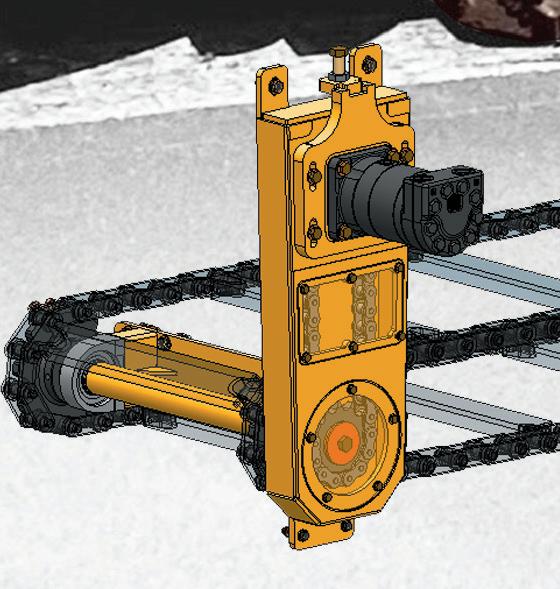

Since its introduction, the Weiler P385 has set the standard for commercial pavers. The P385C raises that standard.

Variable speed and reversible conveyors and augers and a 25% increase in tunnel height provide optimal material output.

Increase to 120 hp with the Cat® C3.6 Tier 4F/Stage V engine.

To elevate your striping game, it’s all about the technology and the tools. We talked to two contractors known for being early adopters, and a company building autonomous striping robots that are available right now, and could change the entire industry.

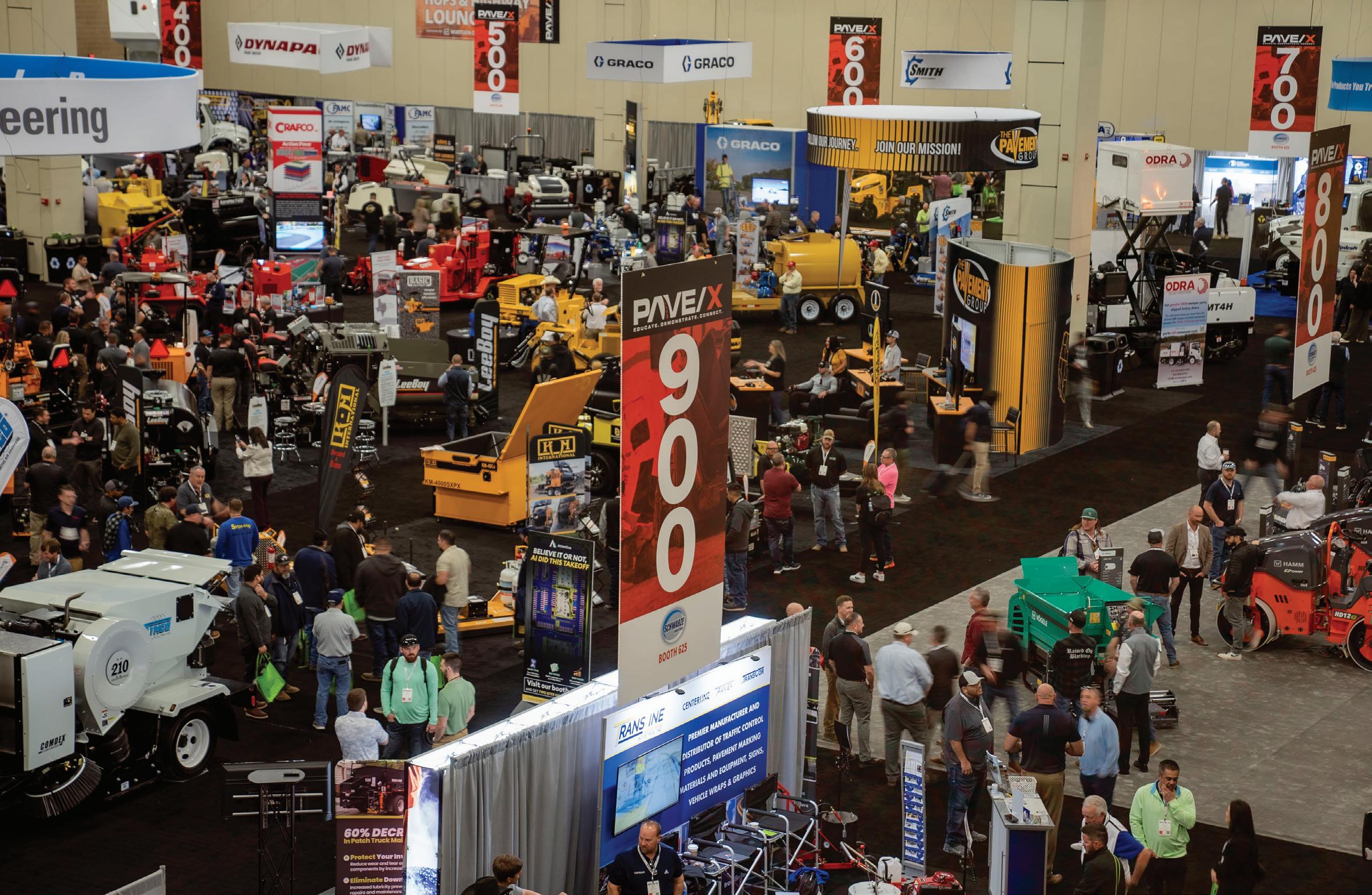

Nashville was hardly big enough to contain everything that World of Asphalt 2024 had to offer, and whether you were there or not, there are plenty of things you might have missed!

Formoreinformationvisit

https://pavemg.com/WOA2024

Kevin Garcia (Trimble) discusses BIM, digital twins, and how the real way to fix your asphalt mat is what’s underneath it.

Formoreinformationvisit

https://pavemg.com/jx470jd3

Tom Chastain, milling project manager for WIRTGEN GROUP, showcases the new W 150 Fi Milling Machine at this year’s World of Asphalt! This machine is particularly suitable for large construction sites with limited space due to its milling width of up to a maximum of 1.80 m

Formoreinformationvisit

https://pavemg.com/1qsl4qj7

My first time at World of Asphalt coincided with my first trip to Nashville. It was a match made in heaven.

Ahead of World of Asphalt 2024, I kept hearing people refer to the destination (Nashville, Tenn.) as “Nashvegas.” Turns out that’s not just a cute moniker given to it by tourists — it’s literally painted on the side of a building on the city’s busiest thoroughfare. Let me tell you, friends, the city lives up to the hype. The food, the parties, the nightlife, and...oh...right...the location of the biggest tradeshow for the asphalt industry.

As of today, it was reported that there was a 38% increase in attendance this year over the record breaking year the show had in 2022. There were 440 exhibitors, 120 educational sessions, and more than 15,800 professionals from all across the asphalt pavement world.

Let me assure you, that from early in the morning of Day One of the show, you could feel every single digit of that 15,800 attendance. It was jam packed with people, sometimes so thick that you would look into a booth, and not be able to see anything but people. At times, there were 2-3 attendees for every 1 booth worker, and everyone looked like they were having a great time.

I was maybe able to visit with 25% of that 440 exhibitors, but I asked every single one, “How’s the show been for you?” and each and every one one of them had the same emphatic answer. They all felt the show was maybe the best ever! Whether I visited big booths or smaller booths, it didn’t matter. Everyone was in high spirits and spoke positively of their time.

That was true, not just of the exhibitors, but also of the contractors I spoke to. There’s one interaction in particular I’d like to highlight.

On the second night of the show, due to some communication difficulties and a reservation error, I found myself on the outside of a dinner that I was originally going to attend with some folks. So, I ended up connecting with some guys from a paving company based out of Georgia. The reason I want to draw attention to this is because it kind of represented to me the real value of these industry events.

We bonded over our shared love of cigars (something that happened to me multiple times at WOA, as people just walked up to me and handed me a cigar) and talked for over two hours about the unsung heroes of this job [shoutout to Luke the bartender at The Ariston]. It takes a lot of people to make it happen every day, and considering the national tragedy that took place that same day where six lives of a road crew were lost when the Francis Scott Key bridge collapsed, now more than ever, these connections with one another are important.

I’m grateful that this job gives me the opportunity to travel and meet the awesome people who do this work around the country. I’m grateful to each of you out there reading this right now, who’ve I’ve been able to spend some time with in one form or another. I’m grateful to all those who’ve taken time to teach me things about asphalt and pavement maintenance.

I’m about to hit two years as your editor, and it really feels like I’m just getting started. There’s a whole lot more to come.

See you on the road! ■

Engineered for safety and efficiency, Crafco’s new EZ Patcher ensures your crew can work with confidence and precision. With intuitive controls and seamless operation, the EZ Patcher maximizes performance while prioritizing safety, making it the ideal choice for fast and reliable repairs on any job site.

Hitachi Construction Machinery Americas has announced the opening of its newest headquarters building in Georgia.

According to a press release: In a strategic move to bolster support for dealers and customers, Hitachi Construction Machinery Americas announces the opening of a sustainable, state-ofthe-art headquarters facility in Newnan, Ga. This adaptive-use facility will help propel the company’s growth in the Americas. It will facilitate the development and production of new machinery and elevate customer support.

Hitachi Construction Machinery

Americas continues to expand employment opportunities as it strengthens customer offerings and support. Since taking the lead for the brand’s construction and mining equipment in the Americas, the company has more than tripled its employee count. Encompassing 88,128 ft2 (8,187 m) of office space and 27,686 ft (2,572 m) dedicated to conference, ConSite command center and training space, the headquarters has been designed to enhance creativity and inspire future growth.

This space is set to play a pivotal role in the company’s future expansion initiatives.

“In March 2022, we set out on a path to establish a more direct connection with customers. Our culture has been very much involved with listening, understanding and implementing customer feedback,” said Al Quinn, CEO of Hitachi Construction Machinery Americas. “By combining the resources of the excavator, loader and mining businesses, the company has experienced a tenfold demand from previous years. The investment in a regional Americas facility helps strengthen that direct connection to the customer.”

