce the volume of waste requiring downstream treatment and disposal, delivering tangible benefits such as lower operational costs, minimized energy consumption, and a reduced environmental footprint. Beyond the semiconductor sector, these membranes hold potential for broader industrial applications where resource recovery from high-strength wastewater streams is essential.

SIT will contribute its expertise in membrane design, formation and fabrication, along with property characterization and performance analysis. This complements Memsift’s industrial experience and intellectual property (IP)

in advanced membrane technologies, creating a strong synergy for the development and optimization of advanced nanofiltration membranes. This exemplifies the impactful interplay between academia and industry to address an important problem in waste management.

Furthermore, SIT students will gain invaluable hands-on experience through this partnership, preparing them for future roles in sustainable engineering. At least three students from the Pharmaceutical Engineering and Chemical Engineering degree programmes will be involved in polymer processing, membrane fabrication, filtration equipment operation, and process analytical techniques.

“This partnership showcases SIT’s deep expertise in membrane technology and commitment to sustainability and innovation. By combining our research capabilities with Memsift’s industry experience, we are developing advanced solutions for high-value manufacturing sectors, while equipping students with hands-on skills to drive real-world impact,” said Associate Professor Zuo Jian, the principal investigator leading the research team from SIT.

This initiative reinforces Memsift Innovations’ position as an emerging player in sustainable water management

technologies. The chemical-resistant NF membranes developed through this collaboration promise to redefine liquidwaste treatment in the semiconductor industry, setting new benchmarks for efficiency, sustainability, and resource recovery.

Memsift Innovations is an emerging leader in membrane-based separation and purification solutions. Their innovative technologies include Improved Membrane Distillation (IMD), which efficiently recovers valuable materials from industrial effluents while reducing environmental impact. Additionally, their Chemical-Resistant Ultrafiltration/Nanofiltration (CR UF/NF) systems set new standards for purification, with the capability to withstand harsh chemicals and selectively separate components.

The Singapore Institute of Technology (SIT) offers industry-relevant degree programs that prepare its graduates to be work- and future-ready professionals. Its mission is to maximize the potential of its learners and to innovate with industry, through an integrated applied learning and research approach, so as to contribute to the economy and society. Its focus on applied research with business impact is aimed at helping industry innovate and grow.

The fact that the automotive industry is constantly pushing the boundaries of technical limits is also reflected in the introduction of sustainable filter solutions as a natural continuation of this drive for innovation. GESSNER’S cellulose media with plant-based resin saturation is currently used in automotive applications such as engine air, oil and fuel filters.

Their lignin saturated cellulose filter media is designed to reduce your product carbon footprint. Unlike traditional filter media, their cellulose filter media is saturated with an eco-friendly plant-based resin, ensuring that your filter element offers best performance, while taking a step into more sustainable filtration solutions.

As a natural polymer which can be found in the cell walls of plants, lignin provides structural support and rigidity. In their filter media they use it for its natural properties, offering an eco-friendly alternative to replace fossil-based resins.

Sourced as a by-product in the processing of wood, it is the perfect, sustainable alternative to phenolic resins in the saturation of cellulose media. Furthermore, the curing process generates significantly lower emissions compared to conventional methods with phenolic resins.

With their eco-friendly lignin saturation for cellulose filter media, GESSNER developed a more sustainable product that does not compromise filtration performance nor its mechanical properties. By maintaining the same functionality and material characteristics lignin can directly replace phenolic resins in the saturation.

With more than 35 years of experience in flame retardance GESSNER has now added a more sustainable solution for market demands. Like with phenol-

based media, their new lignin saturated filter media can be equipped with a flame retardant meeting the highest industry standards.

Compared to standard media, initial calculations show that with the new ecofriendly saturation the cellulose filter media offers a reduced product carbon footprint.

Furthermore, the crude oil that is saved by using a lignin modified resin can be up to 100 kg per one ton of filter material, promoting a more sustainable product lifecycle of the filter media.

