How we invest your super

AustralianSuper is the country’s largest super fund with 2.6 million members and $261 billion at 31 March 2022 in members’ assets. A wide range of investment options ensure your super can benefit from growth opportunities around the world, across di erent types of assets.*

Asset classes and examples of AustralianSuper holdings

AustralianSuper invests in a broad range of asset classes including:

• Listed shares

• Unlisted infrastructure

• Private equity

• Credit

• Direct property

• Fixed interest and cash

Listed shares

Buying listed shares means buying parts of companies listed on a stock exchange, like the Australian Stock Exchange (ASX). Listed shares make money when the share price goes up and from the dividends they pay.

Private equity

Private equity involves investing in companies that aren’t listed on the stock exchange. These can be larger investments (with lower costs) that may perform better than listed shares.

Direct property

Direct property is residential, retail, industrial and commercial real estate investments. Returns are generated from rising property values and rental income.

Unlisted infrastructure

Infrastructure investments are assets that provide essential public services like bridges, roads, airports and power plants.

Credit

Credit is like a loan. Credit investments involve providing finance in exchange for a return.

Fixed interest

Fixed interest investments provide income from interest payments. These investments are defensive and can protect against market volatility.

Cash

Cash investments are short-term money market instruments. These are issued by banks, governments and companies and are considered low risk, with lower returns.

For a comprehensive look at where your super is invested visit: australiansuper.com/investments/how-we-invest

*As at 31 March 2022.

Sponsored by AustralianSuper the information is general information only. We haven’t taken into account your needs or personal objectives when providing the information. You should assess your own fi nancial situation and needs and read the relevant Product Disclosure Statement before making a decision about products on this website. A Target Market Determination (TMD) is a document that outlines the target market a product has been designed for. Find the TMDs at australiansuper.com/tmd . AustralianSuper Pty Ltd ABN 94 006 457 987, AFSL 233788, Trustee of AustralianSuper ABN 65 714 394 898 Superannuation Fund Number (SFN): 2683 519 45, Superannuation Product Identifi cation Number (SPIN): STA0100AU.

ASI HEAD OFFICE

Suite G1, Ground Floor

25 Ryde Road

Pymble, NSW 2073

T: (02) 8748 0180

E: enquiries@steel.org.au

W: https://www.steel.org.au

ASI STATE OFFICES

New South Wales & ACT

David Varcoe on 0419 136 720

Victoria, Tasmania & South Australia

Michael Dawson on (03) 9694 4499

Western Australia

James England on (08) 9355 1544

Queensland & Northern Territory

John Gardner on (07) 3853 5320

ShedSafe Neil Creek on (07) 3853 5204

STEEL AUSTRALIA CONTACTS

Editor Sally Wood on sally@wordly.com.au

Advertising and Distribution Steve Andrew on marketing@steel.org.au

DISCLAIMER

While every effort has been made and all reasonable care taken to ensure the accuracy of the material contained herein, the Publisher does not assume any responsibility or liability for any loss or damage which may result from any inaccuracy or omission in this publication, or from the use of the information contained herein, and the Publisher makes no warranties, express or implied, with respect to any of the material contained herein.

COPYRIGHT

Reproduction of the material is permitted only with the express permission of the Publisher and due acknowledgment of steel Australia.

ABOUT THE ASI

steel Australia is published by the Australian Steel Institute (ASI)—the peak national body of the steel industry. The ASI works to increase the awareness of the benefits of steel and promote Australian made steel as the material of choice. Increasing the competitiveness of the Australian steel industry and its member companies is central to that vision. The organisation conducts engineering seminars and disseminates relevant, timely and detailed information. Expert technical advice, a library and a resource centre are available to all members, along with a range of other member benefits. For further information, please visit: https://www.steel.org.au

INDUSTRY INSIGHTS

Message from the Chair

Message from the Chief Executive

Ray Horsburgh AM

MESSAGE FROM THE ASI CHAIR

As many of you will be aware, the Australian Steel Institute (ASI) has just wrapped up the 2022 Australian Steel Convention. With over 260 people in attendance, the Convention was a great success. It was not a Convention where we asked everyone to sit back, relax and to enjoy.

Rather, it was a Convention where we asked everyone to sit forward in their seats, open their minds, and visualise the type of industry that steel needs to be.

The theme of our Convention was VITAL and ADAPTIVE.

Both words combine to reflect the importance of the steel industry to Australian society.

The need for ADAPTABILITY in our industry is best visioned by drawing a line in the sand—here in 2022—and reflecting on what has changed in the three or four years leading up to this point. We have seen several disruptions occur and it is worth considering the need for being ADAPTIVE.

We are now in an inflationary environment which is very different to what we have experienced in the last decade. Our suppliers are experiencing cost escalation, our own businesses are experiencing cost escalation and our customers are experiencing cost escalation.

Yet our industry must ADAPT and find innovative ways to offset that escalation such that we can offer cost competitive steel solutions to society.

Central banks have increased interest rates to contain inflation, and this is very different to the last decade. Money is no longer effectively free. Uncertainty around interest rates and future currency values is impacting decision making regarding whether projects should proceed, be paused, or be abandoned.

The labour market is the tightest that many of us can recall and this is unlikely to abate in the near term. As an industry we must ADAPT to this situation and find innovative ways to attract and retain critical skills within the industry. We must come together with imaginative programs to enthuse and motivate those coming through high school, our technical colleges, and our universities to aspire to careers across our industry.

The rate of technological change— 5G networks, the Internet of Things, robotics, and automation—has had a profound effect on the way we work and the way our industry operates.

If we consider the 2030 Australian Steel Convention, we will look back and consider that the early 2020s were pedestrian at best. We must ADAPT and prepare ourselves now, for the future of work. We must consider how our customers and suppliers will want to work with us. And, more importantly, how our employees will demand the work be done.

Let’s combine technology with the other discontinuities to visualise the need for ADAPTABILITY in our thinking.

I, like many in the steel industry, can recall technology investment debates in the past. Debates that centred on

questions like how much can I reduce labour costs? How much I can minimise the capital investment? Can I take a ‘slowly as we go’ approach?

The adoption of technology is now a revenue enhancement decision.

Many businesses are operating at 90%, 80%, 70% capacity due to the skilled labour constraints. Consider a competitor who has embraced technology and can run their business at 100% capacity, and above, and circumvent labour shortages – that is the type of ADAPTIVE thinking we must all have.

And so we reach the second half of the Convention theme: VITAL.

Billions of dollars are being invested in infrastructure, housing, agriculture, defence and to meet the public and private needs of Australian society. This is the base economy. Our industry is VITAL to helping society meet each of its aspirations.

On top of the base economy, Australian society has chosen a path forward that is focused on decarbonisation. A focus on renewable energy sources, more carbon efficient buildings and structures. A focus on less carbon intense supply chains.

This is not the world of the future. This is the world of the present. Anything that we have seen to date is minuscule compared to what we will see over the next 20 years.

The architectural and design fraternities are being aggressively pushed to deliver less carbon intense outcomes and they are literally pleading with industries such as ours to innovate, collaborate, and accelerate our efforts towards meeting future needs.

It is VITAL that we heed their calls and act now to position our industry for 2030 and beyond.

Tony Schreiber (Chair, Australian Steel Institute)

MESSAGE FROM THE ASI CHIEF EXECUTIVE

AUSTRALIAN STEEL CONVENTION

The feature of this edition of steel Australia magazine is the 2022 Australian Steel Convention. The Convention was held from 9 to 12 October 2022 at the Four Seasons Hotel in Sydney. It brought together key industry leaders and innovators to discuss opportunities, showcase industry successes and examine what the future can, and will, look like.

With over 260 people in attendance, the 2022 Convention was our most successful yet. Just some of the speakers included the Hon. Ed Husic (Minister for Innovation and Science), Professor Veena Sahajwalla (Director of Sustainable Materials Research and Technology, University of New South Wales), Davina Rooney (Green Building Council of Australia), and Dr Phil Commins (Facility for Intelligent Fabrication). A big thank you to all of our speakers—all the presentations were highly enjoyable and engaging.

The social program was equally as enjoyable, with the Welcome Reception held at the Museum of Contemporary Arts, and entertainment by Diesel at the Convention dinner.

