5 minute read

RT9150E OPERATOR MANUALLUBRICATION

•Check level every 500 hours or 3 months

•Drain and fill every 4000 hours or 2 years

Fill to bottom of hole in housing on the steer cylinder side (2 places)

NOTE: Lube level close enough to the hole to be seen or touched is not sufficient. It must be level with the hole. When checking lube level, also check and clean housing breathers.

CAUTION: Use of non semi-synthetic lubricant may damage components and/or invalidate published lubricant intervals.

CAUTION: If the makeup amount is substantially more than 0.23 liter (0.5 pint), check for leaks.

•Check level every 500 hours or 3 months

•Drain and fill every 4000 hours or 2 years

Fill to the bottom of the level hole in the housing with the fill plug and the oil level mark horizontal (4 places)

CAUTION: Use of non synthetic lubricant may damage components and/or invalidate published lubricant intervals.

20a

20b a. Engine Crankcase b. Filter

Figure5-3

EO-15W/40

Engine Oil

SAE 15W-40

T3 Engine: 6829003483

T4 Engine: 6829104182

EO-5W/40

Engine Oil

SAE 5W-40

6829101560

HYDO

Hydraulic Oil

21 quarts (19 liters)

•Check level every 10 hours or daily

•Drain, fill and replace filter every 500 hours

•Through fill cap to FULL mark on dipstick

•Filter located under radiator

21a

21b a. Transmission, Torque Converter b. Filter

Figure5-3

6829006444

Hydraulic/ Transmission Oil

6829101559

34 quarts (32 liters)

•Check level every 10 hours or daily

•Drain and refill every 1000 hours or 6 months

•Change transmission filter after first 50 and 100 hours of service, then every 500 hours thereafter

Through fill pipe to FULL mark on dipstick

NOTE:

•Check fluid level with engine running at 800 rpm idle and the oil at 180° to 200°F (65° to 90°C). Do not attempt an oil level check with cold oil. To bring the oil temperature to this range, it is necessary to either work the crane or stall the converter. Converter stall should be accomplished by engaging shift lever in forward high range with the brakes applied and then accelerating the engine to half or three-quarter throttle. Hold the stall until the required converter temperature is reached and stabilized. Do not operate the converter at stall condition for longer than 30 seconds at one time. Shift to neutral for 15 seconds and repeat the procedure until the desired temperature is reached. Excessive temperature, i.e, 250°F (120°C) maximum will cause damage to transmission clutches, fluid, converter and seals.

•Drain and fill with the oil at 150° to 200°F (65° to 90°C).

•Transmission filters are located on the outside left hand frame in the area of the hydraulic oil cooler.

•Do not operate the machine in two wheel drive while the machine is up on outriggers. Serious transmission damage could result.

•To add fluid: a. Fill to FULL mark on dipstick b. Run engine at 800 rpm to prime torque converter and lines c. Check oil level with engine running at 800 rpm and oil at 180° to 200°F (82° to 93°C). Add oil to bring oil level to FULL mark on dipstick.

•Check

•Change

•Check

Clean strainer screen after first 100 hours and every 2000 hours or 12 months thereafter.

•Replace primary filter element when indicator shows red (25 in of H20). Replace secondary filter every third time primary filter is replaced.

•In severe dust conditions the precleaner may need to be serviced.

•Drain water trap every 10 hours or daily.

•Change filter every 500 hours or 6 months.

Close shutoff valves. Unscrew hex plug to clean filter.

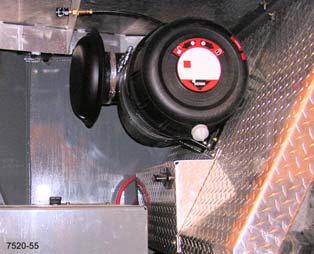

Right hand side of engine hood.

Primary fuel/water separator is located beside the fuel tank. Fuel filter is located on the right side of the engine

NOTE: using hand grease gun until grease comes out of vent tube outlet located near grease nipple.

Do not mix synthetic oil with mineral based oil.

Brush lubricant on ID of jack cylinder support tubes and wear bands four (4) places before installing jack cylinders

Brush lubricant on ID of jack cylinder support tubes and wear bands four (4) places before installing jack cylinders and on outside of support tubes at regular intervals

NOTE:

•Use sight gauge on side of tank, with boom down and all outrigger cylinders retracted.

•Drain and refill as necessary

•Environmental and other conditions can dramatically affect the condition of hydraulic oil and filters. Therefore, specific intervals for servicing/changing hydraulic oil, filters and hydraulic tank breathers cannot be set. However, it is imperative for the continued satisfactory performance of Grove cranes that inspections be performed on the basis of how and where each crane is used. Air borne and ingested contaminants can significantly reduce the life of oil and the condition of hydraulic oil filters and tank breathers.

•Under normal operating conditions, it is recommended that hydraulic oil, filters and breathers be inspected and oils sampled at least every 3 to 6 months and more frequently for severe operating conditions. The inspections should be for air borne and/or ingested particles and water that deteriorate and contaminate the oil (e.g., oil appears “milky” or no longer has a transparent clear to amber color). The return filter by-pass indicator should be observed daily to determine if the contaminants content may be high. If the indicator reaches the red zone or indicates a by-pass condition, the hydraulic oil must be sampled. The hydraulic tank breather should also be inspected to assure that it is not restricting air flow into and out of the reservoir.

