Pavers, rollers, screeds, MTVs, support equipment & more products for the construction of

pavements.

machines, reclaimers, infrared equipment, crack sealing equipment & more for the preservation and surface treatment

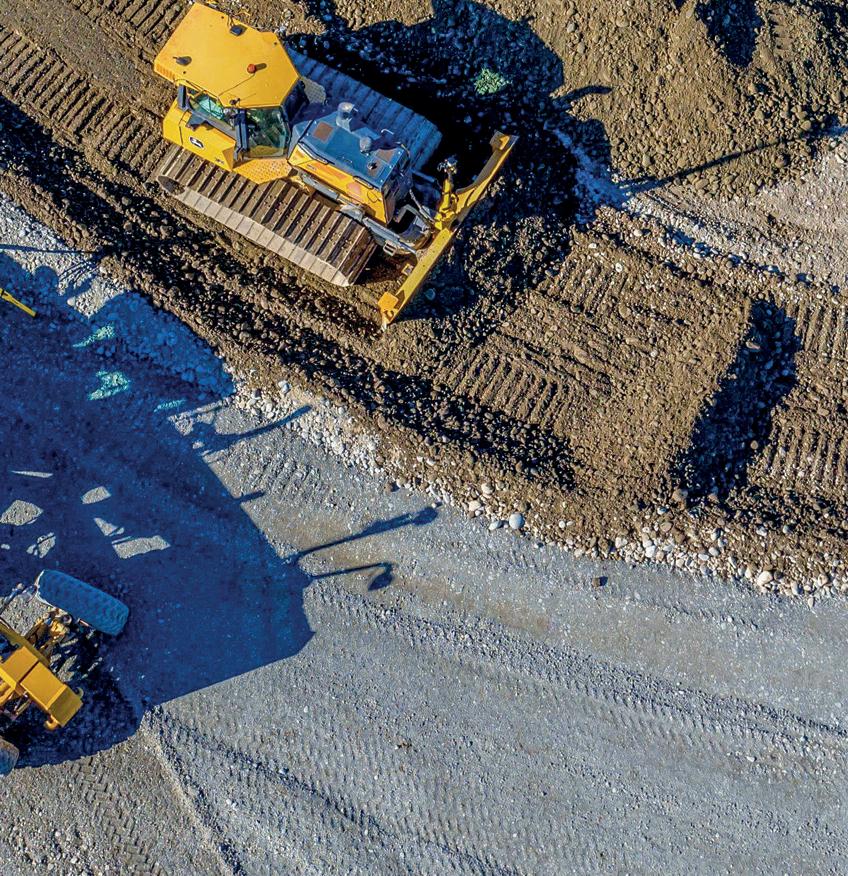

Motor graders, skid steers, haulers, excavators & more to assist in the development of infrastructure.

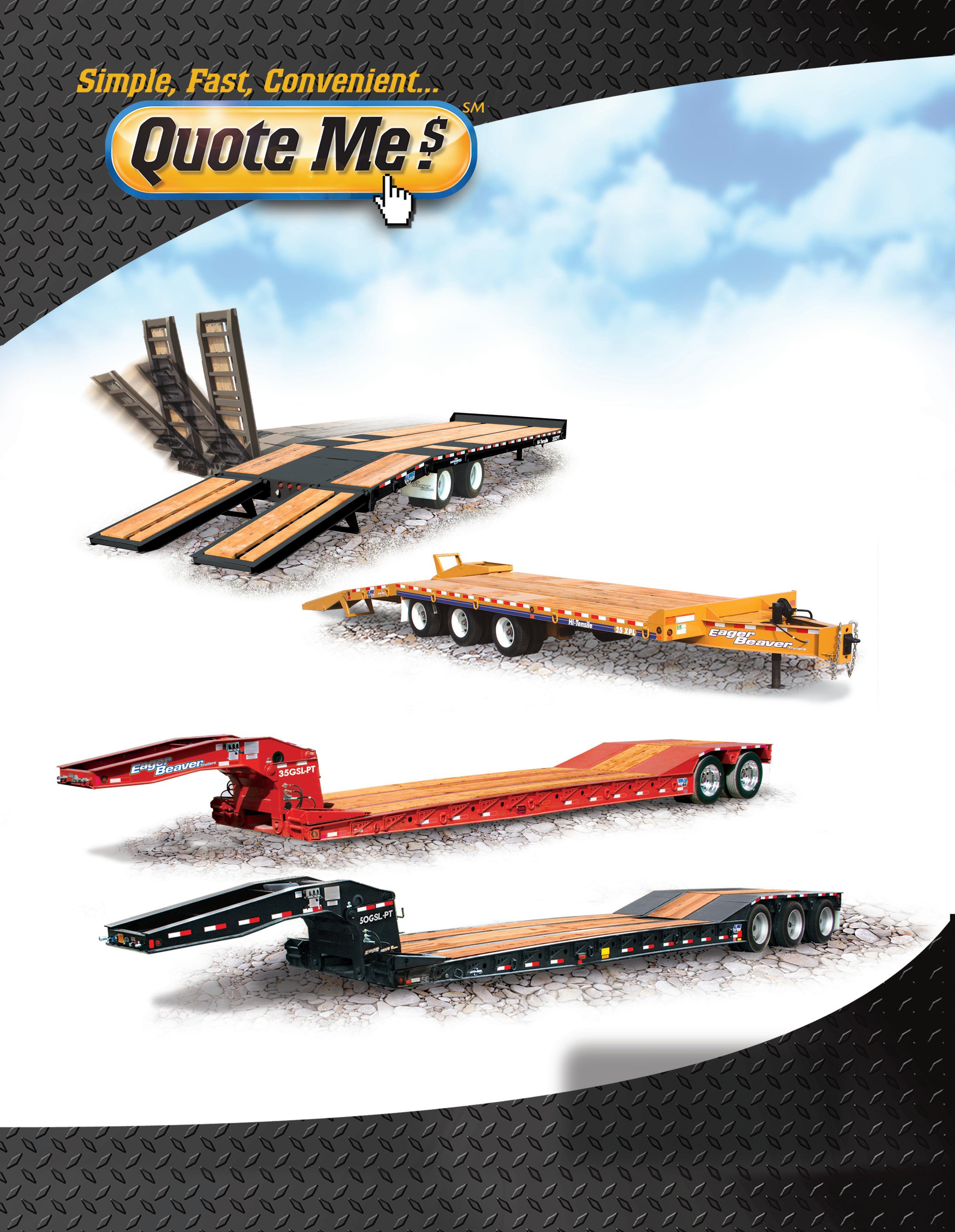

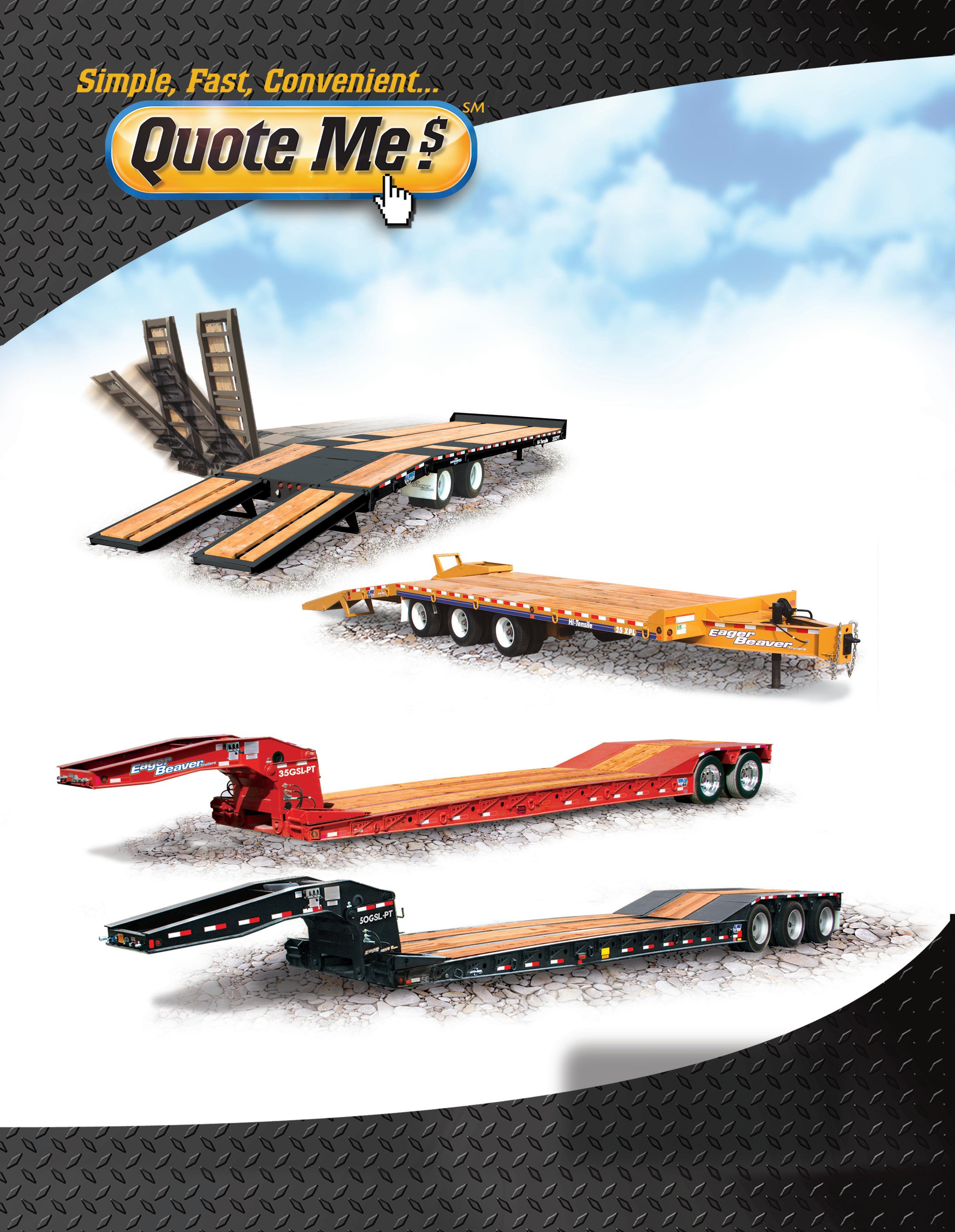

& Trailers: Equipment designed to safely haul your machines and materials.

PPE, flaggers, barriers, technology, and more products to help protect road workers from potential hazards in workzones.

the latest trends that can help improve

and quality for

contractors.

any means, electronic or mechanical, including photocopy, recording or any information storage or retrieval system, without written permission from the publisher.

Asphalt Contractor (ISSN 1055-9205, USPS 0020-688): is published ten times per year: January, February, March/April, May, June/July, August, September, October, November, December by IRONMARKETS, 201 N. Main St. Ste 350, Fort Atkinson, Wisconsin 53538. Periodicals postage paid at Fort Atkinson, Wisconsin and additional entry offices.

POSTMASTER: Please send change of address to ASPHALT CONTRACTOR, 201 N. Main St. Ste. 350, Fort Atkinson, WI 53538. Printed in the U.S.A.

