DUAL ACTION

SECURE YOUR SPOTS AT BOTH INDUSTRY-LEADING EVENTS

THESE EVENTS ARE DIFFERENT, BUT PAIRED TOGETHER SUPPLY THE KNOWLEDGE, RESOURCES AND CONNECTIONS TO SUCCEED IN 2024 AND BEYOND. PAVE/X, the new paving and pavement maintenance trade show, will bring the HEAT with 60+ hours of educational sessions, a fast-paced demonstration showcase, and ample networking opportunities. While, the IGNITE Construction Summit conference pairs well with the large tradeshow by providing business owners and high-level managers an intimate opportunity to discuss the future of the industry and how leaders in the industry are succeedingand how you can too!

LEARN MORE!

THE PAVE/X DIFFERENCE

EDUCATE.

The PAVE/X difference begins with a robust educational program, featuring five tracks: Paving, Striping, Sweeping, Sealcoating & Business Management.

DEMONSTRATE.

Seeing equipment in action is incredibly important in any equipment buying decision and PAVE/X is thrilled to bring a fast-paced demonstration showcase for attendees.

CONNECT.

Over the three day event, there will be an incredible amount of opportunities for nextlevel networking that will create and strengthen the relationships that are vital to the success of business owners.

LIGHT A FIRE WITH IGNITE EDUCATION.

We’ve tailored our two-day curriculum specifically to advancing your construction business in this increasingly competitive market. Business owners and high-level executives will have the opportunity to identify areas within their company that need immediate change and obtain the tools they need to succeed.

NEXT-LEVEL NETWORKING

The exclusive, intimate event allows business owners and high-level managers the opportunity to discuss the current struggles and opportunities present with in the industry, leading to actionable insight and long-term connections. Brought

to you by: CONTRAC TOR ASPHALT LEARN MORE: HTTPS://PAVEMG.COM/EVENTS

SEPTEMBER 2023 www.ForConstructionPros.com/Asphalt ASPHALT WON’T SOLVE WASTE PLASTIC PROBLEM INDUSTRY EXCLUSIVE: ROLLER SPEC GUIDE – BROWSE OVER 175 MODELS TIME TO END BEHIND THE PAVER QUALITY SAMPLING?

YOUR PARTNER ON THE ROAD AHEAD

What does that mean? It means that we are determined to support you in your journey towards greater profitability, safety and environmental stewardship. It means that we will help you forge new paths, shape key trends and offer new solutions to support you on that journey. And it means we will be with you for every step of that journey through application consultancy, personalized trainings; across numerous geographic territories and around the clock.

Tell us where you’re going and we will help you get there.

800-651-0033

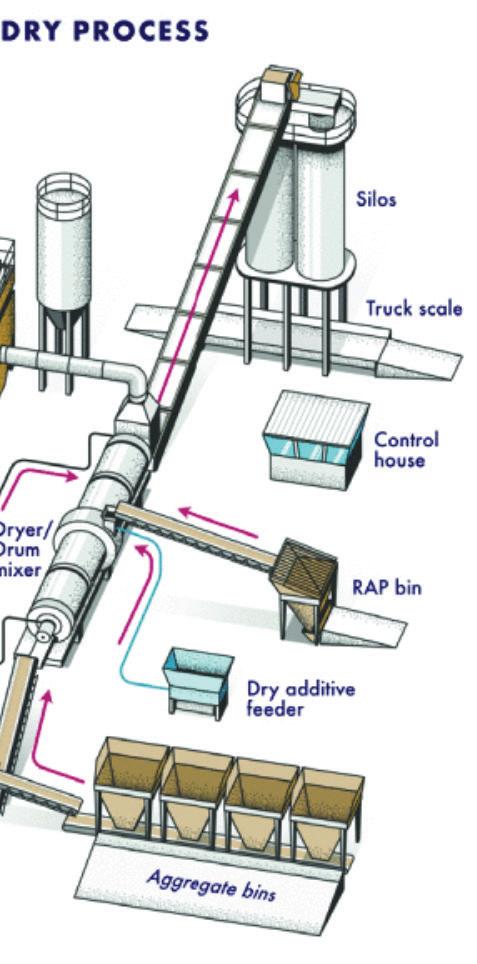

GENCOR, YOUR TRUSTED CHOICE

ON EVERY ROAD AND HIGHWAY, THERE ARE THOSE THAT FOLLOW AND THOSE WHO LEAD.

At Gencor, we’ve led the industry with the most fuel-efficient, environmentally clean and lowest-maintenance design available to the hot mix industry. From the award winning Ultraplant® to the Green Machine, our record is unrivaled in innovative design. That’s the kind of leadership you’ve come to expect from Gencor. THE LEADER IN

Call 407-290-6000 or visit www.gencor.com

INDUSTRIES

INC.

EFFICIENCY

PERFORMANCE AND

TECHNOLOGY MATTERS

10 8 Reasons to Improve Jobsite Connectivity

Jobsite connectivity is essential for construction firms to ensure efficient project management, collaboration, and safety.

PRODUCTION NOTES

20 Why Jobsite Quality Sampling Isn’t The Best Way Forward

The arguments for implementing a serious change are piling up faster than a pile of RAP. A longtime veteran of the industry talks quality control.

JOBSITE INNOVATION

38 Grade Control: Not Just for Earthworks Contractors

Commercial and civil construction projects are adopting grade control as a best practice, facilitated by technology.

PRESERVATION UPDATE

42 It’s Complicated: Asphalt + Plastic

The National Academy of Sciences, Engineering, and Medicine examined potential uses for the growing waste plastic problem and cast doubt on any potential role it can play in asphalt pavement mix designs.

U.S. $45.00, Canada & Mexico $65.00, and $95.00 all other countries (payable in U.S. funds, drawn on U.S. bank). Single copies available (prepaid only) $10.00 each (U.S., Canada & Mexico), $15.00 each (International).

4 ASPHALT CONTRACTOR SEPTEMBER 2023 www.ForConstructionPros.com/Asphalt TABLE OF CONTENTS | SEPTEMBER 2023

Published and copyrighted 2023 by AC Business Media. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording or any information storage or retrieval system, without written permission from the publisher. Asphalt Contractor (ISSN 1055-9205, USPS 0020-688): is published ten times per year: January, February, March/April, May, June/July,

Buyer’s Guide issue published in August by AC Business Media, 201 N. Main St. Ste 350, Fort Atkinson, Wisconsin 53538. Periodicals postage paid at Fort Atkinson, Wisconsin and additional entry offices. POSTMASTER: Please send change of address to ASPHALT CONTRACTOR, PO Box 3605, Northbrook, Illinois 600653605. Printed in the U.S.A. SUBSCRIPTION POLICY: Individual subscriptions are available without charge only in the USA. The Publisher reserves the right to reject nonqualifying subscribers. One-year subscription to nonqualifying individuals:

201 N. Main Street Ste 350, Fort Atkinson, WI 53538 (800) 538-5544 • www.ACBusinessMedia.com www.ForConstructionPros.com/Asphalt Published by AC Business Media. LATEST INNOVATIONS FOR ASPHALT PROFESSIONALS CONTRACTOR CONTR AC TOR LATEST INNOVATIONS FOR ASPHALT PROFESSIONALS ASPHALT CONTR AC TOR LATEST INNOVATIONS FOR ASPHALT PROFESSIONALS A sph a lt LATEST INNOVATIONS FOR ASPHALT PROFESSIONALS CONTRACTOR CONTR AC TOR LATEST INNOVATIONS FOR ASPHALT PROFESSIONALS ASPHALT CONTR AC TOR LATEST INNOVATIONS FOR ASPHALT PROFESSIONALS A sph a lt LATEST INNOVATIONS FOR ASPHALT PROFESSIONALS CONTRACTOR CONTR AC TOR LATEST INNOVATIONS FOR ASPHALT PROFESSIONALS ASPHALT CONTR AC TOR LATEST INNOVATIONS FOR ASPHALT PROFESSIONALS A sph a lt CONTRACTOR SEPTEMBER 2023 Vol. 37, No. 7 Industry Exclusive: Roller Spec Guide Compare over 175 different asphalt rollers to help you decide which will best suit the needs of your team. | 26 COVER STORY IN EVERY ISSUE 8 Editor’s Perspective 48 Last Exit

August, September, October, November, December, with an additional

The Key to 100 Years In Business: People

This episode of Digging Deeper profiles Luck Companies, a family-owned crushed aggregate and environmental performance producer, celebrating 100 years in business.

Watch the video at: https://asph.link/luck

Contractor Lessons From the Game of Golf

Golf has a lot in common with construction. It is very much a game of skill, and risk versus reward. Here are some takeaways that contractors can learn from the game of golf.

Read more at: https://asph. link/golf

Registration Open for PAVE/X 2024

The inaugural event, held Jan. 30 - Feb. 1 in San Antonio, Texas, features over 60 hours of education, live equipment demonstrations and an expansive tradeshow floor.

Read more at: https://asph. link/pavex2024

Adding to Your Fleet During an Unstable Market

Contractors want to understand opportunities to improve equipment efficiency through software and hardware additions to increase their fleet’s productivity.

Read more at: https://asph. link/7iwi7s

Sustainability: A Smart Business Choice

In this webinar, Caterpillar industry experts walk through the sustainability impact profiles of various Cat machines and explain how equipment choices can make a difference.

Read more at: https://asph.link/ sustain

Get social with us! Share pictures of what you’re working with over 29,000 other asphalt contractors on our Facebook page: Facebook.com/Asphalt.Contractor

CONNECTION

www.ForConstructionPros.com/Asphalt DIGITAL

6 ASPHALT CONTRACTOR SEPTEMBER 2023 www.ForConstructionPros.com/Asphalt

BUILT TO CONNECT

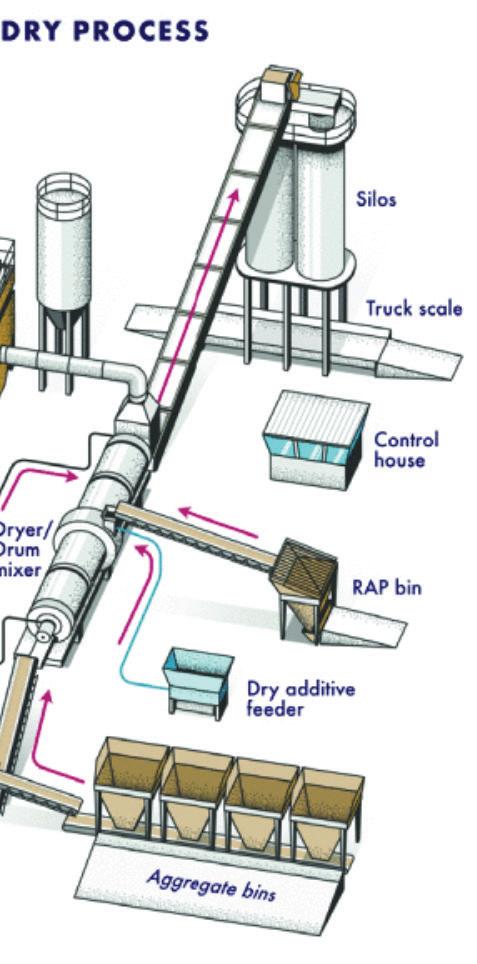

As a decades-long leader for asphalt plant innovation, Astec has introduced numerous products contributing to sustainability. From the Double Barrel® dryer/mixer introduced in 1988 to the debut of the high RAP Double Barrel XHR in 2016. In addition to these industry-changing products, Astec also leads in sustainability with our warm mix system, the V-PAC stack temperature control system, low emission burners, and blue smoke systems. Astec is well-equipped to carry our culture of innovation into the future. Our dedication to sustainability includes new product development teams and an on-staff product manager for sustainability.

