JANUARY 2023 www.ForConstructionPros.com/Asphalt 2023 TOP INDUSTRY TRENDS ON SITE: REPAVING 14 TURNS OF RACING HISTORY TAKE OFFSEASON PLANT MAINTENANCE TO THE NEXT LEVEL

Discover the full line of SealMaster pavement products & equipment at sealmaster.net I 800-395-7325 THE ROAD TO PAVEMENT PRESERVATION Road Maintenance Products & Equipment with Proven Performance

SEALANTS

HOT-APPLIED CRACK SEALANTS

PRO MELTER/APPLICATORS

PRO MASTIC MACHINES

ROAD

CRACKMASTER

CRACK

CRACK

LIQUID ROAD

MASTIC MACHINE

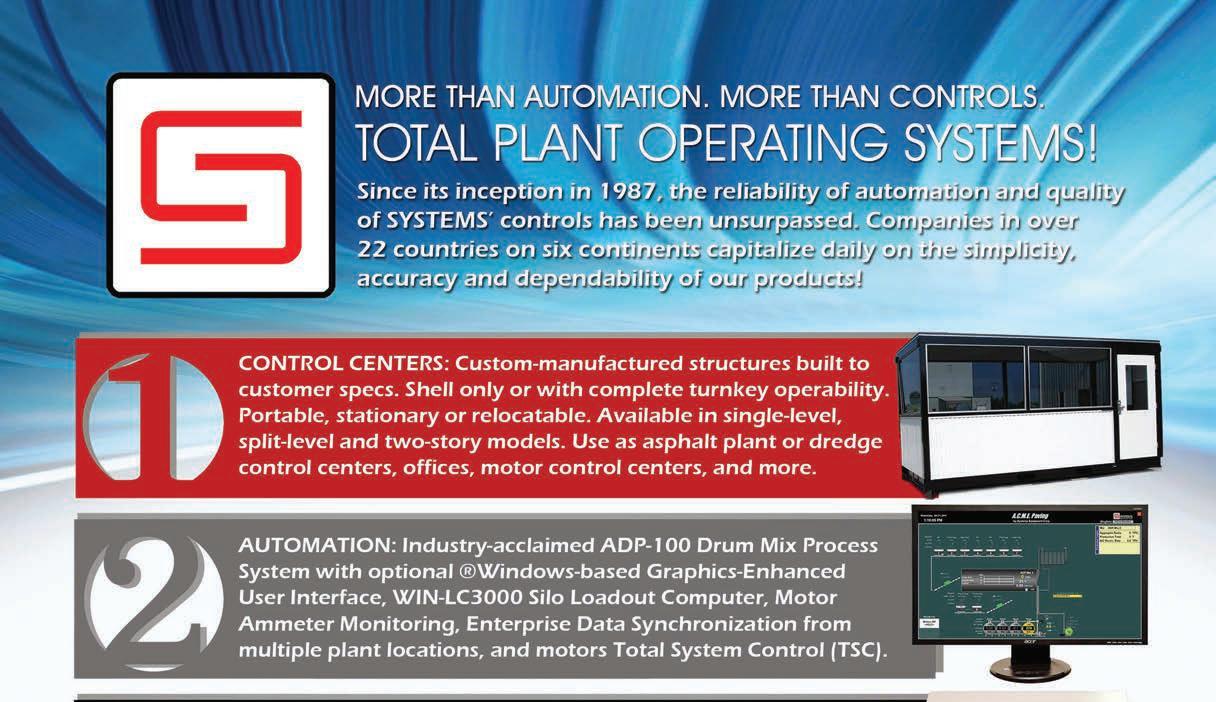

At Gencor® Gencor , we’ve led the industry with the most fuel-efficient, environmentally clean and lowestmaintenance design available to the hot mix industry. Gencor Industries remains focused on proactively serving and satisfying its customers from all aspects.

THE LEADER IN PERFORMANCE AND EFFICIENCY!

INDUSTRIES INC.

Call 407-290-6000 or visit www.gencor.com

Paving 14 Turns of Racing History

28 The Heat Is On

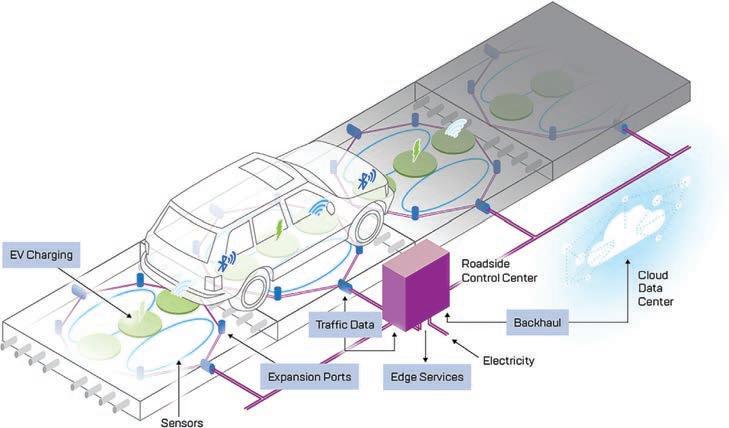

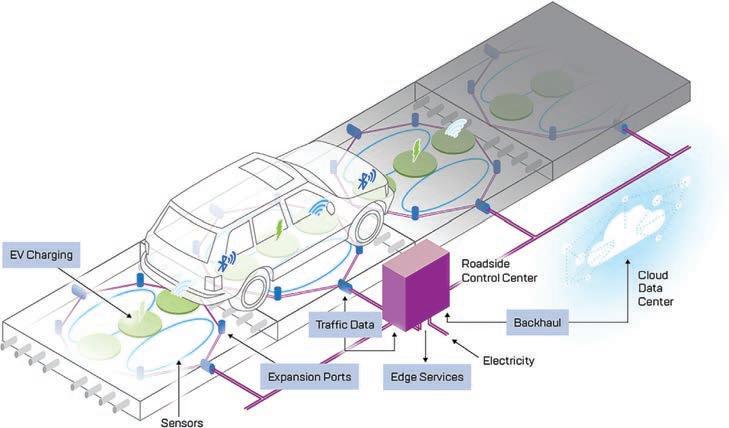

Smart pavements have the potential to transform roadways into support platforms for EVs, autonomous vehicles and, also, for data services. How can road builders utilize this emerging technology and what greater implications could there be?

With fuel and material prices on the rise, asphalt producers are finding it more challenging than ever to keep operating costs under control. Get current with efficient and cleaner heat sources at your plant.

38 Enhancing Pavement Preservation

In Minnesota’s most densely-populated county, the public works department operates hand in hand with the state DOT to expand research on pavement preservation.

4 ASPHALT CONTRACTOR JANUARY 2023 www.ForConstructionPros.com/Asphalt TABLE OF CONTENTS | JANUARY 2023

and copyrighted 2023 by AC Business Media. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording or any information storage or retrieval system, without written permission from the publisher. Asphalt Contractor (ISSN 1055-9205, USPS 0020-688): is published ten times per year: January, February, March/April, May, June/July, August, September, October, November, December, with an additional Buyer’s Guide issue published in August by AC Business Media, 201 N. Main Street, Fifth Floor, Fort Atkinson, Wisconsin 53538. Periodicals

paid at Fort Atkinson, Wisconsin and additional entry offices.

Published

postage

address to ASPHALT CONTRACTOR, PO Box 3605, Northbrook,

Printed in the U.S.A.

POSTMASTER: Please send change of

Illinois 60065-3605.

available (prepaid only) $10.00 each (U.S., Canada & Mexico), $15.00 each (International). 201 N. Main Street, Fifth Floor Fort Atkinson, WI 53538 (800) 538-5544 • www.ACBusinessMedia.com www.ForConstructionPros.com/Asphalt Published by AC Business Media. LATEST INNOVATIONS FOR ASPHALT PROFESSIONALS CONTRACTOR CONTRACTOR LATEST INNOVATIONS FOR ASPHALT PROFESSIONALS ASPHALT CONTRACTOR LATEST INNOVATIONS FOR ASPHALT PROFESSIONALS A sphalt LATEST INNOVATIONS FOR ASPHALT PROFESSIONALS CONTRACTOR CONTRACTOR LATEST INNOVATIONS FOR ASPHALT PROFESSIONALS ASPHALT CONTRACTOR LATEST INNOVATIONS FOR ASPHALT PROFESSIONALS A sphalt LATEST INNOVATIONS FOR ASPHALT PROFESSIONALS CONTRACTOR CONTRACTOR LATEST INNOVATIONS FOR ASPHALT PROFESSIONALS ASPHALT CONTRACTOR LATEST INNOVATIONS FOR ASPHALT PROFESSIONALS A sphalt CONTRACTOR JANUARY 2023 Vol. 37, No. 01 PRODUCTION NOTES 10 New Year, New Products A variety of new industry products on the market now. 12 Offseason Maintenance

SUBSCRIPTION POLICY: Individual subscriptions are available without charge only in the USA. The Publisher reserves the right to reject nonqualifying subscribers. One-year subscription to nonqualifying individuals: U.S. $45.00, Canada & Mexico $65.00, and $95.00 all other countries (payable in U.S. funds, drawn on U.S. bank). Single copies

offseason

plan is

your operation at

performance. TECHNOLOGY MATTERS

The

Make sure your

plant maintenance

keeping

peak

18

Information Super-Highway

SPECIAL REPORT

PRESERVATION UPDATE

Walbec

| 34 COVER STORY IN EVERY ISSUE

Last Exit

The

Group worked with Road America to repave the historic racetrack.

8 Editor’s Perspective 42

VISIT US AT $ ,,,coNEXPD Ill CD N /AG G March 14-18 2023 / Las Vegas NV Booth S-5754

Streamline Paving Operations with Accurate Bidding & Project Planning

Technologies are available to help contractors better manage their processes which can improve efficiencies and profitability

Read more at: http://asphalt. com/b7ltdc

Nominations Open for Asphalt Contractor’s Top 30 Editor’s Choice Products

For nearly a decade Asphalt Contractor Magazine has shared an annual list of the top 30 new, innovative and cutting edge industry products. This year, company’s can nominate their products for the award. Applications close Feb. 3, 2023.

