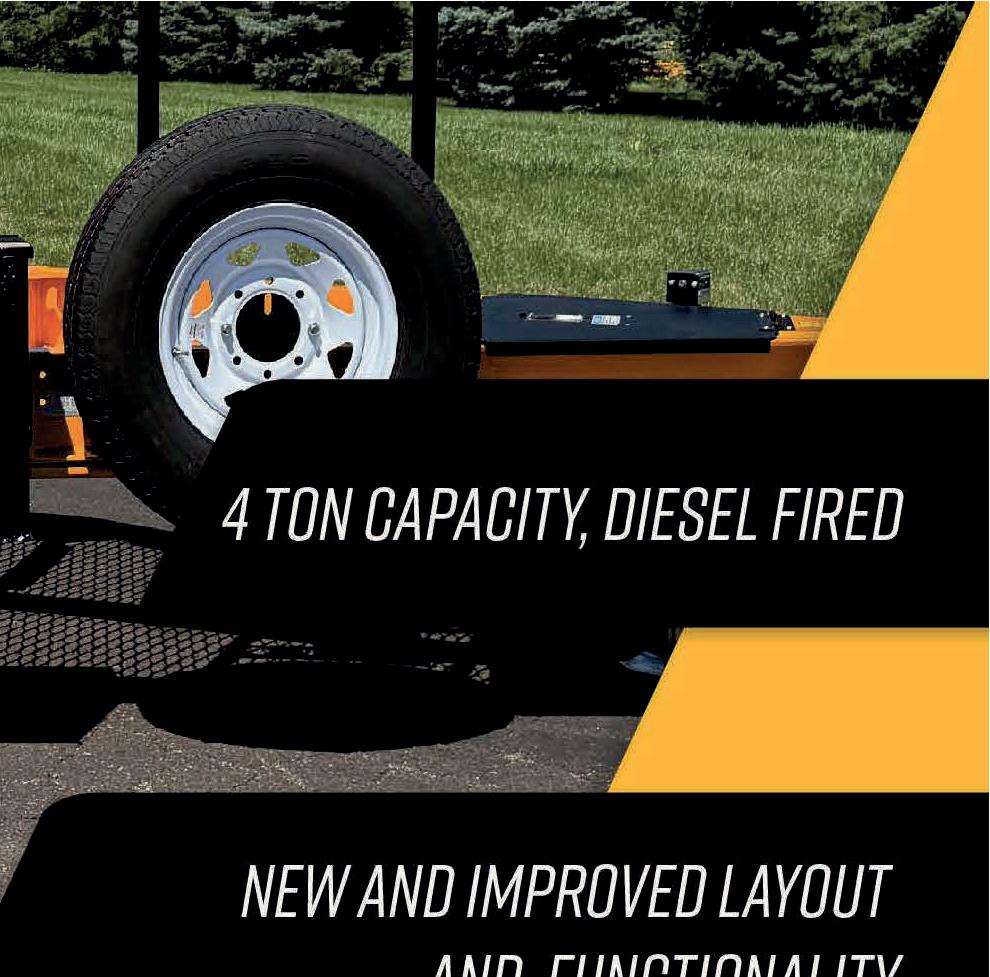

When you need superior pavement marking or rubber removal with small-job maneuverability, the new StarJet™ SRV-2 offers all you expect — and more.

This mid-size unit has a front-mounted, articulating SpinJet® arm for high side-to-side efficiency, with great visibility from the cab. A 40,000 psi NLB pump — featuring our HydraFlex™ closed loop hydrostatic drive — provides dry shut-off with less heat and noise. Typical run time is two hours, thanks to high-capacity water and debris tanks.

See the SRV-2 for yourself at the 2026 ATSSA Traffic Expo in Houston, Booth 525. We hope to see you there!

Ranger Kidwell-Ross challenged the pavement industry to rethink sweeping as a critical tool for protecting water quality and improving the environment.

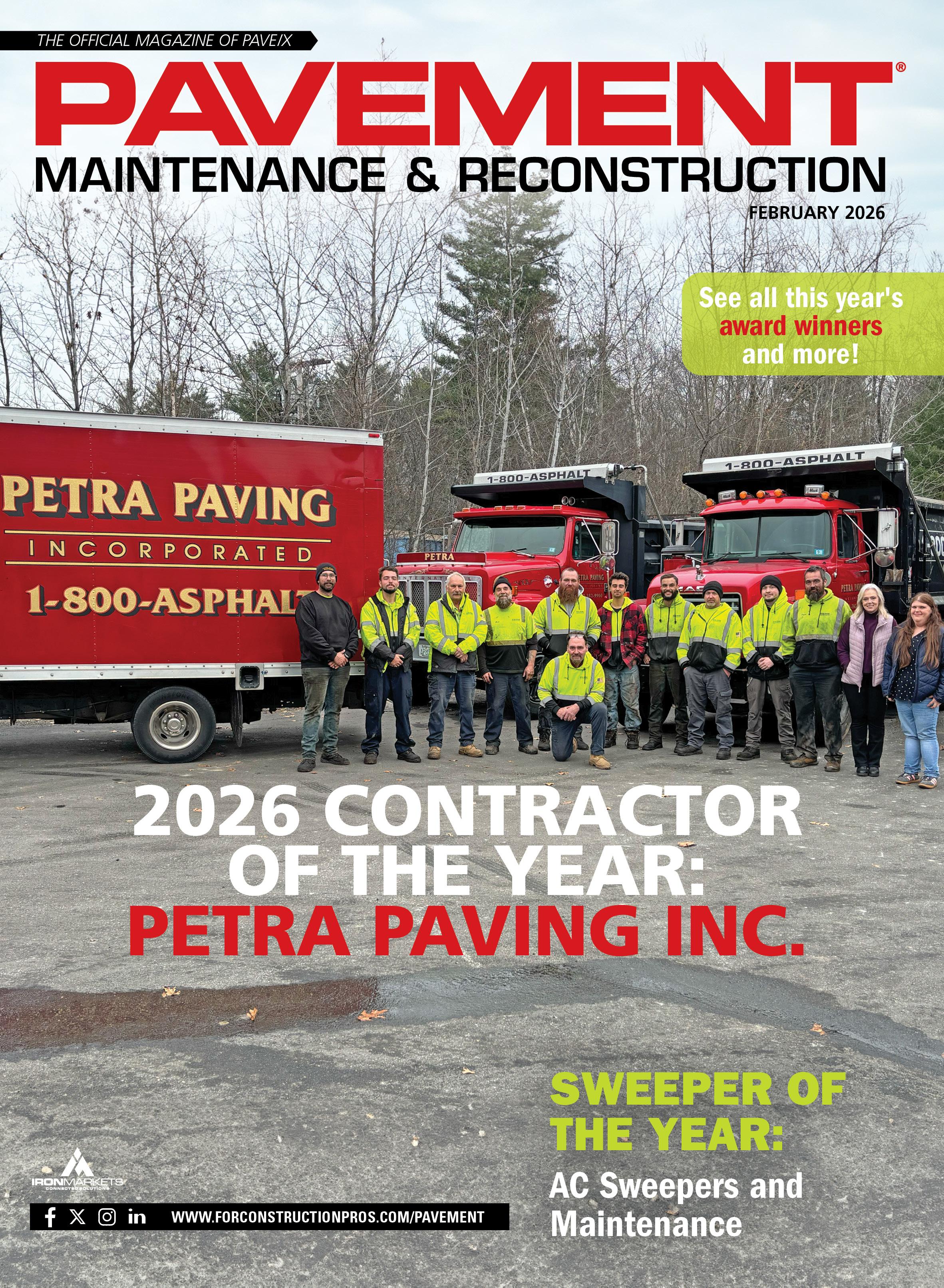

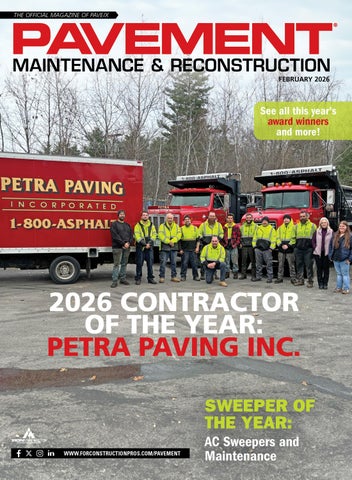

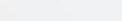

Small beginnings, grit, and an unshakeable family culture built one of the industry’s most respected contractors.

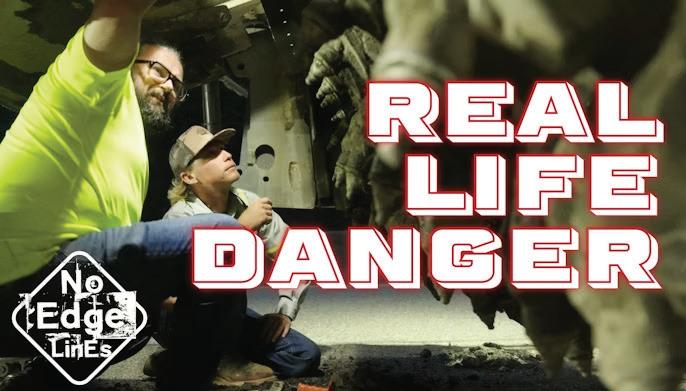

From sweeping routes at night to leading a multi-state operation, AC Sweepers’ journey reflects the adaptability and leadership shaping today’s sweeping industry.

