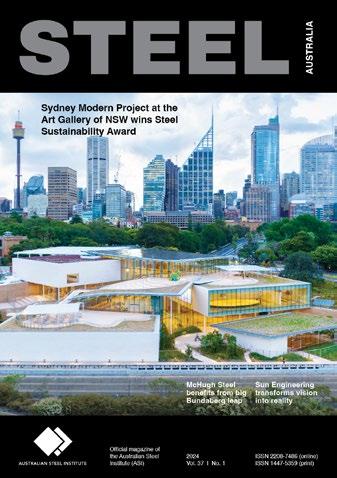

Sydney Modern Project at the Art Gallery of NSW wins Steel Sustainability Award

Sydney Modern Project at the Art Gallery of NSW wins Steel Sustainability Award

As Australia’s largest super fund1, AustralianSuper is an active investor both in Australia and overseas. This breadth of investments means members benefit from opportunities across the world and different types of assets including:

Owning listed shares means owning part of companies that are listed on a public exchange, like the Australian Stock Exchange (ASX). AustralianSuper invests in Australian and international companies.

Private equity involves investing in companies that are not listed on a public exchange like the ASX. AustralianSuper co-invests in private equity along with specialised private equity managers. Private equity has the potential to outperform listed shares over the long-term.

Real assets include unlisted infrastructure and property assets located in Australia and internationally. These investments help support economic development and improve living conditions for communities and includes bridges, roads, airports and power plants. AustralianSuper’s portfolio includes large-scale infrastructure investments in Australia and internationally.

Credit investments involve providing finance for an agreed period in exchange for a return. AustralianSuper has a specialised team that invests in private credit opportunities directly in the property and infrastructure sectors.

Fixed interest investments provide income from interest payments. Fixed interest investments include bonds and debt

Cash investments are short-term money market instruments. These are issued by banks, like the CBA, NAB and Westpac, governments and companies.

AustralianSuper has investments throughout the world. This helps support Australia’s economy while members can benefit from growth in local and international markets. Importantly, this global approach can help reduce investment risk through diversification.

0419 136 720 Victoria, Tasmania and South Australia

Sulfianda Soeleiman on 0437 594 571

James England on 0423 614 860 Queensland

0418 788 870

on 0407 107 415 STEEL AUSTRALIA CONTACTS

all reasonable care taken to ensure the accuracy of the material contained herein, the Publisher does not assume any responsibility or liability for any loss or damage which may result from any inaccuracy or omission in this publication, or from the use of the information contained herein, and the Publisher makes no warranties, express or implied, with respect to any of the material contained herein.

organisation conducts engineering seminars and disseminates relevant, timely and detailed information. Expert technical advice, a library and a resource centre are available to all members, along with a range of other member benefits. For information, visit: steel.org.au

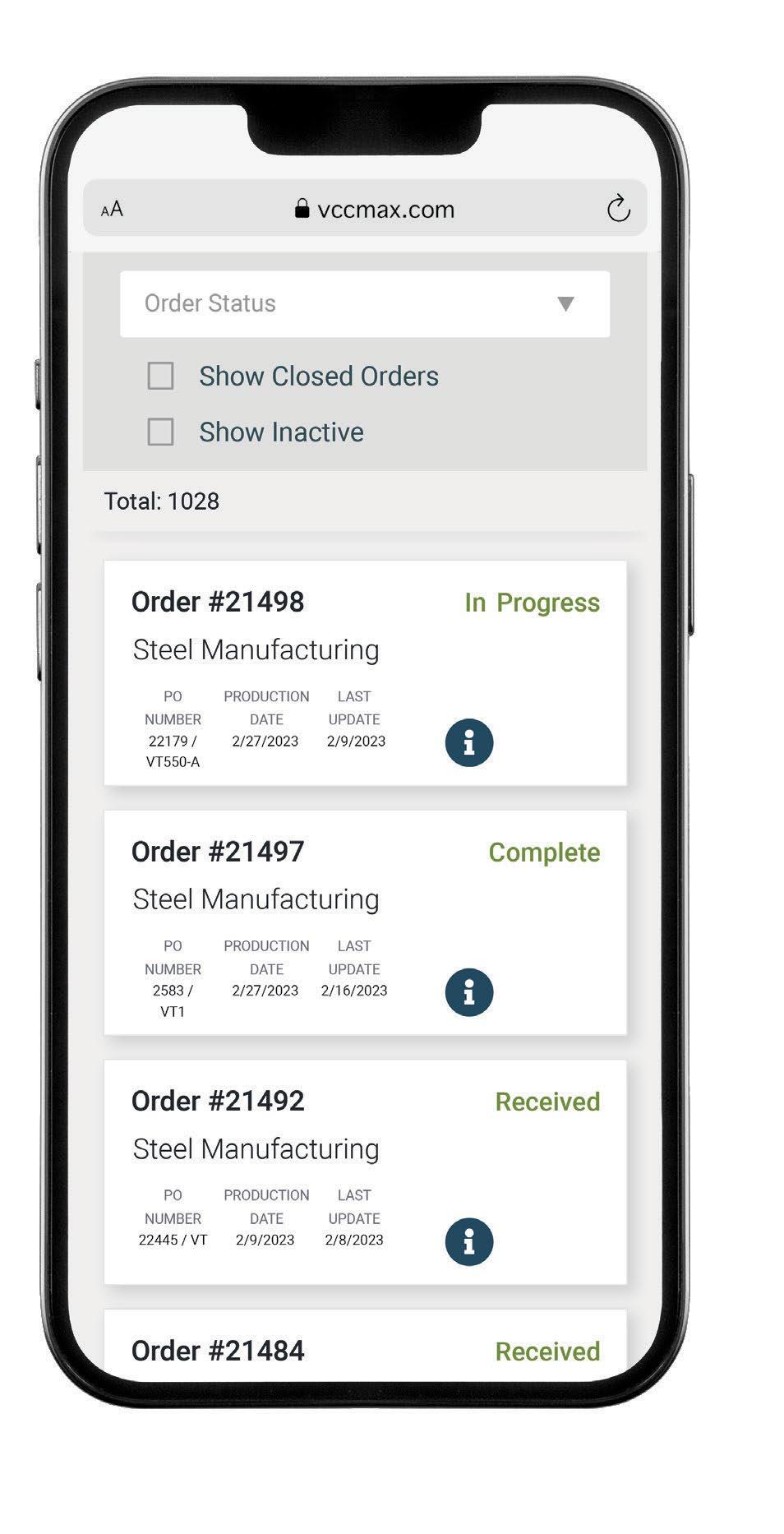

Receive automated alerts at every step and access order documentation from any connected device, with VCC Max.