I'd like to thank all our sponsors and exhibitors, without which the Convention would not have been possible. For further details, please see the article on page 36

ADVOCACY WORK

The ASI continues to advocate on behalf of the Australian steel supply chain on key issues. Energy pricing and security of supply are a critical issue for a tradeexposed industry such as Australia’s domestic steel value chain. We continue to work with all levels of government to address this issue.

Skilled Labour Shortage

We're also aware that the shortage of skilled employees remains high on the priority list for the entire industry. We are working on various fronts to help address this problem. ASI attended two round table meetings in Canberra in the lead up to the Jobs Summit in September.

The first meeting was with the Hon.

Tim Ayers (Assistant Minister for Heavy Industry) and 15 other industry participants to discuss jobs and skills needs for heavy industry. Interestingly, ASI was the only industry association invited. We were able to stress the immediate need for increased skilled immigration. We also highlighted the risk to current employment that high energy costs pose.

The second meeting was with the Hon. Chris Bowen (Minister for Climate Change and Energy). At this meeting, ASI advocated for local steel content in renewable energy infrastructure, including wind towers, solar racking, transmission towers and offshore wind projects. We stressed the need for sovereign capability to mitigate supply chain risks.

Export of Unprocessed Scrap

The ASI is also advocating on behalf of members in the area of bans on the export of unprocessed scrap. In conjunction with the National Waste and Recycling Industry Council, we recently presented our case to members of Department Industry, Science and Resources, and the Department of Climate Change, Energy, Environment and Water. We received very positive feedback following these meetings,

Cain Chief Executive Australian Steel Institute

with our position and aligning with government policy.

Safeguard Mechanism Reform

The Federal Government recently published its Safeguard Mechanism Reforms Consultation Paper, which sets out its proposals to reform the Safeguard Mechanism to drive emissions reductions from Australia's biggest emitters. This is in line with Australia's commitment under the Paris Agreement of reducing CO2-e emissions to 43% below 2005 levels by 2030.

The ASI reviewed the Federal Government's proposed reforms to the Safeguard Mechanism, and undertook consultation with our steel manufacturer members to ascertain the steel industry’s overall position. As a result, we made a formal submission to the Government.

Roundtable on Energy Transition to Net Zero

The ASI was invited to participate in a roundtable discussion on the National Energy Plan, led by the Department of Climate Change, Energy, Environment and Water. As well as emphasising the need for globally competitive energy costs, ASI put forward the need for local manufacturing capacity for renewable energy infrastructure.

MarkNATIONAL CONSTRUCTION CODE

In late August, Federal, State and Territory Building Ministers agreed to endorse the latest National Construction Code (NCC). NCC 2022 has been developed over the last three years under the leadership of the Australian Building Codes Board (ABCB).

The changes associated with NCC 2022 are significant and broad ranging, particularly with regard to management of condensation and energy efficiency requirements. Given this complexity, earlier this year ASI wrote to Building Ministers to recommend a 12 month implementation period prior to full implementation of these more complex elements. Pleasingly, this call has been heeded.

An NCC 2022 industry communication strategy was developed at a half day meeting, attended by approximately 30 industry representatives. NCC 2022 contains a number of significant changes directly impacting steel roofing and walling applications. This will require substantial upskilling of the complete steel product supply and installation value chain to efficiently achieve compliance. To support this effort, a comprehensive communication and awareness raising initiative will be implemented, coordinated by the ASI.

LEADERSHIP IN SAFETY AND COMPLIANCE

Steelwork Compliance Australia (SCA) has been audited and was awarded JAS-ANZ accreditation in late August 2022, for the full scope of AS/NZS 5131 Structural steelwork - Fabrication and erection. SCA is

currently the only Certifying Body with accreditation to the entire Standard. With SCA as the single Certifying Body to utilise the National Structural Steelwork Compliance Scheme (NSSCS), the supply chain now has another level of surety that services provided by SCA are approved and monitored by JAS-ANZ. For further information, please see the article on page 20.

I am also pleased to report that VicRoads has recently specified that any fabrication work tendered by them needs to be certified to AS/NZS 5131; clearly the NSSCS is gaining more and more momentum across the industry.

STEEL SUSTAINABILITY AUSTRALIA

With increasing sustainability demands, the ASI's Environmental Sustainability Charter (ESC) is undergoing a significant transition process. The ESC will transition to the Steel Sustainability Australia (SSA) certification program. The SSA program engages the entire steel value chain by verifying upstream steel producers supplying the steel feedstock and certifying the downstream suppliers against best practice environmental, social and governance.

SSA will adopt the GBCA’s new Green Star Responsible Products Framework, and enable SSA certified companies to access a far greater number of Green Star credit points for building and construction projects, whilst driving best practice sustainability improvements across their operations.

The SSA program has been approved by the GBCA and will go out for public consultation. For further

information, please see the article on page 16

2022 STEEL EXCELLENCE AWARDS

Judging for the ASI Steel Excellence Awards is well underway. The 2022 Awards will adopt the very successful format that was introduced in 2020. This saw state-based award presentations take place online. With a huge digital reach, finalists and winners will also be celebrated via video presentations, as well as the ASI website and social media channels.

All state-based finalists and winners will then be invited to attend the 2022 Australian Steel Excellence National Awards Gala, which will be held in Sydney on Tuesday 22 November 2022. This year’s award categories include:

• Buildings (Large Projects)

• Buildings (Small Projects)

• Steel-Clad Structures

• Engineering Projects

• Innovative Cold Form Steel Building

• Young Designer, Detailer or Tradesperson

We have introduced a new category this year: Innovative Cold Form Steel Building in recognition of the enormous expansion in this space.

Be sure to keep an eye out over the coming weeks for the announcements of the State Award winners. The Summer edition of steel Australia will also feature the National Award winners.

EMPLOYERS SUPER OBLIGATIONS

Australia’s

1. Over the years, the

10.5% in 2022. It will continue to rise by 0.5% a year to

Employees eligible for super

Whether your employees work on a full-time, part-time or on a casual basis (including those on temporary visas), if they’re aged 18 or over, they’re generally eligible to receive super.

There are different rules around employee entitlements, including paying super for contractors.

Calculating your employees’ super

From 1 July 2022, the minimum super rate for eligible employees is 10.5% of their salary2. Sometimes, a higher percentage of super is agreed by an award or employment agreement. For award rates information, please visit Fair Work Australia.

Ordinary time earnings

Ordinary time earnings (OTE) is the amount employees earn for their ordinary hours of work. This generally includes annual leave, sick leave and long service leave. If loading, allowances, overtime and commissions are part of an

employee's pay, calculating the ordinary time earnings can be more complex. The ATO’s OTE checklist identifies payments which could be salary or wages, and highlights if they're part of OTE3

Using OTE to calculate super payments

You can use an employee’s OTE to calculate their super. Simply multiply the employee’s OTE by their super rate.

Super payments on overtime

Overtime is generally excluded from super payment calculations because it falls outside of OTE. But overtime counts as OTE in some instances4

In some cases, you may need to pay super on overtime.

Super payments on leave

With so many different types of leave, it can be confusing to know who’s eligible for what. Paying super on leave depends if it’s part of OTE.

Leave types generally included in OTE:

• Annual leave

• Sick leave

• Long service leave.

Leave types generally excluded from OTE:

• Parental leave (maternity, paternity, adoption)

• Unused annual leave, sick leave, or long service leave as part of a termination payment

• Jury duty

• Defence Forces reserves leave.

Please note: you can choose to pay super on some of the above excluded leave types. For example, parental leave.

Super payments on bonuses

If you offer your employees bonuses on top of their regular wage, you may also need to pay super on bonuses.

Super payments – how often

Super payment frequency for employees is at least once a quarter. You can choose whether it’s one payment, or multiple payments across the quarter. The frequency may depend on whether there are award or employment agreements that set out a specific payment frequency.

1. apra.gov.au - History of super

2. Changes to this rate were legislated at 1 July 2022

3. australiansuper.com - Your super obligations

4. ato.gov.au - Super for employers

Sponsored by AustralianSuper Pty Ltd, ABN 94 006 457 987, AFSL 233788, Trustee of AustralianSuper ABN 65 714 394 898.