SUBSCRIPTION POLICY: Individual subscriptions are available without charge only in the USA. The Publisher reserves the right to reject nonqualifying subscribers. One-year subscription to nonqualifying individuals: U.S. $45.00, Canada & Mexico $65.00, and $95.00 all other countries (payable in U.S. funds, drawn on U.S. bank). Single copies available

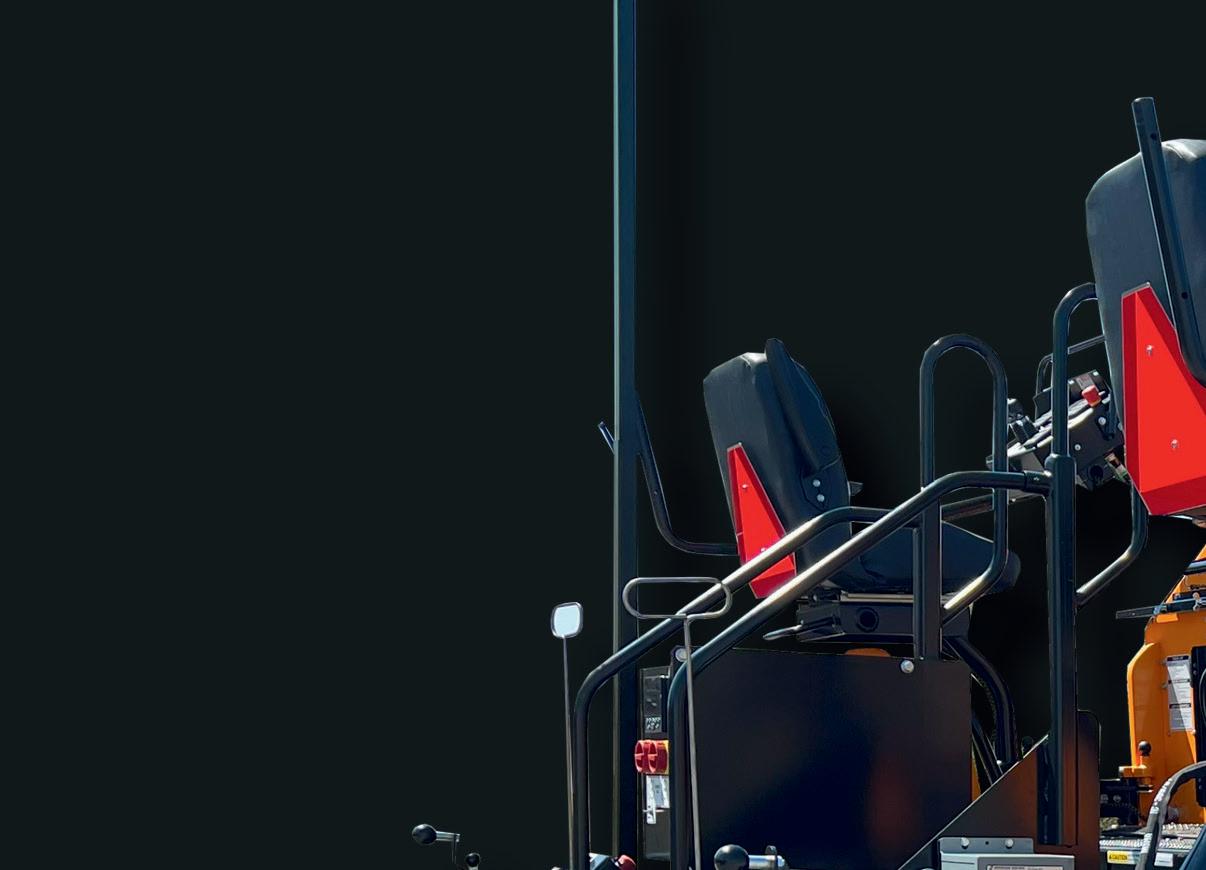

With over a century of innovation to its credit, Blaw-Knox® pavers have earned a reputation for quality, durability, and performance unmatched in the industry. Our continued focus on innovation is what drives our product engineering with designs that improve performance while maintaining user-friendly, ergonomic comfort and reliability for the operator.

BLAW-KNOX, THE LEGACY LIVES ON.

For more information contact your Blaw-Knox dealer or visit www.blawknox.com

Why VRAM might be the most important paving tech you’ve never heard of — until now. Checkout the SEAON FINALE for the best asphalt show on YouTube!

Watch the video at: https://asph.link/dly0a100

From The 2025 NAPA Mid-Year Conference In Louisville

It’s time to start thinking about joining NAPA and getting involved.

Read more at: https://asph. link/3yh7mxjb

What does this consolidation mean for contractors, brand identity, and the future of blacktop equipment in North America?

Read more at: https://asph. link/shc1cmda

The company announced on April 28 that it’s search for a replacement for former president Jamie Roush had come to an end, signaling the start to a new era.

Read more at: https://asph.link/ m6eb0ihr

Those who don’t know their history, are doomed to repeat it. If the United States cannot overcome political pettiness for the greater good, those who come after us will have an even bigger mess to clean up.

Read more at: https://asph.link/ twduzblu

Astec paves the way for sustainable, innovative asphalt plants. The new IntelliPac Moisture System is a revolutionary solution that integrates seamlessly with Astec control systems. This provides unparalleled, real-time visibility into virgin aggregate moisture content. IntelliPac empowers operators to optimize mix design, minimize energy consumption, and reduce environmental impact. With Astec, you get superior asphalt production – better for the environment, better for your business.

Brandon Noel, Editor

bNoel@iron.markets

234-600-8983

It’s

time to join NAPA and get more involved.

Ijust got back from Louisville, Kentucky, and while the bourbon down there flows as freely as a McDonald’s soda fountain—the conversations, ideas, and industry insights at the NAPA Mid-Year Meeting were too.

1. Surface Transportation Reauthorization I had many meaningful conversations about the Big Beautiful Bill (BBB), recently passed by congress and signed into law by President Trump. While it’s a massive piece of legislation, it doesn’t address everything despite its name. The current surface bill, the Infrastructure Investment and Jobs Act (IIJA), passed by President Biden, is set to expire on Sept. 30, 2026.

The big takeaway? There is A LOT of work still to be done. While NAPA is hard at work helping shape what that next wave of infrastructure investment might look like, ultimately, it’s the elected officials who will write the next bill. It was a big reminder to me that even commercial maintenance contractors, those of you not laying highways, still have skin in this game.

Why? When large contractors lose government funding or experience delays, they shift into the commercial space to stay busy. Suddenly, you’re bidding against a company that owns the asphalt plant you buy from and a crew that’s twice your size.

2. Health And Safety Having Its Moment

Extreme heat safety is a topic I’m passionate about, which is why I made it a point to attend the Health And Safety Committee meeting. There were at least sixty-seven days last season labeled as extreme heat related risk, where the heat index rose to at least 105 degrees for at least three hours. Now imagine that on the back of a paver, or working near a hot mix plant.

NAPA’s Health And Safety Committee continues to offer plug-and-play resources that members can use immediately, no need to reinvent the wheel, just adapt and apply. It’s one of the many reasons why membership is more than just a patch on your shirt. Access to these tools could save lives.

Notably, there was an entire standalone session on the second day which revolved around mental health awareness and best practices for turning your workplace into a safe space for employees. This is another topic I care deeply about, and am glad to see the industry taking a progressive stance.

3. Changing The Labor Narrative

And then there was Chris Stricklin from Dunn Construction, who was easily one of the most inspiring speakers I’ve heard at any NAPA event. He shared about his work in Alabama creating a workforce development pipeline, partnering with local businesses, training students, and giving people without opportunity a pathway into the trades. This is what real solutions look like.

It reminded all of us that problems like labor shortages in construction aren’t going away on their own. They’ll take vision, coordination, and yes, hard work. For those looking to change their own narratives on finding quality workers, it would behoove you to look up Mr. Strickland and pick his brain a little on what they’ve been able to do.

Next year’s Mid-Year will be in Columbus, Ohio, my neck of the woods! So, if you’ve been on the fence about getting involved, that’s your chance. Come grab a seat at the table. See you on the road!

EDITORIAL

Editor Brandon Noel bnoel@iron.markets

Content Director, Marketing Services Jessica Lombardo jlombardo@iron.markets

Managing Editor Allyson Sherrier asherrier@iron.markets

AUDIENCE

Audience Development Director Angela Franks

PRODUCTION

Senior Production Manager ...................................... Cindy Rusch crusch@iron.markets

Art Director ............................................................... April Van Etten

ADVERTISING/SALES

Brand Director Amy Schwandt aschwandt@iron.markets

Brand Manager Megan Perleberg mperleberg@iron.markets

Sales Representative Sean Dunphy sdunphy@iron.markets

Sales Representative Kris Flitcroft kflitcroft@iron.markets

IRONMARKETS

Chief Executive Officer Ron Spink

Chief Revenue Officer Amy Schwandt VP, Finance Greta Teter VP, Operations & IT Nick Raether VP, Demand Generation & Education Jim Bagan OEM & IRONPROS Sean Dunphy

Content Director Marina Mayer

Director, Online & Marketing Services Bethany Chambers Director, Event Content & Programming........ Jess Lombardo

CIRCULATION & SUBSCRIPTIONS

201 N. Main St. Ste. 350, Fort Atkinson, WI 53538 (877) 201-3915 | Fax: (847)-291-4816

circ.asphaltcontractor@omeda.com

LIST RENTAL

Sr. Account Manager Bart Piccirillo | Data Axle (518) 339 4511 | bart.piccirillo@infogroup.com

REPRINT SERVICES

Brand Manager Megan Perleberg mperleberg@iron.markets | (800) 538-5544

Published and copyrighted 2025 by IRONMARKETS.

@ASPHALTCONTRACTOR @ASPHALTCONTRCTR

@ASPHALTCONTRACTOR

@ASPHALT-CONTRACTOR-MAGAZINE

Sponsored by

Astec Industries is proud to announce a significant upgrade to our Fiberbed Mist Collector – the addition of charcoal filters. This latest enhancement eliminates odor-causing compounds, improving air quality and community satisfaction at asphalt facilities.

The system effectively captures and controls volatile organic compounds (VOCs) also known as blue smoke,

generated during silo or loadout operations. Charcoal filters trap and neutralize odor-causing compounds, reducing detectable odors and creating a more pleasant work environment.

Blue smoke, which is condensed light ends from asphalt cement, has long been a source of frustration for asphalt facilities. Astec’s Blue Smoke System, which includes the Fiberbed Mist Collector, effectively controls

emission opacity by limiting the escape of vaporized asphalt fumes into the atmosphere. The addition of charcoal filters takes odor control to the next level, providing a powerful tool for facilities seeking to minimize environmental impact and enhance their reputation.

Contact us today to learn more about how our enhanced Fiberbed Mist Collector can benefit you.

Reliable Asphalt Products offers equipment that can be purchased on an”as-is” basis or reconditioned for specifications.

• List thousands of plants and components of all types to meet various requirements

• Batch plant, drum plants, parts and components

• All listings prequalified for quality”

The ALmix Compact Series is designed for portability and a small footprint, this simple yet rugged design meets the needs of the small to mid-size contractor.

• Judicious control of plant frills versus plant cost has yielded a Series of asphalt plants which allow the long time asphalt paver to become a first time asphalt producer

• The “Compact Series” is offered in production ranges from 60-140 tph

The LX series plants are offered in 80, 120, 140 and 160 TPH versions.

• All models are offered with independent cold feed systems or as a combined unit with all components mounted on a tri-axle fifth wheel chassis

• A full line of asphalt storage tanks(with hot oil heaters), asphalt mix silo systems, mineral filler systems and RAP processing equipment are available

The Magnum 150 is a super portable 150tph counterflow drum-mix asphalt plant with up to 30% RAP capability.