The application of their lignin modified saturation is not limited to automotive - any cellulose filter media, which is currently using phenolic resins can be replaced. Whether in liquid or air filtration, their eco-friendly filter media can be easily integrated into existing filter systems, regardless of the application.

GESSNER’s lignin saturated filter me-

p GESSNER’s cellulose filter media with lignin saturation.

The eco-friendly saturation is based on the natural polymer lignin

dia proves that sustainability and performance can indeed go hand-in-hand. By combining excellent filtration performance, a reduced carbon footprint, and fewer emissions, this filter media solution bridges the gap between high performance and sustainability. Whether in automotive or industrial applications, this eco-friendly filter media offers a seamless transition to a more sustainable filtration, helping industries meet their environmental goals without sacrificing performance.

With a broad portfolio of filter media, pleat support and a wide range of filter components, GESSNER became a trusted partner in the filtration and separation industry. By delivering best service and high-quality filter materials into transportation, air and water filtration as well as into different industrial and life science applications. Backed by decades of experience, continuous product innovation and a global supply chain, GESSNER tailors state-of-the-art filtration solutions to the market needs and individual customer requirements.

gessner@mativ.com www.gessner-filtration.com

In a world where sustainability and efficiency are paramount, the fish industry faces significant challenges. According to the World Wildlife Fund (WWF), over four billion people rely on fish and fish products as their primary source of protein. Additionally, the growing health consciousness among consumers has increased the demand for fish oils like omega-3, omega-6, and krill oil. By 2030, aquaculture (widely referred to as fish-farming) is expected to account for over 57% of food fish production, surpassing wild-caught fishing.

Increasing production volumes however is not a sustainable solution to meet growing demand. Instead, the industry must adopt climate-friendly approaches, such as ‘upcycling,’ to recover high-value nutrients from existing production ecosystems.

Upcycling involves processing byproducts or waste streams into high-value ingredients, such as proteins. Food manufacturers often hesitate to upcycle because of the high financial investment needed to repurpose what is traditionally viewed as waste or sometimes simply due to lack of knowledge on the possibilities. Therefore, it’s essential to find efficient, reliable, consistent, and costeffective ways to extract as much high-

quality protein as possible from these byproducts.

Sustainable solutions like membrane processing can help the industry recover high-quality fish protein hydrolysates, a highly premium ingredient used in aquaculture and other feed industries. Products such as Pall’s Membralox® ceramic membranes have been proven on a large scale to provide the most efficient protein transmission, separation, and extraction systems for producing high-value, safe, and functional upcycled protein ingredients.

These crossflow filtration systems are fully enclosed, automated, self-cleaning and operate at optimal temperatures to prevent thermal denaturation of the product. Their modular design allows any feed flow rate, continuous 24/7 operation, sequencing batch processes and the membranes’ lifetime extends over years of continuous operation with consistent separation performances and capacity.

The Challenge

Fish oil and fishmeal is produced by cooking fish meat and pressing it to separate the liquid. This generates two streams: fish oil and aqueous stick water. Stick water, so-called due to its sticky consistency, is recycled, and evaporated before being

mixed with fish meal. However, stick water contains impurities like suspended solids and trace amounts of fat, which if not removed can lead to fouled pipes, fluid movement interruption, additional cleanings, and operational downtime. Traditional processing can also cause equipment scaling, higher energy costs, and larger waste discharge volumes.

The Solution

Pall offers a sustainable filtration solution using its Membralox ceramic membranes. Tangential Flow Filtration (TFF) or Crossflow Filtration (CFF) systems clean the fish stick water before evaporation to remove unwanted suspended solids and oils. This improves drying efficiency and produces a superior quality, more valuable final product.

The stick water, rich in proteins, is then further processed through membranes and evaporators to generate thick liquid fish hydrolysate (up to 80% protein) and dried hydrolysate powder (up to 85% protein), generating a considerable return on investment.