Wirtgen Updates F-Series Compact Milling Machine Cabins

At the start of 2022 the Wirtgen group relaunched its compact milling machine line with a completely redesigned generation. Now they set their sights on major improvements to operator ergonomics with the new “comfort cabin”.

Read more at: http://asphalt. com/n6da3a

Heroes in Hardhats: Hiring Veterans in Construction

While veterans bring their skills to a wide range of industries, some find that construction is a fantastic fit for their interests and capabilities.

Read more at: http://asphalt.com/0fvb2d

Read more at: http://asphalt.com/wfxvol Get

How The Walbec Group Unites Multiple Divisions with Construction ERP

Combined contracting and construction materials conglomerate leverages HCSS, Command Alkon and CMiC.

Read more at: http://asphalt. com/jht7m0

www.ForConstructionPros.com/Asphalt

DIGITAL CONNECTION

social with us! Share pictures of what you’re working with over 29,000 other

contractors on our Facebook page: Facebook.com/ Asphalt.Contractor/ 6 ASPHALT CONTRACTOR JANUARY 2023 www.ForConstructionPros.com/Asphalt

asphalt

BUILT TO CONNECT

Sustainable Innovation

As a decades-long leader in asphalt plant innovation, Astec has introduced numerous products contributing to sustainability. From the Double Barrel® dryer/mixer introduced in 1988 to the debut of the high RAP Double Barrel XHR in 2016. In addition to these industry-changing products, Astec also leads in sustainability with our warm mix system, the V-PAC stack temperature control system, low emission burners, and blue smoke systems.

Astec is well-equipped to carry our culture of innovation into the future. Our dedication to sustainability includes new product development teams and an on-staff product manager for sustainability.

COME VISIT BOOTH C30235

MARCH 14-18, 2023 •

LAS VEGAS, NV

Reach out to learn more about how we can help you meet your asphalt plant sustainability goals.

Brandon Noel, Editor bNoel@ACBusinessMedia.com

Brandon Noel, Editor bNoel@ACBusinessMedia.com

It's Not What You Know

It's a complete cliché, right? But it is almost more relevant than ever before. Despite the increasingly connected, global and technologically-empowered nature of the world and, more specifically, our industry; the relationships that you build mean all the difference.

As I sit here writing this editorial for Asphalt Contractor, I'm less than 48 hours away from flying down to Clearwater, Florida, for the IGNITE Construction Summit. This will be the first industry conference that I've had the opportunity to attend since I joined the editorial team in June 2022. Am I nervous? Sure, a little bit, but I'm also really excited to start forging the kinds of relationships with contractors and business owners who are deep in the trenches of the work.

It also makes me more excited than ever for the upcoming NAPA annual conference and CONEXPO, where I will get to meet even more of the hard working men and women behind the road building and infrastructure side of the asphalt and paving world. I fully intend to work overtime meeting as many of you as possible. I want to learn from the readers of the magazine, and the many other professionals, whose wealth of knowledge and experience I can gleam from.

When I stepped into this role, I knew that the road to learning everything I needed to know wouldn't be accomplished overnight. I was also aware that trying to learn it all from sitting behind a computer screen, Googling things might result in some "book knowledge." However, I'm sure you know that is not going to deliver the kind of true-blue

valuable insight or in-depth knowledge that comes from real-world experience. There's only two ways to gain that level of know-how, you either have to live it first-hand or you have to learn from the people you know.

So, you're going to be seeing me in the months and years to come, and I want to extend this invitation to you. Let this be our ice-breaker, our formal introduction, because we are all colleagues. We want to see the industry succeed, grow and for all our boats to be raised with the tide, so to speak.

I've got a lot to learn, I need your help and I want to get to know it through all of you. Sometimes you can meet people who already know it all—but that isn't me. I'm curious and hungry to keep expanding my knowledge and my network, but I need you to make it happen.

If you aren't going to be able to travel to one of the trade shows or conferences this year, that's fine! You can always reach out and email me, we can set up a call or maybe even a meet-up if you're in my neck of the woods. My proverbial door is always open. I know everyone is always busy, but tell me about what your company is up to. Let me know what's around the corner. What kind of articles, research, reporting and insights are you most intersted in? When we grow and form new relationships, contractor-to-contractor, and contractor-to-editor, (and everything else between) everyone benefits.

EDITORIAL

Editor Brandon Noel bnoel@acbusinessmedia.com

Contributing Editor Jessica Lombardo jlombardo@acbusinessmedia.com

Managing Editor Gigi Wood gwood@acbusinessmedia.com

Technology Editor Charles Rathmann crathmann@acbusinessmedia.com

AUDIENCE

Audience Development Manager ........................ Angela Franks

PRODUCTION

Senior Production Manger Cindy Rusch crusch@acbusinessmedia.com

Art Director April Van Etten

ADVERTISING/SALES

Brand Director Amy Schwandt aschwandt@acbusinessmedia.com

Brand Director ..............................................................Sean Dunphy sdunphy@acbusinessmedia.com

Sales Representative ................................................... Kris Flitcroft kflitcroft@acbusinessmedia.com

Sales Representative ................................................. Tadashi Soma tsoma@acbusinessmedia.com

AC BUSINESS MEDIA

Chief Executive Officer Ron Spink

Chief Financial Officer JoAnn Breuchel

Chief Revenue Officer Amy Schwandt

Chief Digital Officer Kris Heineman

Brand Director, Supply Chain & Green Industry Jason Desarle

Brand Director, Construction Sean Dunphy

VP, Audience Development Ronda Hughes

VP, Operations & IT Nick Raether

Content Director Marina Mayer

Director, Online & Marketing Services ...... Bethany Chambers

Content Director, Marketing Services ...............Jess Lombardo

Director, Demand Generation & Education ............. Jim Bagan

Director, Enterprise Sales Kay Ross-Baker CIRCULATION & SUBSCRIPTIONS

P.O. Box 3605, Northbrook, IL 60065-3605 (877) 201-3915 | Fax: (847)-291-4816 circ.pavement@omeda.com

LIST RENTAL

Sr. Account Manager Bart Piccirillo | Data Axle (518) 339 4511 | bart.piccirillo@infogroup.com

REPRINT SERVICES

Tadashi Soma (800) 538-5544 ext. 1267 | tsoma@ACBusinessMedia.com

Published and copyrighted 2023 by AC Business Media. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage or retrieval system, without written permission from the publisher.

@ASPHALT-CONTRACTOR-MAGAZINE

8 ASPHALT CONTRACTOR JANUARY 2023 www.ForConstructionPros.com/Asphalt

EDITOR’S PERSPECTIVE

The old adage still holds true in 2023.

@ASPHALTCONTRACTOR @ASPHALTCONTRACTOR @ASPHALTCONTRCTR WWW.FORCONSTRUCTIONPROS.COM/ASPHALT Published by AC BUSINESS MEDIA 201 N. Main Street, Fort Atkinson, WI 53538 (800) 538-5544 • www.ACBusinessMedia.com

234-600-8983

10106 SMITH ROAD, FORT WAYNE, IN 46809 (260) 672-3004 www.ALmix.com DESIGN, DETAILS, AND DURABILITY. VISIT BOOTH S6816 MARCH 14-18, 2023 | LAS VEGAS, NV Come meet our team and see our asphalt plant equipment first hand.

BOMAG BM 2200/65 Half Lane Milling Machine

With its lighter, more compact and highly maneuverable design, the BOMAG 60,296-lb. BM 2200/65 halflane mill offers performance, operating ease and comfort for mills in its class.

• 58-in. milling radius improves machine productivity, increasing efficiency in tight-radius applications like small roundabouts

• Allows material to be efficiently discharged into trucks on both sides of the mill

• 630 hp engine effectively matches power with milling speed for greater operating efficiency

• To facilitate transport, the conveyor retracts to a length 23.6 in.

• BMS15L delivers up to 20% fuel savings, the design also extends holder service life to lower costs

www.ForConstructionPros. com/22263119

Earthwave FleetWatcher

Earthwave has integrated its e-ticketing functionality with OnStation to allow users to pinpoint the exact station location where each load of asphalt is placed on a jobsite. This new functionality automatically tracks the load from the time it is loaded at the asphalt plant, through its dumping into the paver on the jobsite. The exact station location becomes a part of the digital e-ticket, with no operator intervention required. Operators and transportation agency officials can know precisely on a jobsite where a specific load of asphalt was laid, so that if a future problem arises, they can investigate other parameters around that location

www.ForConstructionPros.com/22458560

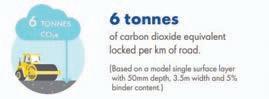

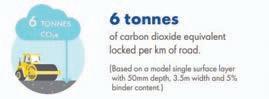

Shell Bitumen CarbonSink

Astec Industries GT2612V mobile high frequency screening plant

Astec Industries’ Materials Solutions Group has launched its newest mobile high frequency screening plant, the GT2612V.

• 2612V Vari-VibeTM high frequency screen

• A unique rotary tensioning system that allows for some of the quickest screen media changes on the market

• Deck-mounted, variable- speed hydraulic vibrators

• The high frequency screen can quickly and efficiently size crushed stone, recycled asphalt pavement, sand, gravel, coal & other materials

• A large hopper with a capacity of eight cubic yards

Volvo EC200E

The Volvo offers the EC200E 20-ton excavator for large-scale building and land projects. Designed for light- to medium-duty digging, its maximum digging reach is 32-ft., 9-in. with a maximum digging depth of 22-ft., 3-in. The excavator has a lifting capacity of 16,138-lbs. It also supports a variety of attachments and is equipped for quick couplers. Its size, versatility and price point make the Volvo EC200E excavator ideal for rental yards.

www.ForConstructionPros. com/22512547

www.ForConstructionPros. com/22405519

JCB Mobile Hydrogen Refueler

Shell Bitumen CarbonSink is a new biocomponent binder that locks carbon within roads instead of releasing it back into the atmosphere. The binder locks carbon into asphalt and bitumen, turning roads into technical ‘carbon sinks.’ As the asphalt is recyclable, most of this carbon will not re-enter the atmosphere, even at the end of its life.

