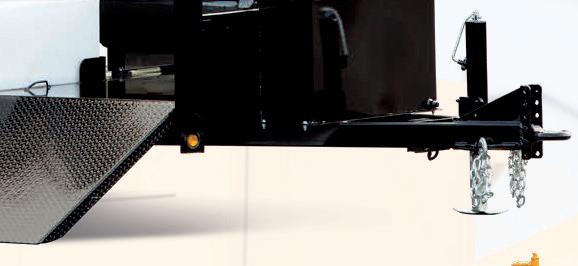

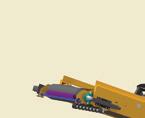

LEADING THE WAY

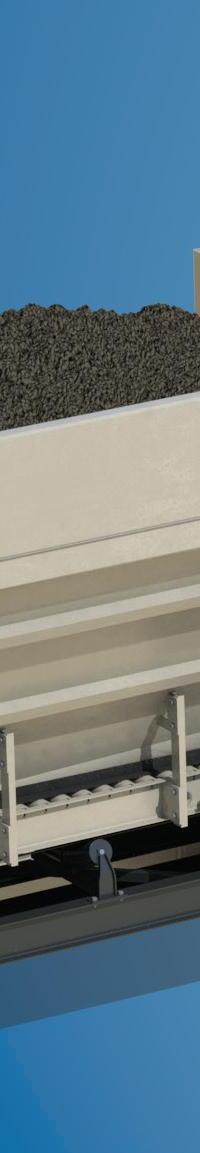

Weiler Material Transfer Vehicles lead the way with proven innovations to provide the lowest cost per ton of operation.

Innovative and reliable operator friendly features such as paver hopper management system with distance to paver, storage hopper management and auto chain tensioning.

Clam shell doors and full width drop down floors provide unmatched access for cleanout and maintenance.

Variable speed elevator and conveyors meet production requirements while minimizing wear.

The multiple, incremental improvements to the 4th generation of chains, sprockets and augers are retrofittable to all machines and provide increased wear life.

E1250C

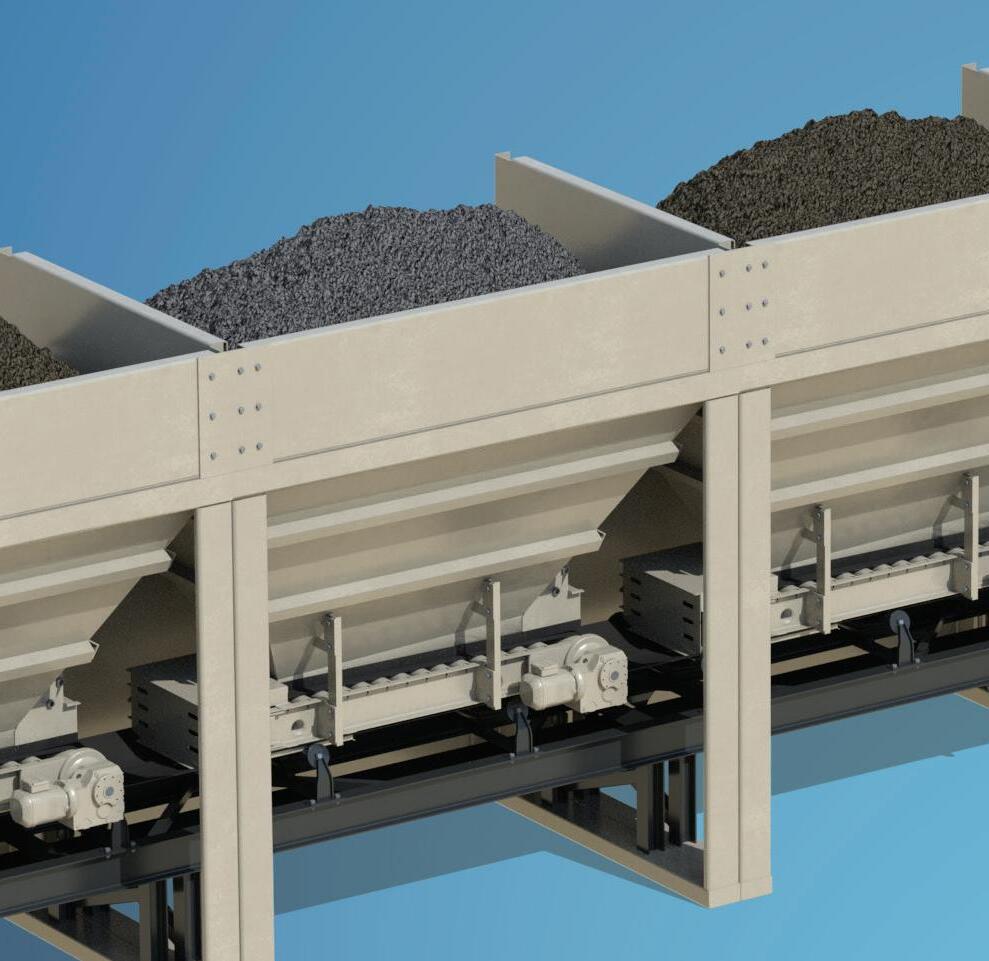

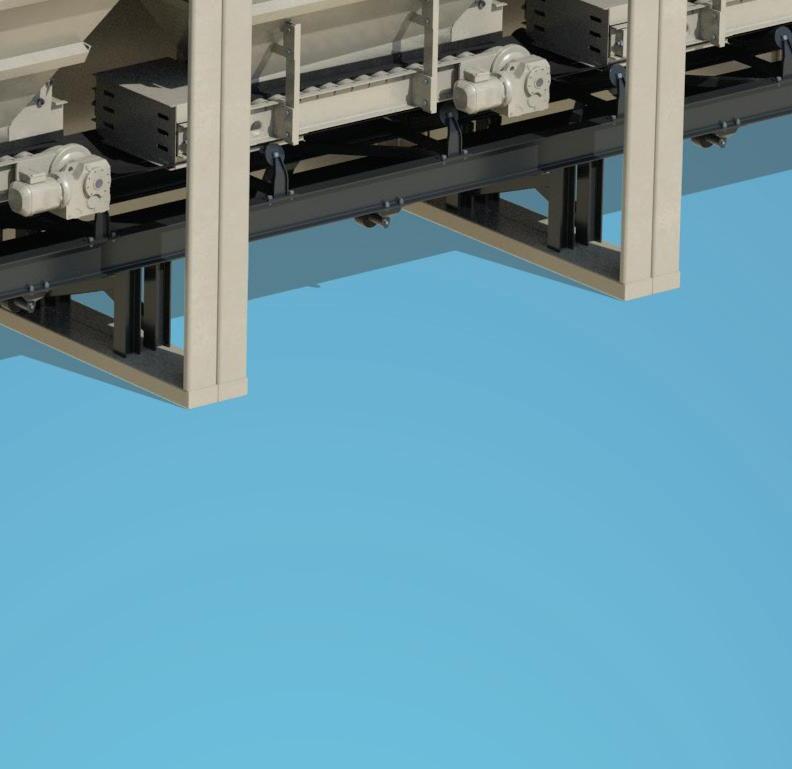

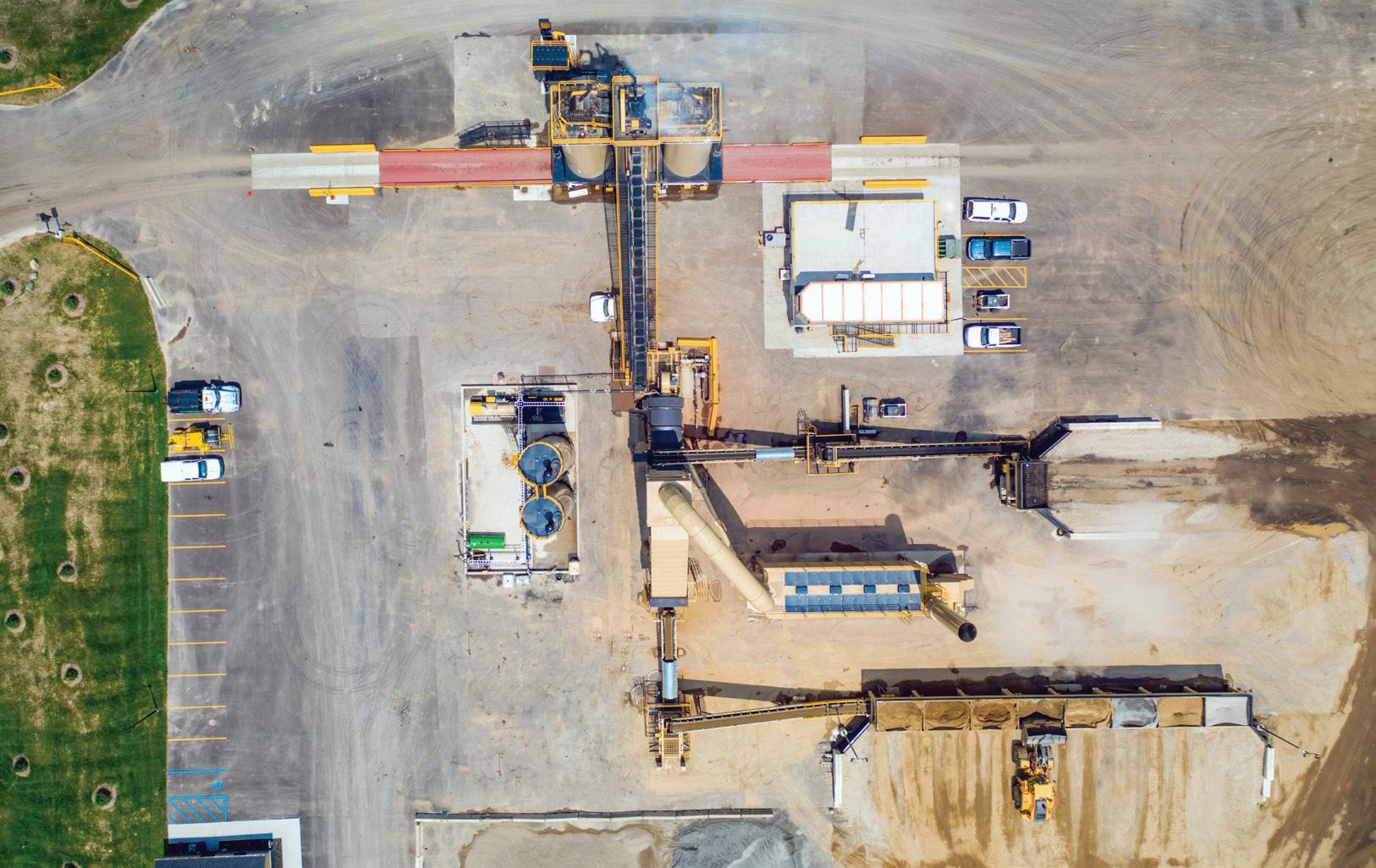

Black Gold skipped the “starter” plant and invested in a high-capacity drum mix facility designed for control, scalability, and long-term growth. | 18

Betting On The Future: A Contractor’s Vision For Growth

TECHNOLOGY MATTERS

14 AI-Powered Digital Twins Create New Data-Driven Era

Companies are adopting digital twins for real-time monitoring, predictive analytics and lifecycle planning as artificial intelligence unlocks more advanced use cases.