Reach out to learn more about how we can help you meet your asphalt plant sustainability goals.

Sustainable Innovation

Sustainable Innovation

Brandon Noel, Editor bNoel@ACBusinessMedia.com 234-600-8983

A Double Edged Sword: Artificial Intelligence

hear, AI tools are not one-size-fits-all, in fact, they are just the opposite. How the models are “trained” influences the final results.

EDITORIAL Editor Brandon Noel bnoel@acbusinessmedia.com

Contributing Editor Jessica Lombardo Jlombardo@acbusinessmedia.com

Managing Editor Gigi Wood gwood@acbusinessmedia.com

Senior Editor, Construction Technology, IRONPROS Charles Rathmann crathmann@acbusinessmedia.com

Senior Editor, Equipment & Workwear, IRONPROS Michael Cheng mcheng@acbusinessmedia.com

AUDIENCE

Audience Development Manager Angela Franks

PRODUCTION

Senior Production Manger Cindy Rusch crusch@acbusinessmedia.com

Art Director April Van Etten

ADVERTISING/SALES

Brand Director Amy Schwandt aschwandt@acbusinessmedia.com

Sales Representative Sean Dunphy sdunphy@acbusinessmedia.com

Sales Representative Kris Flitcroft kflitcroft@acbusinessmedia.com

Sales Representative Tadashi Soma tsoma@acbusinessmedia.com

The first story I read about ChatGPT was about a man who fed all of his recently deceased wife’s digital communication (emails, text messages, etc.) into the artificial intelligence (AI) system, in order to have a final conversation with “her.” It was spooky. That was way back in early 2022, but at the start of this year, the rumblings around AI began popping up more frequently and in more mainstream outlets.

What started out as a slightly morbid curiosity with an analytical tool and it’s ability to mimic human speech patterns, quickly morphed the new herald for AI. Now, ChatGPT and similar platforms, are the definition of AI for many laypeople.

I bring this up in the pages of Asphalt Contractor, because I want all our readers out there to be cautious. Be shrewd in your dealings when it comes to the people that come selling the next AI-powered solution to all your problems, or the next AI tech that can double or triple your sales. There is no shortage of fancy smoke-and-mirror presentations that promise these sorts of things.

There are certainly some useful applications for AI, not just in the asphalt industry, but in the construction industry in general. Just be wary of the sales pitches from those not acquainted with the nuances of this industry in particular. Despite what you might

For the September issue, we have for you our annual Roller Spec Guide! This is a great opportunity for the roller-heads out there to geek out a little bit about all the nuances and variations between roller models and brands. A big CONEXPO year means a lot of shakeups and changes to manufacturer lineups.

This month is, also, historically an issue where we peer behind the curtain of quality control in mix production and all sorts of jobsite situations. Quality is a huge topic, and we have a great article by our senior technology editor, on loan from our IronPros.com platform, about the benefits of grade control.

I also spoke with a long time veteran of the asphalt industry, and board member of NAPA, who shed some light about the history of mix quality sampling. After our conversation I felt that, perhaps, it’s time to let go of gathering samples on-site behind the pavers. For lots of DOTs I imagine it’s controversial, but I felt he made a good case for at the plant testing.

I also did a deep dive into a recently released study about the potential of waste plastics in road pavement mix designs. Depending on how you feel about that topic already, you might be really mad at me, or you might feel vindicated. You’ll have to read to find out which. Remember to send any and all comments to bnoel@acbusinessmedia.com, because my door is always open!

See you on the road.

AC BUSINESS MEDIA

Chief Executive Officer Ron Spink

Chief Financial Officer JoAnn Breuchel

Chief Revenue Officer Amy Schwandt

Brand Director, Supply Chain & Green Industry Jason DeSarle

Brand Director, Construction Sean Dunphy

VP, Audience Development Ronda Hughes

VP, Operations & IT Nick Raether

Content Director Marina Mayer

Director, Online & Marketing Services Bethany Chambers

Director, Demand Generation & Education Jim Bagan

Content Director, Marketing Services ............... Jess Lombardo

CIRCULATION & SUBSCRIPTIONS

P.O. Box 3605, Northbrook, IL 60065-3605 (877) 201-3915 | Fax: (847)-291-4816 circ.pavement@omeda.com

LIST RENTAL

Sr. Account Manager Bart Piccirillo | Data Axle (518) 339 4511 | bart.piccirillo@infogroup.com

REPRINT SERVICES

Tadashi Soma (800) 538-5544 ext. 1267 | tsoma@ACBusinessMedia.com

Published and copyrighted 2023 by AC Business Media. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage or retrieval system, without written permission from the publisher. @ASPHALT-CONTRACTOR-MAGAZINE

8 ASPHALT CONTRACTOR SEPTEMBER 2023 www.ForConstructionPros.com/Asphalt

The biggest buzzword of 2023 continues to garner attention and money, but is it a gold rush or another tech bubble?

EDITOR’S PERSPECTIVE

@ASPHALTCONTRACTOR @ASPHALTCONTRACTOR @ASPHALTCONTRCTR Published by AC BUSINESS MEDIA 201 N. Main Street, Fort Atkinson, WI 53538 (800) 538-5544 • www.ACBusinessMedia.com

BUILDING BETTER ROADS MILLING Better Technology. Better Performance. Better Results. Trust BOMAG mills, pavers and rollers to help you build better roads. We focus on developing new technologies to make our equipment pe rform better, leading to reliable, top-quality results. Want to learn more? Talk to your nearest BOMAG Dealer today for a demo. www.bomag.com/us-en

Reasons to Improve Jobsite Connectivity

Jobsite connectivity is essential to ensure efficient project management, collaboration, and safety — ultimately leading to successful project completion within time and budget constraints.

Construction jobsite connectivity has become increasingly important during the past decade, as the construction industry has undergone a digital transformation. While digital technology has been used in construction for many years, recent advancements in mobile devices, sensors, and software applications have made it possible to connect workers, equipment, and stakeholders on the jobsite like never before.

The widespread adoption of smartphones and other mobile devices has made it easier for workers to access information and communicate with each other and their supervisors. Equipment sensors, telematics devices, and dashcam cameras monitor equipment usage, track materials, and collect data on worker productivity and safety. Cloud computing and the Internet of Things (IoT) have made it possible to store and share product data and documents more efficiently. More and more contractors are embracing digital technology to improve jobsite connectivity because of the many benefits, which include:

Workers communicate with other team members in real time, sharing plans, documents, and updates. Collaboration is crucial on a construction jobsite because many people work on the site, from architects and engineers to contractors and subcontractors. Each person brings expertise and knowledge to the project, and collaboration is necessary to ensure everyone is working toward the same goal. When everyone is on the same page, misunderstandings and errors are less likely to occur. With a connected jobsite, project managers can ensure that team members are working on the correct plan revision; if not, workers can be sent the appropriate plan sheet.

➋BETTER DECISIONMAKING AND PROBLEM-SOLVING

Many decisions must be made on a construction jobsite, such as what materials to use and when materials should arrive, budget allocations, and timelines. Decisions must be made quickly and accurately to ensure project success. As projects operate on tight schedules and

Jobsite

helps track equipment usage and performance, enabling preventative maintenance and repair to reduce downtime and associated costs.

@panuwat - adobe.stock.com

budgets, workers and managers must be able to jointly solve problems and issues quickly and easily. Good decisionmaking can control costs, manage time, maintain quality, ensure safety, and satisfy stakeholders.

➌TRACKING PROJECTS IN REAL-TIME

Workers can monitor progress, identify potential issues, and adjust plans when everyone is connected. This leads to more accurate project timelines and budgeting. Every stakeholder involved in the project has the most up-to-date information so that everyone is aware of plan changes, material issues, labor shortages, and other issues. Project managers can identify potential cost overruns and take corrective action early to avoid costly rework and mistakes.

➊MORE EFFICIENT COLLABORATION WITH CONSTRUCTION TEAMS AND MANAGERS

TECHNOLOGY MATTERS

connectivity

10 ASPHALT CONTRACTOR SEPTEMBER 2023 www.ForConstructionPros.com/Asphalt

The Bonus Round

SmoothRide from Topcon will give you that feeling of perfection in your paving. Load high-resolution, 3D scans into your pavers and milling machines to get an exact read on the road. You’ll pave faster, smoother and with stunning precision, so you can set the curve for your IRI scores. Operate in the black and earn your team extra green.

Make the smooth move to SmoothRide.

To learn more: SCAN HERE

SCAN DESIGN MILLING PAVING COMPACTION

When workers are remote, they can be alerted to changes in the plan, reducing the need to return to the office for updates. Mobile tools empower workers to document their work hours, record safety observations, monitor meter readings, and send maintenance requests. These tools allow crew members to clock in and out and submit information about their work. This information is submitted to payroll so workers are paid more quickly and accurately. Paperwork is reduced as digitized forms and documents are online.

monitored for usage and performance to ensure it is in the proper working order or needs to return to the shop for maintenance. Safety management software gives users instant access to safety meetings, toolbox talks, safety inspection forms, and certifications. Instead of carrying around paper certifications or having to call into the office for verification, the crew leader can use the software to quickly investigate each skill and see the physical copy of the certification and the expiration date. Hence, managers know their crew is completing tasks they are certified in. If there’s an incident out in the field or a potential danger to crews is identified, information can be broadcast to workers as soon as possible.

IMPROVE

The widespread adoption of smartphones and other mobile devices has made it easier for workers to access information and communicate with each other and their supervisors. OnStation

➐COST

A worker in a restricted or hazardous area can be alerted to use the proper safety equipment. Safety checklists can be digitized to ensure that all workers know and follow the required safety protocols. Equipment can be

Jobsite connectivity helps track equipment usage and performance, enabling preventative maintenance and repair to reduce downtime and associated costs. Equipment can be fitted with sensors to monitor mileage, time, run-time hours, and equipment odometers. Instead of using Excel spreadsheets and other paper documents, shop managers can establish and optimize preventative maintenance programs to ensure the equipment runs at peak performance and lasts longer.

ACCIDENTS

Materials and inventory can be tracked and monitored more efficiently, reducing the risk of overstocking or stockouts, leading to costly delays or waste. Jobsite connectivity leads to operational efficiencies and cost savings for improved project outcomes.

➑CREATES A SINGLE SOURCE OF TRUTH, SO CONTRACTORS GET PAID FASTER

When location-based documentation (notes, pictures, videos) from along a roadway is shared with project management, bills are more accurate, and users get paid the correct amount, on time, with less effort. Questions regarding the accuracy of bills are significantly reduced when contractor billing teams can validate and reference project-specific documentation that includes date, time, and station/offset stamps—better documentation results in more bills being approved and paid faster.

