5 minute read

OPERATING CONTROLS AND PROCEDURESRT540E OPERATOR MANUAL

Symbol Description

RCL Override

Status Light Bar Error

Swing Status

Swing Brake

Swing Group

SLI Early Warning

SLI Shutdown

Swing Brake

Telescope Status

Tools Group

Transmission Temperature Warning

Transmission Status

WRL Area Limit

WRL Height Limit

WRL Radius Limit

WRL Swing Angle Limit

General

This section provides procedures for installing the hoist cable on the hoist drum, cable reeving, and erecting and stowing the boom extension.

Installing Cable On The Hoist

Caution

If cable is wound from the storage drum, the reel should be rotated in the same direction as the hoist.

NOTE: The cable should preferably be straightened before installation on the hoist drum.

Install cable on the hoist drum in accordance with the following procedure.

1. Position the cable over the boom nose sheave and route to the hoist drum.

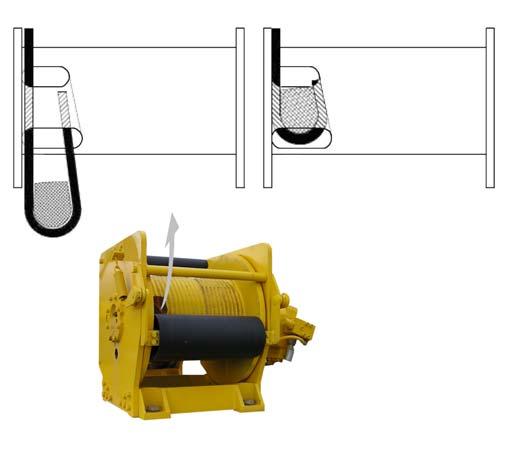

2. Position the hoist drum with the cable anchor slot on top.

3. Insert the cable through the slot and position around the anchor wedge (1) (Figure 4-1).

NOTE: The end of the cable should be even with the bottom of the slot for the anchor wedge.

4. Position the anchor wedge in the drum slot; pull firmly on the free end (2) of the cable to secure the wedge.

5. Slowly rotate the drum, ensuring the first layer of cable is evenly wound onto the drum.

6. Install the remainder of the cable, as applicable.

NOTE: If the wedge does not seat securely in the slot, carefully tap (3) the top of the wedge with a mallet.

ANTI TWO BLOCK (A2B) SWITCH

If a hoist rope has been reeved and two A2B switches are installed, the unused A2B switch must be locked (disabled) to allow all crane operations.

Lock

Caution

If the A2B switch is locked (disabled), the hook block could hit the main boom head or extension, resulting in damage to the hook block, main boom head or extension, and hoist rope. Never lock an A2B switch with a switch weight attached.

1. Remove A2B weight.

2. (A) Remove cap (1) from switch.

3. Pull lanyard (2) down.

4. (B) Secure lanyard (2) in this position using cap (1). A2B switch is locked (disabled).

Before Operation

Check the following electrical connections before operating the crane to ensure the LMI system is properly connected for the crane configuration.

Cranes With Main Hoist Only

If the crane is operated only with the boom and without boom extension or lattice extension, no additional connections are necessary. It must however be ensured that the A2B switch weight is correctly mounted on the main boom hoist rope. With even numbers of rope lines, the lifting limit switch weight shall be attached to the "dead end" of the hoist rope. With odd numbers of rope lines, the lifting limit switch weight shall be attached to the rope line with the lowest operating speed.

If the crane is operated with a main boom extension or top section, the connecting cable must be mounted between the distributor socket on the lattice extension and the distributor socket on the main boom. The main boom A2B switch weight must be disconnected and mounted on the extension or fly boom A2B switch.

Unlock

NOTE: Always remove the switch lock (enable) before installing an A2B weight around the hoist rope.

1. (A) Pull down lanyard (2) and remove cap (1). Switch is unlocked (enabled).

2. (B) Install cap (1) on A2B switch.

Warning

Failure to reposition the A2B weight will prevent the A2B system from functioning properly. No weight shall be mounted on the A2B switch of the main boom when working with the extension/top section.

