Fuel/Lubrication/Cooling NOTE: Arctic Cat recommends the use of new gaskets, lock nuts, and seals and lubricating all internal components when servicing the engine/transmission.

SPECIAL TOOLS A number of special tools must be available to the technician when performing service procedures in this section. Refer to the current Special Tools Catalog for the appropriate tool description. Description

p/n

Electric Choke Test Harness

0444-247

Oil Pressure Test Kit

0644-495

Tachometer

0644-275

KC328B

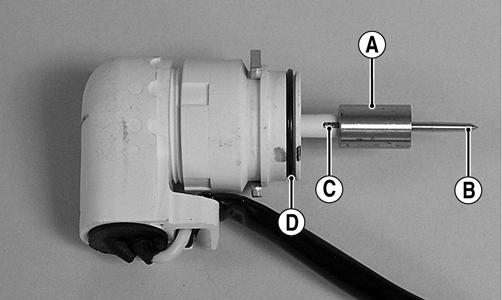

3. Connect Electric Choke Test Harness to the choke connector and a suitable 12 DC volt power supply for 2-3 minutes. Disconnect the power and measure plunger extension. Measurement (B) should be 22.1-23.4 mm.

NOTE: Special tools are available from the Arctic Cat Service Department.

Electric Choke REMOVING 1. Disconnect the electric choke connector from the wiring harness; then remove the screw securing the choke body to the carburetor. 2. Carefully remove the choke assembly from the carburetor taking care not to force the plunger from the carburetor body.

INSPECTING/TESTING 1. Inspect the plunger (A) for scoring or scratches, the needle (B) for damage to the tip, the spring (C) for breakage, and the O-ring (D) for breaks.

KC328C

4. If the choke is damaged or the measurements are not within specifications, the choke must be replaced.

INSTALLING 1. Lightly lubricate the O-ring on the choke body; then carefully insert the choke assembly into the carburetor being careful not to damage the plunger. 2. Secure the choke with the screw and tighten securely; then connect the choke connector to the wiring harness.

KC328A

2. With the choke at room temperature (approximately 70° F), measure plunger extension. Measurement (A) should be 18.6-19.1 mm.

73