Jobsite connectivity is essential for construction firms to ensure efficient project management, collaboration, and safety, ultimately leading to successful project completion within time and budget constraints.

by Patrick Russo, CEO of OnStation and Rateb Almasri, senior product manager at HCSS.

For more information visit https://asph.link/connect

12 ASPHALT CONTRACTOR SEPTEMBER 2023 www.ForConstructionPros.com/Asphalt

➍INCREASED PRODUCTIVITY AS WORKERS CAN INSTANTLY ACCESS IMPORTANT INFORMATION, PLANS, AND RESOURCES WITHOUT LEAVING THE SITE, SAVING TIME AND AVOIDING DELAYS

➎ENSURING SAFETY AS WORKERS HAVE INSTANT ACCESS TO SAFETY PROTOCOLS, TRAINING MATERIALS, AND ALERTS THAT HELP REDUCE THE RISK OF ACCIDENTS AND INJURIES

➏

EQUIPMENT USAGE AND MAINTENANCE

SAVINGS THROUGH INCREASED COLLABORATION, PRODUCTIVITY, AND SAFETY, LEADING PROJECTS TO BE COMPLETED MORE EFFICIENTLY WITH FEWER DELAYS, ERRORS, AND

TECHNOLOGY

Equipment sensors, telematics devices, and dashcam cameras monitor equipment usage, track materials, and collect data on worker productivity and safety. OnStation

LEADING THE WAY

Weiler Material Transfer Vehicles lead the way with

The

weilerproducts.com

proven innovations to provide the lowest cost per ton of operation.

unmatched access for cleanout and maintenance. Innovative and reliable operator

Clam shell doors and full width drop down floors provide

friendly features such as paver hopper management system with distance to paver, storage hopper management and auto chain tensioning.

Variable speed elevator and conveyors meet production requirements while minimizing wear.

multiple, incremental

to

4th generation of

are

life.

E1650A

improvements

the

chains, sprockets and augers

retrofittable to all machines and provide increased wear

E1250C

E2850C E2860C

DESIGN, DETAILS, AND DURABILITY.

We’ve built our business and reputation through our unparalleled focus on equipment durability, attention to detail, and the ability to customize our products for each customer. We apply these foundations to our complete range of asphalt plants and asphalt plant equipment, designed for producers of all sizes.

10106 SMITH ROAD, FORT WAYNE, IN 46809 | (260) 672-3004 | ALmix.com

NEW PRODUCTS

StaCool Vests in Safety Colors

Superior Industries Portable Sentry HSI Closed Circuit Plant

The Portable Sentry HSI Closed Circuit Plant for material processing can process recycled concrete, reclaimed asphalt and pit run materials into valuable salable products. From a single feed, owners and operators will be able to produce up to four unique products. The closed circuit crushing and screening arrangement includes a 4250 Superior brand Sentry Horizontal Shaft Impactor (HSI). It is fed by a 48 x 18 Intrepid Vibrating Grizzly Feeder, which is equipped with interchangeable grizzly cassettes (bars, fingers or punch plates) to accommodate multiple applications. Additionally, a 2-deck Anthem Inclined Screen screens up to three material sizes. Returning material is fed back to the HSI via a patent pending recirculating conveyor, which centralizes the feed for full utilization and extended wear life of the crushers blow bars. Onboard, the cross conveyors are universally designed to be interchangeable, which means owners invest in fewer conveyors since they can be mixed and matched throughout the plant. The plant is equipped to accommodate line power but can also be outfitted with a diesel drive genset unit. Its transport weight, dimensions and axle configurations make it permissible for road travel throughout all of North America.

Features:

• Process recycled concrete and more into valuable products

• Produce up to four unique products from a single feed

• Recirculating conveyor centralizes feed, to extend life of HSI blow bars

• Rotate universally designed, interchangeable cross conveyors throughout the plant

• Accommodates line power, but can be outfitted with a diesel drive genset unitww

StaCool Industries offers the StaCool Vest Core Body Cooling System in luminescent safety colors, helping workers beat the summer heat while allowing Work Zone employees to stay safe. Fully adjustable models are available in safety yellow, orange and green to wear over normal clothing. Under-vests are also available, to be worn under other clothing. Micro-thin breathable materials provide wearers cooling and support mobility in worksites. ThermoPaks around the vest provide hours of cooling. A spare set of ThermoPaks is included with each StaCool Vest to extend cooling time when the initial set thaws. A thermal barrier is built in to minimizing the possibility of getting too cold.

MB Crusher MB-R800 Drum Cutter

The MB-R800 Drum Cutter enables precision cutting, as well as grinding compact materials on construction sites. The MB-R800 can be used for railway, airport, underwater work, tunnels, pipelines and road work. This attachment features a 40-in. cut width and a pick force of 25,003 ft. lbs. Designed for heavy machinery equipment, the MB-R800 offers an output torque of 10,000 Nm. Available accessories include a spare parts kit, fixed coupling, low set drum kit, full set drum kit, dust suppression kit, high oil temperature reducing device, as well as rock and asphalt pick kits.

Etnyre BIG ChipSpreader

• Variable width spread hopper

• 4-wheel drive

• 310 hp Cummins QSB

• 30 in. conveyor belts

• 5 in. gate openings

• Front hopper raise and lower system standard

• 14 in. auger

• 425/65R22.5-L tires

The variable width hopper hydraulically extends and retracts while spreading to cover the entire road and shoulder in one pass. Width is adjusted with a switch. Controls are located at both the driver’s seat and in a mobile control panel located at the right front station. Two independent spread hoppers. Width is variable on the left side, right side, or both sides at once. The hoppers retract with the flip of a switch. Ready for transport only seconds after finishing a job. No need to empty hoppers or remove parts. Available in four sizes: 9’/18’ System, spreads 1’ to 18’ 10’/20’ System, spreads 1’ to 20’ 11’/22’ System, spreads 1’ to 22’ 12’/24’ System, spreads 1’ to 24’.

16 ASPHALT CONTRACTOR SEPTEMBER 2023 www.ForConstructionPros.com/Asphalt

Formoreinformationvisit https://asph.link/asphalt

TRAFFIC PAINTS REPAIR PRODUCTS PAVEMENT SEALERS EQUIPMENT/TOOLS YOUR ONE-STOP SOURCE ONE-STOP YOUR ONE-STOP SOURCE ALSO AVAILABLE • Equipment Rental • Sport Surfacing Products Pavement Products & Equipment sealmaster.net | 800-395-7325 LOCATIONS NATIONWIDE

NEW PRODUCTS

Topcon Aptix

XL Specialized Trailers New Options for Guardian Trailer

XL Specialized Trailers has introduced new options for the XL Guardian 110 Hydraulic Detachable Gooseneck (HDG) trailer, a standardized construction trailer. The new line of options includes an 18-in. loaded deck height version and 60-in. axle spacing option.

“These new options are engineered with the same level of innovation and industry-leading performance as our highly popular and reliable Guardian trailer,” said Tom Hiatt, director of sales at XL. “Our team is excited to release these new options that are on track to meet our growing customer needs.”

In addition to the 22-in. loaded deck height option for the main bed, XL now offers an 18-in. loaded deck height option. Operators can adjust the height of the deck for diverse loads with a five-position variable ride height in the neck and manual ride height in the rear.

“We set out to create an option focused on lower deck heights, which are essential, especially in the northeastern U.S. where bridges tend to be lower,” continues Hiatt. “Our customers have a need for it, and we are happy to deliver it.”

The new 60-in. axle spacing option will be available on both the 18- and 22-in. deck heights. When this option is selected, the main deck will shift to 25 ft. to keep the 53-ft. overall length. This 60-in. option also meets various customer demands and can accommodate axle laws in the western U.S. and Canada.

In addition to the new options for the XL Guardian trailer, each aspect of this low-profile HDG lowboy was designed with the user in mind. It’s made to simplify the process of hauling construction equipment.

The Guardian trailer is 53 ft. long.

Topcon Positioning Systems has introduced Aptix, a new integration-platform-as-aservice (iPaaS) for managing heavy civil construction projects. Aptix integrates Topcon solutions with multiple third-party applications to automate and orchestrate data connections between the office and jobsite. It supports processes and generates insights for construction teams within one platform. Aptix automates and orchestrates the distribution of data, including machine control files, constructible models, project schedules and reports on actuals. It shows, in near real-time, the location of machines with the ability to aggregate as-built data from mixed fleet telematics. It provides real-time reports on people, materials, machines and carbon dioxide emissions, creating visibility for carbon footprint and sustainability initiatives.

Danfoss DM700 Display

Danfoss Power Solutions offers the DM700 display for use on construction work vehicles, including electric skid steers. The display can be found on the third-generation Elise 900 skid steer loader manufactured by FIRSTGREEN Industries (previously known as Kovaco Electric). The all-electric machine uses the display’s 7-in. screen with sunlight viewability and IP66/IP67 ingress protection ratings.

During the design phase of the third-generation Elise 900, FIRSTGREEN Industries customers requested a hard-mounted display instead of the previous control by mobile phone.

Situated in the top right corner of the Elise 900 cab, the Danfoss DM700 display is connected to the skid steer’s CAN bus system, providing reliable communication and high data throughput. The large screen area of the DM700 also provides visibility of machine information for the operator.

Using the display, users can set three profiles customized to the needs of various operators or working conditions, including travel speeds and hydraulic settings. The DM700 has the ability to display error messages and diagnostics.

LiuGong 6612E Single Drum Roller

The LiuGong 6612E Single Drum Roller facilitates soil, gravel or asphalt compaction for road construction and repair. This roller is powered by a 155-hp Cummins QSB4.5 engine and a hydraulic steering system.

Equipped with a single 83.85-in. drum, operators can access two amplitude settings on the machine. Cab features include joystick controls, a digital display and exterior LED lights.

Optional components are available for meeting specific operating or project requirements. An optional rotary beacon supports safety and visibility on busy jobsites, by generating a visible warning signal during use. Additionally, a compaction meter can be added to the 6612E to measure the density of soil or degree of compaction. Location-based monitoring via GPS is also available as an option.

18 ASPHALT CONTRACTOR SEPTEMBER 2023 www.ForConstructionPros.com/Asphalt

BUILDING AMERICA ONE ROAD AT A TIME

LEARN MORE AT WWW.LEEBOY.COM

Three Reasons To Abandon Sampling Behind the Paver

Is it time for serious change?

Certain aspects of quality control testing hasn’t changed all that much over the decades. While it is necessary and extremely important, when working with various Departments of Transportation (DOT) and, potentially, individual districts within a state, parts of the process might be overdue for an overhaul. When dealing with government bureaucracy, however, bringing about change is a lot easier said than done.

In most states, the DOT creates a document called the Schedule of Material Control which dictates the testing frequency (the number of tests), as well as the types of tests that must be conducted. In addition to that, there are also some state DOTs that work with the industry to create test summary sheets. These are basically a large table or spreadsheet that lists the asphalt and aggregate, requirements, or specifications on the left side. To the right are columns that describe a given test’s results.

