HYDRALADA

RH Drive spool (Motor Spool)

RH drive section uses a Series Motor spool. Prior to 2015 these spools have poppets either end of the spool. This design allows fluid to be ported to the lift section while also providing fluid to the RH wheel motor. Allowing the machine to Lift and drive at the same time.

The LH spool section does not have these as it has its own dedicated pump. This uses Parallel motor spool.

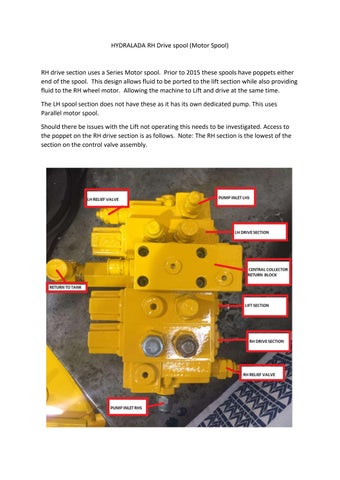

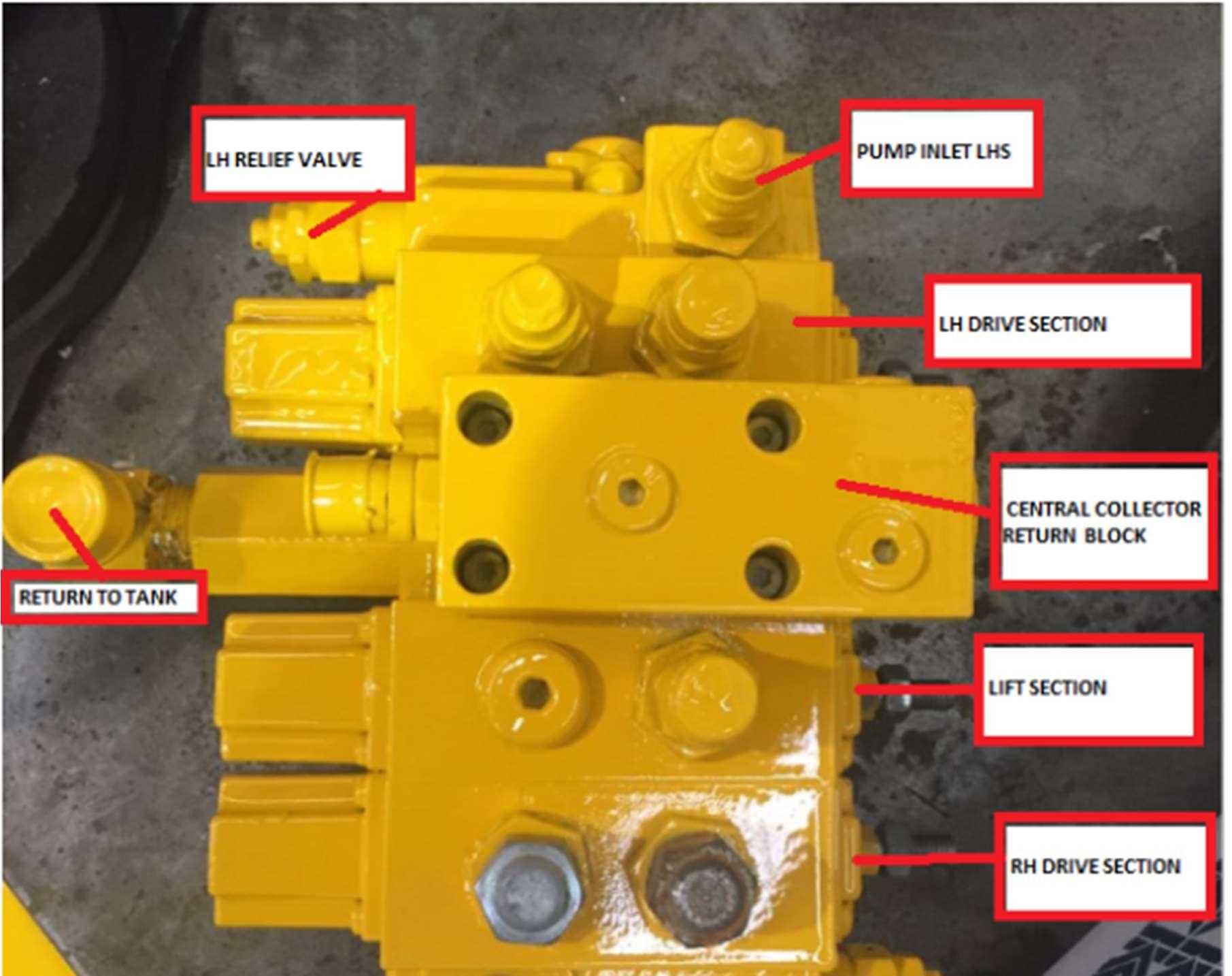

Should there be issues with the Lift not operating this needs to be investigated. Access to the poppet on the RH drive section is as follows. Note: The RH section is the lowest of the section on the control valve assembly.

A wheel motor will not drive in one direction.

Possible cause;

A piece of debris is interfering with the operation of the check valve in the end of the motor spool closest to the work port with the problem.