Honoring Pat Weiler with the 2026 Alan Curtis Industry Service Award.

Big Apple Services earned the 2026 Superior Striper Award for its work on Decatur’s bike lane initiative.

Sealcoat Specialties Inc. earns the 2026 Seal & Stripe: Small Job Award for a six-lot school campus project, overcoming weather, scheduling and logistical challenges to deliver high-quality sealcoating and striping work. 28

With production running 24/7, this massive Hyundai seal and stripe project demanded precision planning, phased execution, and flawless coordination to succeed.

32

When other options proved too costly, Asphalt Contractors Inc. delivered a bold indoor asphalt solution that reshaped an industrial facility.

Howard Company won the 2026 award winner for Paving: Parking Lot for their work on an innovative project beneath lowclearance solar canopies.

Libs Paving earned the 2026 Best Marketing Video Award by showcasing its people, culture and core values in an authentic brand. 38

By donating time, labor, and expertise, Love’s Asphalt transformed a neglected school campus and earned the 2026 Good Neighbor Award.

John Deere to Acquire Construction Technology Firm Tenna

Deere & Company has agreed to acquire Tenna, a construction technology firm that provides mixedfleet equipment and asset tracking solutions.

Formoreinformationvisit

https://pavemg.com/7cymxydb

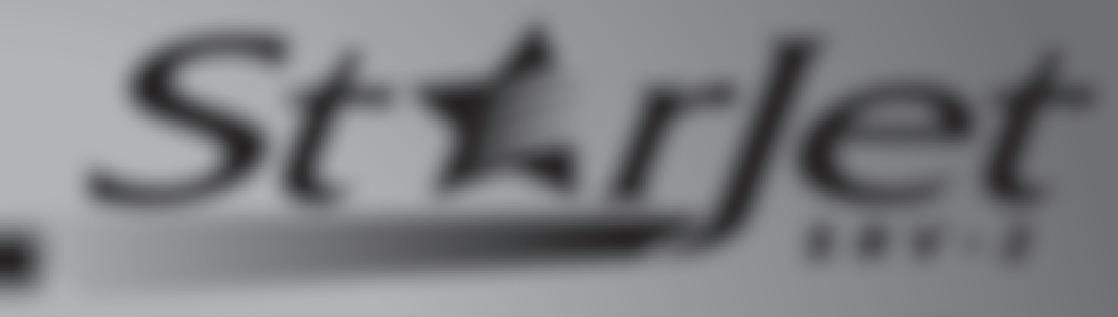

Night Work On A Live Highway | No Edge Lines Season 3 Episode 2

In this episode of No Edge Lines, Brandon travels outside Knoxville, Tennessee, to experience one of the most hazardous environments in road construction: night work on an active highway.

Formoreinformationvisit

https://pavemg.com/u5url8pj

Nominations Open for Pavement Maintenance & Reconstruction’s 2026 Top Contractor Award

This survey of paving and pavement maintenance contractors helps develop an objective and verifiable listing in each of the five industry segments. Submissions close March 27, 2026.

Formoreinformationvisit

https://pavemg.com/vk2um2k5

ADVISORY BOARD

Agua Trucks Inc

Wickenburg, AZ, Scott Duscher

Asphalt Contractors Inc., Union Grove, WI Robert Kordus

Published and copyrighted 2026 by IRONMARKETS. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording or any information storage or retrieval system, without written permission from the publisher.

Individual subscriptions are available without charge in the U.S. only to pavement maintenance contractors, producers and government employees involved in paving or pavement maintenance; dealers, and distributors of pavement maintenance equipment or materials; and others with similar business activities. Complete the subscription form at www.forconstructionpros.com or use your company letterhead giving all the information requested. Publisher reserves the right to reject nonqualified subscribers. One year subscriptions for nonqualified individuals: $35.00 U.S.A., $60.00 Canada and Mexico, and $85.00 all other countries (payable in U.S. funds, drawn on U.S. bank). Single copies available (prepaid only) $10.00 each (U.S., Canada & Mexico), $15.00 each (International). Pavement Maintenance & Reconstruction (ISSN 1098-5875), is published eight times per year: January, February, March, April/May, June/July, August/September, October/ November, December by IRONMARKETS, 201 N. Main St. Ste 350, Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI and additional entry offices.

POSTMASTER: Please send change of address to , 201 N. Main St. Ste. 350, Fort Atkinson, WI 53538. Printed in the USA.

PAVEMENT MAINTENANCE & RECONSTRUCTION is proudly supported by these associations:

Asphalt Restoration Technology Systems, Orlando, FL Connie Lorenz

Brahney Paving, Hillsborough, NJ

Eosso Brothers Paving; Hazlet, NJ

Maul Paving/Concrete/Sealcoating, PLainfield, IL

Parking Lot Maintenance, Lake St. Louis, MO

Petra Paving, Hampstead, NH

Pioneer Paving, Albuquerque, NM

Steven Brahney

Tom Eosso

Chris Maul

Todd Bruening

Chris Tammany

Don Rooney

Roberts Traffic, Hollywood, FL Lisa Birchfield

Show Striping Inc. (SSI), Wisconsin Dells, WI

T&N Asphalt Services, Salt Lake City, UT

Young Sealcoating Inc, Lynchburg, VA

The Paving Lady

JMP Excelsior Services

Amber Showalter

Nick Howell

Steve Young

Mauro Comuzzi

Jim Panzenhagen

Sweeping Industry Veteran .................................................................................. Gabe Vitale

Flat Nickel Management ..................................................................................

Wis-Coat Asphalt Maintenance

Clear Choice Sealing

Jacketta Sweeping Services

Royal Pavement Solutions

ASSOCIATION REPRESENTATIVES:

Michael Nawa

Marvin Joles

Warren Johnson

Debbie Jacketta

Kenneth Roy III

Pavement Coatings Technology Council ....................... Brian Riggs, Executive Director

highway work zone changed how I see safety.

By now I’ve been out on enough asphalt jobsites that I’ve figured out my way around. I no longer feel like a total stranger when I show up to cover a big project for the magazine or to film an episode of our Youtube series No Edge Lines (use the QR code to check it out). The good news is that it means I’ve been learning, if slowly, over the last 3+ years as your editor, and that was the goal, though, it’s changed.

That brings me to the most recent episode of No Edge Lines, where I was in the mountains of Tennessee with GreyRock Milling Group and their owner Griffen Hopkins. Last year in the spring we started planning this episode’s shoot date. This process is more complicated than you might imagine. Most of the time I only have one or two days, at the most, to visit a contractor out in the wild. As all of you know, that doesn’t leave a lot of margin for the types of surprises that frequent the work you do.

Brandon Noel, Editor-In-Chief

bNoel@iron.markets 234-600-8983

EDITORIAL

Editor-In-Chief Brandon Noel bnoel@iron.markets

Content Director, Marketing Services Jessica Lombardo jlombardo@iron.markets

Managing Editor Allyson Sherrier asherrier@iron.markets

AUDIENCE

Audience Development Director Angela Franks

PRODUCTION

Senior Production Manager Cindy Rusch crusch@iron.markets

Art Director April Van Etten

ADVERTISING/SALES

Brand Director Amy Schwandt aschwandt@iron.markets

Brand Manager Megan Perleberg mperleberg@iron.markets

Sales Representative Sean Dunphy sdunphy@iron.markets

The shoot started like any other. There wasn’t anything particularly different about it. As I arrived in Knoxville, TN, I did what I typically do when traveling. I found the closest place that served ice cold beer and good looking chicken wings (shoutout to the crew at Wings Etc.).

However, something was different. The next day was going to be my first time working on a highway at night, and I was feeling more nervous about it than I let on. I told my wife before I left that, while we were taking every precaution, this shoot had some real danger attached to it. I spared her the finer details of how many roadside work zone accidents happen each year so she wouldn’t worry too much. But I was worried.

When I arrived at the Veteran’s Overlook Memorial on Highway 11, about an hour outside of Knoxville proper, my heart was fluttering. I am a talkative type, even more when I’m out filming the show, and still more when I’m nervous. Thankfully, Griffen immediately put me at ease.

After talking with him, I felt a little bit better, but once we got up on top of the milling machine and started to pull out into oncoming traffic my nerves shot right back up.

As the evening went on, I felt more and more relaxed in the environment, and then the sun set. We sent up a drone to take some shots of us, and when I looked at the monitor I was stunned. We were like tiny little islands of light, shinning in the dark hills of Tennessee. There was a strange peacefulness to it, but there was also the constant thought of, “What if?”

From 2013 to 2023, roadside work zone fatalities increased by roughly 50%, and 20,000 road workers are injured per year due to various causes. The direct causes are typically distracted driving, cell phone use, intoxication, reckless driving, and drivers who fell asleep at the wheel. Even Griffen had a story of a drunk driver taking out one of their dump trucks.

As I was crouched under their Wirtgen 220i milling machine, changing out my first broken milling tooth by hand, I felt a huge gust of air rush past us on the ground as a semitruck flew by and my heart went into my throat. While I managed to contain that reaction, I couldn’t help but think of how little it would actually take to drift too far over and clip the side of the machine.