“Those columns categorize the date, test number, sample time, number of tons represented, mix price, mix design

report number, project number, asphalt cement grade, aggregate products, aggregate sources, proportions, and QC actions, etc.” said Rob Kuehborn, Director of Materials and Quality at Central specialties incorporated in Alexandria, Minnesota. He, also, sits on the Board of Directors for the National Asphalt Pavement Association (NAPA). “There’s a lot of information on the test summary sheet. It is essentially a status report of how a given mix is complying, or not, with the properties it has to meet at a given point of production.”

Kuehborn speaks from more than three decades of experience working in the industry, and, specifically, when it comes to the process by which these tests are conducted. From his perspective, it is time to update the status quo, and ditch one method of sample obtaining once and for all.

TOOLS OF THE TRADE

The purpose of these quality control measures is to ensure the product stays within the compliance tolerances of the given specification. While most DOTs will create the worksheet templates and spreadsheets, the physical testing is mostly done by hand in an asphalt mixture labratory.

“Generally speaking, sampling isn’t extremely sophisticated. Samples are usually collected with shovels and buckets,” said Kuebhorn. “There are some more mechanically automated processes available for permanent plants, but they are generally not the norm, yet. Correct sampling methods are critical. Getting

a homogenous and representative sample can make or break the test results.”

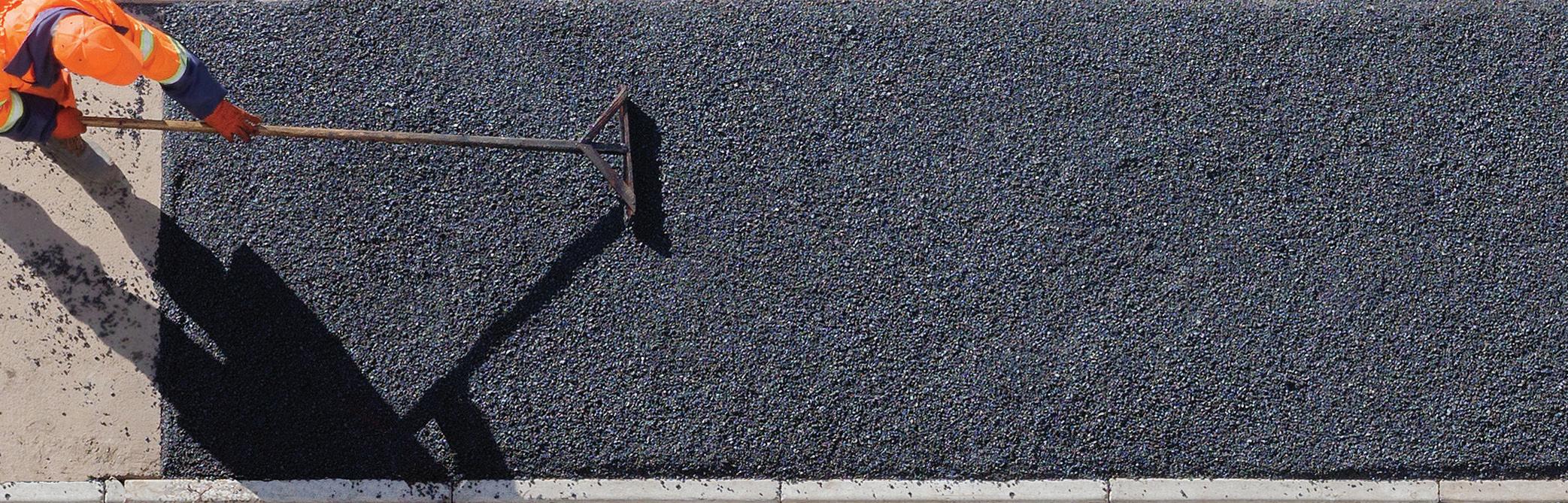

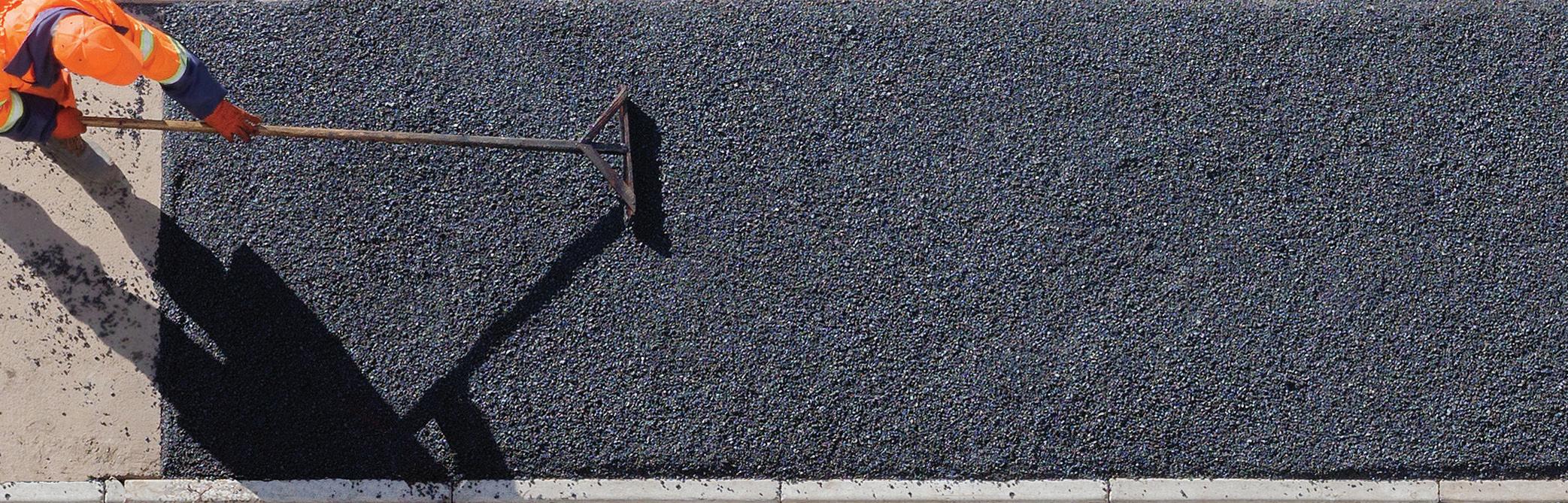

When it comes down to it, there are two primary locations where asphalt mix samples are obtained. The first is at the source itself, the asphalt plant where it’s produced. The other place where sampling occurs, and the one which many DOTs historically prefer, is right at the paver at the exact location where the asphalt mat is constructed or, sometimes, a sample is taken in front of the paver from the windrow, before it’s put into the hopper and through the paver itself.

Kuehborn argues the industry would be better off discontinuing sample collecting at the paving site.

SAFETY CONCERNS

Worker safety is always the primary concern when it comes to anything taking place in an active jobsite. Road construction can be particularly harrowing, and national statistics reveal that work zone related injuries, usually involving distracted drivers, an already unacceptable danger, and it’s on the rise.

“It’s extremely dangerous for technicians to go out on the road, often at night, in active construction, when they are between various pieces of the paving train that they are not normally part of,” Kuehborn said. “Also, they may not be seen by incoming and exiting haul trucks, which can be a particular hazard. Even parking in an active construction zone trucks has risks.”

Compare those risks to the relatively low-level risks involved with taking

PRODUCTION NOTES | By Brandon Noel, Editor

20 ASPHALT CONTRACTOR SEPTEMBER 2023 www.ForConstructionPros.com/Asphalt AdobeStock_237517205 AdobeStock_228402104

TOUGHEST CLEANING JOBS FOR THE

From busting up concrete to blasting away caked-on mud, grime, and oil, our line of rugged-and-tough machines are designed to keep your operation compliant and within budget, while ensuring worker safety and timeliness from the jobsite to the yard.

samples right at the point of production, the plant site. There’s a solid argument to be made to eliminate the chance of quality control engineers and technicians coming into harms way unnecessarily. With that in mind, why do some DOTs still require sampling be done at the construction site?

reason to reconsider this practice. But another significant drawback from this method is the delay between sampling and the testing itself. It’s not unusual for a sample to be collected and then followed by a forty-five minute drive back to the plant/labratory location. Depending on congested traffic and distances, that delay could easily stretch to an hour or beyond. That on top of the hour it typically takes to get lab results. Then, once it arrives, what if the test results reveal a problem that needs to be adjusted and corrected? Kuehborn’s perspective is tough to debate here.

in line at the same time, and if they’re not, you have to figure out how to get that one quality component back in-line without throwing the other ones out.”

It makes sense that those working to achieve that balancing act would prefer to have more timely data, and be able to respond quicker before more out-of-spec material potentially leaves the plant.

“Faster realized test results are definitely in the best interests of the buyer, the seller, and, ultimately, the tax payer,” he said.

According to Kuehborn, it might be rooted in a past distrust between DOTs and the industry. “There’s some agencies that still want their sample from the roadway, and unless they see it taken from it, they can be skeptical,” he said. The questions remains: couldn’t the DOT send its inspectors to the plants, and watch the samples being safely taken from a truck headed to the correct project site?

Some states’ districts have enough of what they call “plant monitors” to visually oversee the technicians doing their job which includes obtaining the samples. In a perfect world, this would be the majority of cases. In reality, however, there often aren’t enough DOT plant monitors to witness sampling at various plants within a given district, thus the requirement to get samples from the road and the hazards that come with it. Ultimately, though, sticking to this method isn’t just less safe. It could also be seen as having a negative impact on the asphalt mix quality itself.

DELAYED QUALITY CONTROL ACTIONS: TIME IS QUALITY IS MONEY

Obviously, to sample from behind the paver, putting a technician in a dangerous environment is one thing, and is a

“You’ve just wasted a whole lot of time which equals a whole lot of production,” he said. “If the mix was tested at the plant, you would know generally within an hour. Instead, you’ve lost an additional hour in an industry where you are producing anywhere from two to eight hundred tons per hour. That’s a lot of material, money, and quality at stake.”

For contractors, however, it’s not just time and material that are factors here, it’s also about the revenue on these projects. Many states utilize what are called “pay factors” where various quality indicators determine the contractor’s percent of unit price paid. These might include, but aren’t limited to: gradation, air void content, asphalt binder content, voids in mineral aggregate, adjusted film thickness (thickness of the AC coating on each particle),coarse and fine aggregate angularity, smoothness, density, etc.

“DOTs normally have Schedules of Mixture Adjustment Costs,” he said. “These schedules outline whether the unit cost of the mixture will be paid for with incentive (bonus), 100 percent (bid price), or disincentive (penalty). They often apply to many of these quality indicators. Achieving a certain level of compliance or non-compliance will dictate the level of price paid to the contractor. If the extent of non-compliance is severe enough, it can result in removal and replacement.”

“It’s a balancing act,” Kuehborn continued. “In a way, it’s like walking a tightrope. The various mix characteristics, smoothness, and desnity are all the basis of payment. They all have to be

DOING MORE HARM THAN GOOD

Major worker risk is enough reason to stop sampling at the paver site, but beyond safety, the delay in material adjustment response time, and the potential loss of payment, behind the paver sampling can also directly damage the new pavement itself. If the goal is to ensure consistent, on-spec, high quality, and long lasting pavements then broader implementation of plant sample procurement should be the way forward.