Published 01-15-2016, Control # 526-01

Machines with Main and Auxiliary Hoists

If the main boom extension or fly section is not used, then the bridging plug must be plugged into the distributor socket on the main boom and the lifting limit switch we ight must be mounted on the main boom.

If the crane is operated with a main boom extension and/or with a lattice extension, then the connecting cable must be mounted between the distributor socket on the extension or on the top section and the distributor socket on the main boom. In addition, weights must be fitted to both the A2B switch of the main boom and the extension or fly section.

If the boom extension or lattice extension are in working position and if the main boom is not equipped with a hoist rope, then the weight of the A2B switch on the main boom must be removed to prevent endangering personnel or damaging equipment.

After electrical connections have been checked to ensure the system is properly connected for the respective crane configuration, the following checks must be made:

1. Check electrical wiring connecting various parts of the system for physical damage.

2. Check A2B switches and weights for free movement.

3. Inspect spring cable drum for smooth running, initial drum tension, and correct cable winding.

4. Inspect mechanical and electrical installation of power measurement sockets on the lattice extension (if present).

Warning

The following tests must be performed with care to prevent personnel injury or crane damage. Proper functioning of the CCS requires successful completion of these tests before starting work.

If the operator cannot see the hook block approaching the pulley head, this task must be assigned to an assistant (slinger).

The crane operator must be prepared to stop the crane immediately if the CCS is not working correctly, i.e. when warning indicators do not display, the acoustic alarm does not sound, and crane movements such as raising, extending and luffing are not disabled.

Check Hoist limit switch warning light and acoustic alarm as follows:

1. Manually raise weight fitted on the A2B switch. As soon as weight is raised, the acoustic alarm should sound and A2B switch warning should display.

2. Using the main hoist, pull hook block slowly against the A2B switch weight. As soon as the hook block raises the weight, the acoustic alarm should be triggered, the A2B switch warning should display, and the main hoist should switch off. Lower the hook block slightly to eliminate this condition.

3. Slowly lower the boom to bring about a potential hoist limit situation. As soon as the hook block raises the weight, the acoustic alarm should sound, the A2B switch warning should display, and the luffing gear should switch off. Lower the hook block slightly to eliminate this condition.

4. Slowly extend (telescope out) the boom to bring about a potential hoist limit situation. As soon as the hook block raises the weight, the acoustic alarm should sound, the A2B switch warning should display, and the telescoping function should switch off. Lower the hook block slightly to eliminate this condition.

Warning

If warning indicators and audible alarm do not function as described and crane movements are not switched off, the system is not working properly. The malfunction must be corrected before starting work.

5. If crane is equipped with a main boom or lattice extension, the inspection procedure must be repeated for the A2B switch of the extension/top section.

6. Check display of main boom length agrees with actual boom length.

7. Check display of main boom angle agrees with actual boom angles.

8. Check display of the crane operating radius agrees with the actual radius.

9. Check load display by lifting a load of known weight. Load display accuracy must be within the tolerance range.

Cable Reeving

NOTE: There are two types of cable (wire rope) available on this crane; 6 x 36 WS and 35 x 7 (non-rotating). Within the limits of the load and range charts and permissible line pull, multi-part lines allow the operator to raise a greater load than can be raised with a single part line. Various cable reeving (part line) is possible with the boom nose and hook block Figure 4-7. This reeving should be performed by a qualified rigger using standard rigging procedures.

Caution

Do not reeve Auxiliary Hoist rope through the rope grab. Do reeve the Main Hoist rope through the rope grab. (Figure 4-1)

NOTE: Also use the rope grab when using the Main Hoist with lattice extensions

In order to quick reeve the hook block without removing the wedge socket on the end of the cable, see (Figure 4-2).

Boom Cable Reeving

When reeving the boom, always reeve the main hoist wire rope through the rope grab; if also reeving the auxiliary hoist rope, reeve the auxiliary hoist rope outside of the rope grab.

Published 01-15-2016, Control # 526-01