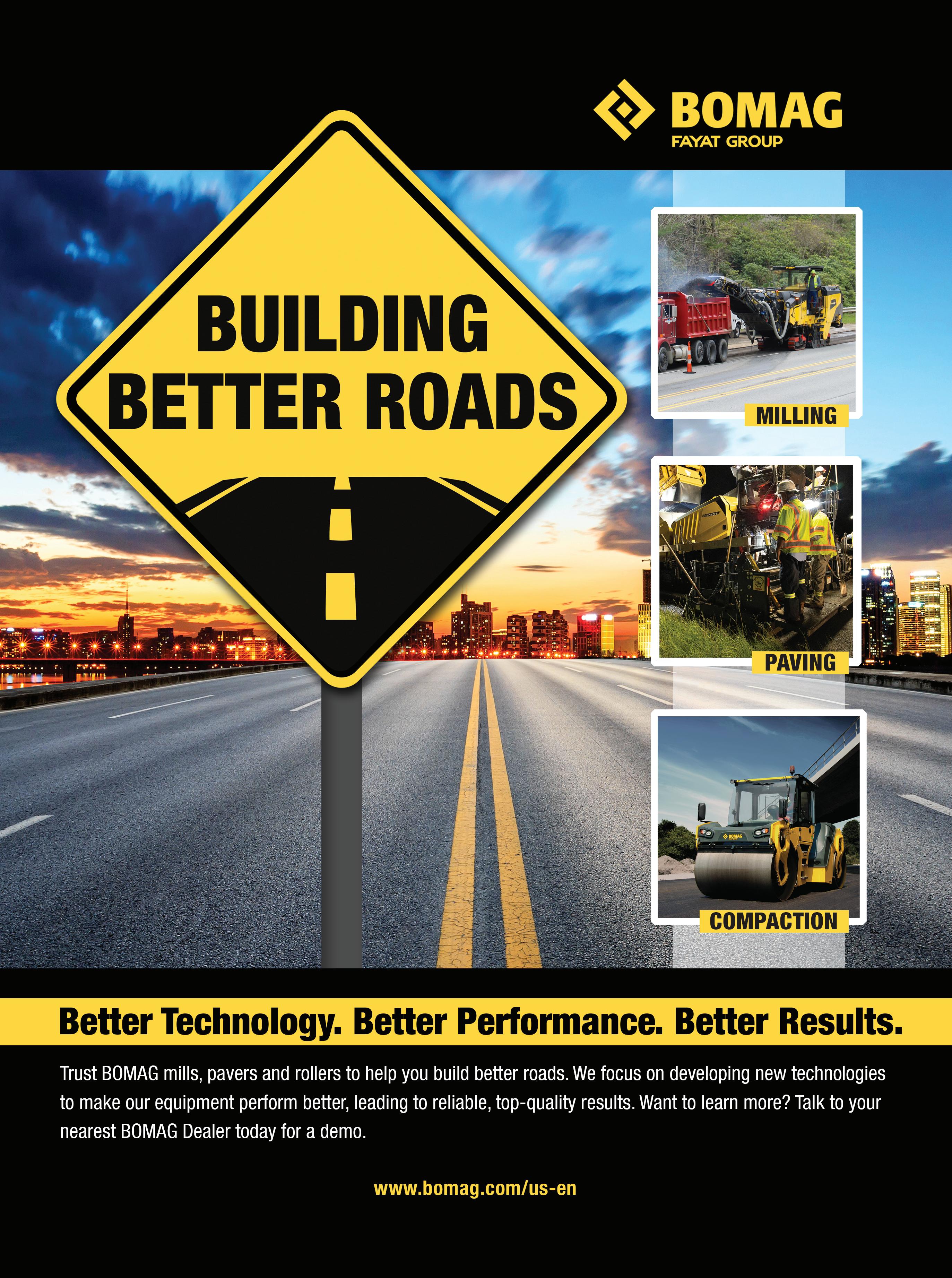

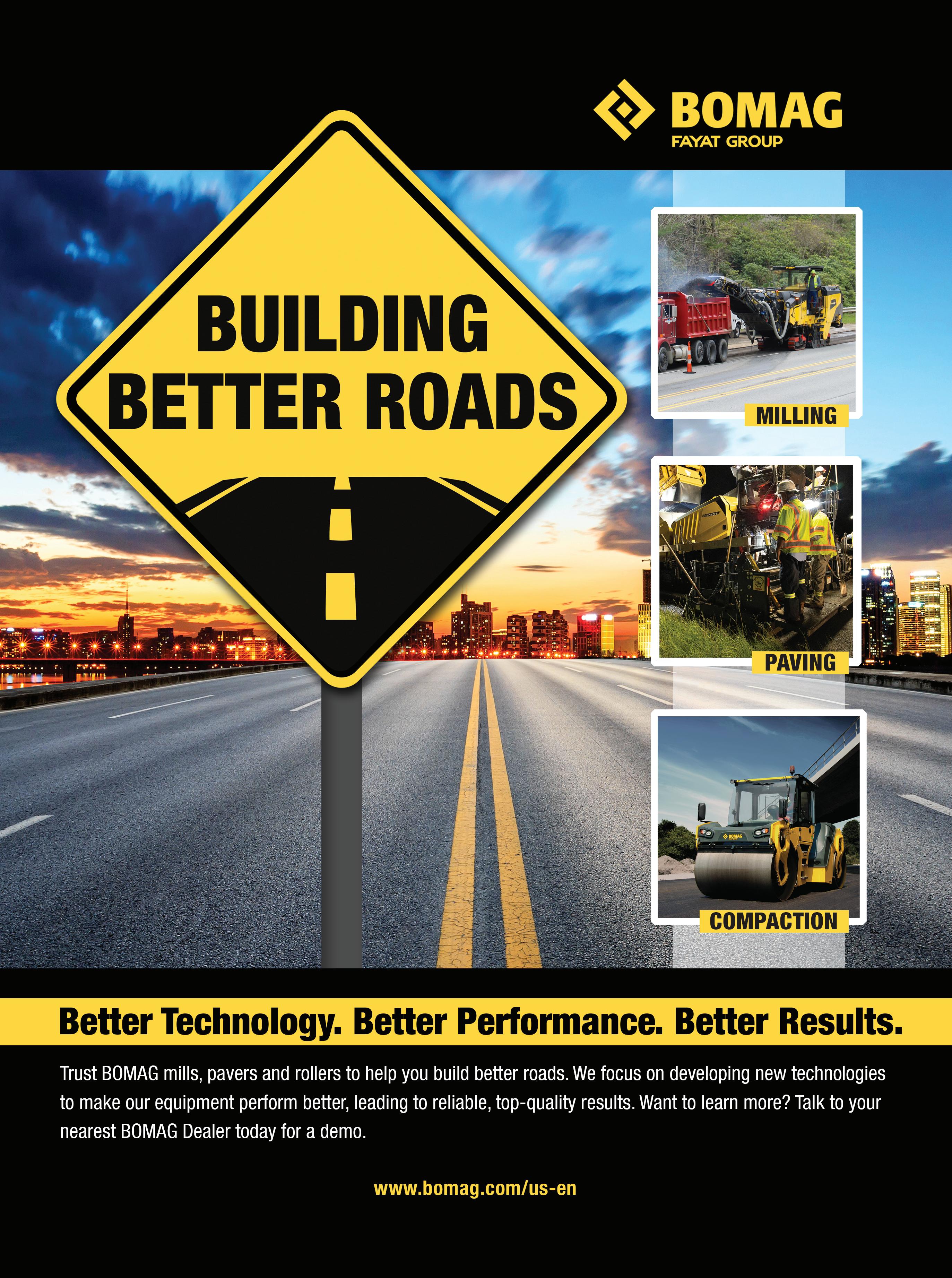

BOMAG Americas announces that Bill Nittinger has joined the sales team as the director of dealer channel sales, western region and Canada. In his new role, Nittinger will be responsible for developing and implementing sales strategy, dealer development, and working with BOMAG territory managers and dealers throughout the region to grow the brand and market share.

Joining the BOMAG Americas team marks a return to OEM sales for Nittinger, who brings 36 years of experience to the position. Most recently, he worked as operations manager for an independent heavy equipment distributor. He also spent 10 years in sales with two larger heavy equipment dealerships, working as operations manager and a sales manager, where he had responsibility for both retail and rental business while growing the dealership’s profitability. Nittinger also offers 10 years OEM experience in the road building industry, working in sales for another road building equipment manufacturer.

Speaking on Nittinger’s appointment, Cole Renken, vice president of sales and marketing for BOMAG Americas offered: “Beyond his decades of working on both the OEM and dealership sides of the business, Bill also has more than 16 years of experience in retail and wholesale finance. His enthusiasm for the business plus his wealth of experience will help drive his success for BOMAG and our dealers in this region. We are excited to have him join the BOMAG team.”

Nittinger added that he is excited to be back in the road building industry where he worked alongside family members during his time with another OEM. “Working with my dad and brothers helped me to develop a passion for road building. Additionally, my experience at the dealership level gave me a better understanding of the tools our dealers need to be successful with their business models. BOMAG is a quality company with quality equipment, and I’m anxious to do my part to help customers get the most out of BOMAG equipment and technology.”

Bergkamp Inc., based in Salina, Kan., is pleased to announce its acquisition of the renowned Flow Boy line of live-bottom material transport trucks. With the ability to unload hot asphalt, gravel, sand, or other materials in one minute or less, all from inside the truck cab, the Flow Boy Live-Bottom offers productivity and efficiency for paving contractors. In today’s asphalt industry, the name “Flow Boy” has become synonymous with “live-bottom transport,” as it is the original live-bottom — renowned for its long-standing quality and performance in the industry. The Flow Boy acquisition by Bergkamp provides a natural expansion of the company’s product lines, in line with its mission of providing customers with the highest-quality equipment. The live-bottom transporter aims to provide a more efficient and safer way to haul material and load their pavers without the height and tipping hazards typically associated with dump-style units.