This information may be general financial advice which doesn’t take into account your personal objectives, situation or needs. Before making a decision about AustralianSuper, you should think about your financial requirements and refer to the relevant Product Disclosure Statement. A Target Market Determination (TMD) is a document that outlines the target market a product has been designed for. Find the TMDs at australiansuper.com/tmd. AustralianSuper Pty Ltd ABN 94 006 457 987, AFSL 233788, Trustee of AustralianSuper ABN 65 714 394 898.

This article was supplied as part of a paid advertising package.

superannuation system celebrated its 30th birthday in 2022 and since its introduction in 1992, it’s been recognised by the World Bank as the ‘world’s best practice for the provision of retirement income’ super guarantee has increased in small increments and currently sits at reach 12% in 2025.VALE RAY HORSBURGH AM

The Australian Steel Institute (ASI) extends its deepest condolences to the family, friends and colleagues of Ray Horsburgh AM, following his recent passing.

Ray was a highly regarded Australian businessman with vast experience in the steel industry. So much so that he was awarded an Order of Australia in 2006 for service to the steel industry and service to disadvantaged youth.

At the time of his passing, Ray was Acting Board Chairman and lead Independent Director of InfraBuild, and served on the LIBERTY Steel Group Board and GFG's Global Advisory Board.

GFG Alliance Executive Chairman, Sanjeev Gupta said, “Ray will be remembered as a much-loved member of our family. He was not only a great supporter of GFG in every way possible, he was also a friend, mentor, and father figure we all relied upon. It feels like a great light has suddenly gone from our lives.”

“Ray was a passionate advocate of the Australian steel industry and Australian manufacturing, and a true ambassador for our business in every sense of the word,” Sanjeev said. “He was a giant of our industry and we are incredibly grateful for his service to the business and the positive contribution he made to the careers of many of our staff.”

Ray was also the Chair of Arbitrium Capital Partners, AFL Victoria and the Bill Hutchinson Foundation, and an Independent Non-Executive Director of the Ponting Foundation—the organisation established by former Australian Test cricket captain Ricky Ponting to help in the fight against childhood cancer.

A HIGHLY DECORATED CAREER

Ray had a highly decorated 30 year career with Australian Consolidated Industries. He started his career as a chemical engineering cadet at the ACI Glass factory in Spotswood. When Alan Jackson took over ACI in 1998, he appointed Ray as his Chief Executive. Under Ray's management, ACI expanded rapidly, including into international markets.

Ray then served as the Chief Executive Officer and Managing Director of Smorgon Steel Group for 15 years, which in 2007 joined the group of businesses that later became InfraBuild.

Mark Vassella (Managing Director and Chief Executive Officer, BlueScope Steel) worked with Ray at Smorgon Steel. Quoted recently in The Weekend Australian, Mark said, "[Ray] was a remarkable man - generous, funny, smart, down to earth, supportive. A slap on the back and a 'she'll be right mate' was his standard pick-me-up. He loved his family, his footy, his cricket and helping people."

"He had a knack of seeing the big picture more than most, which I think many people underestimated. It wasn't only about the short term. He had the vision to put the pieces in place to create significant value in the long run. And he had the patience and confidence to back you over that longer term."

"From a business perspective I've never met a better connected guy. Everyone loved being around him and knowing him. He was larger than life. It didn't matter what you needed, he had a contact somewhere and given his generosity, most were in his debt and only too happy to help. He could operate at the very highest level and yet when he was in a less environment, with our people, engaging directly with them - telling stories, listening to them - he was masterful," Mark said.

Later in his career, Ray transitioned into the role of company director seamlessly, taking on roles such as Chair of ASXlisted Toll Holdings and Calibre Group, and Independent Non-Executive Director of ASX-listed CSR, Pact Group and Traffic Technologies.

Ray was also well known in Australian Football League circles. A longstanding, passionate and dedicated Club benefactor, Horsburgh joined the Essendon Football Club board in 2003 and served as President from late 2005 to 2009.

Ex-Chief Executive Xavier Campbell extended the Club’s condolences to the Horsburgh family. “A proud Essendon man, Ray will be truly missed by the entire red and black family,” Xavier said. “Our club is a better place for the service of passionate individuals like Ray. Ray brought plenty of joy to a lot of Essendon people in the way he went about his involvement at the Club. He will be terribly missed by so many within the four walls of the club."

Source: https://www.theaustralian.com.au/business/australian-industryheavyweights-mourn-onceinageneration-leader-ray-horsburgh/news-story/0ec18 3c442bc660b034ddd5494dd6faf

HELPING YOUR BUSINESS MANAGE RISING INTEREST RATES AND GROWING INFLATION

Although we’ve had four RBA interest rate hikes this year that have taken the official cash rate to 1.85%, many consumers and businesses are yet to feel the full impact.

The last three rate rises (June, July and August) are only just starting to flow through to borrowers, as banks and other lenders pass on each successive rate with a sufficient notice period. So while Aussies are quite subdued by the knowledge that cheap money has ended, many may not feel the cumulative effect in their bank accounts until around November.

Commonwealth Bank CEO Matt Comyn is also quoted as saying the record low level of bad debts is a lagging indicator. Both are compelling reasons to avoid complacency and look to revisit your business forecasts.

Current predictions are that the RBA will continue to lift the cash rate to between 2.5% and 3% until inflation (currently at 6.1%) peaks at 7% to 8% later this year, then falls back to the top of the 2% to 3% target range by some time in 2024.

This has been the fastest annual growth in inflation since 2001, forcing consumers and businesses to shell out more for everything from fuel to food. We haven’t seen inflation grow this fast since the introduction of the GST, so many steel manufacturing businesses haven’t experienced running their business in such an environment.

And while supply chains are beginning to normalise, rolling lockdowns in China can still have an impact. Some suppliers are favouring larger markets like the US, causing headaches for Aussie businesses that need to pivot to different sources.

These and other challenges have the potential to eat into profits and impact your business’ viability. Let’s look at some tactics for mitigating them. This assumes you already know what your margins and operating costs are.

Increasing your prices is the obvious option, but the amount of increase depends on what your market will bear. Regular small price increases might be the way to go, rather than a large price hike. Try testing small and bigger increases on different products to see

how your market responds. If you do increase prices, consider a value-add to keep customers on side. Clear customer communication is essential when you introduce a price increase, as clients are more likely to be supportive and stay with you if they understand the reasons. Keep track of their feedback and watch your sales data.

Look at cutting discretionary costs

Can you switch to alternative cheaper business functions or processes? Negotiate with suppliers or explore others who offer better deals.

Consider being flexible with employee

hours, by adjusting shifts or staffing to match times of high demand and managing with less at times of low activity. That said, hang on to good, effective employees and keep them motivated. Having to replace people in the current tight labour market is costly. Invest in technology that can streamline your business processes and improve efficiency. This could be developing a mobile app to make it easier for customers to order and pay from your business, or 3D printing to get around some supply disruptions. Also look at downloading apps to help you run your business on the go. Many, such as Invoice by Wave (streamlines your invoices), Expensify (helps you quickly upload business expense receipts) or Thrive (helps you keep track of your small business data in real time) are free from the App Store.

Think about stocking up on inventory now to beat further price increases and get ahead of random supply chain disruptions at peak season.

Keep investing in projects that will ultimately boost sales or improve productivity.

Regardless of the tactics used, strong cash flow is essential to help you manage the inflationary headwinds and continue investing in your business. According to Xero, about one in five small businesses experience a cash flow crunch –where expenses exceed revenue – at least 50% of the year. Business loans can help cut through that crunch with the cash you need to move forward, whether it’s managing your supply chain, investing in new assets or simply covering unexpected expenses.

With business loan interest rates rising, and residential property prices set to dip, you’d want to think long and hard before taking out a loan secured to your home or business property. Instead, explore the nonbank lending products out there, like Banjo’s Flexi Working Capital loan, that is much more adaptable to the needs of smaller, high-growth businesses in the steel sector.

This article was supplied as part of a paid advertising package.

THE TOP 3 CONCERNS OF CFO s IN 2022

The trials and tribulations of the economy, business and personal life has taken many turns over the past two and a half years. It has been one of the most challenging periods for businesses and individuals to navigate through.

But what are the current top concerns of CFOs and Credit Managers and what keeps them up at night?

After surveying hundreds of our clients, they have given us an insight into their top 3 concerns for 2022.