• Reduces carbon footprint by 250kg carbon dioxide equivalent per tonne of bitumen based on the biogenic carbon component used

• Based on 5% binder content within the asphalt mixture

• Based on a model single surface layer with 50mm depth, 3.5, width, and 5% binder content

www.ForConstructionPros. com/22275668

JCB has unveiled a mobile hydrogen refueler. The mobile hydrogen refueler provides a way for customers to refuel their machines on site. Around 97% of construction machines have fuel delivered to them while working on site. This means customers are already accustomed to a transportable fuel, allowing refueling to take place in a matter of minutes. The first hydrogen-powered machine to be unveiled was a JCB backhoe loader, followed a year ago by a Loadall telescopic handler.

www.ForConstructionPros.com/22512754

10 ASPHALT CONTRACTOR JANUARY 2023 www.ForConstructionPros.com/Asphalt Formoreinformationvisit https://asph.link/orqb8o NEW PRODUCTS

INNOVATION EAGLE

There’s always something new at Eagle Crusher. Eagle Crusher consistently leads the industry in new product innovations and 2023 will be no exception. Join us at CONEXPO-CON/AGG, and see our newest equipment and technologies on display, including the UltraMax®1600X-OC Portable Impactor Plant and the 8x20 Screen Plant with Integrated Feed Conveyor and Blending Gates.

Learn about the many plant options for asphalt producers from our expert personnel in the booth. Outstanding plant options include onsite RAP systems for crushing and precise screening, allowing product consistency with a minimum of white rock and a minimum of fines. Also available are highly portable plant options for larger-sized jobs with high volumes of material at- or near-spec, allowing most to be removed before crushing to increase overall production and reduce wear.

JOIN US AT BOOTH C30949 800-25-EAGLE www.EagleCrusher.com TRUST THE STRENGTH OF EAGLE CRUSHER TM

The Often Overlooked Keys to Offseason Plant Maintenance

Make sure your offseason plant maintenance plan is keeping your operation at peak performance

Offseason plant maintenance is a critical process in the road to a successful and busy paving season. When things heat up, suppliers and contractors can't afford to lose precious time with breakdowns and operational downtime. Of course, you can't guarantee with absolute certainty those things won’t happen, but what proper offseason maintenance does do is ensure you've done everything in your power to make operations run as smoothly as possible.

There are a lot of available resources for regular offseason maintenance, including articles at ForConstructionPros.com, like one from former Editor Jessica Lombardo in 2020 [http:// asphalt.com/fi1fio], that covers the important essentials.

In this article, we reached out to some industry manufacturers to share with us what are the often overlooked, missed, and/or less common aspects of offseason maintenance that are easy to pass-over, but are tasks that are just as vital to keep updated.

BASELINE VISUAL INSPECTIONS AND WINTER PREPARATIONS

There are several basic items you can check off your list simply by taking a walk around, using common sense and checking for some of these points. Visual indicators of maintenance needs are some of the easiest ways to know when and where work should be performed. If you see something, take action and don't put things off. It is all too easy to put something in the back of your mind for later, and then “later” never comes. That can result in costly outcomes.

According to Daniel Francisco, Vice President of Service and Construction Service at Astec, "Routine plant inspections are the key to building and maintaining a preventative maintenance program. When performing these inspections, pay close attention to any visible signs of wear to the metal of your equipment caused by aggregate contact. These contact areas are where the aggregate slides, oscillates, scrubs or impacts the metal surfaces."

It's difficult when you’re in the busy days of the paving season to check on these potential wear-points, but in the slower, colder months, there should be adequate time to closely inspect your equipment. Year-over-year, you could even start taking pictures of the same important areas. This catalogue could be extremely useful in tracking visual changes that are harder to notice and recall on memory alone.

The service department from Asphalt Drum Mixers (ADM) said that, "Exhaust stack opacity should be checked, and if discolored, corrected. Then review scale calibrations, and if you notice the scales are out, calibrate them immediately. If drag chain tensions are loose, adjust them as needed, as well as conveyor belt tracking and tension. Drum tracking can also need some checking and regular adjustment."

John Hynes, Service Department Manager for Gencor Industries, shared a few checklist items that are a smart starting point ahead of frigid winter temperatures rolling into your area:

RexCon

PRODUCTION NOTES | BY BRANDON NOEL

12 ASPHALT CONTRACTOR JANUARY 2023 www.ForConstructionPros.com/Asphalt

Provide

Easy to change timing belt — only 2 working hours needed

Drum shell is made of highly wear resistant Hardox® steel, ensuring many hours of trouble free running

Record number of passes, potion, temperature and compaction value in real time with Dyn@Lyzer

Eco Mode and automatic idling saves up to 15% fuel while lowering noise level

dynapac.us | 800-651-0033 Designed to perform, Built to last Follow Dynapac North America

high-quality compaction in areas where vibration needs to be reduced with oscillation technology; bridge decks and joints, near foundations and concrete structures and better performance on thin asphalt layers. Industry’s best warranty for oscillation drum shell – 7 years / 7,500 hr pro-rated warranty

Large water tank to prevent more stops for refilling

Full seat rotation with electronic steering to improve comfort an ergonomics

• Place grease and shrink wrap plastic around exposed metal such as air cylinder rams, motor shafts and other components.

• Portable plant cables should be coiled up and placed on plywood then covered with tarps.

• Underground wires should be removed from areas near trapped sources of water, and sealed off from snow and ice build-up around openings.

• Equipment junction boxes should have small weep-holes drilled in the bottom to prevent condensation from accumulating inside of them.

• Gearboxes and equipment with large airspaces should be drained of oil and a corrosion inhibitor applied, such as VCI-105 oil by Daubert Chemical Company or similar product (VCI-105 does not need drained at start up).

• Make sure the drain in exhaust fan bottoms are clean and open.

• Place a cover over hot oil heater stack.

HEADACHES AND PAIN POINTS

There are always aspects of maintenance that are downright avoided, for one reason or another, because they are a major headache. Maybe they are time consuming. Maybe they require a lot of careful attention. Or, perhaps, they are just a complete "pain in the ass," as one contractor put it. These tasks get pushed to the back of the line, they get set on the back burner and saved for last.

If that happens enough times, it can inevitably mean that they don't get done at all. Before too long, it might spell unexpected down time, repair costs and lost revenue. It's called the "gutter effect," as in, if you don't clean out the gutters on your home, eventually you will pay the gutter price. Better to bite the bullet and get these done sooner, rather than later.

Astec's Francisco reported a few of these to us, "The drum, drag/traverses and silos are the most difficult areas to perform maintenance on. The maintenance of these areas of the plant is often planned for winter maintenance or scheduled shutdowns.

Delaying the needed maintenance in these areas will lead to significant downtime, loss of production and safety concerns."

ADM's service department said that, "It's definitely the bearing lubrication. To predict when the bearing will fail is difficult. When the bearing does fail, however, the down time or, as some say, the 'lost time' will be a major issue."

"Before the winter shut down," said Gencor's Hynes, "while the plant is operational at its highest capacities, a list of equipment on the plant should be available to record bearings, gear box and motor temps at their normal levels. This will be a reference for later use, when getting ready to shut down in the winter."

In addition to that, Hynes added this list of common pain point items:

• Use a thickness gauge on silo sidewalls and cones

• Drum shell should also be checked for thickness

• Test new components purchased as spares to be sure they work before storing for future use—never assume that because it is new it will not fail.

TIPS FOR BUILDING A MAINTENANCE PROGRAM

If you don't already have a regularly scheduled maintenance program, whether for the off-season specifically or not, it is a good idea to get one planned and implemented as soon as possible.

As Carlos Machado, Business Development Manager from Ammann, noted, "Asphalt plant maintenance is always a hot topic between operators and the service team. Proper execution of maintenance plans allows customers to get the most out of their products."

He said that Ammann offers control systems solutions and integrated maintenance management systems for their products that, "Registered, structured and visualized directly in the control system screen. The maintenance tasks are supported with fixed periods of time, which can be scheduled based on the operating hours or on the material quantities processed in the plant."

It also includes dynamic messaging notifications to let operators know then it's time to perform certain tasks, as well as the possible risks of not doing them promptly.

RAP feed bin 14 ASPHALT CONTRACTOR JANUARY 2023 www.ForConstructionPros.com/Asphalt PRODUCTION NOTES

Ammann Gencor

www.meekerequipment.com BOOTH - Central Hall - C32553 PATRIOT HEATER Dependable. Reliable. Efficient. MEEKER PATRIOT HEATER Hot Oil Heater Features: • PLC Touchscreen Technology • “SABER” Stack Cuts Down Stack Temperatures and Saves $$$ • All Heaters Are Test Fired at Factory Before Shipping • Personal Service with Strong Commitment to Customer Satisfaction MARCH 14-18 2023 Scan to Learn More Mobile App Provides Remote Access to Heater Your Preferred Asphalt Equipment Resource 4381 Front Mountain Road Belleville, PA 17004 The Meeker Family (888) 333-0323 COMING SOON! Electric Hot Oil Heater Contact us today for details.

"If you are not using a softwarebased system," service reps for ADM said, "Reference the manufacturers’ equipment manuals regularly, and then install an hour meter, if one was not already provided and schedule all work required accordingly. Not just off-season but daily, biweekly, monthly, and yearly maintenances are also in the manuals."

And it's good to know that most manufacturer specific manuals and schedules can be found online, or by calling your plant manufacturer's customer service department, as well.

Hynes added that, "Recordation over the course of time for each plant will determine when maintenance is needed. When you have an issue, record how old the part was, what you replaced it with, and when it might need to be replaced again. Over time, you will have a list of when and what fails on your plant."

