2024 Safety Excellence Awards Benchmarking Report

2024 Safety Excellence Awards Benchmarking Report

I. Introduction

a) Who We Are

b) Purpose of Awards

II. Nominating Sites

III. Award Nominees

IV. Awards Recipients

V. Award Program Methodology

a) Benchmarking Process Goals

b) Procedure

VI. Benchmarking Results

VII. Conclusion

VIII. Contact Information

Table of Contents

2024 Safety Excellence Awards Benchmarking Report

I. Introduction

a. Who We Are

The Greater Baton Rouge Industry Alliance (GBRIA) is a trade association, 501(c)(6), whose membership includes 76 industrial plant facilities throughout the Louisiana Mississippi River industrial corridor. Its membership comprises manufacturers in petrochemical, refining, paper, bulk storage, and other industries. The mission of the organization is to bring value to communities by developing innovative solutions to common industry issues advocated with one voice.

GBRIA Safety, Health & Security Committee members:

Alan Smith, BASF

Amy Robbins, ExxonMobil

Andrew Downing, Westlake

Arthur Pennison, Westlake

Ayanna Burton, Nucor

Beau Braswell, IFF

Branden Bennett, Methanex

Brandon Dove, Methanex

Brandon Soileau, ExxonMobil

Clint Laborde, Olin

Craig Bordelon, Delek

Krotz Springs Refinery

Daniel Cousins, Eastman

Dave Mihalik, BASF

Deuce Leger, ExxonMobil

Don Pulliam, Lion

Elastomers

Drake LeBlanc, Honeywell

Eric Chambers, BASF

Jake Dinger, ExxonMobil

Jake Valenti, OxyChem

Jeremy Acosta, Methanex

Jim Hathcock, Orbia

Jonathan Devall, Placid

Refining

LaShantena Rounds, Nucor

Mark Hudson, Olin

GBRIA Safety Excellence Award Judges:

Adam Rabalais, Westlake

AJ Downing, Westlake

Alan Smith, BASF

Ayanna Burton, Nucor

Baraynia Robillard, ExxonMobil

Brandon Dove, Methanex

Bryan Smith, Shell

Geismar

Buck Dingler, SNF

Craig Bordelon, Delek

Krotz Springs Refinery

Damian Leone, Zen Noh Grain

Daniel Cousins, Eastman

Drake LeBlanc, Honeywell

Febbe Robertson, Orbia

Ivan Caldwell, SNF

Jake Valenti, OxyChem

Jason Zeringue, Dow

Jeff Carkuff, Westlake

Jennifer Garcia, Marathon

Jonathan Devall, Placid

La'Shantena Rounds, Nucor

Mark Morvant, Shell

Catalyst and Technologies

Nick Fontenot, Dow

Nikki Orgeron, NOVA

Richard Laborde, Ethos Energy

Rob Breaux, CF Industries

Ryan Estevens, Westlake

Sam Streacker, Marathon

Seth Arceneaux, Rubicon

Shane Ward, BASF

Thomas Stanga, Orbia

Wade Patrick, Rubicon

Matthew Regan, Shell Geismar

Nick Fontenot, Dow

Peyton Chiasson, OxyChem

Ricky Laborde, Ethos Energy

Ron Banker, Shell Geismar

Roy Landry, ExxonMobil

Sam Steacker, Marathon

Shauna Mitchell, Nucor

Wade Patrick, Rubicon

Will Arnold, ExxonMobil

Zach Boudreaux, TotalEnergies

2024 Safety Excellence Awards Benchmarking Report

b. Purpose of the Awards

The GBRIA Safety Excellence Awards Program recognizes the commendable safety performance of industrial contractor firms and GBRIA member industrial facilities. Furthermore, this program is a review of the management systems and processes that promote successful execution of millions of hours of safe work. The awards are intended to convey strong support by GBRIA members of contractor and plant safety programs and performance, recognizing that contractors have the primary responsibility for the execution of on-site safety while working together with plants and construction project owners to ensure a safe workplace.