1. Sourcing materials and an increase in the costs of goods

Anyone who's building a house will no doubt know the pains of supply delays and increasing raw material costs! In a recent case someone waited an additional eight months beyond their original completion date and had variations of over $50,000 to complete their build. But, the building industry is not the only sector experiencing increases in costs. Food, services, and energy costs have hit the hip-pocket of individuals and increased the expenses on businesses’ P&L.

This naturally leads to higher overall costs and end product increases to the consumer.

2. Labour shortages

Everyone has a story of needing to quickly rebuild or replace positions post the pandemic. The disruptions to the business environment in many sectors led to layoffs or redirection of labour throughout 2020 and 2021. Look at the

challenges facing the travel sector in trying to quickly replace labour to deal with the current and future demands.

Labour short ages also bring a lack of skills in specialist sectors and industries, placing pressure on existing wages and acquisition of new labour.

Many businesses are having higher than ‘normal’ levels of staff changes which compounds to recruitment, training and workflow pressures.

3.

Overdue debts and customer

non-payment 21% of survey respondents highlighted their concerns about increasing overdue debts and non-payments from their customers.

This is a trend which many economists predict will increase further over the next year. Businesses have experienced extremely low insolvency rates and, with government incentives through the pandemic, businesses seemed to be flush with cash.

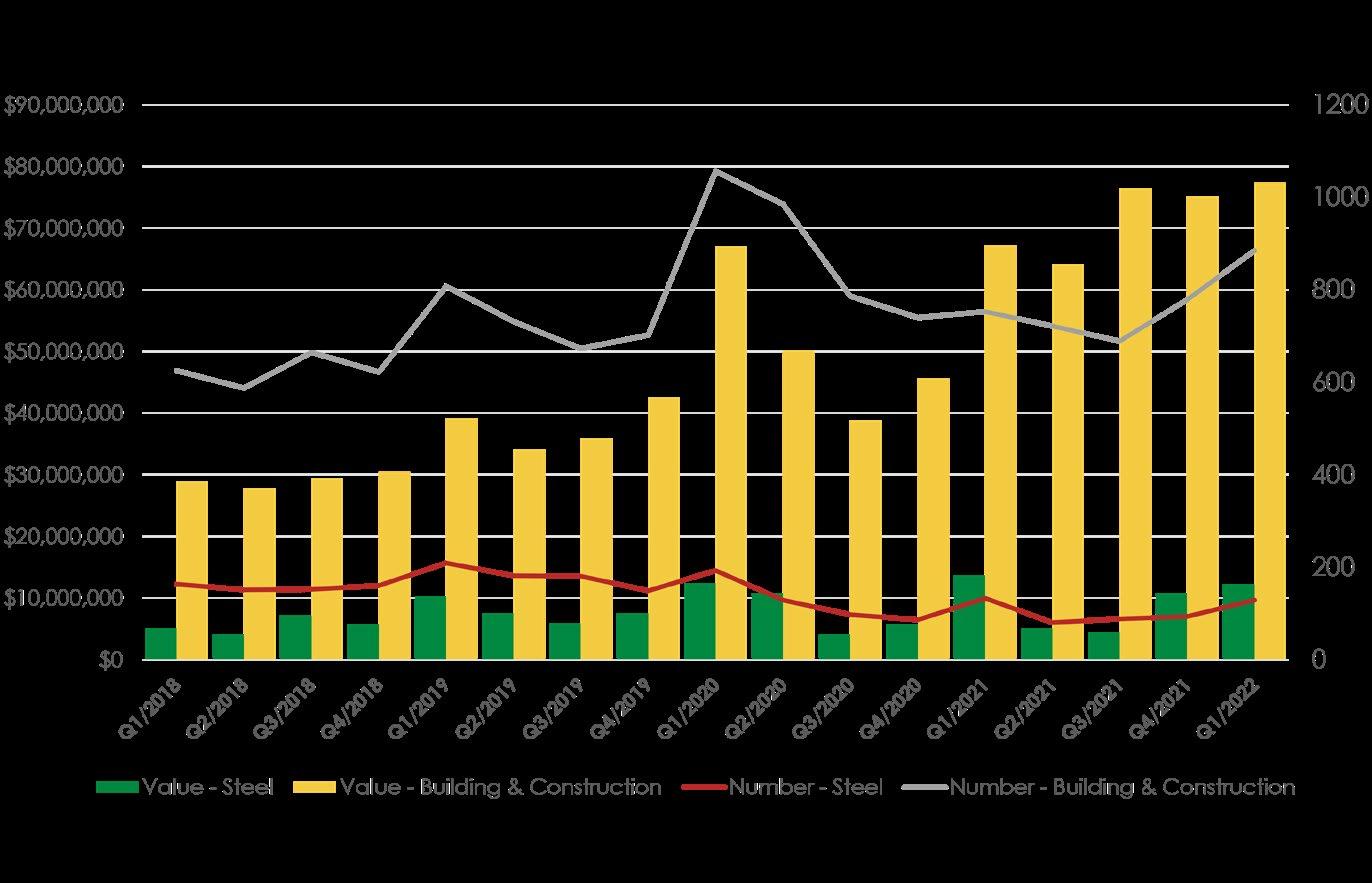

Recent ASIC administration data shows there has been a rebound in business insolvencies and our own NCI data highlights overdue reporting rates increased dramatically at the beginning of 2022. Led by the building construction sector this is a tell-tale lead into further insolvencies.

Cashflow issues, rising interest rates and lower predicted sales revenue were other factors which were concerning our clients.

Whilst sourcing materials and costs, as well as transportation factors, are easing, labour shortages and overdue debts seem to be ongoing factors we will all need to deal with.

So where does your business sit on these concerns?

NCI, with our full range of trade credit services, can support businesses in preparing and sleeping better at night, by removing the worry relating to predicting, and protecting yourself against, non-payment or insolvencies.

Ask yourself these questions:

• When was the last time you conducted a full health check on your customer list?

• What was the impact on your customers throughout the pandemic?

• Do they have the same level of capital and cashflow to maintain their business in a healthy environment?

NCI’s unique database, and ‘secret intel’ can provide a business with early warning signs specific to your customer list. We alert you to those customers who may not be in a position to pay into the future and allow you to make early changes to avoid non- payment and bad debts into the future.

This article was supplied as part of a paid advertising package.

Overcome the Complexity of Sales to Manufacturing Process

HOW TO IMPROVE SALES TO MANUFACTURING PROCESS WITH CONFIGURE-PRICE-QUOTATION

Product customisation is generating more demand for fabrication work. B2B customers are increasingly expecting customisation – material options, delivery schedule, iterations, endless what-ifs. All this impacts your projected price.

This means higher product variations for manufacturers. It also means the need for faster and more accurate quotations, sometimes multiple in a day. Combine that with an expanding product range with multiple complex pricing models, and you have a recipe for confusion and inefficiency among manufacturing and sales teams.

When manufacturers offer hundreds, thousands, even millions, of product options, things can get complicated. This is where Configure-Price-Quote, abbreviated as CPQ, can be a game changer.

CPQ software helps companies quickly and accurately generate quotes for orders. It reduces inefficiencies in the sales to manufacturing process and gets every employee—from the top floor to the shop floor—working on the same page.

The configuration process is guided by your product rules set up in the backend rules engine. These rules codify the knowledge and expertise of your manufacturing and operations teams, making them instantly available to your salespeople in real-time. When product and manufacturing knowledge is built in the system, sales can be confident with

generating quotes, knowing what is sold is optimised and free from error.

Once configured, CPQ software calculates prices based on advanced pricing rules. Considerations are given automatically for volume and bundle pricing, promotional and tiered discounts. Additionally, with CPQ software, quotes can be instantly generated, formatted according to unique brand guidelines, and sent to customers with little, if any, additional modifications.

Another significant advancement in this field is visual CPQ. With visual CPQ, customers, salespeople, and engineers can see lifelike visualisations of custom products as they are being configured. Bypassing technical jargon or indecipherable hand-drawn sketches, visual CPQ reduces miscommunications and misunderstandings due to translation. Remember, errors in the sales to manufacturing handoff process can cost you time and money.

Instead of filling out forms and making sketches, salespeople can simply point and click to change dimensions, colors, materials, parts, and more, watching as their product evolves on screen.