■ This problem usually occurs on new machines, or after the hydraulic system has been apart. This can generally be overcome by jacking the faulty wheel clear of the ground. Start the engine and set it to run at high RPM‘s, and drive the wheel in the direction it does drive OK. After 20 seconds, try the wheel in the other direction. Once the debris has cleared, the wheel will drive as normal in both directions. It may be necessary to repeat this procedure several times before the debris clears. In the unlikely event this procedure is not successful, the spool will need to be removed, and dismantled for inspection

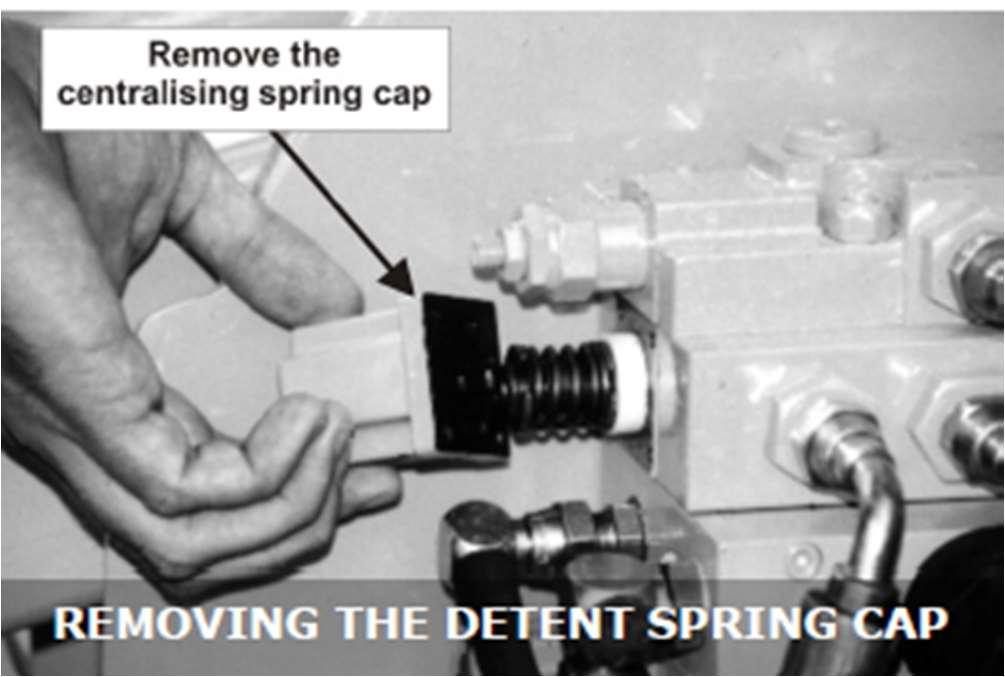

Dismantling the detent spring assembly.

Remove the four small screws mounting the detent spring cap and take away the cap. Remove the forks and the detent spring.

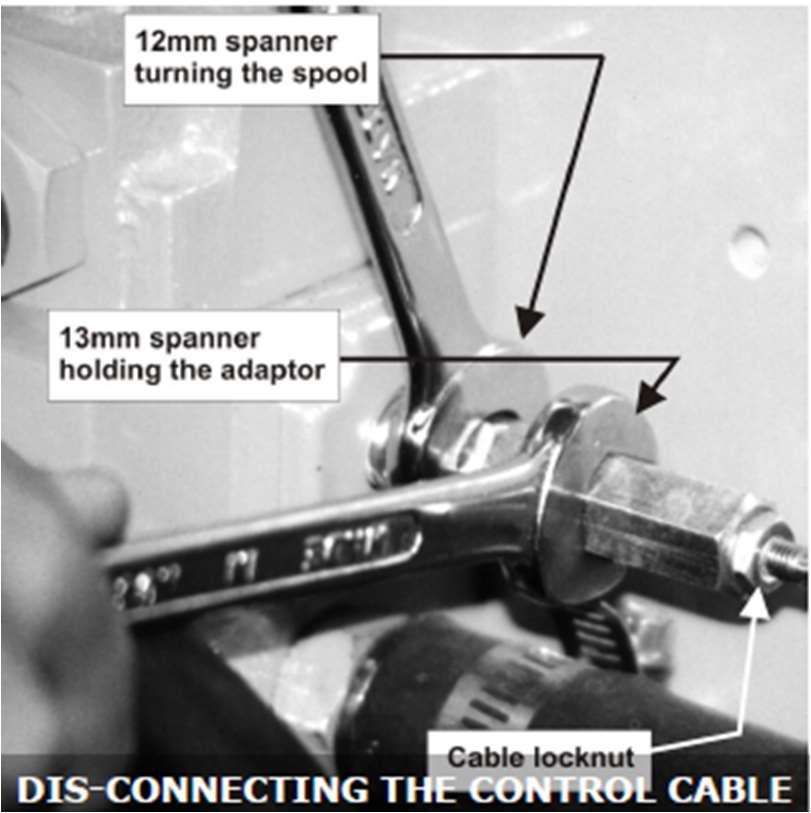

Removing a spool.

Disconnect the cable and remove the front and rear spool seals as detailed above. Remove the spool out of the control valve assembly.

■ Drain the reservoir to below the level of the spool to be removed, or have a pair of suitable corks on hand to plug the ends of the work section once the spool is removed.

Dismantling a series spool. (Bottom Section)

Series connected spools are fitted in the RH motor or Slew sections, and have a small poppet valve mounted behind the detent/cable adaptor ends. Hold the spool using the approved Hydralada service tool, and remove these ends using an 10mm open ender.

When inspecting these, pay particular attention to the poppet valve seat for cracking. Examples have been seen which could only be detected by crack testing which affected the performance of the drive wheels in one direction.

■ After installing the poppet valve and spring, completely fill the remaining cavity with light grease or vaseline before fitting the spool end. Excluding the air in this manner avoids noisy operation of the valve when it is operated.

■ Tighten the spool end to 120 in/lbs (13 Nm). Over tightening these ends will distort the end of the spool, making it tight in the body of the section.