Hal G. Ginn, former Plant Manager of DSM Copolymer and former GBRIA Board member, championed the development of GBRIA’s Contractor Safety Excellence Awards in 1996. The awards and benchmarking program entered its 28th year in 2024.

II. Nominating Sites:

Air Liquide

Albemarle

BASF

CF Industries

Chalmette Refining

Cornerstone Chemical

Delek – Krotz Springs

Refinery

Deltech

Dow

Ethos Energy

ExxonMobil Baton Rouge Complex

ExxonMobil BRPO

ExxonMobil BRPP

Formosa Plastics

Grace

Honeywell Baton Rouge

Honeywell Geismar

Honeywell UOP

INEOS Oxide

Innophos

Linde

Lion Elastomers

Marathon Petroleum

Methanex

NOVA Chemicals

Nucor Steel

Nutrien

Olin St. Gabriel

Olin Plaquemine

Orbia

OxyChem Convent

OxyChem Geismar

Placid Refining

Rubicon

Shell Catalyst & Technologies

Shell Chemical Geismar

Shintech Louisiana

SNF Flopam

Syngenta Crop Protection

TotalEnergies

Veolia Burnside

Westlake Geismar

Westlake Plaquemine

2024 Safety Excellence Awards Benchmarking Report

III. Award Nominees:

3-S Team

Action Industries

Acuren Inspection

Apache Industrial Services

APC Construction

Ardent Services

Arkel Constructors

Austin Fire Systems

Axion Logistics

Barracuda

BGS

BrandSafway

Brock Services Ltd

Brown and Root Industrial Services

Cajun Industries

CAM Industrial Solutions

Camin Cargo Control

Claymar Construction

Coating Services

Conco Services

ControlWorx

Deep South Crane & Rigging

Diamond Refractory

Evergreen North America

IV. 2024 Award Recipients

Specialty Awards

EXCEL

Excel Scaffolding & Leasing

Great River Industries

Industrial Specialists

IRISNDT

ISC

John L Lowery & Associates

JVIC

Koch Specialty Plant Services

Loadstar Product Handling Services

Maviro

Midwest Cooling Tower

MMR Group

Moore Industries

NextGen Scaffold Services

Optimal Field Service

PALA-Interstate Inc

Performance Contractors

Petrin Corporation

Pipe and Steel Industrial Fabricators

Precision Inspection Services

Process Service Specialists

PSC Group

Hal G. Ginn Award (Best Safety Performance Overall)

Cajun Industries

Community Service Awards

RES Contractors

Turner Industries Group

Innovation in Safety Award

Brock Services Group

Repcon

RES Contractors

River Parish Contractors

Specialty Welding and Turnarounds (SWAT)

The McDonnel Group

Total Safety US

Triad Electric and Controls

Turnaround Specialty Group (TSG)