This is the daily (or nightly) reality for the hard working men and women of our industry, and it has given me a new goal. I want to make sure whatever I’m doing in this position, it continues to elevate and highlight those putting their lives on the line to make a living, to provide for their families, and, also, to keep our infrastructure in good, safe condition. The least everyone else can do, is slow down.

See you on the road! ■

Sales Representative Kris Flitcroft kflitcroft@iron.markets

IRONMARKETS

Chief Executive Officer.................................................. Ron Spink

Chief Revenue Officer Amy Schwandt VP, Finance Greta Teter VP, Operations & IT .................................................... Nick Raether

Brand Director, Construction, OEM & IRONPROS Sean Dunphy

Director of Marketing Services Becky Peck

Content Director Marina Mayer

Director, Event Content & Programming Jess Lombardo Director, Lead Generation Operations Bailey Bunescu

CIRCULATION & SUBSCRIPTIONS

201 N. Main St. Ste. 350, Fort Atkinson, WI 53538 afranks@iron.markets

LIST RENTAL

Sr. Account Manager Bart Piccirillo | Data Axle (518) 339 4511 | bart.piccirillo@infogroup.com

REPRINT SERVICES

Brand Manager Megan Perleberg mperleberg@iron.markets | (800) 538-5544

Published and copyrighted 2026 by IRONMARKETS. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage or retrieval system, without written permission from the publisher.

@PAVEMENTMAGAZINE

@PAVEMENTMAGAZINE

@PAVEMENTMAGAZINE

@PAVEMENTMAINTENANCE

Published by IRONMARKETS

201 N. Main St. Ste 350, Fort Atkinson, WI 53538 (800) 538-5544 • IRON.MARKETS.COM

WWW.FORCONSTRUCTIONPROS.COM/PAVEMENT

is purpose-built for wide cracks and surface distresses over 1.5 inches. Its polymer-modified, aggregate-filled design creates a durable, load-bearing repair that stays flexible under traffic and temperature changes, sealing out water and extending pavement life where it matters most.

BOMAG Americas Inc.

BOMAG has launched the BT 30 tamper, a compact compaction tool designed for tight spaces and trench work. Weighing under 70 lb (31 kg), the machine delivers high compaction force through a 5.5-in (140-mm) plate width, 1.8-in (45-mm) jumping height, and adjustable frequency up to 790 vpm (13.2 hz).

The tamper’s lightweight, ergonomic design makes it easier to transport and maneuver around obstacles. Its variable frequency and large stroke allow it to handle a range of soil types — including clay, silt and mixed soils — for jobs such as trench backfilling, foundation prep, landscaping, and pipeline construction.

Durability features include a Honda 4-stroke gas engine, engine cover for protection during transport, a two-stage self-cleaning air filter, and dual fuel filter system to reduce downtime. An isolated steering handle minimizes vibration for the operator and includes a single-point lift for easy handling.

The BT 30 is built for both rental and commercial use, combining mobility, versatility and rugged construction for demanding jobsites.

Caterpillar - Cat

Caterpillar Inc. introduced Cat AI Assistant at CES 2026, marking the construction equipment manufacturer’s entry into artificial intelligence-powered fleet management. The AI solution aims to streamline equipment operations by unifying Caterpillar’s digital applications into a single conversational interface.

Cat AI Assistant leverages the company’s Helios data platform, which manages over 16 petabytes of equipment and operational data. The system targets three primary user groups across construction operations. Fleet managers gain predictive maintenance capabilities to convert unplanned equipment failures into scheduled service events. Technicians can access repair manuals through voice commands while working, receiving step-by-step guidance and parts recommendations without interrupting repairs.

For equipment operators, the in-cab version runs on NVIDIA Jetson Thor platform hardware, providing real-time coaching and machine operation assistance. The system enables operators to access information without switching screens or returning to equipment yards.

Caterpillar - Cat

Cat Footwear has added a new model to its Invader Max line — the Invader Max 8” — built for all-season performance and protection on cold-weather jobsites.

The insulated and waterproof boot features 400 grams of insulation for warmth, a composite safety toe, and a tiretread–inspired outsole with slip-resistant technology. Additional details include metal hardware and a reinforced toe bumper for durability.

Priced at $184.95, the Invader Max 8” is now available at catfootwear.com and select retailers nationwide.

RefrigiWear has updated its ComfortGuard collection of insulated workwear, designed for industrial and outdoor workers in cold, wet and subzero conditions. The refreshed line features lighter insulation, improved mobility, and enhanced weather protection while maintaining durability.

First introduced in 2005, ComfortGuard jackets, coveralls and bib overalls are widely used in the cold chain, agriculture, and construction sectors. The 2025–2026 updates include a flexible elastane-blend, water-repellent outer shell, reduced bulk insulation, and reflective trim for low-light visibility.

Despite these changes, RefrigiWear said the collection retains the performance and ruggedness that have made it a longtime staple for workers in harsh environments.

Komatsu has introduced the PC365LC-11 multifunction excavator to the North American market, featuring an electric swing system, updated operator cab and expanded technology options.

The PC365LC-11 uses a dedicated electric swing motor with a “boom-up” power assist to improve swing speed and reduce cycle times in multifunction applications. An onboard ultracapacitor stores energy generated during normal operation and provides additional power when needed, helping reduce fuel consumption and noise while improving overall efficiency.

The excavator includes a redesigned cab with a heated air-suspension seat and proportional joysticks intended to improve comfort and reduce operator fatigue. Standard technology includes KomVision, a camera system that provides a bird’s-eye view of the machine’s surroundings. An optional Smart Construction 3D Machine Guidance system can be factory-installed.

Attachment operation is supported by a tool control system that allows operators to store hydraulic settings for multiple attachments.

Douglas Dynamics offers the Heavy-Duty (HD) straight blade snowplow for snow removal with skid steers. The attachment provides commercial contractor performance for skid steers under winter conditions. Available in four blade widths, the HD straight blade plow is built with a formed base channel for durability. Six vertical ribs, two angled Power Ribs and a quad design provide torsional strength to prevent blade twisting. The rugged A-frame is constructed of tubular steel to provide the strength necessary to take on harsh jobsites.

By Jessica Lombardo,

Editor

Small beginnings, grit, and an unshakeable family culture built one of the industry’s most respected contractors.

When you ask Chris Tammany, president of Petra Paving, how his company grew from a lean, part-time operation into a respected, highperforming pavement maintenance and paving business, he doesn’t talk about luck. He doesn’t talk about timing. He doesn’t even talk about ambition.

He talks about work. He talks about fear of failure. And above all, he talks about family.

Like many leaders in the pavement industry, Tammany didn’t learn his craft from a business textbook—he learned it by doing.

At eighteen years old, Tammany was very familiar with running chainsaws and bulldozers and everything else. He knew he had found something he was good at.

“I was very comfortable with the construction end of things,” he recalls. “I’d grown up around it my whole life—running all the equipment on the farm and everything else. It was just something I knew.”

Tammany started working in the forestry industry, but with a wife and kids at home, Tammany knew he needed to find something that would make him more money.

“In 1989 this guy I knew had purchased a bunch of seal coating equipment, and he flopped miserably,” Tammany says. “He was telling me about it and that he didn’t know what he was going to do with the equipment and I told him, “I’ll buy it.” Two weeks later, I sealcoated my in-laws’ driveway for nothing and the rest you can say is history.”

Tammany worked at night doing odd jobs sealcoating and striping with his own equipment and worked for a company called Petra Paving during the day.

“It was a career that was good for me,” he says. “The harder I worked, the better I could do.”

In 1991, the owner of Petra Paving decided to sell the business to Tammany.

“At the time, I had literally just built a house,” Tammany said. “I came home and I said to my wife, ‘we need to go to the bank and get a mortgage.’ She just looked at me like I was crazy, and I told her I wanted to jump on this opportunity.”

That simple, blue-collar faith to seize an opportunity laid the foundation for Petra Paving: if you showed up, worked hard, and refused to quit, the results would follow.

But the early years weren’t easy.

Overcoming Challenges: The Moment Everything Almost Collapsed

Every successful contractor can point to a moment where the company could have gone one of two ways. For Petra Paving, that moment came early—and almost ended everything.

In the beginning, Petra tried to do it all.

“When I took over, we were doing just residential paving, just driveways that first two years,” Tammany said. “I tried to do sealcoating as well, but I got so overwhelmed with the paving end of things that we got out of seal coating because I was trying to make the paving end of things work. It was a little bit more than I think I had anticipated”

In the winter of 1999, Tammany decided he wanted to add a dirt crew to the mix. That decision came with a new set of challenges.

“We bought a bunch more equipment, put on a second crew to do dirt work only, and we split up the paved crew and the dirt crew. So we had two crews doing that. Unfortunately, I was just about ready to file bankruptcy because I added all this extra overhead and everything else. I realized that at the end of the first year with two crews, we were almost $70,000 shy of paying the hot top company.”

So Tammany went to his first national pavement show, searching not for inspiration—but for answers.

“That’s why I’m so passionate about the PAVE/X show,” he says. “If it wasn’t for the show, I wouldn’t be here.

I remember telling Brad Humphrey, ‘I came here to find the secret to the business—or go home and file bankruptcy.’”