• To enhance the portability and quick installation of the Magnum 150, a new one-piece cold feed unit complete with scalping screen/aggregate weigh conveyor, bag house and SE60 selferect hot mix storage system have been designed to allow rapid installation with minimum site preparation

• The SE60 self-erect hot mix storage system can be erected in 30 minutes, with all remaining equipment, which is prewired, being able to be positioned and put to work within a matter of days

Combo Plants combine new, used or reconditioned equipment from different suppliers and manufacturers to create an effective and low cost alternative to buying an all brand new plant.

• Can save the contractor $1 million, $2 million or more over the price of an all new hotmix asphalt facility

Asphalt Drum Mixers Inc. offers its line of SPL hot-mix asphalt plants as an affordable option for contractors with low production requirements.

• Includes all necessary components for drum-mixing asphalt production yet fits on a single trailer frame

• Available in 60-, 100- and 160-tph production rates and come standard with a drying/mixing drum, wet wash, cold feed bin and surge system

• Portable or stationary configurations with the option of automated or manual operation

• Customized components include cold feed bins, hot oil asphalt cement tanks(both horizontal and vertical), direct-fired horizontal cement tanks, portable and stationary bag houses, mineral filler systems, RAP systems, self-erect and stationary silos, weigh and drag conveyors, weigh batchers and fuel oil tanks

The ABP HRT(High Recycling Technology) plant is an ideal fit for asphalt manufacturers who need to incorporate large proportions of RAP without sacrificing production capacity and quality. The HRT is a“two-in-one” plant featuring both warm and cold recycling systems that can be used in combination. One is the conventional RAP dryer for RAP additions of up to 60 percent and the second is Ammann’s latest development in warm recycling, the RAH100, which can utilize 100 percent RAP. Production capacity is 440 U.S. short tph.

The new Gencor G Series are small portable hot mix plants providing asphalt producers and contractors with all the features of Gencor’s award winning Ultraplant in a smaller compact highly mobile plant that can be erected and operational virtually anywhere.

• The firing end of the burner extends into the dryer beyond the mix section so as not to overheat the aggregates and liquid asphalt as they are mixed together

• Highly-efficient Ultraflo baghouse is coupled to the drum at a 90° angle with Gencor’s exclusive self-erecting ductwork and stack

• The G Series also includes Gencor’s proven and highly portable Silo

The RAPpro is an economically priced hot plant specifically designed to efficiently produce high quality HMA utilizing 100% RAP.

• This plant utilizes a revolutionary multi-tube in-direct heated, continuous flow patent pending drum design

• When coupled with PelletRAP rubberized binder material used as a RAP rejuvenator, very high quality mixes at extremely economical pricing are produced

The BG 1800 Batch Plant series features a modular design that is fully customizable to meet the needs of the plant owner.

• Can produce up to 70% RAP

• Easy set-up

• Perfect for municipalities who need to produce many different mix designs

A high-production capacity and total hydraulic and electrical autonomy, the versatile Blend Mobile A240 Plant can be transported easily on a standard low-loader truck.

• Transportable on a standard lowloader truck

• Maximum granulometry aggregate size: 2.3 in.

• Onboard PLC controls dosing of water, emulsion, and additives

Combined with a full line of auxiliary equipment, the UF Series is the heart of a complete plant setup ideal for all sizes.

• The UF Series is offered in both portable and skid-mounted configurations, each available in multiple drum sizes with production outputs ranging from 120 to 500+ tons per hour

• All offered in a simple, ‘Unified’ design capable of producing high-specification mixes, exceeding environmental requirements, and performing exceptionally for years in the field

The Astec Ventura asphalt mixing plant maximizes the performance capabilities for a compact, ultra-portable plant. This highly portable version of the Astec continuous mix asphalt plant effectively uses field-tested and proven core components to reliably deliver a production rate of 140mtph. Can be transported in a single load.

Our UL asphalt tanks have properly sized normal and emergency venting as standard.

All structural attachments are OSHA approved and are af xed to our tanks per code.

All tanks are tested to UL142 Section 42.2.1a 10th Edition.

All weld joints are per UL142 standards.

Your asphalt tanks will be properly labeled and registered with UL142.

Perfect for those who have a number of small jobs in varied locations and where frequent transport is required, and for paving contractors looking to introduce asphalt production into their businesses. The plant excels at specialty mixes, such as those used for paving tennis courts and running tracks. The ACM 140 Prime offers output of up to 154tph. Engineered for smaller volumes, prudcing them efficiently, delivering cost savings in fuel and electrical energy consumption.

The Voyager 140 can produce up to 140 tph with up to 50% RAP.

• Portable plant can be transported and set up and tested in about a weeks time due to fixed duct work

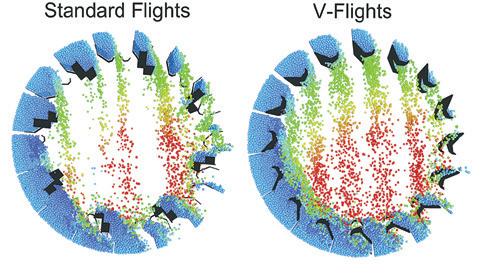

• Double Barrel Drum with standard V-Flights provide uniformity of aggregate veil for effective and efficient heat transfer

The Magnum Bullet series has been designed with many upgrades including high efficiency drying& mixing zone, railroad bearing trunnion roller assemblies, direct drive gear motors, and drum insulation& cladding as standard. Designed with an emphasis on substantially reduced installation time to provide a market leading set up time within 2 days when combined with a portable self-erecting hot mix storage system.

EX Series plants produce up to 425 TPH and can handle up to 50% RAP. Using counterflow technology, these plants provide the longest aggregates drying and mixing times in the industry to ensure consistent, quality asphalt that meets all federal and state specifications.

SYSTEMS control centers are designed with attention to rugged construction, operator comfort, and safe, logical integration of plant controls and switchgear. Custom buildings sold as shell only or with full turnkey operability. Most structures include installed electrical outlets, lighting, heating and air conditioning, cabinets, countertops, controls, and outdoor security lighting.

Innovative custom-manufactured buildings are available in portable, stationary or relocatable models, as well as single-level, two-story, and split-level designs. All custom building specs considered. Structures can be used as asphalt plant control centers, offices, portable laboratories, weigh shacks, barge dredging control centers, switchgear enclosures, and more.

Some available features include:

• All-steel welded frame construction

• Fully insulated floor, sidewalls and roof

• Acoustical ceiling panels

•Air conditioning and electrical heat

• External vertical steel siding

• White interior glass board wall paneling

Many additional options offered. All custom options considered.

A sustainable approach to road construction that minimizes the environmental impact. By reusing RAP materials and mixing them at ambient temperatures, the system significantly reduces the need for both virgin aggregate and energy for heating the mix. This conserves natural resources and lowers carbon emissions. One of the primary advantages of Astec ReMix CCPR is its ability to consume evergrowing RAP stockpiles effectively. With this system, road construction projects can contribute to the circular economy by incorporating recycled materials, thereby reducing the overall environmental footprint.

The EX 8845, like all EX Series plants, was thoughtfully designed to get the most out of your hot-mix asphalt production, combining high volume, high efficiency, and environmental friendliness in a compact package. The plants’ efficient design goes even further to help save labor costs, through their single-operator capability, easy troubleshooting, and simple maintenance. When it comes to configuring just the right asphalt plant for your operation’s specific needs, EX Series plants are designed to be highly customizable with any of ADM’s standard components, making them a great choice for all your hot-mix production needs.

Designed for contractors demanding high mobility, rapid installation with minimal foundations and quality assurance of the final mix, the RoadStar range is renowned for being a true contractors plant and is considered to be the most portable range of batch production asphalt plants on the market today. The 120tph RoadStar 1500 will be erected in its working position along with the portable dryer, burner and integrated primary dust multi-cyclone system.

•

•

•

•

•

• Built for asphalt plant use in sizes up to 120,000 cfm

• Jet-pulse design great for retrofit applications

• Solenoid valves enclosed for easy operation in cold weather

• Even distribution of air across baghouse

Known as the Eco-Foam II, is a motionless static mixer in which fluids are injected and rapidly mixed by a combination of alternate vortex shedding and shear-induced turbulence, which produces superior fluid mixing.

• Unmixed asphalt flows to the static mixer and is forced through the mixer restriction

• Water/additive is injected into the low-speed reversed flow region downstream of the mixer tabs

• Water is injected and rapidly mixed with the hot liquid asphalt by a combination of alternate vortex shedding, and turbulence

• Double swirl pattern guarantees injected water will be rapidly mixed downstream of the mixer resulting in a homogeneous“foamed asphalt” mix

Extends the range of mixes that can be produced without requiring the flights be adjusted. Its use of variable frequency drives(VFDs), which provide control of the drum rotational speed, are keys to the control system managing an asphalt plant’s exhaust gas temperature and increasing overall efficiency. Automatically controls exhaust gas temperature across a range of mix types and operating conditions by making drum speed changes.

The 125,000,000 BTU/hour multifuel burners deliver increased efficiencies and reduced operating cost per ton. This multi-fuel register-style burner for asphalt rotary dryers allows users to shape the flame by automatically controlling the register vanes to optimally fit their dryer and combustion zone.

Improve the cost efficiency of your plant and boost RAP utilization with the ADM Recycle System.

• Available in various portable and relocatable configurations, designed to tackle the many mix specifications you handle

Gencor Industries introduces the Quick Draw-a unique concept that combines both fast load-out time and reduced segregation. The Quick Draw silo system is designed to eliminate the jogging or reversing of trucks while on the scale.

• System allows your operation to produce hot-mix asphalt with as much as 50% recycled material

• Multiple capacities available to suit almost any operation

• All-welded recycle bin can be reinforced with optional grizzly bars for superior durability

Forged from Hardox HiTemp– a unique blend of heat resistant and wear resistant steel. This innovative material selection ensures maximum durability, allowing the flighting to outperform and outlast typical OEM flights. In fact, while an average OEM flight often needs to be replaced within just two years, our heat resistant flighting has demonstrated remarkable longevity. It also offers unparalleled heat resistance, capable of withstanding temperatures of up to 903 degrees Fahrenheit. This high heat tolerance not only ensures the flighting’s longevity in harsh operational conditions but also enhances safety and reduces the risk of equipment damage caused by overheating.

A complete system that can provide direct heat to the asphalt tank, while also supplying hot oil for the plant.

• Drywell-style electric heating elements provide and maintain heat to keep AC at desired temperature

• Circulates oil through scavenger coils and thermostat-controlled electric booster heating elements to provide hot oil to heat jacketed lines, pumps and valves, drags, silo cones, and other plant components

• Provides flow up to 85 gpm at 140 ft.

Designed to eliminate material bridging, with steep sided ¼-in. tapered walls, self-relieving throat and welded beater plates on the sides of the bins.

• With the rack and pinion gate design, material height can be easily adjusted to suit any feed rate

• Variable speed drives assure steady consistent flow at varying production rates

• Feature unitized heavy I-beam construction and are available in portable, stationary, or skid-mounted configurations

• Dual no-flow sensors |Variable-Frequency or Eddy Current drive system

ADM’s call box notifies operators of an event at the plant. The call box can be tied to most plant systems, but it is most often used to monitor asphalt tank temperature.