CPQ automates all the formatting and number-crunching, saving vast amounts

of precious selling time while eliminating the errors inherent in manual processes. It is impossible for salespeople to configure technically or financially nonviable products. They are guided through a series of calibrated questions and prompts (via upsells and cross-sells) that ensure every configuration is perfectly optimised.

Integrating CPQ solution with the production system allows the synchronisation of complex data that influences supply, demand, and fulfillment. This information can be gathered from the supply chain, eCommerce store, plant floor, and warehouse to get sales and manufacturing working together. Apart from saving time and improving accuracies, the other big benefits of CPQ include scalability, and enhancing the overall customer buying experience.

Sales and manufacturing are more complex than ever before. B2B customers want product customisation and a frictionless path to purchase. With CPQ software, you can provide both.

This article was supplied as part of a paid advertising package.

THE EVOLUTION OF ASI'S ENVIRONMENTAL SUSTAINABILITY CHARTER (ESC)

Sustainability in the building, construction and industrial markets plays a significant role in business practices—in much the same way as safety and quality did decades ago. Momentum in this space is now shifting up a gear, with sustainability quickly becoming a licence to operate. In response, the ASI's Environmental Sustainability Charter (ESC) will transition to the Steel Sustainability Australia (SSA) certification program in late 2022—a new sustainability certification program that engages the entire steel value chain.

According to the World Green Building Council, 75% of annual global greenhouse emissions are from the built environment (encompassing buildings and infrastructure). Buildings are responsible for approximately 30% of global energy consumption, 30% of greenhouse gas emissions and, on average, 50% of emissions in major cities.

In June 2022, Prime Minister Anthony Albanese pledged to cut carbon emissions by 43% from 2005 levels by 2030, up from the previous government's target of between 26% and 28%. Prime Minister Albanese also reaffirmed the Federal Government’s commitment to net zero emissions by 2050. The new target brings Australia more in line with other developed economies' Paris climate accord commitments.

All these factors make the building and construction sector a high priority target for decarbonisation. Momentum for change is being driven across a broad range of fronts: all tiers of government, large corporates such as BHP and Lendlease putting their supply chains on notice, influence from a growing array

of not-for-profit and community groups, ‘green finance’ such as the global green bond market, and super funds targeting investments in public companies with high sustainability credentials.

We are seeing increased sustainability credential demand in a broadening range of building projects. A growing number of project proponents, builders and government departments are requiring steel supply from fabricators, rollformers, reinforcing suppliers, small manufacturers and steel processors that are members of ASI’s Environmental Sustainability Charter (ESC). These projects include major infrastructure, utilities such as water, sporting structures, office complexes, commercial and apartment buildings and even churches.

BACKGROUND TO THE ESC

The Environmental Sustainability Charter (ESC) was established in partnership with the Green Building Council of Australia (GBCA) in 2011, with the objective of delivering ongoing meaningful improvement to the environmental footprint of certified steelwork fabrication and steel processing companies, reducing the reliance on fossil fuel derived energy, waste minimisation, broadening participation in the circular economy, protecting the environment, and the management of air contaminants on the shop floor. Participants plan and log environmental sustainability projects which often measure the effectiveness of new processes and technological enhancements on energy reduction. The ESC has experienced rapid growth over the last three years, and is widely recognised as the premier sustainability certification for downstream steel fabricator and processing businesses. Performance is documented through an online environmental management

QUICK GUIDE: WHAT'S CHANGING AND WHY?

The ESC is undergoing an indepth revision and will transition to the Steel Sustainability Australia (SSA) certification program in late 2022.

The revision aims to:

• Respond to the increasing demand for more sustainable, and responsibly sourced materials in the construction industry

• Meet current and future expectations of multidimensional sustainability (ESG) requirements across the broader steel supply chain and support participating steel suppliers with a program that demonstrates compliance

• Align with the Responsible Products Framework under GBCA's revised Green Star rating tool

system (EMS) which is verified annually by a third-party auditor and certified to a level of performance. An ESCcertified steel supplier attributes 1 credit point towards a Green Star project under GBCA's Green Star Design and As Built rating.

ESC TRANSITIONS TO STEEL SUSTAINABILITY AUSTRALIA (SSA)

With increasing sustainability demands, ESC is undergoing a significant transition process, and will soon adopt the GBCA’s new Green Star Responsible Products Framework.

A broad array of new Environmental Social Governance (ESG) initiatives will enable SSA certified companies to access a far greater number of Green Star credit points for building and construction projects, whilst driving best practice sustainability improvements across their operations. We believe Green Star credit points and proof of sustainability accreditation will be in growing demand for construction projects.

The key principles of GBCA’s New Green Star Responsible Products Framework are:

• Responsible: the manufacturer is transparent about its product’s impacts and contents.

• Healthy: the manufacturer’s products are low or nontoxic and drive valuable social outcomes.

• Positive: the manufacturer’s processes avoid significant environmental impact, and deliver net zero products.

• Circular: the manufacturer is ready for low-carbon production and the circular economy.

THE NEW STEEL SUSTAINABILITY AUSTRALIA (SSA) PROGRAM

As part of the ESC’s next stage of evolution, it will transition to the Steel Sustainability Australia (SSA) certification program. The SSA program engages the entire steel value chain by verifying upstream steel producers supplying the steel feedstock and certifying the downstream suppliers against best practice environmental, social and governance (ESG) indicators (as shown in the table below). SSA will offer:

• A tiered certification model providing 4 pathways to achieve certification. Levels 1 and 2 (2A and 2B) will be active in the first release (late 2022), and Level 3 will be released in a further iteration

• Compliance to broader sustainability indicators including environmental, social and governance (ESG) requirements for steel producers and downstream fabricators, rollformers, and reinforcing processors

• Alignment to the revised Green Star tool by complying to the Responsible Products Framework, allowing certified SSA suppliers to contribute up to five Green Star credit points* towards the structure on a project

The SSA program has been approved by the GBCA and will go out for public consultation. To keep up to

date with the latest SSA news, visit steelsustainability.com.au by scanning the QR code below.

BENEFITS FOR SSA CERTIFIED SUPPLIERS

• Provides assurance to customers that the steel supply is reducing its environmental and social impact

• Competitive advantage for members enabling them to stay current in the market

• Ability to contribute up to five Green Star credit points* towards the structure on a project

• Potential cost savings by identifying and implementing operational efficiencies

• Access to sustainability resources such as a Life Cycle Analysis tool when SSA Level 3 is released

• Enables members to build a strong sustainability brand through a suite of relevant and fit for purpose ESG, circular economy and carbon reduction initiatives

THE TRANSITION

Current ESC members, and new members that join prior to the SSA taking affect, will be certified to the existing ESC until 30 June 2023. ESC members will have from the release date of SSA (late 2022) to next year's audit (April-June 2023) to prepare for their chosen level of SSA certification (Level 1 or 2).

* Refer to the GBCA website for further information on theGreenStarprogram

THE BENEFITS OF AUTOMATION IN CUTTING AND DRILLING INCREASED PRODUCTIVITY AND SAFETY WITH FICEP

FICEP is a world leader in the production of automatic systems for the steel construction industry. The company has designed, manufactured and installed more than 150 fully automatic layouts in different configurations worldwide.

Safety First is a mantra that resonates in all industries with heavy production processes. The automation offered by FICEP helps shift employees away from strenuous and dangerous work. This improves safety in the workplace for employees, as well as their overall health and wellbeing.

Automation also addresses another important critical issue that the industry is currently facing: the shortage of skilled workers. By automating production processes, employees can be redeployed to higher value-added tasks.

The automation of processes improves speed and efficiency, as well as time-to-market savings. Automation can also improve quality, precision, accuracy and repeatability of processing.

FICEP'S VALIANT AND KATANA

As an integrated technology partner, FICEP offers VALIANT in combination with the KATANA sawing machine. When integrated with advanced automatic handling systems (like roller conveyors and cross transfer tables), this technology meets the production needs of the steel construction industry. By increasing automation, this technology boosts productivity and provides a safe working environment for operators.

FICEP's VALIANT drilling center is capable of handling beams up to 1,200 mm. It guarantees top production performance in processing all profiles used in civil and industrial steel constructions.

VALIANT can position the beam and perform all programmed processes without repositioning. The new extended subaxis spindle positioning enables simultaneous drilling on all three surfaces even when the holes are not aligned. It can be equipped with three automatic 14-position tool changers, one for each spindle, which provides superior performance with a significant reduction in cycle times.

