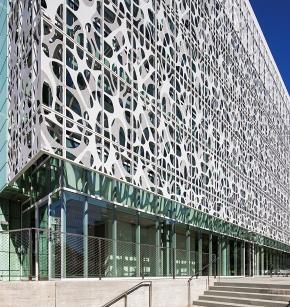

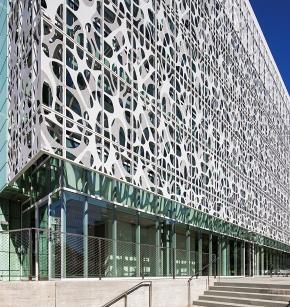

Project: Apple Central & Wolfe Campus

Product: Vitrabond FR

Finishes: Custom Pewter and Renaissance Silver

Project: Apple Central & Wolfe Campus

Product: Vitrabond FR

Finishes: Custom Pewter and Renaissance Silver

Fairview Architectural North America is family owned and operated, like many of our clients. We understand how hard you work to build your business, or maybe to expand the legacy begun by your grandparents.

With generations of experience, let us become a trusted partner in your success story!

Spreading success through quality business relationships and being structured to respond to market demands.

The most convenient source for premium building façade products, bringing material safety and innovation to the industry.

The only customer-success focused building façade manufacturer that drives industry innovation for construction professionals in North America in an era of sustainability and technological advancements.

• Bill your client for stored materials!

• Ensure batch consistency!

Ask our Customer Service Team for more details.

• We pick them up at no cost to you!

• You earn FREE FREIGHT!

Ask our Customer Service Team for more details.

Vitranar® is a flexible resin coating developed specifically for formed aluminum applications in architecture. This high quality coating technology allows the resins to flow and flex when aluminum is folded or bent to reduce or even eliminate cracking or crazing, depending on the forming methods used. Eliminating the post-painting process saves time, money, and labor.

DURABLE PRE-FINISHED ALUMINUM TO STREAMLINE MANUFACTURING AND FABRICATION

• Flexible Resin Coating Technology withstands forming and fabrication.

• Increase project throughput by reducing manufacturing steps.

• Increase the performance of your finished product with a higher quality finish.

Comparison between using pre-finished aluminum in manufacturing, compared to manufacturing first and then applying the finish.

Manufacture using Vitranar® Pre-Finished Aluminum

Flexibility

Processes

The resins used in coil coatings are formulated to be elastic and bendable, allowing many forming and bending methods to be used without cracking or peeling the paint.

Manufactured goods are immediately ready for shipping.

Manufacture uncoated aluminum, followed by spray painting or powder coating

Spray-applied coatings do not have flexible resins and therefore crack when material is bent or formed after painting.

Manufactured goods need to go through a painting process, and often require further manufacturing steps after painting.

Complex Designs

Cost

Environmental Impact

Form complex shapes and intricate designs with the assurance of uniform and accurate coating of the entire manufactured component.

Coil coating is a high-volume automated process, and it reduces additional manufacturing costs

Low environmental impact due to controlled, high-efficiency process, leading to minimized waste, lower VOC emissions, and improved energy efficiency.

Uniform coverage may not be achieved in the difficult to access features of complex shapes.

Spray coating is often manually applied, or when machine applied it can require manual touch up to ensure full coverage.

High environmental impact with high VOC emissions due to overspray, less efficient recapture systems, high waste

Durability

Consistency

Color Options

Due to the higher quality resins and controlled application methods, Vitranar® pre-finished aluminum can be backed by warranties as high as 40 years, even in coastal environments.

Precision controlled automated uniform application system ensures consistency in coating thickness and color.

The Vitranar® Pre-Finishing process allows for endless colors, finishes and patterns.

Lower quality ingredients and inconsistent application methods result in a less durable finish with a lower warranty.

Manual or semi-automatic application has variety in thickness resulting in variation in color and inconsistencies.

Spray-Painting can only achieve monolithic colors.

• Shadow Boxes

• Infill Panels

• Spandrel Panels

• Back Pans

• Fins

• Column Covers

• Slab Edge Covers

• Rainscreen Panels

• 3D Panels

• Perforated Screen Walls

• Louvers

• Sun Shades

• Parapet Caps

PURCHASING TIPS

• Use custom widths and lengths to optimize your purchase

• Choose any finish you need there are no standard finishes on solid aluminum plate and sheet material

AVAILABILITY MATRIX

Aluminum: 3003 H14, 5052 H32

MATERIALS

NOMINAL THICKNESS:

Steel: 24GA, 26GA

0.020” up to 0.125” (Typical for this application is 0.032” and 0.040”)

Custom nominal thicknesses may be available upon request

WIDTHS: STANDARD: 48”, 60”, 62” CUSTOM: 36” to 62” (+-1/4” Tolerance)

LENGTHS: STANDARD: 122”, 146”, 196” CUSTOM: 100” to 240” (min 20 sheets each)

ALLOYS

NOMINAL THICKNESS:

3003 (other alloys may be available upon request)

0.020” up to 0.125” (Typical for this application is 0.032” and 0.040”)

Custom nominal thicknesses may be available upon request

WIDTHS: STANDARD: 48”, 60”, 62” CUSTOM: 48” to 62” (+-1/4” Tolerance)

LENGTHS: STANDARD: 122”, 146”, 196” CUSTOM: 100” to 240” (min 20 sheets each)

NOTE: Separate sheet widths may be from separate coating runs, and in some cases could results in a perceivable color difference.