By adopting membrane filtration technologies, processors can upcycle fish byproducts into high-value protein hydrolysates, enhance profitability, sustainability, and product quality, and help meet the growing global demand for fish and fish products. www.pall.com

Breakthrough Performance/Premium Quality/Unbelievable Technology

Pleating Systems & Equipment – a leading supplier of high-quality manufacturing equipment and contract pleating services – specializes in helping filter manufacturers to select the right type of equipment and solutions to fit their filter production needs.

The principals of “PSE” have owned and operated the largest privately owned filter manufacturing facility in the United States from 1996, while simultaneously owning the most successful pleating machine distributorship for over 25 years. We are experts in filter manufacturing, pleating machinery and accessories and understand the challenges manufacturers face. At PSE, we are third-generation filtration family and continue to provide outstanding solutions for our customers.

The all-new ROTH MFM3-S CNC Digital Blade Pleater. Next level performance packed with groundbreaking speeds while maintaining utmost precision. ROTH Composite Machinery has set the bar high with industry leading engineering and patented core on an all-new highspeed design.

The ROTH MFM3-S, an incredibly engineered high-speed blade pleating machine, now producing a NEW recordbreaking speed of up to 510 pleats per minute! A perfect balance of high precision pleating and extreme speeds without compromising its robust strength.

The remarkable MFM3-S is built to last a lifetime running 24 hrs/7 days a week, process approved.

Roth Industries, partnered with Pleating Systems & Equipment, was founded in 1947, is supported by over 1,000 employees globally, and has long been respected as an innovator in the areas Building &

PSE continuously runs multiple contract pleating lines to accommodate customer’s overflow pleating requirements, interim machine sale pleating. Our production lines feature our new CroyBilt Integrated Mini Pleat Systems and the latest High-Speed CNC ROTH Blade Pleaters. Capabilities include 4-300mm pleat heights including glue bead application.

Used pleating equipment can be a great way to get started or expand your growing filtration business. PSE regularly acquires used pleating equipment, often via our trade-in program. Customers can frequently check our website to see what treasures we have in our warehouse.

High Speed CNC Blade Pleaters

Integrated Mini-Pleat Systems

Servo Rotary Pleaters

USED Equipment

Contract Pleating

OEM Parts & Service

www.pseusa.com

By Caryn Smith, Chief Content Officer, IFN

The sustainability story of WaterSurplus began before it became a trending topic. The concept of recycling and redeploying idle water treatment assets has been the core business model of the Illinois-based company since 1999. CEO John Barelli saw an opportunity to deploy recycled surplus water and wastewater treatment systems to the farthest corners of the globe to address water filtration demands and solve emergency, short- or long-term filtration challenges. Today, the vast majority of the company’s business involves new and rental equipment, but WaterSurplus still maintains the largest marketplace of surplus and used water treatment equipment, membranes, and resin.

The company’s case studies illustrate its ability to not only respond to customers’ operational needs but also deploy equipment to address emergency situations such as the following natural disasters.

In the summer of 2024, the firm responded quickly to a natural disaster in Louisiana. Lower than normal water volumes flowing down the Mississippi River led to a saltwater surge moving north from the Gulf of Mexico. This so-called salt wedge put at risk many water treatment systems that were designed to draw in and treat fresh surface water from the lower Mississippi River. In coordination with the Army Corps of Engineers and other organizations, WaterSurplus deployed and held in reserve enough state-of-the-art reverse osmosis (RO) filtration systems to produce

JOHN BARELLI Founder of WaterSurplus

more than 4 million gallons of potable water per day to address the crisis.

In response to the September 2024 Hurricane Helene disaster, the University of North Carolina, Asheville called upon WaterSurplus to help restore essential water treatment services to reopen their campus to UNCA’s 1,600 students. Extensive flooding had caused significant disruption to water infrastructure in western North Carolina. The company sent an advanced mobile water treatment system, in collaboration with Onsite Water Management, LLC, and the United States Army Corps of Engineers. The system, when connected to the

campus’s water distribution network, provided up to 280,000 gallons of potable water.