Brad’s response changed everything:

“He goes, ‘I think you’re salvageable.’ And that’s when we got to work with what we learned.”

With new systems, new finanresponse changed salvageable.’ And that’s when we

With new systems, new financial discipline, and a clearer understanding of pricing and job costing, Petra started climbing back.

“Sheer determination and grit got me here,” Tammany reflects. “I’m scared to death of failure. The thought of failing horrifies me.”

That fear, channeled into discipline, became a weapon rather than a weakness.

As Tammany implemented changes from his time with his peers at national events and tightened operations, Petra Paving pulled out of the red.

“We were back pretty flush and the financial strain was gone,” he says. “So we spent the next couple years streamlining and getting out of strictly residential work. We started building ourselves into more commercial and municipal jobs.”

With stronger margins, better systems, and a growing reputation for reliability, Petra found its footing. But their growth wasn’t just about scale—it was about raising standards. Tammany is unapologetic about the company’s image and professionalism.

“I won’t put a piece of equipment out in front of the public if it’s not

With new systems, new financial discipline, and a clear understanding, Petra started climbing back.

painted and lettered and identical to everything else we own,” he says. “We’re pretty good about keeping stuff clean and decent looking. We invest a lot in that.”

That pride carries into scheduling, an area where Petra is famously intense.

“We’re very particular about our calendar,” Chris admits. “If we give someone a date once, it’s happening on that date. People joke that once it

goes on Petra’s calendar, that’s it—no moving. People notice and appreciate that.”

The result? A reputation built on showing up exactly when promised and delivering what they say they will.

As the company grew, the Tammany family became central to Petra’s success. Tammany credits his sons, his key team members, and the tight-knit culture that formed around them.

“We don’t know when to give up,” he says. “And we’ve always had good people in key positions—trustworthy people. That makes it easier for myself and my sons to go out and do our jobs. It helps tremendously.”

Trust, consistency, and accountability run deep in the company—mirroring the values Tammany learned decades earlier.

And when he’s asked what he believes is the number-one factor behind Petra’s long-term success, his answer is simple:

“Know your numbers inside and out,” he says. “I’m blown away by guys

five times our size who don’t do job costing and don’t know their numbers. That’s the key to success—along with surrounding yourself with people you can trust.”

Petra Paving’s story isn’t about explosive growth or a flashy overnight success. In fact, the company employs just eighteen full time workers operating on four crews. The story however is about a leader whose fear of failure drove him to excellence. And it’s about

a family—both blood and chosen— that built a company on consistency, accountability, and grit.

From humble beginnings to regional respect, from lean weekends to municipal contracts, Petra Paving embodies what it means to be a Contractor of the Year: A company built on character, strengthened through adversity, and dedicated to the people who make the work possible. ■

No fumes. Less noise. Less maintenance. Same pro-grade results.

Dependable airless performance

SmartControl™ monitors and adjusts performance for perfect results

Eliminate costly downtime

Swap pumps on the jobsite in minutes with ProConnect™ replacement system

Easy gun adjustments

Perfect gun setup every time with easy-to-use Guide Mark System

• Proven LineLazer Performance

• No engine noise, vibration or fumes

• Designed for traffic paints

By Brandon Noel, Editor-in-Chief

From sweeping routes at night to leading a multi-state operation, Latasha Crenshaw’s journey reflects the adaptability and leadership shaping today’s sweeping industry.

When you visit AC Sweepers & Maintenance website, there’s a quote right at the top of the page that greet you:

If a man is called to be a street sweeper, he should sweep streets even as Michelangelo painted, or Beethoven composed music, or Shakespeare wrote poetry. He should sweep streets so well that all the hosts of heaven and earth will pause to say, here lived a great street sweeper who did his job well.

-Dr. Martin Luther King, Jr

The immediate follow-up makes sure to recognize that this statement applies to women who find themselves called to the commercial contract sweeping industry. That is the immediate vibe

that Crenshaw communicates when talking about how she came into the industry. It’s something of a calling.

There are people who enter the sweeping industry by accident. And then there are people who arrive by inheritance, resistance, necessity, and eventually, a choice. And Latasha Crenshaw, founder and director of business development at AC Sweepers & Maintenance, is all four of these rolled into one person.

As the 2026 Sweeper of the Year recipient, one of the pavement maintenance industry’s highest honors, AC Sweepers is recognizes not only for their technical competence or fleet size, but leadership, longevity, and influence. It is an award reserved for contractors who have shaped how sweeping is conducted

in their market and executed within the broader maintenance ecosystem.

However, Crenshaw’s path to that recognition was anything but linear.

“I JUST GRADUATED FROM COLLEGE. I’M NOT GOING TO DEAL WITH GARBAGE.”

Crenshaw was first introduced to the sweeping industry in 2000, when her parents (Cynthia and Michael Crenshaw) started All Chicago Sweepers and Maintenance, Inc., in the Chicagoland area. At this time, she was fresh out of college and firmly embedded in corporate America, training as a technical sales representative for IBM during the lead-up to Y2K.

Her response to her parents’ new

venture was immediate and emphatic.

“I said this exactly,” she recalled. “‘I just graduated from college. I’m not going to deal with garbage.’”

But it was not arrogance. It was conditioning. Crenshaw had been just finished a high level education and it trained her, explicitly, that success meant Fortune 500 companies, corporate ladders, and defined career paths. Entrepreneurship was not part of the curriculum. But corporate America, as it often turns out, had other plans.

Over the next decade, Crenshaw was laid off three separate times as companies merged, restructured, or were acquired. Computers. Pharmaceuticals. And another pharmaceutical firm that sold to a Japanese company. Each move

required reinvention. Each layoff forced a recalculation.

“To be uncomfortable three times in ten years,” she said, “that changes you.” It also reframed how she saw her parents’ business.

As Crenshaw helped her mother explore minority- and woman-owned business certifications, she found herself learning the mechanics of entrepreneurship from the inside. Corporate minutes. Compliance requirements. Contract language. The unglamorous but essential infrastructure of running a company.

“That’s how I learned how to do business,” she said. “All the things they needed, I helped to put together.”

She began identifying growth opportunities her parents were not interested in pursuing. Large portfolios. Expanded service areas. New clients. Her mother graciously declined.

“Who’s going to do that?” she asked. Crenshaw raised her hand.

In January 2012, she started AC Sweepers & Maintenance in the Atlanta market, one contract at a time, built largely on referrals from relationships.

And when she secured those first accounts, she made another shrewd decision.

“If I’m going to get a [sweeping] truck,” she remembered thinking, “I better learn how to use it.”

For six months, Crenshaw did it all. She sold contracts during the day and ran routes at night, learning the physical realities of sweeping firsthand. It was not a symbolic gesture, it was a demand put upon herself, by herself.

“You need to know what you’re asking people to do,” she said. “You need to understand the job.”

Eventually, the demands of parenting, running the business, and being the operator made that model unsustainable. Crenshaw hired her first two employees, turned over the routes, and focused on scaling what she’d already built. What she carried forward from that first year was

not just operational knowledge, but credibility.

Crenshaw’s background in enterprise sales became one of her greatest assets. This is a huge factor. While contractors who own and manage their businesses are often good-to-fair when it comes to selling their business to clients, there can sometimes be a disconnect. Crenshaw had worked on the inside of the types of large scale corporations that she was now trying to partner with as a vendor. Consequently, that experience gave her an added way to understand and connect with their needs.

“We learned how to read people,” she said of her time at IBM. “We learned how to adapt to different environments.”

That ability translated directly into construction and facilities work, where sweeping is often one moving part in a larger, high-pressure operation.

“They don’t need us to be a problem,” she said. “They need us to be a solution.”

Whether working with superintendents, property managers, or national retailers, Crenshaw tailored her approach to what the customer actually needed, not just what she wanted to sell.

“That’s how you get in the door,” she said. “But more importantly, that’s how you stay.”

From the beginning, AC Sweepers & Maintenance was built for adaptability. Today, the company operates more than 30 sweepers, ranging from small parking lot units to air trucks and broom trucks. Its workforce fluctuates between 45 and 50 employees, scaling with demand. Crenshaw is deliberate about fleet decisions, choosing equipment based on application rather than brand loyalty.

“I want the best tool for the job,” she said. “It’s like shoes. You don’t run a marathon in the same shoes you wear every day.”

That mindset has allowed the company to service everything from small

commercial lots to Hartsfield-Jackson Atlanta International Airport, the busiest airport in the world.

“It doesn’t matter how small or how large you are,” she said. “The expectation is the same.”

Over the course of her career, Crenshaw has watched the sweeping industry change in fundamental ways.

“What used to be quality over price,” she said, “has completely flipped.”

Today, customers often expect more service, more technology, and more accountability at lower rates, even as equipment costs continue to rise.

“Twenty years ago, my mom could charge more than I can now,” she said. “That’s wild.”

To survive, sweeping contractors have had to become value-added partners, offering supplemental services and flexible solutions without losing control of margins.

“Sweeping keeps the lights on,” Crenshaw said. “But to grow, you have to do more.”

The pandemic accelerated changes that were already underway. Store hours shrank. Night windows tightened. Expectations intensified.

“You’re not getting more money,” Crenshaw said. “But you’re getting less time.”