NOTE: Minimum order quantity per color, width and thickness.

Reduce your environmental footprint while achieving superior finishes.

Vitranar® uses a precision controlled application process to minimize waste, emissions, and energy use compared to traditional spray methods.

Lower VOC emissions | Reduce waste | Increased efficiencies

Flawlessly translate your vision onto aluminum cladding.

Here's how our exceptional color matching empowers your designs:

• Unparalleled Versatility: Match any color, finish, or texture imaginable.

• Seamless Design Continuity: Achieve flawless color consistency across your entire facade, even for complex geometries or large-scale projects.

• Unleash Creativity: Explore a wider design palette than ever before and go beyond conventional options

Partner with us and unlock the full potential of your architectural facades with our industry color matching technology.

STANDARD TEST

PROPERTIES

ASTM E136 Fire Performance of 3003 Aluminum ΔT< 86°F PASS

THERMAL PERFORMANCE

ASTM D696 Coefficient of Linear Expansion

13.8x10-6 in/in/°F (Aluminum)

PVDF Coating Descriptions Test Test Result

ASTM B117 Salt Spray Resistance

5% salt fog at 95°F Passes 4000 hrs. Less than 1/16” avg creepage from scribe. None or few #8 blisters

ASTM D523 Specular Gloss Test Standard @ 60° Varies per finish

ASTM D1308 Alkali Test 10%, 25% NaOH, 1hr No Effect

ASTM D714 Blistering of Paint Test

ASTM D2244 Exterior Exposure

ASTM D2247 Water Resistance

100% Relative Humidity @ 95°F Passes 4000 hrs.

10 years @ 45° South Florida PASS - Max. 5 fade

100% Relative Humidity @ 95°F No #8 blisters

ASTM D2794 Reverse Impact 1.5 x metal NOMINAL THICKNESS (Aluminum) No cracking or adhesion loss

ASTM D3359 Adhesion Reverse impact 1/16” crosshatch No adhesion loss

ASTM D3363 Film Hardness Pencil Test F - 2H PASS

ASTM D4145 Flexibility T - Bend 0 - 2 T - Bend, No pick off

ASTM D4214 Chalk Resistance

10 years @ 45° South Florida Pass - Max. 8 Chalk

½ Pre-Consumer + Post-Consumer Recycled Content Up to 32.5%

A standard finish warranty of up to 20 years is available on all Vitranar® coated products, with an extended warranty of up to 40 years available.

Our unwavering commitment to quality ensures superior products by following strict ISO9000 standards, guaranteeing consistency and continuous improvement

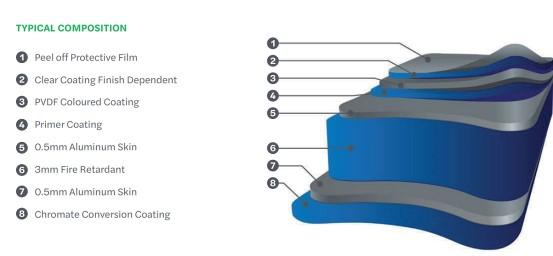

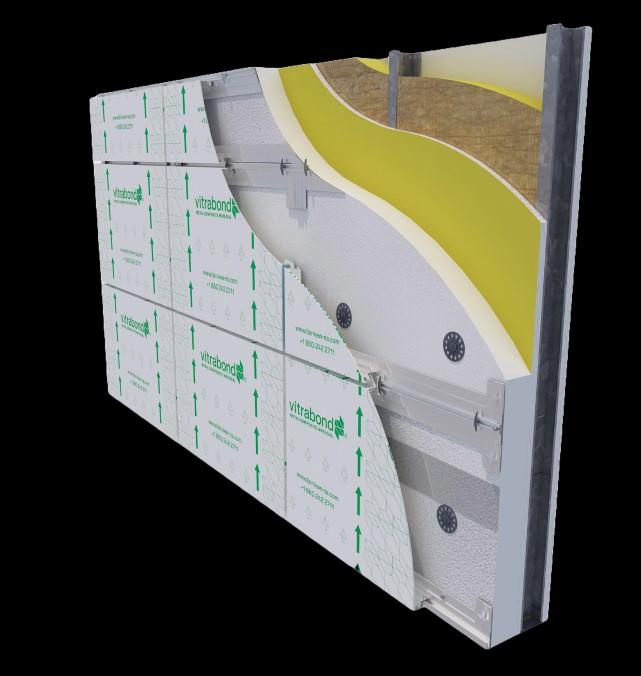

VitrabondFR is a 4mm Aluminum Composite Panel that is comprised of a fire resistant core sandwiched between two 0.020” aluminum skins, or other natural metal sheets such as zinc, copper, or stainless steel. Versatility in finish options and workability allows it to exceed any design intent

Vitrabond FR is a metal composite panel that is comprised of a fire-resistant core sandwiched between two aluminum sheets or other natural metal sheets such as zinc, copper, or Stainless steel. This product composition results in outstanding surface flatness and a high strength to weight ratio.