Another area of focus for the company is providing rapid response water treatment equipment for municipalities that identify per- and polyfluoroalkyl substances (PFAS) in their water supply. Despite the urgent desire to stop delivering PFAS contaminated water, the lead time for the capital equipment that removes PFAS is typically more than three years. In anticipation of this crisis, WaterSurplus spent the last several years investing in the development of a fleet of mobile PFAS treatment systems that can be rented for temporary use or purchased for permanent use and can be delivered within a matter of weeks.

The company recently sold a PFAS removal system to the city of Kalispell, Montana to treat forever chemicals detected at their Grandview Wells site, which surpassed EPA established limits. In August 2024, Kalispell Public Works Director Susie Turner said that the system can treat up to 2,000 gallons per minute.

“We’re able to keep our wells online, provide that treatment and not jeopardize capacity,” Turner said to the local news outlet, Daily Interlake. The paper had reported that in 2023, “officials detected forever chemicals, also known as PFAS, at the two Grandview Wells located near the Flathead Valley Community College, a residential community, and a park.”

WaterSurplus also has proprietary innovations to offer. To learn more, we spent

p WaterSurplus sent an advanced mobile water treatment system, in collaboration with Onsite Water Management, LLC, and the United States Army Corps of Engineers to restore water services to 1,600 students at the University of North Carolina, Asheville.

time with Barelli to discuss the company’s innovative approach to supplying water filtration systems, and the innovations that keep them responding to the immediate needs of the industrial water and wastewater filtration marketplace.

International Filtration News: Give us a brief history of the company.

John Barelli: After working in water treatment at the beginning of my career, in 1989, I founded Pure Solutions, Inc., which served as a manufacturer’s representative company selling new equipment focused on water treatment for large industrial users. In 1998, sensing a void in the marketplace, we developed a market-wide sustainability strategy of repurposing surplus water treatment assets and renamed the company Surplus Management, Inc. Then in 1999, I ultimately rebranded the company as WaterSurplus.

We gradually began serving many markets, including the municipal mar ket. As water quality and scarcity issues grew, water availability and water reuse became more important and, to us, more interesting.

Now, through thirty-five years of continued investment in the industry, we have established

a foundation of consistent growth and more recently, rapid innovation with our excellent team of over sixty people working to replenish the world’s water and serve customer needs, collaborating with important industry partners where we have established key relationships.

Contaminants on the rise like iron, manganese, radium, and arsenic became pressing concerns, and then, of course, the big one – PFAS. We were fortunate to have already been working in this space when PFAS became a major issue.

Recognizing the growing demand for solutions, we continued investing in the municipal sector, and over the last 10 years, we’ve been very focused in that marketplace.

IFN: What common problems do new customers typically need solved or customized to their unique challenges?

Barelli: There’s definitely a common requirement of having to meet drinking water standards. As people drill wells and need more water, problems may arise – such as a well failing to provide water within standards. We often deal with common groundwater contaminants regulated by drinking water standards. One area where we excel is radium removal. Jim Groose, our municipal groundwater expert, has a lot of experience treating radium. Other issues include iron and manganese.

We approach projects by building relationships with engineering companies and municipalities. We take our time to understand the problem in its entirety and act like a consultant for our customers. Typically, we run pilot plants to ensure proposed engineering designs work as planned. Quite often, we learn things from the pilot that help the customer operate more efficiently and sustainably. By doing our research upfront, we can optimize our systems for customers.

IFN: Is there an increase in different kinds of contaminants over the last 10 years?

Barelli: For sure. There are various emerging contaminants we keep an eye on. Even existing contaminants behave differently over time. For example, someone might have a well where the iron level is within safe limits, but two years later, changes in well structure or water quantity push it out of compliance.