That reality forced sharper decision-making and more disciplined operations. It also reinforced the importance of adaptability, a theme that

runs through Crenshaw’s leadership philosophy.

“You have to be able to make quick decisions,” she said. “And you have to be okay with that.”

For Crenshaw, one of the greatest modern challenges is not equipment, but technology.

“I love technology,” she said. “But it moves too fast.”

Systems are implemented, replaced, and updated in rapid succession, often faster than teams can be trained to use them effectively.

“You get the tech,” she said. “And then you don’t have the people.”

The result is a constant tension between innovation and execution, one Crenshaw navigates carefully.

“At the end of the day,” she said, “AI is not a real person. People are.”

When asked what advice she would give her 2012 self, Crenshaw did not hesitate.

“Invest in my employees,” she said. “Build them up.”

That answer surprised her as much as anyone.

“You can have all the technology in the world,” she said. “But it’s the people who make it work.”

She likened employee investment to fuel.

“You put premium gas in your car so it runs better,” she said. “It’s the same with people.”

That philosophy has shaped how AC Sweepers & Maintenance approaches training, leadership, and retention, even in an industry where turnover is common and competition for labor is fierce.

The Sweeper of the Year Award is not given for growth alone.

It recognizes contractors who have demonstrated resilience, adaptability, and leadership across economic cycles, technological shifts, and cultural change.

Latasha Crenshaw represents all three.

She is a second-generation sweeper who initially rejected the industry, only to return to it on her own terms. The true-blue hero’s journey of sweeping. A corporate-trained sales professional who learned the job from the ground up. A business owner who understands that sweeping may be overlooked, but it is never optional.

She has built a company that can stretch without breaking, adapt without losing its core, and lead without forgetting where it started.

For those reasons, and for the example she sets within an industry still defining its future, Latasha Crenshaw and AC Sweepers & Mainteance is the 2026 Sweeper of the Year. ■

CURTIS AWARD

By Jessica Lombardo, Contributing Editor

Honoring Pat Weiler with the 2026 Alan Curtis Industry Service Award.

In the paving and pavement maintenance industry, leadership is rarely loud. It doesn’t announce itself with bold claims or grand gestures. Instead, it reveals itself over time—through consistency, integrity, and a steady commitment to doing what is right for customers and the industry as a whole. That quiet, enduring form of leadership defines Pat Weiler, this year’s recipient of the Alan Curtis Industry Service Award.

Pat’s career spans more than 45 years in equipment development and manufacturing, yet his path into the paving industry was anything but conventional. It was not driven by a master plan or a desire to dominate a market. Rather, it grew organically—from listening to customers, responding to unmet needs, and allowing the industry itself to guide the direction forward.

Before entering the paving space, Pat spent decades in equipment development and contract manufacturing. In 2005, while operating primarily as a manufacturer for other companies, he was approached by Ziegler Caterpillar, a local Iowa dealership facing a challenge. Caterpillar was discontinuing its road widener product line, yet dealers still had machines sold and customers waiting.

“They came to me and said they had a need,” Pat recalls. “Caterpillar was discontinuing that product, and they still had customers. So they brought me into a conversation with Cat paving management.”

That conversation ultimately led Pat to acquire the intellectual property for the road widener—followed shortly thereafter by the windrow pickup machine—around 2006. At the time,

Pat had no background in paving and admits the industry did not initially spark his interest.

“I had never had any exposure to paving,” he says. “At first it wasn’t very interesting to me. But the more I thought about it, it was an opportunity to get into an industry I hadn’t been involved with—and one that didn’t compete with friends of mine in other manufacturing spaces.”

What began as a practical solution to a dealer problem soon became the foundation of a new product line—and eventually, a full-fledged and successful presence in the paving and pavement maintenance industry.

From the very beginning, Pat resisted the idea of chasing growth for growth’s

Since its introduction, the Weiler P385 has set the standard for commercial pavers. The P385C raises that standard.

Variable speed and reversible conveyors and augers and a 25% increase in tunnel height provide optimal material output.

Increase to 120 hp with the Cat® C3.6 Tier 4F/Stage V engine.

Modular conveyor drive and sealed chain case increase feeder system reliability and life.

Enhanced heat system performance with direct-drive hydraulic generator and elimination of GFCI breakers.

sake. Instead, he allowed customers to shape the direction of product development.

“We would talk to customers about a road widener or a pickup machine, and they’d say, ‘Why don’t you build this?’” Pat explains. “And the dealers would hear it too and say, ‘Yeah, why don’t you do that?’”

That straightforward feedback loop became the cornerstone of the company’s growth. Over time, the product lineup expanded beyond road wideners and pickup machines to include material transfer vehicles and commercial paving equipment, and eventually compactors, soil stabilizers and brooms.

“I didn’t wake up one day and say, ‘I want to be a paving manufacturer,’” Pat says. “The customers took us there”

This philosophy—build what customers ask for, and build it well—may sound simple, but it requires discipline, patience, and humility. It also requires the willingness to understand that engineers and executives don’t always have the best answers.

Prototypes were placed with contractors, feedback was gathered directly from operators, and designs were refined based on how machines actually performed in the field. The result has been equipment known for its practicality—machines that crews can understand, maintain, and trust.

Pat recalls countless conversations where customers asked for seemingly contradictory features—simplicity and autonomous capability, durability and light weight, premium product and low cost. “That’s where it gets interesting,” he admits. “Listening when they’re telling you and hearing what they want are two different things. Figuring out how to make that work is challenging and fun.”

As an engineer by background, Pat has always valued technical expertise—but he is equally aware of its limitations.

That “challenge accepted” mindset has let Pat’s influence extend well beyond equipment design. Over the years, he has remained actively involved with industry organizations such as the National Asphalt Pavement Association (NAPA) and the Association of Equipment Manufacturers (AEM), believing that a strong industry benefits everyone within it.

“Anything that helps our customers be profitable is good for us,” Pat says. “If they’re making money, they’re going to buy more equipment, and it’s important to do the work that helps keep our people busy.”

“Engineers are very smart,” he says. “But they don’t use the equipment. If you’re not careful, you end up building what engineers want, not what customers want—and that really isn’t very effective.”

That awareness led to a development process rooted in real-world use.

“What I’m most proud of,” he says, “is customers telling me how much they like our products. I get texts, emails and have so many conversations with contractors about what we’re doing—that means a lot.”

Internally, he points to culture as an equally meaningful measure of success.

“We’ve been able to hire great people who fit our culture,” he explains. “You can hire a lot of people, but if they don’t fit, it doesn’t do much good.”

That people-first mindset has also shaped the company’s future. In recent years, all three of Pat’s children—each with careers outside manufacturing— have returned to become involved in the business. What began as informal conversations evolved into board meetings, shared accountability, and ultimately, shared leadership.

“They started challenging me,” Pat says with a laugh. “And I realized I better start taking board meetings seriously.”

That mindset reflects a broader understanding of service—one that connects individual company success with the health of the entire paving and pavement maintenance ecosystem. Through advocacy, participation in industry discussions, and support of events and associations, Pat has helped advance conversations around workforce challenges, regulations, and long-term industry sustainability.

“At this stage,” he adds, “you start thinking more about giving back.”

Legacy may be a cliche buzzword, but for Pat Weiler, it is something lived rather than defined. His career has been marked by steady decisionmaking, respect for customers, and an unwavering belief that the best ideas often come from listening rather than leading.

When asked about accomplishments, Pat is quick to redirect attention away from himself.

When told he would receive the Alan Curtis Industry Service Award, Pat’s response was characteristically humble.

“It’s truly an honor to be recognized,” he says. “I want to thank our customers, employees, dealers and vendors. Without all of them, it’d still just be me and a couple people.”

That sentiment captures why Pat Weiler is such a fitting recipient of this award. His service has never been about recognition. It has been about building trust, supporting people, and helping an industry move forward—one conversation, one machine, and one relationship at a time.

We’re honored to recognize Pat Weiler with the 2026 Alan Curtis Industry Service Award and induct him into the Pavement Hall of Fame. ■

By Brandon Noel, Editor-in-Chief

For decades, he challenged the pavement industry to rethink sweeping as a critical tool for protecting water quality and improving environmental outcomes.

The Pavement Maintenance Hall of Fame exists to recognize more than success. It exists to recognize influence. The effects a person and their career had and continues to have on the work, even if they are no longer actively on the job.

And while some facets of our industry that are more visible and more visibly apparent, like fresh asphalt going down behind a paver or crisp striping snapping a parking lot into order, sweeping has never been that.

Yet, for more than three decades, Ranger Kidwell-Ross, the executive director of the World Sweeping Association, has insisted that sweeping may be one of the most important jobs happening on pavement anywhere in the country, whether anyone is watching or not.

That insistence is why Kidwell-Ross is being inducted into the Pavement Maintenance Hall of Fame in 2026, as well as due to his constant work to further the science, methodology, and excellence within the profession.

If there is a single question that defines Kidwell-Ross’ career, it is a deceptively simple one: What happens after the pavement is built?

Long before sustainability became a standard headline or stormwater credits entered everyday industry conversation, Kidwell-Ross understood something most of the pavement world did not want to think about. Pavement is not neutral. What happens on it does not stay on it.