Multi-functionality and versatility are among the most appreciated aspects of VALIANT. An example is the 4-axis underside scribing device with sub-axis positioning to permit up to four-side simultaneous scribing operations. Other processes like tapping, countersinking, milling (slot and cope) save many working hours while increasing productivity.

VALIANT technologies can achieve weld access holes also known as rat holes and weld preparation greatly reducing or eliminating secondary processes at the ends of the beams. The latter makes it possible to increase the degree of precision of the beam joint, eliminating the subsequent finishing phase, which is often carried out manually. VALIANT requires only one operator to carry out several operations yet is also flexible to allow manual intervention to be bypassed completely when required.

FICEP's revolutionary Direct Drive spindles—that transmit 100% of motor power to the tool—offer maximum processing performance. They meet even the most demanding requirements and heavy-duty cycles with great efficiency.

VALIANT automated systems can be supplied 'stand-alone' or combined with the KATANA sawing system, FICEP's latest evolution in the field of band sawing. The KATANA has a closed loop feedback, making it one of the fastest cutting in the market. KATANA can perform cuts up to 60° mitered in both directions and at the highest quality. KATANA is integrated with an automatic unloading device with a magnet that allows the processed short pieces to be unloaded automatically. This is done without the intervention of an operator, improving workplace health and safety; this task can be particularly dangerous when handling heavy pieces.

Both the VALIANT and KATANA can be operated by a single numerical control developed in-house by FICEP. Pegaso guarantees better performance and a substantial reduction in cycle times. Pegaso is equipped with a powerful processor, expanded memory, up to 15 controlled axes and multiple communication protocols (Canbus, Profinet, Ethercat). It also comes with an innovative, easy-to-use offline programming software.

Thisarticleispartofapaidadvertisingpackage.

ALLTHREAD AWARDED GOLD IN AUSTRALIAN GOOD DESIGN AWARDS

Allthread Industries is delighted to announce that its wind-turbine anchor cages were awarded the Gold accolade in the engineering category of the 2022 Australian Good Design Awards. The Awards are the highest honour for design and innovation in the country, recognising projects that demonstrate excellence in design and highlight the impacts of a design-led approach on business success, social and environmental outcomes.

Allthread’s low-impact anchor cages are revolutionising costs, environmental impacts and productivity in the local wind farm industry, significantly reducing the time, labour and safety challenges involved in installation. This is especially important in an increasingly carbon-constrained, renewable energy-powered economy.

In announcing the award, the jury commented, "Great to see this safe and environmentally-conscious innovation contribute to such an important area of our economy and society. Congratulations on this way to improve productivity and strengthen local industries!"

Allthread is an Australian manufacturer, prioritising not only the environment, but local manufacturing as well. This results in improved quality and products, reduced environmental impacts, and benefits to the local economy and industries. Its anchor cages are designed, manufactured and preassembled in the Allthread factory in Sydney, then delivered for on-site installation. (Most anchor cages are made in China and imported as flatpacks.)

Local, sustainable solutions are prioritised: all steel and 98% of each cage’s total content is Australian, with 50% also recycled.

"We are thrilled to have our achievements recognised’, said Simon Preston (Group General Manager, Allthread Industries). "This accolade is an acknowledgement of the innovative design solutions we use to produce better, safer, cheaper and more reliable anchor cages, at the same time slashing environmental impacts and supporting the local economy."

Wind-turbine anchor cages are an important component of wind power developments. These enormous steel cages are installed below ground and filled with concrete, their weight keeping the massive turbine towers stable, even under huge wind forces. Designs vary, but thick steel baseplates with hundreds of bolts attached (4 metres long, 50 kilograms) are put in pits and buried in concrete, the bolts are then attached to the turbine’s base.

The Good Design Award is the latest recognition of Allthread’s innovations, which have drastically reduced delivery and installation times, costs and environmental impacts while supporting local industry. Some of the benefits of Allthread cages include:

• Decreased costs: For example, on the Murra Warra 2 Wind Farm, the Allthread anchor cages were approximately $200,000 cheaper than imported

alternatives (around 5% of cage costs, including installation and labour).

• Reduced installation time: 90 minutes using two workers plus a crane, versus two days with six workers and heavy machinery.

• Phenomenal time savings: one example is at Murra Warra 2 Wind Farm, where installation was completed two weeks early, despite commencing two weeks late.

• Reliable delivery: trucks versus shipping (seven weeks versus three months).

• Supports local industry and jobs: manufactured locally with 98% Australian content.

• Increased safety: no reported incidents. All manual lifting and finger pinch opportunities eliminated, and working at heights minimised.

• Increased environmental sustainability: including half the carbon footprint.

• No waste on delivery, saving 15 tonnes of landfill per project.

This award comes in what has already been a great year for the company. A recent Independent Life-Cycle Assessment study showed that Allthread’s anchor cages have a far lower overall environmental impact than similar overseas products, including a 47% lower carbon footprint.

Since beginning to supply the Australian market, Allthread has shipped more than 1,200 anchor cages, with current contracts for 332 anchor cages across MacIntyre, Clarke Creek and Goyder wind farms.

STEELWORK COMPLIANCE AUSTRALIA

NOW ACCREDITED BY JAS-ANZ

The Australian Steel Institute (ASI) continues the journey to ensure clients, engineers, architects, constructors and fabricators have the tools to ensure compliant outcomes for structural steelwork.

ASI congratulates Steelwork Compliance Australia (SCA) which has now been audited and awarded JAS-ANZ accreditation for auditing to the full scope of AS/NZS 5131 Structural steelwork – fabrication and erection. SCA is currently the only Certifying Body with the entire standard accreditation.

AS/NZS 5131 defines good practice for the fabrication and erection of structural steelwork for projects in Australia, using a risk-based fit-for-purpose approach. It provides the technical basis for the National Structural Steelwork Compliance Scheme (NSSCS) and establishes a quality benchmark that is responsive to the needs of both projects and clients.

With the ASI authorising SCA as the single Certifying Body to utilise the National Structural Steelwork Compliance Scheme (NSSCS), the supply chain now has another level of surety that services provided by SCA are approved and monitored by JAS-ANZ.

NATIONAL CONSTRUCTION CODE 2022 (NCC)

ASI championed the revision of AS 4100 which now references AS/NZS 5131. As a result, AS/NZS 5131 is set to become law, with the National Construction Code (NCC) 2022 revision due to be published in October 2022.

DERISK YOUR PROJECTS

By engaging an SCA certified fabricator, clients, building contractors and engineers can significantly de-risk their projects. Certified fabricators that have been audited fully to AS/NZS 5131 and certified to demonstrated elements, are listed on the SCA website, ensuring currency of certification is easily verified.

START THE JOURNEY TOWARDS CERTIFICATION

Gaining your certification will demonstrate to clients your ability to fabricate and erect structural steelwork in accordance with AS/NZS 5131.

SCA certification de-risks the construction industry by providing certainty that certified fabricators have the capability to produce compliant products and services to the relevant Construction Categories as outlined by the engineer. ASI member companies receive substantial discounts on their audit fees with SCA.

For more information, contact Bushan Salunke (General Manager, SCA) on bushans@scacompliance.com.au or 0400 592 530.

IMPROVES QUALITY

Works to improve processes, procedures, traceability and skill levels of the whole Australian industry to a consistent quality benchmark.

DECREASES RISK

Decreases level of risk for asset owner and constructor; Fabricator must clearly demonstrate competence to a CC based on industry best practice.

INCREASES PRODUCTIVITY

Provides comprehensive technical prequalification by independent 3rd Party experts; saves pre award time and dollars and increases industry productivity

FIT FOR PURPOSE

First Australian Standard specifically for steelwork fabrication and erection. So it's a fit for purpose, risk based Standard and approach to auditing and certification.

MINIMISES REWORK

Minimises rectification and re-work, and associated costs, reducing costs, project delays and environmental impacts due to waste and additional freight.

BOOSTS LOCAL CAPACITY

Increases local capacity and capability to supply to large projects by facilitating fabricator resource pooling under a common quality framework.

LEVELS THE PLAYING FIELD

Having steel fabricators grouped into 4 certification levels enables them to compete against similar fabricators, which enhances supply chain effectiveness.