• Highly-portable design for increased mobility

• Cut a path up to 8 in wide

• Wide variety of cutters and accessories for job flexibility

• Depth control lever and dial for fine-tuning your removal

• Adjustable handlebars and vibration-reducing grips for operator comfort

• Reliable 6.5 HP and 9 HP Honda® gasoline engines

• Graco GrindLazer Standard Series scarifiers are great for removing trip hazards and smaller traffic markings. These highly-portable scarifiers pack a ton of capability into a light, compact package that’s easy to load into the back of a truck. This makes them ideal for tackling multiple smaller jobs quickly or working in urban areas with limited parking.

by Jessica Lombardo, Director, Event Content & Programming

by Jessica Lombardo, Director, Event Content & Programming

Sights set on an even better year two!

First of all, a sincere thank you to everyone who attended the inaugural PAVE/X event in San Antonio in February. We were so thrilled to bring this new event to an industry we love and are still carrying the excitement with us from those sunny Texas days out in the demo lot.

As we build year two, we want you to know that we heard you. We listened to every contractor who was kind enough to give us feedback and are actively working to make the 2025 event in Chattanooga even more epic.

BIGGER.

As of right now, space is more than 80% sold out and will fill up fast. You can always view the current showfloor map here: https://pavex25.expofp.com/

Attendees in 2024 let us know they wanted more showfloor space and extended hours and we are happy to be able to provide that in 2025. The showfloor will be open early alongside the education and stay open later during the live demos so attendees can choose where to best spend their time.

In addition, the showfloor in Chattanooga is double the size from San Antonio. We are intentionally filling that space with exhibitors we know will provide the most value to attendees. Have someone you’d like to see in Chattanooga? Have them reach out to us at info@pavexshow.com.

On top of advanced tradeshow hours, we’re also bringing even better education to the 2025 program. We are working to build a mix of introductory classes, coupled with high-level business courses to provide classes for contractors at every level.

Brad Humphrey will be giving a 3-hour workshop on Monday, 1/27 to jumpstart contractors on their business operations before the full conference program begins on Tuesday.

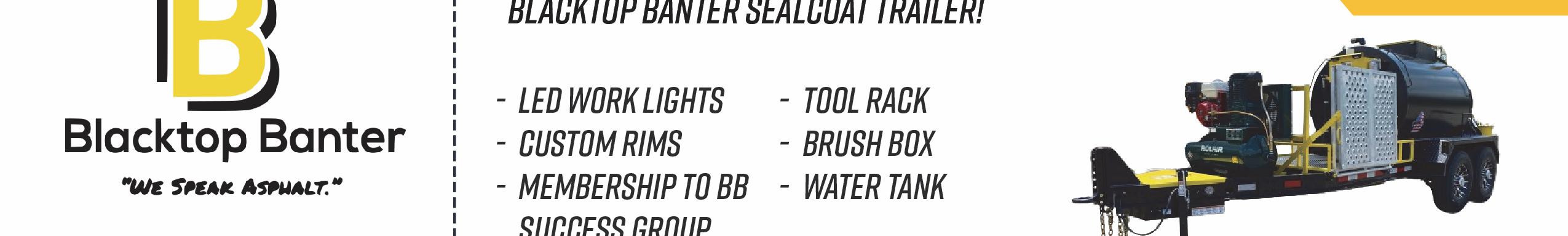

The Blacktop Banter kickoff party will also be that night at The Coker Museum with even more space and fun to start the week.

The Industry Roundtable experience will also be revamped. These are valuable contractor connection points and we want to give them the time and the space they deserve so that they can continue to be a great resource for contractors.

BOLDER.

Did you think the demos in 2024 were fun? Just wait to see what we have planned for 2025 - actual seat time for contractors. Our demo lot, behind Naked River Brewing and BBQ, offers ample space for our manufacturers to give attendees time to run their equipment around. Each manufacturer with a demo slot will have a lane where operators can sign up for a time to run the machine in that lane, to really get a feel for the equipment before they buy.

There will also be static outdoor demo spots for smaller equipment so contractors can get their hands on the machines and ask questions from the experts.

As we continue to build an event experience that the paving and pavement maintenance industry professionals find worthy of their time, please keep in touch with us. Whether it’s a speaker, outdoor demo, event experience or manufacturer, we want to know what you are hoping to see next year.

Reach us at info@pavexshow.com. Registration for PAVE/X 2025 will open in July. Keep in touch until then and we’ll see you in Chattanooga! ■

For more information visit https://pavemg.com/pavex

the world’s first-ever all-electric skid-steer loader, the Bobcat S7X.

Operating on lithium-ion batteries like its compact track loader counterpart, the Bobcat T7X, the two machines promise high performance with electric power. Additionally, neither produce emissions.

“As a result, operators can tackle tough jobs on environmentally sensitive worksites or indoors where exhaust is restricted,” said Joel Honeyman, vice president of global innovation, Doosan Bobcat.

Aside from emission control, both loaders offer high productivity and reduced noise levels when compared to other similar equipment on the market, despite being more powerful than their diesel-hydraulic equivalents. Of equal importance, they feature electric drive motors, ball screw actuators, and electric actuation and propulsion, instead of hydraulics.

“Since they’re both powerful and quiet, they can be operated at all hours

of the day, too, including in dense, urban areas, in which noise often limits operators’ work hours,” Honeyman added.

Due to their minimal vibration and quiet operations, the all-electric loaders enable operators to have comfortable, smooth experiences with each use. They’ll also notice a considerable increase in power, in comparison to the traditional diesel-powered loaders they previously used. As an example of this boost in power, the S7X can be operated for up to six hours at a time, while the T7X can operate for up to four hours on one charge, depending on the application.

“It’s important to note that, unlike diesel machines, when the S7X and T7X are at idle, they’re not consuming energy,” Honeyman said. “Apart from routine recharge cycles, each lithiumion battery, which, again, is featured on every all-electric loader, doesn’t require any maintenance, either.”

With regard to maintenance, the compact, all-electric loaders’

straightforwardness is noticed well beyond their lithium-ion batteries, as they each include roughly half the

parts that diesel-powered compact loaders do, along with nearly 20% fewer electrical connections. Since they are equipped with fewer parts and electrical connections, the compact loaders—which have been created in partnership with Moog Construction, a motion control components and systems developer—also have fewer components to maintain and repair.

“These all-electric loaders take about 2 gallons of eco-friendly coolant and a half-gallon of gear box oil, compared to the nearly 60 gallons of fluids that are required in diesel-powered loaders, leading to cost savings on a short- and long-term basis,” he emphasized.

Much like Bobcat’s S7X and T7X, VOLTEQ Equipment’s electric mini

skid steer, the SKY 1000, offers a variety of benefits, including emission control. For example, the SKY 1000 is built with fewer components than diesel-powered skid steers, leading to less maintenance and, in turn, a lower total cost of ownership than diesel-powered offerings.

The SKY 1000 also provides operators lower operating costs, along with a reduced need for planned maintenance and the convenience of not having to warm up engines. Furthermore, the skid steers don’t consume any energy when idling.

“Unlike diesel engines that continue running, even when machines are in idle, our electric mini skid steers will automatically switch off whenever operators stop them, thus minimizing unnecessary energy consumption,” said Mike Slattery, vice president of business development, VOLTEQ. “Consequently, they offer significant advantages, in terms of both operating and maintenance costs.”

The mini skid steers also feature immediate slow speed control and provide instant torque, resulting in faster responsiveness and more precise, controlled movements. And, as is the case with the S7X and T7X, VOLTEQ’s SKY 1000 operates quietly, almost silently, in fact, enabling them to be utilized in cities, as well as indoors, according to Slattery.

“They excel in indoor environments especially, due to their zero emissions and quieter operation, making them suitable for automating tasks like cleaning, debris removal and material placement in confined spaces,” Slattery continued. “When they’re equipped with remote control technology, they can be automated for tasks in hazardous or hard-to-reach areas, thereby enhancing safety and reducing operators’ risks.”

As a result of their battery packs, electric skid steers offer low centers of gravity, too, leading to high stability, said Martin Havrda, chairman of the board of directors at FIRSTGREEN Industries.

“Due to the maintenance-free nature of electric skid steers’ lithium batteries,

along with their simplified mechanical systems, they also reduce the risk of breakdowns and the costs of sourcing and fitting replacements,” VOLTEQ’s Slattery stated. “This translates to lower maintenance expenses and increased uptime for construction projects.”

By utilizing electric skid steers, operators can also easily automate their bucket levelling, which is electronically controlled and, subsequently, capable of quickly reacting to acceleration, deceleration and gradient changes.

“Bucket loads are automatically estimated, as well, in order to prevent machine overloading,” Havrda said. “Data is then uploaded into a remote diagnostic tool, which simplifies troubleshooting, resulting in more efficient operations.”

With regard to construction automation as a whole, Slattery has noticed a variety of trends:

• First, due to mobile electronics’ advancements, manufacturers can offer operators automated functionalities, such as self-leveling loader arms, which have float control, in an easier and more cost-effective manner than before.

• Second, as a result of return-to-dig, along with the ability to lock in a desired speed, operators’ equipment can automatically travel at that preferred speeds as soon as they move their joystick.

• And, finally, several tasks, including the movement of materials from one area to another in an effortlessly mapped environment, can be automated, via GPS and light detection and ranging LiDAR technologies.

Meanwhile, according to Havrda, another key trend is being noticed, concerning construction automation: electric skid steers that can react to outside conditions. For instance, FIRSTGREEN Industries’ electric skid steers can drive with full loads, while their electric motors automatically adapt

to prevent overheating, especially as outdoor temperatures rise.

“The automation of certain tasks is also a new development, when it comes to activities that are repeated, including materials offloading into containers,” he said. “Electric skid steers, designed for automation, will have a higher number of sensors and cameras too, which will function as their ‘eyes and ears’.”

Simultaneously, according to Bobcat’s Honeyman, digitization is “changing the game,” with regard to compact equipment, including skid steers.

“Automation, when applied intentionally and strategically, pushes productivity to new heights, resulting in more effective worksites,” he stressed. “For instance, technology features can reduce the number of operators that are needed on a jobsite, thus reducing costs and enhancing construction teams’ productivity.”