Sweeping, he realized early on the important role that pavement played in regards to our precious water sources.

“I learned that sweeping was really the first line of defense for pavementbased pollutant runoff and clean water,” Kidwell-Ross said. “When I realized that, and I realized that water is going to get more and more scarce, I decided that’s what I wanted to teach.”

That realization became the backbone of a career that blended acts of journalism, education, advocacy, networking and industry building in ways that rarely fit cleanly into one title. Ranger Kidwell-Ross was all-in.

His entry point into sweeping came through industry communication. While working with Schwartz Industries, he helped produce one of the first dedicated sweeping newsletters, learning the realities of street sweeping and contractor life from the inside.

That exposure did more than familiarize him with equipment or operations. It showed him how fragmented the industry was and how little consistent, accessible education existed for contractors who could not attend trade shows, seminars, or expensive coaching programs.

“I wanted a business that could do something, perhaps for the planet, rather than just be a job,” he said.

That mindset led to the creation of American Sweeper magazine and later WorldSweeper.com, which has now been active for more than two decades. Together, they formed the foundation for what would eventually become the World Sweeping Association (WSA).

The World Sweeping Association was not born out of ambition. It was born out of frustration. It’s no secret that he had strong opinions, and a mind to follow his own internal barometer of what was important and what wasn’t. So, KidwellRoss made a decision that would define the next chapter of his career.

“I decided I’ll just start an association,” he said. “It really bothered me that there was incorrect information being relied on.”

He started the WSA largely on his own, supported by a small advisory group and a commitment to transparency and education that would define the organization’s mission.That commitment was not symbolic.

For years, the association delivered two educational messages per month, published hundreds of articles, conducted more than one hundred contractor interviews, and created practical

resources contractors could use in the field and in how they ran their business, from payment disputes to customer education. He also wrote short-form articles printed in every issue of Pavement Maintenane& Reconstruction

“I wrote updated information, educational information, as best I could all the time,” Kidwell-Ross said. “The idea was to make contractors more professional and answer any kind of questions.”

Now, as he eyes retiremnent, the association houses more than eight hundred articles and exists as one of the most comprehensive sweeping knowledge bases in the world.

One of Kidwell-Ross’ most consistent themes is accessibility.

Trade shows, he believes, are invaluable. He’s always been a big supporter of contractors gathering together when they can, but not everyone can attend them, and not every contractor has the staff or budget to send multiple people.

“So many people couldn’t go,” he said. “If you can’t, the next step is to read about it. Read an article. Understand what was said.”

That philosophy shaped how information was gathered and shared. Seminar content was recorded when possible. Research was summarized and translated into practical language. The emphasis was always on raising the baseline knowledge of the industry, not creating an insider class of those who “have” access to the best practices and information and those who ‘have-not.”

“Educated contractors are better than ignorant contractors,” he said plainly.

While Kidwell-Ross spent years advocating for sweeping as an environmental tool, validation came through independent research.

Studies conducted in Florida and Minnesota examined multiple methods of removing nitrogen and phosphorus from roadway runoff. Sweeping was not just competitive. It was dominant. That surprised some people, but not Ranger.

“They discovered that sweeping was five-to-seven times more cost-effective per pound to pick up these pollutants,” Kidwell-Ross said. “Why would you do something else?”

That data changed how municipalities began to think about sweeping. In some jurisdictions, sweeping now earns stormwater credits based on material collected, further reinforcing its value within environmental compliance frameworks.

For him, those results were both a relief and motivating.

“That’s now proven,” he said. “And that’s been very validating to me.”

Despite the data, Kidwell-Ross believes sweeping remains undervalued, even within pavement maintenance circles. Too often, sweepers are treated as support equipment rather than essential infrastructure tools. Maintenance is deferred. Technology adoption lags. Unified messaging is absent.

One of his enduring frustrations is the lack of a manufacturers and suppliers association for sweeping.

“We don’t have a unified voice,” he said. “Public works directors and stormwater managers would have a better chance to understand the value if we spoke together.”

He also points to missed opportunities around technology, from vehicle-notification apps to better data tracking, and the industry’s slow movement toward reducing water use in sweeping operations.

“These are solvable problems,” he said. “They just require coordination and will.”

As Kidwell-Ross looks to steps back from day-to-day industry involvement, his legacy is not defined by a single organization or publication. It is defined by an over arching commitment and a message he never stopped repeating.

“Sweeping is the first line of defense for water quality,” he said. “That’s the message I’ve tried to provide.”

He hopes contractors take pride in that role and that municipalities begin

to recognize sweeping not as an afterthought, but as one of the most costeffective environmental investments they can make.

“Sweeping is something you can take a lot of pride in,” he said. “It has all this value, but it hasn’t received the validation it deserves.”

Ranger Kidwell-Ross influenced how sweeping is understood, justified, and defended within the pavement maintenance industry. He built platforms when none existed, challenged assumptions when it was uncomfortable, and stayed focused on education long after it would have been easier to move on.

He did it largely alone, from a home office in the Pacific Northwest, publishing and teaching because he believed the work mattered.

That belief changed the conversation. And that is why his name belongs in the Hall of Fame. ■

By Brandon Noel, Editor-in-Chief

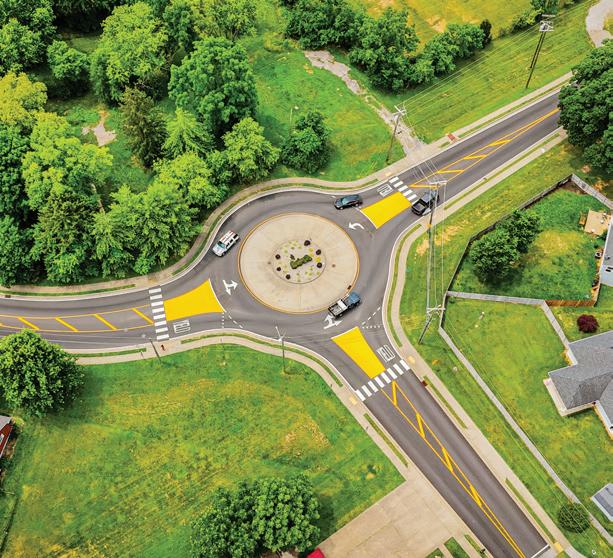

Big Apple Services earned the 2026 Superior Striper Award for its work on Decatur’s bike lane initiative.

Striping projects rarely get the luxury of ideal conditions. They happen in traffic. They happen under deadlines. They happen after design revisions and construction fatigue have already worn everyone down.

That is exactly why Big Apple Services’ work on the City of Decatur, Georgia’s ongoing bike and pedestrian initiative stood out and earned the company the 2026 Superior Striper Award.

The project transformed a busy arterial corridor into a reconfigured, multimodal roadway. A former four-lane section was condensed into two travel lanes with bike lanes added on both sides.

The work took place along one of the most heavily traveled routes feeding into downtown Decatur, a city known for its walkability and strong public support for pedestrian and cycling infrastructure.

By the time Big Apple was called in, the project was already two years behind schedule.

“There were constant design changes, both from the engineering side and from seeing how things worked in the field,” said Clint Anderson, Co-CEO, Operations at Big Apple Services.

Their first order of business was to work with the city engineers, civil engineers and general contractors to bring the requirements of the design together with the realities of the project location

One of the defining elements of Big Apple’s role was how early they became involved. Rather than waiting until final paving was complete, the company applied temporary markings through multiple paving phases to maintain safe traffic flow for crews and the public.

That approach required flexibility, patience, and daily coordination with professional traffic control teams. Every phase of the project demanded lane shifts, signage adjustments, and relayouts as conditions evolved.

“Being on one of the busiest roads in Decatur, professional traffic control was a necessity for every phase of the project,” Anderson said.

Once final paving was complete, Big Apple laid out the entire corridor using marking paint so engineers could review lane geometry, bike placement, and intersection movements before permanent materials were installed. That step proved critical, especially since the realworld traffic behavior revealed issues with the city’s plan that drawings alone could not have predicted.

At Church Street and East Ponce de Leon Avenue, the team completed full thermoplastic striping and signage before city engineers asked to revisit the layout.

“They saw how it was operating in the field and decided changes needed to be made,” Anderson said.

After observing traffic movements, the city determined that configuration created unnecessary conflict points for cyclists. The solution required removing newly installed thermoplastic and MMA markings and re-striping the intersection entirely.

Was it a headache? Sure. But it’s a lot less of one when the changes aren’t

your fault, and you’re just one helping the customer make it right. To that end, Big Apple used hydroblasting to remove the materials without damaging the new asphalt underneath, avoiding what would have otherwise required milling and repaving.

“That would have been triple the cost, and we wanted to avoid that,” Anderson said.

The ability to adapt without compromising quality or schedule became a defining characteristic of the project.

The Decatur initiative called for a wide range of striping materials and application methods across asphalt and concrete surfaces. Big Apple installed hotapplied thermoplastic, preformed thermoplastic, Rollplast MMA, and cold-spray MMA, depending on location, color requirements, and durability needs.

Preformed thermoplastic played a significant role, especially for bike symbols, legends, arrows, and decorative elements. These materials arrive in puzzle-like sections that are assembled and heat-bonded directly to the pavement.