SCA

STEELWORK COMPLIANCE AUSTRALIA

BENEFITS FOR THE CONSTRUCTION INDUSTRY

• Providing greater certainty of construction outcome

• Reducing the incidence of bogus supply

• Boosting productivity by minimising the need for rework and repair over the lifecycle of a project

• Providing a national pool of pre-qualified fabricators to AS/NZS 5131, reducing the time needed to vet and qualify suitable fabricators for your projects

• Reducing risk consistent with the Workplace Health and Safety Act and Regulations

BENEFITS FOR CLIENTS AND GOVERNMENT

• Assurance that the steelwork contractor is competent as assessed by an expert process

• Assurance that the tender offer is based on a like-for-like quality comparison and not compromised on quality, therefore minimising likely costly rework and remediation

• Management of risk and your duty of care under the Workplace Health and Safety Act (Safe design of structures)

• Utilising a steelwork fabricator that has invested in training, apprenticeships, systems and capability over those that quote on price alone

• The ability to specify an open compliance scheme that has been independently accredited by JAS-ANZ

• Support development of a world class steelwork fabrication industry in Australia

BENEFITS FOR BUILDERS

• Avoids the cost of setting up an in-house fabricator quality capability assessment team

• De-risks steelwork procurement

• Provides an assessor with intimate knowledge of steelwork fabrication

• Provides the ability to nominate a fabricator for which the builder can request assessment

• Is fit-for-purpose based on risk assessment, and is therefore cost effective

• Provides a mechanism to feedback project outcomes and request special fabricator assessment

• Reduces costs of rectification and rework, utilising fabricators proven to meet the minimum requirements of Australian Standards

• Frees up valuable personnel to focus on the project issues and delivery they were trained for

BENEFITS FOR FABRICATORS

• A proven commitment to capability based on certification level will help distinguish you in the eyes of clients

• A de-facto ‘National Technical Prequalification Scheme’ that in time will become common across the industry, increasing productivity, saving significant time and cost in tender submissions and multiple certifications

• The site audit and ensuing gap analysis can prompt demonstrable improvements in internal process efficiencies

• A uniform transparent quality bar to support fair competition with your peers

ON THE BEAM

Each quarter, the Australian Steel Institute (ASI) brings you news and views from around the steel industry in our regular column: On the Beam. From projects won and completed, through to new product launches and company announcements, you can find it all here.

WATKINS STEEL CELEBRATES THE OPENING OF A NEW FACTORY

Watkins Steel recently celebrated the official opening of their new factory at Raubers Road in Banyo, Queensland.

Watkins Steel was established in 1968, with its first workshop located underneath a suburban house in Hendra. The company soon rented some smaller factories, before building its first factory in 1978 on Toombul Road in Virginia.

Every decade since then, Watkins Steel has progressed into larger facilities until the company's last move to Depot Street in 2008. 14 years later, Watkins Steel has officially expanded into its entire Raubers Road factory, taking their overall footprint from approximately 2,500m2 to 10,000m2 This expansion is testament to the ongoing growth of the business and the incredible work of their employees across estimating, drafting, fabricating, installation, research and development, business services and Holovision.

Watkins Steel combines the latest 3D technology with advanced robotics to produce a variety of steel structures with unparalleled accuracy. Specialising in small structural steel, metalwork, urban artscapes, architectural structures, and refurbishment projects, Watkins Steel's range of services also includes steel detailing and 3D laser scanning.

ASI SUBMISSION TO NSW GOVERNMENT’S FUTURE INNOVATION GREEN PAPER

ASI has made a submission to the NSW Government’s Securing future innovation and global competitiveness in NSW Green Paper. Consultation was sought on "on the forces driving substantial, rapid and ongoing change across the economy", to help the Government with industry policy reform in NSW over the next 10 to 15 years.

Key points in ASI's submission were:

• Transition to net zero emissions by 2050 is the single biggest challenge and opportunity for the steel industry over the next 20 years.

• All the major Australian steel producers have announced their intention to meet a net zero emissions by 2050 commitment, which is supported by comprehensive, published sustainability plans.

• The single most critical business operating environment constraint is the availability of skilled personnel to fill industry wide vacancies.

• ASI believes the single most effective means of encouraging local industry innovation and growth is for the NSW Government to set mandatory local participation targets for major projects.

FIRST GREENSTEEL-READY PELLETS MADE IN WHYALLA

FROM LOCAL MAGNETITE

GFG Alliance’s mining arm, SIMEC Mining has produced its first high quality GREENSTEEL pellets that will underpin the future of decarbonised steel production in Whyalla, South Australia.

The pellets were produced from the company’s Duchess South drill core in the Southern Middleback Ranges using innovative technologies proposed for SIMEC’s magnetite expansion operations. As part of routine production, a small parcel of concentrate was successfully converted to pellets in the existing pellet plant.

The successful production of the Direct Reduction grade pellets is another significant step forward in GFG Alliance’s GREENSTEEL transformation at Whyalla, and is coupled with the successful commissioning of a 400tph demonstration pilot plant to test an innovative technology integral to current and future mining operations.

Both milestones build on GFG’s announcement earlier this year of its magnetite expansion project and construction of a debottlenecking process to increase magnetite concentration production to 2.5Mtpa. Processed magnetite concentrate is a high-quality energy efficient iron ore product which is needed to feed the Direct Reduced Iron (DRI) process. DRI enables the use of hydrogen as an alternate reductant to fossil fuels, and when fed by renewable energy it makes GREENSTEEL.

This magnetite expansion work offers GFG the chance to increase exports

to its steelworks in Europe and to strengthen its position as a consistent supplier of premium quality magnetite to support low carbon intensive steelmaking.

GFG Alliance’s Executive Chairman, Sanjeev Gupta, said, “Our purpose is to create a sustainable future for industry and society and that starts right here with magnetite – a critical enabler of our global GREENSTEEL strategy. Thankfully it’s an iron ore we have in abundance right here in Whyalla.”

SIMEC also provided an update on its Dry Low Intensity Magnetic Separation (DLIMS) plant, which rejects nonmagnetics from a coarse crushed fraction of the feed material, thereby upgrading the quality of feed to the magnetite concentrator.

Performance of the plant has exceeded expectations by rejecting over 20 percent of the feed mass as waste, while still recovering more than 98 percent of magnetics to product.

SIMEC’s magnetite expansion plan continues with a feasibility study underway for Stage 2, which is evaluating a new 5Mtpa magnetite concentrate supply chain to supplement the existing Stage 1, 2.5Mtpa facility.

The current optimised mine shell contains 443 million tonnes of magnetite ore from the JORC compliant Duchess South reported resource of 614 million tonnes. The proposed flowsheet for processing this ore generates a product containing 68 – 70 percent Fe magnetite concentrate with less than 2 percent silica. This quality is referred to as direct reduction, or DR quality product.

The life of the mine is estimated to be in excess of 20 years, with the mine producing 7.5 million tonnes per annum of magnetite concentrate, and generating annualised revenue of more than $800 million over that time.

According to Interim CEO Primary Steel and Mining and Director Industrial Projects, Theuns Victor, “This grade of magnetite is a key enabler to Whyalla’s GREENSTEEL future, and strengthens its position as a consistent global supplier of premium quality magnetite to support low carbon intensive steelmaking.”

“When combined with renewables, particularly solar from our Cultana Solar Farm, our port, a skilled workforce, and supportive community and government, we have all the ingredients to create a world leading GREENSTEEL hub at Whyalla and fulfil our CN30 mission.”

SIMEC Mining General Manager Magnetite Expansion and Growth, Gavin Hobart, said, “Our existing ironore operation in Whyalla is home to some of the highest purity and most desirable deposits of magnetite in the world. The high quality of our ore makes it a critical resource to enable GREENSTEEL manufacturing and this successful pellet production is a significant milestone toward realising our plans.”

“Stage two of our magnetite expansion project represents a generational opportunity for economic growth in Whyalla. Once operational, the project is expected to employ more than 1,200 workers and support around 3,500 people in the broader community.”

AUSTRALIAN STEEL INSTITUTE UNDERGRADUATE STEEL DESIGN AWARDS

The Australian Steel Institute (ASI) is pleased to announce the winners of the 2022 undergraduate steel design awards. Sponsored by the ASI each year, the awards recognise students across the country who have achieved the highest grade in their third year steel design subjects. The awards play a vital role in fostering the next generation of architects and engineers.