SPECIAL REPORT

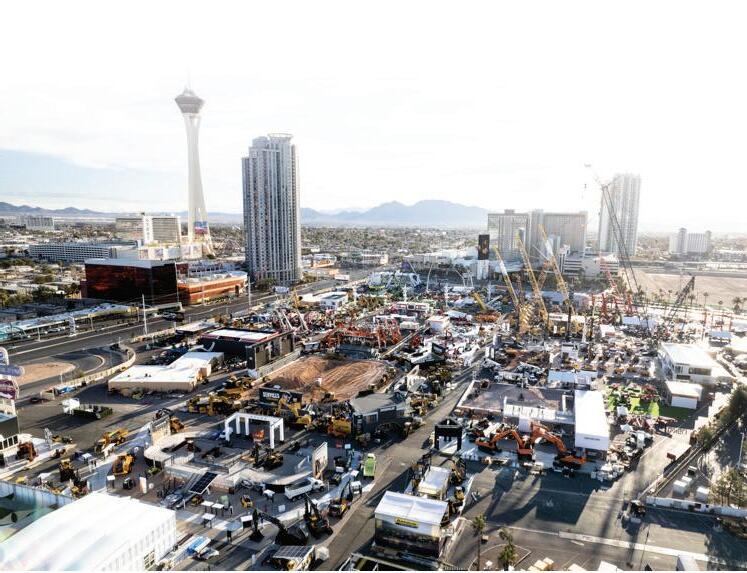

24 Asphalt Contractor’s CONEXPO 2026 Preview Guide

It only happens once every three years, and everyone is gearing up for the BIG SHOW with new equipment, products, and services.

FACE OF THE INDUSTRY

38 FORCE: Building Leaders

A new women-forward initiative focused on mentorship, connection, and leadership.

JOBSITE INNOVATIONS

42 Self-Healing Asphalt: Fact Versus Fiction

Here’s what contractors need to know about what’s real, experimental, and what still pays the bills.

PRESERVATION & SUSTAINABILITY

46 Tools For Managing Rising Highway Construction Costs

Pavement preservation techniques offer lower-cost repair solutions that last for decades.

Published and copyrighted 2026 by IRONMARKETS. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording or any information storage or retrieval system, without written permission from the publisher.

Asphalt Contractor (ISSN 1055-9205, USPS 0020-688): is published ten times per year: January, February/March, April, May, June/July, August, September, October, November, December by IRONMARKETS, 201 N. Main St. Ste 350, Fort Atkinson, Wisconsin 53538. Periodicals postage paid at Fort Atkinson, Wisconsin and additional entry offices.

POSTMASTER: Please send change of address to ASPHALT CONTRACTOR, 201 N. Main St. Ste. 350, Fort Atkinson, WI 53538. Printed in the U.S.A.

SUBSCRIPTION POLICY: Individual subscriptions are available without charge only in the USA. The Publisher reserves the right to reject nonqualifying subscribers. One-year subscription to nonqualifying individuals: U.S. $45.00, Canada & Mexico

Night Work On A Live Highway | No Edge Lines Season 3 Episode 2

In this episode of No Edge Lines, Editorin-Chief Brandon Noel travels outside Knoxville, Tennessee, to experience one of the most hazardous environments in road construction: night work on an active highway.

Watch the video at: https://asph.link/NELS3E2

John Deere and Wirtgen Group Showcase New Equipment

John Deere and the Wirtgen Group will display worldpremiere machines, digital solutions and hands-on demonstrations at CONEXPOCON/AGG 2026.

Read more at: https://asph. link/3v4c94mk

DICA Introduces New Ground Protection Mats

DICA has launched new ground protection and access mats, expanding its product lineup for construction jobsites.

Read more at: https://asph. link/4wcis2f8

IPAF Safety, Training and Innovation at

CONEXPO-CON/AGG 2026

Find Mobile elevating work platform safety, training and leadership at CONEXPO/ CON-AGG 2026.

Read more at: https://asph.link/ dlk4ym6l

Haver & Boecker Niagara to Showcase Screening Technology

Haver & Boecker Niagara will exhibit mineral processing and screening technologies at CONEXPO-CON/AGG 2026 in Las Vegas.

Read more at: https://asph. link/3h6vcgs1

Signup for the Roadbuilding Update, a free bi-monthly newsletter for the most up-to-date DOT, FHWA, asphalt, and other industry news

NEW IntelliPac ™ Moisture System

Astec paves the way for sustainable, innovative asphalt plants. The new IntelliPac Moisture System is a revolutionary solution that integrates seamlessly with Astec control systems. This provides unparalleled, real-time visibility into virgin aggregate moisture content. IntelliPac empowers operators to optimize mix design, minimize energy consumption, and reduce environmental impact. With Astec, you get superior asphalt production – better for the environment, better for your business.

BUILT TO CONNECT

Brandon Noel, Editor-in-Chief

bNoel@iron.markets

234-600-8983

Feeling Safe Vs. Being Safe

A real highway work zone changed how I see safety.

Ihave been out on enough jobsites now that I no longer feel like a total stranger when I show up to cover a big project for the magazine or to film an episode of our Youtube series No Edge Lines (use the QR code to watch). I’ve been learning, if slowly, over the last 3+ years as your editor, and that was my goal, though, not the only one. Recently, I filmed a video in Tennessee with GreyRock Milling and their owner Griffen Hopkins. What I experienced changed me forever.

A REFRAMING OF THE MISSION

The shoot started like any other. There wasn’t anything particularly different about it, in my memory, as I arrived in Knoxville, TN, and did what I typically do when I’m traveling by myself for work. I found the closest place that served ice cold beer and good looking chicken wings that isn’t a place I have back home in Ohio (shoutout to the crew at Wings Etc.). However, something was different. The next day was going to be my first time working on a highway at night, and I was feeling more nervous about it than I let on. I told my wife before I left that, while we were taking every precaution, this shoot had some real danger attached to it. I spared her the finer details of how many roadside work zone accidents happen each year so she wouldn’t worry too much.

But I was worried.

When I arrived at the staging area at the Veteran’s Overlook Memorial on Highway 11, about an hour outside of Knoxville proper, my heart was fluttering. I am predominantly a talkative type, even more when I’m out filming the show, and even MORE so when I’m nervous. Thankfully, Griffen immediately put me at ease. After talking with him ahead

of the shift, I felt a little bit better, but once we got up on top of the milling machine and started to pull out into oncoming traffic -- my nerves shot right back up.

As the evening went on, I felt more and more relaxed in the environment, and then the sun set. We sent up a drone to take some shots of us, and when I looked at the monitor I was stunned. We were like tiny little islands of light, shinning in the dark hills of Tennessee. There was a strange peacefulness to it, but there was also the constant thought of, “What if?”

From 2013 to 2023, roadside work zone fatalities increased by roughly 50%, and roughly 20,000 road workers are injured per year due to various causes. The direct causes are typically distracted driving, cell phone use, intoxication, reckless driving, and drivers who fell asleep at the wheel. Even Griffen had a story of a drunk driver taking out one of their dump trucks.

As I was crouched under a Wirtgen 220i changing out my first broken tooth by hand, I felt a huge gust of air rush past us on the ground as a semi-truck flew by and my heart went into my throat. While I managed to contain that reaction, I couldn’t help but think of how little it would actually take to drift too far over and clip the side of the machine.

This is the daily reality for the hard working men and women of our industry. I want to make sure whatever I’m doing in this position, it continues to elevate and highlight those people, their stories, and how it makes a difference. The least everyone else can do, is slow down.

See you on the road!

EDITORIAL

Editor-In-Chief Brandon Noel bnoel@iron.markets

Content Director, Marketing Services Jessica Lombardo jlombardo@iron.markets

Managing Editor Allyson Sherrier asherrier@iron.markets

AUDIENCE

Audience Development Director Angela Franks

PRODUCTION

Senior Production Manager Cindy Rusch crusch@iron.markets

Art Director April Van Etten

ADVERTISING/SALES

Brand Director ........................................................... Amy Schwandt aschwandt@iron.markets

Brand Manager ..................................................... Megan Perleberg mperleberg@iron.markets

Sales Representative Sean Dunphy sdunphy@iron.markets

Sales Representative Kris Flitcroft kflitcroft@iron.markets

IRONMARKETS

Chief Executive Officer Ron Spink

Chief Revenue Officer ............................................ Amy Schwandt VP, Finance Greta Teter VP, Operations & IT Nick Raether

Brand Director, Construction, OEM & IRONPROS Sean Dunphy

Brand Director, Supply Chain Brian Hines

Director, Marketing Services ..................................... Becky Peck

Content Director Marina Mayer

Director, Event Content & Programming Jess Lombardo Director, Lead Generation Operations Bailey Bunescu

CIRCULATION & SUBSCRIPTIONS

201 N. Main St. Ste. 350, Fort Atkinson, WI 53538 afranks@iron.markets

LIST RENTAL

Sr. Account Manager Bart Piccirillo | Data Axle (518) 339 4511 | bart.piccirillo@infogroup.com

REPRINT SERVICES

Brand Manager Megan Perleberg mperleberg@iron.markets | (800) 538-5544

Published and copyrighted 2026 by IRONMARKETS. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage or retrieval system, without written permission from the publisher.