REAL-TIME TRACKING ALERTS YOU AT EVERY STEP.

If there’s one thing we know at Valmont Coatings, it’s that the time you spend chasing down orders is time you simply don’t have. With VCC Max real-time order tracking and notifications, you’ll always know where your product is – and when it’s complete.

And as Australia’s largest hot-dip galvanizing company and recognized leader in protective metal coatings, you have the added assurance that the steel products you make remain protected for as long as you want – up to 100 years.

WHY WAIT?

Learn more about our hot-dip and spin galvanizing capabilities at valmontcoatings.com.

In this edition I want to acknowledge one of the ASI Board members Maria Mavrikos, who is the founder and managing director of leading Victorian steel fabricator Structural Challenge. This is a story to read in full as Maria made an incredible impact on me in March 2024.

International Women’s Day was on 8 March this year. I did what many do, and supported various workplace events within my business. I participated in a company-wide virtual panel where, along with several women within our company, we shared our thoughts and experiences and identified challenges women face when advancing their careers in the steel industry.

International Women’s Day done for the year...or so I thought.

On 19 March I saw a LinkedIn post (scan the QR code opposite to read the post) in which Maria shared insights into her own journey to become an outstanding business person, ambassador of our industry, and supporter of the communities that we serve. Maria spoke of the challenges in not being readily accepted for what she was – the leader of a steel fabrication company.

Maria shared observations and her thoughts on how to attract and advance women in the steel industry by working consistently with structured initiatives, specific goals, tangible opportunities, and open communication challenges to receive feedback from the frontline.

Maria’s closing paragraph was a compelling call to action for us all: If women do not consider steel a career option, an annual celebration with a cute pink cupcake won’t do the job. We need as many men as possible in this industry to take ownership of the Women in Construction Strategy. It’s a great strategy; it’s time to bring it across the line.

Maria has put her own words into action, founding Steel Chicks (www.steelchicks.com)—a community for women breaking into, re-entering and developing within the steel industry.

The Australian steel industry is dedicated to helping Australia realise its societal ambitions. We come together across the value chain and supply chain to make the unbelievable happen. We make structures that astound the eye. We make gathering places like stadiums, campuses, and shopping centres that connect people. We make public and private infrastructure that house, support and educate the community. We make a difference.

In support of Steel Chicks let us all resolve to make a difference in the speed by which our industry removes barriers, impediments or traditions that demotivate women from aspiring to enter our industry. Let us all resolve to enable women maximum equality in our industry. Let us resolve to make our industry open for all Australians.

Please be an advocate for initiatives such as Steel Chicks, Women in Construction, and many other programs. Dare to be more than an advocate and recall Maria’s words—we need as many men as possible in this industry to take ownership.

Tony Schreiber Chair, ASI

Introducing the digital Steel Australia magazine

In response to the evolving needs of our members and audience, the ASI has launched a state-of-the-art digital version of Steel Australia magazine.

This digital leap is not just about going paperless; it’s about creating a more interactive, accessible, and engaging platform that meets you wherever you are – office, home, or on the move. You’ll be able to access the latest insights, immersive content, and a wealth of knowledge online via steelaustralia.com.au (or scan the QR code opposite).

ASI understands the timeless value of a tactile reading experience. That’s why we’re not only keeping our printed magazine, but have given it a comprehensive facelift. The sleek, modern design in the first edition for 2024 not only appeals to the eye but also enhances readability.

Promoting a sustainable and de-carbonising industry

We recently announced the winners of the inaugural Steel Sustainability Awards. The awards provide an opportunity to showcase the achievements of the end-to-end supply chain including architects, designers, engineers, steel manufacturers, distributors, fabricators, processors, builders and constructors in delivering steel-related solutions that result in positive sustainable impact.

The Australian Steel Institute congratulates all the winners, highly commended, and organisations who made a submission to the awards. The winners and highly commended were:

Large project ($10 million and above):

Winner: Arup for the Sydney Modern Project at the Art Gallery of NSW

Highly Commended: Fitzroy Bridge Alliance for the New Fitzroy River bridge

Small project (less than $10 million):

Winner: ACT Steelworks for Umbagong district park pedestrian bridges

Company project or initiative:

Winner large business: InfraBuild for The road to sustainability through good health and safety

Highly commended large business: Liberty Primary Steel for BOS slag utilisation

Winner small business: Galserv for Shore Brace 400

ASI would like to thank our sponsors, including major sponsor BlueScope, category sponsors Liberty and AA Steel Works, and distributor sponsors BlueScope Distribution, Calibre Steel, GAM Steel Service, InfraBuild, Orrcon Steel, Southern Steel, United Steel and Vulcan. For further details, see the article on page 10.

The Steel Sustainability Australia (SSA) certification program continues to grow. The program engages the entire steel value chain to comply with best practice sustainable operations in steel manufacturing, fabrication and processing. Four mill sites have been verified, 39 sites have already been certified, and another 42 sites are currently undergoing certification.

The ASI advocates for better and fairer conditions across the steel sector. Over recent months, the ASI has continued to

work with all levels of government to address these issues. The ASI drafted a discussion paper after discussions with six different NSW fabricators over a two-week period. All were quite concerned about the significant increase in the incidence of losing jobs to low-priced imported fabricated steel. One fabricator has estimated the annual quantity of imports as being between 200,000 and 250,000 tonnes. Options for follow-up action are being discussed with local steel suppliers.

We are also working with various state and federal government departments and private developers on major projects, including the Torrens to Darlington project that will require 170,000 tonnes of reinforced steel over the construction timeline; the Marinus Link project in Tasmania; the Suburban Rail Loop East project in Victoria; and the NSW Renewable Energy Plan.

2024 Australian Steel Convention

Planning is well underway for the 2024 Australian Steel Convention. With the theme of What it takes: sustainable building and infrastructure , the convention will be held from 8 to 10 September at the Pullman Brisbane King George Square.