Vitrabond FR’s versatility also extends to its workability in that it can be easily curved, folded or shaped to be used for rainscreen panels, fascia, soffits, column covers, interior cladding applications and much more.

PVDF KYNAR 500® or FEVE paints known for their high durability, optimum weather resistance and industrial pollution protection.

Carry less waste and order less material by taking advantage of the 110% Stock and Color Program. See page 18 for more details.

Millions of square feet of Vitrabond FR material are in-stock and ready to ship in just 2-5 days.

Fairview can match any color, even if it is from a police officer’s uniform (and yes, true story).

Vitrabond sheets can be routed, cut, roll-bended, folded, and perforated to turn any vision into a reality.

Easy to form and assemble into panels using our Arrowhead® Rainscreen Panel Installation Systems

MIXED-USE | RESIDENTIAL | CORPORATE HQ

STADIUMS | CONVENTION CENTERS | CASINOS

CORPORATE CAMPUS | DEALERSHIPS | FRANCHISES

UNIVERSITIES | HOSPITALS | RESEARCH LABS

These Samples are Made

FV1634

FV1633

FBC6548-01

FBC6548-06

Samples

FV1692

FV9801

FV9601

FV4150

FV4460

FV5282

FV9314

FV9409

FV4265

FV5292

FV9809

FV4540

GARNET VBC11701-14

JADE GREEN METALLIC FV9031

FV4435

BEECH VBC10244-02

MAPLE VBC8685-01

FV8719

FV8379

SAWN OAK FV8340

TIMBER VBC10244-01

FIR VBC6527-01

ZEBRAWOOD LIGHT VBC12480-07

MAPLE FV8123

FV8390

FV8724

CALIFORNIA REDWOOD FV8723

Zinc Composite | Stainless Steel Composite | Copper Composite | Anodized

| FV5850 AUTUMN CHERRY VBC13274-07

• Use custom widths and lengths to optimize your purchase

• Fairview has millions of square feet in stock check inventory for other finishes that may not be in this manual!

MINIMUM ORDER QUANTITY: No minimum order

AVAILABLE THICKNESSES: 4mm, 6mm

WIDTHS: STANDARD: 62”

LENGTHS: STANDARD: 196”

CUSTOM:

CUSTOM: Other sheet sizes may be available, depending on the finish being requested.

MINIMUM ORDER QUANTITY: 2,500 sf (per width and color)

NOMINAL THICKNESS: 4mm, 6mm

WIDTHS: STANDARD: 39”, 49”, 62”

LENGTHS: STANDARD: 122”, 146”, 196”

CUSTOM: 39” to 62” (+-1/4” Tolerance)

CUSTOM: 100” to 240” (min 20 sheets each)

MINIMUM ORDER QUANTITY: 10,000 sf (per width and color)

NOMINAL THICKNESS: 4mm, 6mm

WIDTHS: STANDARD: 49”

LENGTHS: STANDARD: 122”, 146”, 196”

CUSTOM: 49” to 62” (+-1/4” Tolerance)

CUSTOM: 100” to 240” (min 20 sheets each)

NOTE: Separate sheet widths may be from separate coating runs, and in some cases could results in a perceivable color difference Natural metal finishes have different coil widths and minimum quantities than what is published. Contact Fairview for more details.

Vitrabond® has one of the highest warranties in the ACM market. A product warranty of up 20 years is provided when installed by a licensed installer. An MCM coating warranty is issued on a project specific basis and is available up to 30 years per Fairview architectural approval.

Warranty details and length can change depending on finish type, number of finish layers, gloss level, and sustainability requirements. If you have any questions regarding warranties on your project, our team will be glad to discuss that with you.

For data specific to Natural Metal finishes, please contact Fairview directly.

STANDARD TEST

PROPERTIES

ASTM E136 Fire Performance of 3003 Aluminum ΔT< 86°F PASS

ASTM C393 Core Shear Ultimate Stress

ASTM C393 Flexure Stress

>150 psi [1.03 MPa] (Test Specimen Average) PASS

>15695 psi [108.21 MPa] (Test Specimen Average) PASS

ANSI FM4473 Severe Hail Exposure Test PASS/FAIL PASS

THERMAL PERFORMANCE

ASTM D696 Coefficient of Linear Expansion 13.8x10^-6 in/in/°F (Aluminum)

BOND INTEGRITY

ASTM C297 Flatwise Tensile Strength

ASTM D1781 Climbing Drum Peel Test

ASTM D1002 Peak Shear Strength

FIRE PERFORMANCE

>400 psi [2.76 MPa] PASS

>22.5 in-Ib/in [100 mm-N/ mm] PASS

>515 psi [3.55 MPa] PASS

ASTM E84 Flame Spread <25 PASS

ASTM E84 Smoke Development <450 PASS

NFPA 285 Fire Propagation Characteristics PASS/FAIL PASS

CAN/ULC – S134 Fire Test of Exterior Wall Assemblies PASS/FAIL PASS

A product warranty of up 20 years is provided when installed by a licensed installer. An MCM coating warranty is issued on a project specific basis and is available up to 30 years per Fairview architectural approval.