Putting your plan in place is also a function of the various other operations and demands on the job, so, as Francisco said, "Prioritize each of these events and estimate the required manpower, parts and time needed to complete each task. Document and record the maintenance you perform; this data collection will allow you to analyze and improve your maintenance program over time."

Tracking all of these things is vital. Knowing what has happened will help you know what will happen in the future and being able to predict the future is the key to avoiding catastrophic failures.

We asked the experts what are some the most common types of failures they encounter when dealing with their customers after a breakdown occurs.

Hynes said, "Trunnion adjustments should be monitored over the season. Any sign of flaking or other difference in the appearance of the tire or trunnion should be addressed ASAP."

"Bearing and gearbox failures are common failures at facilities that do not practice routine maintenance," Francisco told us. "These types of failures can easily be overcome, though, by establishing a robust maintenance program."

According to ADM's team, the most common issue they come across is that the programs themselves are simply underdeveloped, insufficient and the people in charge of them exhibit a sense of disregard for maintenance. That's a bad sign.

If a facility has the “Run it until it breaks mentality,” the cost of unplanned and/or emergency repairs due to the lack of maintenance will typically cost a minimum of 50% more than proactive measures. Being proactive minimizes untimely breakdowns and reduces the hectic nature of reactive repairs.

SIMPLE AND STILL IMPORTANT

Not everything that falls under your maintenance plan will be at the top of the priority list. Not everything should or can be equally as important; that wouldn't be a good list. It needs to be organized in such a way that you can plan around the job's importance to production and operations. By this logic, what are some of those bottom-of-thelist items that still should receive your attention once the top teirs are taken care of? What things can put your plant over the top?

"Some people may not consider this to be maintenance," Francisco said, "but good housekeeping around the facility is simple and is often overlooked. Good housekeeping practices enable maintenance personnel to quickly pinpoint potential problem areas and it establishes a safer work environment."

ADM's team said that it's, "Lubrication and lubrication type. So many will purchase the lesser expensive lubrication, a one-type-fits-all type and then experience bearing failures down the road."

And Hynes told us that, "Paint peeling or burnt looking areas at the stack of the drum happens due to vailing inside the drum and indicates the need for flighting upgrade or positioning.”

No matter where your current maintenance plan is, it is never a bad idea to take a fresh look at it and review possible improvements, changes and ideas to make it even better. Take this offseason and make it the year your team is more prepared for the spring than they've ever been.

For more information visit https://myfc.pro/af03g0

ALmix Astec Industries 16 ASPHALT CONTRACTOR JANUARY 2023 www.ForConstructionPros.com/Asphalt PRODUCTION NOTES

It takes a road to get there.

CLOSE TO OUR CUSTOMERS

And a world of experience to build that road. As the global leader in road construction and minerals processing technology, we‘ve seen just about everything there is to see. In every climate, every condition, every twist, turn and terrain. And we put that world of experience in your hands, so you can sustainably build North America’s infrastructure today, for future generations.

wirtgen-group.com

DEERE COMPANY

A JOHN

WIRTGEN VÖGELE HAMM KLEEMANN

THE INFORMATION

SUPER-HIGHWAY

Smart pavements have the potential to transform roadways into support platforms for EVs, autonomous vehicles and, also, for data services. How can road builders utilize this emerging technology, and what greater implications could there be?

The Infrastructure Investment and Jobs Act (IIJA) was a landmark piece of legislation, the impacts of which will continue to unfold and be felt for many years to come. One of the various programs and funding initiatives it put in place was the Biden administration’s plan for a national electric vehicle (EV) charging station network. At first glance, this plan doesn't appear to have a large effect on the contractors’ and business owners’ direct on-the-job, day-to-day activities. However, as the country slowly shifts to a greater reliance on EVs, the charging station network alone may not be able to sustain the eventual number of EVs on the road. Other innovations and solutions will need to be developed and implemented if an electrified future is to come out from the realm of science fiction and into the real world.

It is precisely within this eventual and expected "gap" that smart pavements want to step into the

conversation. Integrated Roadways provides merely one example of what is emerging as tool for connected cities. What are they? Well, they are probably pretty close to what you imagine when you consider other "smart" technology and devices on the market, which can likely be found throughout your home. It was probably inevitable; with the proliferation of smart TVs, smart watches, smart refrigerators, etc., it was only a matter of time before our roadways would become “smarter.” This concept and others like it, have been around for a lot longer than you may think.

A FUTURE WE REMEMBER

The aspiration of intelligent roadways

has an ambitious history. At the 1939 World's Fair in New York, General Motors featured its Futurama exhibit that astonished visitors with a vision of the "far future," where cars would navigate the highways at optimal speeds using automatic radio signals embedded within the roads themselves. It predicted this revolution would roll out by 1960. Incredibly, at the 1964 World's Fair, General Motors returned with a second iteration of the same exhibit, the "City of Tomorrow," with a forecast of a much more ambiguous timeline of the "near future." As was the case in 1939, visitors were delighted at the prospect of a world devoid of congested traffic jams and a possible an end to collisions.

18 ASPHALT CONTRACTOR JANUARY 2023 www.ForConstructionPros.com/Asphalt TECHNOLOGY MATTERS | BY BRANDON NOEL, EDITOR

Provided by Integrated Roadways

SUPER-HIGHWAY

pressing concerns of the time.

The biggest takeaway from that experiment was that contemporaries indicated there were many “apparent and unknown complexities” that would require new technologies to adequately address. At best, a 2030 to 2060 timeline was floated as somewhat reasonable, but others doubted it would ever be feasible. While electronic sensors and embedded monitors have been in wide use for data purposes for decades, the mid-century utopian vision remains elusive. Here we are, almost caught up to the predicted timeline of the 1990s. How close are we, and how do smart pavements like those produced by Integrated Roadways factor in?

WHERE'S MY JETPACK?

It's clear to see the line that can be drawn from the futurist conceptions of technologically-advanced roads to today's smart, Internet-connected pavements. Seemingly, technology has progressed to a sufficient level to deliver on the promises of the last century.

It's easy to see why this idea popped back up in a serious way in 1991 when the Intermodal Surface Transportation Efficiency Act authorized the U.S. Department of Transportation's (USDOT) Automated Highway System (AHS) development program.

The program resulted in a highly popular and successful demonstration in August 1997, which worked flawlessly on a segregated portion of the I-15 freeway over the course of four days. Further developments were scuttled less than a year later, when it was deemed too costly to continue in the face of other, more

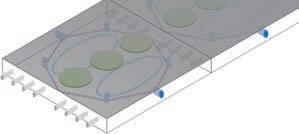

Tim Sylvester founder, CEO and Chief Technology Officer from Integrated Roadways spoke to us about the products his company are currently supplying, how they might fit within a road building contractor's repertoire, and whether we are poised for a true paradigm transformation. Naturally, our first question was to get a fix on what these smart pavements really are.

"Smart pavement is a modular, prefabricated paving system that contains sensors, communication elements, wireless charging, navigation and support for autonomy," he said. "It's all operated

by a micro data center that lives at the edge of the unit and provides a host of telecom capabilities for current communications like Wi-Fi, 4G, and 5G." But, according to him, that's just the beginning of what these systems can do.

"It also provides vehicle-specific things, like tire pressure monitoring systems, Bluetooth low energy systems, as well as being an integration point for IGS (Integrated Geotechnical Solutions) equipment, signals, digital signage and all of the other technology that means to live in the roadway. Really, it's converting the road into a managed service platform for next-generation mobility."

Let's step back a second and take a look at the Integrated Geotechnical Solutions (IGS) equipment that Sylvester mentioned and what it can mean for the industry beyond automation and EV charging.

According to their website, IGS is "A leading provider of monitoring systems, consultation services and risk management solutions...used in the construction, aggregate, subway, civil engineering, historic structures, mining and oil and gas exploration industries."

They provide services like compliance monitoring with turnkey solutions in the realms of surface cracking, dust, noise, soil movements, vibration, water and even weather. This made me wonder if the smart pavements were now smart enough, not only to communicate with the cars on the road, but whether or not this technology could benefit the road building industry in other ways.

IF ROADS COULD TALK

The plan for these prefabricated sections is to offer a broad range of applications,

www.ForConstructionPros.com/Asphalt JANUARY 2023 ASPHALT CONTRACTOR 19

Brighton Blvd Installation

including the roads telling contractors a lot more about their condition, erosion, performance and environment. Collecting precise data on traffic, weight, weather and more, the implications are pretty exciting. That's a lot of prospective technology going into the ground, but smart pavements are designed to mitigate some of that complexity in the way they’re designed and produced.

There are a host of potential benefits when systems like these are prefabbed, delivered on-site to be installed, rather than constructed on site. It becomes something any road building contractor could utilize.

Sylvester said, "It creates the opportunity to incorporate advanced technologies that are not feasible with site-based construction, due to the amount of time it takes, specialized labor, along with traffic and environmental concerns and risks."

The end result is a series of sensitive instruments that can take all these measurements, all these various data points previously mentioned, and turn them into useful probability models and, even more importantly, pavement condition index models.

At one end of the spectrum, it can be used to create predictive maintenance models that apply, not only to the section of the road where the prefab nodes are installed under the road, but, it can be applied to the surrounding roads connected to it.

At another point on the spectrum, the data can be utilized in the dynamic flow of traffic when connected to an automated traffic signal system. It is a

large leap past the traditional methods of traffic monitoring.

Sylvester explains how it works, "What we can do is take the entire local or regional network and feed that into a real-time traffic flow map that constantly adjusts the signal phases for the connected signals in order to provide those green light corridors and keep clumps of traffic flowing together as a group. It can make adjustments for leaders and stragglers, and prevent conflicts with cross traffic."

Both of these possibilities combined underlay a powerful tool for road builders and road construction contractors. When the traffic data about regular day-to-day patterns is taken into account and used alongside the maintenance modeling, it becomes a lot easier to plan detours, re-routes, lane closures and other adjustments for maximum efficiency. Contractors can have a better understanding of what drivers are doing on what days of the week, and know more precisely when the work will likely need to be done.

