2 minute read

Full Web Cutting (Unidirectional

from CAT Roof Support Щитовая крепь 5501650-2X1414-1500 Инструкция по эксплуатации Manual – PDF DOWNLOAD

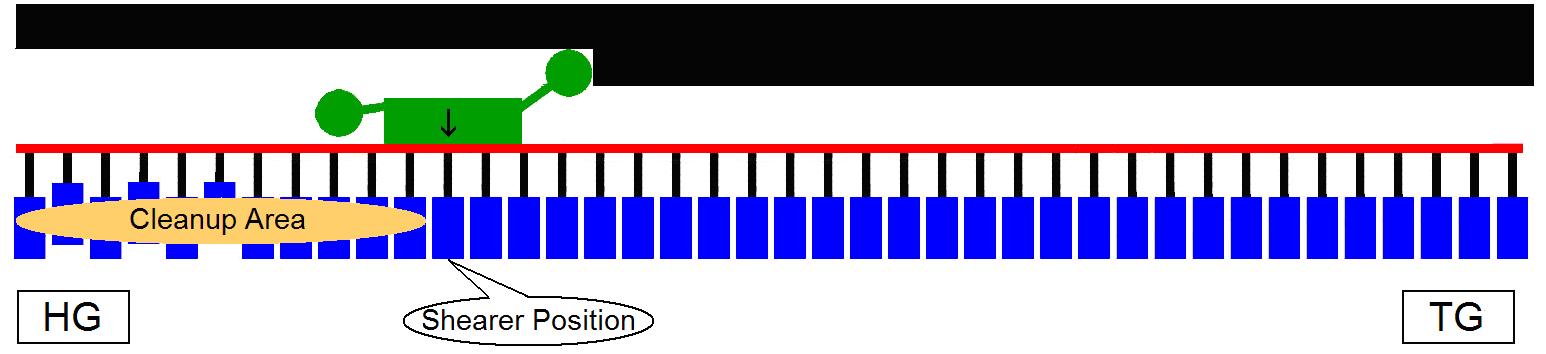

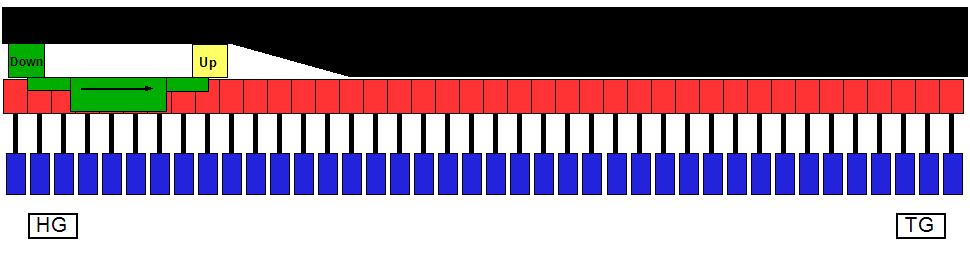

When the shearer reaches the headgate, the coal face will be straight, all shields except the headgate will be advanced, and only the tailgate shields will have pushed the conveyor, as shown below. The picture below shows the longwall state when the shearer reaches the headgate.

Full-Web Cycle – Step 2 – Shearer at HG

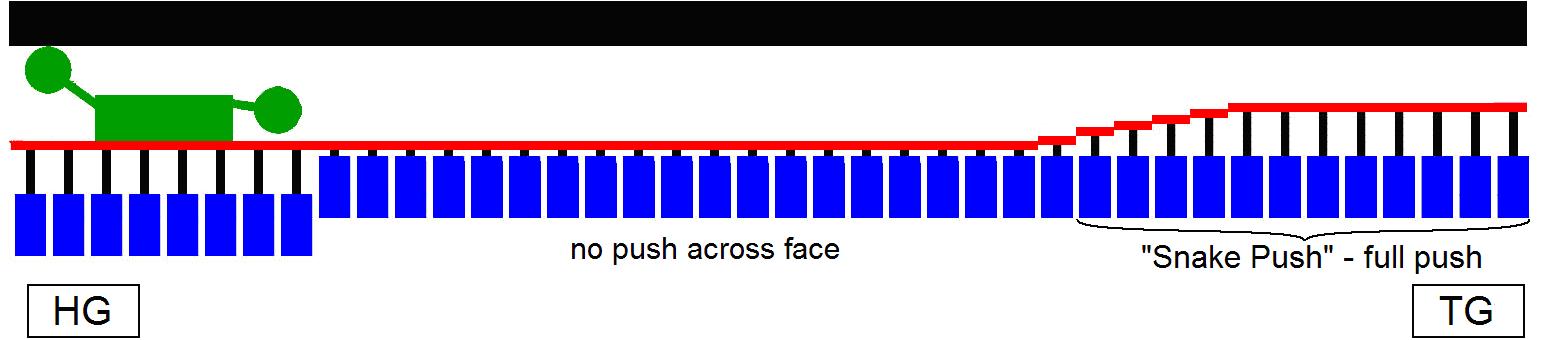

After reaching the HG, the system is ready for the shearer to travel back towards the TG, remove any bench of coal and grade the floor. Again, the operators can stay on the HG side of the machine to avoid exposure to dust. Following the shearer, the conveyor will push as determined by SRB parameter “H->T Push Stroke”. This will usually be set to 100. The picture below shows the longwall state as the shearer cuts back towards the tailgate.