Bobcat provides digital offerings like Bobcat MaxControl and Bobcat Machine IQ, which enable operators to acquire as much from their investments as possible since they’re able to leverage smart, simple tools, to achieve more of their goals. As an example of its intelligence and ease of use, Bobcat MaxControl allows operators to control each of their Bobcat loaders and attachments from outside of their cabs, while using a compatible device.

According to Honeyman, Bobcat MaxControl is especially useful when operators are shorthanded on their jobsites, as two-person jobs can be handled by only one person. By using Bobcat MaxControl, operators can avoid repetitive trips in and out of their cabs. While utilizing Bobcat Machine IQ, equipment owners can also monitor their Bobcat skid steers’ health, while remotely tracking information that enhances maintenance, security and performance. ■

Chris Lewis is a freelance writer for the construction industry.

For more information visit https://pavemg.com/ e6dfes

The best uses for mastics and crack sealers in various applications.

Iwas recently scrolling on social media (I know, surprising) and I saw a video of my longtime peer Ryan, over in Massachusetts, doing some mastic work. I have zero experience using mastic. It just isn’t a “thing” here in rural Wisconsin, but I am always fascinated by the demos and videos I have seen of it in use. For those of you who don’t know already, I am an asphalt

maintenance geek, and that stuff is what fills up most of my feed. So, when speaking to the editor of this magazine, Brandon, recently at a conference, I asked how I could help create some content for Pavement Magazine and he said an article about this very topic would be appreciated. I knew just who to speak with. Luckily, the asphalt and asphalt maintenance contractor

community are a tight knit group and always open to sharing info, knowledge, and experience. Ryan is no different.

Ryan has been at it for a long time now. Upon asking, I was fortunate enough to have my friend from Premier Sealcoating and Line Striping out of Oxford, Mass., join me on the Blacktop Banter Podcast to talk about his use of mastic and crack sealant, along with the pros, cons, and prep for each. Let’s jump into the highlights of that conversation

now:

What is it?

Ryan explains that mastic is a block, or brick, of asphalt binder and on top of it (inside the box) is a bag of aggregate that gets mixed into the machine with the binder block. Then heated and agitated to create a thoroughly mixed

Dynapac’s CC900G/CC950, are modern small tandem rollers designed for small-scale compaction work such as patching, bicycle paths, parking lots, driveways, etc. These machines are equipped with reliable Honda gas or Kubota diesel engines and the largest drum diameter in the class (23 inches). The drive motors connected in series, together with the large drum diameter provide excellent gradeability and productivity.

Go the extra mile with a pressurized water system and spring loaded scrapers

Simple and easy operating controls

Service components are easily accessible

Reliable Honda gas (900G) or Kubota diesel (950) engine

Maintenance free heavy duty articulation hitch

Long lasting drum with the thickest drum shell in its class. (0.4 in)

Highest rated operator comfort with insulated front and rear drums

$

Now available with industry-leading finance options

Foldable ROPS for easy transport and working under low height jobs

Longer paving time between refills with large capacity water tank (50 gal)

Pave against walls with high curb clearance (18 in)

Better quality mat with the largest drum diameter in its class (23 in).

material. It is applied with heated tools to prevent build up and assist with spreading. Keep in mind, it doesn’t have the elasticity of crack sealant rubber.

What is it used for?

Ryan explains in the interview, that mastic has many uses. Great for patching over “spider-cracks” or shattered areas. Anderson also expressed that failing seams in asphalt and cracks over 1-in. in diameter are a great problem for mastic to be used on for repairing. He also expressed that it can be used for “smaller” pothole areas, if need be, but keep in mind that mastic is a maintenance item and not a permanent solution. Primary uses are in municipal areas and parking lots.

What do we need to know about getting into mastic service offerings?

Anderson expressed that, “Prep is Key,” many times during the interview, adding that making sure the area of service is completely dry, then cleaned very thoroughly to remove any moisture, dust, or particulates, that may inhibit bonding. He also told us that the barrier to entry into offering mastic services is high, as the machines cost more than most of their crack sealant melter counterparts, as well as the material costs.

What is it?

Ryan explained that crack-sealant, or “rubber,” is comprised of asphalt binder,

rubber bits and other ingredients, as mixtures vary depending on supplier and elasticity. It is primarily applied by hand with pourpots, squeegees, speedbanders or MA-10s when using the DF (Direct-Fire) version. It is melted with oil-jacketed melters when it is the OJ (Oil-Jacketed) version of the material and can be applied by a wand machine, often “pull-behind” in this mode.

What is it used for?

It is primarily used to fill and “band” longitudinal and latitudinal cracks in fractured asphalt pavements, but is also used on fractured concrete as well. It can often be used to fill/ cover divots, scars or very small, shattered areas as well. It is not ideal for any patching applications due to the possibility of it sticking to tires or other objects and causing failure. Ideal use for driveways and parking lots, as well as municipal crack-sealing at a larger scale.

What do we need to know about getting into hot-crack sealant service offerings?

Anderson said safety and PPE with this material is a must because it is very hot when melted and is commonly used in an asphalt maintenance business, versus mastic, which should also be used carefully and with PPE. As expressed with mastic, Ryan told us, “Prep is Key” and to be sure any moisture, dirt, vegetation or debris is

clear for proper adhesion to existing pavement. Cost varies with different versions or brands of this material but the barrier to entry, to offer this service is much more affordable when compared to mastic.

Personally, I have seen a couple of mastic demos live and most recently at Pave/X with the Crafco Patcher 4. The system and application process in that demonstration seemed to run very smoothly and safely, once the process is understood, and a high-quality machine is the foundation. The area that the Crafco mastic was applied to was too wide and too deteriorated for Crack Sealant to repair.

We personally use a Crafco crack sealant melter/applicator at my asphalt maintenance business, Wis-Coat, and the process of applying OJ material with that machine, over DF material, is definitely more cost effective and more efficient in certain situations, but we also use DF widely in other situations where the OJ process is less efficient.

I implore you to see what material suppliers and equipment dealers/ renters are near you and ask for a demo or information regarding both these services, products, and more. You could be missing out on an opportunity to expand your services and chance to offer more value to your customers.

As always, if you have any insight or criticisms about this article or anything in it (which I have a feeling there will be), please feel free to email us at marvin@blacktopbanter. com and of course, reach out to us at Blacktop Banter on any form of social media. I also want to mention Crafco is a partner of my media company, Blacktop Banter, but we used their products long before that partnership was formed. Also, they weren’t a part of creating this article. ■

Marvin Joles III, is the owner of Wis-Coat and host of the Blacktop Banter podcast.

For more information visit

https://pavemg.com/fdbyom

By Brandon Noel, Editor

By Brandon Noel, Editor

Back in the day, if you had a freshly paved pavement surface, and a layout design for 100 stalls, you’d have to get your measuring wheel, your chalk lines, and a calculator to check yourself and get everything right. You can still go out there and do it this way, but it will certainly mean you’re doing things the hard way.

“If I had a 100-stall rectangle and had to go out there by myself, and do it by hand with no technology, it’s going to take me at least three hours just to go snap all the lines,” said Cam Roberts.

Roberts is the host of the Stripe-ItUp podcast, and also the owner of Laser Pavement Solutions based out of Prince George, British Columbia. He also sat on a panel at the 2023 IGNITE conference, where he discussed the future of the pavement maintenance industry. Topics ranged from automation, mobile apps, and, of course, artificial intelligence,

Roberts was on the side of early adopters.

“Using a machine that has automatic layout technology, it’s not a stretch to say that I could do the same exact [100 stall] job in 15 minutes,” Roberts said. That’s roughly a 1,100% increase in raw efficiency, and tough to ignore.

The automation systems have the ability to measure the exact size each stall needs to be in a given design, based on the number required, versus the area. It uses an actuator tied to a solenoid wheel, and sprays a paint marking on the surface at the exact distance that each stall width needs to be.

While these tools have been on the market awhile, there are still plenty of contractors who haven’t adopted them.

“Even with an automatic layout, it’s still up to you to square it up,” Mark Estrada, co-founder of Marathon Solutions Group LLC, aka Captain Striper. He spoke at the recent, first-ever PAVE/X, sharing wisdom to other contractors. “It’s still up to you to find Point A and Point

B. However, once you get comfortable with the system, you’ll see the magic. You’re replacing a measuring tape with a calibrated laser.”

An automatic layout system can set up its skip mode to measure the distance between multiple stall columns in a single parking lot, to include the needed space between them for traffic.

“It’s spraying 36 feet across, and then it’ll stop with a 24-foot offset for the drive lane or whatever you want it to do; it’s fully programmable,” said Estrada. “Honestly, though, the biggest level-up was getting the line-driver. It boosted our production to the next level.”

“If you’re using a push-behind striper this will blow your mind,” Estrada continued. “The turning point for us was when we landed a massive distribution center, and we pushed through it. It was terrible. We hadn’t seen that level of highvolume striping yet. So, the next season we decided to get our first line-driver.”

There was no looking back after that. “It just changed our operations forever,” Estrada said. “You cut out fatigue, increase production speed and efficiency, but, also, you just kind of make striping really fun.”

Obviously, if you came to work on a parking lot that had an existing layout, you’re probably going to repaint it the way it was. But what about a new parking lot? With all this talk about technology, who’s deciding where and how to put the first lines down? Are the contractors using a layout software? Are the thermoplastic Picassos just painting the parking lots to how they see fit?

Estrada explained that you always have to find your base, set your square, but he was assuming a baseline knowledge about striping design, and that, hilariously, assumed far too much of me.

“Normally, it’s working from the most important part of the parking lot. You know what the most important part of the parking lot is, right?”

I thought about it for a second, and it seemed obvious, so I said, “The entrance to the business.”

“Not just the entrance,” Estrada told me. “But the part of the parking lot that connects to the entrance, and has the ADA (Americans with Disabilities Act) compliant ramps and crosswalks to the parking areas. You must figure out where your ADA requirements are, then you work out from there.”

There are tech platforms, AI, and tools to make you more efficient; but what’s might be the next real game changer? Estrada, for one, believes that it could be materials based. He recently decided to get more involved using epoxy based striping material — moving away from paint or thermoplastics.

Roberts incorporates AI and looks for ways in which it can make the business more efficient.