@ASPHALTCONTRACTOR

@ASPHALTCONTRCTR

@ASPHALTCONTRACTOR

@ASPHALT-CONTRACTOR-MAGAZINE

NEW PRODUCTS

TransTech NonNuclear PQI 380+

This version of the PQI is fully equipped with a touch screen and a user friendly graphical user interface.

The PQI 380+ uses Microsoft Windows 10 for smooth operation, easy software upgrades and enhanced user support. IOS, Android application for data transfer and cloud storage, instantly send measurement data from the gauge to the cloud with just a QR code scan.

• Density readings in 3 seconds

• Instantly send measurement data from the gauge to the cloud

• Streamlined Workflow for Field Operators

• Data management screen and the ability to disable data logging

• Rugged, lightweight, aluminum shell

GEHL Launches

5 New Large-Frame Skid Steers and Compact Track Loaders

GEHL has expanded its lineup with five new large-frame skid steers and compact track loaders ranging in rated operating capacity from 3,250 to 3,600 pounds.

The models feature vertical lift arms, hinge pin heights up to 136 inches and optional counterweights that boost capacity to 3,800 pounds. Hydraulic performance includes standard and high-flow auxiliary options, and load-sensing hydraulics.

The new machines are equipped with connected technology through the myGEHL app.

JCB 3CX and 4CX Backhoe Loaders

JCB recently released a range of advanced models, on its 3CX and 4CX platforms, designed to deliver superior digging and loading performance. With advanced hydraulics and a strong loader arm, it delivers excellent lift capacity and breakout force.

Updates across the line include four-wheel drive and an automatic torque lock, improving traction and reducing fuel consumption when roading. High-flow hydraulics system allows operators to run powered attachments efficiently. The Parallel Lift Loader Arms ensure that materials stay level during lifting. All new models have six-speed transmission for enhanced operator control, while the high-capacity hydraulic pump allows for smooth, efficient operation even under heavy loads. The redesigned cab features a 7-inch display, Bluetooth connectivity, ergonomic joystick controls, and improved visibility through larger mirrors and LED work lights.

Wirtgen W 210 XF Milling Machine

The Wirtgen W 210 XF large milling machine is designed for high-production milling on freeways, highways, airports and other large-scale projects. Powered by a 580-kW John Deere engine and equipped with a two-speed powershift transmission, the machine delivers a wide range of milling drum speeds to balance productivity, fuel efficiency and surface quality at milling depths up to 330 mm.

The W 210 XF features Wirtgen’s MILL ASSIST machine control system, which automatically optimizes performance, cost or quality. Interchangeable milling drums, including Multiple Cutting System (MCS) options, allow operators to adapt quickly to changing job requirements, with milling widths ranging from 2.0 to 2.5 meters.

Additional features include LEVEL PRO ACTIVE for precise, automated leveling and WPT Milling for jobsite documentation, performance tracking and emissions reporting.

Cat Footwear Launches Invader Max 8” Boot for Winter Jobsites

Cat Footwear has added a new model to its Invader Max line the Invader Max 8” built for all-season performance and protection on cold-weather jobsites.

The insulated and waterproof boot features 400 grams of insulation for warmth, a composite safety toe, and a tire-tread–inspired outsole with slip-resistant technology. Additional details include metal hardware and a reinforced toe bumper for durability.

The Invader Max 8” is now available at catfootwear.com and select retailers nationwide.

STUDSON SHK-1

Helmet Featuring New HighBar OneStrap Fit System

STUDSON released its SHK-1 Type II safety helmet equipped with the new HighBar buckle-free retention system.

The HighBar system replaces traditional four-point nylon chinstraps with a single polymer strap for a more adjustable and hygienic fit.

The simplified system aims to improve worker wear and safety on busy jobsites with a more breathable, comfortable fit. The polymer strap is easy to clean and helps keep workers cooler.

Doosan Bobcat Introduces New AI and Electric Equipment Concepts

Doosan Bobcat Inc. has introduced several prototype technologies aimed at improving equipment operation, service efficiency and jobsite awareness.

Bobcat Jobsite Companion is an AI-enabled system designed to assist operators with machine tasks through voice commands and onboard automation.

Bobcat also unveiled Service.AI, a service-support platform intended to help technicians access repair information and diagnostics more quickly.

CM Labs to Debut New Simulation Training Features at CONEXPOCON/AGG 2026

CM Labs Simulations will return to CONEXPOCON/AGG in March 2026 with several updates to its Intellia Training System and an expanded lineup of construction equipment simulations.

The company plans to introduce new features aimed at improving instructor oversight and boosting training efficiency. CM Labs will also showcase additional equipment models to give contractors more options when developing operator training programs.

Volvo CE Introduces Short-Swing Excavator with Efficiency and Lifting Upgrades

Volvo Construction Equipment has introduced the ECR355, the latest update to its short-swing radius excavator line, designed for building and utility work in limited space.

The model delivers up to 7% better fuel efficiency than its predecessor. Electric cooling fans operate only when needed to help reduce fuel use, noise and engine load. Updated work modes, automatic engine shutdown and other efficiency features are also included.

The ECR355 offers a 7% increase in lifting capacity and 4% more tractive force.

Topcon Launches HiPer XR GNSS Receiver

Topcon Positioning Systems has announced the launch of the HiPer XR, its latest Global Navigation Satellite System (GNSS) receiver for surveying, mapping and construction applications. The HiPer XR supports all major satellite constellations. The new receiver features advanced Topcon Integrated Leveling Technology (TILT) compensation featuring a calibration-free and magnetic interference-immune integrated IMU. The receiver keeps data reliable, even in areas with interference or tampered signals.

Ignite Attachments Introduces 80-Inch Severe-Duty Bucket for Skid Steers

Ignite Attachments has introduced an 80-inch severe-duty bucket designed for skid steers and compact track loaders in the 75- to 100-plus-horsepower range.

The bucket is Ignite’s largest to date and is intended for demolition cleanup, site grading and material handling. A heaped capacity of 16.7 cubic feet allows transport of larger volumes of material in fewer passes.

The bucket includes added steel reinforcement along the bottom and sides to improve durability.

The attachment features a universal skid steer quick-attach interface for compatibility across a range of machines.

Brass Knuckle Releases SmartFlex BK360 Cold-Weather Work Glove

Brass Knuckle has introduced the SmartFlex BK360, a cold-weather work glove designed to keep hands warm, dry, and agile in low temperatures.

The glove features a 13-gauge nylon shell over a soft 7-gauge acrylic liner for insulation and comfort. A full foam latex coating on the palm and fingers provides grip and protection, while remaining flexible in cold conditions. Three-quarter coverage on the back of the hand adds extra warmth without restricting movement.

The SmartFlex BK360’s foam latex coating draws moisture away from the palm to help maintain a secure grip in wet conditions, though it is not recommended for oil exposure. A seamless, stretchable knit wrist keeps out debris and cold air, while black-on-black styling conceals dirt.

We’ve built our business and reputation through our unparalleled focus on equipment design, durability, and attention to detail. We apply these foundations to our complete range of asphalt plants and asphalt plant equipment. Let us customize to your request - big or small. Meet Us in Las Vegas - March 3 - 7, 2026.

Construction companies are adopting digital twins for real-time monitoring, predictive analytics and lifecycle planning as artificial intelligence unlocks more advanced use cases.

TAI-Powered Digital Twins Drive New Era of Data-Driven Construction

he construction industry is incredibly fast-paced, meaning that any innovation that can accelerate operations will immediately pique the interest of construction professionals. However, this increased efficiency must not come at the expense of safety, as a safety incident could be catastrophic — not to mention deadly. The digital twin is the rare innovation that promises to offer both improved efficiency and safety for fields such as construction.

Outside the construction field, many may not realize the fundamental role that data plays in the construction process. Data can (and should) be a key part of an informed decision-making process. In the world of construction, better decision-making can impact several aspects of performance, such as cost-effectiveness, efficiency, safety, quality and more. It’s no wonder that so many in the construction industry are embracing data-driven tools to improve their operations.

Many construction companies have begun to leverage data in their operations by using digital twin technology. Digital twins are virtual representations of real-world objects. What makes a digital twin so useful is the immense level of detail it reflects thanks to data gathered from sensors. In this way, digital twins are much more realistic than the typical simulation, allowing them to be a beneficial innovation for a wide range of use cases.

digital twins can help power decisionmaking. For example, in supply chain management, digital twin technology can be used to monitor a supply chain for disruptions, allowing leaders to make more informed decisions that contribute to greater efficiency on the job site.

THE BENEFITS OF USING DIGITAL TWIN TECHNOLOGY IN CONSTRUCTION

Thanks to this accuracy, digital twins have become an incredibly useful tool for several purposes, including training, real-time monitoring, and simulations. In the construction industry, some of the most beneficial functions of digital twin technology are real-time monitoring and predictive analytics. In other words, digital twins allow construction leaders to see and understand both the current status of their machines and their expected status under a set of expected conditions.

Construction operations that implement digital twin technology can expect to see a plethora of benefits for their operations. Some of the primary benefits of digital twin technology include:

• Increased safety: One key benefit of digital twins for the construction industry is improved safety.

• Better cost management: Digital twins can also be a pivotal tool for cost management. During the design process, using digital twins can reduce the financial burden of physical prototyping by allowing designers to work out kinks in a virtual space before building costly real-world prototypes. When construction companies use digital twin technology for predictive maintenance, they can reduce loss due to downtime and malfunctioning equipment.

HOW AI IS TRANSFORMING USE CASES FOR DIGITAL TWIN TECH IN CONSTRUCTION

Construction sites are full of hazards, not the least of which is machinery. When used in the training process, digital twins can allow workers a riskfree, low-stakes opportunity to learn how to use construction equipment. Beyond this, the ability to take a proactive approach to processes like prototyping and maintenance allows job sites to prioritize safety before dangers arise.

• Improved efficiency: When used effectively, digital twin technology can help construction operations become more efficient. Because of the immense level of data they provide in an easy-to-understand interface,

counterparts. As a result, digital twin technology is now valuable for construction leaders through every step of a project’s lifecycle — from ideation and blueprinting to production and long-term maintenance. Digital twins can allow construction teams to simulate potential challenges to the build, such as inclement weather or simple wear and tear over time, which can help them create more resilient systems.