• Custom automated alerts via text message or phone call allow operators to be in the know when they are away from the plant

• Operations choose from landline or cell phone configurations, with the cell phone being more reliable in the event of a power outage

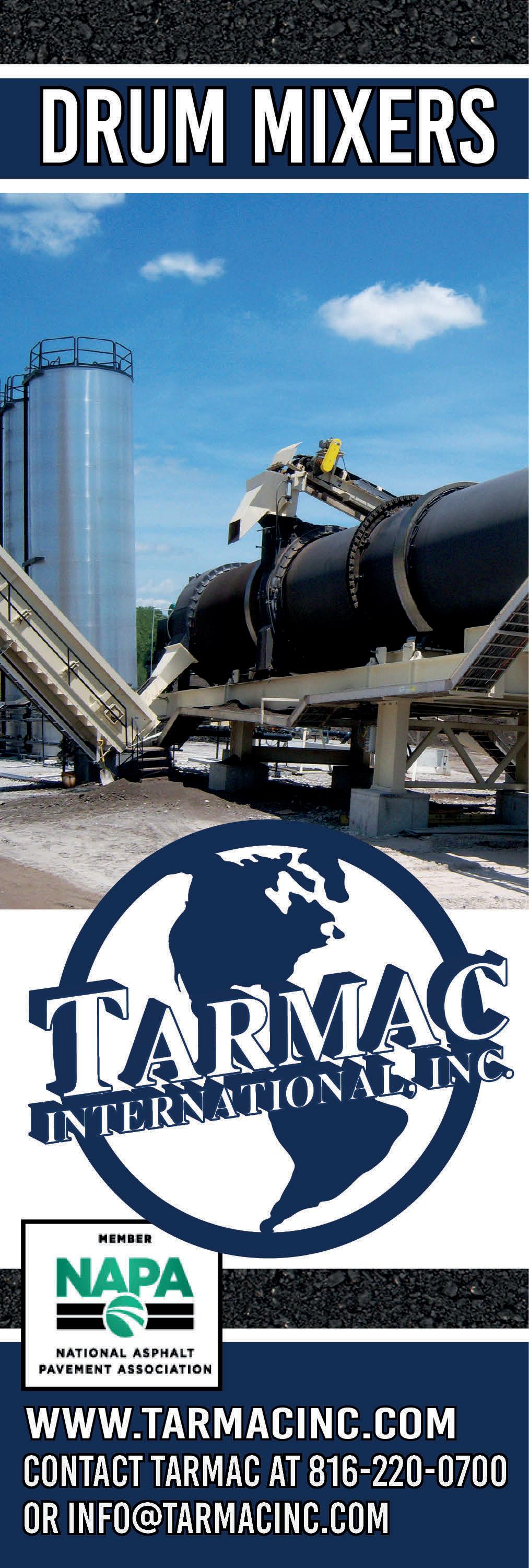

The 8-ft x 50-ft counter-flow drum mixer is built by BROCK in Chattanooga, TN.

The benefits of WMA, such as reduced energy consumption, lowered emissions, and elimination of visible smoke, are well-known in the asphalt paving industry and the latest generation of the Astec warm mix system simplifies production of warm mix asphalt.

• Achieves a lower temperature at a lower cost by eliminating the need for additives or special AC

• Instead, the Astec warm mix system injects a small amount of water into the liquid AC to create microscopic steam bubbles

• These small bubbles act to reduce the viscosity of the liquid AC, allowing the mix to be worked at lower temperatures

Engineered to take the day-in, day-out abuse associated with high-volume plant production while incorporating the features that allow the precision required for today’s high-spec mixes:

• Incorporates a direct connected helical gearbox and fully-digital flux vector technology allowing the flux

• Equipped with a material flow detector to alert the plant operator if material ceases to flow

• Tail shafts equipped with an optical encoder which allows automatic feeder control through the IC

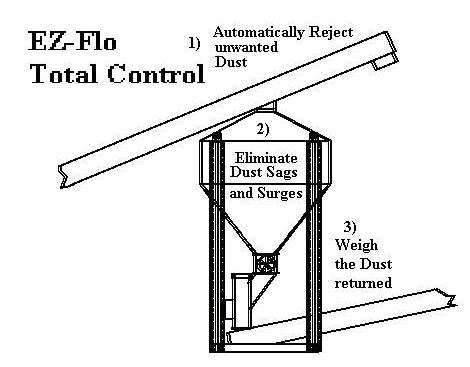

The EZ-Flo Dust Control System helps eliminate the sags and surges of dust delivery coming from the baghouse. When the aggregate contains too much dust, the system will deliver a required amount of dust to the mix and automatically reject the difference.

The operator shall operate the system differently when rejecting dust. When rejecting dust, it is easier to operate the system when the Surge Bin is always full of dust and the Blend Controller just delivers the amount of dust required by the mix design. When using all the dust, the system takes out the sags and surges.

Implementation of this technology has been proven to virtually end calls from nearby neighbors regarding odor and visual emissions. Similar to X-VOCS, the Blue Smoke Control system is retrofittable with few plant modifications.

• Features proprietary carbon absorption technology designed to filter and remove up to 99 percent of odors and VOCs

• Five-stage filtration system. In the first 3 stages, a series of filters remove more than 95 percent of targeted particulates down to 0.3 microns. In the final 2 stages, carbon filtration beds remove remaining odors.

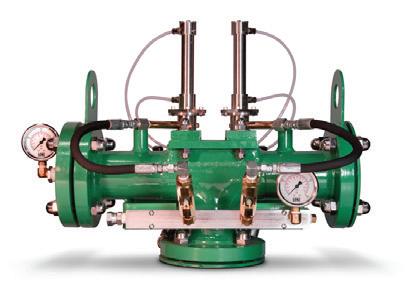

Since 1892, Homestead continues to be the most reliable manufacturer of asphalt valves. With cast iron and ductile iron material options, we offer a complete source of valves for any liquid asphalt application.

Our full line of hot-jacketed 2-way shutoff & 3-way diverter valves provide a ready solution to meet your flow requirements.

Homestead’s cutting-edge actuation design allows you to easily add actuators to your existing Homestead valves, in-line, without modification

Our fully stocked warehouse of valves and actuators offers you security in knowing that the valve you need is only a phone call away.

The ALmix Split-Level Control House is designed to provide a safe, refined, and fully mobile environment for your asphalt plant operators, plant automation systems, and load-out. These larger, two-room control houses feature a full operators room with 270-degree views as well as UL-Approved Motor Control Centers(MCC) complete with manual backups for each bucket. Hurricane-rated windows and double entry doors, rubberized flooring, and industrial-coated roofing materials are standard. Outdoor-rated transfer switches allow switching between power sources and outdoor main disconnects are offered to greatly reduce arc-flash risk potential.

Ruggedly built for years of use under the harshest conditions.

• Unique bin design provides steep sided tapered bin walls and a selfrelieving throat to virtually eliminate bridging and material flow problems

• A rugged rack and pinion gate design provides easy material height adjustment to suit a variety of material gradations

• All feeders are available with either eddy current or variable frequency drive to assure accurate flow at varying production rates, and also include two material flow indicators

• Optional features include a skirtless feeder design for lower maintenance and longer belt life, bin vibrators and bin extensions for increased capacity.

A robust build and simple, accessible construction makes the Astec Fury burner a low cost alternative to more expensive total air designs. Designed to put 50% more combustion air through the burner than competitive designs with the balance of the combustion air drafted in around the burner nose. This means higher combustion quality, better emissions and higher combustion efficiency throughout the entire firing range. Rapidly swirling, high-energy air is the key to the Fury burner’s efficient combustion. The swirling air and flame are created by the fixed internal spin vanes, high-pressure blower and high velocity nose. The Fury burner cleanly and efficiently burns oil or gas. Its compact flame makes it compatible with virtually all drum designs without complicated drum modifications.

By providing operators with the ability to make informed decisions and adjustments in real time, the system contributes to a more efficient and cost-effective asphalt production process. The visibility it offers into moisture levels not only enhances the quality of the final product but also transforms the way asphalt production is managed, ultimately leading to substantial savings and increased operational excellence. One of the standout features is its comprehensive data logging functionality. The system records virgin aggregate composite moisture levels, enabling operators to track and analyze historical trends. This historical data serves as a valuable resource for optimizing processes and making informed decisions.

Foamix Eco represents an evolution within the Foamix cold-lay asphalt solution, achieving carbon neutrality through the integration of carbon negative aggregates and biogenic binders. Using mobile plant on-site recycling, Foamix Eco reduces the associated vehicle movements and therefore the associated carbon footprint. Providing a truly sustainable approach to pavement solutions. This development is a testament to extensive research and collaboration across the supply chain, marking a significant step towards achieving net zero ambitions in infrastructure construction.

EZ Flo Scales for continuous weighing and process control accuracy.

• Contain material flow through scale while placing pressure on load cell in proportion to amount of material passing through

• Retrofits into existing process

• Scale size determined by flow rate and material density

• Able to modify or custom engineer

• Options available to protect load cell when product temperatures elevated

• Successful in applications requiring 20lbs/min, @ 2 lbs/cu ft upwards to 100’s of tons per hour@ 100lb/cu ft

• Accuracies depend upon application(baghouse dust, mineral filler, recycled asphalt shingles)

• Costs less than truck scales

• Automatic batching and blending

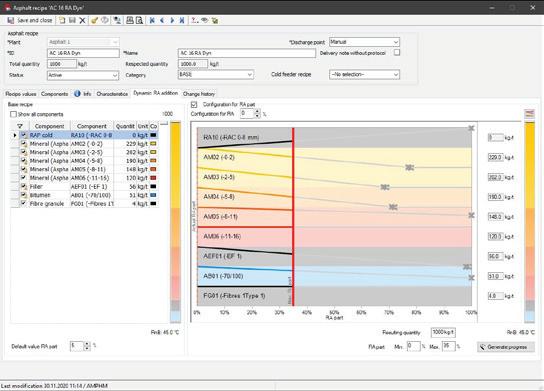

A unique product for effectively handling RAP content in various proportions and in varying conditions is the Ammann Dynamic RAP Addition.

• This module is part of Ammann’s proprietary as1 Control System

• Dynamic RAP Addition allows modification of the RAP ratio– even during production runs

• The system helps plant operation and quality assurance staff compensate for the qualitative and quantitative attributes of the RAP

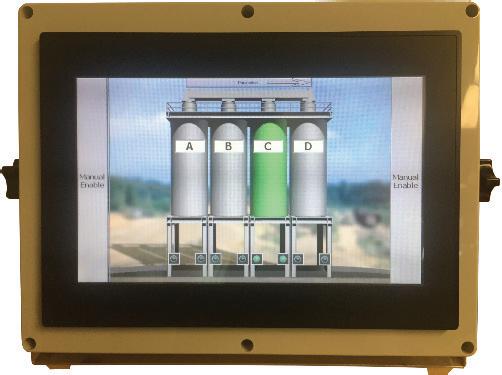

The NextGen Silo Safety System guards against the most dangerous and expensive accident that can occur at an asphalt plant– inadvertently opening the wrong silo. Equipment damage, personal injury, litigation and lost production are all consequences of a silo accident. The NextGen3 Silo Safety System is designed to dramatically reduce these risks. Infrared sensors enable each silo, if and only if, the truck is in the proper position. Fully graphic touch screen display indicates sensor and silo gate activation to the operator. Manual override mode with redundant loadout system interlock for scenarios not meeting standard vehicle and loadout situations.

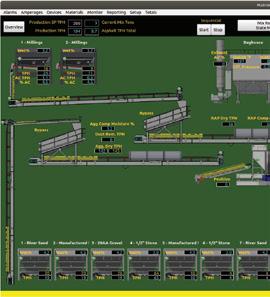

Asphalt plants often have dozens or even hundreds of switch wires. An HMI can help reduce the number of wires to just a few paired with a communication cable. This can mean reduced downtime during maintenance.