By showing the actual breakdown of traffic over time and by location, contractors can make decisions based on what's going to minimize the traffic impact. Planners can optimize construction phasing and the sequencing of when to do different lanes,just by having a better understanding of what traffic is where and when.

While not necessarily a one-to-one realization of GM's fantastical "City of Tomorrow" showcased in the 1960s, it definitely seems to have plenty of varied uses, and we haven't even talked much about the way it can wirelessly transmit electrical charge to EVs. That's arguably what opened the door to this conversation, and our interest in the technology as a concept, only to discover that it could offer a lot more on the back-end for contractors and city governments.

However, like all technological advances, it would be irresponsible to avoid deeper questions about other,

less-obvious implications all this new data creates.

A GREAT BIG BEAUTIFUL TOMORROW

There's a catchy song that plays during the “Carousel of Progress” ride at Disney World, a stage show that looks at the amazing technological history and advancement over the last century. It felt pretty dated even when I was growing up in the 1990s, but the final act of the show is a vision of the near future, what's “just around the corner.”

It shows examples of the kinds of tech you might imagine: virtual reality video games, advanced computers and even smart kitchen appliances. These are all things that we actually have in our homes today. What they don't sing about in the final verse, however, is how data collection and privacy issues would rise alongside these amazing advances, almost like its dark shadow.

Every new device that tech companies bring to market comes with two price tags. One is the upfront cost you charge to your bank account, and the second, and much more lucrative, is the vast sea of data the new, convenient software or device will collect about you. The most notorious of these, and the ones we are most dependent upon, are our smartphones. They are the closest analogue to the potential for data gathering, and its value to third parties, when it comes to what smart pavements could potentially know about you. This isn't to say that smart pavements are a bad idea.

As we've covered here already, they have a whole host of benefits to offer. Every person with an iPhone or Android in their pocket makes a decision everyday that the exchange of their data for the use of the device is acceptable, if not unavoidable. It is conceivable that between our smarter cars and smarter roads, a new data gold mine could be available for companies like Starbucks or McDonald’s, or even law enforcement, to access and exploit the same data that is a helpful tool to contractors and city managers. The data and its collection isn't inherently bad, of

20 ASPHALT CONTRACTOR JANUARY 2023 www.ForConstructionPros.com/Asphalt TECHNOLOGY MATTERS

RI-

--

THE POWER

Join Us In Booth S5467

Donnie & T.J. Reed, Madison Asphalt

With ADM’s standard components, the choice is yours. We can customize any plant we make to your specific production needs.

“ADM helped with everything we needed to get the right plant for our business. From zoning ordinance restrictions to environmental testing, ADM was with us every step of the way.”

TO CHOOSE

admasphaltplants.com

60-425 TPH

T.J. Reed, Madison Asphalt Madison County, NC

260-637-5729

Plants available from

course, but who is going to use it and to what end?

He explained, "When we do a contract with a public agency, we include in that contract a requirement that we cannot collect personally-identifiable information. We designed our system so that it does not know who you are. It makes inferences that are not attached to an individual person."

That's a good thing to know, and a great policy to have in place. However, Sylvester went on to explain just how compelling the data can be, even without the inclusion of your identity.

"The level of data that we can provide has an immense amount of value, even without knowing you as a person. We can get everything that's relevant without digging in beyond that," Sylvester said. "We can tell you what kind of vehicle it is, the make and model. We can even provide a demographic and socio-economic profile. That's a probabilistic model of who it might be, based on the population, ownership, and census details. We don't need to know an individual in order for the information to be useful. We really only need to know general characteristics so that we can build marketing audiences."

If we are going to realize a future where EVs are the dominant form of personal transportation, we will need smart pavements or something similar to them. This is even more true when it comes to the type of support that fully autonomous vehicles will no doubt require. But these questions and issues should be in front of contractors as they figure

out how to utilize, implement, or offer smart pavements.

FROM CONCEPTUAL TO APPLICABLE

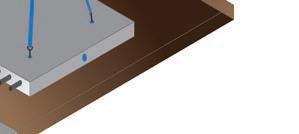

Security and privacy issues aside, there is a lot of applicability here for road building contractors, and the ability to be ahead of the curve in some areas. We asked Sylvester what he thought about the uses asphalt paving companies could have for what is essentially a precast concrete slab.

According to Sylvester, "Asphalt still has quite a large role to play in this environment. It's common to use asphalt as an underlay for precast, where you partially compact the asphalt and then you lay the precast down on top. Then we can just pull it out to reach the utilities underneath, which is why we think this is a great way for asphalt contractors to adopt wireless charging, because it helps them deliver what public agencies need without creating the unnecessary headaches. You really only need small segments of it right now. You might put it in an extremely high traffic area, such as immediately behind the stop bar of an intersection. It's not

uncommon to have asphalt roads with concrete intersections.”

Asphalt contractors know how to build roads, they do a fantastic job and smart pavements potentially provide a means for contractors of any stripe, to be able to add new technologies to the roadways they build without significant new investment on their part. It does possibly create significant new business opportunities to get involved in the future of mobility related to connected, electri, and autonomous vehicles.

Charging Station Alternatives

Above ground, standard charging stations cannot feasibly act as the sole solution to EV needs. There are situations where they are impractical, such as in larger cities and densely populated areas where owners might not have garages to install home chargers or where they might be subject to damage out in the open. These are real equity gaps for EVs that aren't just their mostly prohibitive retail costs.

The prospect of installing segments of wireless charging areas in the roadways makes it much more possible for people to access future electric vehicles, even if they don't have the ability to plug in where they live. Another benefit is that the system is completely invisible and effectively impervious to vandalism or the elements.

24 ASPHALT CONTRACTOR JANUARY 2023 www.ForConstructionPros.com/Asphalt TECHNOLOGY MATTERS

What About the Grid?

Since the announcement of the national EV charging station network plan, there's been a lot of fuss and grumbling over the current state of the power grid and it's ability to take on a growing fleet of electric vehicles in the United States. It's a fair question when states like Texas are experiencing rolling blackouts and issuing requests for citizens to utilize less A/C in the middle of the summer. Despite that reality, it appears that the EV demand would, on average, be mostly negligible.

According to a report by ClimateNexus the current U.S. fleet of approximately 2.5 million EVs uses less than .5% of the total energy output in 2021. Even if the number of EVs jumped 80%, it would only lead to an increased demand of 10%-15% on the grid. In addition to that, global electricity supply is projected to increase by at least 60% by 2026.

Smart pavements are currently

designed to tie into local electrical grids, but according to Sylvester, "They can be deployed anywhere it can benefit a community, and the core power draw is relatively low, which means that the system is agnostic to the source of its power. We believe that roadway power demands can — and should be — fully sustainable, especially as project sizes start to grow large enough to justify more innovative approaches."

Who Foots the Electric Bill?

The plan for many smart pavement design systems describe a world where those with traditional gasoline-powered vehicles will continue unaffected by the charging system (data collection will likely still be a factor even in non-smart cars). However, if you want to charge your EV at the red light, it will come in the form of pay-per-charge. That would take the form of a subscription service where the amount of charging your car receives is billed to your personal account.

THE MATRIX OR THE JETSONS?

Here at the end, reflecting on all the open questions and ideas that this product and concept make one consider, I want to speak more directly and plainly. I feel that's fair, if you've made it this far into a rather lengthy article.

Perhaps, I can leave you with a few thoughts to chew on for yourself rather than telling you whether or not a future of smart pavements is good or bad. That's not for me to decide anyways. That would be like trying to say whether an excavator was good or bad — they're just tools.

As it concerns the wireless charging aspect, I've already said and will reiterate here, it is likely an inevitable need if we are to overcome climate change and reduce the use of carbon based fuels. They could power not only our personal cars but charge electric public transportation. Likewise, as autonomous vehicles continue to improve, their success will

26 ASPHALT CONTRACTOR JANUARY 2023 www.ForConstructionPros.com/Asphalt TECHNOLOGY MATTERS JOIN US AT CONEXPO-CON/AGG MARCH 14-18, 2023 LAS VEGAS

RES

II #CONEXPOCONAGG CONEXPO CON / AGG #CONEXPOCONAGG2023 BOOTH #: C31332 Learn more and register at: www.conexpoconagg.com

Bearcat BC-502 Distributor Etnyre Var. Width Chipspreader

PavementSaver

only be further enhanced when they are able to communicate with the road itself. These are both net positives.

But something is still sticking in my brain about the "connected" nature of this platform, that I just can't shake. These final thoughts don't have to do so much with the road building or the contractor side or things, so I understand if this is where you decide to dip out.

When I was growing up in the 1990s, the Internet was coming into its own, and you needed to actually "log on" to use it. People referred to it as the "Information Super Highway.” That felt evocative. In retrospect, it felt like an exciting new tool. Now, it's such an integral part of our daily existence, and sometimes it seems like the tool we once used, has been turned around and pointed back at us.

Powerful and wealthy forces found ways to monetize and capitalize our every tap, glance and scroll. Our habits, our likes, our choices and

our movements about the web are bought, sold and traded invisibly between corporations looking to sell us something. If we knew what it would be like, would we have safe guarded the Internet's development as it matured into what it is today.

Perhaps we should pay attention, be involved, advocate for stronger personal data and privacy legislation. If I had to describe what the digital side of our world is like, I'm not sure I would use the language of a technological utopia. The exciting and optimistic ones that futurists once used to dazzle people with at the World's Fair. At times, it can seem more like a dystopia from some a sci-fi novel or film.

Personally, I don't enjoy the possibility of advertisements being pushed to the console screen of my car when the sensors detect I'm at a stop. No one is saying that's the plan, but if I'm considering it, you better believe that a marketing strategist for Arby's or Amazon

is. If I was working for McDonalds, I'd want to take this road data, pair it with the phone data, and direct potential Big Mac consumers to my drive-thru with precise wait times and coupons connected to the car itself.