The advent of artificial intelligence has proven to be a transformative moment in both the capabilities and the proliferation of digital twin technologies. AI and its capabilities accentuate those of digital twins, allowing their combined efforts to offer even more impactful benefits to businesses across sectors. Because artificial intelligence can process such large amounts of data so quickly, digital twins that use AI can become more advanced and accurate than ever before.

The combined power of the spatial computing technology of digital twins with artificial intelligence has paved the way for even more advanced, customized use cases in the construction industry. Now, the utility of digital twins no longer stops with individual machines. Enterprises can use digital twins to simulate entire systems and supply chains, which is particularly useful for industries like construction, which feature so many complex and disparate moving parts.

Another key function that digital twins will allow in the construction industry is predictive maintenance. When sensors are affixed to the real-life counterparts of the digital twin, they can feed information to the user on the virtual platform. With this insight, users can make better decisions about when they need to replace certain components, perform repairs before machines break, and ensure that regular maintenance occurs according to schedule. This can lead to better efficiency and longevity for machines and systems.

Digital twin technology has also proven influential in reshaping collaboration in the construction industry. Because digital twins are accessed via the metaverse, this means that anyone anywhere in the world can access these tools — often requiring no special hardware, such as a VR headset. Many digital twins can now be accessed from a simple mobile phone. In the construction industry, this can allow everyone, including architects, engineers, contractors, and clients, to work from a shared and interactive model, which improves communication and reduces errors.

For example, digital twins can enable better lifecycle planning in construction. With a new tool known as the “inception twin,” it is now possible to create digital twins before their real-world

Indeed, construction leaders who wish to stay on the cutting edge of the industry should embrace the transformation that will be offered by digital twin technology. Digital twins are paving the way for a future of construction that is more connected and data-driven. We are experiencing a transformation in how large-scale construction projects will be planned, built, and maintained, and the technological innovators are those who will come out on top.

Joseph

Callahana, CEO of Ciright

By Brandon Noel, Editor-In-Chief

BETTING ON THE FUTURE:

A Contractor’s Vision For Growth

Why Black Gold skipped the “starter” plant and invested in a high-capacity drum mix facility designed for control, scalability, and long-term growth.

For many paving contractors, the idea of owning an asphalt plant sits somewhere between a long-term ambition and a calculated risk. It promises greater control over mix quality, scheduling, and costs, but it also comes with its own set of stringent demands capital, expertise, and a willingness to climb a steep learning curve. For Black Gold, based in West Michigan, that decision became unavoidable.

CHOOSING FLEXIBILITY

From the outset, Schaendorf said the decision wasn’t just about owning a plant. It was about owning the right plant.

ability to produce consistently during peak paving season was a non-negotiable requirement.”

“The volume we were doing was beginning to be more than our suppliers could handle,” said Jody Schaendorf, owner of Black Gold. “We knew we had the talent and equipment as well as an excellent site for a plant. Easy highway access and central to the needs of the area.”

That realization set Black Gold on a path that would fundamentally change the company’s trajectory. In 2021, the contractor commissioned its first asphalt plant near Dorr, Michigan, entering plant ownership at a scale that many first-time owners are nervous to take on. Rather than buying a minimal configuration plant to get their feet wet, Black Gold invested in a highcapacity, expandable drum mix plant designed to support long-term growth from day one.

Interestingly, Black Gold’s growth mirrors the plant’s capabilities. Schaendorf started in the early 1990s working for Bob Thompson, owner of Thompson McCully Co, operating various paving equipment. From there, he began doing small paving projects, driveways, small parking lots.

Today, the company operates as a full-service contractor. “We have our own asphalt milling machines, trucks, and excavating equipment,” Schaendorf said. “We can be a full-service paving company where many of the asphalt plants out there do not.”

“We chose this plant configuration because it gave us the flexibility to run a wide range of mixes efficiently,” he said. “The combination of high-production capacity, multiple silo options, and integrated recycle capability was a perfect match for the type of work we do in West Michigan.”

That flexibility extended beyond mix design. Layout and material flow were central to their decision-making process when they set out to shop for the right asphalt plant for them.

“The configuration allowed us to streamline material flow while minimizing truck wait times,” Schaendorf said. “The plant layout, orientation, and load-out system aligned well with how we stage our trucking fleet and structure our daily operations.”

However, ease of maintenance was another major sticking point that drove their decision making process.

“We specifically selected a plant design that made maintenance access simple, reduced downtime, and improved reliability,” he said. “The

That capability has opened doors. “We have grown from doing driveways to million-dollar State contracts,” he said.

LOOKING FOR THE LONG-HAUL

When Black Gold evaluated plant manufacturers, Schaendorf said the focus was less on what the shiny, well curated brochures could show them, and more on the support that would come after the plant sale and commissioning. They weren’t just looking for a manufacturer; they were looking for someone to partner with them for the foreseeable future. That can be a challenge in the current industry environment, where many companies are stretched thin when it comes to staffing and availability, and acquisitions frequently shake up company structures and relationships.

“Dependability and long-term support were essential,” he emphasized. “We needed a manufacturer known for strong service response, reliable parts availability, and ongoing technical assistance during Michigan’s tight paving windows.”

Ultimately, their diligent search led the Black Gold to ALmix and, specifically, to an ALmix 114UF UF Series Asphalt Plant.

Photos provided by:ALmix Inc.

Future growth was built into the design from day one.

“We looked for a company with a proven history of building plants that perform reliably under high production demands and variable operating conditions,” Schaendorf said. “Energy efficiency, environmental performance, and mix quality were major selection criteria.”

Equally important was the willingness to collaborate. Obviously, every asphalt plant location comes with its own unique challenges and the solutions couldn’t be one-size-fits-all. Black Gold wanted someone who would tailor their solutions alongside them every step of the way.

“We wanted a manufacturer that would collaborate on project-specific layout needs rather than supplying a generic configuration,” he recalled. “Flexibility and engineering support were critical.”

LONG-TERM MINDSET

From ALmix’s perspective, the plant was never envisioned to be static.

“The plant was selected with future scalability in mind,” Schaendorf said. “Additional silos, higher RAP capability, and expanded material-handling systems can be integrated as operations grow. Improved operational efficiency and reduced per-ton costs directly support our strategic goal of staying competitive while delivering high-quality asphalt products.”

“The plant is capable of producing 400 tons per hour under normal operating conditions,” said Mark Martin, service manager at ALmix. “That aligns well with Black Gold’s current annual production of approximately 400,000 tons, with room to grow.”

BY THE NUMBERS

Since commissioning of their 114UF, Black Gold’s plant has become the backbone of its entire operation. They’ve had a few years now with it, now, and have a level of comfort and understanding of what it can deliver on a daily basis.

“We produce approximately 400,000 ton per year,” Schaendorf said. “It has grown steadily since the plant was erected in 2021.”

The storage alone has been a major driver of overall efficiency. “With 900 tons of storage capacity we have been able to increase our laydown capacity and crew downtime is at a minimum,” he added.

That success led to other additions, ensuring that capacity has continued to expand. “Since we erected the plant we have added four more cold feeders and an additional 300 ton storage silo,” Schaendorf said. “We have plans for additional equipment to be added in the near future.”

Martin said storage was intentionally prioritized. “With 1,200 tons of hot mix storage at commissioning and an additional 300-ton silo added later, the plant supports continuous paving operations while minimizing truck wait times and crew downtime.”

For Schaendorf, the most immediate benefit was operational control.

“We have been able to serve our customers better and have had more flexibility when bidding municipal and State projects,” he said. That’s been the real prize, and customer feedback has reinforced that decision.

“Our customers have commented that the location and layout of the plant site is ideal for staging and access to the highway,” Schaendorf said. “They also commented that the quality of the material is excellent.”

That maintenance access they were adamant about having has, also, proven to be more than a convenience.

“The accessibility of all major components has been one of the standout features,” Schaendorf said. “The plant was engineered with maintenance platforms, clear access

Schaendorf explained the plant wasn’t just a response to their current demand levels. It was a strategic investment in what Black Gold wanted to become, where they wanted to go. That in itself is a risk, especially in the current economic environment of uncertainty, but they believed that the future was worth betting on.

“A major long-term goal for Black Gold is increased production autonomy,” he said. “This plant gives us the ability to control our own mix schedule, support additional crews, and expand project capacity.”

points, and logical equipment spacing, which significantly reduces downtime during inspections and routine service.”

INNOVATION AS A FORCE MULTIPLIER

Technicians can log into the control system, review alarms, analyze sensor data, and pinpoint the root cause of most issues without waiting for on-site support.”

“Identifying failing bearings, worn flights, or compromised seals before production starts will save an enormous amount of time during the season.”

However, at the end of the day, there’s no substitution for good training.

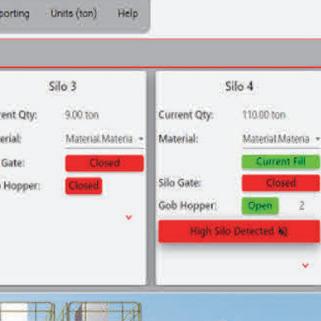

One of the big drivers for their continued growth has been the level of innovative features and benefits their new plant came with. For instance, ALmix’s in-house automation has played a major role in stabilizing production and improving consistency.

“The Insignia Control System has dramatically improved our mix consistency by controlling key variables such as burner settings, feed rates, drum temperatures, and silo management,” Schaendorf said. “Real-time sensors and automated adjustments keep production stable even during high-tonnage runs.”

The 114UF utilizes ALmix’s Insignia Control System, a total plant control system that leverages a plant-wide Ethernet network. This design not only allows all major plant components to operate as a single, unified system but also greatly simplifies control wiring, enhances plant data collection, and provides robust remote support and diagnostic capabilities.

On the ALmix side, they said that this increased level of connectivity has changed the service relationship with customer, as well.

“Software updates and system diagnostics can now be performed in real time. Due to the level of access provided by the ethernet network, many typical control-related problems that once required a service visit can often be resolved within minutes by our team of program engineers located in Fort Wayne, IN.”