An exciting line-up of presenters and panels will examine: costeffective, sustainable, and resilient steel solutions; case studies showcasing steel’s versatility, reusability, and traceability; demands and opportunities of the Australian infrastructure initiatives and projects pipeline; and the current and future requirements and capabilities of the Australian steel supply chain. Register via steel. org.au or scan the QR code oppposite.

Mark Cain Chief executive, ASI

Not sure what terms like bull markets and bear markets mean? AustralianSuper helps break down the terms and provide an understanding of what they are and how it can impact your super.

The finance industry and investment markets can be complicated, with the language used equally hard to understand. Let’s simplify some common terms and look at how different share market conditions may affect your super.

A bull market happens when investor confidence is strong, with share prices rising faster than average over a consistent period. Bull markets typically, but don’t always, happen alongside periods of strong economic growth, with investors attracted to the potential of higher returns.

The term ‘bull market’ takes its name from the upward shape of an attacking bull’s horns, representing a rising market. The bull symbol has also become famous thanks to the bronze bull sculpture located in New York’s financial district.

A bear market happens when share market prices are falling and there’s a drop in investor confidence. It’s typically driven by a poor economic outlook. Bear markets are often linked to major economic downturns, such as the Great Depression in the 1930s and the global financial crisis in 2008-09.

It’s thought the term originated with American bearskin traders, who would gamble that the price they pay for skins would continue to fall. Another explanation is it’s simply a reference to the way a bear attacks, with claws

shaped in the downward direction of the share market.

If your super is invested in an option that includes shares, your super balance can follow the ups and downs of the share market:

During a bull market, where investor confidence is strong and the share market value is rising, your super may grow too.

In a bear market, with share prices falling and investor confidence weak, your super may experience a fall in value.

In periods of heightened market volatility, remember super is a long-term investment. While it can be tempting to switch options when markets become volatile, being invested in a diversified portfolio over the long run can help grow your super.

If you’re concerned about changes to your super balance and the impact on your retirement plan, consider speaking to an accredited financial adviser. Speaking to an adviser can help you review your retirement goals and consider your investment options1 Speak to an AustralianSuper financial adviser to better understand markets and investment options for your future. Visit https://www.australiansuper.com/ investments

This article was supplied as part of a paid advertising package.

1. Personal financial product advice is provided under the Australian Financial Services Licence held by a third party and not by AustralianSuper Pty Ltd. Fees may apply.

This information may be general financial advice which doesn’t take into account your personal objectives, financial situation or needs. Before making a decision about AustralianSuper, you should think about your financial requirements and refer to the relevant Product Disclosure Statement available at australiansuper.com/pds or by calling 1300 300 273. A Target Market Determination (TMD) is a document that outlines the target market a product has been designed for. Find the TMDs at australiansuper.com/tmd. Sponsored by AustralianSuper Pty Ltd, ABN 94 006 457 987, AFSL 233788, Trustee of AustralianSuper ABN 65 714 394 898.

The inaugural ASI Steel Sustainability Awards shone a light on innovative practices paving the way for a better future. The awards celebrate sustainable practices across the entire supply chain, including the use of steel in building and construction projects, and company steel-related programs.

Chief executive of the Australian Steel Institute Mark Cain said the awards provide the perfect platform to inspire companies in the sector to adopt more sustainable steel practices. “The awards reflect the growing importance of environmental stewardship and responsible business practices. The ASI congratulates all the winners, highly commended teams, nominees and members who are making strides when it comes to maintaining corporate social responsibility and the environment.”

The Sydney Modern Project at the Art Gallery of NSW won the large projects (over $10 million) award. The standalone building is Sydney’s most significant cultural development since the Opera House was opened more than 50 years ago. Engineers adopted a whole-of-building approach to the 152-year-old building, which led to a 54 per cent reduction in the carbon emissions relative to the reference building. The project received a 6 Star Green Design rating for its conservation and reuse of important existing structures. This recognition celebrates leadership in sustainable building practices.

The judges also awarded a high commendation in this category to the New Fitzroy River Bridge. This project was honoured for its social and economic benefits, which set the benchmark for remote community infrastructure.

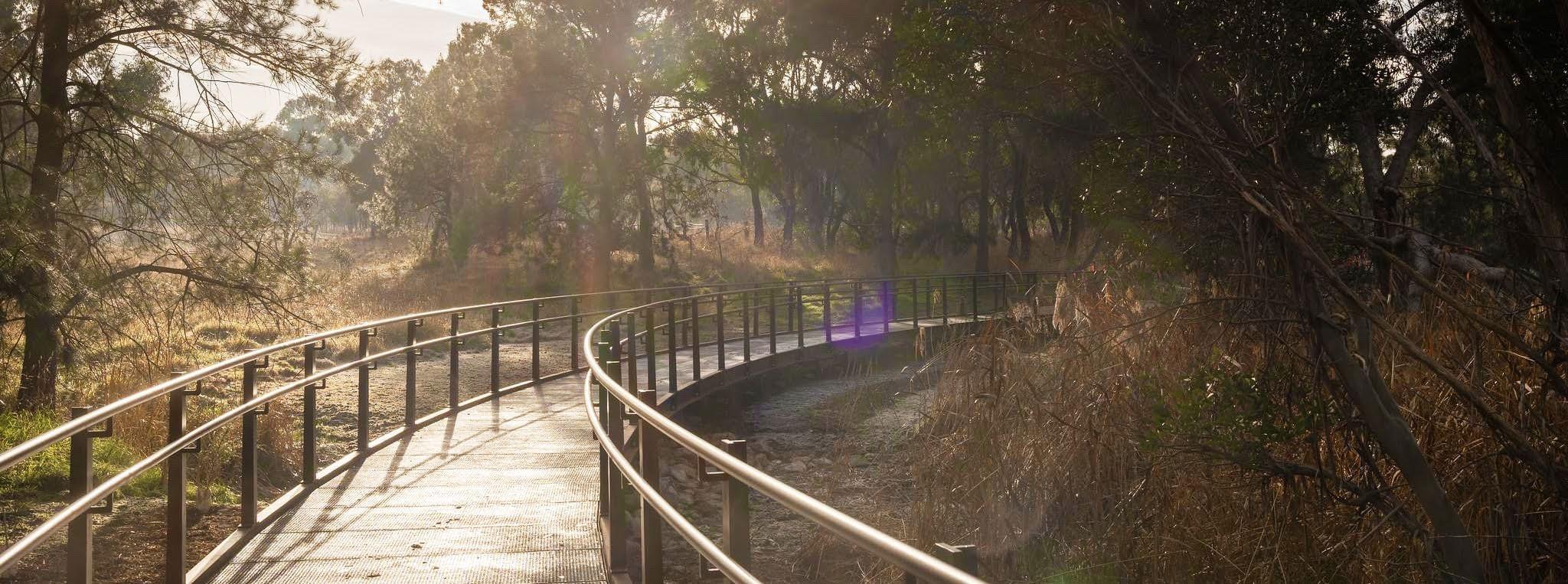

The Umbagong district park pedestrian bridges won the award for small projects (under $10 million). The handrailed steel bridges complement the natural surroundings at one of the ACT’s most serene grassland areas. The three bridges offer a unique place for visitors to experience the clear air and local wildlife. The judges commended the project for navigating several constructability challenges while maintaining positive environmental outcomes.