• ADM offers Human Machine Interface (HMI) Controls to help simplify plant control houses. This involves replacing manual switches with a programmable logic controller (PLC)-based HMI control system, such as a monitor and mouse or touchscreen

• Troubleshooting problems within the control house often requires checking switches and following wires to try to determine the problem. Replacing hundreds of wires with one can cut the time spent figuring out the issue by more than half.

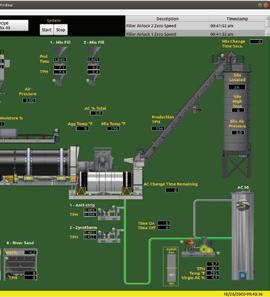

Accu-Track Advantage Control is a comprehensive system for controlling your entire plant, from proportioning the cold feed bins to selecting the storage silos and everything in between. With today’s high production rates and stringent state specifications, it is essential that all possible control be provided to insure maximum plant operation with minimum downtime and superior mix quality. The system is the only one in the asphalt industry to control all operations using standard components manufactured in the USA.

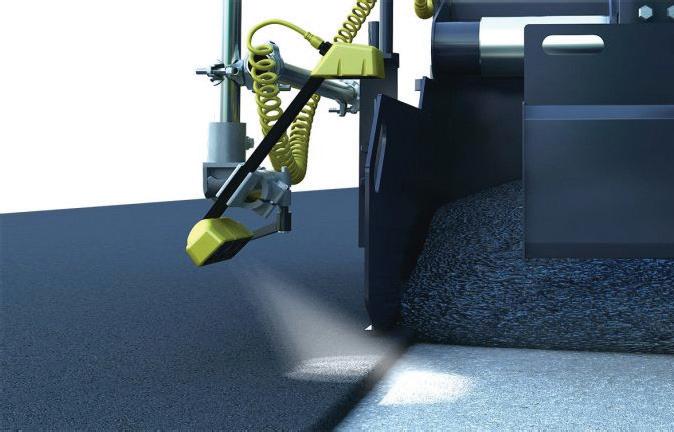

The ION Dust Shield was specially developed for cold milling machines to transfer dust away from the operator and eliminate fine particles(PM 2.5, PM 10) by up to 80%. In addition to visible dust, a considerable amount of particulate matter is also produced when removing an asphalt surface and the ION Dust Shield binds the fine particulate matter by electrically charging the particles. The particles clump permanently to harmless coarse dust and can be easily removed which leads to a reduction in particulate matter of over 80%.

The CMI Impulse series of total asphalt plant control systems utilizes Programmable Logic Controller(PLC) technology and Windows based operator interface software to precisely control and monitor asphalt plant operations, on-site or remotely. Total plant control featuring plant diagnostics, remote plant monitoring, step by step instructions to guide the operator through the calibration procedure, data recordation, alarm log, activity log, mix cost analysis. Impulse series comes complete with every new asphalt plant from CMI and is a popular choice as an aftermarket retrofit to other brand asphalt plants

The Roadworks Paving Control Platform for Asphalt Compactors enables operators to accurately control the compaction process, while reducing unnecessary passes that can result in over compaction.

• Intuitive Android-based software maximizes ease of use

• Asphalt temperature mapping provides color-coded data to allow operators to compact at the correct temperature

• Compatibility with Trimble WorksOS and WorksManager software

The FAMC GT1 series paving system is a cost-effective system that allows you to pave to a fixed thickness to the surface below. The dual sonic sensors, placed on each side of the screed, in conjunction with the slope sensor gives you precise control over slope and grade. This system will also make your machine Leica 3D ready regardless of manufacturer or year.

• Able to control elevation, screed endgate, and steering capability.

• Can be installed on any make, model, or year asphalt paving machine.

• Screed control is easy using the intuitive Danfoss interface that is designed with the operator in mind.

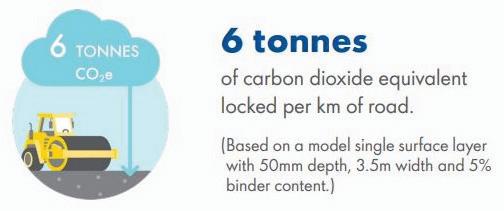

A new bio-component binder that locks carbon within roads instead of releasing it back into the atmosphere. The binder locks carbon into asphalt and bitumen, turning roads into technical‘carbon sinks. As the asphalt is recyclable, most of this carbon will not re-enter the atmosphere, even at the end of its life. High levels of asphalt recycling ensure that carbon is kept within a circular economy and stored within other applications. The technical carbon sink created by Shell Bitumen CarbonSink reduces the carbon footprint of 1 tonne of bitumen by up to 250kg of CO 2 equivalent and the carbon footprint of one tonne of asphalt by up to 13kg of CO 2 equivalent. This means up to 6 tonnes of CO 2 equivalent can be locked in per kilometre of road.

Process Heating Company Lo-Density

Unitized Storage Tank Heaters, FuelOil Preheaters and Hot-Oil Heaters provide unique electric heat benefits for asphalt plants.

• Drywell-style heaters dissipate controlled heat as low as three watts per square inch on the sheath to prevent damaging of materials

• Electric heaters require little maintenance; elements are accessible from outside, allowing service without draining the tank

• Electric heat is environmentally friendly, heating without combustion, emissions, or spills

• Provides 100% efficient heat over their lifetime

Pave Start Assistant is an optional machine management tool that simplifies setup for repeatable performance on job sites with similar paving requirements.

• The integrated system records the functioning conditions of both the paver and screed including paving width, paving speed and tow-point position to name a few

• When moving to a similar job site, the operator activates a previously recorded profile from the display menu, and the system matches machine setup specifications for reliable performance

Features the very latest in asphalt plant automation technology within the framework of an easy-to-navigate, point-and-click design. A comprehensive main screen is paired with a series of information-infused, operator-focused screens available at the click of a mouse.

The optional ALmix mobile application allows management real-time remote viewing of plant data and critical plant information.

• Automatic plant start-up and shut-down with sequence interlock

• Multi-point capability for all calibrations

• Burner ignition sequence and fault display, and much more...

This feature improves the safety and efficiency of tandem asphalt rolling operations. The new Echelon Mode addresses the unique challenges of echelon rolling, a common technique used in highway-class paving.

• Millimeter-wave radar or 3D LiDAR to detect potential collisions with personnel or equipment, warn the operator progressively, and automatically brake if needed.

• Echelon Mode allows two SAKAI SW884(79”) or SW994(84”) asphalt rollers, equipped with Guardman, to operate in close proximity.

• Enables closer, more efficient echelon formation, maximizing productivity.

• Minimizes unnecessary braking interruptions, keeping operations running smoothly.

Trimble Roadworks for Mills and Cold Planers runs on an Android operating system and enables operators to control cutting depth of the mill or cold planer, according to project design. The intuitive system allows operators to meet demanding specs for complex projects, minimizing over-cutting and creating a smooth surface on airport runways, highways, racetracks and other projects that require smoothness. The 3D design is displayed to the machine operator showing areas that are on, above or below grade, comparing the actual drum position and slope with the digital design. The platform automatically guides the milling drum to cut the depth and slope without string lines or manual adjustments.

Designed for the new F-Series Roadtec pavers, SmartEdge is a revolutionary joint detection technology that uses laser technology to precisely generate a 3D model of any concrete or asphalt vertical edge which allows for precision joint matching during paving. This ensures improved longitudinal joints and correct overlap.

• Increased Productivity & Accuracy: SmartEdge automates screed extension adjustments.

• Operator Safety: Potential for removing operator from traffic side or pinch point.

• A lane edge sensor utilizing laser technology.

• Control head unit with touchscreen.

Hamm is now expanding Smart Compact by adding a central measured value: the real-time asphalt density.

It is the decisive parameter for qualitative assessment during the compaction process and is becoming the key parameter for precisely meeting regulatory requirements and minimizing financial deductions. Smart Compact Pro closes the gap by integrating a new “Realtime Density Scan” sensor into the automated compaction process, by measuring the dielectric conductivity of the asphalt mix to be compacted, and forming the basis for the correlation with the asphalt density or the void content. Both parameters are decisive for selfmonitoring or control testing. With the help of real-time density, Smart Compact Pro can provide construction companies with a decisive advantage.

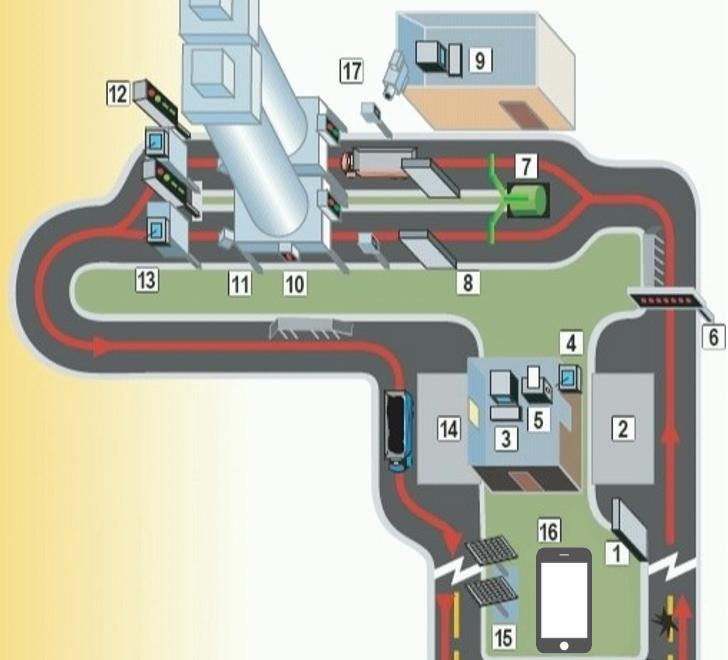

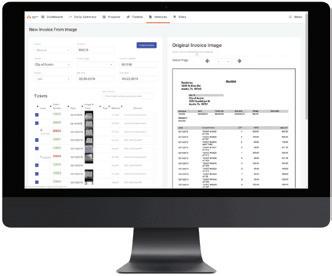

The Asphalt Yard program helps to automate the asphalt plant ticketing process. The program can help automate the following areas:

• RF-ID and Automatic License Plate Recognition

• Traditional and in-motion scale

• Attend and unattended ticking, including remote video, voice, cash, check, and credit card

• Electronic signature, self-cut printer

• Unattended ticketing- solar power

Volvo CE’s entry-level intelligent compaction system, Compact Assist Start, provides operators with real-time information on pass and temperature mapping. Pass mapping gives a clear view of the roller’s coverage of the asphalt, highlighting stop points and overlaps so adjustments can be made quickly and efficiently without missing a spot. Temperature mapping ensures that compaction is completed at the optimum pavement temperature. Adding a productivity service like Compact Assist Start is a comprehensive solution.

At Dimensions 2025, connection is magnetic.

Plug into a powerful network of industry experts, unlock hidden potential within your Trimble solutions, and master the latest techniques driving the future of your work. Discover innovative workflows and solutions, and solve your toughest challenges alongside peers, partners and Trimble professionals.

November 10–12, 2025 | The Venetian Resort Las Vegas Trimble.com/Dimensions Register now to reserve your spot at Trimble Dimensions

Superior Industries offers its new portable plant configuration— the Tandem Guardian Screen Plant.