It’s also concerning how law enforcement or other agencies might abuse their authority to peer into the data, or use algorithms and probabilistic profiles inappropriately. It's already happened with phones, cell towers and geofencing.

Despite all this, there are legitimately high hopes about smart pavement's positive potential. However, who would say that they like the way you have to watch badly-produced TV commercials while standing outside, pumping your gas? You know what I'm talking about. So, I'm dubious about where that ad-spend will go when people don't need to pump gas anymore.

For more information visit https://asph.link/9ywso6

Dependable, Economical, Available …

Since 1892, Homestead continues to be the most reliable manufacturer of asphalt valves. With cast iron and ductile iron material options, we offer a complete source of valves for any liquid asphalt application.

Our full line eted 2-way shutoff & 3-way diverter valves provide a ready solution to meet your flow requirements.

Homestead’s cutting-edge actuation design allows you to easily add actuators to your existing Homestead valves, in-line, without modification

Our fully stocked warehouse of valves and actuators offers you security in knowing that the valve you need is only a phone call away.

www.ForConstructionPros.com/Asphalt JANUARY 2023 ASPHALT CONTRACTOR 27 ® 610-770-1100 asphaltvalves.com Fax: 610-770-1108 sales@homesteadvalve.com ©2023 Olson Technologies, Inc. RIGHTRIGHTRIGHT RIGHTValve RIGHTPrice RIGHTNow! THE ASPHALT VALVE EXPERTS Valve Types Full Port – Standard Port 2-Way Shutoff and 3-Way Diverter Patterns 1"-8" Flanged and 1/2"- 4" Threaded Steam/Hot Oil Jacketed Transflo Plug Proportioning Plug Valve Materials Cast Iron – to 450° F Ductile Iron – to 650° F High Temperature Seals Actuator Types Pneumatic Electric Open-Close Modulating

The Is On

When choosing energy for asphalt heating, it’s important to look at the entire picture. Cost-per-unit of energy to heat asphalt and oil is certainly part of the puzzle — but it is not the only cost. Also important is the heater’s thermal efficiency. A small difference in efficiency can make a big difference in how much fuel a heater burns over its lifetime.

Supplied by PHCo

Supplied by PHCo

28 ASPHALT CONTRACTOR JANUARY 2023 www.ForConstructionPros.com/Asphalt SPECIAL REPORT | BY MARY MCCAIG

Supplied by PHCo

Get Current with Efficient and Cleaner Heat Sources at Your Plant

With fuel and material prices on the rise, asphalt producers are finding it more challenging than ever to keep operating costs under control. Add new environmental regulations and initiatives into the mix, and they have what might seem like an impossible mission — to not only find the most efficient and costeffective ways to run the plant, but also reduce or eliminate its emissions. There is an oft-overlooked aspect of asphalt production, however, that can make a difference in both realms — that of energy choices for heating asphalt and emulsions.

There’s no denying that energy costs contribute significantly to the operating costs of an HMA plant. But fuel choices can impact producers in more ways than just cost. And the form of energy they choose to heat their asphalt tanks, hot oil circulating systems and fuel oil preheaters can actually help producers reach their goals.

Typically, the first question operators have is what’s the cheapest form of energy for heating? The answer, unfortunately, isn’t simple — and it is dependent on several variables, including local energy costs and the age of the equipment. Operators often make energy choices for heating their plant’s components based on current energy pricing trends. But the cost of natural gas, LP gas, fuel oils and electricity have all fluctuated over the years.

Electric heaters are simple to install in most asphalt plants: A complete installation of the heater, plumbing, piping and electrical hookup can be completed two days or less. Low-watt-density electric heaters not only provide 100 percent efficient heat, but they also require little to no maintenance, further reducing a plant’s operating costs.

Supplied by PHCo

www.ForConstructionPros.com/Asphalt JANUARY 2023 ASPHALT CONTRACTOR 29

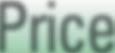

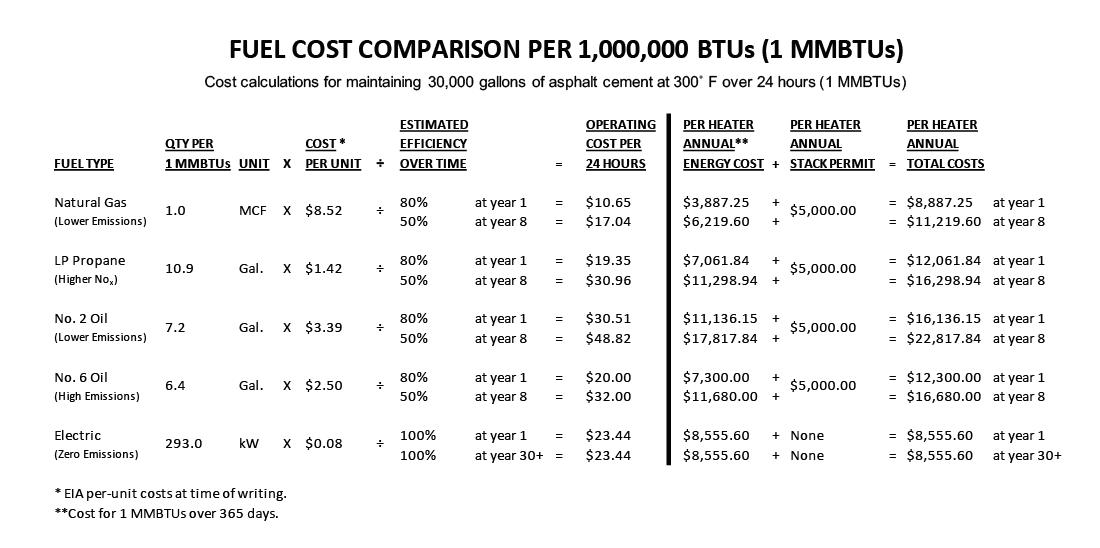

FUEL COST TABLE

In an initial assessment, looking at operating cost in Year 1, it would seem that natural gas, followed by LP propane gas, are the cheapest forms of heat energy. But we already know that fossil-fuel burners operate at only 80 to 85 percent efficiency at best — and their efficiency drops over time. When true efficiencies are considered, along with aging burners and poor maintenance practices, the cost gap narrows dramatically — especially keeping in mind that electric heaters operate at 100 percent efficiency throughout their lifetime. Add the cost of an annual per-heater stack permit, where electric heat requires no stack, and electric heat suddenly becomes the least expensive option.

Costs Per-Day and Per-Ton

Process Heating Company (PHCo) performed tests over a 3-week period, the electric tank heater consumed 192 kilowatt hours (kWh) per day. Using current industrial electric cost of $0.08 per kW (see Table 1), the cost for heating the tank over 192 kWh is $15.36. The hot oil system used 422 actual kWh per day during the same period, thus the cost per day to heat the plant’s hot oil is $33.76. The cost per ton of output can be determined using: $28.99 / 2,400 tons produced per day, or $0.014 (1.4 cents per ton). The plant had two identical asphalt storage tanks and the hot oil system, the total electricity costs per day using electric heaters would be $15.36 x 2 = $30.72 + $33.76 for a total of $64.48. Total cost per ton of output is $64.48 / 2,400 tons produced per day, or $0.0268 (2.7 cents per ton).

A Little More Math

An average drum mix asphalt plant using a PHCo hot oil heater will require a 140 kW heater, which is adequate for two 30,000-gallon asphalt tanks and associated jacketed pumps, meters and asphalt lines running ~4 hours a day in the summer and ~6 hours a day in the winter. The same plant would use ~20 gallons of diesel fuel per day in the summer and ~27 gallons per day in the winter.

At current industrial electricity costs of $0.08 per kW, a 140 kW heater running 4 hours per day would accrue $44.80 in daily costs, and 6 hours per day would accrue $67.20 in daily costs. Alternately, with diesel fuel costs of $3.36 per gallon, daily asphalt heating costs would total the following: 20 gallons of diesel fuel at $67.20/day and 27 gallons at $90.72/day. [At time of print, diesel costs avg. $5.82]

The Emissions Enigma

Electric heat eliminates some need for expensive permits because it operates without combustion or emissions. Adding a single stack at a plant can increase the annual permit cost by $5,000 or more, and No. 6 Oil produces high emissions. This type of fuel often requires preheating, and typically uses special burners. LP propane gas produces greater levels of NOx. And while today’s No. 2 Oil produces lower emissions than it has in the past, that energy source, as well as natural gas, both create some level of emissions at the plant — with associated stacks, permits and expenses. Electric heat can help producers meet ustainability goals, and also eliminates a source of fuel spills.

Additional Advantages of Electric Heat

Low-watt-density, drywell-style electric heaters not only provide 100 percent efficient heat, but they also require little to no maintenance. Because they typically last more than 30 years, electric-powered plant heaters also enjoy a lifespan that lasts three to four times longer than fossil-fuel burners, which must be replaced every eight to 10 years — reducing capital costs.

Better product quality is another benefit to using electric heat. Low-watt-density heaters, which dissipate controlled heat as low as 3 watts per square inch on the heater’s sheath, can prevent the coking and damaging of temperature-sensitive materials that often occurs with fossil-fuelfired burners. In hot oil systems, this reduces or eliminates the need to change out expensive heat transfer oil.

30 ASPHALT CONTRACTOR JANUARY 2023 www.ForConstructionPros.com/Asphalt SPECIAL REPORT

Supplied by PHCo

From innovative designs to Caterpillar dealer service and support, Weiler is paving the way to success for contractors across North America. Weiler material transfer vehicles, commercial pavers, road wideners, windrow elevators, compactors, soil stabilizer, rock drills, grader, screeds and tack distributors are engineered with proven features to increase productivity while reducing operating costs. Weiler equipment is sold and serviced exclusively at Caterpillar dealers throughout North America, providing unmatched support with factory trained technicians and readily available parts to keep your operation up and running.

weilerproducts.com

In order to achieve optimal electric rates, electric heaters can be interfaced with other large electric-using equipment to avoid adding to demand charges. By utilizing time clocks to operate during off-peak hours, producers can take advantage of the lowest possible electric rates without impacting performance or operation of the plant.