Turnaround Welding Service

Turner Industrial Maintenance

Turner Industries Group

Turner Specialty Services

United Plant Services

Veolia Water North America

Operating Services

Volks Constructors

Water Works Industrial Services

Westgate

2024 Safety Excellence Awards Benchmarking Report

2024 Safety Excellence Awards Benchmarking Report General Construction and Maintenance Division I: 1st Place: PALA-Interstate 2nd Place: RES Contractors 3rd Place: Action Industries Division II: 1st Place: Cajun Industries 2nd Place: CAM Industrial Solutions 3rd Place: JVIC, A Zachry Group Company Division III: 1st Place: Brown & Root Industrial Services 2nd Place: Turner Industries Group 3rd Place: Performance Contractors Specialty Construction 1st Place: Arkel Constructors 2nd Place: The McDonnel Group 3rd Place: APC Construction Crane & Rigging 1st Place: Deep South Crane & Rigging Specialty Trade Hard Craft Division I: 1st Place: Westgate 2nd Place: Midwest Cooling Tower 3rd Place: No Placement Division II: 1st Place: Koch Specialty Plant Services 2nd Place: ControlWorx LLC 3rd Place: Process Service Specialists Division III: 1st Place: MMR Group 2nd Place: ISC Constructors 3rd Place: No Placement Specialty Trade Soft Craft Division I: 1st Place: Coating Services, The Foust Group 2nd Place: Diamond Refractory 3rd Place: No Placement Division II: 1st Place: Turner Specialty Services 2nd Place: BrandSafway 3rd Place: Industrial Specialists Division III: 1st Place: Brock Services 2nd Place: Apache Industrial Services 3rd Place: No Placement Specialty Trades - Environmental Division I: 1st Place: Conco Services LLC 2nd Place: No Placement 3rd Place: No Placement Division II: 1st Place: Evergreen North America 2nd Place: No Placement 3rd Place: No Placement Technical Support Division I: 1st Place: Loadstar Product Handling Services 2nd Place: Precision Inspection Services 3rd Place: Axion Logistics Division II: 1st Place: Camin Cargo Control 2nd Place: IRISNDT 3rd Place: No Placement Division III: 1st Place: Acuren Inspection, Inc. 2nd Place: Total Safety U.S. 3rd Place: No Placement

IV. Award Program Methodology

The methodology used for compiling the survey and benchmarking report includes the process goals and procedures.

a. Benchmarking Process Goals

This benchmarking process is part of an initiative by GBRIA members to gain a better understanding of current safety records and efforts in Southeast Louisiana. The review data collected was used to:

a) Publish this report (all data is confidential, and no company is identified or identifiable from this report data) that will allow plants and contractors to benchmark their Safety efforts to work toward continuous improvement.

b) Serve as a basis for selecting companies with excellent efforts for a GBRIA Safety Excellence Award.

c) Improve programs for safety development.

b. Procedure

1. The “Call for Nominations” was sent to GBRIA members on December 4, 2023. The notification included a link to an online nomination form. Plants were encouraged to nominate their contractors and contractors were encouraged to request them. Nominations were collected between December 4, 2023, and January 12, 2024.

2. Once the nomination period closed, nominees were notified of their nomination and sent instructions to complete the GBRIA Safety Excellence Awards Application, which included a series of questions asking for safety statistics and narrative responses to 19 questions spanning 5 sections: Commitment, Training and Development, Innovation, Learning Organization, and Community Service. Reference documents were required for select questions throughout the application.

3. After the application period closed, judges from across GBRIA’s membership received their judging assignments. Each application was assigned to 3 judges, with special consideration to diverse judging panels, e.g., professional disciplines and companies. Judges reviewed applications between February 12th – 23rd, submitting their scores via an online submission form.

4. Scores from judge reviews were downloaded, averaged, and presented to the assembled judges at a meeting on February 29th. Here, judges confirmed correct placement of nominee category and division, as well as setting a minimum cut score to receive an award. Judges also reviewed overall award placements and agreed, by consensus, that the placements accurately reflected the application quality and programs highlighted therein. Note: Nominees were placed into like or similar categories for a fair comparison, considering the scope of work performed by the nominee. In each category, where applicable, nominees were also divided into divisions I, II, or III, to group companies of a similar size and with similar resources based on total hours worked company wide.

5. After award placements were made, judges were tasked with a 2nd round review of all nominees who placed 1st in their respective divisions, as contenders for the Hal G. Ginn Award, the award recognizing the top performer. Judges were also tasked with reviewing

2024 Safety Excellence Awards Benchmarking Report

submissions for the Innovation in Safety and Community Service Awards. Nominees for these awards were selected from the initial application review, where all three judges flagged the nominee’s submission for further consideration by the entire judging committee.

6. Judges convened for a final time on March 7th to review nominees for the Hal G. Ginn, Innovation in Safety, and Community Service Awards to make their final placement decisions, on a consensus basis.

7. Nominees were notified on March 6th of the finalist status, indicating if their company would receive an award at the banquet. Award placements were announced during the banquet on March 21st .