Each year, the Australian Steel Institute (ASI) offers awards to the students who achieve the highest grade in their third year steel design subjects at Australian universities across the nation.

Students are assessed by their own university based on the results of their steel related subjects. The winning students receive an eLearning voucher, so that they can take advantage of the ASI's diverse range of online courses.

According to ASI Chief Executive, Mark Cain, "The ASI's Undergraduate Steel Design Awards play an important role in building a relationship with the next generation of engineers and architects. These high performing students usually go on to be employed in design or engineering positions with high profile engineering consultants due to their academic ability."

"As the nation's peak body representing the entire Australian steel supply chain—from the manufacturing mills right through to end users in building and construction, heavy engineering and manufacturing—it is vital that we foster the academic and professional careers of these individuals."

"In the future, these students may be in a position to influence a decision to use steel in a structure due to their familiarity with steel design. It's important that the next generation does not perceive steel design as a difficult process. Through initiatives such as these awards, the ASI is

helping to provide tools and education to promote the use of steel in Australia," said Mark.

"Supporting the work of Australian universities is also important. Universities are hotbeds of innovation and entrepreneurship. They help provide students with the skills to compete in increasingly global workplaces and shape the minds of the future."

The ASI would like to congratulate all of the winning students for 2022:

• Bendigo Kangan Institute: Phillipe Noel

• James Cook University: Christopher Konidis

• University of New South Wales (UNSW) Sydney: Chang Chen

• University of Sydney: Toby Hoggett

• University of the Sunshine Coast: Patrick Adams

• Monash University:

• Jeffery Dean Fong

• Liam Craig White

• Taylor Poon

• Western Sydney University: Kuer Duot

• CQ University: Sean Kerlin

• University of Technology Sydney: Hussein Daoui

“

The ASI's Undergraduate Steel Design Awards play an important role in building a relationship with the next generation of engineers and architects. It is vital that we foster the academic and professional careers of these individuals."

STUDENT PROFILE: KUER DUOT

Kuer Duot won Western Sydney University's 2022 ASI Undergraduate Steel Design Award.

According to Kuer, her decision to study a Bachelor of Engineering (Honours) (Civil Engineering) was an easy one to make. " I actually didn't know what to study, but my sister suggested engineering. I’m a very curious person. I want to know how things work, and I love mathematics."

"I majored in civil engineering, and with this course, I had the opportunity to learn about the engineering behind just about everything—not just roads and building. I was also able to study sustainability and risk engineering, which will help us in the future. This is what I love about the course—it's practical."

"This semester I am completing my thesis, which is a practical project that I’m working on with my supervisors. We're analysing a new flooring system, which is a steel deck that can reduce the height of a building. The steel decking features cavities, through which services and cables can be run, which is relatively new within the moment. We're looking at the structural behaviour of the decking."

"Steel is very light to use, sustainable, and saves time during construction. It will be a very useful material in the future."

"Winning the ASI Undergraduate Steel Design Award meant a lot to me. At first, I was very confused about what I wanted to do when I graduated. Now, I know I want to do steel design. I want to become a structural engineer," said Kuer.

ENGINEERING AT WESTERN SYDNEY UNIVERSITY

Western Sydney University's Bachelor of Engineering (Honours) is a four year full-time undergraduate engineering program. The program is designed to meet Engineers Australia professional accreditation requirements –Competency Stage 1 Professional Engineers, and Australian Quality Frameworks (AQF) Level 8.

Students have opportunities to choose a discipline area by selecting a major in Advanced Manufacturing, Civil,

FREE ASI MEMBERSHIP FOR STUDENTS AND ACADEMICS

Did you know that the ASI offers free memberships to both students and academics?

If you're not already an ASI member, take advantage of this opportunity today.

Student Membership

Student membership is available to full-time students who are studying subjects such as engineering, architecture, construction and welding at universities and TAFEs in Australia.

What's included:

• Full access to online eLibrary

• Member discounted rates for all bookshop purchases (limit one copy per publication)

• Member pricing for all events and webcasts

• Special discounted student rates for all eLearning courses

• Regular industry updates and newsletters

Construction, Electrical, Materials, Mechanical, Robotics and Mechatronics, and Sustainability Engineering. In addition, students can specialise by selecting one minor that will complement their chosen discipline. Meanwhile free elective subjects help students broaden their learning by developing knowledge and skills from other disciplines and professional fields for the future.

Students can also apply their program knowledge to fascinating, real-world challenges, such as Western's ongoing Solar Car project, Formula-SAE project and Unlimited Robotics Club. Plus, at the end of their third year, students complete a 12 week work placement, to finish their studies with real-world experience.

Academic Membership

Academic membership is available to lecturers in engineering, architecture or construction at Australian universities and TAFEs offering courses that further the steel industry as part of its curriculum. Academic members can benefit from the library service for teaching aids and assistance with guest lectures from State Managers as required.

What's included:

• Full access to online eLibrary

• Borrow hard copy books from library

• Member discounted rates for all bookshop purchases

• Member pricing for all events and webcasts

• Discounted member rates for all eLearning courses

• Member only exclusive offers with selected partners

• Regular industry updates and newsletters

• Opportunity to vote at the ASI's AGM

For further details, contact membership@steel.org.au

SOTO : ENGINEERING EXCELLENCE FOR 25 YEARS

For 25 years, Soto Consulting Engineers has worked collaboratively with major companies in the heavy industrial, mineral resources and construction sectors to design, build and refine engineering solutions that enable them to compete in global markets. Their team of specialists has a wealth of experience across engineering disciplines and a strong track-record of delivering solutions.

Frank Soto and Associates Consulting Mechanical Engineers was officially registered in January 1998. Originally from Whyalla, Frank Soto has never been far away from heavy industry, moving from one iron and steel town to another: Wollongong. Although Frank claims he is first and foremost a mechanical engineer, he is also a process engineer by training.

In the early days, Frank worked with a small team of talented and specialised professionals, designing and drafting in a ‘tin shed’ behind a fabrication shop in Kemblawarra, Wollongong.

According to Frank, "We came from humble beginnings. We started out picking up small packages of work, helping local manufacturers, machining shops and fabrication shops, as well as undertaking equipment assessments

for mining and steel sector companies. That soon expanded into the cement and refractory sectors."

Moving from that ‘tin shed’, Frank celebrated his success and moved to Unanderra. There, he renovated the old chicken shop, and gradually expanded the company's footprint to take in the premises downstairs, and eventually the bank building next door.

As Jim Allan (Chief Operating Officer, SOTO) explained, "To become the businessman he is today, Frank has navigated the company through times of significant change in competitive industrial and commercial environments. He appointed himself Principal Engineer in 1990 and, over the years, has overseen many defining moments and major developments."

EXPANSION

To keep pace with growing demands for their services, Frank Soto and Associates expanded from a small, family business, with a predominantly local client base, into a medium-sized firm providing leading quality design engineering to heavy industries and mining companies outside of the Illawarra.

Additional skilled engineers and draftspersons were brought into SOTO, diversifying the company's skillset to take on new projects that increasingly involved civil and structural design. More complex mechanical engineering challenges brought about the establishment of a computational analysis team.

Team diversification became the hallmark of the SOTO business, and with their expansion, a name change

Frank Soto (General Manager)became necessary to illustrate to the marketplace that the company was no longer just a small, local, family business.

As Leonardo Da Vinci—arguably the greatest engineer of all time—once said, "Simplicity is the ultimate sophistication". So, from Frank Soto and Associates Consulting Mechanical Engineers, the company became SOTO.

"As time went on the team grew, and so did our clients, but many things remain the same to this day; our passion for solving engineering problems; our diverse team of specialists keen to be the best at their job; our focus on integrity and values; and our commitment to the Illawarra community and economy," said Jim.

"That passion, seeded two decades ago, created the foundation for our growth and has led to a thriving business with a reputation for pinpoint sharp, innovative, engineering solutions all around Australia, and importantly to us, a name synonymous with Illawarra industry. Through Frank’s determination, persistence

and our team’s innovative designs, we’ve played a significant part in the metamorphosis of local manufacturing, steel and heavy industry, improving safety, efficiency and productivity wherever we contact our client’s business."