The Shore Brace 400 took out the company or project initiative - small business award. The hydraulic bracing system uses various extension beams to support excavations up to 20m. The judging panel celebrated this initiative for filling a gap in the market because of its circularity principles, which minimise the requirement of hiring one-off support products.

The winner of the company or project initiative - large business award was InfraBuild’s program The road to sustainability through good health and safety. This initiative encourages ongoing improvement to operations through targeted social, environmental, sustainable and economic outcomes.

This organisational approach is an excellent example for others in the sector to follow. The judges also awarded a high commendation in this category to the basic oxygen steelmaking slag utilisation initiative, developed by Liberty Primary Steel. The project seeks to reduce virgin resources and waste stockpiling on site, and represents a breakthrough in the way the business addresses sustainability.

ASI would like to thank to our sponsors, including major sponsor BlueScope; category sponsors Liberty and AA Steel Works, and distributor sponsors BlueScope Distribution, Calibre Steel, GAM Steel Service, InfraBuild, Orrcon Steel, Southern Steel, United Steel and Vulcan.

THE AWARDS REFLECT THE GROWING IMPORTANCE OF ENVIRONMENTAL STEWARDSHIP AND RESPONSIBLE BUSINESS PRACTICES.

When Combilift was established, no one could have imagined that a forklift over 16 tonnes could run on electricity alone. But the flagship C-Series has always been ahead of its time.

In a move that reinforces its sustainable credentials, Combilift has responded to customer demand and electrified an already ground-breaking range of forklifts.

Combilift Country Manager for Australia Chris Littlewood said it was impossible to ignore the wave of support for greener machines. “We pride ourselves on listening to customer feedback – it fuels our value of innovation – and electric options were high on the list,” he said. “Where before we offered the choice between diesel or LPG, electric engines are now available on C-Series capacities up to 18-tonne.”

The manufacturer first established the C-Series’ multidirectional concept in 1998, becoming the world’s first to develop the internal combustion multidirectional forklift.

Since then, Combilift has been proactive in delivering machines which meet and exceed customer expectations of performance and sustainability.

Considering this history of innovation, it’s no surprise that Combilift is shifting the dial in heavy forklift design. The

C-Series also removes the need for cumbersome built-on cast weight at the rear and instead incorporates it into the chassis. This allows operators to navigate narrower aisles and improves the efficiency of warehouse floorplans. This also supports Combilift’s drive for greater sustainability, as an efficient warehouse means a reduced footprint and associated costs of heating, lighting, and maintenance.

This ethos is the reason for Combilift’s complementary warehouse optimisation service. Some of the manufacturer’s customers have doubled their storage capacity simply by switching to Combilift forklifts and redesigning accordingly.

Chris said this is especially important to his Australian customers where industrial real estate is at a premium. “Warehouse space may be a hot commodity, but building more of them isn’t necessarily the answer,” he said. “At Combilift, we believe we should start by optimising the floorspace we do have and the reassessing our needs from there. That way, we’re not building new facilities unnecessarily or prematurely on land that could be used more effectively.”

Who could have imagined the farreaching benefits of Combilift’s multidirectional technology when it was conceived in 1998?

Of course, emissions regulations and electric vehicles were hardly discussed back then, but Combilift has combined

the best in productivity and sustainability to suit modern requirements.

The C-Series is effectively three forklifts in one, saving customers on warehouse space, turnaround times, and overall asset management. So, while the electric motor saves emissions, operators can save time and money for their business.

The design combines the advantages of a counterbalanced forklift, side loader and very narrow aisle forklifts, suiting a wide range of industries. These include aluminium, building materials, concrete, logistics, metals, plastics, steel, and timber.

The vehicle was designed to navigate awkward loads through doorways as narrow as 2.8 metres, while also perfect for palletised loads, block stacking, and loading in confined areas.

Chris affirmed that it really is the perfect all-rounder. “We thought for years that the C-Series was perfect as it was, with the functionality to tackle so many logistical nightmares,” he said. “But only when we electrified the motor did we realise there is always more innovation to be done. This addition has only bolstered an already impressive machine.”

The next step for Combilift is to electrify even more models from the C-Series range, allowing more businesses to meet their own sustainability goals.

This article was supplied as part of a paid advertising package.

Combilift provides handling solutions specifically tailored to solve the challenges faced by the Steel industry. Our ethos is helping customers increase storage without the need to expand the size of their facility. Understanding the available space and how it is being used is critical to running a more sustainable and profitable business.

Our range of multidirectional forklifts, pedestrian reach trucks, straddle carriers and container loaders will allow you to maximize the capacity, productivity and enhance the safety of your facility.

To find out how Combilift can help you unlock every inch of your storage space.

LARGE PROJECTS (OVER $10 MILLION)

THE SYDNEY MODERN PROJECT HAS TRANSFORMED THE 152-YEAR-OLD ART GALLERY OF NEW SOUTH WALES INTO A TWO-BUILDING ART MUSEUM CAMPUS. THE EXPANSION HAS ALMOST DOUBLED THE EXHIBITION SPACE, AND CREATED NEW ART AND CULTURAL EXPERIENCES, WITH SEAMLESS CONNECTIONS BETWEEN INDOOR AND OUTDOOR SPACES.

Japanese architectural firm SANAA designed the Art Gallery’s new building to respond to the site’s topography and integrate with existing infrastructure. The project site is on a steep escarpment in The Domain, north of the original art gallery building. The new and original buildings are separated by a ‘land bridge’ over a multi-lane motorway, the Eastern Distributor.