• Includes two 7 x 20 triple deck screens, each with 50-hp, 1,200-rpm motors

• Bottle jack lifting points simplify and speed spring replacement

• Segmented belt guard and sectioned tailgate lighten the loads of these two features, requiring only one person to remove and return guards and gates during maintenance

• Bolt-locking, hinged access doors

• Fully-enclosed belt guard

• Integrated, onboard tensioner accelerates maintenance to motor belt

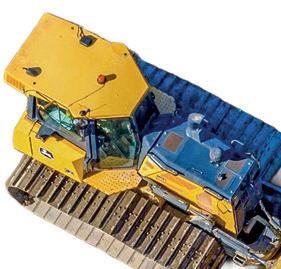

The Ammann three-in-one RSS 120-M prepares recycled asphalt for use in an asphalt plant. The RSS 120-M functions as a shredder, iron spearator and screener and can recycle asphalt ranging in size from millings to slabs.

• Protective processing maintains desired grain sizes.

• Shredder utilizes two low-speed, electrically driven shredder-rotating shafts.

• Milling cutters with interchangeable teeth. Crush hard and soft materials.

• Electric motors for consistent crushing and screening

• Process up to 198 tons of recycling materials per hour

The TCI Portable Screen with Bin(PSB) plant is designed for screening reclaimed asphalt pavement(RAP).

• Feed hopper with grizzly

• Folding discharge conveyors

• Electrical pane and diesel generator for either diesel or line power

• 6x18 DD high-frequency screen minimizes

The Tyler F-Class Portable Plant easily maneuvers between areas in mines and quarries. Its advanced double eccentric shaft design and four-bearing technology maintain consistent performance under surge loads, preventing material contamination.

• The portable plant includes a hydraulic system that raises the vibrating screen to its inclined operating position

• Producers can move and set up the portable F-Class in less than 30 minutes in nearly any location

• Businesses can customize the portable F-Class setup to include a crusher, conveyors or other components for enhanced productivity

• Ideal for scalping and classifying ores, minerals, stones, sand and gravel

Available in two- or three-deck models featuring heavy-duty, high-energy, twobearing screen boxes for sorting a wide range of materials.

• 12-cu.yd. hopper, 129-hp Cat diesel engine

• Sort up to three sizes with two-deck unit or four sizes with three-deck unit

• Change out the screen media on each deck for control over end product size

• Feed conveyor with adjustable speed

• Tail conveyor sorts material into stockpiles up to 15 ft. 2 in.

• Two side conveyors with adjustable speed to sort into stockpiles up to 16 ft. 8 in.

• Solid, heavy-duty steel chassis

Universally adaptable plant is suited for processing both blasted natural stone, asphalt and demolition waste as well as producing a first-class end quality product

• Crusher inlet size of 52-in. x 36-in.

• Maximum input capacities of 450 tph can easily be attained

• In primary screening, an independent double-deck pre screen is applied

• The Kleemann Continuous Feed System(CFS) manages a more equal loading of the crushing area, in which the conveying frequencies of the feeder trough and the prescreen are adapted independently of each other to the level of the crusher, boosting performance

The CRC320 features the TG320 bushing cone crusher that can be easily set up to deliver peak cost per ton by selecting the optimum crushing cavity and eccentric throw to suit the application requirements. The 300hp, 1,800-rpm motor and crusher are mounted on a rubber-isolated frame. The plant combines the cone crusher and a 15-hp, 42-in.-wide discharge conveyor on a portable all-electric chassis. The crusher is fitted with an overflow chute and removable overflow panel so the overflow can buffer feed surges in a closed-circuit application.

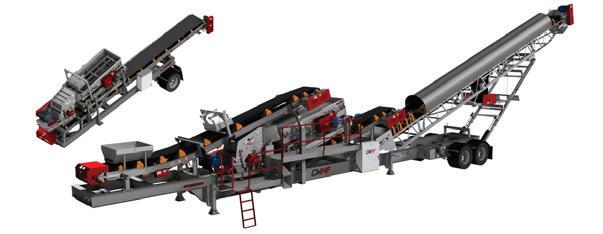

The KPI-JCI and Astec Mobile Screens ProSizer 3600 single-load crushing plant is the ideal choice for closed circuit portable impact crushing. The highly mobile and versatile plant is easy to move from site to site for a wide range of applications, from virgin aggregate to recycled materials, at up to 300 TPH. The 36-in. x 46-in. horizontal shaft impactor can be paired with a 5-ft. x 28-ft. conventional screen or 6-ft. x 18-ft. high frequency screen to meet your application needs. The ProSizer Series was designed with maintenance in mind, making your equipment sustainable, even in dirty environments.

From a single feed, owners and operators will be able to produce up to four unique products. The closed circuit crushing and screening arrangement includes a 4250 Superior brand Sentry Horizontal Shaft Impactor(HSI). It is fed by a 48 x 18 Intrepid Vibrating Grizzly Feeder, which is equipped with interchangeable grizzly cassettes(bars, fingers or punch plates) to accommodate multiple applications. Additionally, a 2-deck Anthem Inclined Screen screens up to three material sizes. Returning material is fed back to the HSI via a patent pending recirculating conveyor, which centralizes the feed for full utilization.

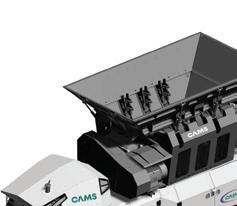

CAMS RU-m series is designed in compact size. Powered by electric energy, it reaches the highest production capacity with the lowest fuel consumption. Thanks to the low rotation speed of the shredding shafts, the RU-m series produces low dust and acoustic emissions.The RU-m range processes RAP and asphalt slabs preserving 100% of original bitumen content for efficient recycling operations. RU-m series meet every possible output rate requirement, with the highest level of efficiency and reliability. Comes in four models: RU 120m, RU 160m, RU 200m, and the RU 260m. CAMS shredders are designed for recycling. Both the primary and secondary shredders operate according to the shear shredding principle. During the process, the material is dumped directly on the shafts and grabbed by the picks, without the need for a feeder.

Equipped with an 8-ft. x 18-ft. top deck and an 8-ft. x 12-ft. bottom deck.

• Patent-pending screen design features externally-mounted vibrators at the ends of the tappets for a more aggressive screening action which creates a higher G-force and reduces heat load from material to motors as compared to single, center-mounted vibrators

• Similar to other PTSC plants, the 2818VM features a nominal 54-in. x 38-ft. delivery conveyor with hydraulic drive and full-length skirtboards

• Chassis is fitted with manuallyoperating support legs, outriggers for additional support

Keestrack’s R3 plant is available as diesel-hydraulic or fully hybrid ”e”-version.

• Production rates up to 250 tph

Allow hot mix and crushed asphalt producers to minimize material handling, reduce or eliminate RAP crushing costs, and reduce RAP product moisture. This RAP crushing machine brings together top equipment like the Honey Badger crusher and our Tremor Shaker scalping screen to crush it right every time. The RAP Boss lets you take your crushed asphalt show on the road. The portable crusher and scale systems leverage industry-leading equipment, including the Honey Badger hammer mill 40 and a 4×10 Tremor Shaker single deck. It also incorporates a tandem axle chassis, a 30’ x 50’ virgin scale conveyor, a 30’ x 30’ scale feed conveyor, a 30’ x 27’ scale feed conveyor, a magnet, a controls package, and a portable chassis with conveyor. For more cost savings, the RAP Boss Jr. offers a slightly scaled-down version that eliminates the feed conveyors.

The 1600X-OC plant features the UltraMax 69X Impactor with a 69” x 51” feed opening to allow larger material into the impactor to increase throughput, up to 1,000 TPH. The plant’s massive, solid-steel rotor weighs in excess of 13 tons and crushes even the largest feed material in a single pass.

• Flexible processing of a large variety of raw and recycling materials

• Pre-screening

• High-performance impact crusher 48 ICR 100-00 with 770 x 960 mm inlet opening

• Heavy-duty 920 mm rotor(44-in. diameter)

• Optional 9-ft. x 4-ft. single-deck with reciruclation conveyor after screening unit

MB Crusher offers the BF70.2 bucket crusher attachment for large-scale projects, including construction, road works, forest maintenance, recycling aggregate, demolition and urban sites. This attachment features a 29-in. wide mouth opening. The BF70.2 can be installed on heavy equipment and can crush materials during use. Furthermore, the crushed materials from the bucket can be recycled and used for many purposes and applications, including asphalt production. Available accessories include a spare parts kit, fixed coupling, iron separator, hour meter and dust suppression kit. These additions support specific operating requirements at the jobsite.

The implementation of the TC1300X cone crusher features 400 hp, an increase in power over the previous version. The use of roller bearings enables several advancements that support performance and functionality. This complete configuration increases stroke from 45mm to 70mm that results in increased thruput and a different quality product shape. Automated cone controls and large closed side settings. The portable plant includes an oversize quickrelease cone feed hopper extension with overflow chute, a 42-in. rugged straight-line product conveyor, a metal detector for off-plant feed conveyor.

The new 8x20 Screen Plant with Integrated Feed Conveyor can produce up to four products simultaneously, three with absolute sizing, or return the oversized product for further reduction. The integrated 60” feed conveyor remains on for transport and eliminates the need for a separate conveyor, while each screen deck features four blending gates to allow for a wide range of custom product mixes to meet specific product needs.

The Komplet K-IC 70 impact crusher enables contractors to recycle waste materials on jobsites. The K-IC 70 can be used for crushing and stockpiling in diverse recycling applications including construction and demolition waste, asphalt paving, clay and concrete bricks and blocks, porcelain, ceramics, glass and other solid waste. This machine is powered by a 100-hp Doosan Tier 4 final engine. A 25- x 20-in. jaw allows the crusher to handle different types of materials during use. The K-IC 70 is equipped with a vibrating feeder with chamber level sensor and rubber pads bolted on metal track chains for safe transportation.

The right paver for every application: Vögele covers a wide range of pavers to make sure you have the right paver for every application. The Vögele paver is a state-of-the-art solution for asphalt paving, renowned for its precision and efficiency. Designed for various applications, it ensures a smooth and uniform surface, ideal for roads, highways, and parking lots. Equipped with advanced technology, the Vögele

paver offers excellent visibility and control, enhancing operator comfort and productivity. Its modular design allows for easy maintenance and adaptability to different job requirements. With a focus on durability and performance, the Vögele paver is a reliable choice for contractors seeking to deliver high-quality results on every project. Experience superior paving with Vögele’s innovative engineering.

These pavers can be perfectly harmonized with the Hamm HD 120i VIO-2 HF rollers to achieve maximum compaction using vibration and oscillation.

Learn more about the Vögelelineofasphalt pavers. https:// pavemg.com/4jczeb

Ammann Group has launched a line of premium asphalt pavers for applications ranging from narrow paths, to city streets, to wide lifts for roadways and airports. The line includes 17 models with tracked and wheeled versions available in three major size groups: compact pavers(including the mini paver), city pavers and large pavers. Compact pavers have production capacities of 300 tph and maximum paving widths of 10 ft. The four city paver models can place 350 tph with maximum widths of 15 ft. Large pavers can reach 1,100 tph with maximum widths of 46 ft. Screed options include tamping/vibrating, high-compaction and rigid-frame.

The 8-ft. AP600F wheeled paver and AP655F rubber track paver with Mobil-Trac undercarriage come with a standard Eco-mode or Advanced Ecomode with auto engine speed control.

• 173-hp C4.4 ACERT Tier 4 Final engine

• Max paving widths 21.3 to 26.3 ft.