Supplied by PHCo

At one time, fuel oil was the cheapest form of energy for heating. By the late 1990s, electricity became far less expensive than fossil fuels to use for heat. In the past 10 years, natural gas has become the least expensive energy choice for heat — if you’re looking only at energy prices.

But producers often overlook the fact that their energy choices create impacts that go beyond operational costs, and what seems to be a simple challenge actually requires additional considerations to reach optimal efficiency. When choosing energy for asphalt heating, it’s important to look at the entire picture. Cost-per-unit of energy to heat asphalt and oil is certainly part of the puzzle — but it is not the only cost. Also important is the heater’s thermal efficiency. A small difference in efficiency can make a big difference in how much fuel a heater burns over its lifetime.

THE ISSUE WITH EFFICIENCY

It is widely accepted that most fossilfuel-fired burners only operate at 80 to 85 percent efficiency when new. What this means is on its best day, a burner is actually wasting 15 to 20 percent of its heat, which goes into the air as heat, exhaust, and burner emissions. Then, as the burner ages, its efficiency drops. And because fossil-fuel-fired asphalt heaters are maintenanceintensive, if they are not properly maintained and tuned, their efficiency drops even more significantly. In fact, by the time a fossil-fuel burner is 7 to

8 years old, its efficiency can easily have dropped to just 50 to 60 percent — meaning that up to 50 percent of the heat is wasted, going into the air as exhaust.

In comparison, an electric-powered asphalt tank or hot oil heater operates at 100 percent efficiency from day one — 100 percent of the heat is applied to the product, with no heat or emissions exhausted into the air. And over the lifetime of the heater, the electric efficiency never drops.

Table 1 on page 30 shows a recent fuel cost comparison between different forms of energy per 1 million BTUs, which is the approximate number of BTUs required to maintain 30,000 gallons of asphalt cement at 300˚ F over 24 hours in a tank with 3 inches of insulation.

For more information visit https://myfc.pro/30gvaa

Electric heat eliminates some need for expensive permits because it creates zero emissions. A single stack at an asphalt plant can cost upwards of $5,000. But beyond costs, and with increasing emission regulations across the country, electric heat can help producers meet regulations and their sustainability goals — including NAPA’s “The Road Forward” climate action plan.

Supplied by PHCo

32 ASPHALT CONTRACTOR JANUARY 2023 www.ForConstructionPros.com/Asphalt SPECIAL REPORT

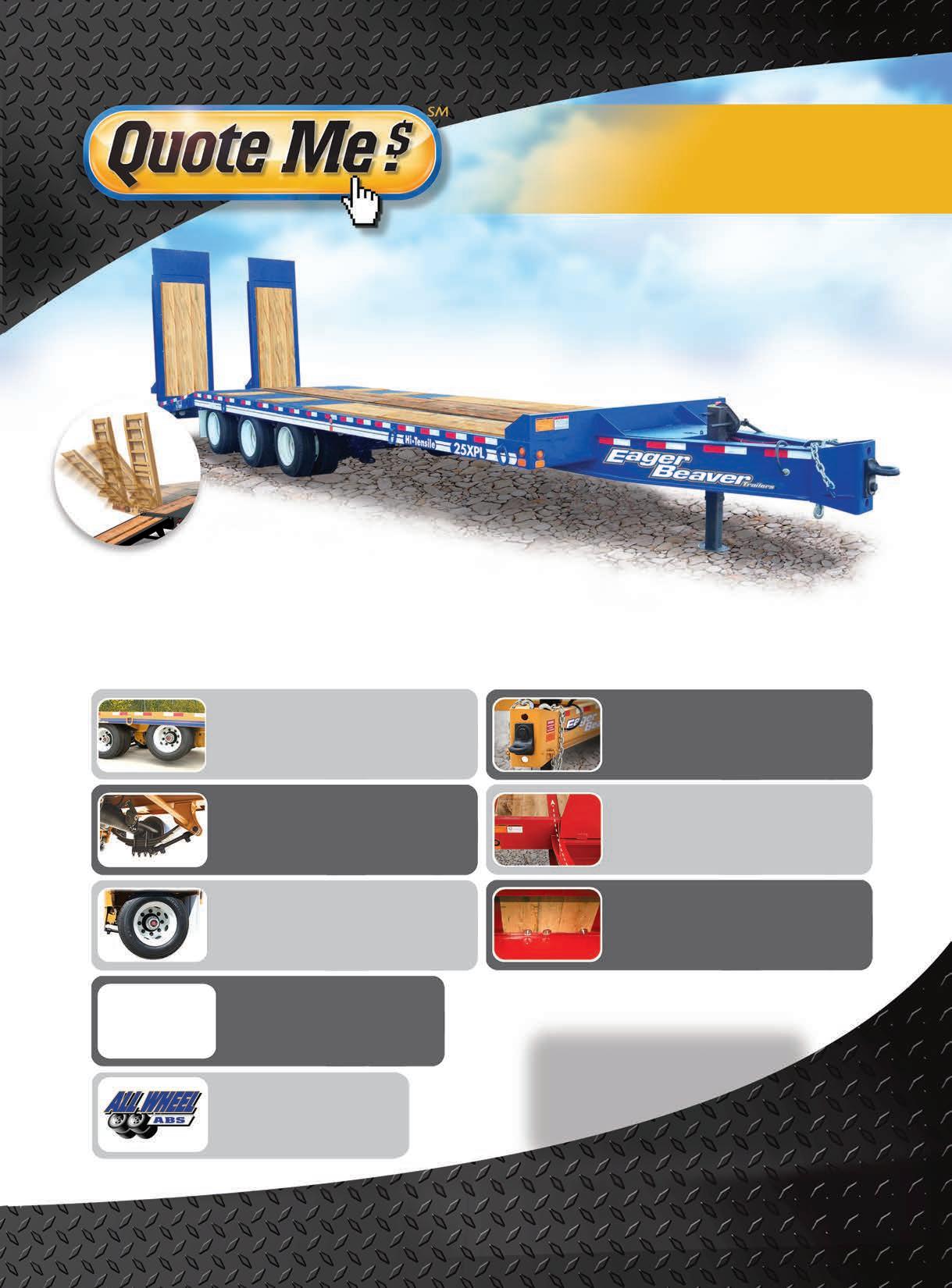

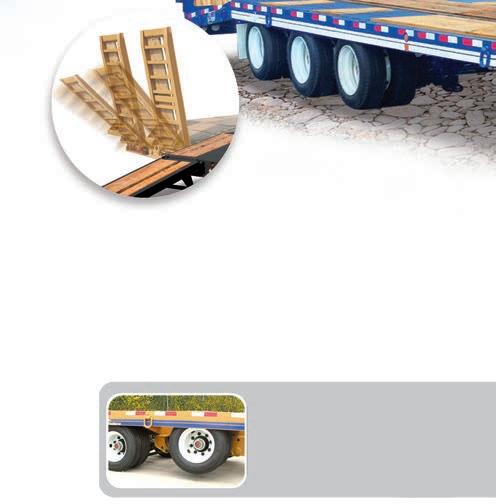

• CAPACITY: 50,000 lbs.

• 25 Ton Tri-Axle, Air Brakes

• 8 Degree Loading Angle Low Profile

• Trailer Weight: 11,720 lbs.

• Overall Width: 102", Length: 34'4"

• Deck Length: 22' Flat, 6' Beavertail

• Deck Height: 34"

• Ramps: 72" Long x 36” Wide

• Tires: Twelve 215/75R17.5 (H)

• Brakes: Air (Full ABS System)

• Lighting:100% Sealed Wiring harness and L.E.D. Lights

Standard Features on 25XPL Easy Loaders

AIR LIFT FRONT AXLE COMPAC-TRAC SUSPENSION

Ultra lift design requires no frame modification, maximum lift and ground clearance.

ADJUSTABLE 3-LEAF SUSPENSION

Standard on all 15-25 Ton trailers.

SUMITOMO BRAND TIRES

National Dealer Supported. HUB PILOTED WHEELS Outboard brake drums for easier maintenance.

Eager Beaver WIDE TRACK AXLES: 98”

Some Competition - 92”

ALL WHEEL ABS with Spring Brakes on all axles. Standard on all air brake trailers.

ONE PIECE CAST LUNETTE EYE

Tested @ 275,000# and wrap around nose plate. Standard on all trailers.

HIGH TENSILE MAIN RAIL

One piece and cold formed. CROSS MEMBERS pierced through Main Beam for lowest possible deck height and more unitized frame.

APITONG/COMPOSITE DECK

Durable Composite Decking is fastened to the crossmembers with bolts and deck washers making it easier to replace decking when required.

1946-2023

>> Eage rBeaverTrailers.co m

a quote on any model, please call

For

800-257-8163 25XPL

98” WIDTH 92” WIDTH

Simple,Fast,andConvenient!

* Shown with Optional Hydraulic Ramps

77 ANNIVERSARY

th

Paving 14 Turns of Racing

HISTORY

The Walbec Group worked with Road America to repave the historic racetrack

Nestled in the rolling hills of small town Wisconsin lies Road America, a racetrack unlike any other in the world. The 4.048-mile track features 14 turns and sits on 640 acres of land with natural slopes and superelevation changes that thrill racecar drivers and enthusiasts alike. The track hosts dozens of races each year and countless other community events, making it a truly unique — and busy — piece of the racing world.

Last paved in 1995, the Road America course was due for a makeover. The track has deep roots dating back to 1955 however, and the team at Road America, along with fans of the track, didn’t want to see any major changes made to this historic course.

“The initial design was the vision of Clif Tufte. He wanted to evoke the essence of the surrounding roads and how road racing courses were laid out when the sport began. Complete with high speed straights, sweeping turns and several types of elevation,” John Ewert, communications director at Road America says.” Clif walked the land and staked out the configuration himself. Making sure to not change the

existing landscape or topography. What fans see today is the same configuration as in 1955 and we wanted to make sure we didn’t tarnish that history when we made upgrades to the course.”