“Anytime you disturb the mat you’re creating inconsistencies,” said Kuehborn emphatically, who became quite passionate during this portion of the discussion. “Whether you take a two-by-two or a four-by-four square foot sample behind the paver, you’ve disturbed the integrity, density, and smoothness of what was laid down. Really, it could well be the first stage of a future pothole.”

Some people sample better than others, but you can never truly get the sample location in the same condition as that which was originally placed by the paver. You’ve dehomogenized the mix and left it in a less dense state. The rollers are unlikely to get the same density there as the rest of the mat. You may also create a bump. These are things that a lot of agencies don’t seemingly want to acknowledge.

22 ASPHALT CONTRACTOR SEPTEMBER 2023 www.ForConstructionPros.com/Asphalt PRODUCTION NOTES

AdobeStock_279377401

Rob Kuehborn contributed to this article beyond the quotes that appear.

For more information visit https://asph.link/wmjikv

THE POWER

Donnie & T.J. Reed, Madison Asphalt

Donnie & T.J. Reed, Madison Asphalt

TO CHOOSE

With ADM’s standard components, the choice is yours. We can customize any plant we make to your specific production needs.

“ADM helped with everything we needed to get the right plant for our business. From zoning ordinance restrictions to environmental testing, ADM was with us every step of the way.”

admasphaltplants.com

T.J. Reed, Madison Asphalt Madison County, NC

260-637-5729

60-425 TPH

Plants available from

With so many options available, purchasing a new piece of equipment that meets your needs is not an easy decision. If you’re in the market for a tandem roller, however, this is your best resource. Here, we’ve complied the industry’s only Tandem Roller Spec Guide, featuring equipment specifications for nearly 175 models. For an even easier way to compare, visit the exclusive, interactive and customizable version of this spec guide at http://www.forconstructionpros.com/specguide/ roller to sort and compare models based on your requirements.

HAMM (WIRTGEN GROUP)

HAMM compaction technology boosts paving contractor productivity and profitability. Its expanded series of DV+ rollers offers split drums for compacting tight radii with vibration front and back, or vibration-oscillation. The new HD+ 90i PH VV offers power hybrid technology, combining diesel engine for base load with hydraulic accumulator to meet peak loads, saving fuel, operating and maintenance expenditures. www.ForConstructionPros.com/10073218

*specs are for front vibratory drums only. See additional oscillation drum specs on website for more detail

26 ASPHALT CONTRACTOR SEPTEMBER 2023 www.ForConstructionPros.com/Asphalt

Model No. Engine HP (net) Operating Weight (lbs.) Drum Width (in.) Drum Diameter (in.) Amplitude (in.) Frequency (vpm) Centrifugal Force (lbs.) Notes HD 8 VV 21.8 3,506 31.5 24.4 0.017 / 0.017 2880 / 3,660 2475/ 3,825 vibration-vibration HD 10 C VV 21.8 3,704 39.4 24.4 0.015 / 0.015 2888 / 3,660 2475/ 3,825 vibration-vibration HD 10 VO 25 5,568 39.4 28.3 0.018 / 0.018 3,120 / 4,020 4.725 / 7,875 vibration-oscillation HD 10 VV 25 5,457 39.4 28.3 0.018 / 0.018 3,120 / 4,020 4,725 / 7,875 vibration-vibration HD 12 VO 25 6,075 47.2 28.3 0.018 / 0.018 3,120 / 4,020 5,400 / 9,000 vibration-oscillation HD 12 VV 25 5,942 47.2 28.3 0.018 / 0.018 3,120 / 4,020 5,400 / 9,000 vibration-vibration HD 12i VV 32.2 5,942 47.2 28.3 0.018 / 0.018 3,060/3,900 6,750/11,025 vibration-vibration HD 13i VO 50.1 9,338 51.2 35.4 0.012 / 0.020 3,060 / 3,600 8,775 / 14,400 vibration-oscillation HD 13i VV 50.1 9,184 51.2 35.4 0.012 / 0.020 3,060 / 3,600 8,775 / 14,400 vibration-vibration HD 14i VO 50.1 10,000 54.3 35.4 0.012 / 0.020 3,060 / 3,600 8,775 / 14,400 vibration-oscillation HD 14i VV 50.1 9,779 54.3 35.4 0.012 / 0.020 3,060 / 3,600 8,775 / 14,400 vibration-vibration HD+ 70i VO 74.2 16,383 59 45 0.014 / 0.025 2,880 / 3,480 15,525 / 18,900 vibration-oscillation HD+ 70i VV 74.2 15,832 59 45 0.014 / 0.025 2,880 / 3,480 15,525 / 18,900 vibration-vibration HD+ 70i VV HF 74.2 15,832 59 45 0.014 / 0.025 2,700 / 4,020 16.650 / 20,700 high-frequency vibration HD+ 80i VO 74.2 16,802 66 45 0.013 / 0.024 2,880 / 3,480 15,525 / 19,575 vibration-oscillation HD+ 80i VV 74.2 16,626 66 45 0.013 / 0.024 2,880 / 3,480 15,525 / 19,575 vibration-vibration HD+ 80i VV HF 74.2 16,626 66 45 0.013 / 0.024 2,700 / 4,020 17,325 / 20,700 high-frequency vibration HD+ 80i VV-S 74.2 17,331 66 45 0.014 / 0.020 2,520 / 3,000 14,175 / 14,175 vibration with split drums HD+ 90i VO 114 20,176 66 47 0.013 / 0.024 2,520 / 3,000 13,500 / 16,875 vibration-oscillation HD+ 90i VV 114 20,176 66 47 0.013 / 0.024 2,520 / 3,000 13,500 / 16,876 vibration-vibration HD+ 90i VV HF 114 20,176 66 47 0.011 / 0.019 2,700 / 4,020 15,075 / 18,900 high-frequency vibration HD+ 90i VV-S 114 21,234 66 47 0.016 / 0.024 2,520 / 3,000 17,550 / 18,900 vibration with split drums HD+ 90i PH VV 74.2 19,955 66 47 0.013 / 0.024 2,520 / 3,000 13,500 / 16,875 vibration with hydraulic hybrid drive HD+ 110i VO 114 21,885 66 47 0.019 / 0.032 2,520 / 3,000 22,275 / 27,000 vibration-oscillation HD+ 110i VV 114 22,711 66 47 0.019 / 0.032 2,520 / 3,000 22,275 / 27,000 vibration-vibration HD+ 110i VV HF 114 22,711 66 47 0.013 / 0.029 2,700 / 4,020 28,800 / 33,075 high-frequency vibration HD+ 120i VO 154 27,596 78 55 0.014 / 0.035 2,400 / 3,000 21,375 / 38,925 vibration-oscillation HD+ 120i VV 154 26,978 78 55 0.014 / 0.035 2,400 / 3,000 21,375 / 38,925 vibration-vibration HD+ 120 VV HF 154 27,684 78 55 0.011 / 0.028 2,700 / 4,020 33,075 / 38,925 high-frequency vibration HD+ 140 VO 154 28,257 84 55 0.013 / 0.034 2,400 / 3,000 21,375 / 40,500 vibration-oscillation HD+ 140 VV 154 27,816 84 55 0.013 / 0.034 2,400 / 3,000 21,375 / 40,500 vibration-vibration HD+ 140 VV HF 154 27,860 84 55 0.010 / 0.027 2,700 / 4,020 33,750 / 40,500 high-frequency vibration DV+ 70i VV-S 74.2 17,166 59 45 0.017 / 0.024 2,520 / 3,000 15,075 / 15,300 vibration with split drums DV+ 70i VO-S 74.2 17,232 59 45 0.017 / 0.024 2,520 / 3,000 15,075 / 15,300 split-drum vibration with oscillation DV+ 90i VV-S 99.7 21,014 66 47 0.016 / 0.024 2,520 / 3,000 17,550 / 18,900 vibration with split drums DV+ 90i VO-S 99.7 20,617 66 47 0.016 / 0.024 2,520 / 3,000 17,550 / 18,900 split-drum vibration with oscillation Sponsored by

For more information visit https://asph.link/i61dlr

HYUNDAI CONSTRUCTION EQUIPMENT AMERICAS

The Hyundai HR series tandem-drum rollers offer hydrostatic vibration system at both drums and automatic vibration mode (double / single vibration) – combined with front and rear scrapers to keep the drums free of material buildup.

www.ForConstructionPros.com/10073348

SAKAI

Sakai America specializes in asphalt rollers, soil rollers and light compaction equipment for the road paving and construction site preparation markets. Sakai is one of the compaction industry’s most experienced manufacturers and is known for its Japanese reliability, quality and operating simplicity. Long-life drum isolators, heavy-duty center-pin hitch and gear-driven drums limit down time for operators. 4,000 vpm high frequency vibration in both drums available.

www.ForConstructionPros.com/10074524

www.ForConstructionPros.com/Asphalt SEPTEMBER 2023 ASPHALT CONTRACTOR 27

Model No. Engine HP (net) Operating Weight (lbs.) Drum Width (in.) Drum Diameter (in.) Amplitude (in.) Frequency (vpm) Centrifugal Force (lbs.) SW354 24 6,525 47 27 0.012 4,000 6,520 SW354W 24 6,745 51 27 0.011 4,000 6,520 SW504 43 8,955 51 31 0.011 / 0.014 3,300 / 3,300 5,955 / 7,710 SW504W 43 9,260 54 31 0.010 / 0.013 3,300 / 3,300 5,955 / 7,710 SW654 73 15,585 58 42 0.011 / 0.021 3,000 / 4,000 13,940 / 15,510 SW654ND 73 16,250 58 42 0.020 vibe / 0.030 osc 2,940 / 2,940 15,285 vibe / 27,875 osc SW774 110 22,090 66 49 0.012 / 0.020 2,500 / 4,000 9,665 / 23,155 SW774ND 110 23,270 66 49 0.020 vibe / 0.024 osc 3,000 / 3,000 25,180 vibe / 30,800 osc SW884 130 28,415 79 55 0.013 / 0.025 2,500 / 4,000 14,160 / 39,790 SW884ND 130 29,165 79 54 0.022 vibe / 0.024 osc 3,000 vibe / 2,800 osc 35,585 vibe / 38,600 osc SW994 130 29,255 84 55 0.013 / 0.026 2,500 / 4,000 15,285 / 41,590 SW994ND 130 29,960 84 54 0.021 vibe / 0.022 osc 3,000 vibe / 2,800 osc 35,585 vibe / 38,600 osc CR271 16 3,245 35 22 0.014 4,000 2,965 R2H-4 73 30,955 83 (combined) 64 Static Static Static GW754 Vib. Tire 110 19,510 77 (overall) 38 0.004-0.029 2,400 1,350-13,040

Model No. Engine HP (net) Operating Weight (lbs.) (with ballast) Drum Width (in.) Drum Diameter (in.) Amplitude (in.) Frequency (vpm) Centrifugal Force (lbs.) HR25T-9 31 5,952 39 30 0.02 3,180 / 3,660 4,833 / 6,295 HR26T-9 31 6,393 47 30 0.02 3,180 / 3,660 5,620 / 7,644 HR30T-9 31 6,614 49 30 0.02 3,120 / 3,480 6,519 / 8,318