• Refined heat distribution of screeds combines with the 70-kW integrated generator to bring the screed to proper temperature in approximately 15 minutes

• Feature intuitive touch screen operation, single-button feeder system activation, auto fill feeder system, quick-change heating elements and front wheel assist

The CR 820 Series 8-ft. pavers come in rubber or track models with a 10-ton hopper capacity and a 160-hp Tier 4 Final diesel engine.

• Stretch 16 hydraulically extendible screed offers 8- to 16-ft. infinitely variable paving widths and a 12-in. maximum paving depth

• Quick-connecting extension kits deliver a maximum paving width of 20 ft.

• Three-Point suspension floats the paver over subbase irregularities and maintains preset screed slope and grade

• Operator station includes dual swing-out seat and consoles with 7-in. color display

The RP-195 features a fully oscillating track frame to provide a smooth ride and lay a smoother mat. The RP-195 is also equipped with our exclusive anti-segregation design of the feed tunnel, discharge and rear augers. The heavy-duty frame, solid front axle and sturdy conveyors are engineered for durability. Seats on the dual operator stations can move hydraulically out beyond the sides of the machine to give the operator an excellent view down the sides of the paver.

• Weight: 39,220 lbs.

• Paver class: Highway

• Standard paving width:10 ft. to 19 ft., 6 in.

• Maximum paving width: 30 ft.

• Engine: 230 hp Stage 5/ T4F Cummins B6.7

• Maximum pave speed: 210 ft./min.

Powered by a Cummins QSB 6.7 watercooled, turbo-diesel, Tier 4 Interimcertified engine rated for 200 hp at 2,200 rpm.

• “Infinitely variable eco mode” produces less noise and decreases fuel consumption

• Choice of high-density tamping bar screeds

• Vario screeds offer an 8-ft. minimum and 32-ft. maximum work width

• Can be outfitted with VarioSpeed drive option with auto load sensing

• Hydraulic push rollers minimize impact from the truck during asphalt delivery

• Operator’s platform can slide hydraulically from side-to-side

The 8530 has a 125-hp turbocharged engine, enhanced cooling systems, independent hopper wings, reversible augers and conveyors, m aterial cut-offs that automatically close in reverse and q uick-change auger assemblies.

• 4,150-lb. Legend HD PRO Screed includes heavy-duty flight screws, heavy-duty crown and valley mechanism, angle-of-attack adjuster with vertical height adjustment, sloping screed extensions and pre-strike off adjustment

• Dual operator control platforms come with multi-position, pivoting seats

• Actuator-driven hood lift, front conveyor chain adjustments, auger single lube system and ground-level access point enable ease of service

The 10-ft. F1000W wheeled and F1000T tracked pavers can be equipped with either a center auger drive system or outboard auger drive system.

• Center drive auger system has a 6-in.-wide chain box and 17-in.-diameter flights to ensure continuous, uniform material flow

• Outboard auger drive system for paving wide roads and for normal speed paving applications

• Auger-conveyor feed-control system uses four ultrasonic sensors to measure material and automatically adjust conveyors and augers to optimize flow

The 8616D asphalt paver provides consistent material flow and delivers a paving width up to 15 ft. 6 in.

• Legend HD PRO screed features spring-loaded end gates, HD flight screws, heavy-duty crown and valley mechanism and an angle-ofattack adjuster with vertical height adjustment

• Includes independent hopper wings, reversible augers and conveyors, hydraulic tow point cylinders, material cut-offs that can be set to automatically close in reverse and a quick-change auger assembly

• Stylish operator platform includes dual operator control platforms, and multi-position, pivoting seats

The Weiler P395 incorporates proven designs with new innovations to provide optimal performance, reliability and mat quality in a wide range of applications. Its 4,400-lb., 7-ft. 8-in. front mount screed is hydraulically extendable to 15 ft. 4 in. The 96-in. track length with 74-in. of ground contact and 140-mm track chain pitch provide smooth ride and enhanced flotation. Automatic track tensioning ensures performance and maximizes component life. Swing-out consoles provide greater visibility, while the adjustable, magnetic-resistance intelligent steering system allows for reliable control. A joystick allows for automatic functions. Highwayclass chains, conveyor and auger bearings provide long-term reliability.

The AP1055F high-production, rubber track paver provides a 25-ft. maximum paving width using the SE60-Series or XW-Series screeds.

• 225-hp Tier 4 Final engine with Ecomode and automatic engine speed control

• 70-kW integrated generator

• Dual operator stations

• Mobil-Trac undercarriage

• Cat Grade Control

The EZIV Screed provides a reliable, heavy-duty screed platform for commercial, municipal and highwayclass applications.

• Available in 8- and 10-ft. models

• Can be mounted to all current North American asphalt pavers offered by the major manufacturers

• Can be retrofitted onto nearly any previous North American highwayclass paver

Combining spraying and laydown produces a high-quality mat with a strong bond between layers. A spray bar just in front of the paver’s auger distributes the liquid through computer-controlled, self-cleaning valves. An onboard microprocessor precisely controls the rate of flow. Valves can also be controlled manually and are arranged in sets of three, providing plenty of spray capacity so you can move fast. To cut down on refill stops, the SP-200 is equipped with a 2,100-gallon tack tank, the largest tank available on the market today.

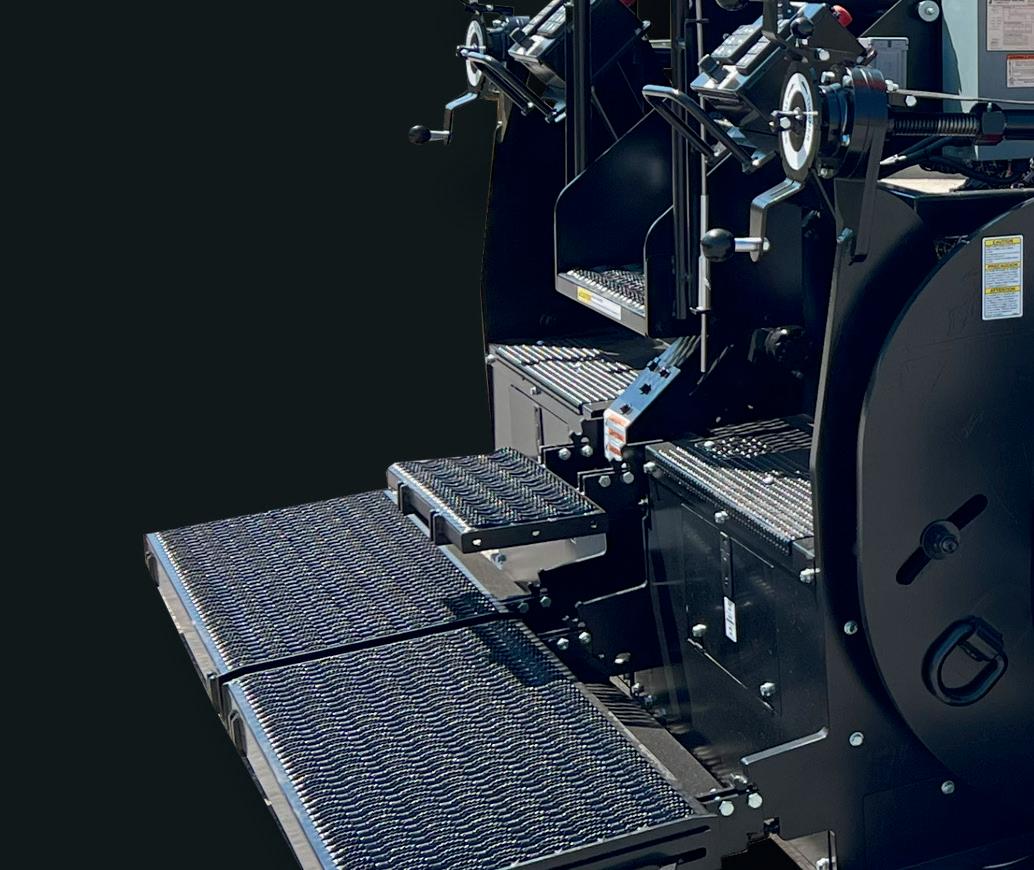

Weiler Material Transfer Vehicles lead the way with proven innovations to provide the lowest cost per ton of operation.

Innovative and reliable operator friendly features such as paver hopper management system with distance to paver, storage hopper management and auto chain tensioning.

Clam shell doors and full width drop down floors provide unmatched access for cleanout and maintenance.

Variable speed elevator and conveyors meet production requirements while minimizing wear.

The multiple, incremental improvements to the 4th generation of chains, sprockets and augers are retrofittable to all machines and provide increased wear life.

Blaw-Knox’s fuel efficient Tier 4 Final D8 235 hp engine in the PF-7110B Blaw-Knox Tracked Paver improves fuel efficiency by up to 5% and provides superior quality, reliability, durability and ease of operation. The PF-7110B is a true highway-class paver with an independent auger and conveyor system, and stable hydraulic screen extensions for delivering perfect placement of bituminous base, binder, or surface mixes

• The fuel efficient Tier 4 Final engine meets emission regulations and fuel efficiency

• All-around visibility with rotating and extending operator seats for a full view of the whole paving process

• Basic width: 10 ft. | Engine power: 235 hp | Max width: 26 ft.

The BOMAG CR 1030 T-2 brings versatility to the highway paving class.

• A large multifunction color touchscreen display on both consoles.

• The ergonomically designed operator console groups similar functions

• Dual, swing-out operator stations feature BOMAG SIDEVIEW innovation

• The independent auger conveyor control regulates the flow of material

• Screed controls are centralized on the left and right sides with remotes

• MOBA integration is standard

A 125 hp workhorse. Standard machine assets include the 3,450 lb. Legend HD screed with, heavy-duty conveyor chains, dual seating and sliding main controls and many other enhancements. LeeBoy’s wide, slow-moving conveyor system moves material from the truck to the screed without segregation. The machine features a Kubota Tier 4 Final diesel engine, paving widths variable up to 15 ft., and a 9-ton hopper. The machine also includes remote-mounted SCR for improved visibility, dual electronic steering, and efficient wide conveyor material management.

The Weiler designed 2,800 lbs. (1,270 kg) screed delivers mat quality and a wide paving range. The 7 ft., 8 in. (2.3 m) front mount screed is hydraulically extendable to 15 ft. (4.6 m). Highway class chains, conveyor and auger bearings provide long-term reliability. Remote grease lines located on the front counterweight provides easy daily maintenance.

• Heaviest in class screed for industry’s best compaction

• Standard sonic controlled variable speed four auger material feed system for consistent head of material control

• 110 hp Tier 4 Final turbocharged diesel engine

• 9.5 ton hopper capacity

• Seamless paving up to 16 ft.

The AP300F(wheel-type) and AP355F(rubber track-type) models are designed specifically for efficient production in mid-sized applications, including parking lots, urban streets, cycling and walking paths, trenches, and narrow shoulders.

• Equipped with new electrically heated SE34 Series screeds

• Available in vibration-only and vibration/tamper-bar configurations

• Cat C3.3B engine, rated at 55 kW(73.8 hp)

• Eco-Mode

• Auto-fill feeder system

• Single-touch feeder system activation

ShoulderMaster LLC announced the launch of the world’s first skid steer center paver. This product is designed for versatile applications like narrow paving projects, utility trenches, and paving asphalt between rail tracks. Its efficient design includes a universal skid steer attachment quick connection, ensuring easy setup and operation.

• Wireless remote-control system

• Easily transported

• Equipped with two built-in cameras for better monitoring and precision

• Hopper capacity of 88ft³ allows for efficient material handling

• The paver can take material from conventional-size trucks

The Sakai GW754 vibratory pneumatic tire roller is widely versatile for various types of materials from hot mix asphalt (HMA) mixes to soils.