PVDF Coating Descriptions

Test

Test Result

ASTM B117 Salt Spray Resistance 5% salt fog at 95°F Passes 4000 hrs. Less than 1/16” avg creepage from scribe. None or few #8 blisters

ASTM D523 Specular Gloss Test Standard @ 60° Varies per finish

ASTM D1308 Alkali Test 10%, 25% NaOH, 1hr No Effect

ASTM D714 Blistering of Paint Test

100% Relative Humidity @ 95°F Passes 4000 hrs.

ASTM D2244 Exterior Exposure 10 years @ 45° South Florida PASS - Max. 5 fade

ASTM D2247 Water Resistance

100% Relative Humidity @ 95°F No #8 blisters

ASTM D2794 Reverse Impact 1.5 x metal NOMINAL THICKNESS (Aluminum) No cracking or adhesion loss

ASTM D3359 Adhesion Reverse impact 1/16” crosshatch No adhesion loss

ASTM D3363 Film Hardness Pencil Test F - 2H PASS

ASTM D4145 Prepainted Metal Coating Flexibility T - Bend 0 - 2 T - Bend, No pick off

ASTM D4214 Chalk Resistance 10 years @ 45° South Florida Pass - Max. 8 Chalk

½ Pre-Consumer + Post-Consumer Recycled Content

Vitrabond FR 4mm 12.75%

VITRABOND

MINERAL FILL AS PERCENTAGE OF CORE MATERIAL

Vitrabond FR >70%

PRODUCT WEIGHT 1.5 lb/ft^2

Access the most recent Vitrabond Technical Evaluation report by DrJ Engineering by scanning the QR code.

Vitrabond® complies to AAMA 508 and AAMA 509 when installed with Arrowhead and meets the test protocols TAS201, 202, and 203 in accordance with the Florida building code for high velocity hurricane zone and Miami Dade County requirements.

Standard Test

ASTM E238 Air Leakage of Test Buck (without panel system installed)

ASTM E1233 Cyclic Static Air Pressure Differential (pressure cycling)

ASTM E330 Uniform Load Deflection and Uniform Load Structural L/175 of Stiffener Length

AAMA 509 DRAINED AND BACK VENTILATED ARROWHEAD RAIN SCREEN

Standard Test Arrowhead LEAN Results Arrowhead FLEX Results

E283 Air Leakage V1 V3 ASTM E331 Static Water Penetration

Vitrabond® using the Arrowhead Flex system meets TAS 201, 202, and 203 test protocols in accordance with the Florida building code for the high velocity hurricane and Miami Dade County requirements.

TAS 202 - 94 Uniform Static Air Pressure (+100/-150 psf)

TAS 201 - 94 Large Missile Impact Procedures

TAS 203 - 94 Cyclic Winds Pressure Loading

(+100/-150 psf) PASS

(+100/-150 psf) PASS

Our dedication to fulfilling our customer’s expectations is reflected in our superior quality control system, beginning at the point of specification and continuing through to delivery of our guaranteed products. All activities are carried out in a manner that:

• Uses the framework of ISO9000 Quality Standards to verify the quality of our systems

• Ensures that our products and services are of the highest standards

• Create continuous improvements to our product through the application of the best quality practices