“Anytime somebody wants anything other than traffic white or traffic yellow, it’s going to be preformed thermoplastic,” Anderson said. “Bike graphics, arrows, legends. It’s the cleanest way to get consistent color and shape.”

Rollplast MMA was used in hightraffic areas where skid resistance was critical. Unlike reflective glass beads, rollplast incorporates aggressive antiskid directly into the material.

“If you slide your foot on it, even when it’s wet, it’s not sliding at all,” Anderson said.

The diversity of materials required crews who were cross-trained and comfortable switching between systems depending on the day’s scope and weather conditions.

At the conclusion of the project, Big Apple was invited to bid on additional thermoplastic and MMA striping work directly with the City of Decatur. The award was not just about finished markings. It was about how the company handled a complex, evolving project from start to finish. For a municipality, or any public sector client, that can mean more than anything.

Big Apple Services was founded in the early 2010s by Steve Epstein. He was frustrated by inconsistent subcontracted striping quality and decided to take control of the work in-house. Co-Owners Josh Cagliani and Clint Anderson continue to push an emphasis on quality and accountability that still defines the company today.

“We return phone calls. We return emails,” Ty Ansley, project manager and

sales, said. “We get calls all the time from general contractors saying another company won’t answer anymore.”

Today, Big Apple employs roughly 25 in-house staff and scales higher with subcontractors as needed. The company balances commercial and public work throughout Georgia and the Southeast, often serving as a specialty partner on complex urban projects.

“Multiple customers tell us, ‘You’re not the cheapest, but we’re going with you because we know your work and we know you’ll do what you say,’” Anderson said.

Urban striping projects like Decatur’s bike initiative leave little room for error. Lane widths, turning radii, and bike placement all affect safety long after the crews leave the site.

One thing the team at Big Apple wanted to include was a recognition of

their supplier Geveko Markings out of Gainesvill, GA, who provides all their MMA, thermo, and preforms.

“They help us out a ton, and are always willing to give our name out to companies that need our type of services,” said Ty Ansley, sales and estimating at Big Apple.

Big Apple’s Superior Striper Award, only the second ever bestowed, isn’t just for their clean lines and striping excellence. It represents their overall commitment to quality work and an amazing client experience wherever and whenever they are called upon.

On one of Decatur’s busiest corridors, Big Apple Services proved that striping is not the final step in a project. It is the step that makes everything else work. ■

capability to lift the fully loaded deck at 2500 p.s.i.

5-position adjustable fifth wheel height

1-1/2” apitong deck w/ 20”cm spacing.

12” cast swinging/removable extension

brackets w/ double hook-on in 1st position

+3/-3 adjustable height control in rear air suspension

axle frame reinforcement is

Boom well w/ extra low 1st cross member between the tires in rear section. Dropped center rear light panel. Air ride suspension w/55” axle spacing.

18 lash rings on deck and rear

Amber L.E.D. Strobes with Battery back-up

3 Axle air lift rd

Raising & lowering valve.

Multiple models and options available.

1333 South Daysville Road

Oregon, Illinois 61061

1333 South Daysville Road Illinois 61061 815-732-2116

Sales: 815-732-2116

Sales: sales@etnyre.com

Sales: sales@etnyre.com

Parts/Service: 888-586-1899

Parts/Service: 888-586-1899

By Allyson Sherrier, Managing Editor

Sealcoat Specialties Inc. earns the 2026 Seal & Stripe: Small Job Award for a six-lot school campus project, overcoming weather, scheduling and logistical challenges to deliver high-quality sealcoating and striping work.

Sealcoat Specialties Inc. has been named the 2026 Seal & Stripe: Small Job Award winner, a title they’ve now taken two years in a row. This award recognizes the best combination sealcoating and striping project completed during the calendar year on pavements smaller than 200,000 square feet.

The winning project involved sealcoating, crack filling and restriping six parking lots across three K–12 school campuses for a local Wisconsin school district. While limited in overall square footage, the project stood out for its logistical complexity, tight deadline, and the perseverance required to deliver it on time.

For owner Cody Helstern, the recognition reflects both craftsmanship and legacy. Sealcoat Specialties traces its roots back to the 1960s, when Helstern’s grandfather began taking on small sealcoating jobs using little more than brushes and brooms. The business went full time in 1979, and Cody grew up working alongside his grandfather before purchasing the company in 2017. Since then, he has modernized operations while maintaining a reputation

built on word-of-mouth and quality workmanship.

“I started working for him when I was 12, and eventually bought the company from him,” Cody said. “It was all word of mouth until I took over — no website, no Google page. But that’s what built the reputation we have today.”

Sealcoat Specialties currently focuses exclusively on sealcoating work, serving residential customers, but they hope to venture into more municipal and township clients for their area. Operating in northern Wisconsin means working within a short weather window — often just five reliable months — making planning, scheduling and execution critical.

“We thrive on word-of-mouth advertising because we do a great job and people pay attention,” Cody said. “And we care about who we’re doing work for. If a project is too far gone, I’ll tell someone it doesn’t make sense to throw money at a bandaid. I can make it pretty, but it’s going to cost them more down the road.”

Those weather and time constraints were evident from the start of the award-winning school district project. After receiving a request to submit a

bid, the proposal moved slowly through multiple school board meetings, delaying approval and putting more pressure on the construction schedule. Once the project was awarded in mid-June, the crew at Sealcoat Specialties had less than six weeks to complete the work before the start of the new school year.

Weather quickly became the biggest obstacle. Persistent spring rain limited available workdays, while summer school sessions and athletic events further restricted site access. When a narrow window finally opened during the week leading up to the Fourth of July, the team mobilized quickly, knowing there would be little room for error.

The challenges didn’t stop there.

Equipment failures, unexpected rain showers and material supply issues threatened to derail the schedule. With the nearest sealcoat supplier located nearly two hours away, maintaining enough material required constant coordination and last-minute adjustments. Cody recalled, “Every setback, we kept moving forward. We persevered. We had to repair hoses in the field, improvise when tools failed and adapt to constant changes in schedule.”

Despite the obstacles, the crew adapted on the fly, making field repairs, adjusting sequencing and working extended hours to stay on track. Line striping was carefully timed around pavement temperatures to ensure clean, durable results. Cody’s wife Alissa Helstern noted, “Honestly, our crew’s attention to detail is incredible. They’re hardworking, care about the work, and it shows. Customers notice that, and they call to tell us how happy they are with what our guys did.”

In total, the project included nearly one mile of edging and brushing, approximately 9,000 linear feet of 4-inch striping, 312 square feet of crosswalk bars, 15 directional arrows and 12 accessible parking spaces across the three campuses. The finished work exceeded expectations. After completion, the district’s director of buildings and grounds

joked that he wanted to keep the lots closed through the Fourth of July weekend to keep them looking pristine. Cody laughed, “He didn’t want anything or anyone to ruin how good they looked.”

Judges cited the project’s consistency across multiple sites, the team’s ability to overcome repeated challenges, and the high level of workmanship achieved under pressure. “It turned out so beautiful in spite of it all,” Alissa said. “All the weather, scheduling and equipment issues — it still came out perfect.”

Cody credits the company’s success to its crew. While he now focuses primarily on sales and steps in only on larger projects, the day-to-day execution is handled by a tight-knit team known for its attention to detail and strong work ethic. “I mostly handle sales now, and 85–90% of the time it’s the crew doing everything,” he said. “I really want to recognize our

guys. Without them, nothing would get done.”

As Sealcoat Specialties looks ahead, the company is exploring opportunities to expand into chip sealing for local township roads — a move that would fill a service gap often left to much larger contractors.

For now, the 2026 Seal & Stripe: Small Job Award underscores what has defined Sealcoat Specialties for decades: persistence, pride in workmanship and a commitment to doing the job right — even when the odds are stacked against it.

By Brandon Noel, Editor-in-Chief

With production running 24/7, this massive Hyundai seal and stripe project demanded precision planning, phased execution, and flawless coordination to succeed.

Some seal and stripe jobs are defined by square footage, others are defined by pressure. The project that earned this year’s Seal & Stripe: Large Job Award was defined by both. This year’s winner won the first ever Superior Striper Award in 2025, and came back this year looking to take home a new prize. The team at G-Force Alabama wasn’t dissapointed.

At Hyundai Motor Manufacturing Alabama’s massive manufacturing facility, production does not stop. Cars come off the line. Trucks move continuously. Employees arrive and leave around the clock. Logistics operations run on precision timing. That reality shaped every decision on a sealcoating and striping project that covered 673,000 square feet, required nearly 24 miles of striping, and had to be completed in just five days without disrupting operations.

“There was no downtime,” said Rob Young, owner of G-Force Alabama. “That was never an option.”

From the outset, this project demanded a different mindset than a traditional large commercial lot. Hyundai’s campus is not just big, it is active. Access to loading zones, employee parking, and internal roadways had to be maintained throughout the project.

To make that possible, the team developed a zone-based, phased work plan that allowed sections of the lot to remain open while others were cleaned, sealed, and striped. Each phase was sequenced to maximize curing time

while keeping traffic flowing.

“Everything had to be timed,” Young said. “One area curing, another being cleaned, another being striped.”

Daily coordination with Hyundai’s facility, safety, and logistics teams was essential. Morning briefings confirmed closures, reopenings, and traffic flow for the day. Adjustments were made in real time as plant needs shifted.