Adding complexity was a pair of decommissioned Navy fuel tanks below the site, built during WWII in a former sandstone quarry. The new building is formed from interlocking art pavilions nestled into the landscape over five levels, resting lightly on the land bridge and the fuel tanks. Each pavilion connects with the outdoors, via roof terraces, walkways, and landscaped gardens.

SANAA’s concept was for a light and expansive design that provides new types of spaces to enhance the presentation of art, performance and learning facilities. With increased space, the art gallery can showcase more of its outstanding collection and attract more of the best national and international exhibitions to Sydney.

A particular feature is a new prominent destination for Aboriginal and Torres Strait Islander art and culture, both inside the new building and across the campus including a major commission in the art garden that links the new and original buildings.

The building’s structure consists of a series of linked steel-framed structures, built over a reinforced and post-tensioned concrete podium structure, set in a deep excavation into the steep hillside.

Much of the new building is founded on existing structure. This includes the fuel tanks, constructed of reinforced concrete in 1941, and the land bridge, constructed in 2000 from in-situ and precast reinforced and pretensioned concrete elements.

The design transforms the southern of the two fuel tanks into a unique art space of 2,200m2. The intent of the art gallery was for this space to be left ‘raw’, with the only spatial interventions being a new floor and drainage, new openings cut into the walls for egress, and a spiral stair inserted through a circular penetration in the roof.

Designed by SANAA, the new building was realised through a collaboration between the art gallery and Infrastructure NSW. The project’s executive architect is Architectus, with Arup providing multi-disciplinary engineering including structural, civil, acoustic, fire, hydraulics and services, lighting, security and traffic.

It was delivered by lead contractor Richard Crookes Constructions (RCC), with the building’s structural steel fabricated and erected by Samaras Structural Engineers.

Secondary steel elements formed part of the façades and the landscaping, which were delivered by subcontractors Kingston Group and Landscape Solutions respectively.

Structural steel was even present in the artworks commissioned for the project. Francis Upritchard’s sculptures in the welcome plaza were engineered by Arup and fabricated by Italian contractor Lanaro Steel technology. The majority of the structural steel on the project was produced in Australia.

Entering Organisation: Arup

Architect: Architectus, SANAA

Engineer: Arup

Head Contractor: Richard Crookes Constructions

Steel Fabricator: Samaras Structural Engineers

The Umbagong district park pedestrian bridges won the small projects (under $10 million) category at the Steel Sustainability Awards. The project saw the replacement of existing timber walking bridges in favour of more secure steel alternatives.

The original timber walkway was constructed in 1986. Since then, it has become one of the ACT’s most serene spaces for recreational activity and wildlife. However, a safety audit found the existing timber bridges were not fit for purpose.

ACT Steelworks— the only fabricator servicing the ACT to be SSA certified—led the project alongside architect TCL; engineer Sellick Consultants; and head contractor Complex Co.

The project manager from ACT Steelworks James White said the team worked harmoniously to navigate some of the project’s constructability challenges. “This was crucial to ensure minimal environmental impact and develop a safe method of work.”

The bridges were designed to have a minimal impact on the local environment, both during the construction process and for the lifetime of the structures. Designers used the existing bridges as a guide for the location of their steel replacements. Meanwhile, engineers capitalised on the natural rock outcrops as structural foundations. This saved on the number of new materials entering the environment.

The three bridges were designed to be wider than their original counterparts to improve access for pedestrians, cyclists, and increase accessibility for mobility scooters and wheelchairs. In addition, the larger bridge incorporates a new lookout area and seating. “An efficient design was paramount to ensure the safety and wellbeing of the community could be maintained,” White said.

The design team developed smaller steel member sizes into typical and recurring modules, which allowed manual handling of all components. This eliminated the need for haul roads, crane pads and heavy machinery.

All steel used in this project was procured through InfraBuild, who optimised efficiencies in the materials while ordering. The team also reused the existing timber bridge components to create new seating throughout the park.

Meanwhile, the offcuts of steel plates were used as a plaque for each of the seats. All other wastage was separated into appropriate material types for offsite recycling.

Corrosion protection for the bracing included hot

dip galvanizing, while the support columns were painted in a PUR7 system offsite at an industrial coatings specialist, Dean Industrial. This protection is durable for 25 years to first maintenance.

“This steel design would far outperform the timber design and with a rusted steel appearance blending in with the surrounding native environment, the pedestrian bridges will retain their appearance for decades to come without the need for maintenance,” White said.

The rusted finish of the bridges was designed to complement the natural setting and colours of the Umbagong grasslands. The rusted finish was achieved offsite by lightly abrasive blasting the fabricated assemblies prior to the application of three even mist coats of a 1:10 Ferric Chloride to water mix. Shortly after, the assemblies were rinsed with water to neutralise the coating.

“The Umbagong district park pedestrian bridges project was one all stakeholders can be proud of,” White said.

“A very low impact solution that truly capitalises on the ACT inland exposure classification and opportunities to touch the ground very lightly.” ~ Judges

PROJECT TEAM

Entering Organisation: ACT

Steelworks

Architect: TCL

Engineer: Sellick Consultants

Head Contractor: Complex Co.

Steel Fabricator: ACT Steelworks

InfraBuild’s commitment to environmental, social, and corporate governance was celebrated at the inaugural ASI Steel Sustainability Awards. The road to sustainability through good health and safety initiative has reshaped InfraBuild’s culture across its several worksites. The program took out the award for company or project initiative - large businesses.

“This transformative journey InfraBuild has led...has clearly fostered a new culture to allow workers the confidence to speak up, intervene, listen and be part of these improvement programs.” ~ Judges

Prioritising health and safety is crucial for achieving sustainability. A workplace that prioritises health and safety cultivates a culture of trust, care and responsibility, fostering teamwork, reducing the likelihood of incidents, and promoting overall wellbeing. Employees are more likely to be engaged and feel valued, which contributes to job satisfaction and long-term commitment.

Between 2019 and 2022, over 400 World Steel Association members lost their lives because of work-related incidents.

CEO and executive director of InfraBuild Francisco Irazusta believes the health and wellbeing of people within the company is paramount.

“At InfraBuild, we believe one injury is one too many. No task, target or activity is more important than the safety of our team. At InfraBuild, we take psychosocial safety just as seriously as physical safety.”