VOLVO CONSTRUCTION EQUIPMENT

Double-drum asphalt compactors from Volvo Construction Equipment offer features that support productivity, accuracy and sustainability. Many models have optional 8-amplitude settings, and the new DD25 Electric is a quiet, emissionsfree machine with performance greater than or equal to its conventional equivalent. Compact Assist, the Volvo Intelligent Compaction System, provides real-time density calculations as well as pass and temperature mapping. ActiveCare Direct, Volvo’s managed telematics program, focuses on simple case alerts rather than complex fault codes. www.ForConstructionPros.com/10075146

WACKER NEUSON

Wacker Neuson’s Pro-roller family includes the RD45 which offers a variety of operator-friendly features including an ergonomic work platform designed for low vibration and comfortable operation, excellent line of sight to the drums and work site, intuitive operator’s display with all functions clearly labeled and activated with the push of a button, and dual operator control lever for right or left hand operation of drive and activation of vibration/oscillation energy.

www.ForConstructionPros.com/10075166

28 ASPHALT CONTRACTOR SEPTEMBER 2023 www.ForConstructionPros.com/Asphalt

Model No. Engine HP (net) Operating Weight (lbs.) Drum Width (in.) Drum Diameter (in.) Amplitude (in.) Frequency (vpm) Centrifugal Force (lbs.) RD12L-90 20.8 2,964 35.4 22 0.043 4,200 3,400 RD18-80 19.8 3,483 31.5 24.4 0.02 3,900 5,620 RD18-100 19.8 3,681 39.5 24.4 0.02 3,900 5,620 RD24-100 24.8 5,456 39.5 28.4 0.02 4,020 10,341 RD24-100o* 24.8 5,566 39.5 28.4 2,340 10,341 / 9,000** RD28-120 24.8 5,941 47.3 28.4 0.02 4,020 11,690 RD28-120o* 24.8 6,073 47.3 28.4 2,340 11,690 / 9,000** RD40-130 49.3 8,741 51.2 35.5 0.02 3,600 14,400 RD40-130o* 49.3 8,851 51.2 35.5 2,340 14,000 / 16,200** RD45-140 49.3 9,579 54.4 35.5 0.02 3,600 14,387 RD45-140o 49.3 9,777 54.4 35.5 2,340 14,000 / 16,200**

Model No. Engine HP (net) Operating Weight (lbs.) Drum Width (in.) Drum Diameter (in.) Amplitude (in.) Frequency (vpm) Centrifugal Force (lbs.) DD15 16.4 3,372 35.4 22 0.015 4,000 3,500 DD15 (wide drum) 16.4 3,601 39.4 22 0.016 4,000 4,000 DD25B 25 5,545 39.4 27.6 0.021 3,300 / 4,000 5,732 / 8,430 DD25B (wide drum) 25 5,776 47.2 27.6 0.0197 3,300 / 4,000 6,227 / 9,127 DD30B 49.6 6,839 49.2 29 0.015 4,000 8,005 DD35B 49.6 8,185 54.1 29 0.013 4,000 8,005 DD105 114 22,051 66.1 48 0.02 / 0.03 2,400 / 3,000 22,256 / 25,179 DD105OSC 114 21,718 66.1 48 "Front Drum: 0.02 / 0.030 Rear drum: .0539" "Front drum: 2,400 / 3,000 Rear drum: 2,340" "Front drum: 22,256 / 25,179 Rear drum: 32,373" DD110C 148 24,355 67 51 0.010 / 0.025 3,800 16,240 / 41,170 DD120C 148 27,700 79 55 0.014 / 0.0349 3,000 / 4,000 30,020 / 42,070 DD120C (8 amplitude) 148 27,700 79 55 0.0149 / 0.0276 3,400 22,980 / 42,680 DD128C 148 28,430 79 55 0.0033 / 0.03 3,000 / 4,800 11,750 / 41,790 DD140C 148 30,486 84 55 0.0139 / 0.0346 4,000 / 2,700 36,680 / 41,720 DD140C (8 amplitude) 148 30,486 84 55 0.0129 / 0.0249 3,200 21,810 / 42,170

* Oscillating drum; ** Oscillation force

Sponsored

by

The right paver for every application

WORLD TESTED. CONTRACTOR APPROVED: As the global leader in paving technology, we‘ve seen just about everything there is to see. In every climate, every condition, every twist, turn and terrain. And we put that world of experience in your hands, so you can experience exceptional performance and results at every phase of the paving process.

www.wirtgen.com

WIRTGEN AMERICA, INC. · 6030 Dana Way · Antioch, TN 37013 · Telephone: (615) 501-0600 A WIRTGEN GROUP COMPANY

BOMAG AMERICAS, INC.

BOMAG offers three different types of vibrator/ exciter systems – standard, TanGo oscillation and Asphalt Manager directional vibration – to meet customer needs.

30 ASPHALT CONTRACTOR SEPTEMBER 2023 www.ForConstructionPros.com/Asphalt Standard (circular excited) vibration Model No. Engine HP (net) Operating Weight (lbs.) “Operating Weight (lbs.) w/ ROPS” Drum Width (in.) Drum Diameter (in.) Amplitude (in.) Frequency (vpm) Centrifugal Force (lbs.) BW900-50 20.0 - 2,646 35.4 22.0 0.020 4,200 3,372 BW90AD-5 20.2 - 3,527 35.4 22.8 0.020 2,520 / 3,780 1,776 / 3,867 BW100ADM-5 20.2 - 3,748 39.4 22.8 0.016 2,520 / 3,780 1,776 / 3,867 BW100SL-5 24.8 - 5,181 39.4 27.6 0.020 4,320 1,709 / 7,644 BW120SL-5 24.8 - 5,512 47.2 27.6 0.020 4,320 2,023 / 8,992 BW100AD-5 33.0 - 5,512 39.4 27.6 0.020 3,780 / 4,020 6,744 / 7,644 BW120AD-5 33.0 - 5,953 47.2 27.6 0.020 3,780 / 4,020 8,093 / 9,217 BW135AD-5 45.7 - 8,929 51.2 35.4 0.020 3,000 / 3,360 8,700 / 10,858 BW138AD-5 45.7 - 9,921 54.3 35.4 0.020 3,000 / 3,360 10,116 / 12,814 BW141AD-5 * 74 15,212 14,881 59.1 43.3 0.009 / 0.028 4,200 / 3,000 11,911 / 17,754 BW151AD-5 * 74 16,755 16,424 66.1 43.3 0.009 / 0.026 4,200 / 3,000 11,911 / 17,754 BW154AD-5 74 18,298 17,967 66.1 43.3 0.012 / 0.024 3,300 / 2,700 14,608 / 20,001 BW161AD-5 * 127 22,046 21,605 66.1 48.0 0.016 / 0.031 4,020 / 3,000 24,046 / 25,844 BW190AD-5 * 127 26,566 26,125 78.3 48.0 0.012 / 0.034 4,200 / 3,000 23,822 / 35,957 BW191AD-5 * 141 29,763 29,322 78.3 55.1 0.010 / 0.029 4,200 / 3,000 23,822 / 35,957 BW206AD-5 * 141 31,085 30,644 84.1 55.1 0.010 / 0.028 4,200 / 3,000 23,822 / 35,957 TanGO Oscillation BW161ADO-5 * 127 21,385 20,944 66.1 48.0 0.016 / 0.031 4,020 / 3,000 24,046 / 25,844 BW190ADO-5 * 127 25,574 25,133 78.3 48.0 0.012 / 0.034 4,200 / 3,000 23,822 / 35,957 BW191ADO-5 * 141 29,542 29,101 78.3 55.1 0.010 / 0.029 4,200 / 3,000 23,822 / 35,957 BW206ADO-5 * 141 29,763 29,322 84.1 55.1 0.010 / 0.028 4,200 / 3,000 23,822 / 35,957 Asphalt Manager BW151AD-5 AM 74 17,417 17,086 66.1 43.3 0 - 0.035 2,760 0 - 28,316 BW161AD-5 AM 127 22,487 22,046 66.1 48.0 0 - 0.035 2,760 0 - 34,170 BW191AD-5 AM 141 30,644 30,203 78.3 55.1 0 - 0.032 2,760 0 - 46,520 BW206AD-5 AM 141 31,967 31,526 84.1 55.1 0 - 0.030 2,760 0 - 46,520 Pivot Steer BW154AP-4V 74 15,873 - 59.1 43.3 0.013 / 0.026 2,400 / 3,300 14,163 / 15,512 BW174AP-4V 100 20,283 - 66.1 48 0.008 / 0.018 3,600 / 2,700 13,713 / 17,985 BW154APO-4V 74 16,094 - 59.1 43.3 0.013 / 0.026 2,760 / 2,700 14,162 / 15,512 BW174APO-4V 100 20,944 - 66.1 48 0.008 / 0.018 2,760 / 2,700 13,713 / 17,985 BW154AP-4V AM 74 16,094 - 59.1 43.3 0-0.032 2,700 / 2,700 0-26,752 BW174AP-4V AM 99 20,944 - 66.1 48 0-0.029 2,700 / 2,700 0-32,822 BW154AP-5 74 15,653 - 59.1 43.3 0.016 / 0.029 3,600 / 2,820 19,102 / 22,706 BW174AP-5 100 20,724 - 66.1 47.2 0.014 / 0.024 3,600 / 2,820 19,327 / 22,706 BW154APO-5 74 16,094 - 59.1 43.3 0.016 / 0.029 2,820 / 2,820 11,690 / 22,706 BW174APO-5 100 21,385 - 66.1 47.2 0.014 / 0.024 2,820 / 2,820 11,915 / 22,706 BW154AP-5 AM 74 16,094 - 59.1 43.3 0 - 0.032 2,820 0 - 28,091 BW174AP-5 AM 100 21,385 - 66.1 47.2 0 - 0.033 2,820 0 - 35,732 BW174AP-5 HYBRID 74 21,385 - 66.1 47.2 0.020 / 0.009 2,820 / 2,820 8,318 / 19,109

www.ForConstructionPros.com/10072222

Search:

CATERPILLAR, INC.