Roberts said. “These [technologies] compound, they become more complex layer-by-layer, those who are getting ahead of it will have an advantage of one kind or another going forward. It could mean the difference between getting a job and not getting a job.”

Estrada is looking ahead on the hardware side of things.

“Thermoplastics are hot-applied, and it’s only good for so many surfaces,” said Estrada. “It loves asphalt, but it hates concrete. So, we found that epoxy is just a little bit more versatile, and our minds were blown by just how durable it is.”

Epoxy has some additional benefits:

• It becomes embedded in the surface

• It flashes quickly

• Glass blend creates anti-skip surface

• Cool-applied, one-to-one set up Versus some of the challenges that thermoplastics can present:

• Hot applied, needs onsite melters

• Requires extra labor, flaggers on road

• Reflective glass beads in mixture can create slipping liabilitys

“You might need a three-to-five person team to run large-scale thermoplastics comfortably,” explained Estrada. “That’s not the case with the epoxy set-up, it’s all on one platform. You have a Part A and B, and a fusion gun mixes the two. The magic happens right there.”

In a tight labor market with many employers dealing with high turnover, all these technologies can still require time to properly train new stripers. That’s where the Estonian based company 10Lines is hoping to take the striping industry into the future.

10Lines offers a fully autonomous striping robot capable of taking high quality visual mapping data and turning it into striping perfection. It’s the product of its co-founders Janno Paas and Tarmo Prints, who already have a contractor in South Florida using the robot regularly to complete jobs.

The idea came to Janno when he was the owner of a small striping company. Like many places in the United States, for about five months a year in Estonia, they couldn’t work outdoors, and were forced to take on jobs indoors, frequently at factories.

“We saw a lot of robotics,” Said Paas. “I imagined that surely we could get robots to paint some nice straight lines.”

With that, he left the striping business, and worked with Prints on the concept. They started with established spraying technology, and built the robot around it.

“We knew if it was too small it couldn’t carry enough paint with it, and it wouldn’t be very stable,” said Paas. “However, we wanted it to be easy enough to transport quickly .”

What they started together in 2018 quickly advanced.

“It doesn’t require any pre-marking or layout lines,” Paas continued. “It’s all done in our software and once you go to the site, you let it loose and it will start placing the lines exactly where they have to be. In fact, the consistency of the angles and the lines would not be achievable by a manual method.”

While you can map out what the 10Lines robot will do from a photo, that is not the way to get the best results. It is best paired with an off-the-shelf drone paired with their proprietery software. It flies back-and-forth across the parking lot (or any designated project area) gathering high-fidelty spacial data.

Once loaded into the software, it

generates a digital model by stitching together the scans. Using this model on a laptop, desktop, or tablet, the layout can then be mapped.

“The program uses a drag-anddrop system; it’s very easy,” said Prints. “Once you have everything in place and you confirm it, the robot immediately sets out to complete it.”

“You can divide the job by section, and with multiple units, they could each be assigned a section at the same time,” added Paas.

But the current goal is to have one person with one robot, monitoring it, making changes as needed. As far as efficiency stands, 10Lines put it in these terms. A large job that might require three workers three days to complete, the robot would allow one person to complete that same job in a day. The only real need for an additional robot on site, 10Lines admits, would be in a case where you might have two spraying colors, and a robot dedicated to each rather than switching colors in the one.

They are committed to the needs of the market, even while based in Estonia.

“We U.S.-based technicians make sure we provide support,” said Prints. “We are building that network of spare parts and even spare robots if needed. We want to ensure that, even though it’s a new technology, that it is convenient.”

The margins are getting thinner out there, and having the latest tech just might mean the difference. ■ For

With a CONEXPO in 2023, the first-ever PAVE/X, and now World of Asphalt in back-to-back months — the blacktop business is bursting at the seams with cool, new, and innovative hardware (and software). We formulate our Top 25 listing in a few ways. First, we try to focus on what’s new. What haven’t our readers seen before? Second, we use our website metrics to guide our selection process by examining what products contractors are most frequently looking at. Lastly, the editorial team uses our own in-house experience and relationships with people in the industry to find a good balance of items from all corners of the industry.

While the HD+ 120i V-VIO 12 t tandem roller features a vibrating roller drum (50 Hz or 3,000 vpm) at the front and a VIO drum at the rear, the HD+ 120i VIO-2 HF provides additional application options with two VIO drums. An automatic control feature on the HD+ 120i VIO-2 HF keeps the front drum (in relation to the direction of travel) always working in vibration mode, while oscillation or static compaction is used on the rear drum. The HD+ 120i VIO-2 HF has also been designed as a high-frequency machine (HF), offering a vibration frequency of 67 Hz or 4,020 vpm (front and rear). Both models are powered by a 115 kW (154 hp) Deutz engine. The tandem rollers also have the ability to switch between vibration and oscillation or, in the case of the HD+ 120i VIO-2 HF, combine two vibration and oscillation drums together, removing the need to switch machines or deploy an additional machine and another operator on the construction site.

Wacker Neuson’s APU3050e is a first battery-powered reversible plate that delivers an innovative and practical solution for compaction tasks. This emission-free plate meets the needs of job sites with environmental and noise guidelines. The APU3050e is ideal for the rental market because it is extremely easy to operate. It is simply started with a push of a button and is comfortable to operate using the intuitive guide bar that allows continuous change of direction and speed by just moving the handle. The machine is designed for excellent handling and maneuverability on soil and asphalt. The low working height makes it ideal for working indoors, in trenches and other confined areas. The Battery One system, that powers the plate, can also be used on other Wacker Neuson battery-powered rammers and plates, making it very flexible for the rental center. Depending on the application, one battery charge may be sufficient for smaller applications, but having two batteries and a quick charger available is recommended for larger jobs, which is typical for a reversible plate. Battery changes are easy with no special tools necessary. The APU3050e required minimal maintenance since the motor is mounted directly to the base plate and does not require a v-belt, reducing operating costs and spare parts expenses, another important benefit for rental center operators.

Powered by a lithium-ion battery, the loader emits zero emissions, giving operators the flexibility to work in new places, including environmentally sensitive jobsites, in noise-restricted areas and even indoors. To create the all-electric S7X, Bobcat eliminated all hydraulics, instead using electric drive motors and ball screw actuators for lift and tilt functions. By eliminating the hydraulics, the S7X has 50% fewer components, simpler componentry and 96% less fluids, and lubricants than its diesel-equivalent counterpart. The powerful loader promotes both sustainability and increased performance. The S7X offers operators a smooth and comfortable experience with minimal vibration and quiet operation. This improves comfort, reduces fatigue and enhances the user’s experience.

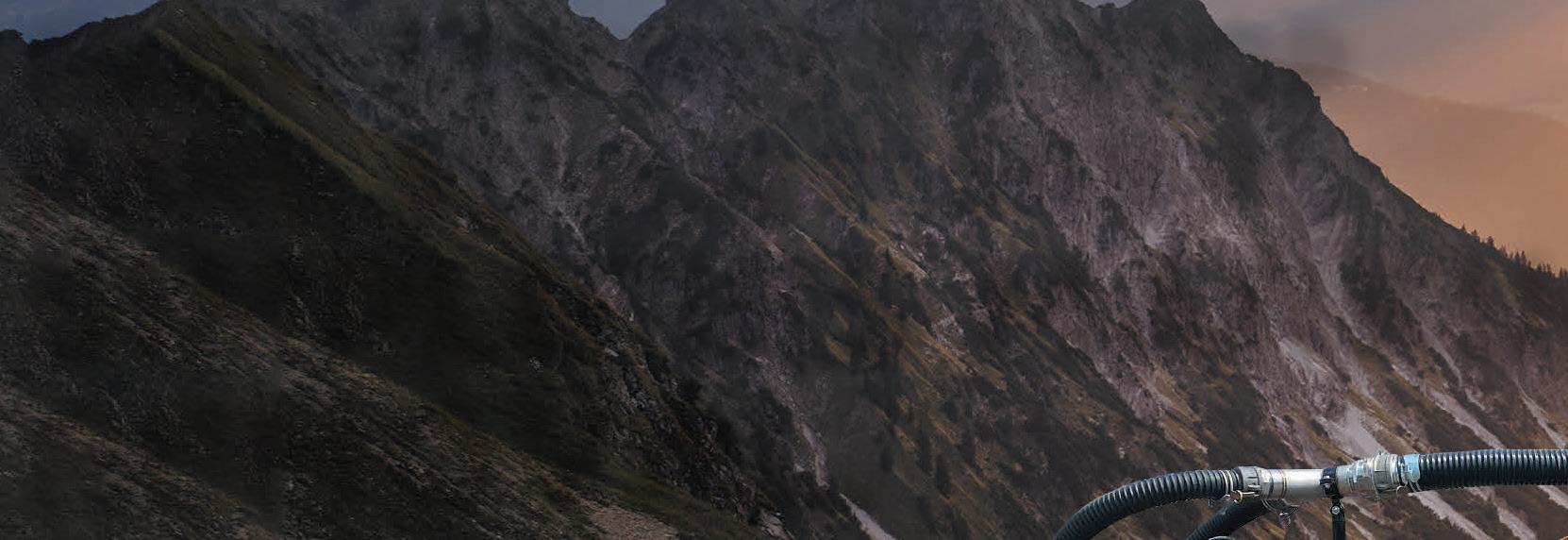

Wirtgen’s W 150 F(i) compact milling machine features a milling width of 1.80 m (6 ft.) and is designed for use on major construction sites with restricted space. The intuitive operating design, digital assistance systems and the LEVEL PRO ACTIVE leveling system allow for one-man operation. The agile front loader with a standard working width of 1.50 m (5 ft.) features eco-friendly engine technology compliant with EU Stage 5/U.S. Tier 4 Final exhaust emission standards. The 9L John Deere engine offers a maximum rated output of 315 kW and has been specially adapted to meet the needs of cold milling applications. It offers high torque and simultaneously low noise emissions under various load conditions. Milling is possible to a maximum working depth of 330 mm.