PFAS are now newly regulated, and that’s a dynamic issue. If a municipality has multiple wells and one is out of compliance, shutting it down can lead to PFAS appearing in other wells. It’s a complicated problem – not just from a chemistry and treatment perspective, but also in terms of hydrology, pumping, and water management. We work closely with government agencies, operators, and engineers to provide optimized solutions rather than just quoting to specifications.

IFN: Besides municipalities, what other kinds of customers do you serve?

Barelli: We have a strong presence in multiple industries. Food and Beverage is a big market for us – we do a lot with bottled water, carbonated beverages, and alcohol production.

Our expertise in filtration and membrane separation leads us to projects across different industries. We’ve built strong relationships with major beverage companies. If you treat them right, they keep sending you projects, and you build a pattern of success. The same happens in the municipal world – our good reputation keeps bringing in more projects from different communities and engineering firms.

IFN: With PFAS concerns, what is the state of plastic bottled water packaging?

Barelli: What we are seeing is a trend toward glass and aluminum cans in the beverage industry. A lot of drinks that could be in plastic bottles are moving toward cans. The canning sub-sector is very dynamic. The microplastic issue seems incredibly overwhelming, but it’s an emerging contaminant that might be even more regulated with time. However, at this time, our treatment methods don’t change based on packaging. The shift toward non-plastic options seems to be more about consumer awareness and brand positioning.

IFN: Can you give us an overview of your innovations?

Barelli: Many of our innovations are rooted in improving efficiency. That can mean different things in different situations. It can mean less water to drain, fewer chemicals, a reduction in energy consumption, a smaller building to house the equipment, or fewer membrane elements and filtration media to the landfill over the life of the system. That said, our portfolio of IP falls into two major categories, filtration and reverse osmosis.

For filtration, we have developed a family of catalytic media, OxiPlus75TM, OxiPlus12TM, and SandPlusTM that improve efficiency in treating radium, arsenic, iron, and manganese. For reverse osmosis, our flagship patents are ImpactROTM and NanoStack TM. NanoStack is a bio-inspired, superhydrophilic-coated membrane resistant to scale and fouling, which extends membrane life and reduces offline cleaning needs. ImpactRO is a revolutionary multi-stage brackish RO with several patented innovations, optimized to deliver the smartest and most efficient RO performance in the world. ImpactRO delivers up to 96% recovery, reduced energy consumption, significantly reduced membrane fouling, and increased system uptime. membranes, lengthening the time between offline clean-in-place (CIP) Occurrences, improving the recovery of flux after each CIP, and decreasing antiscalant consumption, water to drain, and energy use, and thereby, operational expenditures.

IFN: What does it mean to offer a PFAS Rapid Response System?

Barelli: It is interesting how we entered the PFAS market. We were already in the rental market and recognized that communities were struggling with PFAS compliance while waiting for regulations, permits, and funding. The lag time from identifying the problem to potential solution was significant.

Our first entry into the PFAS space was through temporary rental assets using an ion exchange resin to capture PFAS, and quickly return the water to compliance. We were the first to bring PFAS solutions

like this to Wisconsin and completed the first PFAS temporary rental in Canada. We even deployed one to a military base in California.

IFN: What is the company’s “rapid response” capability in emergencies?

Barelli: Our project in Kalispell, Montana, is a great example. They called us, and we had a system on-site within two to three weeks. Two weeks later, it was operational. So, in about five weeks, they had a solution. That requires a big capital investment – we stock specialized resin and keep equipment ready to deploy.

For some smaller communities, renting the system indefinitely makes more sense than building a permanent one. We offer that flexibility and work with customers to find the best solution for their needs.

Our approach is really driven by our core values – being proactive and resourceful. We aren’t necessarily a disaster relief company, but because we have such a large inventory of equipment and expertise, we can respond quickly when communities are in need.

For example, during the Asheville situation with the University of North Carolina, it wasn’t part of a strategic plan for disaster relief. But when we saw we had the right equipment to help, we jumped in. That mindset is what guides us – being ready and willing to help where we can.