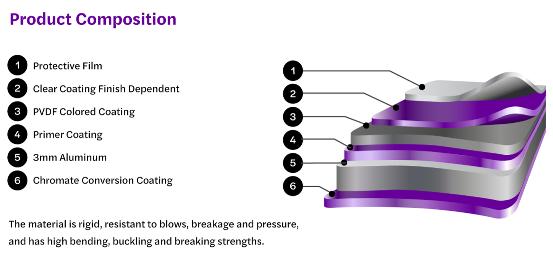

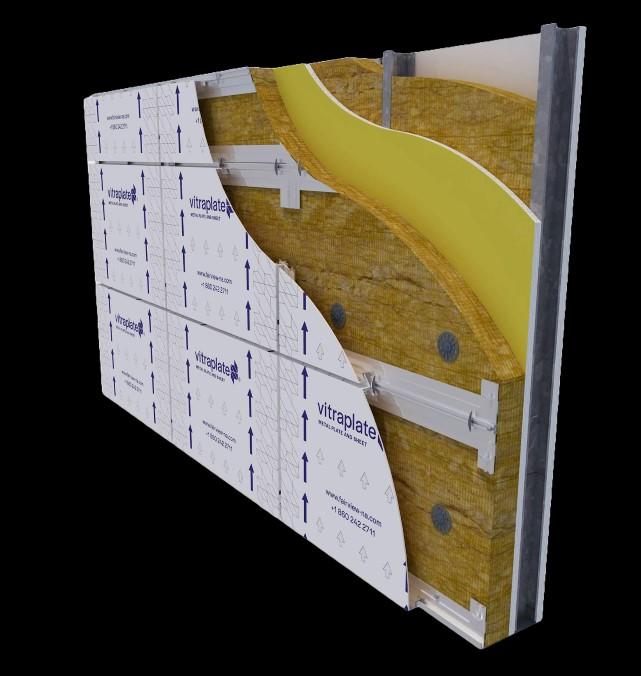

Vitraplate® is a 3mm (1/8”) thick, non-combustible aluminum panel manufactured in the United States. It comes pre-finished, eliminating the need for post-painting, saving time, labor and money.

Vitraplate® is a pre-finished 100% solid aluminum cladding panel product that is coated with any finish using Vitranar flexible resin coating technology. This flexible resin coating allows panels to be fabricated without the need for costly post-finishing after fabrication as the sheets come pre-finished with protective film applied. This helps reduce lead times and risk associated with each project.

PVDF KYNAR 500® or FEVE paints known for their high durability, optimum weather resistance and industrial pollution protection.

NON-COMBUSTIBLE

Our Vitraplate® solid aluminum is certified non -combustible to meet or exceed the everchanging fire codes.

With an industry-leading lead time as low as 4 weeks, Vitraplate® allows you to meet the tightest deadlines.

VERSATILE

Optimize your project costs with custom widths, lengths, and low minimums.

Vitraplate® can be coated in any finish, from solids and metallics, to patterns and anodized.

QUICK INSTALLATION

Easy to from and assemble into panels using our Arrowhead® Rainscreen Panel Installation Systems

AIRPORTS | TERMINALS | PORTS OF ENTRY

STADIUMS | ARENAS | CONVENTION CENTERS

ENERGY & INFRASTRUCTURE

WASTEWATER | POWER PLANTS | BRIDGES

-

MIXED USE | RESIDENTIAL | CORPORATE

PURCHASING TIPS

• Use custom widths and lengths to optimize your purchase

• Choose any finish you need there are no standard finishes on solid aluminum plate and sheet material

• Specify whether your project requires 3003 H14 or 5052 H32 aluminum plate. Both alloys are available for Vitraplate and offer different mechanical properties for strength, corrosion resistance, and formability.

AVAILABILITY MATRIX

MINIMUM ORDER QUANTITY:

2,500 sf (per width and color) 7,500 sf (applies to custom widths only)

NOMINAL THICKNESS: 3mm (1/8”) nominal (for other nominal thickness see Vitranar®)

WIDTHS: STANDARD: 48”, 60”, 62”

LENGTHS: STANDARD: 122”, 146”, 196”

CUSTOM: 36” to 62” (+-1/4” Tolerance)

CUSTOM: 100” to 240” (min 20 sheets each)

MINIMUM ORDER QUANTITY: 5,000 sf (per width and color) 7,500 sf (applies to custom widths only)

NOMINAL THICKNESS: 3mm (1/8”) nominal (for other nominal thickness see Vitranar® )

WIDTHS: STANDARD: 48”, 60”, 62”

LENGTHS: STANDARD: 122”, 146”, 196”

CUSTOM: 48” to 62” (+-1/4” Tolerance)

CUSTOM: 100” to 240” (min 20 sheets each)

MINIMUM ORDER QUANTITY: 9,000 sf (per width and color)

NOMINAL THICKNESS: 3mm (1/8”) nominal (for other nominal thickness see Vitranar® )

WIDTHS: STANDARD: 48”, 60”, 62”

LENGTHS: STANDARD: 122”, 146”, 196”

CUSTOM: 48” to 78” (+-1/4” Tolerance)

CUSTOM: 100” to 240” (min 20 sheets each)

MINIMUM ORDER QUANTITY: No minimum order (in-stock sheets) 2,500 sf (per width)

NOMINAL THICKNESSES: 3mm (1/8”)

WIDTHS: STANDARD: 48”, 60”

LENGTHS: STANDARD: 122”, 146”, 196”

CUSTOM: 39” to 78” (+-1/4” Tolerance)

CUSTOM: 100” to 240” (min 20 sheets each)

NOTE: Separate sheet widths may be from separate coating runs, and in some cases could results in a perceivable color difference.

