1 minute read

Battery Maintenance

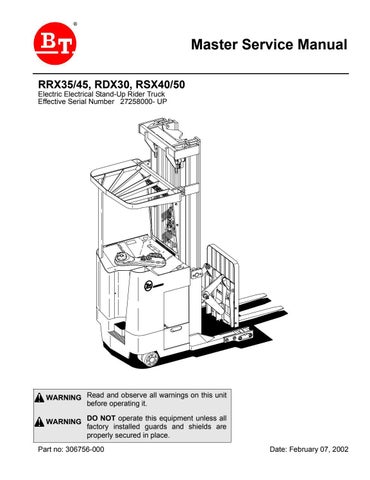

from BT Electric Electrical Stand-Up Rider Truck RRX35/45 RDX30 RSX40/50 Master Service Manual 306756-000

F-code Section C-code PS S5.5 5110 Battery

Version no T-code 000 395/396/397/398/399

3. Battery Maintenance

The following information does not supercede or replace information supplied by the battery and battery charger manufacturer. Read, understand, and follow the procedures in the manual supplied with the battery and battery charger. Notify your supervisor if there are any concerns or questions regarding battery safety or procedures.

3.1. Battery Inspection and Care

NOTE! Read, understand, and follow procedures, recommendations, and specifications in the battery and battery charger manufacturer’s manuals.

Batteries in industrial trucks pick up various kinds of dirt and dust depending on their surroundings and the types of material handled. If cells are overfilled and electrolyte collects on the covers, the following occurs: 1.The top of the battery becomes wet and stays wet, since the acid in the electrolyte does not evaporate. 2.This moist surface, in combination with certain kinds of dirt, becomes electrically conductive and permits stray currents to flow externally over the top of the battery. This degrades battery performance and truck operation. 3.The acid also causes corrosion of cell posts, nuts, connectors and the steel battery case. When inspecting batteries, check the following: 1.Wet covers can indicate overfilling, leaky seals at posts, or excessive gassing during charge. If covers are wet, determine the cause and correct the problem. 2.Make sure batteries cannot move more than 0.5 inch (13 mm) in any horizontal direction. Shim or block to restrain them.

F-code Section C-code PS S5.5 5110 Battery

Version no T-code 000 395/396/397/398/399

3.2. Battery Exterior Cleaning

Refer to recommended battery manufacturer’s guidelines for details.

3.3. Charging

OSHA regulations require that battery charging installations be located in areas designated for that specific purpose. Such areas must provide for flushing and neutralizing spilled electrolyte, fire protection, protecting charging equipment from damage by trucks and adequate ventilation of fumes from gassing batteries. To charge a battery, direct current is passed through the battery cells in the direction opposite that of discharge. Charging time is 5% to 20% longer than discharge time.

Read, understand, and follow procedures, recommendations and specifications in the battery and battery charger manufacturer’s manuals.

NEVER plug the battery charger into the truck. This will severely damage the truck’s electrical system. Plug the charger ONLY into the connector from the battery.

CAUTION