4 minute read

Secondary steering indicator 46 Parking brake indicator

TRAININGMANUAL

PROGRAMMINGTHEINFORMATIONCENTER

Testing the Park Brake

The operator can test the park brake by using the diagnostics built into the information center. The transmission must be in 3rd gear manual mode to perform the test. If the transmission is left in any other gear during the test the transmission will be disconnected from the engine. To perform the test use the following procedure:

1 Start the machine. 2 Make sure the transmission selector switch is in 3rd neutral, the automatic switch is in the manual position,and the park brake switch is on. 3 Select the display field number 011 using the programming entry procedure listed previously. 4 Press the up count switch once so the display reads 01. 5 Shift the transmission selector into 3rd forward and slowly increase the engine RPM's. The park brake should hold the machine at full throttle. 6 Reduce the engine RPMís and shift the machine into neutral. 7 Press the reset switch to exit the test mode. 8 Turn off the machine.

If the park brake does not hold the machine at full throttle refer to the brakes section of this manual for troubleshooting procedures. Up count Program

Down count Reset

Transmission Clutch Calibration

The 21 C series wheel loaders have the ability to adjust the clutch modulation between shifts to allow for smooth shifting between gears. This procedure should be done after the first 250 hours of operation and after every 1000 hours of operation after that. For more information on why and how this occurs refer to the transmission section of this manual.

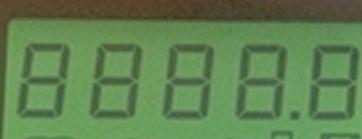

Before adjusting the clutch calibration it is important to understand how the controller communicates to you while the calibration is taking place. In the main instrument cluster display window there are five digits that will be displayed to the operator. They are numbered 1 - 5 starting at the left with the 5th position and continuing to the right with the 1st position. The calibration Main Code status will be displayed in the 3rd and 4th spaces and the 1st and 2nd digits will display the calibration ìSub Codeî The calibration Main Code will inform you where the machine is in the process of calibration, or where the machine was in the process when the calibration was aborted due to a malfunction. The calibration Sub Code will inform you why the process was aborted. The meanings of the Main and Sub Codes are listed in the following tables

The 5th digit shows 2 during calibration process.

5th digit 4th digit 3rd digit 2 nddigit 1st digit

TRAININGMANUAL

PROGRAMMINGTHEINFORMATIONCENTER

CLUTCH CALIBRATION MAIN CODES

Main codes Meaning Main codes Meaning

00 Clutch calibration was not initiated because a requirement was not met 07 Calibration completed 08 Operator aborted calibration procedure 01 1st gear calibration 09 Aborting while adjusting 1st gear 02 2nd gear calibration 10 Aborting while adjusting 2nd gear 03 3rd gear calibration 11 Aborting while adjusting 3rd gear 04 4th gear calibration 12 Aborting while adjusting 4th gear 05 FW gear calibration 13 Aborting while adjusting FW gear 06 RV calibration gear 14 Aborting while adjusting RV gear

CLUTCH CALIBRATION SUB CODES

Sub codes Meaning Sub codes Meaning

00 Calibration in process 05 Low transmission oil temperature 01 Fault present 06 High transmission oil temperature 02 Shifter not in neutral 07 Low engine RPM 03 Park brake not engaged 08 High engine RPM 04 Output speed not 0 Km/h

The transmission oil temperature must also be heated above 50o C in the sump before the test can be

performed. If the transmission is not heated to the required temperature you will get 2 00 05 in the display. The 05 sub code is telling you that the transmission oil is not up to temperature. You must use the stall test procedure to raise the oil temperature above 50o C in the transmission valve. Up count Program

Clutch calibration procedure

1 Start the machine. 2 Use the stall test procedure listed in the hydraulics section of this training manual to warm the transmission oil above 50o C. 3 Make sure the transmission selector switch is in 3rd neutral, the automatic switch is in the manual mode, and the park brake switch is on. 4 Select the display field number 011 using the programming entry procedure listed previously 5 Press the up count switch once so the display reads 02. At this time you will see 2 00 00 flashing in the display.

Approximently one second later the calibration Main Code will be displayed in the 3rd and 4th spaces and the calibration Sub Code will be displayed in the 1st and 2nd spaces. During the calibration sequence random numbers will flash on the screen to inform you that the calibration is taking place. If an error occurs the code will show continuous on the display. Down count Reset

NOTE: The calibration sequence may take up to 5 minutes to complete.

6 When the calibration procedure is completed you will see 2 07 00 in the display. Press the reset switch to exit the calibration mode. 7 Turn off the machine..