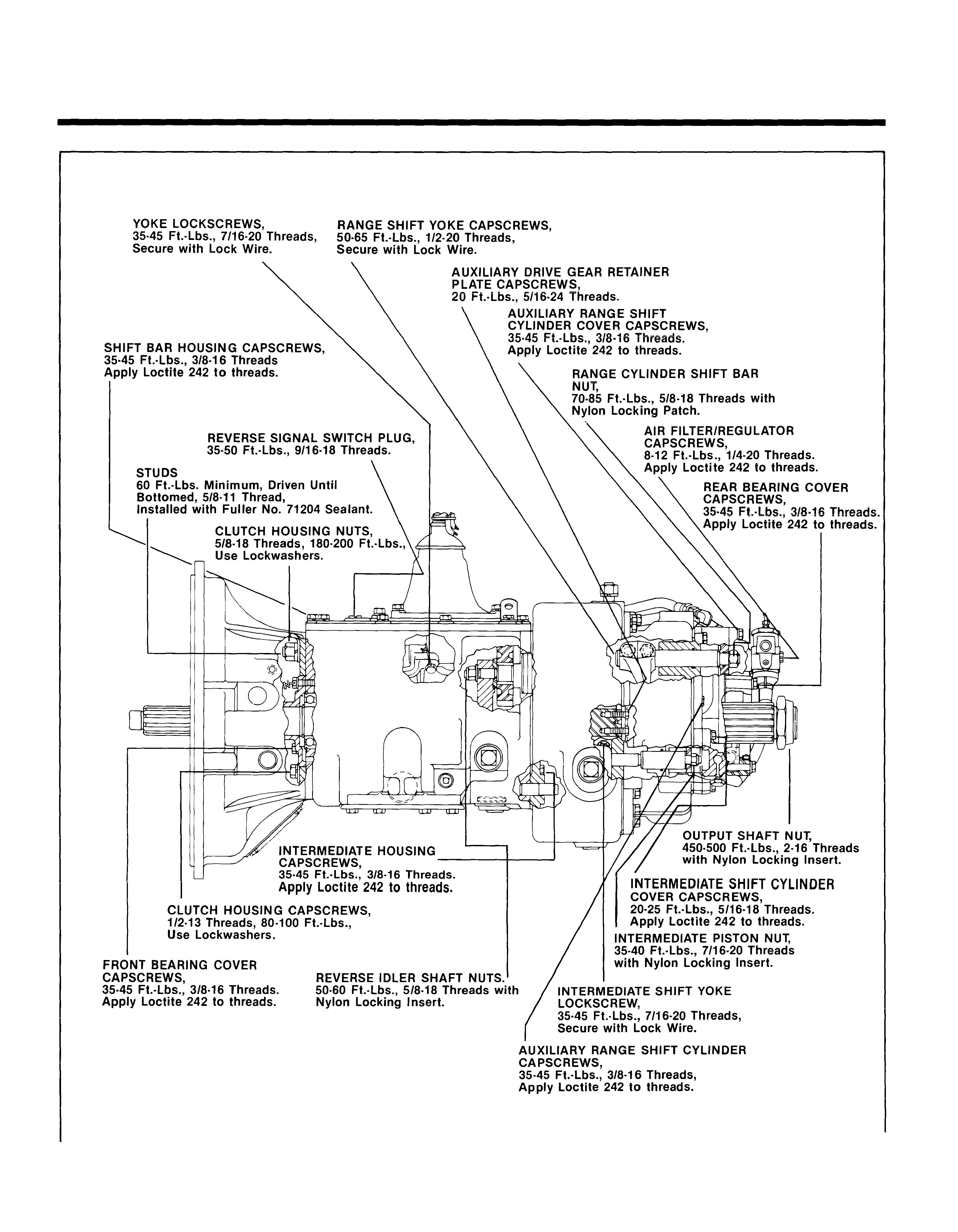

TIMING Timing Procedures: All ModeIs C. Meshing marked countershaft drive gear teeth with marked main drive gear teeth. (After placing the mainshaft assembly into case, the countershaft bearings are installed to complete installation of the countershaft assemblies.) 1. When installing the bearings on left countershaft, mesh the marked tooth of countershaft drive gear with either set or two marked teeth on the main drive gear. 2. Repeat the procedure when installing the bearings on right countershaft, making use of the remaining set of two marked teeth on the main drive gear to time assembly.

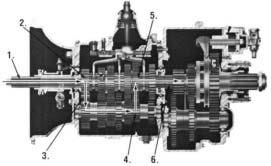

All Fuller twin countershaft transmissions are “timed” at assembly. It is important that proper timing procedures are followed when reassembling the transmission. Timing assures that the countershaft gears will contact the mating mainshaft gears at the same time, allowing mainshaft gears to center on the mainshaft and equally divide the load. Timing is a simple procedure of marking the appropriate teeth of a gear set prior to installation and placing them in proper mesh while in the transmission. In the front section, it is necessary to time only the drive gear set. And depending on the model, only the low range, deep reduction, or splitter gear set is timed in the auxiliary section.

Front Section A. Marking countershaft drive gear teeth. 1. Prior to placing each countershaft assembly into case, clearly mark the tooth located directly over the keyway of drive gear as shown. This tooth is stamped with an “O” to aid identification. Cut

A. TOOTH MARKED ON EACH COUNTERSHAFT DRIVE GEAR FOR TIMING PURPOSES

7300B

C. DRIVE GEAR SET PROPERLY TIMED

Auxiliary Section Refer to page 89 for detailed instructions on timing the auxiliary section.

Cut 7300

B. Marking main drive gear teeth. 1. Mark any two adjacent teeth on the main drive gear. 2. Mark the two adjacent teeth located directly opposite the first set marked on the main drive gear. As shown below, there should be an equal number of unmarked gear teeth on each side between the marked sets.

B. TEETH MARKED ON MAIN DRIVE GEAR FOR TIMING PURPOSES Cut 7300A

11