Full-Web Cycle – Step 3 – Cutting Head to Tail

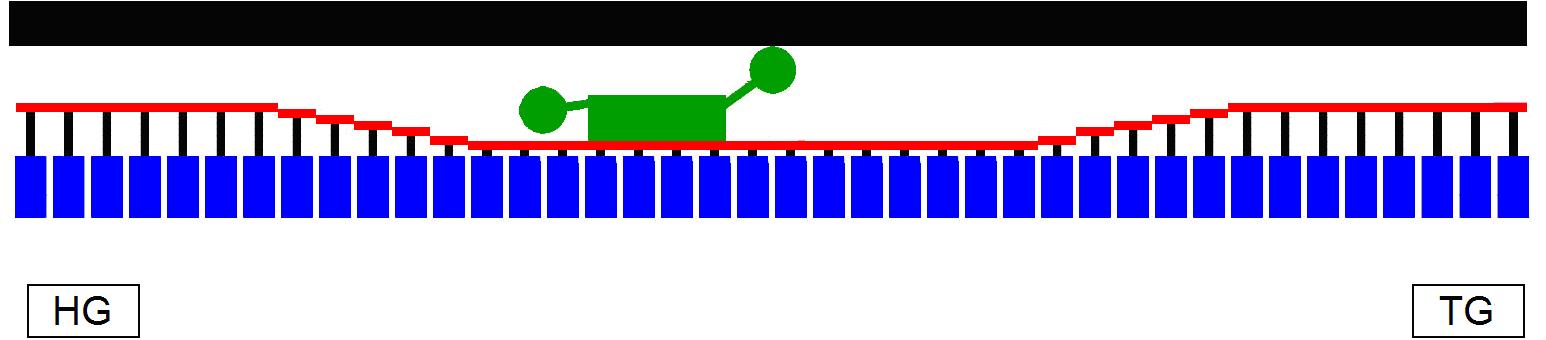

The full push will follow the shearer all the way to the TG until the entire conveyor is pushed. The picture below shows the longwall state when the shearer reaches the tailgate.

Full-Web Cycle – Step 4 – Shearer in Tailgate

When the shearer reaches the tailgate, it will again be a full-web in the coal. The coal face has one snake (at the tailgate), the shields are straight and the conveyor is completely pushed on the entire face. The longwall is in the same state as the Initial Position picture shown previously. The system is ready for the shearer to go back to the headgate and repeat the entire cycle. © Caterpillar

If the shearer does not clean-up sufficiently to allow the shields to push to a full 100% stroke, the parameter “H->T Push Stroke” can be set to a lower value, such as 90%. In the above description, the phrase “completely push” or “full push” refers to this value. The tailgate pushes to this value as the shearer is cutting to the head, and the rest of the face will push to this value on the head to tail pass.

B i d i r e c t i o n a l C u t t i n g C y c l e

SRB parameter “Cycle” must be set to “BIDI” to use SRB in a bidirectional cutting cycle.

Parameter “Cycle”

When using the bidirectional cutting cycle, the shearer cuts the entire top and bottom coal, full depth, as it travels in both directions. In both directions, the shields are advanced and the conveyor is pushed. When the shearer reaches the endgate, a double cut is required to keep the gates even with the rest of the face.

Bidirectional Cutting Cycle Beginning at Headgate

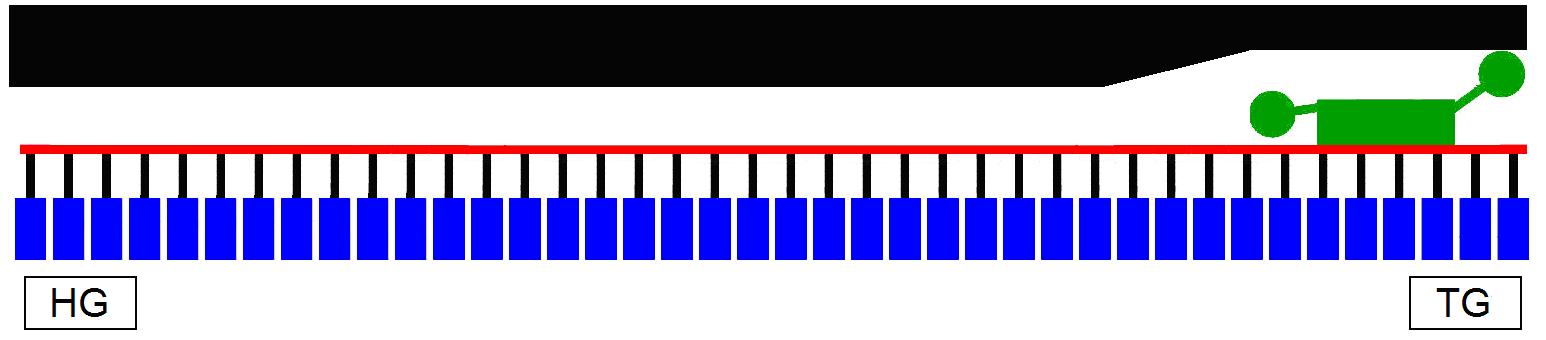

The bidirectional cutting cycle can begin with the shearer at either the head or tail end of the face. The picture below shows the shearer at the HG ready to start. The shearer is already in the coal; the coal face has a snake at the headgate. The shields and conveyor are completely straight and completely pushed.

Bidirectional Cutting Cycle – Initial Position

The picture below shows that the shearer has just left the HG Cleanup Area as it cuts towards the tailgate and SRB has triggered the headgate shields to advance.

Bidirectional Cutting Cycle – Step 1 – Leaving HG