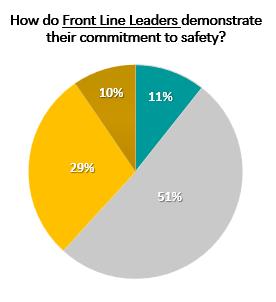

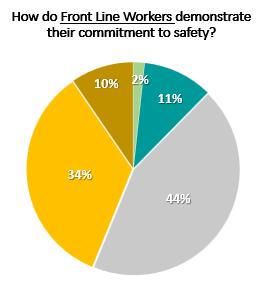

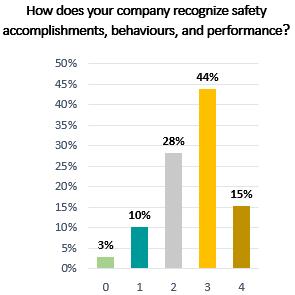

V. Benchmarking Results

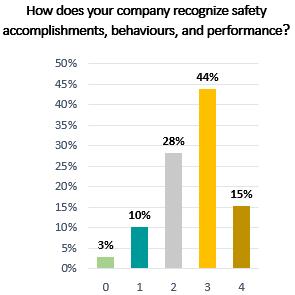

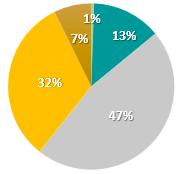

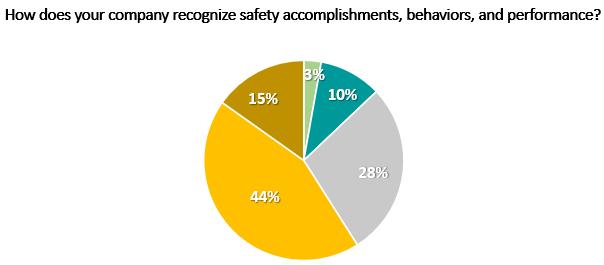

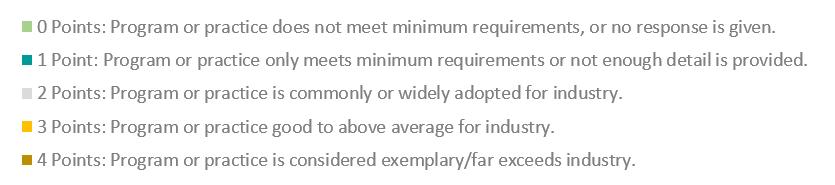

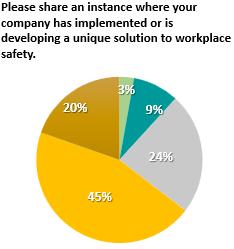

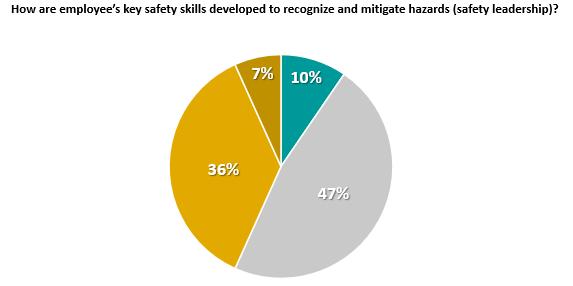

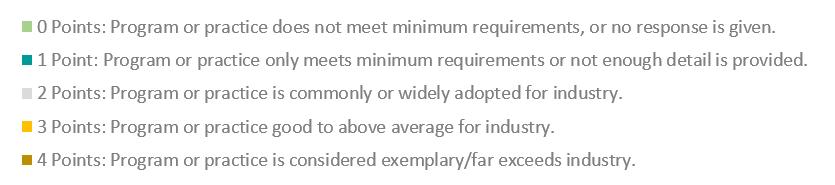

The results of the benchmarking effort include the average scoring for each question by all the nominees on a 0-4 grading scale.