• Vibrating tires massage materials dynamically and compact them more uniformly which helps to cut operating cost on jobsite

• Tier 4 final Kubota V3800 turbo charged engine, rated at 110 hp and equipped passive regeneration

• Traveling speed of 7.5 mph

• 2400 vpm and four amplitude settings, changeable on the fly

• Smaller size of machine, weighing 22,440 lbs., vs. static pneumatic tire roller which weighs 55,000 lbs.

• Maximum of 45 dB at 50 ft.

SEISMIC Asphalt technology automatically detects the natural resonance frequency of the asphalt, works together with it, and applies the correct amount of energy exactly when required. While conventional vibratory compactors deliver a rapid succession of impacts to the soil surface at a frequency that is either pre-set at a high or low amplitude or at a frequency that is adjusted manually, SEISMIC Asphalt does it differently. The CC2200 VI weighs 7.6 tons and features a 59-in. drum, which is ideal for finish rolling on a variety of job sites. It includes a Tier 4 Final diesel engine, efficient patented eccentric weights, and an ECO Mode for fuel efficiency.

This BOMAG BW 174 AP-5 AM is adjustable and automatically controllable due to some of its ASPHALT MANAGER technology design. The roller is capable of getting the optimum number of passes based on the layer information that the operator inserts.

• 21,385 lbs. | Working width of 66.1 in.

• Has optional heated and electrically adjustable front side mirrors, four additional mirrors, and various camera systems (passive & active) available.

• The sprung seat can be adjusted to the driver’s weight and the cab is also decoupled and mounted on vibration-damping bearings- factors that ensure significantly fewer jolts and vibrations.

Allows the host machine to drive safely on flat ground while compacting sloping shoulders, ditches, trenches and other hard-to-reach areas alongside roads.

• Attaches to most loaders, graders, compact track loaders and skid steers and operates off the carrier’s engine and hydraulics

• Drums come in 2-, 3- or 4-ft. interchangeable sizes, pivot up to 30° and reach up to 30 in. below the mounting point

• Attachment operation controlled via the remote control

• Vibratory feature operates between 2,500 to 3,500 vpm for optimal compaction of stone, asphalt, gravel, topsoil and other materials

• Compatible with standard- and highflow hydraulics

The rollers have high curb clearance and no overhangs for small- to mid-size compaction applications.

• Drums can be offset to further improve access and performance during turns

• Powered by a 43.5-hp Tier 4 Final engine

• Feature 8,290- to 10,340-lb. operating weights, selectable dual frequencies (2,700/3,420 vpm) and automatic or manual vibration engagement

• ISO-mounted operator platform with standard lateral-sliding seat

• Standard 50-gal. water tank with pressurized water system

• Compatible with the CASE ACE Force

Offers below-the-axle exciters that produce a more efficient transfer of compaction energy to the soil. The simple lower end design is fully sealed with lifetime lubricated drive gears and maintenance-free exciter gears and bearing. All the hydraulic hoses have been shortened and re-routed to avoid wear and improve serviceability. The unit is powered by a 19.8-hp Kohler diesel engine and produces a high and low compaction force (15,400/7,700 lbf).

The Dynapac CA1400 soil compactor is a vibratory roller designed for compaction operations in streets, parking lots and pipe trenches.

• Compaction width is 66-in. and static linear load 20 kg/cm, giving the machine the ability to compact sand and gravel down to 20 in

• Two amplitudes, high at 0.067 in. and low at 0.032-in., makes the machine versatile and suited for all supporting and reinforcement courses

• The Padfoot version is especially suitable for the compaction of silt and clay soils and can compact silt and clay at a depth of 18 in.

• Kubota Stage Tier4 final engine at 75 hp, latest emission standard and ECO is standard

The 6000 asphalt roller features a 6,000lb. operating weight and a 24-hp Kubota engine.

• Adjustable 2-in. drum offset

• Large-diameter drum

• 54-gal. pressurized water system

• Designed for operator comfort

Wirtgen offers Hamm HC 250 C VC (Tier 3) and HC 250i C VC compactors for construction projects. These machines are able to crush and compact mixed soils, stones such as basalt and granite in a single workstep. As with the predecessor series, this is indicated by the initials “VC” (Vibration Crusher) in the type designation. Featuring reinforced components around the front frame, three-point articulation and the underbody, the new compactors are designed for tough applications. The separate “C” in the type designation also symbolizes a reinforced drum drive, capable of inclines of up to 60%. The 25t machines are supplied with heavy-duty tires for rocky terrain.

The SW9994ND oscillatory (OSC)/vibratory tandem roller provides dual drum oscillation and vibration.

• Enables switching on the fly from vibe for high compaction efforts to OSC for smooth finish of the pavement surface

• Optimized dual drum OSC achieves target density of thin lift pavement (1 to 1.5 in.) in fewer passes and increases paving train speed

• OSC achieves density on no-vibe jobs where structural integrity is a concern

The Tier 4 Final PT240D pneumatic roller has an operating weight of 21,380 lbs. and the ability to ballast up to 52,910 lbs.

• Tire configuration (four in front and four in back) features a 2-in. overlap and a total compaction width of 78 in.

• Kneads HMA gently at the surface as it rolls for greater asphalt density and fewer voids in the finished product

• Iso-static front axle allows each of the front tires to oscillate 3° in either direction, as well as up and down

• All primary service points centrally grouped for ease of access

The DD25 Electric asphalt compactor from Volvo Construction Equipment brings the advantages of lower noise and zero emissions to road building and hardscaping. It requires significantly less time and money related to maintenance. Charging a battery is typically more cost-effective than buying diesel fuel, and there’s no need for engine-related maintenance products like oil, filters or DEF. The DD25 Electric can operate for a typical full shift on a single charge, depending on the type of job and intensity of the work cycle. The machine comes with an integrated on-board charger that enables charging from zero to 100% in as little as three hours.

The double-drum CC1300VI and CC1400VI feature high-frequency compaction with a choice between dual frequencies (3,240/2,940 vpm), depending on the conditions and applications.

• Available dual amplitude function provides added flexibility to compact different layer thicknesses

• Kubota Tier 4 Final engine with ECO

• Optional dual edge pressers, asphalt temperature meter, front right-mounted edge presser/edge cutter, dual front right and left edge presser/edge cutter and rearmounted chip spreader

The largest model in the Volvo soil compaction portfolio with an 84-in. smooth-drum and operating weight of 26,565 lbs. (12,050 kg). The SD125 features a powerful Tier 4F 4-cyl. Volvo engine with 147.5 hp (110 kW). Active DPF regeneration eliminates material build-up, reducing emissions. The center joint provides +/-35 degrees of articulation and +/-12 degrees of drum oscillation for stable and flexible performance over rough terrain. Because the drum is in constant contact with the ground, compaction is smooth and uniform. The additional static weight on the drum frame facilitates the ability to negotiate 35% slopes for gradeability.

The CCS9 is a 9-metric-ton vibratory combination compactor that combines the smooth front drum of a soil compactor, with smooth rear tires similar to a pneumatic compactor. In addition, the water spray system utilized on Cat Asphalt Compactors keeps the drum and tires wet for excellent performance on asphalt. It offers outstanding operator comfort while continuing the legacy of durability, reliability and ease-of-service that contractors worldwide have come to expect from Caterpillar machines. Touch pad machine functions enable the operator to fine tune engine speed control, travel speed, and water spray intervals for efficient operation.

With the addition of the CT380 and CT430, JCB has expanded its tandem roller lineup to four models, which also includes the compact CT160 and mid-size CT260. Powered by 48.9 hp, 3 cyl. engines, the CT380 and CT430 are built to handle rigorous daily use. Their operating weights, 8,820 lbs. and 9,920 lbs. respectively, strike a balance between easy transport and heavy-duty performance. Features:

• Dual-drum widths of 51 in. (CT380) and 55 in. (CT430) deliver centrifugal forces of up to 13,800 lbs. and 14,600 lbs. per drum

• Maximum travel speeds of 6.2 mph, enabling efficient movement

The BOMAG BW 154 AD-5 is a tandem roller for typical asphalt layers in road and farm track construction, as well as applications on car parks and access roads, antifreeze agents, and light earthworks.

• 17,637 lbs. Working width of 66.1 in.

• ECONOMIZER and BOMAP help avoid unnecessary passes and document the compaction progress.

• EasyService helps reach all maintenance points from the ground without any grease nipples.

• Offers three vibration systems, with double vibration, TanGO, and ASPHALT MANAGER to choose from.

• ECOMODE provides load-dependent and economical working without high engine speeds.

Features a vibrating roller drum (50 Hz or 3,000 vpm) at the front and a VIO drum at the rear, the HD+ 120i VIO-2 HF provides additional application options with two VIO drums. An automatic control feature on the HD+ 120i VIO-2 HF keeps the front drum always working in vibration mode, while oscillation or static compaction is used on the rear drum. The HD+ 120i VIO-2 HF has also been designed as a high-frequency machine (HF), offering a vibration frequency of 67 Hz or 4,020 vpm (front and rear). Both models are powered by a 115 kW (154 hp) Deutz engine.

BARC is derived primarily from natural plant oils free of VOC and the traditional solvents making this technology now available to address the environmental issues surrounding the removal of bitumen, asphalt and heavy duty grease.

• Available in 5L, 20L, 264 Gallon IBC Tote or 55 Gallon Drum

Use an asphalt lute to ensure that asphalt is spread quickly and evenly. Level and smooth asphalt with a variety of head and handle options.

• Handle made of lightweight magnesium

• Thinner wall thickness on economy grade line reduces overall weight; larger handle diameter increases strength against bending

• Small handle diameter on premium grade line allows heavier wall thickness to resist bending without increasing weight of lute

• End capped with rubber tip

• Head made of wear-resistant aluminum alloy

• 1/8-in.-thick tee-beam with smooth edge on one side and serrated edge on the other

• Standard head serrated with full tooth at each end

The 3D-MC Asphalt is designed to control any paver right from digital site plans.

• Produces exact thickness at exact slope automatically with fast and accurate 3D transitions through horizontal and vertical curves

• Millimeter level accuracy

• 2,400-meter horizontal working range and 40-meter vertical working range

• Pave horizontal, vertical or combined transitions

• Accommodates multiple users in the same zone

Provides a more efficient and safe form of heat for asphalt and emulsion distributor truck tanks than fossil-fuel-fired systems.

• Simply plugs the heater in at the end of the day, and it maintains the emulsion at the correct temperature overnight or over a weekend

• With no open flame, these heaters eliminate concerns about the ever-present dangers associated with lighting and operation of burners

• In addition to improving productivity, safety and asphalt/emulsion quality, Lo-Density electric heat also can reduce operating costs for distributor trucks

• The heating units are suitable for a kilowatt rating of up to 1,000 kW; voltages up to 600 VAC, in single or 3-phase; and watt densities of 3 watts per square inch of heater surface being standard

Optimize your speed and accuracy of single application and resealing liquid asphalt applications with Etnyre’s Maintenance Distributors.

• 600-gal to 1,000-gal capacities

• Trailer, truck or skid mounted

• One person operations- all spraying functions can be controlled from the truck cab

• Meets federal regulations for hot products

• Hydraulic drive system

Road Science’s NovaGrip line of liquid anti-stripping additives safeguards workers from the hazards of traditional liquid anti-strips by using chemistry that is less hazardous.

• Eradicates the smoke, odor and dust problems typical of traditional antistripping additives