“The integrated control reduces delays, improves response time to material changes, and ensures the entire production sequence stays synchronized,” he added, but noted that the remote access capabilities have been equally impactful in minimizing plant downtime.

“Remote troubleshooting has become one of our most valuable tools.

MAINTENANCE LESSONS FROM A FIRST-TIME OWNER

Annual maintenance has become a structured process, now, at Black Gold. This was important to them, as part of the process to ensure they maximized the return on their big investment.

“We approach annual maintenance with a structured shutdown plan, prioritizing major wear components such as the drum, baghouse, drag slat, and conveyors,” Schaendorf said. “We inspect everything on a scheduled interval and document all findings to track wear patterns from season to season.”

He offered some well-seasoned advice to other first-time plant owners, and those considering commissioning a plant of their own.

“Never cut corners on preseason inspections,” he emphasized.

“A well-trained crew can diagnose issues early, operate the plant more efficiently, and extend the lifespan of critical components,” Schaendorf said.

And Martin echoed that perspective.

“The customer who succeeds long term are the ones who plan shutdowns carefully, inspect wear components proactively, and keep critical spare parts on hand,” he said.

Looking back, Schaendorf doesn’t sugarcoat the challenge.

“When you put up a plant there is a very steep learning curve,” he said. “But when you have the best people working for you, the finest equipment, and the knowledge, you can achieve what you set out to do.”

For those looking to take the plunge for themselves, Schaendorf had one final piece of wisdom to impart.

“Know your market and your strengths,” Schaendorf said. “Set your goals and focus on where you want to go, the rest will follow.”

Martin sees Black Gold as a great model for first-time owners.

“They selected a plant that met current needs but didn’t limit future growth,” he said. “That long-term mindset is where real success happens.”

By Brandon Noel, Editor-In-Chief

ASPHALT CONTRACTOR’S CONEXPO 2026 PREVIEW GUIDE

It only happens once every three years, and everyone is gearing up for the BIG SHOW with new equipment, products, and services.

This is not a trade show for the faint hearted, casual, tire-kicking type of crowd. If you’re attending CONEXPO 2026, taking on the cost and time required to see the largest show room floor space in North America, then you don’t want to waste a lot of your visit wandering around trying to find what you’re really looking for.

We reached out to some of the largest and most in-demand manufacturers in the asphalt and road building industry, to try and help you have a head start on what to go see when the flood gates open on March 3. Of course, we will be there too, so make sure to stop by North Hall — N12463 and meet the team behind Asphalt Contractor. You might even see me there, catching my breath between booth visits!

ALMIX INC. (#SV3119)

Split-Level Control House

The ALmix Portable Split Level Control house features a 2-room, split-level layout with a full operator’s room and a secondary room housing a full MCC, all available in a fully portable design. The SplitLevel control house at CONEXPO will be outfitted with the latest ALmix Insignia Control System and Insignia Loadout System.

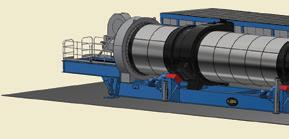

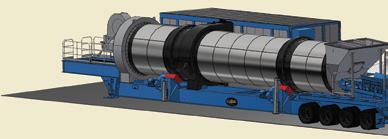

ALmix 88UFP Portable Drum Mixer

The ALmix 88UFP Drum Mixer is a fully portable, counterflow drum mixer featuring a total air, long-nose burner. ALmix portable drum mix plants deliver features that allow portable operators to set up, produce, and move to another location quickly and costeffectively without sacrificing heavy-duty drum and component construction.

• Available as portable, relocatable, or stationary

• Optional high wear package

• Elastic tire supports

As with all EX Series asphalt plants, the EX 300 achieves maximum heat transfer and fuel efficiency through separate drying and mixing zones with its single-drum counterflow-system technology. This technology provides the longest aggregates drying and mixing times in the industry, ensuring consistent, quality asphalt that meets all federal and state specifications.

FAYAT MIXING PLANTS to Introduce Its New VISION Control System

ASPHALT DRUM

(#SV2067)

ADM FAYAT GROUP EX 300

Designed to fill a high-demand product niche in the North America marketplace, the new EX 300 asphalt plant has a capacity of 300 TPH, and, like all EX Series hot-mix plants, can handle up to 50% RAP. The plant features a single drum diameter and high efficiency CBS total air burner with variable drive frequency (VFD), and much more.

Unique features of the EX 300 counterflow asphalt plant include:

• Single drum diameter

• High efficiency CBS total air burner with variable drive frequency (VFD)

• Trunnion drive with VFD, no V belts

• Drum insulation with stainless steel cover

• Flights designed for easier maintenance

In addition to the EX 300, an ADM FAYAT GROUP 12’ x 32’ control room will also be on display in Booth SV2067 at CONEXPOCON/AGG. Step inside the control room and experience the FAYAT MIXING PLANTS new VISION, unified control software, a ground breaking shift for the industry. VISION was driven by innovation, research, and forward-thinking to make information clearer, more intuitive, and most of all, user friendly for operators.

Vision is a unified “language” that connects all systems, features simple, user-friendly display modes, with dynamic animation and visuals that track the flow of materials, and also features a digitized “notepad” to simplify daily orders. With VISION, operators can schedule daily production, utilize a predictive maintenance application, and take advantage of a virtual assistant that provides the best actions for maintaining plant efficiency during the production process, and much, much more.

ALMIX INC.

ALMIX INC.

ASPHALT DRUM MIXERS (ADM)

MIXERS

BOMAG (CENTRAL HALL, #C30932)

Next Generation Paving

The BOMAG exhibit includes the latest advancements in highway class pavers. The CR Series paver on display delivers intuitive paver and screed operation with its updated human-machine interface (HMI) featuring grouped functions for both the paver and screed control panels. A large, 7-in (177.8mm) multifunction color screen display at each console includes the latest operating system program. This allows operators to make quick paver setting changes and view critical functions and gauges using either the touchscreen display or dial control.

The paver features a sloped engine hood design to provide a clear view into the hopper from the operator’s seat. Sound-insulated, the hood helps to deliver quieter paving to improve worker comfort. Dual swing-out operator stations boast BOMAG’s SIDEVIEW innovation in which both the seat and console swivel outward at different angles to deliver unobstructed views to the paver’s side and screed spreading augers.

Technology

The rollers on display will show BOMAG’s 360˚ compaction technology, including conventional vibration, oscillation and exclusive directed/vectoring vibration. The BW 161 ADO-5 heavy tandem

roller features BOMAG’s TanGO tangential oscillation, which uses an optimized oscillation amplitude that allows the drum to remain in constant contact with the mat. This technology is ideal for compacting joints, thin layers and bridges. TanGO provides a gentle compaction effect that minimizes the risk of aggregate crushing and eliminates bow waves, even at higher rolling speeds.

The displayed BW 191 AD-5 AM roller features BOMAG’s exclusive ASPHALT MANAGER technology. Pioneered by BOMAG, ASPHALT MANAGER controls compaction by adjusting the direction of vibration, rather than relying on constant operator-selected amplitude changes. Easy to operate, the system requires only mix type and lift thickness to be entered by the operator. As material stiffness increases during compaction, the vibration vector is automatically adjusted from predominantly vertical toward a more horizontal orientation, optimizing energy transfer and helping to prevent over-compaction. These flexible rollers can effectively replace multiple traditional compaction setups in one machine, and the vibration direction automatically reverses with travel direction, helping eliminate the bow wave effect.

Additionally, BOMAG team members will have details on the latest updates to the BOMAP smart compaction control technology. Offering transparent and real-time compaction control, BOMAP allows operators to monitor soil and asphalt compaction results, regardless of the roller manufacturer. This allows operators to immediately see where the material has been optimally compacted or where further passes are required. Once the app is installed on a mobile device, it’s immediately ready for use. In its base version, BOMAP uses the mobile device’s internal GPS to detect roller positioning to simplify surface covering compaction control. Alternatively, an external GPS receiver can be connected to the mobile device to more accurately detect roller positioning and tracking

Pneumatic Rollers

The exhibit will also include details about the BW 18 RH pneumatic tire roller. The displayed machine will include wrapped decaling showing both the BW 18 RH and BW 28 RH, giving insight into the flexibility of machine design. Built as a BW 18 RH, this 8-tire pneumatic roller has a maximum operating weight of 39,683 lb (18,000 kg) and a maximum wheel load reaching 4,960 lb (2,250 kg). Powered by the 74.2 hp (55.3 kW) Deutz TCD 2.9L4 HT engine, the BW 18 RH doesn’t require diesel exhaust fluid (DEF) to meet emissions standards and offers a maximum travel speed of 9.9 mph (15.9 kmph). Offering an 80.4-in (2,042-mm) rolling width, this roller delivers excellent compaction results on chip-and-seal and finish and intermediate rolling applications.

Material Supply

Material Supply helps asphalt producers improve raw materials inventory accuracy and reduce manual tracking that can lead to stockouts and production interruptions. By streamlining how inbound supply and usage are managed, teams can improve visibility into inventory, reduce risk, and better support consistent plant operations.

