2 minute read

MAINTENANCEME12002

ChangingHydraulicOil:NewStyle

1.Position the excavator on a level surface.

Excavator Position for Checking and Changing Hydraulic Oil

2.Fully extend the bucket and boom, and retract arm as shown in Figure 2-16.

3.Lower the bucket and dozer blade to the ground. See Figure 2-16. Shut-off the engine. Remove the ignition key and take it with you.

4.Slowly open the filler cap (1) to relieve pressure. Remove the cap and clean debris out of the strainer. See Figure 2-17.

7.Shut-off the engine. Remove the ignition key and take it with you. Follow the “Mandatory Safety Shutdown Procedure” in the Operator‘s manual.

8.Crawl underneath the chassis between the tracks. See Figure 2-18.

9.Open the drain plug (3) and drain oil into a suitable container. Re-install drain plug and tighten securely. See Figure 2-19.

5.Remove the hydraulic oil tank cover (2). See Figure 2-17.

6.To access the hydraulic oil tank drain plug (3), rotate the cab to an angle of slightly less than 45°, as shown. See Figure 2-18.

IMPORTANT:Always dispose of hydraulic fluids according to environmental laws or take to a recycling center for proper disposal. DO NOT pour onto the ground or down a drain.

10.Remove bolts and filter cover (4). Remove and discard old filter (5). Install the new filter (5) into reservoir. See Figure 2-20.

11.Reinstall filter cover and bolts (4). See Figure 2-20.

12.Reinstall the hydraulic oil tank cover (2). See Figure 2-17.

13.Fill tank with hydraulic oil until oil level is between red and black marks on sight gauge.

14.Re-install hydraulic oil filler cap and tighten securely.

15.Start engine and let it idle for a few minutes.

16.Rotate cab to normal position as shown. See Figure 2-21.

17.Cycle all front attachment hydraulic functions and check the hydraulic oil level. See “Checking Hydraulic Oil Level: New Style” on page38.

ChangingHydraulicOil:OldStyle

1.Position the machine on a level surface.

2.Fully extend the bucket and boom, and retract arm as shown in Figure 2-16. Lower bucket and dozer blade to the ground. Turn off the machine.

Maintenanceme12002

3.Slowly open the filler cap to relieve pressure. Remove cap and clean strainer of any debris.

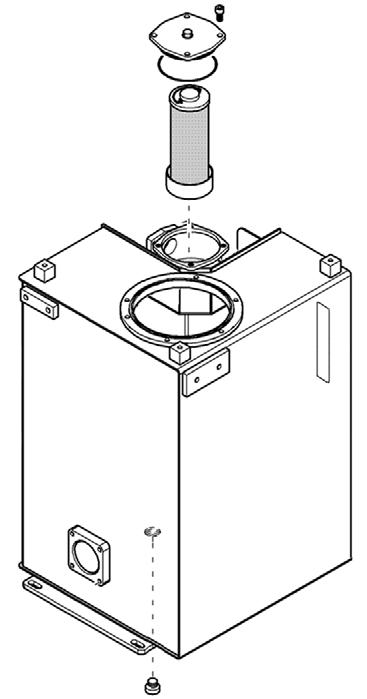

4.Remove the hydraulic reservoir cover as shown. See Figure 2-22.

5.Open the drain plug and drain oil into a suitable container. Re-install drain plug and tighten securely. See Figure 2-22.

IMPORTANT: Always dispose of hydraulic fluids according to local regulations or take to a recycling center for proper disposal. DO NOT pour onto the ground or down a drain.

6.Remove bolts and filter cover. Remove and discard old filter. Put clean hydraulic fluid on the filter gasket and install gasket and new filter into reservoir. See Figure 2-22.

7.Reinstall filter cover and bolts.

8.Fill reservoir with hydraulic oil until oil level is between red and black marks on sight gauge.

9.Re-install hydraulic oil filler cap and tighten securely.

10.Start engine and let idle for a few minutes.

11.Cycle all front attachment hydraulic functions. Re-check hydraulic oil level.

DieselEngine

EngineOil/FilterChangeMaintenance Schedules

NOTICE:All of the following prerequisites must be fullfilled in order to perform the 500 hrs. maintenance schedule. Perform the standard maintenance schedule (see below) if the following prerequisites are not fullfilled.

500hrs.MaintenanceSchedule Requirements

•If operating in extreme working conditions (high dust concentration, high temperature, using the hydraulic hammer [pile driver]), the standard schedule engine oil/filter maintenance must be performed.

•The engine oil/filter has to be changed a minimum of once per year.

•First engine oil/filter change must be performed after 50 hours.

•No modifications to the diesel engine or its cooling system.

•Mustang OEM filter must be used.

•Must use API CI-4, API CH-4, ACEA E3E4 rated engine oil.

•Applies to units with both Yanmar 4TNE106T-NS engine (SN AB00473AB03158), and John Deere 4045TF270 engines (SN AC02633 and up).

EngineOil/FilterSchedule

First change after 50 hrs.First change after 50 hrs.

Then every 125 - 250 hrs.Then every 500 hrs.

FuelSystem

FuelCircuitJohnDeereEngineModel4045TF270(SNAC02633andup)

Fuel Return (Leak-Off) Line

Fuel Supply Pump

Fuel Shut-Off Solenoid

Figure 2-23 Fuel Circuit

In-LineFuelInjectionPumpOperation

Supply pump (F) draws fuel from the vented fuel tank through primary filter (B). The supply pump pressurizes the fuel so that it flows through the filter and into the injection pump galley. Supply pump output pressure varies depending on load and application.