InfraBuild took matters into its own hands. In 2020, the company began a transformative journey towards a better workplace culture. To

drive this transformation, a comprehensive roadmap was developed, known as the WRIB (We are InfraBuild) Safe Way.

Underpinning this are four strategic pillars with the overarching goal of creating a world-class safety culture and safety performance: enabling performance critical incident prevention interdependent safety culture fit for work and fit for life

“We’ve been on a journey to reshape our safety culture since 2020. It is about the behaviour, it’s our approach to safety that is most transformative,” Irazusta said.

The company has reported a 300 per cent increase in the number of interventions from 2021 to 2023.

“We did this by giving our team the tools and the training, 95 per cent of employees have been trained in our behavioural safety program, Safety Connect.”

Internal leaders delivered the Safety Connect program to all levels of the organisation across a series of face-to-face seminars. It focused on the impacts and

mechanisms of incidents, and the lines of defence in how to prevent or respond to situations that may end in an error.

An automated electronic report is sent to all leaders daily, with all relevant safety entries from the previous day for them to discuss in the pre-start meetings, including at risk behaviours, unsafe conditions, and incidents.

The daily report focuses on the ‘why’ and ‘what’ rather than the ‘who’ to emphasise the organisational learnings and avoid any perception of blame.

The intergenerational nature of the program puts the onus on all members of the organisation. It supports InfraBuild’s five-year plan to achieve premiere safety performance by 2025.

Irazusta said employees at all levels are using their confidence to speak up, listen, intervene, and take part in the pursuit towards ongoing development.

“No matter who you are in the organisation, we have created a culture of trust where people are empowered to speak up and intervene if they seek

someone working unsafe or at risk.”

More employees are reporting potential situation in which an error may be on the cards. As such, the company has recorded a 51 per cent spike in the number of hazards reported proactively year-on-year.

Sixty-four per cent of people reporting error-prone behaviour are identified as ‘unique’. This means more people are reporting risks more frequently, whether they are leaders, or work floor operators.

“I’m very proud of what the team has achieved. I am very humbled for obtaining this award from the ASI; we really appreciate it,” Irazusta said.

The Shore Brace 400 initiative is an exemplar of modern Australian engineering. Hot-dip galvanized for Shore Hire by the experts at Galserv (part of NEPEAN Building & Infrastructure), this hydraulic bracing system isn’t just built for the now—it delivers an extended lifespan that is unique in the for-hire market.

The Shore Brace 400 is a modular hydraulic bracing system comprising varioussized extension beams. It features double-pinned joints for increased capacity and incorporates double-acting hydraulics for smooth operation in extension and retraction. This is complemented by hydraulic lock-off valves for unparalleled control and safety.

On the ground, the Shore Brace 400 is a force to be reckoned with. The system can support rectangle, square or multi-sided excavations up to 20m without cross supports. From cofferdams to complex basement constructions, it can shore up large tank and pipeline installations as well as substantial building foundations. With a fleet that now weighs in at around 250 tonnes, the Shore Brace 400 system is a formidable player in the structural support game—and the only Australian-made product of its kind.

Designed and developed by Shore Hire, the Shore Brace 400 was first conceived in 2018 and was followed by five years of rigorous R&D to ensure their product would meet the requirements of long life for a tough application. According to general manager at Galserv Joshua Nolan, a hot-dip galvanising specialist firm with over 60 years’ experience, “The most pleasing aspect of the Shore Brace 400 project was Galserv’s collaboration with our customer, providing ongoing technical support from inception to delivery of the new product to market.”

The engineering team used double-pinned joints and double-acting hydraulics for increased capacity. Through a rigorous design process, engineers settled on a series of highly complex connector points, holes for pins, and interlocking fingers, which are strengthened by an internal crossbar. Hydraulic lock-off valves are used for additional control and safety. Together, this assists with the system’s smooth operation in extension and retraction.

Nolan said these steel components provide unmatched benefits. “The Shore Brace 400 system is made from five-star 460 grade steel and has been specifically galvanised by Galserv for longevity and product design line creating a unique forhire system.”

This innovative, safe, sustainable, and cost-effective solution could pave the way for a future of sustainable for-hire practices. “This enables the system to be rehired as many times as possible across many projects, significantly reducing carbon footprint associated with the product when compared to single use bespoke steel walers which generally get scrapped after use,” Nolan said.

Galserv’s Yagoona facility is accredited to AS/NZS ISO 14001 which places environmental performance at the heart of operations. It ensures a standardised approach to managing a business with an environmentally friendly and sustainable focus. Galserv is proud to recover and recycle all scrap materials, including steel and ash.

Meanwhile, the company’s zinc wastage—generated during the galvanising process— is reused in future works. Shore Hire’s engine-free product fleet reduces emissions when compared to other solutions in the sector. The launch of this product has attracted a market share increase and interest from other companies.

“An excellent and innovative solution developed with a client to serve an identified need in market. Uses circularity principles well in creating a product for hire and reuse to replace one-off supports.”

~ Judges

ENERGY SOLUTIONS FOR ASI MEMBERS BY AWARD

WINNING SOLAR & ENERGY PROCUREMENT EXPERTS!

50+ satisfied steel, truss & timber customers

Total $1M saved over 24 months $20k savings on average

Enquire Today

Services

Complimentary energy assessments

Metering, and bill error management Network demand and tariff review

Solar funding with little-to-no budget

choiceenergy.com.au

In a time when every dollar counts, Australian Steel Institute members are turning to Choice Energy. Thirteen members of the Australian Steel Institute (ASI) have already pocketed over $90,000 in savings on their energy bills, thanks to Choice Energy’s solutions.

We all know running a business isn’t cheap, especially in industries like steel where costs seem to rise faster than steel prices.

But while everyone’s sweating over expenses, Choice Energy makes managing energy costs as easy as possible.

Choice Energy isn’t just about saving money, though. They’re all about making things easy. In a world where the energy market feels like a maze, they’re the friendly guide showing businesses the shortcut to savings.

With their tailor made plans and expert advice, business owners can gain peace of mind knowing they’re making the smartest energy choices.

So, while business owners grapple with tight margins and growing costs, having Choice Energy in their corner is having an expert by their side. With their help, businesses can power through these challenges.

Access your free energy assessment and have an expert on your side.

Further information

For more, visit: choiceenergy.com.au.

For a no-obligation assessment of your energy and solar opportunities contact alex.townsend@choiceenergy.com.au or and 0435 080 646 and mention you are an ASI member.