BOMAG

BOMAG

BOMAG

COMMAND ALKON

COMMAND ALKON (#N12513)

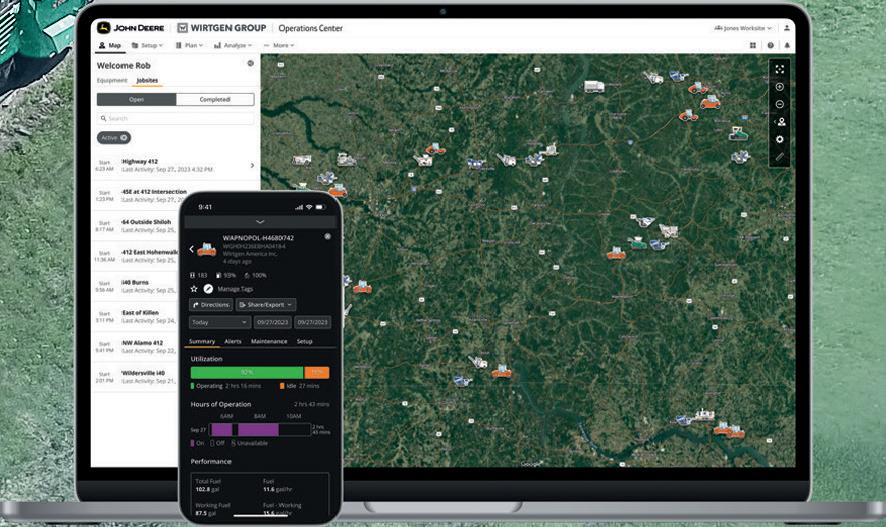

Jo hn Deere Operatio ns Center™

Manage Construction S ite s – Anyt ime An d An ywh ere

CLOSE TO OUR CUSTOMERS

THE FUTURE OF CONSTRUCTION SITE MANAGEMENT. John Deere Operations Center™ provides tools to gnidulcnI data-driven recommended courses of action and integrated maintenance schedules. The user-friendly dashboard can be accessed as a web-based tool or as an app on a mobile end device at any time. For more transparency, efficiency, and productivity.

www.w irtge n- group.c om/operat ions-cent er

Key benefits for asphalt operations:

• Improves raw material inventory accuracy and reduces manual processes

• Helps prevent plant disruptions tied to inventory surprises and stockouts

• Supports more consistent production planning and operational visibility

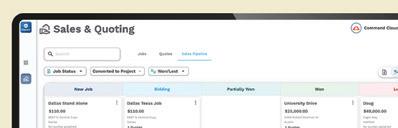

Sales & Quoting

Sales & Quoting streamlines pricing and quoting workflows for heavy building materials operations by standardizing quote creation, improving pricing consistency, and helping teams convert opportunities into projects that are ready for operations.

Key benefits for asphalt operations:

• Centralizes quoting and pricing management for improved consistency

• Helps teams move away from manual spreadsheets and disconnected workflows

• Improves sales pipeline visibility and speeds the transition from quote to execution

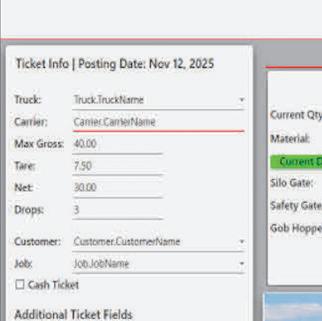

Dispatch & Scale Ticketing

Dispatch & Scale Ticketing is a cloud-based dispatch and scale ticketing solution built for bulk materials distribution, helping teams keep trucks moving

while improving the accuracy and timeliness of ticketing and invoicing workflows.

Key benefits for asphalt operations:

• Cloud-based ticketing supports accuracy and timeliness for material and invoice distribution

• Helps reduce bottlenecks and keep trucks moving

• Centralized, secure data supports remote operations and scalability

EAGLE CRUSHER (C31414)

Eagle Crusher E-Plant

The industry’s only true highproduction triple-deck screening/ crushing system on one chassis. Transports in one pull, for the asphalt, aggregate, and recycling industries. Enables processing up to five products (including three spec products) at one time. Also available in a double-deck version. The triple-deck E-Plant will be on display at the Eagle Crusher booth.

TalonTrax

TalonTrax is designed for ultramobile crushing without sacrificing power or production on the job site. At the heart of TalonTrax, is Eagle Crusher’s new TalonMax (TM-15) impactor, featuring an open-rotor design that reduces weight while still providing the same crushing capabilities for which Eagle Crusher equipment is known. The plant features a dual-motor, under-crusher pan feeder with industry-leading discharge clearance in excess of 23” to enable greater material flow and virtually eliminate clogging; and an easily removable discharge

conveyor that allows for quick access to under-crusher area, as well as to the discharge conveyor itself, for inspection, maintenance, and cleaning of both.

EAGLE CRUSHER

TalonStack

The new TalonStack self-propelled, radial stockpiling conveyor is designed to improve productivity and mobility while minimizing operator costs. On display at the Eagle Crusher booth will be the TalonStack 65. TalonStack is available in a wide range of sizes.

IROCK CRUSHERS (#C32316)

The TJ-450 Mobile Jaw Crushe r features one of the most powerful jaws in the market. This class leading eccentric shaft offset provides aggressive crushing action to maximize production and minimize blockages.

IROCK

The TJ-150S Mobile Jaw Crusher offers all the features you are looking for in a crusher including low fuel consumption, a reversible jaw, a rotating side conveyor, and user-friendly controls.

The IROCK TS-518 Mobile Scalping Screen is designed for durability, reliability, and utilizes high-quality components, resulting in a highly efficient machine with class leading features.

COMMAND ALKON

COMMAND ALKON

EAGLE CRUSHER

EAGLE CRUSHER

IROCK

IROCK

Superior Durability for Your Asphalt Operations

EccoFab President, Gerry Bauer is constantly pushing the boundaries of design, engineering, and innovation to create wear parts that not only withstand the toughest conditions but provide superior durability and exceptional heat resistance. Realizing that clients were experiencing shortened wear life using traditional OEM wear parts, he began experimenting with Hardox® steel in 1988. In 2000, EccoFab was invited to be part of the launch of the domestic U.S. Hardox® Wear Parts Network where Gerry has been the leading expert.

Bringing Unparalleled Durability and Less Downtime to Your Asphalt Operations

EccoFab’s asphalt drum flights, crafted from Hardox® HiTemp steel, exemplify the robustness and reliability that is critical in the asphalt industry. Subject to continual friction and heat, these components are critical to the overall efficiency of your operation. EccoFab drum flights, renowned for their heat and wear resistance, make them the perfect choice for your highintensity asphalt production.

Extended Lifespan Equals Cost-Efficiency

In contrast to conventional OEM flights that require replacement within two years on average, EccoFab’s Hardox® HiTemp steel drum flights offer significantly longer life. Even after 4 years and 1.2 million tons of material our flights are still going strong and we estimate at least another four years of rigorous use. This extended lifespan means fewer replacements, reducing your operating costs over time.

With EccoFab's Hardox® HiTemp steel drum flights, strength isn't just a feature – it's the foundation. This isn't just any wear plate; it's a 375 Brinell fortress against wear, thriving in scorching conditions up to 500°C (932°F). Forget buckling, say goodbye to cracks. In the world of asphalt production, only the strong survive. Welcome to the era of unstoppable asphalt production.

Whether you’re ramping up production or aiming for smoother, more efficient operations, EccoFab’s Hardox® steel asphalt drum flights are the smart choice. By focusing on durability, cost-efficiency, and temperature resilience, we ensure you get the best value out of your production process. Trust EccoFab to elevate your asphalt operations to the next level.

If your business is in the asphalt industry you need to talk to Gerry.

Industry Expertise

Strongest Wear Parts Constant Innovation

This asphalt bucket has processed 1.2 million tons of material, is 4 years old and will get up to 8 years before replacement.

IROCK provides mobile and portable crushing plants, screening plants, conveying equipment, and other related products for the demolition, recycling, and aggregate industries. IROCK’s robust equipment will increase production and profits while also reducing downtime and operational expenses. In addition to a premier product line that is easy to service and operate, IROCK Crushers provides true support, expertise, and outstanding service from a staff of industry experts. Headquartered outside of Cleveland, OH, IROCK Crushers is committed to providing quality, innovative, and productive equipment that has set the marketplace standard for over 30 years.

LEEBOY

LEEBOY (CENTRAL HALL — C30932) PR900

The PR900 is a dual-tank maintenance distributor that offers versatility and precision with its independent front and rear tanks. Operators benefit from an advanced in-cab controller that gives them the ability to control material application rates and make adjustments to spray widths. Offering a range of optional accessories such as hand spray wands and convenient tool storage, the PR900 is designed for efficient and adaptable performance on various jobsites.

TDC600

wireless remote controls, allows you to complete many of your daily tasks with efficiency and ease. Uniquely configurable, the customizable options give the contractor the ability to create a solution specific to their exact needs.

NB15

LEEBOY

The Rosco NB15 is a threewheeled, self-propelled sweeper engineered specifically for professional use. It features a comfortable, ergonomic design and a powerful brush core for quality cleaning. The machine is also designed to be easily towed, making transport simple. This makes the NB15 a perfect fit for rental companies or any operation needing dependable sweeper for paved surfaces.

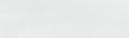

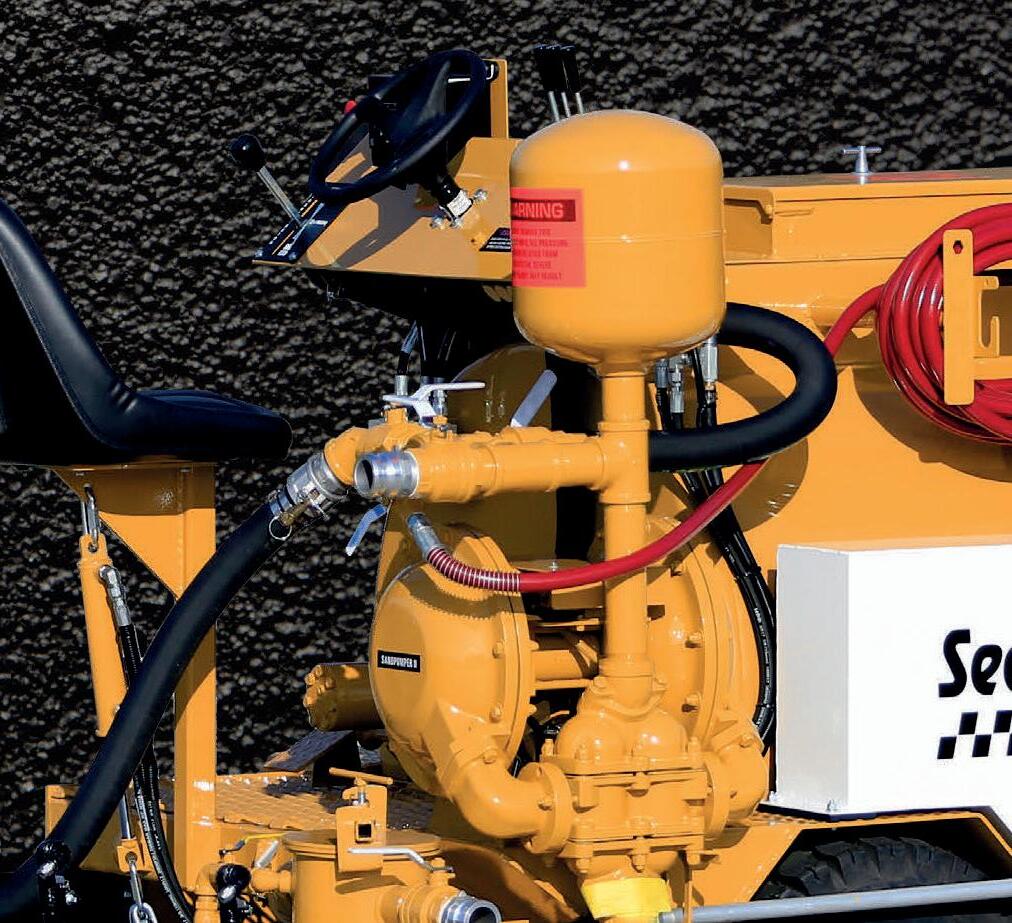

SEALMASTER (#C31573)