STANDARD TEST

FIRE RESISTANCE

TEST STANDARD RESULT

ASTM E136 Fire Performance of Aluminum ΔT< 86°F Non-Combustible

ASTM E84 Flame Spread <25 PASS

ASTM E84 Smoke Development <450 PASS

NFPA 285 Not Applicable to Non-Combustible products

ASTM E119 Not Applicable to Non-Combustible products

THERMAL PERFORMANCE

ASTM D696 Coefficient of Linear Expansion 13.8x10-6 in/in/°F (Aluminum)

PVDF Coating Descriptions Test Test Result

ASTM B117 Salt Spray Resistance 5% salt fog at 95°F Passes 4000 hrs. Less than 1/16” avg creepage from scribe. None or few #8 blisters

ASTM D523 Specular Gloss Test Standard @ 60° Varies per finish

ASTM D1308 Alkali Test 10%, 25% NaOH, 1hr No Effect

ASTM D714 Blistering of Paint Test

100% Relative Humidity @ 95°F Passes 4000 hrs.

ASTM D2244 Exterior Exposure 10 years @ 45° South Florida PASS - Max. 5 fade

ASTM D2247 Water Resistance

ASTM D2794 Reverse Impact

100% Relative Humidity @ 95°F No #8 blisters

1.5 x metal NOMINAL THICKNESS (Aluminum) No cracking or adhesion loss

ASTM D3359 Adhesion Reverse impact 1/16” crosshatch No adhesion loss

ASTM D3363 Film Hardness Pencil Test F - 2H PASS

ASTM D4145 Prepainted Metal Coating Flexibility T - Bend 0 - 2 T - Bend, No pick off

ASTM D4214 Chalk Resistance

10 years @ 45° South Florida Pass - Max. 8 Chalk

½ Pre-Consumer + Post-Consumer Recycled Content Up to 32.5%

Our dedication to fulfilling our customer’s expectations is reflected in our superior quality control system, beginning at the point of specification and continuing through to delivery of our guaranteed products. All activities are carried out in a manner that:

• Uses the framework of ISO9000 Quality Standards to verify the quality of our systems

• Ensures that our products and services are of the highest standards

• Create continuous improvements to our product through the application of the best quality practices

Complies to AAMA 508 and 509 when installed with Arrowhead and meets the test protocols TAS201, 202, and 203 in accordance with the Florida building code for the high velocity hurricane zone and Miami Dade County requirements.

Standard Test

ASTM E238 Air Leakage of Test Buck (without panel system installed)

ASTM E1233 Cyclic Static Air Pressure Differential (pressure cycling)

E331 Static Water Penetration

ASTM E330 Uniform Load Deflection and Uniform Load Structural L/175 of Stiffener Length

Standard Test

E283 Air Leakage

ASTM E331 Static Water Penetration

AAMA 501.1 Dynamic Water Penetration

A standard product warranty of up to 20 years is available on coil-coated or coil-anodized Vitraplate®, with an extended warranty of up to 40 years available on select finishes.

RapidWrapCI® is a fully engineered wall assembly that allows you to eliminate vertical furring and standoffs.

RapidWrapCI® is available in 2 different wall assemblies, and is designed to be used on any project where there is continuous insulation requirements behind the metal composite or metal plate panel system.

See page 32

NFPA

See page 34 Life

Non-Combustible and NFPA285 Compliant Wall Assemblies available

Integrated Products Tested Together in one Assembly

High Velocity Hurricane Zone (HVHZ) Compliant

Minimize Risk with Guaranteed Compatible Components

Free-Floating Panels with Easy Panel Replacement

Third Party Evaluation with Product Tracing

Eliminate Furring and Thermally Broken Standoffs

Reduce Energy Costs with an ASHRAE 90.1 Compliant Continuous Insulation

Reduced Time and Material Costs

• Use custom widths and lengths to optimize your purchase.

• Consider bundle sizes for the insulation and RapidWrapCI® Anchors

INCREASE

INSTALLATION CAPACITY

PRODUCTIVITY

ENERGY EFFICIENCY

MOQ for in-stock insulation is 1 pallet.

DECREASE ELIMINATE

MATERIAL PURCHASES

NUMBER OF FASTENERS

PROJECT SPECIFIC ENGINEERING

VERTICAL FURRING & STANDOFFS

FURRING INSTALLATION LABOR

® MINERAL WOOL

1.5”

3.0”

3.5”

4.0”

x72” 648

24”x48” 384

pallet (768 sf)

pallets (14, 976 sf)

(14,688 sf)

(13,056 sf)

pallets (11,648 sf)

pallets (11,016 sf)

pallet (384 sf)

pallets (9,792 sf)

RAPIDWRAPCI® ANCHORS

• Use custom widths and lengths to optimize your purchase.