MMA (methyl-methacrylate) twocomponent pavement marking materials provide increased durability and life. Graco LineLazer 200MMA 1:1 stripers deliver superior MMA 1:1 performance with guaranteed ratio assurance in a compact and affordable package. Achieve faster MMA 1:1 applications and lower costs. The Graco LineLazer 200 MMA 1:1 with 1 or 2 guns is a reliable walk-behind solution that delivers superior MMA 1:1 performance and guarantees ratio assurance in a compact and affordable package.

Ideal for Multiple MMA

Applications:

• High Traffic Areas

• Intersections

• Busy streets/highways

• Bike & Pedestrian Lanes

The new 255 and 265 loaders are powered by Cat C2.8T and Cat C2.8TA engines respectively, which offer 74.3 hp (55.4 kW). The new engines maintain horsepower across a wider rpm range and feature torque increases – gains of 13% for the 255 and 43% for the 265 for working performance. A redesigned engine compartment mounts the engine and cooling package lower into the frame for stability when handling heavy loads. The new 255 loader delivers lift height, and compared to the 259D3, delivers 36% more tilt breakout, 26% higher lift breakout force and a 24% increase in rated operating capacity (ROC). Standard hydraulic system pressure is increased to 3,500 psi (24130 kPa). New for these next generation machines, the closed-center auxiliary hydraulic system allows the 255 and 265 to operate all Cat Smart Attachments, including the Cat Smart Dozer Blade, with the standard auxiliary hydraulics provided.

The best new products for every pavement maintenance need!

• Precise MMA 1:1 Ratios

Innovative Flow Divider guarantees 50% material flow of each component

• Built-in bypass valve for independent pump operation

• Lowest Operating Cost No need for expensive solvents

• No solvent pumps or tanks to maintain

• Eliminates solvent disposal concerns

• Automatic Guns Reduce operator fatigue with push button control

• Eliminate tape measures and premarking with chalk

• LiveLook Display with SmartControl Real-time Job Performance Data

• Tracks all aspects of your job

• USB download for proof-of-job performance

• Graco Fusion ProConnect Gun Mixes materials “at-the-gun”

Features:

• 48 kWh Battery Pack

• J1772 / CCS Combo 1 Charging Receptacle, North American EV Standard.

• Level 1 (120 VAC) and Level 2 (240 VAC) Charging With On-board Charger

• Level 3 DC Fast Charging Enabled and Is Compatible With North American EV Charging Stations and Battery Trailers.

• Convenient Console Mounted Brush Controls.

• Forward Reverse Foot Pedal Transmission

• 10’ Inside & 18’ 9” Outside Turning Radius

• Variable Brush Down-Pressure Control

• Climate-Controlled Cab

The Elgin-manufactured “Broom Badger” represents the company’s dedication and attention to the demands of today’s ever-shifting industry needs. The new model incorporates several enhancements based directly on the feedback from consumers. The result? A more highly compact platform with gains in both maneuverability and job site flexibility.

• 19,500 lb GVWR class 5 cab-over chassis, non-CDL requirement to operate, boasting a 120” sweep path, comprised of a 58” main broom and dual 42” side brooms

• 4 yd3 side-hopper capable of dumping its 9,400 lb capacity at variable heights (18” min, 120” max) with 2 stage scissor lift

• Fully redesigned hydraulic system boosts overall platform efficiency, reduces waste and shortens cleaning/servicing times

• 65-hp Kabuto T-4 final engine, variable speed broom controls, up to 2700 RPM

• Compact 109” wheelbase and tight 16’9” turning radius results in exceptional maneuverability for a wide range of situations

Crafco has unveiled the EZ Patcher skid steer attachment for pavement repairs. Designed by Crafco’s Equipment Engineering department from the ground up, this patented technology offers safe application of repair material. The EZ Patcher provides roadwork agencies and contractors with a method for repairing long, linear cracks such as deteriorated longitudinal joints or utility cuts, using a repair material known as mastic – a binder and aggregate mix that is heated and applied to distressed pavement for a durable, weightbearing repair without extended road closures. The new EZ Patcher joins the Crafco family of mastic melter/ applicators, including the trailermounted Patcher II (200-gal. capacity) and Patcher 4 (400-gal. capacity), as well as the 10-gal. Hot Mastic Applicator cart.

JCB has introduced two new tandem roller compaction machines, the CT160 and CT260, to the North American market. At 3,770 to 6,041 lbs., these machines can be trailered for transportation. The CT160 offers a choice of either a 31.5-in. (800 mm) or a 39.3-in. (1000 mm) drum. The CT260 comes with a 47.2-in. (1200 mm) drum. The machines will be branded once again with ‘Vibromax,’ after the German company JCB acquired in 2005. On both machines, the responsive directional drive lever enables fore and aft movements. From a bird’s eye view the CT160 and CT260 have an hourglass profile, a shape that enables operators to see the drum edges. On the CTs’ control panels, work modes are visible and the switches are sized to create tactile feedback even with gloved hands. Anti-vibration mounts isolate the operator from drum vibrations.

The CP130 challenges the status quo while providing contractors a machine unmatched in performance. Featuring a 130hp (97kW) Cummins Tier IV Final engine, heavy-duty wear components and class-exclusive armrest controls, the CP130 is paired with the EZCSS single slide 8’-15’ screed, combining our legendary extension support system and award-winning paving performance.

• 130-hp Cummins QSF3.8 Tier 4 Final engine

• One-piece forward tilting hood, large side doors and access panel in the hopper for service and accessibility to engine compartment

• Class-exclusive armrest controls, swing out operator stations and 3-man configuration provide leading ergonomics and visibility

• Heavy-duty, highway-class wear components, including fully replaceable floor plates, strongest chains and slats in their class, fully sealed auger bearings and Carlson’s exclusive horizontal sliding damper doors

• Single-slide EZCSS 8-ft. to 15-ft. electrically heated screed with power extension height, power slope and power crown for unmatched mat

Attentive.ai has announced the launch of its automated blueprint takeoff software for general construction disciplines. Attentive.ai’s construction takeoff software enables users to upload design blueprints and receive auto-generated takeoffs. This update minimizes the manual effort required for takeoffs, accelerating the estimating process and allowing businesses to submit more bids and refine their estimates.

• Trailer Mounted 4 Ton Hopper

• Thermostatic Diesel Burner

• 110 VAC Overnight Heater

• Single Material Unloading Door

• Full Width Shoveling Platform with Integrated Material Shutes

• Hydraulic Dump Hopper

• Curb Side Operation

• Cantilever Side-to-Side material loading doors

This mechanical broom sweeper is suited for a wide range of applications while benefiting from a tight turningradius.

• Kubota V2403-CR 65hp, Tier 4 final engine

• Six grease points for easy maintenance

• Non-CDL chassis mounted design

• 4-cu.yd debris hopper capacity

• 90-second cycle time

• Simplified operator controls with international symbols for all switches

• 220-gal. water system capacity

TransTech Systems flagship product, the PQI 380 non-nuclear asphalt density gauge. Precise pavement density measurement almost instantly (3 seconds) without the hassle of nuclear regulatory training and certification.

• Full color VGA display

• LED backlight for easy visibility in light or dark situations

• Customizable project and mix entries

• Data management screen with the ability view, print or download data via USB drive

• Fast, reliable, accurate and repeatable readings in real time

• No badges, licenses or storage and transport concerns

Milwaukee Tool’s MX FUEL 20-in. Plate Compactor is designed for stabilizing soil and surfaces in asphalt projects. The MX FUEL Plate Compactor offers multi-direction capability and fast or slow speed control for maneuverability around forms. Control settings are facilitated by pushbuttons on the handle. When paired with the MX FUEL REDLITHIUM HD12.0 battery pack, the machine delivers 30 minutes of continuous runtime or 4,500-sq.-ft. per charge. This portable plate compactor features Bluetooth tracking for wireless equipment monitoring, management and security.

Weiler’s P385C paver continues to raise the standard for commercial class pavers with improvements to provide performance, reliability and outstanding mat quality in a wide range of applications. The P385C features a Cat C3.6 Tier 4F/Stage V engine with an increase to 120 hp (90 kW) for power and performance. The best-in-class undercarriage features 90 in. (2,286 mm) track length, 68 in. (1,727 mm) of ground contact and 140 mm track chain pitch provides smooth ride and excellent flotation with automatic track tensioning.

Speed and direction can be changed instantly from the driver’s seat, whose console includes a touch screen and real-time monitoring (front and rear).

These are just a few of the features that make the SRV-7 the most productive marking removal system available. For details, visit NLBCORP.COM/STARJET

The StarJet® SRV-7 puts UHP water jets where you need them at the touch of a button. An articulating carriage on the front of the cab lets the operator position the heads with minimal back-and-forth, removing arrows and stop bars almost as efficiently as centerlines. It also provides higher curb clearance for entering and exiting highways.

The StarJet® SRV-7 puts UHP water jets where you need them at the touch of a button. An articulating carriage on the front of the cab lets the operator position the heads with minimal back-and-forth, removing arrows and stop bars almost as efficiently as centerlines. It also provides higher curb clearance for entering and exiting highways.

NEXT GENERATION

SOFTWARE FOR PAVING COMPANIES

• Accurate estimating: Maximize efficiency and precision with custom templates. Refine margins and dynamically update pricing throughout the year to ensure profitability all season long.

• Regained time: Save time on estimates, proposals, work orders, and invoicing with one integrated cloud-based software platform. Stay organized with all of your documents in one place.

• Financial insights: Understand your business and finances more thoroughly than ever before. Learn your numbers and adapt your business to drive future growth, improving both your top and bottom line.

• Integrations: Tie OneCrew into your existing operations with HubSpot and QuickBooks Online Integrations (more coming soon).

The Dynapac D12C is the ultimate solution for achieving exceptional paving results in widths ranging from 3.9 to 7.3 ft, even under the most demanding urban conditions. This compact paver, equipped with a stateof-the-art screed, ensures impeccable mat quality and adaptability to challenging job site requirements. Enhanced by the cutting-edge RC360 remote control, operators can enjoy unparalleled flexibility, safety, and smart control while paving. Designed for versatility and efficiency, the D12C is the go-to choice for urban paving projects, combining performance with ease of use for a superior paving experience.

