Hydralada Park Brake ring replacement

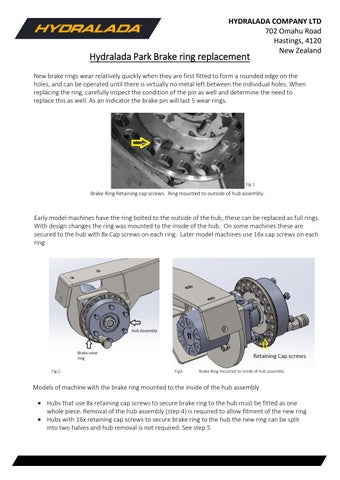

New brake rings wear relatively quickly when they are first fitted to form a rounded edge on the holes, and can be operated until there is virtually no metal left between the individual holes. When replacing the ring, carefully inspect the condition of the pin as well and determine the need to replace this as well. As an indicator the brake pin will last 5 wear rings.

Early model machines have the ring bolted to the outside of the hub, these can be replaced as full rings. With design changes the ring was mounted to the inside of the hub. On some machines these are secured to the hub with 8x Cap screws on each ring. Later model machines use 16x cap screws on each ring

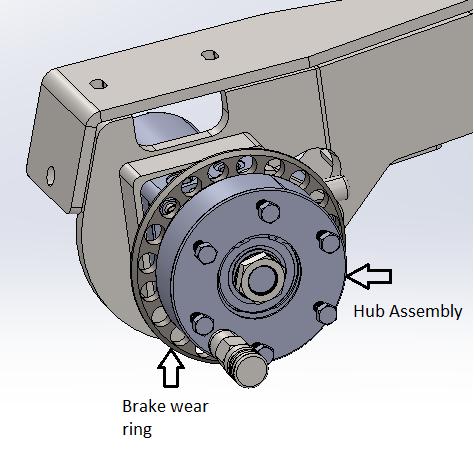

Models of machine with the brake ring mounted to the inside of the hub assembly

• Hubs that use 8x retaining cap screws to secure brake ring to the hub must be fitted as one whole piece. Removal of the hub assembly (step 4) is required to allow fitment of the new ring

• Hubs with 16x retaining cap screws to secure brake ring to the hub the new ring can be split into two halves and hub removal is not required. See step 5

Removal:

1. Jack machine drive wheel off ground and remove drive wheel.

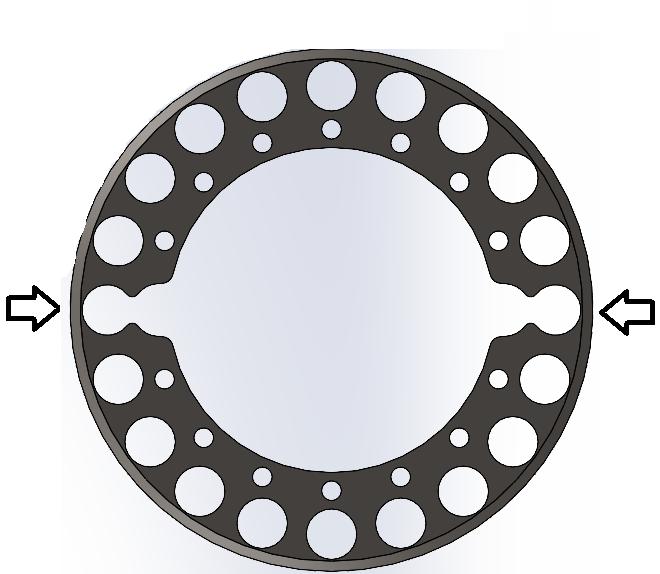

2. Inner hub mounted ring, cut the brake ring with a cut off disc at the wasted portions 180deg apart on the ring. Refer fig 4.

3. Remove cap screws and ring.

4. Inner hub mounted rings with 8x retaining cap screws, remove hub assembly from wheel motor. To avoid damage to the wheel hubs, use the Hydralada puller set in combination with the applicable hub plate.

Fitment:

5. For inner hub mounted brake rings with 16 cap screws, take the new rings and cut in half at the wasted portions as marked below 180deg apart with a cut off disk.

6. Mount ring or ring halves to the hub, assemble cap screws with loctite 263. Machines with 8 cap screws fit to every second hole.

Caution:

For Hubs with 8x cap screws the ring must not be cut and must be mounted as a whole ring.

7. Torque retaining caps crews to 40 ft/lbs

8. Hubs that required removal. Refit hub to wheel motor, taper on the shaft and hub should be clean. Using correct socket, run the nut home firmly and torque hub nut to 350 ft/lbs.

10.If the hub was removed, Start the Hydralada and drive it on a firm surface, abruptly changing direction backwards and forwards to stress the hub. Re-tension the hub nut as described in step 8 If there is any significant movement of the nut on the second re-tensioning, the procedure must be repeated again to be certain the hub is fully bedded onto the axle shaft.