• Consider bundle sizes for the insulation and RapidWrapCI® Anchors

INSTALLATION CAPACITY

PRODUCTIVITY

ENERGY EFFICIENCY

MATERIAL PURCHASES

NUMBER OF FASTENERS

PROJECT SPECIFIC ENGINEERING

VERTICAL FURRING & STANDOFFS

FURRING INSTALLATION LABOR

RAPIDWRAPCI® POLYISO

ACCEPTABLE POLYISO BRANDS DuPont Thermax

AVAILABLE THICKNESSES 1.55”, 2”, 2.5”, 3”

MINIMUM ORDER QUANTITY (MOQ): 12 rolls

ROLL SIZE 4” x 50’

RAPIDWRAPCI® ANCHORS

MINIMUM ORDER QUANTITY (MOQ): 1 Box

Base Wall Steel Studs

Stud Spacing

Exterior Sheathing

Approved sheathing

Insulation

NFPA 285 Wall Assembly

Non-Combustible Wall Assembly

Water-Resistive Barrier

NFPA 285 Wall Assembly

Non-Combustible Wall Assembly

Arrowhead Installation System

Approved fastener

Fastener spacing along base extrusions

Maximum cladding assembly weight*

Arrowhead T-Clips

Exterior Cladding

Approved exterior cladding materials

Color match flashing material

20 ga. (min.)

24” o.c. (max.)

½” Exterior Gypsum Sheathing

⅝” Exterior Gypsum Sheathing

RapidWrapCI® Polyiso Insulation

RapidWrapCI® Mineral Wool Insulation

4” RapidWrapCI® Flashing Tape

Installed at Polyiso Seams

Approved WRB per Arrowhead TER 2006-02

RapidWrapCI® Anchor

At each stud, 24” o.c. (max.)

5 psf

16” o.c. horizontally (max.)

1 at each vertical corner

Vitrabond® FR metal composite material

Vitraplate® prefinished solid aluminum plate

Edgeline® metal flashing material

RapidWrapCI® is a fully tested and compliant wall assembly containing components that have been tested and/or engineered together as one assembly. As such, Fairview recommends securing all components through Fairview or a RapidWrapCI® certified fabricator to ensure product test compliance. Using products not purchased from Fairview is at your own risk.

MIXED USE | RESIDENTIAL | CORPORATE

PUBLIC | HIGHER EDUCTION | SPECIALTY

CORPORATE ID

DEALERSHIPS | RESTAURANTS

HOSPITALS | OSC/ASC | SPECIALTY

RAPIDWRAPCI® MINERAL WOOL INSULATION

“k” @ 75º [24ºC] BTU.in/hr. sq. ft. ºF 0.24

“R” value per inch of NOMINAL THICKNESS 4.2

Combustibility Non-combustible

Available Thicknesses 1.25”, 1.5”, 2”, 2.5”, 3”, 3.5”, 4”

Standard Dimensions

48”x72”

Recycled Content Minimum 70%

RAPIDWRAPCI® POLYISO INSULATION

“R” Values

Surface Burning Characteristics, ASTM E84 for both foam core and finished product

Class A

Available Thicknesses 1”, 1.55”, 2”, 2.5”, 3”

Standard Dimensions

48”x96”, 48”x144”

Continuous insulation, otherwise known as CI, is when insulation continuously wraps the exterior of a building to improve the performance of the building envelope. It is also defined in American Society of Heating, Refrigerating and Air-conditioning Engineers 90.1 (ASHRAE 90.1) as:

“Continuous Insulation is insulation that is uncompressed and continuous across all structural members without thermal bridges other than fasteners and service openings. It is installed on the interior or exterior or is integral to any opaque surface of the building envelope.”

Based on the above definition of CI, it is questionable if even using thermally broken standoffs would constitute an ASHRAE 90.1 compliant CI system. In contrast, the only penetrations through the insulation in the RapidWrapCI® system are service openings and the RapidWrapCI® Anchors, which makes RapidWrapCI® a truly ASHRAE 90.1 compliant system.

RapidWrapCI® Anchors do not create any more of a thermal bridge than the fasteners that already hold the insulation to the wall of the building. Both polyiso and mineral wool insulation are fastened directly into the studs, and as RapidWrapCI® Anchors use the exact same method of attachment, there is no additional thermal bridging created.

RapidWrapCI® meets the voluntary test standards of AAMA 508 (pressure equalized rainscreen) and AAMA 509 (drained and back ventilated rainscreen). RapidWrapCI is an NFPA 285 compliant wall assembly or is non-combustible when installed using Vitraplate and mineral wool insulation. Further details can be found in our Technical Evaluation Report produced by Dr J Engineering

AAMA 508 PRESSURE EQUALIZED ARROWHEAD RAIN SCREEN

ASTM E238 Air Leakage of Test Buck (without panel system installed)

ASTM E1233 Cyclic Static Air Pressure Differential (pressure cycling) Cycle Time Lag 0.08 sec max.

ASTM E330 Uniform Load Deflection and Uniform Load Structural L/175 of Stiffener Length

AAMA 509 DRAINED AND BACK VENTILATED ARROWHEAD RAIN SCREEN

Standard Test ArrowheadLEAN Results ArrowheadFLEX Results

E283 Air Leakage

ASTM E331 Static Water Penetration

AAMA 501.1 Dynamic Water Penetration

RapidWrapCI® using the Arrowhead Flex system meets TAS 201, 202, and 203 test protocols in accordance with the Florida building code for the high velocity hurricane and Miami Dade County requirements.