This article was supplied as part of a paid advertising package.

McHugh Steel has opened a new steel framing factory in Bundaberg, underscoring their three-decade legacy of innovation and flexibility in steel product design and finishes. The factory, which will produce up to 15 house frames weekly, marks a pivotal expansion for the family-run company— it will fortify McHugh Steel’s position as a leader, with a reputation for quality, reliability, and ShedSafe accreditation.

One of Queensland’s largest steel manufacturers and providers recently opened a framing factory to take their business to the next level.

Since 1992, McHugh Steel has offered flexibility in steel product design and finishes. The company’s team consists of over 50 staff who work across shed, patio, roofing, steel framing, and roll forming needs.

Managing director of the family-run company Rob McHugh said a positive workplace culture is central to operations. “With over three decades of industry experience, we uphold pride and value in every aspect of our operations, from initial planning to final execution. Our team comprises seasoned professionals well-versed in our industry and product offerings,” he said.

The new Bundaberg steel framing factory has the capacity to manufacture up to 15 house frames each week, equating to 3,800 tonnes per annum.

It was designed to service the local housing market, home builders, and a variety of commercial and industrial clients. “Given the factory size, we were able to do commercial and residential status. One of the recent projects we did is the Red Rooster in Bargara Road, Bundaberg and Oporto Bundaberg,” McHugh said.

A site supervisor leads the detailing team to ensure all products and services are delivered on time and budget, and meet the highest quality standards.

“Our team of detailers utilises Enduroframe and Framecad for project detailing. Periodically, they undergo training sessions to enhance their skills and stay abreast of the latest advancements in their field, ensuring excellence in their work.”

McHugh Steel is an Australian Steel Institute ShedSafe member—an initiative designed to set the industry standard for manufactured steel sheds in Australia.

Through the ShedSafe third-party accreditation program, McHugh Steel’s customers can be confident the company is following regulations set out by the National Construction Code.

For example, the company recently delivered works for the Palm View School on the Sunshine Coast. McHugh Steel was tendered by the FKG Group for the supply and installation of steel wall frames and trusses for the new State Primary School and Special School, which both consisted of a one and twostorey block.

“In total, we supplied more than 180 tonnes of material down to the Palm View site, which roughly equated to 40 semi-trailer loads over three months. Our team of experts worked tirelessly to ensure that every aspect of the project was handled with precision and care,” McHugh said.

The company’s shedding team are Queensland Building and Construction Commission fully-licensed builders, who are competitive when it comes to delivering results. All personnel pay close attention to individual needs by offering flexibility in design and finishes.

“Central to our culture is prioritising our personnel. We firmly believe that their contributions are integral to our achievements. By fostering a culture of fairness and respect towards our employees, we aim to enhance their productivity and overall performance.”

“At McHugh Steel, we emphasise the importance of achieving a balance between work responsibilities and personal well-being,” McHugh said.

“By fostering a culture of fairness and respect towards our employees, we aim to enhance their productivity and overall performance.”

Sun Engineering is a one-stop shop for the design, procurement, manufacturing, and installation of steel products. The company was founded by Patrick McMonagle, who opened a small workshop in Ipswich in 1974. The business expanded rapidly, which prompted the move to a nearby facility in Carole Park. Today, this site continues to provide clients with the convenience of turnkey solutions.

One of Sun Engineering’s most recent projects includes the Breakfast Creek Green Bridge in Newstead, Brisbane. Business development manager Sourou Thenet said the project highlighted the company’s full-service suite.

“The scope of work, including detailed drafting, procurement, manufacturing, protective coating, and delivery, showcased Sun Engineering’s capabilities in providing end-to-end solutions for complex infrastructure projects.”

Over 35,000 labour hours were required before the bridge was assembled into one unit at the port-side lay down area, and then lifted into place using a barge along the Brisbane River. The steel portion of the bridge measured over 90m wide, 15m high and a weight of 290 tonnes.

“During manufacturing our team continuously used 3D scanning to ensure the cambers and curves of the arches were built to the design specification,” Thenet said.

Similarly, Sun Engineering was awarded the contract for the fabrication of steel

pontoons at the Southbank and Howard Smith Wharf Terminals, which are familiar for users of the CityCat Ferry service in Brisbane. The ferries are an essential public transport link allowing for travel along the Brisbane River.

The project team undertook detailed drafting, procurement, fabrication, protective coating, and delivery of the pontoons. The team used steel fenders, crumple zones, and structural steel for the roof.

“Due to the overall size of each terminal, pontoons had to be fabricated in sections and designed in a way to enable transportation to the port for assembly and eventual launching of each unit,” Thenet said.

The project team navigated several challenges associated with engineering design, planning, material selection, environmental considerations, regulatory compliance and community impact.

“The significance of such projects often lies in enhancing public transportation infrastructure, providing accessibility to different parts of the city, reducing traffic

congestion, and contributing to the overall development and connectivity of urban areas,” Thenet said.

The Carole Park facility offers more than 28,000m2 in space for fabricators to transform their vision into reality. It boasts four carbon steel workshop areas, a stainless steel workshop, painting booth and fitting bay.

“Sun Engineering’s diverse manufacturing capabilities, ranging from OEM items, process tanks, mining equipment, steel bridges, piping, complex plate structures, road infrastructure, gas skids and other bespoke products demonstrate our ability to cater to a wide array of industries and projects,” Thenet said.

Sun Engineering’s skilled tradespeople can manufacture single items up to 40m in length and 8m high. The Carole Park facility was awarded the 2022 Queensland Premier’s export awards in the manufacturing and advanced materials award category. “This recognition is a testament to the Sun Engineering’s dedication to exporting quality Australian fabricated steel to the global market,” Thenet said.

From a small shed in Geelong to a leading force in Australian steel manufacturing, JH Stephenson (part of the Steeline Group) recently marked a century of unparalleled growth, innovation and resilience.

In 1923, Joseph Hamsterly Stephenson started a business manufacturing plumbing supplies in Victoria.

Australia had received record rainfall and local infrastructure was unable to cope with the increased demand. At the same time, work was underway on some of the nation’s largest steel infrastructure projects, like the Sydney Harbour Bridge.

Stephenson had a background in plumbing and gas fitting. However, his work ethic and entrepreneurial spirit saw him manufacturing supplies like pressed spouting, ridges, downpipes and water tanks.

