Drive System/Brake System GENERAL INFORMATION

The die-cast aluminum housings have been assembled with thread-rolling screws (trilobular). When assembling with these screws, start the screws carefully into the housing; then use the following torque values: Size

New Housing Reassembled Housing 8-9.5 ft-lb 6.5-9 ft-lb (10.9-12.9 N-m) (8.8-12.2 N-m) M8 (Torx T-40 Recess) 25-31 ft-lb 21-25 ft-lb (34-42.2 N-m) (28.6-34 N-m) M10 (Torx T-50 Recess) 37-45.5 ft-lb 31-38 ft-lb (50.3-61.7 N-m) (42.2-51.7 N-m) M6 (Torx T-30 Recess)

XR329

3. Remove the cap screws and lock nuts securing the A-Arm brace to the frame. Discard the lock nuts. Remove the A-Arm brace.

SPECIAL TOOLS

A number of special tools must be available to the technician when performing service procedures in this section. NOTE: When indicated for use, each special tool

will be identified by its specific name, as shown in the chart below, and capitalized. Description Backlash Measuring Tool (24-Spline Axle)

p/n 0544-010

Backlash Measuring Tool (27-Spline Axle)

0544-011

CV Boot Clamp Tool

0444-120

Hub Retaining Wrench

0444-270

Internal Hex Socket

0444-104

Pinion Gear/Shaft Removal Tool

0444-127

Gear Case Seal Installer Tool

0444-224

NOTE: Special tools are available from the Service

Department.

XR330A

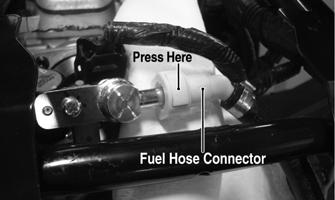

4. Remove the two cap screws and nuts securing the front differential to the frame. Account for the washers and their location. 5. Disconnect the actuator from the main harness. 6. Using a T-30 Torx wrench, remove the mounting cap screw from the driveshaft side of the actuator.

Front Drive Actuator/Differential Lock NOTE: The actuator is only serviceable as an assembly. NOTE: The actuator will operate only when the ignition switch is in the ON position.

The front drive actuator is located on the side of the front drive input housing. With the engine stopped and the ignition switch in the ON position, a momentary “whirring” sound can be heard each time the drive select switch is shifted or the differential lock is activated. If no sound is heard, see Electrical System. If the actuator runs constantly or makes squealing or grinding sounds, the actuator must be replaced. REMOVING

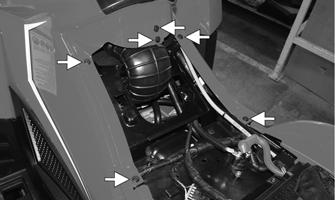

1. Lift the vehicle and support with jack stands; then remove both front wheels. 2. Remove both upper A-arm cap screws and lock nuts. Discard the lock nuts. 116

XR331

7. Lift the differential up to gain access to the cap screw on the suspension side. Remove the cap screw.