1 minute read

CHAPTER 12 STORAGE

At the end of the harvesting season it is suggested that the following steps be performed:

1.The Electrical Control Box should be stored in a dry place. Install the Dust Caps, where provided, over the ends of the Wire Harness Plug Connectors.

2.Clean the Harvester thoroughly of all dirt, trash, excess grease and any other material that will absorb water and cause rust. If a pressure washer was used to clean the Harvester, all Bearings should be lubricated after cleaning.

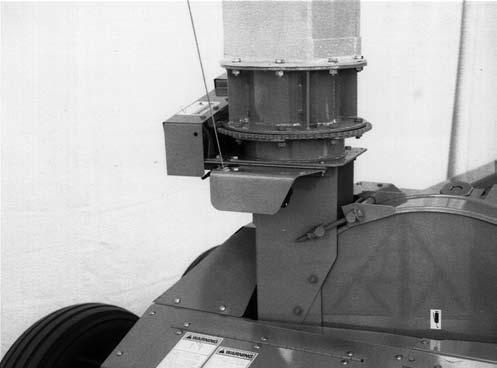

IMPORTANT: If a pressure washer is used to clean the Harvester, do NOT aim water stream directly at electrical devices such as the Metal Detector, or at Bearings. Water will enter the electrical components and damage them. Water will enter the Bearings and cause them to corrode during storage.

3.The Crop Processor MUST be thoroughly cleaned inside the Housing. Rotting forage will cause severe corrosion damage to the Crop Processor Rolls.

4.Thoroughly lubricate the Harvester as indicated in the Lubrication chapter.

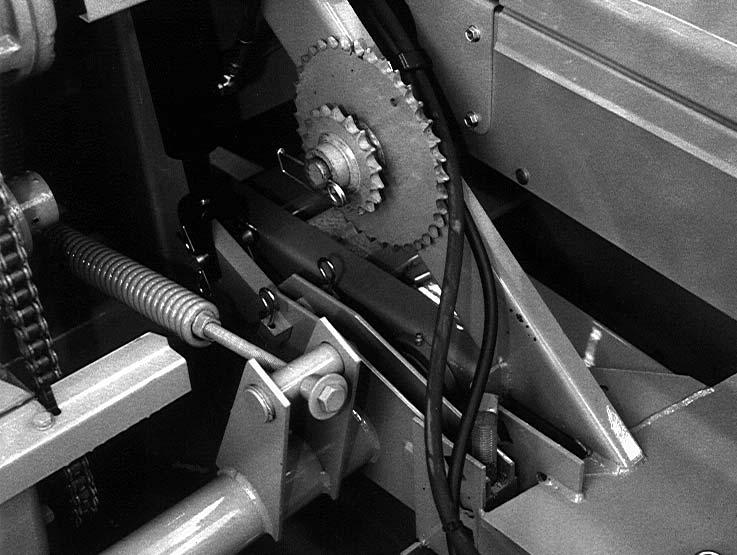

5.Clean and oil all Drive Chains and Sprockets.

6.Paint all the parts from which the paint has been worn to prevent rust.

7.Replace any worn or damage parts so the Harvester will be ready to operate the next season. For your safety and continued proper operation, use only genuine GEHL service parts.

8.Store the Harvester in a dry place where it is neither exposed to weather nor livestock.

9.Release tension on the Blower, Auger and Crop Processor Roll Drive Belts if the Harvester is going to be out of operation for more than a month.

Protection Of Unpainted Surfaces

Apply a rust preventative oil or grease to the following unpainted surfaces:

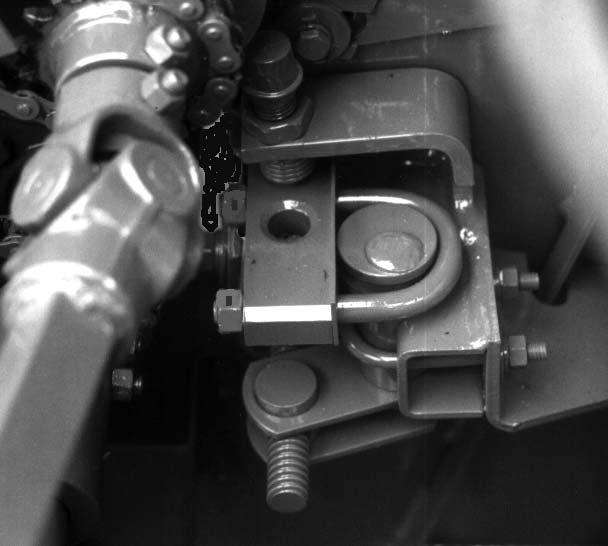

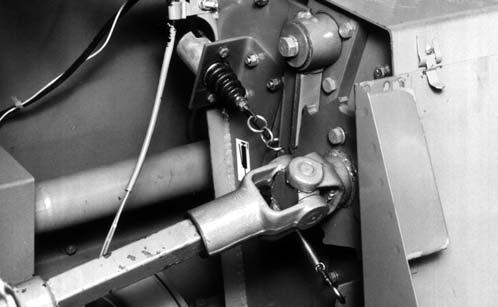

1.The Front Telescoping Drive Yoke Hub at the PTO drive end.

2.The Front Bevel Gearbox Shaft Splines.

3.The Length-of-Cut Sprocket Splined Shaft.

4.The entire surface of both Crop Processor Rolls.