Before any sealcoat was applied, the pavement itself presented a major challenge. Years of heavy industrial use had left the lot dusty, dirty, and worn. Layers of dirt and gravel had to be removed before the surface was ready to accept material.

The crew performed multiple mechanical sweeps, working section by section to stay ahead of the sealcoating operation. Cleaning alone became its own production line, with crews moving ahead of the sealcoat rigs to keep the schedule intact.

“We cleaned about 200,000 square

feet the first day,” Young said. “Then we sealed that area while cleaning the next.”

Having in-house sweeping equipment was crucial and allowed the team to stay flexible and avoid delays, a critical advantage given the compressed schedule.

The condition of the pavement also meant much of the previous striping was no longer usable as a reference. Faded and worn beyond recognition, the existing markings could not simply be traced or refreshed.

Instead, the team treated the project as a full new layout.

Using aerial imagery, existing plant maps, and field measurements, the layout was rebuilt from scratch. Reference markers were established to ensure alignment across the vast property, maintaining consistency across parking stalls, drive aisles, and internal roadways.

“It wasn’t a [traditional] restripe,” Young said. “It was essentially starting over.”

That level of layout precision was critical on a site with an

irregular footprint and constant vehicle movement.

To meet performance and scheduling demands, the team selected SealMaster Coal Tar Ultra, a fast-drying sealer capable of handling heavy vehicle traffic shortly after application. Nearly 17,000 gallons of material were applied using a disciplined, repeatable process.

“We used four tankers,” Young said. “We had a tanker company there every day.”

Sealcoating operations were executed at a pace of roughly 200,000 square feet per day, with two full coats applied. As soon as one zone cured, striping crews moved in behind it.

For striping, the team applied industrial-grade, high-visibility traffic paint using calibrated precision equipment to achieve uniform lines across the entire site. Multiple striping crews worked simultaneously in different areas, coordinated to avoid conflicts and maximize productivity.

The result was a clean, consistent layout spanning nearly twenty-four miles, completed within the five-day window.

Unlike a retail or office complex, the Hyundai facility required constant coordination with on-site logistics. Tractor

that familiar or that interested in sealcoat as a service for their surfaces. However, after a smaller sealcoating test area was completed the previous year, it proved to be a turning point. After seeing the finish, durability, and minimal disruption, Hyundai moved forward with the full parking lot project.

“They realized it was a long-term investment,” Young said. “It wasn’t just about appearance.”

trailers, employee shuttles, and internal traffic never fully stopped.

Access to critical areas had to be preserved at all times. That meant careful sequencing of closures and reopenings, with no room for missed communication.

“Daily coordination was non-negotiable,” Young said. “Everybody had to know what was happening, every day.”

The team provided daily progress updates and shared layout maps to maintain transparency. When adjustments were needed, they were addressed immediately, keeping trust intact on both sides.

This project did not come to Young in a vacuum. Everything about the project was intentional, and that intentionality is something he and his team apply to everything, not just the field work. Getting this project was the result of a relationship that had been built over multiple years and multiple scopes of work.

The team initially began working with Hyundai on the logistics side of the operation. That work led to additional striping on internal roadways, which Hyundai requests twice a year, particularly ahead of executive visits.

“They want everything looking right,” Young said.

Initially, the Hyundai group wasn’t

What stood out to the awards advisory board was not just the size of the project, but the discipline behind it. This was a job where time management, communication, surface preparation, layout accuracy, and material selection all had to align. Any misstep could have impacted production at one of the largest manufacturing facilities in the region.

Instead, the project finished on schedule, with production uninterrupted and the site transformed. Before the work began, the lot was faded and disorganized. Afterward, it reflected the standards of a worldclass manufacturing operation: clean, structured, and efficient.

Large seal and stripe projects often test a contractor’s limits. This one tested everything at once.

By combining strategic planning, real-time coordination, and disciplined execution, the team delivered a result that met Hyundai’s operational demands while setting a new benchmark for large-scale pavement maintenance.

It is that combination of scale, precision, and professionalism that earned this project the Seal & Stripe: Large Job Award, and why it stands as a model for what is possible when preparation meets execution. ■

SBy Brandon Noel, Editor-in-Chief

When other options proved too costly, Asphalt Contractors Inc. delivered a bold indoor asphalt solution.

ome paving awards celebrate scale, while others celebrate difficulty. The Paving: NonParking Lot Award exists to recognize two types of projects:

Roadway jobs that can push a team to its limits. And less common projects that stretch the definition of where asphalt belongs.

If you don’t know who Bob Kordus is, then let this be your introduction, but make sure you find him at the next PAVE/X and spend some time letting him share his wealth of knowledge and experience.

Kordus, owner of Asphalt Contractors Inc., has been a fixture in the blacktop industry for nearly five decades. He has paved in places most contractors never will, across more states than many companies ever touch, and at a scale that reflects both ambition and confidence. That confidence was on full display in Bristol, Tennessee, inside a former Exide Battery factory that had been left to deteriorate for years.

When Asphalt Contractors Inc. was first asked to look at the project, the scope seemed straightforward on paper but overwhelming in reality.

The building’s original concrete floor had sustained decades of abuse. Failed joints. Thousands of divots and potholes. Steel posts cut off flush with the surface. Elevation changes from additions and remodels layered over one another. Years of dust and dirt ground into the slab.

The building’s owner initially planned to epoxy the floor, and multiple

contractors quoted partial repairs followed by epoxy coatings. The price tags came back at roughly ~$2.2 million for incomplete coverage, with warnings that large sections of concrete would still need to be removed and replaced.

Kordus was asked to quote the epoxy work as well. He did. And like the others, his proposal only covered part of the building due to the extent of the damage. Then he had a radically different idea.

“I had an idea,” Kordus explained humbly. “Why don’t I pave the most deteriorated areas in the floor with asphalt.”

Paving indoors was not new to him. Over the course of nearly 50 years, Kordus had paved inside agricultural pole buildings, airport hangars, and industrial structures. Just not one this large. At first, he proposed a hybrid solution: paving the worst areas and epoxying the rest. When the owner saw the cost comparison, the question came back quickly.

Could the entire interior be paved?

“My response was, ‘Why not!’” Kordus said.

That answer was not just a casual optimism he was offering to a customer desperate for a solution. It was backed by experience, planning, and a company culture built around solving problems others avoid.

By shifting the solution from epoxy to asphalt, the economics of the project changed dramatically for the client. The owner was now able to pave the entire interior of the building and add some exterior paving as well, all for less than

half the cost of the original epoxy proposals. More importantly, the finished surface met the building’s intended future use as a warehousing facility.

Asphalt Contractors Inc. developed a detailed scope of work and plan of action. The interior floors were swept, base patched, and wedged as needed. A tack coat was applied, and asphalt paving followed across the massive footprint.

Over 2,000 tons of asphalt were placed inside a building in just four days, with the entire project completed in one week, from October 6 through October 10, 2025.

Obviously, ventilation was a primary concern when you imagine paving asphalt in an inclosed space. While many people claim to love the smell of asphalt, it is not safe to be hot-boxing those fumes. So, Kordus designed a cross-flow exhaust system using gasoline-powered fans, as well as massive barn fans, to maintain air quality throughout the operation.

The next thing you probably would consider a problem is how to actually bring the asphalt into the space. Truck access presented another major constraint, as only one area of the building had sufficient height for dump trucks to unload indoors. So while they used that one safe spot to bring it inside, the asphalt then had to be transported to the paver using skid loaders.

“Originally we were going to use [just] two skid loaders to feed the paver,” Kordus said. “But the flow was not fast enough.”

The solution was simple, but not obvious.

“We eventually added more loaders until we had a total of four feeding the paver,” he said. “This created a steady paving rate.”

Once that balance was achieved, trucking, paving, and compaction moved in sync.

Paving asphalt over concrete inside a building introduces a different set of performance considerations. Because of the reduced fines in the mix and the rigid concrete base below, the crew used a knock-down roller immediately behind the paver, achieving over 90 percent compaction early in the process.

“This left the finish roller time to get a perfect finish roll on the mat,” Kordus said. “This will also result in less marks in the future.”

Where the main paver could not

reach, a path paver was deployed to work around columns, floor drains, and tight areas. The result was a surface Kordus described without hesitation.

“The floor is flat as a pool table and has an extremely smooth ride,” he said.

Asphalt Contractors Inc. selfperforms all of its work. The company operates in thirty-eight states, owns two asphalt plants, two gravel pits, five aggregate recycling yards, and employs more than one hundred fifty people.

“Not too bad for a company started by two guys with a pickup truck, two drums of sealer, and a home-made blower,” Kordus said.

The Bristol project earned the PAVING: Non-Parking Lot Award not simply because it was unusual, but because it was executed expertly.

By rethinking logistics, ventilation, and material flow, his crew placed

thousands of tons indoors safely and efficiently. By controlling mix design and compaction strategy, they produced a finished surface that met the owner’s long-term needs.

It is the kind of project that could only be delivered by a contractor who has spent decades learning where the limits are, and how to push past them. In a building where most saw a problem, Bob Kordus and Asphalt Contractors Inc. saw a blank canvas and answered the only question that mattered. Why not? ■