IFN: What research projects are you currently working on?

Barelli: We are conducting a lot of PFAS research, testing different media and pilot programs. Every pilot is essentially a research project because each scenario presents unique challenges. Additionally, we recently completed a grant-funded study with the Bureau of Reclamation on ImpactRO and NanoStack for groundwater contaminants in high-recovery RO applications. Another major project is with Orange County, California, a leader in water reuse. They are testing our NanoStack membranes and seeing great results with lower pressure and energy use.

We’ve also just patented NanoScopeTM, a predictive monitoring system integrated into our ImpactRO. NanoScope detects membrane fouling up to 15 times faster than traditional RO monitoring systems, allowing proactive interventions. With over 30 installations, we continue collecting data to improve performance.

IFN: You mentioned your large inventory a few times. How important is that to your ability to respond quickly in these situations?

Barelli: It’s absolutely critical. Our rental fleet, combined with our ability to build and customize systems quickly, is what allows us to respond in days or weeks, not months. For example, in April and May of 2024 two tornados hit the town of Minden, Iowa. One destroyed the town’s only water treatment plant. We had filtration systems on the road within 48 hours. Without that inventory, the people of Minden would have been without clean water for much longer. It’s all about having the resources on hand and mobilizing them immediately.

IFN: Can you talk a bit more about how that project unfolded?

Barelli: That one hit close to home – both literally and figuratively, Minden is only a few hours away from our headquarters in Illinois. The first of two tornados ripped through the small town and took out their water treatment plant. The Iowa Rural Water Association (IRWA), in partnership with the Iowa Department of Homeland Security and Emergency Management, reached out to us for help. Our VP of Municipal Water, Jim Groose, was on the phone with our mobilization team throughout the weekend. Because we had the right equipment ready to go, we loaded a filtration system onto a truck and had it there within days of the storm. The contractors connected it quickly, despite a second tornado hitting the town and within a week or two, they had potable water flowing again. It’s one of those moments where you see directly how your work impacts people’s lives.

q Emergency filtration system installed in Minden, IA to mitigate damage from back to back tornados in 2024. WaterSurplus

And an interesting note about that project is that they are still deciding whether to purchase that system for permanent use or commission a new system. But either way, it’s a win. If they return it, we can redeploy it to another town. If they buy it, they have a great long-term solution. It’s about flexibility –helping communities when they need it, but also making sure our assets are ready for the next call.

of spending millions and waiting months to build something new, they came to us and got what they needed in weeks for a fraction of the cost. That means they can test their ideas faster and bring solutions to market sooner. So, sustainability, for us, isn’t just about conserving resources –it’s about accelerating progress.

IFN: How do you see water treatment challenges evolving?

Barelli: They’re accelerating – faster than people realize. Groundwater depletion is a real and growing problem. We’re seeing more communities fall out of compliance with water quality standards because their water sources are shrinking and becoming more concentrated with contaminants. At the same time, climate change is driving more extreme weather events – floods, droughts, hurricanes –that disrupt water supplies. All of this is pushing demand for innovative solutions like water reuse, mobile treatment units, and advanced filtration systems.

IFN: Why is sustainability such an important value for your company?

Barelli: For us, sustainability is practical and intelligent business. It’s not just about ESG or reducing our carbon footprint – though those are important. It’s about efficiency. Reusing and repurposing equipment reduces waste and costs. For example, if we can take a system from a closed facility and repurpose it for another company at a fraction of the cost, that company can invest the savings into job creation or innovation. Sustainability isn’t just good for the environment – it’s good for businesses and communities.

IFN: Talk more about how repurposing assets creates opportunities beyond costsavings.

Barelli: One of the things people often overlook is that repurposing assets drives innovation. We’ve worked with a lot of startups and innovators who needed water treatment systems for pilot projects. Instead

IFN: Do you think that public awareness is keeping pace with the urgency of the problem?