Caterpillar has a wide range of compaction products designed to make customers more successful. An extensive Cat dealer network gives customers the best lifetime value from their equipment allowing them to focus on getting the job done. We build the machines that build a better world. For more information visit CAT.com. www.ForConstructionPros.com/10075307

on page 34

32 ASPHALT CONTRACTOR SEPTEMBER 2023 www.ForConstructionPros.com/Asphalt

Model No. Engine HP (net) Operating Weight (lbs.) Rolling Width (in.) Drum Diameter (in.) Amplitude (in.) Frequency (vpm) Centrifugal Force (lbs.) Notes CB1.7 24.7 3,538 35 22.5 0.019 4,200 3,057 CB1.8 24.7 3,825 39 22.5 0.019 3,900 3,057 CB7 100 17,615 59 44 0.012/0.026 3,200 / 3,800 11,982 / 17,603 Two Amplitude, Two Frequency vibratory system CB8 100 20,187 67 44 0.012/0.026 3,200 / 3,800 11,285 / 17,018 Two Amplitude, Two Frequency vibratory system CB10 120 21,642 67 47 0.012/0.032 2,400 / 3,800 15,692 / 15,871 Two Amplitude, Two Frequency vibratory system (Option 1) CB10 120 21,642 67 47 0.010/0.034 2,400 / 3,800 13,084 / 19,491 Versa-Vibe vibratory system operating on high frequency Rear drum oscillation system for CB7, CB10, CB13, CB15, CB16 0.044 2,400 – Standard drum CB13 142 27,557 79 51 0.026/0.030 2,520 16,950 / 19,963 Versa-Vibe vibratory system operating on low frequency CB13 142 27,557 79 51 0.012/0.016 3,800 17,422 / 23,222 Versa-Vibe vibratory system operating on high frequency CB13 142 27,557 79 51 0.012/0.019/0.026/0.032/0.038 2,520 7,800 / 24,728 Five Amplitude vibratory system CB15 142 28,958 84 51 0.022/0.026 2,520 16,950 / 19,963 Versa-Vibe vibratory system operating on low frequency CB15 142 28,958 84 51 0.010/0.013 3,800 17,422 / 23,222 Versa-Vibe vibratory system operating on high frequency CB15 142 28,958 84 51 0.016/0.026/0.033/0.037/0.041 2,520 12,409 / 31,069 Five Amplitude vibratory system CB16 142 31,941 84 51 0.022/0.026 2,520 16,950 / 19,963 Versa-Vibe vibratory system operating on low frequency CB16 142 31,941 84 51 0.010/0.013 3,800 17,422 / 23,222 Versa-Vibe vibratory system operating on high frequency CB16 142 31,941 84 51 0.016/0.026/0.033/0.037/0.041 2,520 12,409 / 31,069 Five Amplitude vibratory system CB2.5 48.2 5,546 39 28 0.51 3180/3840 4,592/6,696 CMV Optional CB2.5 GC 24.6 5,546 39 28 0.51 3000/3720 3,925/5,885 CMV Optional CB2.7 48.2 5,936 47 28 0.52 3180/3840 5,437/7,928 CMV Optional CB2.7 GC 24.6 5,936 47 28 0.52 3000/3720 4,646/6,968 CMV Optional

Continued

WEILER

When static compaction is required, the Weiler C310A, C307A and C303 perform in a wide range of applications with a splint front drum that enables the outer half of the drum to rotate faster than the inner half resulting in quick work on corners and curves, without mat tearing.

www.ForConstructionPros.com/10075409

www.ForConstructionPros.com/Asphalt SEPTEMBER 2023 ASPHALT CONTRACTOR 33

by CB2.9 48.2 6,415 51 28 0.50 3180/3840 5,559/8,108 CMV Optional CC2.7 48.2 5,718 47 28 0.52 3180/3840 5,437/7,928 CMV Optional CC2.7 GC 24.6 5,718 47 28 0.52 3000/3720 4,646/6,968 CMV Optional CB4.0 48.2 7,971 51 32 0.50 2700/3300 5,037/7,524 CMV Optional CB4.4 48.2 8,362 55 32 0.49 2700/3300 5,240/7,827 CMV Optional CC4.0 48.2 7,889 51 32 0.50 2700/3300 5,037/7,524 CMV Optional CB16 142 31,941 84 51 0.016/0.026/0.033/0.037/0.041 2,520 12,409 / 31,069 Five Amplitude vibratory system CB2.5* 48.2 5,546 39 28 0.51 3180/3840 4,592/6,696 CMV Optional CB2.5 GC* 24.6 5,546 39 28 0.51 3000/3720 3,925/5,885 CMV Optional CB2.7* 48.2 5,936 47 28 0.52 3180/3840 5,437/7,928 CMV Optional CB2.7 GC* 24.6 5,936 47 28 0.52 3000/3720 4,646/6,968 CMV Optional CB2.9* 48.2 6,415 51 28 0.50 3180/3840 5,559/8,108 CMV Optional CC2.7* 48.2 5,718 47 28 0.52 3180/3840 5,437/7,928 CMV Optional CC2.7 GC* 24.6 5,718 47 28 0.52 3000/3720 4,646/6,968 CMV Optional CB4.0* 48.2 7,971 51 32 0.50 2700/3300 5,037/7,524 CMV Optional CB4.4* 48.2 8,362 55 32 0.49 2700/3300 5,240/7,827 CMV Optional CC4.0* 48.2 7,889 51 32 0.50 2700/3300 5,037/7,524 CMV Optional

Sponsored

Model No. Engine HP (net) Operating Weight (lbs.) Drum Width (in.) Drum Diameter (in.) Amplitude (in.) Frequency (vpm) Centrifugal Force (lbs.) C307A 74 20,500 50 40/53 N/A N/A N/A C310A 74 26,580 50 40/53 N/A N/A N/A C303 24 5,700 38/44 30 N/A N/A N/A

CASE CONSTRUCTION EQUIPMENT

CASE E Series vibratory rollers feature a completely redesigned operator interface for intuitive operation and improved ergonomics. New control features include an electronic travel lever with an extended range of functions right at the operator’s fingertips, including RPM settings, drive settings, sprinkler system controls, parking brake and more.

www.ForConstructionPros.com/10072356

DYNAPAC NORTH AMERICA

Dynapac tandem asphalt rollers offer productivity, serviceability and optimized ergonomics. Operators achieve high-quality surface finishes through features such as soft starting and stopping to prevent unevenness or cracking.

www.ForConstructionPros.com/10072810

Continued on page 36

34 ASPHALT CONTRACTOR SEPTEMBER 2023 www.ForConstructionPros.com/Asphalt

by

Sponsored

Model No. Engine HP (net) Operating Weight (lbs.) Drum Width (in.) Drum Diameter (in.) Amplitude (in.) Frequency (vpm) Centrifugal Force (lbs.) DV23E 33.5 4,960 39.4 27.4 0.02 3,480 / 3,960 9,217 DV26E 33.5 5,490 47.2 27.4 0.02 3,480 / 3,960 10,566 DV36E 43.9 8,290 51.2 33.5 .016 - .024 2,460 / 3,300 11,668 DV45E 43.9 10,252 54.3 33.5 .016 - .024 2,460 / 3,300 12,949 DV36E 43.9 8,290 51.2 33.5 .014 - .022 2,700 / 3,420 11,240 DV45E 43.9 10,340 54.3 33.5 .014 - .022 2,700 / 3,420 12,364 DV209D 100 21,080 66 48 .013 - .0276 2,520 / 3,300 15,737 / 18,884 DV210D 100 22,930 66 48 .014 - .032 2,520 / 3,120 17,535 / 26,977 Model No. Engine HP (net) Operating Weight (lbs.) Drum Width (in.) Drum Diameter (in.) Amplitude (in.) Frequency (vpm) Centrifugal Force (lbs.) CC800 24 3,400 31 23 0.016 4,200 3,800 CC900 24 3,500 35 23 0.016 4,200 3,800 CC900G 19 2,800 35 23 0.016 4,200 3,800 CC900S 24 3,600 35 23 0.013 4,200 3,800 CC950 20 3,000 35 23 0.016 4,200 3,800 CC1000 24 3,700 40 23 0.013 4,200 3,800 CC1100 VI 35 5,300 42 27 0.02 3,660 / 3,960 5,600 / 6,500 CC1200 VI 35 5,700 47 27 0.02 3,660 / 3,960 6,500 / 7,600 CC1300 VI 50 8,600 51 35 0.008 / 0.020 3,240 / 3,660 4,700 / 8,500 CC1400 VI 50 9,500 54 35 0.008 / 0.020 3,240 / 3,660 4,950 / 9,675 CC2200 74 16,800 59 45 0.01 / 0.03 2,880 / 4,020 15,060 / 17,540

RISE TO MEET THE ROAD

© 2023 Caterpillar. All Rights Reserved. CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Corporate Yellow,” the “Power Edge” and Cat “Modern Hex” trade dress as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission. / ASPHALT PAVERS / VIBRATORY SOIL COMPACTORS / UTILITY COMPACTORS / ASPHALT COMPACTORS / ROAD RECLAIMERS / COLD PLANERS

job site demands your focus, your e ort and your abilities. With Cat® paving, rise to meet any challenge that comes your way. Trust the leader in paving to deliver superior equipment so you can complete work on time and on spec. Count on your local dealer for unmatched parts and service support to keep costs down and productivity up. When it comes to tackling what’s next in paving — from growing your business to adapting future technologies — we’re right there with you. Visit cat.com/risetomeettheroad to learn more.

Every

Sponsored by 36 ASPHALT CONTRACTOR SEPTEMBER 2023 www.ForConstructionPros.com/Asphalt Model No. Engine HP (net) Operating Weight (lbs.) Drum Width (in.) Drum Diameter (in.) Amplitude (in.) Frequency (vpm) Centrifugal Force (lbs.) CC2300 74 18,800 59 45 0.008 / 0.02 2,880 / 4,020 13,260 / 16,190 CC3200 74 17,000 68 45 0.01 / 0.03 2,880 / 4,020 16,880 / 20,250 CC3300 74 19,800 68 45 0.01 / 0.02 2,880 / 4,020 16,190 / 18,440 CC4200 VI 130 22,000 66 51 0.012 / 0.031 3,060 / 4,020 18,880 / 28,780 CC5200 VI 130 26,000 77 51 0.012 / 0.031 3,060 / 4,020 20,910 / 32,370 CC6200 VI 130 27,300 84 51 0.012 / 0.031 3,060 / 4,020 23,160 / 35,300 CO2200 74 17,000 59 45 0.011 / 0.027 (0.06 - Oscillation Drum) 2,880 / 4,020 (2,400 osc) 15,060 / 17,540 (23,100Oscillation Drum) CO4200 VI 130 21,830 66 51 0.012 / 0.031 (0.06 - Osillcation Drum) 3,060 / 4,020 (2,400 osc) 18,880/ 28,780 (27,450 - Osillation Drum) CO5200 VI 130 25,800 77 51 0.012 / 0.031 (0.06 - Osillcation Drum) 3,060 / 4,020 (2,400 osc) 20,910 / 32,370 (27,450-Osillation Drum) CO6200 VI 130 27,300 84 51 0.012 / 0.031 (0.06 - Osillcation Drum) 3,060 / 4,020 (2,400 osc) 23,150 / 35,300 (34,400-Osillation Drum) CC3300C 75 17,400 68 45 0.01 / 0.02 2,880 / 4,020 16,190 / 18,440 CC4200C VI 130 20,700 66 51 0.012 / 0.031 3,060 / 4,020 18,800 / 28,780 CC5200C VI 130 22,700 77 51 0.012 / 0.031 3,060 / 4,020 20,910 / 32,370 CS1400N 75 27,800 41.7 rear/ 22.4 front 59 Static Static Static CC1400 VI 50 9,500 54 35 0.008 / 0.020 3,240 / 3,660 4,950 / 9,675 CC1400C VI 50 8,600 54 35 0.008 / 0.020 3,240 / 3,660 4,950 / 9,675 CC1300 VI 50 8,600 51 35 0.008 / 0.020 3,240 / 3,660 4,700 / 8,500 CC1300C VI 50 8,200 51 35 0.008 / 0.020 3,240 / 3,660 4,700 / 8,500 CO2200 75 17,000 59 45 0.01 / 0.03 (0.06 - Oscillation Drum) 2,400 15,060 / 17,540 (23,100 - Oscillation Drum) CO6200 VI 130 27,300 84 51 0.012 / 0.031 (0.06 - Oscillation Drum) 3,060 / 4,020 23,150 / 35,300 (34,400-Osillation Drum) CC900S 24 3,600 35 23 0.013 4,200 3,800 CC900e 10 kW drive motor, 8.4 kW vibe motor 3730 35 23 0.016 3600 3060 CC1000e 10 kW drive motor, 8.4 kW vibe motor 3910 39 23 0.014 3600 3060 CC1100C VI 35 4,900 42 28 0.02 3,660 / 3,960 5,600 / 6,500 CC1200C VI 35 5,100 47 28 0.02 3,660 / 3,960 6,500 / 7,600 CC1300C VI 50 8,200 51 35 0.008 / 0.02 3,240 / 3,660 4,700 / 8,500 CC1400C VI 50 8,600 54 35 0.008 / 0.02 3,240 / 3,660 4,950 / 9,675 CC2200C 74 16,300 59 45 0.012 / 0.028 2,880 / 4,020 15,060 / 17,540 CC2300C 74 16,800 59 45 0.008 / 0.02 2,880 / 4,020 13,260 / 16,190 CC3200C 74 17,000 68 45 0.012 / 0.028 2,880 / 4,020 16,880 / 20,250 CC3300C 74 17,400 68 45 0.01 / 0.02 2,880 / 4,020 16,190 / 18,440 CC4200C VI 130 20,700 66 51 0.012 / 0.031 3,060 / 4,020 18,800 / 28,780 CC5200C VI 130 22,700 77 51 0.012 / 0.031 3,060 / 4,020 20,910 / 32,370

