2. Using a T-30 torx wrench, remove the mounting cap screw from the driveshaft side of the actuator.

Drive System GENERAL INFORMATION

Gear cases are 4.0:1 ratio (500 or 3.6:1 ratio (700). The die-cast aluminum housings have been assembled with thread-rolling screws (trilobular). When assembling with these screws, start the screws carefully into the housing; then use the following torque values. Size M6 (Torx T-30 Recess) M8 (Torx T-40 Recess)

New Housing 9 ft-lb 28 ft-lb

Reassembled Housing 8 ft-lb 23 ft-lb

NOTE: Never reuse a lock nut. Once a lock nut has

been removed, it must be replaced with a new lock nut.

WC938A

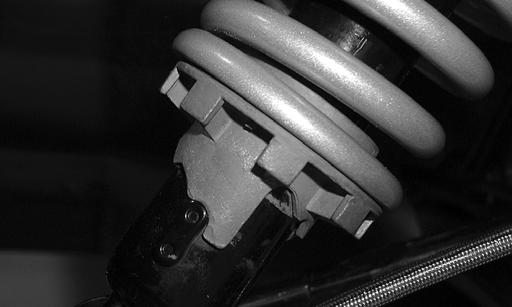

3. Remove the mounting cap screw from below the actuator on the suspension side.

SPECIAL TOOLS

A number of special tools must be available to the technician when performing service procedures in this section. Refer to the current Special Tools Catalog for the appropriate tool description. NOTE: When indicated for use, each special tool will be identified by its specific name, as shown in the chart below, and capitalized. Description Backlash Measuring Tool (24-Spline Axle) Backlash Measuring Tool (27-Spline Axle) CV Boot Clamp Tool Internal Hex Socket Pinion Gear/Shaft Removal Tool Gear Case Seal Installer Tool Hub Retaining Wrench U-Joint Separator Tool

p/n 0544-010 0544-011 0444-120 0444-104 0444-127 0444-273 0444-270 0444-128

WC940A

4. Loosen but do not remove the mounting cap screw at the front of the actuator; then slide the actuator to the rear enough to clear the slotted mounting tab and the selector shaft. Remove through the bottom of the frame.

NOTE: Special tools are available from the Arctic Cat Service Department.

Front Drive Actuator NOTE: The actuator is not a serviceable component. If it is defective, it must be replaced. NOTE: The actuator will operate only when the ignition switch is in the ON position.

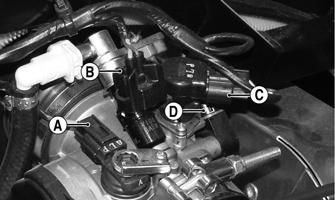

The front drive actuator is located on the left side of the front differential input housing. With the engine stopped and the ignition switch in the ON position, a momentary “whirring” sound can be heard each time the drive select switch is shifted. If no sound is heard, see Electrical System. If the actuator runs constantly or makes squealing or grinding sounds, the actuator must be replaced. REMOVING

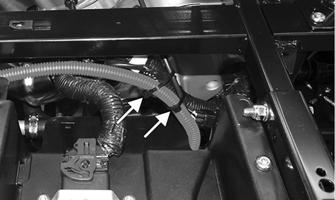

1. Select LOCK on the drive select switch; then disconnect the connector on the actuator harness. Remove the front six cap screws securing the skid plate to the frame.

WC939A

INSTALLING

1. Lubricate the O-rings on the actuator; then ensure all mounting surfaces are clean and free of debris. 2. Align the actuator with the selector shaft and slide it forward onto the shaft taking care to engage the cap screw in the slot of the front mounting tab. NOTE: Make sure to properly align the differential lock actuator lever with the hole in the differential lock plunger.

155