Application Section Scoring

0 Program or practice does not meet minimum requirements, or no response is given.

1 Program or practice only meets minimum requirements or not enough detail is provided.

2 Program or practice is commonly or widely adopted for industry.

3 Program or practice good to above average for industry.

4 Program or practice is considered exemplary/far exceeds industry.

Overall Application Scoring

0 The application is incomplete or missing significant sections and/or attachments.

1 The application shows the beginnings of systemic processes/efforts but is below the expectations of industrial contractors or the application lacks completeness.

2 The application shows sound, systemic processes/efforts that correspond with baseline expectations for industrial contractors, i.e., lacking evidence of continuous improvement, leadership across all levels of the program, etc.

3 The application shows sound, systemic processes/efforts, and methods of continuous improvement, indicating practices that are above average for industrial contractors.

4 The application shows exemplary systemic processes/efforts, mature programs with sustained results, and indicates world-class programs/practices.

2024 Safety Excellence Awards Benchmarking Report

2024 Safety Excellence Awards Benchmarking Report

2024 Safety Excellence Awards Benchmarking Report

2024 Safety Excellence Awards Benchmarking Report

2024 Safety Excellence Awards Benchmarking Report

b. Total Hours and Number of Employees per year

The 63 nominees represent an approximate total of 227,287,005 million hours worked in the industrial sector over that last fiscal year. The hours are broken down into following categories:

• General Construction & Maintenance -103,983,249 Hours

• Specialty Trade Soft Crafts – 51,527,216 Hours

• Technical Support- 32,267,303 Hours

• Specialty Trade Hard Crafts – 32,018,691 Hours

• Specialty Trades Environmental- 4,620,532 Hours

• Crane and Rigging – 1,694,426 Hours

• Specialty Construction (Commercial & Civil) – 1,175,588 Hours

2024 Safety Excellence Awards Benchmarking Report

VI. Conclusion

The new application and review processes have allowed this awards program to enter a new era of review and recognition of not only safety performance, but also the programs, initiatives, and work processes to drive that performance. A move in this direction allows GBRIA and industry, plant members and contractors alike, to learn from each other the best practices that help them excel in their day-to-day work and send their employees home happy, healthy, and safe.

The overwhelming majority of nominated companies scored in each question and overall, at or above expectations for an industrial contractor. It is the opinion of the judging panel that most of the scores falling below the average reflected the time spent preparing the application and/or providing enough detail and clarity in the responses to garner a score more reflective of their programs and processes.

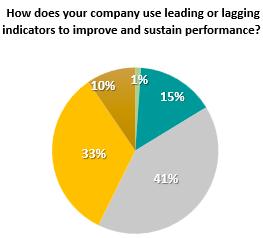

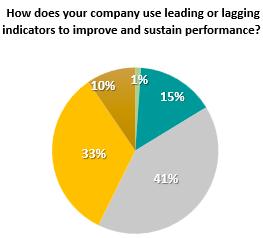

Nevertheless, the scores indicated above still point to several areas of interest where industrial contractor can move from average to above average programming, such as developing and supporting leadership training, which has ripple effects on other areas of a company’s performance, developing and implementing a broader range of leading indicators to identify areas of concern before they become a lagging indicator, implementing a systematic approach to training relevancy, retention, and effectiveness in both safety and work skills, and strengthening incident investigation and communication processes that allow others to identify similar conditions on other job sites and increase transparency in the findings close out process.

VII. Contact Information

For more information on this awards and benchmarking survey program, please contact:

Brandon M. Smith, CSP

Director of Safety, Health, Security, Workforce Development, and Operational Strategy

Greater Baton Rouge Industry Alliance (GBRIA)

8555 United Plaza Blvd., Suite 202

Baton Rouge, LA 70809

Tel: 225-769-0596

brandon@gbria.org

www.gbria.org

2024 Safety Excellence Awards Benchmarking Report

2024 Safety Excellence Awards Benchmarking Report

2024 Safety Excellence Awards Benchmarking Report