CrackPro 260 Dual Pumper

SEALMASTER

TR

575 SprayMaster with Extended Deck

The TR 575 SprayMaster is built to mix and apply pavement sealer with or without sand. Its air-driven dual-diaphragm pump provides reliable, low-maintenance operation and shifts to neutral automatically when the flow stops. The 575-gallon tank uses fullsweep hydraulic agitation to ensure consistent material mixing. A 75foot hose and spray wand offer flexibility on the job. Heavy-duty axles, trailer lighting and a safety breakaway system add durability and peace of mind. The TR 575 is a solid, contractor-ready unit designed for dependable daily use.

SP

575 Dual Spray/ Squeegee Machine

The SP 575 Dual Spray/Squeegee Machine provides versatility with spray bar, wand and squeegee application options. Its full-sweep agitation system and Sand Pumper II pump help produce a smooth, uniform finish. The quick-change squeegee assembly allows operators to adapt to changing pavement conditions. All-wheel drive and power steering improve maneuverability, while easy-open valves simplify operation. Built for productivity and consistent results, the SP 575 is a dependable choice for professional sealcoating jobs.

TRIMBLE INC.

The TDC600 Tack Distributor provides a cost-efficient option for large projects and is perfect for the all-inclusive commercial paving contractor. This chassis mounted tank, along with its many standard features, such as long-ranged

The CrackPro 260 Dual Pumper delivers fast, efficient crack sealing with an all-diesel power system designed for reliability and performance. Its heated hose technology keeps material at the proper temperature from the tank to the wand, ensuring smooth and consistent flow. The unit offers industry-leading heatup times, full-sweep agitation and a liquid-cooled Kubota diesel engine. An advanced control cabinet manages safety functions and system monitoring. Together, these features make the CrackPro 260 a dependable choice for professional, high-volume crack sealing.

TRIMBLE (#W40420)

Trimble will be announcing several new products, collaborations and integrations, as well as featuring its industry leading connected workflows and solutions for the construction industry. From earthmoving and grading to marine

LEEBOY

SEALMASTER

SEALMASTER

construction and infrastructure, Trimble’s portfolio connects field and office workflows across every phase of construction.

Trimble is also hosting two educational sessions that go beyond product demonstrations to explore real-world integration challenges and collaborative approaches to solving them.

Embracing Mixed Fleet: OEMs and Tech Providers ComingTogether Tuesday, March 3, 2:30-3:15 p.m.

A panel of industry leaders, moderated by AEM’s VP of the Construction& Utility Sector, will explore the challenges and opportunities of bridging proprietary ecosystems, specifically paying attention to the new ISO 15143-4 standards relating to data sharing across job sites.

Moving Mountains: How Advanced Technology is Powering 25 Million Cubic Yards of Earthworks for South Carolina’s New EV Plant Wednesday, March 4, 1-2 p.m.

This discussion will highlight the technology that enabled the development of nine million square feet of building space, two roadways and four dammed ponds on a 1,600-acre site.

Show attendees can stop by Trimble Booth W40420 in the West Hall for product demonstrations of the newest hardware and software solutions, and to have their questions answered about the advanced technologies empowering the construction industry with precise data collection, advanced modeling and seamless collaboration.

They will also gain insights on estimating, operations, visualization, positioning and financial and project management. Trimble’s industry-leading solutions connect workflows, people and data, and enhance efficiency, accuracy and compliance across the entire asset lifecycle.

VOLVO CE (FESTIVAL GROUNDS - F24029)

Volvo EWR170 Wheeled Excavator

The fully updated EWR170 brings a refreshed design and improved capabilities to the medium size class. It’s a short-swing model, optimized for confined spaces with an industry-leading tail swing radius and a front swing radius that’s nearly two feet shorter than its predecessor’s.

A never-before-seen feature that operators will love is an electronically retractable access ladder that swings down from a recess in the side of the machine for safer, easier cab entry and exit. With this patented technology, the machine cannot swing or move while the ladder is in the down position.

The revamped EWR170 wheeled excavator has wider lift cylinders for more lifting capacity over the front of the machine and a longer two-piece boom for added reach. Four-wheel steering will be available as an option later this year, which is an industry first for this class and dramatically reduces turn radius.

An integrated rearview camera and right-side camera improve visibility, as does the optional Volvo Smart View with a high-definition, 360-degree real-time view of machine surroundings. For peace of mind, the frame, boom and arm are backed by the Volvo Lifetime Frame and Structure Warranty for the entire initial ownership period.

The EWR170’s redesigned cab provides an excellent operator experience with low noise levels, ergonomic controls, more storage options, wireless phone charging, USB connections, automatic in-cab lights and an optional air compressor for cleaning. Comfort can be tailored even further with more seat and joystick options and electronically adjustable heated side mirrors.

Key specifications on page 35.

Next-Gen A60 Articulated Hauler

For hydraulic attachments, the X1 and X3 auxiliary lines are now larger to reduce pressure losses, and flow on the X3 has increased from 18.5 to 31.7 gallons/minute, providing the pressure needed to operate a tiltrotator. A third line (X4) is optional.

The A60 and its new all-Volvo powertrain includes a robust transmission and axles that enable full power to be used in all gears. Its active hydraulic front suspension enables fast hauling speeds while its automatic drive combinations (including 100% differential locks), all-terrain bogie, and hydromechanical steering deliver stability and control. Volvo Dynamic Drive, a predictive gear selection function, uses sensors for incline, wheel speed and weight to skip to the best gear for the job, saving the fuel that is typically burned by shifting through multiple gears. Another intelligent function, Terrain Memory, is part of the automatic traction control system, identifying and remembering slippery road segments and proactively adjusting the differential locks to prevent wheel slip and preserve productivity in adverse conditions. The A60

VOLVO CE

VOLVO CE

VOLVO CE

includes the Volvo Engine Brake, downhill speed control, cruise control, wet brakes on all wheels, and a service brake retarder system. These highlights, alongside proven Volvo CE features like OptiShift with Reverse By Braking, provide off-road mobility and keep operators and sites as safe as possible.

Tangible and technological changes make a difference too Visually, the A60 ADT got a makeover with its lower hood and additional LED light and camera options, contributing to a field of vision that exceeds industry standards. The cab — already an industry favorite — is even more operator-friendly with a refreshed layout, a bigger integrated Volvo Co-Pilot display, lower noise levels and impressive handling. Its reinforced axles can withstand heavier loads and higher levels of torque and stress. Maintenance costs are reduced by up to 5% over 12,000 hours of operation thanks to simplified servicing and longer change intervals compared to the previous generation. The rotating hitch is maintenance-free and sits higher than competitors’ designs for better ground clearance and stability. Digital tools like Haul Assist with onboard weighing, Hill Assist and Connected Load Out further optimize productivity and uptime. In North America, the A60 is compatible with the ActiveCare® Direct advanced telematics system and backed by the Volvo Lifetime Frame and Structure Warranty, which covers the frame and articulation joint for the entire initial ownership period.

WEILER INC. (#C32302)

Weiler P385C Paver

Weiler’s P385C paver continues to raise the standard for commercial class pavers with improvements to provide performance, reliability and outstanding mat quality in a wide range of applications. The P385C features a Cat® C3.6 Tier 4F/ Stage V engine with an increase to 120 hp (90 kw) for unmatched power and performance. The best-in-class undercarriage features 90” (2286 mm) track length, 68” (1727 mm) of ground contact and 140 mm track chain pitch provides smooth ride and excellent flotation with automatic track tensioning. The improved conveyor drive system features a sealed chain case, hydraulic motor with heavy duty bearings and splined shaft for increased reliability. An updated hydraulic system with proportional valving provides variable speed and reversible conveyors and augers. The larger tunnel height allows for lower conveyor speeds without loss of material output.

The Weiler designed 3,700 lb (1678 kg) screed features a paving range of 8’ to 15’ 8” (2.2 m to 4.8 m) with industry leading

WEILER INC.

mat quality. The redesigned heating system eliminates GFCI breakers and utilizes insulation monitoring for increased reliability and performance. Three different operating positions allow for optimal visibility and control with the adjustable, magneticresistance steering system. Optional screed mounted control panels give operators additional function control from screed level.

Weiler D560 Top Hammer Rock Drill

Weiler top hammer rock drills have a heritage that runs deep with a proven, reliable hammer, innovative software and unmatched parts availability and support. The D560 and D460 are the only top hammer drills manufactured in the North America. Weiler manufactures all the hammer components in-house with a dedicated grinding room for precision machining. Weiler manufacturing, software design and common Cat ® components provide quick response with minimal downtime.

The D560 is powered by a Cat C9.3 Tier 4F/Stage V engine with 375 horsepower and a 550 ft 3/ min compressor for 3.5” to 6” hole diameter at a max depth of 102’. Multiple drifter options are available and provide low cost of ownership and reliability through at simple design and high strength materials. The six rod carousel holds multiple diameter rods with a precise position function that indexes and locks, eliminating switches and sensors for increased reliability. The mast accepts a start rod of up to 20’ for a max single pass depth of 18’ 6”. The frame and robust undercarriage provide durability for the demands of drilling and navigating rough terrain with excellent maneuverability due to a low center of gravity, high ground clearance and independent track oscillation.