•To inspect hydraulic oil, fill a small glass container with a sample of reservoir oil and another glass container with fresh oil. Let the samples stand, undisturbed, for one to two hours and then compare the samples. If the reservoir oil is heavily contaminated with water th e sample will appear “milky” with only a small layer of transparent oil on top. If the “milky” appearance was due to air foaming, it will dissipate and the oil should closely match the fresh oil. Should you have any questions, please contact your local authorized Manitowoc distributor.

•The hydraulic oil shall meet or exceed ISO #4406 class 19/17/14 cleanliness level.

Fill Procedure for Hydraulic Tank (Operation below +5°F (-15 °C)

–Drain existing oil.

–Fill tank with hydraulic/transmission oil (6829013503) and cycle all cylinders

–Drain oil

–Fill tank with oil (6829013503)

41 Hydraulic FilterFigure5-6------ Change filter when the indicator is red

CAUTION: Do not mix synthetic oil with mineral based oil.

•Check

•Drain and fill every 1000 hours or 12 months thereafter.

Fill to level on sight gauge

NOTE: Rotate the turntable 90° and apply grease to fittings. Continue rotating 90° and grease the fittings until the whole bearing is greased.

CAUTION: Do not mix synthetic oil with mineral based oil.

•Check and fill every 50 hours or weekly

•Drain and fill every 1000 hours or 12 months

Ensure hoist is level. The oil must have settled for 20 minutes with the temperature in the 21°C ± 7°C (70°F ± 20°F) range. The oil level must be between the 'MIN' and 'MAX' marks on the sight gauge. Variations in oil temperature will cause oil level to fluctuate.

To add or refill the oil, remove hose at top of sight gauge. Fill hoist through hose until the oil level is visible between the 'MIN' and 'MAX' marks on the sight gauge.

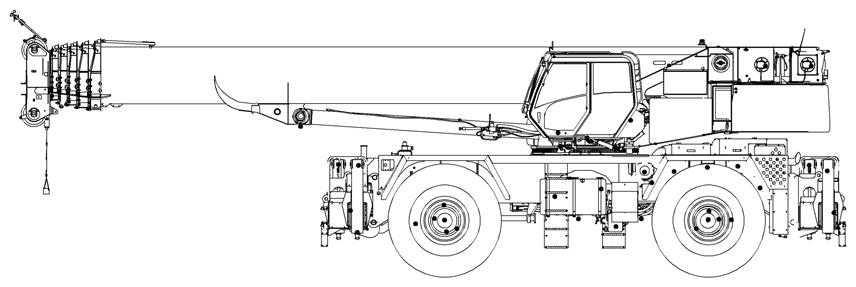

Boom Lubrication Procedure

Telescope Section 1

•Extend telescope section 1 to 100%.

•Using a brush or roller, apply grease to lower slide faces.

•Apply grease to the upper wear pads at fitting (item 131).

•Lubricate locking pins at fitting (item 132).

•Lock and unlock the section to distribute the grease.

•Extend section 1 to 50%

•Apply grease to the upper wear pads at fitting (item 131).

Fully retract section.

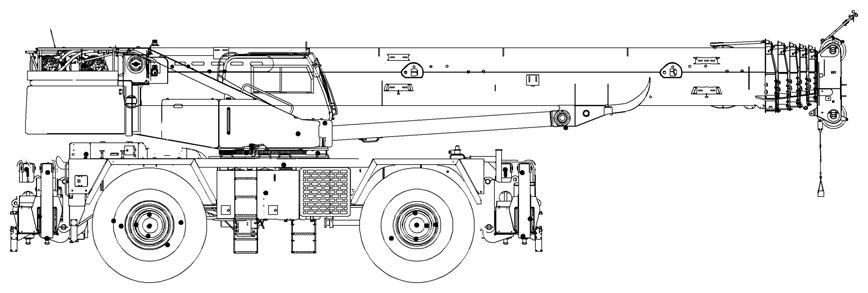

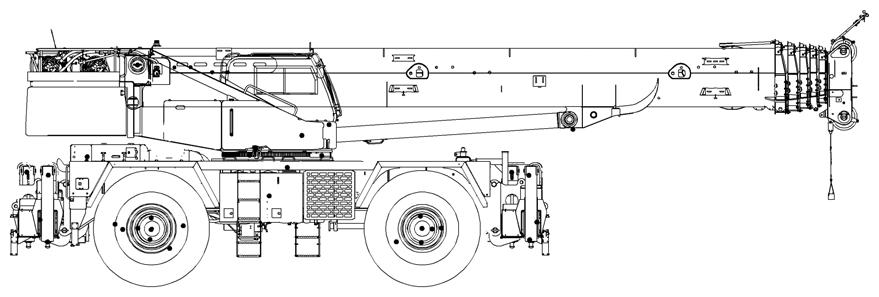

Telescope Section 2 - 5

•Extend telescope section 5 to 100% and telescope section 4 to approximately 25%.

•Using a brush or roller, apply grease to the lower slide faces.

•Apply grease to the upper wear pads at fitting (item 131).

•Lubricate locking pins at fitting (item 132).

•Raise the main boom to 15 degrees.

•Retract telescope section 4 to 0% and telescope section 5 to approximately 50%.

•Lock and unlock telescope section 5 several times to distribute the grease.

•Lower the main boom to 0 degrees. Do not lower less than 0 degrees.

•Extend telescope section 4 to approximately 75%.

•Apply grease to the upper wear pads at fitting (item 131)

•Raise the main boom to 15 degrees.

•Retract telescope sections 4 and 5 to 0%,

•Fully extend and retract telescope section 5 to distribute the grease.

•Lower the main boom to 0 degrees.

•Lubricate telescope sections 2, 3 and 4 in the same method.