Alongside his father, the pair began operating from a shed behind their family home in Geelong West—once the heart of Victoria’s industrial development.

After some time, the company had outgrown its humble beginnings, and the shed was no longer fit for purpose.

The family business, J & JH Stephenson, shifted from

its initial base on Latrobe Terrace to Baxter Road, and then again to Victoria Street. This expansion was challenged during the Great Depression, which saw the nation’s unemployment rate peak at 32 per cent.

The company soon reverted to selling chickens and eggs to help pay for a new spouting gutter press. However, the father-son business navigated these troubled waters and expanded their facilities once again, replacing the existing iron sheds with a brick factory.

It was the first of many storms the company weathered then and still continues today.

As the business recovered from the height of economic uncertainty, rainwater goods were in high demand. As such, J & JH Stephenson began to supply to local plumbers and wholesalers.

As economies and businesses were getting back on their feet, the WWII caused widespread devastation. The global conflict meant steel supplies

for domestic purposes were reduced to a trickle.

J & JH Stephenson’s work largely became manufacturing goods for the Australian Defence Force. Harvey Stephenson, who has followed in his ancestor’s footsteps, said they were lucky to have opportunities following WWII.

“After the war, materials became available and business increased due to the housing boom in Geelong. The family worked with a modest amount of machinery,” he said.

Several years after WWII, the business had recovered and the old Weller Street home was demolished to make room for a larger factory.

“By 1963, it was decided to form a company and the business was registered as JH Stephenson & Son Pty Ltd which is still part of the company trading name today.”

“In 1977, the company was starting to expand with its product range and rainwater components. Due to the expansion land was acquired

in Victoria Street in North Geelong and a purpose built roll forming plant was established in 1986,” Stephenson said. The company has continued to embrace innovative technology and techniques to give their steel manufacturing a competitive edge in the local market.

Today, a fifth generation of family are at the helm of the company, known as JH Stephenson, which stands tall as an independent Australian manufacturer.

Grassroots approach to steel manufacturing JH Stephenson stands tall as an exemplar of Australian steel manufacturing. Today, the Stephenson family leads the business, which specialises in high-quality steel roofing structure.

“The grass roots of the company has always been to supply our clients with great products with a high service level in the domestic, commercial and industrial sectors,” he said.

In 2002, the company joined the Steeline Group, who

“The grass roots of the company has always been to supply our clients with great products with a high service level in the domestic, commercial and industrial sectors.”

“Success in the company has really come from integral relationships all round. From our staff members, our key suppliers and most importantly our clients and customers.”

in Australia.

“This allowed us to have a national brand with other privately owned and operated roll forming companies similar to ours,” Stephenson said.

The shift to align with

Steeline has been the catalyst in unmatched benefits for JH Stephenson, who are able to take on a wider feat of projects. It has also transformed the company’s facilities. Today, JH Stephenson has a head office in the industrial precinct of Corio and a purpose-built warehouse

in Truganina, which caters for some of the larger commercial and industrial clients. The 8,800m2 workspace provides plenty of potential for steel staff to work together on some of the company’s more complex projects. The company also operates from facilities in Dandenong and

North Geelong. “Further expansion happened again with the acquisition of a roll forming plant in Dandenong, which was pivotal to being able to supply to both the east and west of the greater Melbourne suburbs.”

“With four branches and multiple manufacturing lines

we are efficient in being able to meet our clients scheduling all over Victoria and in more recent times New South Wales,” Stephenson said.

As part of the Steeline family, JH Stephenson offers an impressive suite of products and services. “JH Stephenson manufactures a wide range of steel building products, rainwater goods, roofing, purlins and fencing products,” Stephenson said.

One of the company’s recent projects was Project Oxygen, where 70,000 linear metres of purlins and girts were constructed for a distribution centre in Ravenhall, located in Victoria’s west.

JH Stephen also supplied 65,000m2 of Coolmax .48 Lokdek 700, the premium product in the Colorbond range, for Project Oxygen. This project navigated several layers of complexity because the material does not use roof-piercing fasteners to keep it in place. The project was completed with extraordinary efficiency, with large volume loads in excess of 24.000m2 delivered to site constantly, despite tight site access.

Bringing projects such as to life relies on a dedicated workforce who manufacture roofing and building products in Australia for Australians.

Each of Steeline’s stores are independently owned and run, which means JH Stephenson is well-positioned to work closely with the local community. JH Stephenson understands the local area like no other. As such, the company can advise on products to withstand the nearby conditions and surroundings. This includes products made for bushfire-prone areas and manufacturing goods to maximise energy efficiency in steel framed buildings.

In 2023, JH Stephenson marked 100 years in business—a remarkable feat for any Australian manufacturing business.

“Success in the company has really come from integral relationships all round. From our staff members, our key suppliers and most importantly our clients and customers,” Stephenson said.

Technology has been the driver of change in Stephenson’s business. From operating in an iron shed, to growing into multiple locations, the company has become a pioneer in the local steel manufacturing sector.

Stephenson said the company has never lost sight of its true intentions. “JH Stephenson has prided itself on producing a great product in the industry with high quality machinery. We have never steered away from this process in all our time roll forming.”

Ed u ca t ion

E v en ts ; We ca sts ; e ea r ning co urs e s

Re s o ur ce s

e i r a ry ; eBook s ; Book s ho p ; i r a ry loan s

P r o o t e y o ur b r and Ind ustry Di r ec t o ry i st ing

ASI logo

U s e t he SI logo t o demon str a t e y o ur supp o rt

Ne tw o r king

Wi t h like - minded pr ofe ss ional s and commi tt ee s

Advocacy Advocacy for better and fairer conditions across th e steel supply chain

S t eel A ustr alia aga z ine

Deli v e r ed t o y o ur doo r o r in o x

Me be r e x cl us i v e o e rs

Offe rs ust fo r y o u - s a v ing s and di s co u n ts

Tec nical ad v ice

On st eel w o r k de s ign and con stru c t ion

A w a r d s

S t eel E x cellence , eal t h & Safe ty , S ust aina ili ty

Ann u al st eel con v en t ion

B r inging ind ustry st akeholde rs t oge t he r

Job s boa r d and ca r ee rs cen tr e

B r o ws e t he la t e st v acancie s , ad v e rt i s e y o ur r ole

and di s co v e r r e s o ur ce s fo r ca r ee rs in st eel