The pressurized cab with positive filtration provides a quiet and comfortable work environment with high-visibility safety glass, climate controlled with heat and AC, six-way seat adjustment and roll-up shades. The 10.1” color touch-screen display and multi-function joysticks provide full drill control at your fingertips. Push-button anti-jam and sync thread functions simplify operation while increasing productivity. Easy-to-fill auto greasers reach hammer, thread and chassis locations while multiple large doors provide excellent access to engine, hydraulic and compressor components.

Weiler B400 Front Mount Broom

The B400 is the most innovative self-propelled broom on the market with features designed with years of industry experience. Built to withstand the demands of road construction, milling operations and all construction site needs. The broom features a quick change brush head, available in 77’5” or 89.5” lengths, with variable down pressure and available 24” side shift. The hydraulic arm allows for broom changes in less than two minutes.

The fully enclosed cab provides excellent operator visibility and features 2 cab doors with tinted sliding windows. The cab is pressurized with a high efficiency filter system. The B400 features intuitive controls with a multifunction joystick, full color display and foot pedal or joystick propel option. Optional Bluetooth® radio with 2 speakers available. The B400 features the Cat® C2.8 Tier 4 Final/ Stage V engine with 74 hp powers the 2-speed wheel motors with high speed transport mode and low speed sweeping mode. The hydraulic tilting cab provides

access to the optional 100 gal (379 L) water tanks. Multiple doors provide access to the engine and hydraulic components.

WIRTGEN GROUP (#SV2415)

Wirtgen is introducing the new generation of wheeled cold recyclers and soil stabilizers of the WR Series X-Tier. The machines cover various areas of application: from cold recycling – structural road repair – to the stabilization of various building materials such as soil stabilization.

Vögele is introducing the latest generation of Dash 5 pavers to the North American market. These machines are characterized by optimized operating ergonomics, faster set-up times, more automated processes, and an efficient drive concept. A special highlight includes the world premieres of the 10 ft. Class: the SUPER 20005 X tracked paver, and the SUPER 2003-5 X wheeled paver.

At Hamm, the focus is on the automation of compaction processes. For example, the well-known Smart Compact

WEILER INC.

WEILER INC.

WIRTGEN GROUP

WIRTGEN GROUP

WIRTGEN GROUP

Basic has now been expanded to include the decisive parameter for qualitative evaluation during compaction: real-time asphalt density. It is determined in the Smart Compact Pro system via the new real-time density scan on the machine and forms the basis for the automated control of compaction energy and modes in both drums on tandem rollers of the HD+ and HX series.

Kleemann is showing its new PRO-Line screening plant for the first time in the North American market with the MOBISCREEN MSS 1102 PRO coarse material screening plant. The robust plant is designed for outputs of up to 750 t/h and is ideal for use in quarries.

SPECTIVE CONNECT is now also available for Kleemann screening systems. Thanks to the digital application, the operator receives all relevant data such as speed, consumption values, and fill levels directly to their smartphone.

John Deere Operations Center, the digital telematics platform for solutions for process, machine and service optimization brings together all information for the holistic management of construction sites. Among other things, previously created order data can be transferred directly to milling machines and pavers via the integrated Work Planner, so that the machines implement projects in a semi-automated manner.

With 24 world and market premiers in the machine exhibition, the latest technologies and digital solutions, John Deere and the Wirtgen Group offer visitors a customer-oriented experience. In the center of the joint booth there is an Innovation Center, which shows the John Deere Operations Center. The site-oriented tool serves as a digital hub in which all machine and work data converge.

14 Wirtgen Group machines alone are equipped with the latest technologies such as the Wirtgen Group Performance Tracker, AutoPilot 2.0, Smart Level Pro, Smart Pave, Smart Compact Pro and SPECTIVE CONNECT. They enable the automation of work processes as well as the collection and evaluation of performance data. In this way, the group of companies supports customers in implementing construction processes holistically more efficiently, transparently, and profitably.

WIRTGEN GROUP

By Brandon Noel, Editor-in-Chief

FORCE: Building Leaders In The Pavement Industry

A new women-forward initiative focused on mentorship, connection, and leadership development in the asphalt and pavement industry. Here’s why it matters.

Given the fact that I only came into this industry about four years ago, I can still clearly remember what it felt like when I was new and had zero clue about anything. I felt a little lost and awkward, and I felt very overwhelmed by everything I didn’t understand. The good news is that I had great mentors that were able to help me build a strong base, and because of that, I’ve been able to grow and build something solid on top of that foundation.

Amy Schwandt, Chief Revenue Officer, and Jessica Lombardo, Director of Events and Content Programming, were the people who shepherded me through my first introductions to the asphalt world. From there, I was kind of set-loose on the industry, and went on to make my own connections and relationships.

However, when I sat down to talk with them about their new female-forward initiative called FORCE, I quickly understood how different our entry points were, as well as, why building up and empowering women in the asphalt pavement space will make the whole pavement industry better.

EVERYONE’S JOURNEY IS DIFFERENT

“Literally, before the asphalt industry, I sold office supplies door-to-door. It was horrible,” said Schwandt, as she recounted her first position as an insidesales rep. At that time, she recalled being met with some interesting challenges.

“I was twenty-one years old, and I didn’t have any female professional contemporaries. There wasn’t anyone in the space, and there definitely wasn’t anyone

my age. So, I had to learn the ropes as a woman in a man’s world. That was ok. I did it, but things can be better.”

Unknowingly, the very seeds of what would give rise to FORCE were planted out of that experience, but they were

still missing their other half. When Lombardo came on board with the editorial team for the asphalt and pavement brands, she was just as green to the industry as Schwandt. However, in addition to the guidance

Adam Rahn

she received from long-time editor Allan Heydorn, she also had something Schwandt didn’t: A female mentor in Schwandt herself.

“You can read about it, and you can watch videos, but until you have somebody who takes the time to show you, you can’t really understand,” said Lombardo. “Amy taught me how to know the industry in an entirely different way than Allan did, and she helped me see that I didn’t have to be afraid of being a woman whenever I found myself in rooms or spaces where I was the only one.”

This gets at the heart of what FORCE is, and what sets it apart as an idea and going forward as an organization. While the end goal may result in an increase for women working in the asphalt and pavement industry, Lombardo believes its real and central effort is about providing that belonging and mentorship to women already in the industry.

REPRESENTATION IS NOT A BUZZWORD

On more than a few occasions I’ve come across people who seem to fundamentally misunderstand the purpose of representation, as well as how powerful it can be to the people who aren’t accustomed to the same level of access commonly and unconsciously enjoyed by those who already have it.

For example, the first time I went to a trade show as an editor, I had no idea what was normal and what wasn’t. On top of that, I was juggling a large amount of imposter syndrome, and I was afraid to voice a lot of the questions I had because I didn’t want anyone to know what I didn’t know. I didn’t want to think of how they might think of me differently. So, I just carried on, anxiously faking it.

I didn’t feel completely safe to ask for help, or if I was even doing things right. By contrast, when I went to my first National Asphalt Pavement Association (NAPA) meeting, they had a meetup

specifically designed for “newbies” to attend and meet other first-timers. When I attended that, it gave me the instant liberty to approach anyone and commiserate. Almost instantly, I didn’t feel like I was an “outsider” at an exclusive club, where I wasn’t “in” on things.

That is a rather elementary way of explaining why representation in our industry is so vital for women, and why creating spaces for them to connect to others who instantly share in their experiences, perspective, and background is essential to longterm success.

WHAT IT IS AND WHAT IT ISN’T

“FORCE isn’t about separating women from the industry,” said Lombardo. “It’s about strengthening and elevating leaders in general. One thing I hear frequently from people, men and women, who come to PAVE/X is that they wish they had a mentor. For women, however, there are just a lot fewer female mentors.”

LowBoy LowBoy

axle frame reinforcement is

to allow for 35” of vertical travel with the

capability to lift the fully loaded deck at 2500 p.s.i.

5-position adjustable fifth wheel height

1-1/2” apitong deck w/ 20”cm spacing.

12” cast swinging/removable extension brackets w/ double hook-on in 1st position

+3/-3 adjustable height control in rear air suspension

Boom well w/ extra low 1st cross member between the tires in rear section.

Dropped center rear light panel.

Air ride suspension w/55” axle spacing.

18 lash rings on deck and rear

Amber L.E.D. Strobes with Battery back-up

3 Axle air lift rd

Raising & lowering valve.

Multiple models and options available.

1333 South Daysville Road Oregon, Illinois 61061

1333 South Oregon, Illinois 61061

Sales: 815-732-2116

sales@etnyre.com

Sales: sales@etnyre.com

Parts/Service: 888-586-1899

Parts/Service: 888-586-1899

This was the inception point for FORCE, and how it came together as a facilitation for something that, in many cases for men, often happens naturally or with much less effort seeking it out.

“FORCE is a space where women can know, in advance, other female leaders will be, a space where they can easily find one another,” Lombardo added.

That’s critical for women to find, because, like it or not, many of the ways men handle situations on a jobsite or in the office, must be handled in a different manner for women. As any woman can tell you, the dynamics of leadership are always different depending on your gender, and if that is a surprise to you, then just ask the women in your life.

“This was Jessica’s idea, she was really passionate about it,” said Schwandt. “She had the conversations on the contractor side, then started including me in those, and that was when I knew this was going to be really important. Because there are just different ways that

women tend to communicate, absorb information, and understand things.”

Schwandt went on to relay an important, recent event that helped solidify what FORCE could eventually be for women in the asphalt pavement industry. A few weeks prior, she’d attended the Women in Supply Chain Forum, which is hosted by our sister publication Supply & Demand Chain Executive.

“I’d never been to a women-centered, women-focused conference in more than twenty years,” said Schwandt. “Instantly, I felt a huge difference. By the time I left two days later, I knew. The discussions we had, the openness, the topics that were brought up. It was special, we learned so much from each other.”

In any job setting, there are all sorts of unwritten, unspoken codes or ways of operating that no one talks about, but are still somehow maintained.

For example, when I worked at the steel mill, I still wasn’t fitting in the way I wanted to, even after nine months on

the job. Guys would still come around every day and give me grief and harass me, until I finally snapped and gave back to the guys equal to how they were needling me. Some choice words were exchanged. Suddenly, they all laughed, gave me a fist-bump, and from then on I was one of them.