Whether you’re sweeping city streets during leaf season, cleaning up on a construction site or sweeping behind a milling machine or road reclaimer, getting the job done with the Model 600 is quick to perform and easy to operate. Not only is it built using the highly efficient, time-tested TYMCO Regenerative Air System that provides unprecedented reliability, but it also delivers incredible performance and an amazingly clean sweep.

The Model 600 is, quite simply, the sweeper that changed the industry. Before it, all sweepers were designed in one of two ways – either a mechanical main broom (100% broom sweeping) or a vacuum (which still requires a main broom for 75% of the sweeping path to transfer debris to the vacuum head).

• Engine - John Deere 4045 turbo FT4, 4 cyl.

• Displacement - 275 in3 (4.5 L)

• Power - 99 HP @ 2200 RPM (74 kW)

• Net torque - 315 lb-ft @ 1600 RPM (427 Nm)

• Air cleaner - Heavy duty, w/pre-cleaner, scavenge vacuum hose, and in-cab air restriction indicator w/gauge.

• Operates gutter broom(s), dump and pick-up head

• Drive - Gear driven from auxiliary engine

• Flow rate - 8 GPM (30.3 LPM)

• Water spray nozzles for dust suppression

Going electric isn’t just about a cleaner world. Sustainability can support efficiency, productivity, and better business, too.

Per mile, electricity is less expensive than diesel and gasoline. But the value of going electric is about more than what powers the vehicles. With technologies like telematics and managed charging, everything is connected, from how your electric sweeper runs routes to when they plug into your charging stations. This increased integration and planning can enable fleets to charge when it’s most efficient and avoid costly demand charges, leading to significant savings over time.

The differences between electric trucks and their diesel counterparts go far beyond power sources. Electric trucks have a much simpler design that features fewer moving parts. Ultimately, that translates into longer service intervals, fewer operational disruptions, and less downtime on repairs in the long run.

Batteries, electric motors, and electronics typically need little to no maintenance. Brakes last longer, too, thanks to brake regeneration, which enables the motor to slow the vehicle down by converting mechanical motion back into an electrical charge that can be stored in the batteries. Did we mention no diesel, no oil, no DEF?

One of the places where electric sweepers make the most significant impact is on the job. The M6 Avalanche EV rides smoothly and doesn’t create any fuel odors or noise pollution, which can contribute to a more pleasant working environment throughout the day. And the happier operators are, the more likely they will keep working hard for your business.

The first time you operate the M6 Avalanche EV, its acceleration might surprise you. That’s because an electric truck can provide near-instant, maximum torque at low RPMs – essentially from a standing start. But why is instant torque important? Not only does it enable the truck to get up to speed quickly and transfer power to the sweep gear more efficiently, but it also takes less force to do so. More efficient power leads to significant savings on charging costs.

Take a load off and increase productivity up to four times when compared to walking. The LazyLiner Series will help you drive profits and tackle large jobs with ease.

MAX OPERATING: PRESSURE2700 psi (Hydraulic), ENGINE: Honda GX160 Pull Start.

• Standard pneumatic tires (16” x 4.5”)

• Multi-position seat (forward/back, side to side)

• Height adjustable foot pedals

• Max Speed:Forward 0-12 MPH

• Reverse 0-7 MPH

• Compatible with PowrLiner™ 2850–8955

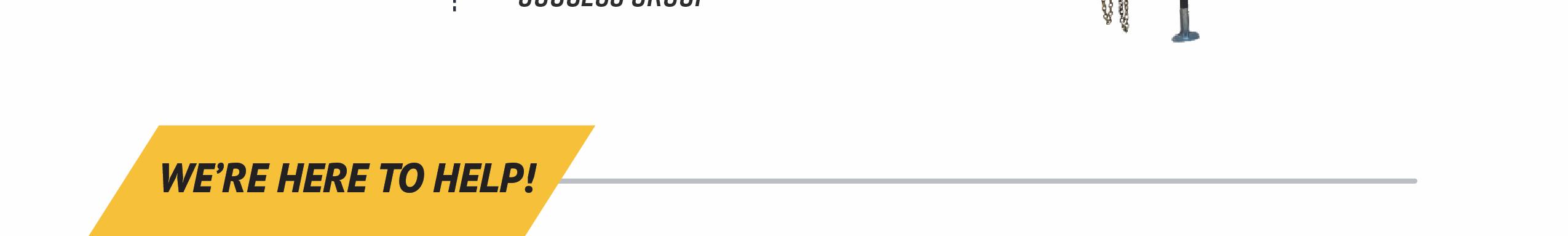

With 48 square feet of infrared heating area, the KM 4-48 is KM International’s largest infrared asphalt recycler. The KM 4-48 is the work horse of the infrared industry, and its large size enables contractors to repair asphalt defects of any size.

Features:

• Easy Transportation: Fold into single axel self-trailering unit

• Maneuverable: Mounted on 4 independent swivel casters

• Efficient: Heat cycling technology

• Safety: Automatic pilot ignition

• Versatile: 4 independently controlled heating zones

Hiring the right people for your team is critical to the sustainability of your business. High turnover rates can have a detrimental impact on profitability.

To get the right people, you need to make sure you have an effective hiring process. Your hiring process should involve multiple methods for evaluating potential candidates, including applications, interviews, assessments, and reference checks. One interview is not sufficient to find the right team member.

The first step in your hiring process is to make a job posting for potential candidates to review. Be clear in your job description. Set clear expectations. State the role, the responsibilities involved, and the outcomes you expect. Once you have a clear job description, post to the

appropriate job boards that will get in front of the largest pool of candidates. Your local market will determine the best place to post your jobs. Consider attending job fairs, posting at local establishments, and using online job boards.

Make sure you have some form of application process for your open positions. This does not have to be extensive, but you want to know that your potential candidates are going to put forth some effort to apply to your job. Add some initial screening questions that are important to you when you consider candidates. Ask about relevant experience. Ask about why they are looking for a new position. Ask about why they are interested in your company. You can get a good feel for how a candidate might fit within your organization by asking a few simple questions up front.

You should have at least two interviews with a potential candidate. These two interviews do not have to be extensive, but it is important to have multiple interviews for a couple of reasons. First, it helps to ensure you’re getting the same person on a different day. It’s amazing how many candidates can nail the first interview, only to show up as a totally different person the next time you meet them. It’s also important to have more than one person involved in the interview process when possible. Maybe as the owner, you perform the initial interview for every candidate, but the second interview is done by the direct supervisor. Regardless of who is involved, if it’s possible, conduct at

least two different interviews with two different people. Don’t skimp on this.

If you are hiring for a position that requires a certain level of technical expertise, you may want to have candidates take a technical assessment or give them some job situations for them to work through. This will help to ensure they really do have the experience they are telling you that they have, or that is represented on their resume or application. Trust but verify the skills and experience they are selling.

Your hiring process does not stop at the job offer. Once you have hired a new team member, you need to ensure their onboarding process is smooth and gets them up and running quickly. This ensures that all new team members have a positive experience from the first day they walk through the door. Make sure any new hires are properly set up for work before their first day. Welcome them. Celebrate them. Make them feel a part of the team. And then train the heck out of them!

Getting the right people on your team can mean the difference between a successful company and one that struggles year in and year out. Your hiring process is critical to getting those people on your team that are going to contribute to your success. Don’t rush it. Take your time. ■

Shauna Huntington is the founder and CEO of Fortiviti.

BY NICK HOWELL

BY NICK HOWELL

According to a LinkedIn survey, 80% of professionals say they experience the phenomena with more than 90% of millennials and Gen Z reporting they feel it.

What is that you say?

Sunday Scaries?

Iwill admit, I do often find myself “mentally” working Sundays — usually going over the job schedule or planning specific jobs in my mind, checking weather, trying to remember any last-minute details for Monday. Until I read about the Sunday Scaries, I thought it was just part of being an entrepreneur (some truth to that!). But I wondered if most contractors face it and how (or if) they try to control the Sunday Scaries.

At the recent PAVE/X 2024 in San Antonio, I brought up this concern to numerous contractors and I found that virtually everyone experiences the Sunday Scaries to one degree or another. So, how do they combat it? Everyone’s first suggestion was more organization and better planning – certainly the right place to start.

But there’s more to it than that.

We run a very organized operation with plans down to small details.

Projects are scheduled well in advance; materials are ordered, and equipment and personnel are assigned to each job. In fact, we often don’t even plan for larger projects to commence on a Monday, just to allow that extra day of prep time. But for years, I found myself creating a level of anxiety in my mind.

Some of it is part of my desire to triple check everything and not forget – it’s just in my nature. Some is the fact that the buck ultimately stops with me, and forgetting something could be a problem that ultimately could cost crews time, cost us money, and even worse cost us a client.

Don’t get me wrong, some of that Sunday Scaries mental energy was certainly spent in excitement for a job,

so not all bad. But it was all still taking up space in my mind; I was expending mental energy, making it difficult for me to relax on what I always hope will be an “off day” amid the busy season. I was still mentally entrenched Sunday evenings.

So, I turned to life coaching. As a business owner I had previously hired a life coach, Kellie Madsen Coaching, to help me with mindset strategy. Many of you may know her, as we have co-presented sessions at the pavement shows.

Her coaching helped me realize that the Sunday Scaries was all a mindset issue for me. I couldn’t fix anything

Sunday evening at home, and really, we had already prepped to the best of our ability at work for the upcoming jobs. So, I had to train my mind and convince myself that things were set, and to trust that thought and be able to keep work out of my mind. I know the importance of being able to relax, even a little, so if I couldn’t do this, it only made the upcoming week harder and increased the likelihood of mid- or laterseason burnout.

As I said, we are a planning and organization machine, and life coaching helped me learn to trust our system. We start planning the week before each scheduled job. I pull the teams together to review the job, equipment, materials, any onsite issues, even client expectations. Crew members can ask questions and by the time that meeting is finished, we have tools and materials set and crews lined out with personal job responsibilities. Then, we check

the weather and schedule accordingly. By Friday, everything that was needed – everything we could control – was completed.

