4 minute read

Fuse Panel - Steering Column

Additional Fuses

Note: Machines equipped with cabs will have a fuse panel located in the engine compartment.

Older machines have an additional fuse panel in the engine compartment. Newer machines have these fuses located in-line in the wire harness under the operator’s platform

Note: Fuses shown in the Standard Fuse Block are located in-line in the wire harness under the operator’s platform.

Battery

Before servicing the battery or electrical system, be sure the battery disconnect switch is in the “OFF” position.

Refer to “Electrical System” on page31 for battery specifications. To access the battery, tilt the loader platform. See “Tilting the Platform” on page77.

The battery top must be kept clean. Clean it with an alkaline solution (ammonia or baking soda and water). After foaming has stopped, wipe the battery top with a damp towel. If the terminals and cable connection clamps are corroded or have a build-up, disconnect the cables and clean the terminals and clamps with the same alkaline solution. Thoroughly dry the battery using a clean towel.

Explosive gas is produced while a battery is in use or being charged. Keep flames or sparks away from the battery area. ALWAYS charge the battery in a wellventilated area.

Never lay a metal object on top of a battery, because a short circuit can result.

Battery acid is harmful to skin and fabrics. If acid spills, follow these first-aid tips:

1. Immediately remove any clothing on which acid spills.

2. If acid contacts skin, rinse the affected area with running water for 10 to 15 minutes.

3. If acid contacts eyes, flood eyes with running water for 10 to 15 minutes. See a doctor at once. Never use any medication or eye drops unless prescribed by the doctor.

4. To neutralize acid spilled on the floor, use one of the following mixtures: a.0.5 kg (1 lbs.) of baking soda in 4 L (4 qts.) of water b.0.5 L (0.5 qts.) of household ammonia in 4 L (4 qts.) of water

Whenever the battery is removed, be sure to disconnect the negative (-) battery terminal connection first.

Using a Booster Battery (Jump-Starting)

Note: The machine may be equipped with the optional remote battery terminal, allowing for easy access to booster terminals. See “Remote Battery Terminal” on page103.

Important: Only complete these steps if the loader cannot be started using the ignition key switch. See “Engine Start” on page49.

If the loader does not start because of a “dead” (discharged) battery, start the loader using a battery jumper cable connected to the battery of another vehicle.

Note: The loader cannot be tow-started because no direct mechanical connection exists between the wheels and the engine. Attempting to tow-start the machine may damage the drive train.

Do not jump-start a frozen battery, or it may explode. A discharged battery can freeze at 10°C (14°F).

Note: Check that the battery disconnect switch is not turned off before jump starting.

The booster battery must have a nominal voltage of 12-volts. The capacity (Amphour rating) of the current-supplying battery must be approximately equal to that of the discharged battery. Factory-installed batteries are approximately 74 Ah in capacity.

Keep metal parts on your clothing and metal watchbands away from the positive (+) pole of the battery — risk of short circuit.

1.Turn the key switches of both machines to OFF. Be sure the machines are in neutral and NOT touching each other.

2.Check that battery jumper cables have a sufficient diameter.

3.Connect the positive jumper cable to the positive (+) terminal on the discharged battery.

4.Connect the negative jumper cable to the negative (-) terminal on the discharged battery.

Note: If the machine is equipped with the optional remote battery terminal, connect the cables to the terminal studs on the remote battery terminal. See “Remote Battery Terminal” on page103.

5.Connect the free end of the positive jumper cable to the positive (+) terminal on the booster battery.

6.Connect the free end of the negative jumper cable to a convenient ground on the machine carrying the booster battery.

7.Start the machine with the discharged battery. If the engine does not start immediately, stop cranking after 10 seconds and repeat starting procedure after approximately 30 seconds.

Warning

When the engine is running, components in the engine compartment rotate. Before removing the jumper cables, be sure that no loose clothing can become caught in the rotating components.

8.After the engine is running, remove the negative jumper cable connected the booster machine grouond.

Important: DO NOT allow the booster cable ends to touch when removing them. Arcs and direct short circuits can cause severe damage to the electrical system.

9.Disconnect the jumper cables from the machine with the discharged battery.

10.Remove the positive jumper cable from the booster battery.

11.Close the engine cover and confirm it is latched securely. Allow the machine to run for at least 30 minutes to re-charge the battery.

Remote Battery Terminal (Option - Standard on later AL500 Series Machines)

The optional remote battery terminal allows access to the battery terminals for jump-starting purposes.

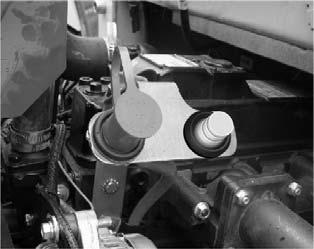

Open the engine hood to access the remote battery terminal. Remove cap (1, Figure 105) for access to the remote connection for the positive battery terminal stud. Stud (2) provides a remote connection to the machine ground.

Storing the Loader

Before Storage

If the loader is to be stored for a long period, in excess of two months, the following procedures are suggested:

1.Wash off entire machine.

2.Fully inflate the tires.

3.Lubricate all grease zerks.

4.Check all fluid levels and replenish as necessary.

5.Add stabilizer to the fuel per the fuel supplier’s recommendations.

6.Remove the battery, charge fully and store in a cool, dry location.

7.If the machine will not be operated for a month or longer, apply grease to all exposed hydraulic cylinder rod areas or retract all cylinders so rod exposure is minimized. Apply grease to any remaining rod areas.

8.Protect exposed cylinder rods.

9.Protect against extreme weather conditions such as moisture, sunlight and temperature.

After Storage

1.Check the tire air pressure and inflate the tires if they are low.

2.Connect the battery.

3.Check the fan belt tension.

4.Check all fluid levels (engine oil, transmission/hydraulic oil, engine coolant and any attached implements).

5.Start the engine. Observe all indicators. If all indicators are functioning properly and reading normally, move the machine outside.

6.When outside, park the machine and let the engine idle for at least five minutes.

7.Shut off the engine and walk around machine. Make a visual inspection looking for evidence of leaks.