• CAPACITY: 40,000 lbs.

• 20 Ton Air Brakes

• 8 Degree Loading Angle Low Profile

• Trailer Weight: 8,380 lbs.

• Overall Width:102", Length: 31'4"

• Deck Length: 21’ Flat (model shown)

• 6’ Beavertail

• Deck Height: 34"

• Tires: Eight 215/75R17.5 (H)

• Brakes: Air (Full ABS System)

• Ramps: 72" Long x 22” Wide Range: 102" Max. 29" Min.

• Lighting:100% Sealed Wiring harness and L.E.D. Lights

Standard Features On All Easy Loaders

ONE PIECE CAST LUNETTE EYE

Tested @ 275,000# and wrap around nose plate. Standard on all trailers.

HIGH TENSILE MAIN RAIL

One piece and cold formed. CROSS MEMBERS pierced through Main Beam for lowest possible deck height and more unitized frame.

APITONG/COMPOSITE DECK

Durable Composite Decking is fastened to the crossmembers with bolts and deck washers making it easier to replace decking when required.

Eager Beaver WIDE TRACK AXLES: 98”

Some Competition - 92”

ALL WHEEL ABS with Spring Brakes on all axles. Standard on all air brake trailers.

SUMITOMO BRAND TIRES

National Dealer Supported. HUB PILOTED WHEELS

Outboard brake drums for easier maintenance.

th 76 6

ANNIVERSARY

1946-2022

Eage

m For a quote on any model, please call 800-257-8163

>>

rBeaverTrailers.co

20XPT

98” WIDTH 92” WIDTH HEAVY DUTY 2-SPEED PARKING JACK 70,000# static capacity. Standard on all 15-25 Ton trailers.

3-LEAF SUSPENSION Standard on all 15-25 Ton

ADJUSTABLE

trailers.

Simple,Fast,andConvenient!

GRADE CONTROL: Not Just for Earthworks Contractors

Excavators and other equipment with machine control are becoming a common sight on more types and sizes of projects.

JOBSITE INNOVATIONS |

by Charles Rathmann, Senior Editor, Construction Technology,

IRONPROS

CASE 38 ASPHALT CONTRACTOR SEPTEMBER 2023 www.ForConstructionPros.com/Asphalt

Construction equipment machine control vendors are making their products more affordable and accessible, and based on anecdotal accounts from contractors, they are finding rapid adoption in light commercial and residential settings.

New entrants in the market have sought to shave cost and complexity off of machine control by offering machine guidance solutions that provide an indication of where to dig based on a model but no blade or bucket control—akin to CAT Grade with 2D but as an aftermarket solution. Not to be outflanked, a new offering from Trimble delivers a similar minimalist approach, but also offers contractors a path to step up to a more fully-featured Trimble automation solution.

“This is machine guidance, and we are not automating the operation of the machine but are offering visual indicators for the operator,” Trimble Civil Construction Product Manager Jack Young said on the launch of the product at CONEXPO-CON/AGG 2023. “But not only can the contractor continue to use this system after upgrading into our automation solution, but we are offering a stepping stone into the more advanced technology. It is extremely buildable and very good. So it is not a dead end.”

Tommi Kauppinen, vice president of technology at Leica Geosystems’ machine control division, suggested his group, which is part of Hexagon, had focused on enabling adoption not just by launching products aimed at a broader market, but by helping contractors hasten the learning curve.

“We’ve invested in how-to videos that focus on the functional aspects of

our features and a new, state-of-the-art training facility at our headquarters in Denmark,” Kauppinen said. “This facility is dedicated to facilitating onmachine training, allowing our users to gain hands-on experience with our solutions. By providing immersive and practical training sessions, we aim to equip our customers with the skills necessary to optimize their utilization of our products in real-world scenarios. We have also simplified our software, making it even more user-friendly. We understand that ease of use is paramount for our customers, and our team of experts has worked to refine the interface and streamline the user experience.”

WHAT CONTRACTORS SAY ABOUT GRADE CONTROL

Efforts to make grade control affordable and accessible to diverse types of contractors seems to be working, according to accounts. Will Copp, principal of Knox Concrete Contractors, a commercial contractor with locations in Knoxville, Tenn., swears by the technology.

“I have found that using grade control on equipment is an absolute game changer in the construction industry,” Knox said. “The technology has revolutionized the way we approach projects by providing accurate and efficient grading solutions. By utilizing sensors and GPS systems, our machines are able to determine their exact location and adjust accordingly to match the desired slope or elevation of the project site. This not only saves time, but also reduces material waste and ensures precise results.”

Grade control also allows them to work in challenging terrain with ease, while maintaining high levels of productivity.

SEPTEMBER 2023 ASPHALT CONTRACTOR 39

“With the help of advanced sensors and GPS systems, contractors can now monitor and adjust their machinery’s position in real-time to ensure they are working at the exact level required by the project specifications.”

ER

— Austin Iron Fences Co-Owner John Ward

bins

“Overall, incorporating this technology into our workflow has greatly improved our efficiency and accuracy on all types of construction projects,” he said.

For Austin Iron Fences Co-Owner John Ward, grade control technology is an essential tool for achieving accurate and efficient results. The Austin, Texas-based contractor completes security projects, including technology-enabled gates and fences. “With the help of advanced sensors and GPS systems, contractors can now monitor and adjust their machinery’s position in real-time to ensure they are working at the exact level required by the project specifications. This not only improves accuracy but also increases productivity by reducing the need for manual adjustments or rework. The feature allows us to work smarter, not harder, saving time, money and minimizing errors. Whether we’re grading land for a new construction site, or laying down asphalt on a highway project, grade control technology has become an invaluable asset in improving our workflow efficiency.”

In Seattle, meanwhile, SEA Concrete Contractors co-owner Daniel Sarrero relies on grade control to execute residential and commercial concrete jobs, ranging from concrete slab foundations, driveways, patios, sidewalks and more around the Seattle area.

“As a contractor who utilizes grade control technology on my equipment, I am constantly impressed by the precision and accuracy it offers,” Sarrero said. “This innovative tool allows me to ensure that every aspect of a project is completed with the utmost attention to detail, from grading roads and excavation sites to laying foundations for buildings. The keyword plays a crucial role in this process as it enables me to set specific parameters for each job, ensuring that my machines operate within precise boundaries. With just a few clicks on my computer or mobile device, I can program my equipment to achieve millimeter-level accuracy—an impossible feat without this advanced technology. It saves time and increases efficiency on projects.”

Contractors working in a number of disciplines—even security contractors, are finding grade control an attractive investment, perhaps because operators are spending a smaller fraction of their time on the machine and become more efficient than a more

40 ASPHALT CONTRACTOR SEPTEMBER 2023 www.ForConstructionPros.com/Asphalt

JOBSITE INNOVATIONS coldfeed

www.tarmacinc.com contact tarmac at 816-220-0700 or info@tarmacinc.com We’ve Updated Our Website!

experience and dedicated operating engineer.

“I’ve found that using grade control technology is an essential tool for achieving accurate and efficient results,” Ward said. The contractor performs security projects, including technology-enabled gates and fences. “With the help of advanced sensors and GPS systems, contractors can now monitor and adjust their machinery’s position in real-time to ensure they are working at the exact level required by the project specifications. This not only improves accuracy but also increases productivity by reducing the need for manual adjustments or rework. The feature allows us to work smarter, not harder, saving time, money and minimizing errors. Whether we’re grading land for a new construction site or laying down asphalt on a highway project, grade control technology has become an invaluable asset in improving our workflow efficiency and delivering highquality results to our clients every time.”

GRADE CONTROL EVOLUTION

Even as the technology has become indispensable, vendors are not sitting still as they continue to invest in adding value to the products. Grade control is, for instance, being augmented by horizontal steering control for the machine itself. It is also a popular option on widely-used equipment classes like compact skid steers and compact track loaders.

For more information visit https://asph.link/grade

Invigorate® additive is that much better.

After two years of testing the top asphalt rejuvenators in mixes with 40% RAP, Invigorate beat the competition by 300%. For more information on the results, call us at 1-888-663-6980.

www.ForConstructionPros.com/Asphalt SEPTEMBER 2023 ASPHALT CONTRACTOR 41

asphalt-auto-automotive/Pexels

colorbioticsasphalt.com

Brandon Noel, Editor

IT’S COMPLICATED: ASPHALT + PLASTIC

A new study released by the National Academy of Sciences, Engineering, and Medicine examines potential uses for the growing waste plastic problem and casts some doubt on any potential role it can play in asphalt pavement mix designs.

In a recent conversation about the asphalt industry with Charles Goodhart, executive director, Pennsylvania Asphalt Pavement Association (PAPA), he said, “Our industry has historically been seen as the dumping ground for other industrial sectors who have a lot of something they want to get rid of, and don’t know what to do with it.”

There are a lot of examples, as in:

ground up roofing shingles, sulfur, pulverized old tires, instances of asbestos was even used in some mixes, and even more recently in the news, the Florida state government is trying to make it legal to incorporate radioactive waste into their roads. Many have wondered if, and some have been hopeful that, waste plastic was the next big thing.

STRANGE BEDFELLOWS