I then had to tell myself – convince myself — that we were indeed completely set and ready to go. I wasn’t going to allow any more mental thought or internal discussion in my mind doubting that things were ready.

And it’s working.

I’m now more likely to be able to enjoy a full weekend without the “Sunday Scaries” or that anxiety that previously used to build up to the point of even affecting my sleep. Realizing that it wasn’t lack of planning or preparation, but rather a mindset issue, allowed me to control my thoughts about it and really look forward to the week instead of dreading it.

Turning to a life coach helped me adjust my thinking and gave me my mental free time back – but you don’t

have to rely on a life coach to get the same result. Just make sure you’re doing all you can to organize and plan well in advance for each week, then trust your system. Control the things you can control, then they won’t be controlling you with the Sunday Scaries. ■

For more information visit

https://pavemg.com/9zys7k

Nick Howell, president of T & N Asphalt Services, Salt Lake City, Utah, has been a regular presenter at National Pavement Expo since 2008 and a member of the Pavement Advisory Board since 2007. Let him know your thoughts on “From the Owner’s Desk,” and if you have a question or topic you’d like covered – let him know that too! You can reach Nick at nick@tnasphaltservices.com.

This process is crucial for improving the environment, as it helps to eliminate pollutants from these areas.by Nancy Terry

We’re excited to share that the North American Power Sweeping Association (NAPSA) has released an updated version of their Power Sweeping Standard, version 2.0! This is an improvement on the first-ever power-sweeping standard published in 2018, and it has been reviewed under the American National Standards Institute (ANSI) guidelines. This updated standard provides details on sweeping processes that companies should follow.

Power sweeping is an essential process that involves using specialized

equipment to remove dirt and other contaminants from parking lots and other areas. This process helps to eliminate pollutants from these areas. By removing dirt and debris, the pavement is protected from abrasive particles that cause wear and tear.

Power sweeping and property management companies often face safety issues, such as slip and fall accidents which result in litigation. That’s why NAPSA has developed a practical tool that can be used to clarify expectations and create baselines of understanding for processes. The standard upholds objective minimum criteria for the determination of competence, responsibility, and obligation in power sweeping. The standard’s approval will help contractors in defending against litigation and should result in reduced insurance rates. These benefits arise because

contractors can now show that they have met an approved national standard for service and operation instead of relying upon arbitrary interpretations.

If you are interested in learning more about this defendable solution to frivolous lawsuits, visit: www. powersweeping.org/about-napsa/ napsa-power-sweeping-standard/

The North American Power Sweeping Association can be reached at info@ powersweeping.org. We’re always here to help! ■ The North American Power Sweeping Association (NAPSA) is a nonprofit association made up of 200+ contract sweepers, service providers and sweeping equipment dealers, manufacturers and suppliers. NAPSA is dedicated to providing beneficial support to the membership and enhancing services to the sweeping industry. NAPSA is committed to promoting and educating the power sweeping community while enhancing the environment. For more information on NAPSA membership, please visit www.powersweeping.org or call (888) 757-0130.

Pavement striping and sweeping are services that enhance parking areas.

by Ranger Kidwell-Ross

Before striping can be applied effectively, it is crucial to have a clean pavement surface. This is where sweeping plays a critical role. Airand vacuum-based sweeping methods are preferred over mechanical broom units because they remove dust and fine particles more effectively.

Contractors specializing in parking area sweeping have the advantage of recognizing when their clients require striping services. This insight opens up opportunities for collaboration between sweeping and striping contractors. They can either refer business to each other or establish a profit-sharing arrangement. For instance, a sweeping contractor

might receive a finder’s fee, typically around 15%, from the striping contractor for each referral. This arrangement benefits both parties, as the striping contractor gains business, and the client receives quality service.

When establishing such partnerships, it is essential to verify the credentials and reputation of the striping contractor to ensure high-quality work. Some sweeping contractors prefer to handle billing directly, while others leave it to the striping contractor. A selling point is the assurance that the striping contractor has been pre-vetted.

For sweeping contractors considering expanding their services, adding striping to their offerings could be a strategic move. The investment in striping equipment is relatively low compared to sweepers, and the profit margins can be attractive. However, it’s important to note that striping services are typically

required less frequently than sweeping. Overall, whether through referrals or as an added service, integrating pavement striping and sweeping can create a profitable synergy for contractors, ensuring clients receive comprehensive maintenance for their parking areas.

As part of WSA membership benefits, members are provided with a handout on this topic as well as many others, along with over 250 articles designed for sweeping contractors, an email update bulletin twice-a-month and much more. ■

WSA contributor Ranger Kidwell-Ross has been providing information to the power sweeping industry since 1988. He is editor of WorldSweeper.com, an information resource for power sweeping, as well as founder and executive director of the World Sweeping Association. For more information about WSA visit www.WorldSweepingPros.org or contact Kidwell-Ross at director@worldsweepingpros.org.

Recognizing talent, work ethic, and determination, Brian Sugg sees the way forward by counting on his core people.

While at PAVE/X in San Antonio, I met a lot of new faces from all across the United States. Sometimes we met for the first time on the showroom floor, other times it was out by the live demo area — only one contractor introduction happened in an elevator. I was headed back up to my room, and a guy walked on at the last second. Neither of us were wearing our PAVE/X badges yet, but he LOOKED like an asphalt guy. I’ve been doing this job long enough that I now believe that I can spot a blacktop person. I decided to test that, and just asked him directly, “Here for PAVE/X?”

He said, “Yup! You?” and I told him that I was here for the same reason.

That was Keaton Coley, who works for Aegis Asphalt Construction. When I got to my room, I told myself I needed to try and remember his name, so that if I saw him again out on the show floor I wouldn’t look like a jerk. Of course, when I did run into him again that night at the hotel bar, along with the owner of Aegis, Brian Sugg, it had left me.

He tried to help me remember by relating it to Batman. As in, Michael.... Keaton. Over the course of the next few days I kept running into Keaton and the crew from Aegis, and it felt like I had to introduce them to the readers of the magazine. They haven’t been doing the work as long as some people, but they have a seriously bright future.

For Sugg, his early introduction to the business is similar to what many people in the business can relate to. When he was young, his grandfather first introduced him to the blacktop work, and from there it really never left him. All during his school years, it was a side hustle that he

would go back to continually.

“Back in 2009 I started the company after a career with big construction firms,” Sugg said. “I just started as a weekend hustle or weekend warrior kind of setup, but I continued to put a lot of my energy into it over time. Then for the start of the 2018 season I left my career job and devoted 100% of my time into just asphalt.”

The business had finally reached a point where it was able to support the transition, “It’s been really nice growing the company the way I did, because I was able to do it very slowly and learn all of the ins-and-outs of operating a business.”

When he went full-time, Aegis had six people on the crew, working an estimated 1,000-1,200 hours in a season, and, now, they have about 15 core employees. Almost triple the crew size in just five seasons.

Keaton joined the team in 2020, and, interestingly, he came on originally as just a temp worker. What set him apart almost immediately was a serious work ethic, and a supercharged entrepreneurial spirit. He took to the work and the lifestyle quickly.

“When I was 19, I was working in south L.A., sweeping construction sites five days a week, for 40 hours, I would watch the superintendent, direct all the

guys, and keep the jobsite going, and I always thought I could see myself in that position. In 2020, I found myself in Oregon,” Keaton said. “Becoming a part of Aegis, I think it was kind of just lucky timing, too. When I moved up here, Brian was growing the company and needed someone to fill the maintenance role. And I think he saw the drive in me. I really didn’t have a clue what was going on, but with trust and great interest and investment, I started with managing small residential driveways and continued growing. I am now currently overseeing all the pavement maintenance, from estimating, developing systems and training new members.”

Since joining the team, Keaton has helped grow the commercial maintenance work greatly, and they now do some of the most visited parking lots in their area of Oregon, while looking to expand into the municipal market.

“Kudos to Keaton, because he made himself available,” said Sugg. “Where most guys are, you know, laid off when the rains come and hours go down, he made himself available. We started showing him the different processes and computer systems we were using and he was able to really pick it up and run with it. By doing that, he really created the position needed to support him in the offseason.”

In their little corner of Oregon, there can be some unique challenges that you don’t often see in other parts of the country. Perhaps the biggest in their area isn’t one you would ever guess.

“Moss,” said Sugg. “You’re dealing with carpets of moss. I mean, here we have a sort of shortened seasonal work window, but definitely the moss. It grows in every damn shady spot.

They also deal with a fair number of clients who have never had any previous

maintenance work done. When trying to sell or explain a service, that can be a hurdle sometimes.

“A lot of our commercial clients have never done any sealcoating, and they don’t really understand the process,” Sugg said. “So, in our conversations with them we have to educate and communicate a lot with them about it and how it works, how to keep their business open, and what the product really offers them.”

“Many of them just think it’s black water on the ground,” explained Keaton. “That’s been a real opportunity for us to explain this service that can add years of life onto their property, protect it, and improve it esthetically. It takes time, but we’re making progress.”

Sugg takes the plan very seriously, and, after the years he’s spent in his market area, his immediate goals for the company are to reach that $5 million mark, as they are putting in some improved controls for in-house management and systems, and, of course, he wants to see the business continue to grow well beyond that as the years continue. However, he also wants to see his employees grow in their own way, too.

“Our true goal, in say, 10 years, is employee ownership,” said Sugg.

This really blew me away. I wrote about the benefits of employee ownership back in the January 2023 issue of the magazine, and I’m a firm believer in it. However, Sugg was the first pavement maintenance business owner to bring it up to me.

“We’re trying to lay the foundation for that,” he said. “Establish a strong culture through our mentors, increase our value in our community through our quality, and eventually we want to get to that point. That’s what we would like to do.” ■

For more information visit https://pavemg.com/ fdbyom

The cost of quality is zeroed out when we do things right the first time.

At the first PAVE/X Conference in San Antonio this past February, I must have hit a real nerve for many contractors and field leaders. When asking leaders if they had a challenge with workers making mistakes that needed to be reworked or that caused a “go back,” the response ranged from smiling, nodding their heads in agreement, or just displaying frustration. To make matters even more realistic, I then shared what the “cost of quality” is for mistakes that are made.