HIGH-END PREP WORK

To ensure racing history was preserved at Road America, discussions and preparations began years before any repaving would begin. Road America wanted to take the opportunity to give the entire facility the upgrades it needed and worked with Northeast Asphalt, a Walbec Group company, to get the extensive project moving.

“Walbec has a long history of success with Road America. Some of the team

34 ASPHALT CONTRACTOR JANUARY 2023 www.ForConstructionPros.com/Asphalt JOBSITE INNOVATIONS | BY JESSICA LOMBARDO

members who worked on repaving the main track in 1994/1995 are still with the company and worked on the repave in October,” Heather Sayler, project manager at Walbec said. “Walbec has partnered with Road America on their go-carting track, repaving the corners on the Road America track, as well as numerous track maintenance projects and other paving contracts on the property. The course repave was one we were all excited about.”

Officials also wanted to take the opportunity with the repave to update the drainage system in eight areas by switching out worn metal culverts with DOT plastic culverts. They also upgraded pitlane infrastructure and updated

spectator areas. All work Walbec was able to help facilitate.

“On this extensive project, the Walbec Group was able to provide all the services needed, from managing the quality of the aggregates, asphalt mix, testing and paving, as well as the engineering for drainage and pipe work installation,” Sayler said. “The team also has experience paving other tracks like the Milwaukee Mile.”

During preparations for this repave, the Walbec team worked to identify and document the uniqueness of the track in 2021. They completed a topographic survey to record and study existing track geometry and placed 18-inch long rebar, 6-inches below the track, to create 25 survey control points.

The entire survey consisted of 7,261 total data points to study the surface of the track and some drainage areas, allowing Walbec to complete massive amounts of prep work before any paving would begin.

TRACK GEOMETRY

Track Length: 21,373 feet

Asphalt Width: 30 feet

Front Straight: 4,400 feet

Number of Turns: 14

Elevation Change: 205 feet

Curve Radius: Varies from 62 feet to 455 feet

Maximum Grade: 12%

Total Track Acreage: 640

Finally, a drone survey was completed to provide high-quality aerial images for further planning purposes. The survey backed up the field work Walbec did while also verifying timing loops and markings along the track.

To prepare the track before paving, Walbec removed 4-inches of old asphalt from the track. Approximately 20,360 tons of asphalt was milled and hauled away from the site.

The entire track was then fine graded to maintain the existing character of the raceway. The motorgraders used robotic technology, along with traditional staking, when completing the grade work. This helped to ensure the edges of the pavement, cross slopes, superelevation transitions and crown lines were all maintained and would stay true to the original track.

www.ForConstructionPros.com/Asphalt JANUARY 2023 ASPHALT CONTRACTOR 35

“The elevation of the Road America track is unique, and our team worked extremely hard to ensure the existing grades and layout were going to retain those distinctive features of the track,” Sayler said. “We wanted to put everything right back where it was.”

“FANCY” ASPHALT

They also wanted to ensure that the work they did would provide years of life for the track, and to do that they needed the right mix and the right processes throughout every step of re-pave.

Like any race track paving project, a lot of research and planning goes into the mix design of the asphalt put down and that started with the rocks. At Road America, the aggregate and asphalt components were sourced from all over the state of Wisconsin.

“This is really fancy asphalt,” Sayler said. “Aggregates were sourced from different locations in the state in order to meet strength requirements for

longevity. The mix needs to hold up to the heat and friction of the race cars when they are on it and it needs to survive our winters.”

For a year and a half before paving began, Walbec tested materials. At their locations throughout Wisconsin, they processed and stockpiled the right aggregates for this mix so they were ready when mix production needed to begin at the end of October 2022.

The 2-1/2-inch base course installation began on October 10th, 2022. Crews put down 12,500 tons of this 19mm mix.

“This was a standard 3 MT 58-28 mix for the lower layer,” Sayler said. “This is a mix you’d see out on the highway, but we are using a beefed up V oil which is a heavy traffic, very firm oil.”

For the surface course design, the Walbec team worked with NASCAR engineers to help determine the best mix and process for installation.

“We came up with a mix that was similar to other road courses, but still designed for this specific location,” Sayler says. “The mix is a 9.5mm virgin mix with 82-28 polymer modified asphalt. We put that down at an inch and a half.”

The crews paved in echelon to avoid any cold center joints and minimize center seam visibility. Approximately 7,890 tons of asphalt was put down on the surface course and multiple tests were performed throughout the project to ensure the surface would handle the weather and racing stresses. The special polymer mix required an agitation tank at the plant which Walbec produced at their Larsen location, 67 miles from Road America.

The work at Road America was amazingly completed in a month’s time from removal of the old surface on October 3 2022 to the ribbon-cutting ceremony November 3, 2022, commemorating the project’s conclusion. In all, the full project cost to complete the upgrades at Road America will total more than $4 million.

“This is a massive endeavor, and we are extremely excited to have a new racetrack for competitors and fans to enjoy,” Ewert with Road America concluded. “The goal was to keep it the same as our founder Clif Tufte envisioned, and we’re certain we met that goal.”

For more information visit https://myfc.pro/zpstki

36 ASPHALT CONTRACTOR JANUARY 2023 www.ForConstructionPros.com/Asphalt JOBSITE INNOVATIONS

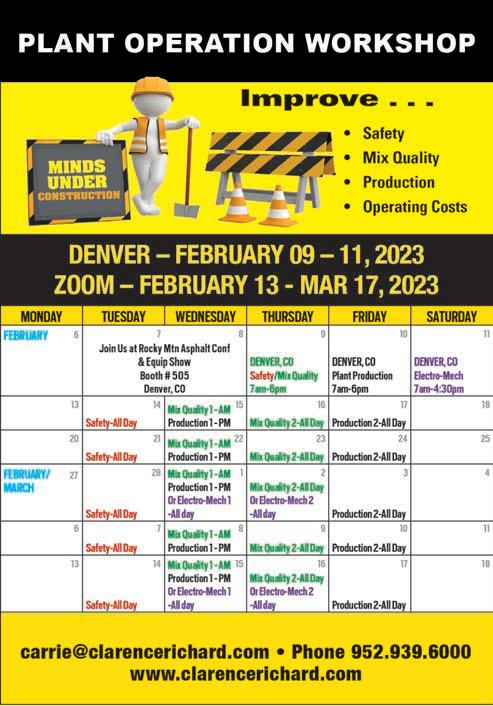

Brought to you by ForConstructionPros.com and AC Business Media. CASE & Gorman-Rupp are the official vest sponsors for this progam Win $100 Just for wearing your CASE or Gorman-Rupp safety vest at It Pays to Stand Out It’s easy to win BIG. Pick up your free ANSI-approved safety vest from CASE’s or Gorman-Rupp’s booth and wear it during CONEXPO-CON/AGG & IFPE. Attendees wearing the vests will be selected at random to win $100 CASH! Supplies are limited. Booth #C30016 in the Central Hall Booth #W40800 in the West Hall 2023 [March 14-18, Las Vegas, NV] CONEXPO-CON/AGG & IFPE BIG THE SHOW THOUSANDS IN CASH! will be awarded during the show!

Enhancing the Science of PAVEMENT PRESERVATION

In Minnesota’s most densely-populated county, the public works department works hand-in-hand with the state DOT to expand research on pavement preservation

Transportation officials, whether local, state or federal, share a common goal: getting the best bang for the buck. That is the raison d’etre for Paul Nolan, research project supervisor in the Materials and Road Research office of the Minnesota Department of Transportation (MnDOT). Nolan serves as a technical resource for cities, counties, and townships, helping to identify, test and implement new tools for agencies and engineers’ pavements and pavement preservation toolboxes. His role is to ensure that the right products and techniques are used in pavement projects, so all parties, including government agencies, taxpayers and travelers, benefit.

In Hennepin County, home to the state’s largest city — Minneapolis, Nolan is working with the public works department to apply an asphalt rejuvenator and learn how its benefits will impact pavement performance both in the county and throughout the state.

LAYING THE FOUNDATION

Testing first took place in 2019, when representatives from Hennepin County Public Works (HCPW) and MnDOT initially applied Delta Mist, a plantbased asphalt rejuvenator designed to prevent cracking, in six different applications, including pavements of varying age and traffic load. The rejuvenator is manufactured by Lowell, Mass.-based Collaborative Aggregates LLC.

Initial considerations included how the rejuvenator would affect striping, friction, cracking, crack sealant and mastic. “In our first trial, MnDOT tested the reflectivity of the pavement markings,” adds Trudy Elsner, P.E., who serves as road and bridge senior professional engineer at HCPW. She noted that while a decline was observed immediately after application, it rebounded.

After being applied on a cool, fall day, the road was reopened to traffic after 90 minutes, using an abundance of caution to ensure it was dry.

Hennepin County Public Works

Hennepin County Public Works

Applications tested how the rejuvenator performed under various traffic loads by testing it on high and low traffic pavements, parking lots and some of the state’s numerous recreation trails. To date, research has been

38 ASPHALT CONTRACTOR JANUARY 2023 www.ForConstructionPros.com/Asphalt

PRESERVATION UPDATE | BY THERESE DUNPHY

Asphalt Testing Solutions & Engineering are analyzing both control and treated core samples. Additional core samples will be taken and studied over the next two years.

promising. It has shown that the rejuvenator aids with the retention of the fines, but road officials want to see how that retention plays out in terms of extended pavement life. They are also watching cracking to see if it helps prevent secondary and tertiary cracking.

BUILDING UPON THE BASE

In September 2022, the county undertook a second round of trials. This time, it tested the rejuvenator on a newer pavement to evaluate the impact of application earlier in the pavement’s lifecycle and at a lower application rate. It also reapplied the rejuvenator on some of the 2019 trial sections to see if a second application offered additional preservation benefits.