4 minute read

ENGINE COOLING SYSTEM

Service Specifications

Every 10 hours of operation.........................Check radiator coolant reservoir level Every 250 hours of operation......................................Check radiator coolant level Every 2000 hours or once each year.................................Change system coolant Coolant capacity.........................................................16.5 litres (17.5 U.S. quarts) Thermostart.........................................................83° C to 95° C (181° F to 203° F) Radiator cap..................................................................................1.02 bar (15 psi) Fluid type........................................................50% water and 50% ethylene glycol

Coolant Solution

A mixture of 50% ethylene glycol and 50% water must be used in this machine. This mixture is used if the lowest ambient temperature is above -37° C (-34° F). If the ambient temperature is lower, adjust the mixture to attain a lower freeze point using the freeze point-concentration chart on the label of your antifreeze concentrate or see page 102 “Operating in Cold Weather”. Never use a coolant solution containing more than 60% glycol. It is recommended that ethylene glycol and water be used in your machine all year. NOTE: After you fill the cooling system, mix the ethylene glycol and water completely by running the engine at operating temperature for approximately five minutes. This procedure must be done when the machine is in temperatures below 0° C (32° F).

Cleaning Between the Radiator and the Hydraulic Cooler

Locate the latch lever on the right side of the hydraulic cooler. Lift up on the latch lever and swing the hydraulic cooler away from the radiator.

2

3

1.HYDRAULIC COOLER LATCH 2.EARLY PRODUCTION MACHINES HYDRAULIC COOLER LATCH 3.LATE PRODUCTION MACHINES HYDRAULIC COOLER LATCH

1

BP97F004/BD01G120

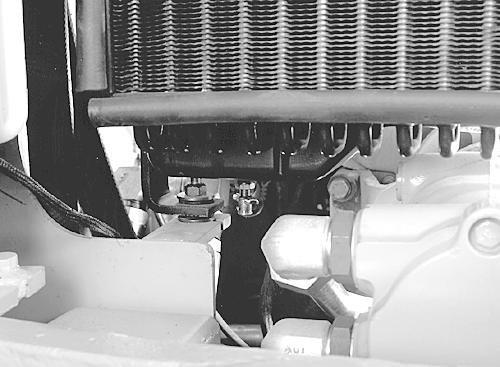

1.Release the hydraulic cooler from the radiator by lifting the latch handle straight up. 2.Swing the hydraulic cooler out.

BP96N065

3.Clean the radiator and hydraulic oil cooler with soap and warm water.

Flush with clean water. 4.After the radiator and hydraulic oil cooler are clean, swing the hydraulic oil cooler shut.

A.For Early Production Machines secure the latch (2) by pushing down on the latch.

B.For Late Production Machines secure the latch (3) by releasing the latch.

Engine Coolant Reservoir

Check the coolant reservoir level every 10 hours of operation or at the start of each day. Check the level when the engine is stopped and the coolant is cold. Do not remove the radiator cap during this check. The coolant level must be between the add and the full mark on the coolant reservoir bottle. If the coolant level falls below the add mark, add the proper coolant solution of 50% ethylene glycol and 50% water.

2

1

1.ENGINE COOLANT RESERVOIR 2.ENGINE COOLANT RESERVOIR FILL CAP

BP96N024

WARNING: Hot coolant can spray out if radiator cap is removed. To remove radiator cap: Let system cool, turn to first notch, then wait until all pressure is released. Scalding can result from fast removal of radiator cap. Check and service engine cooling system according to maintenance instructions.

Radiator Coolant Level

SA023

Every 250 hours check the radiator coolant level when the engine is stopped and the coolant is cold. Open the rear door and remove the radiator cap. The coolant level must be up to the radiator cap opening.

IMPORTANT: Only add the correct mixture of 50% ethylene glycol and 50% water to the radiator.

1

1

BP96N072

1.RADIATOR CAP

BP96N025

Cleaning Cooling System

Drain, flush, and refill the engine coolant every 2000 hours of operation or each year, whichever occurs first. Clean the system and replace the coolant if the coolant becomes dirty or has the color of rust.

DO NOT remove the radiator cap if the coolant is hot.

WARNING: Hot coolant can spray out if radiator cap is removed. To remove radiator cap: Let system cool, turn to first notch, then wait until all pressure is released. Scalding can result from fast removal of radiator cap. Check and service engine cooling system according to maintenance instructions.

SA023

1.Use a suitable container to drain the coolant. Remove the radiator cap. Attach a 9.5 mm (3/8 in) I.D. hose to the radiator drain valve and extend the hose out the rear of the machine into the container. Open the radiator drain valve. 2.After all coolant is removed, close the radiator drain valve.

3.Add cleaning solution to the cooling system and fill the cooling system with clean water. Follow the directions included with the cleaning solution. 4.After you drain the cleaning solution, flush with clean water. 5.Check the hoses, elbows and water pump for leaks. 6.Make sure that the outside of the engine and radiator is clean. 7.Fill the cooling system until the coolant level is up to the top of the radiator cap opening and install the radiator cap. 8.Fill the coolant reservoir up to the

FULL mark on the reservoir. 9.Start the engine and increase the temperature of the engine coolant.

When the coolant is at operating temperature, stop the engine and allow to cool. Check the coolant level at the coolant reservoir only.

Do not remove the radiator cap. 10.Dispose of drained coolant responsibly. Do not pour on ground or down drain.

1

1.RADIATOR DRAIN VALVE

BP96N071