VITRABOND FR PANEL OVER ARROWHEAD Standard Test

TAS 202 - 94 Uniform Static Air Pressure (+100/-150 psf) PASS

TAS 201 - 94 Large Missile Impact Procedures (+100/-150 psf) PASS

TAS 203 - 94 Cyclic Winds Pressure Loading (+100/-150 psf) PASS

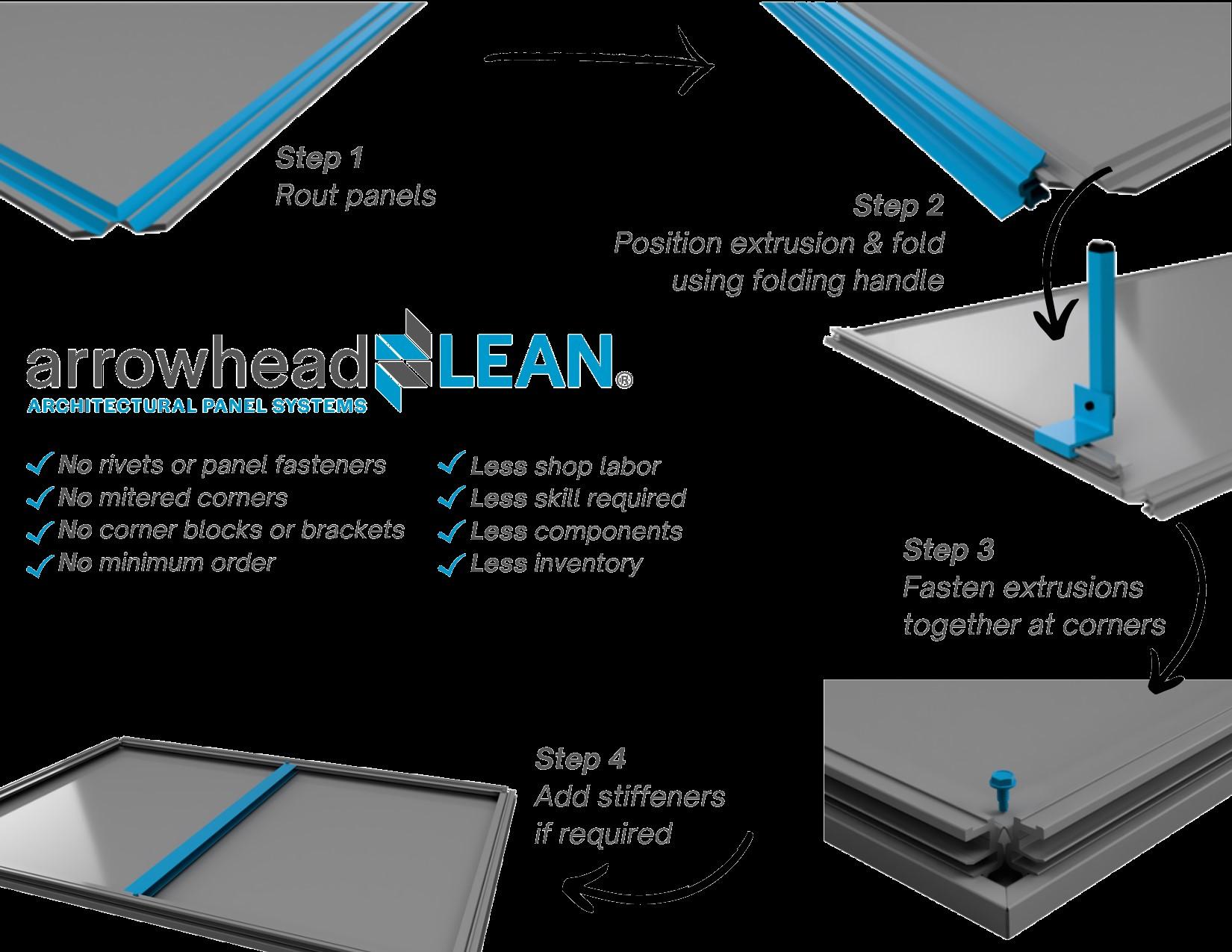

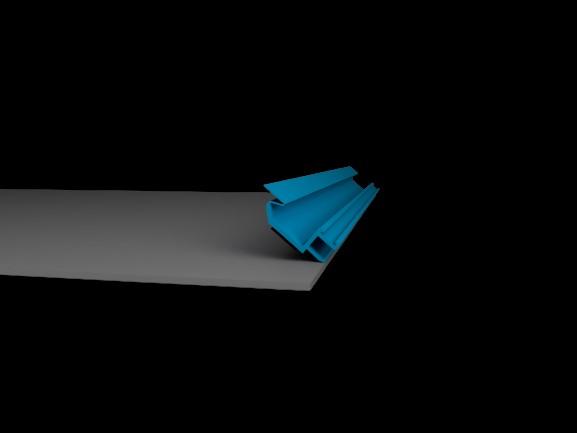

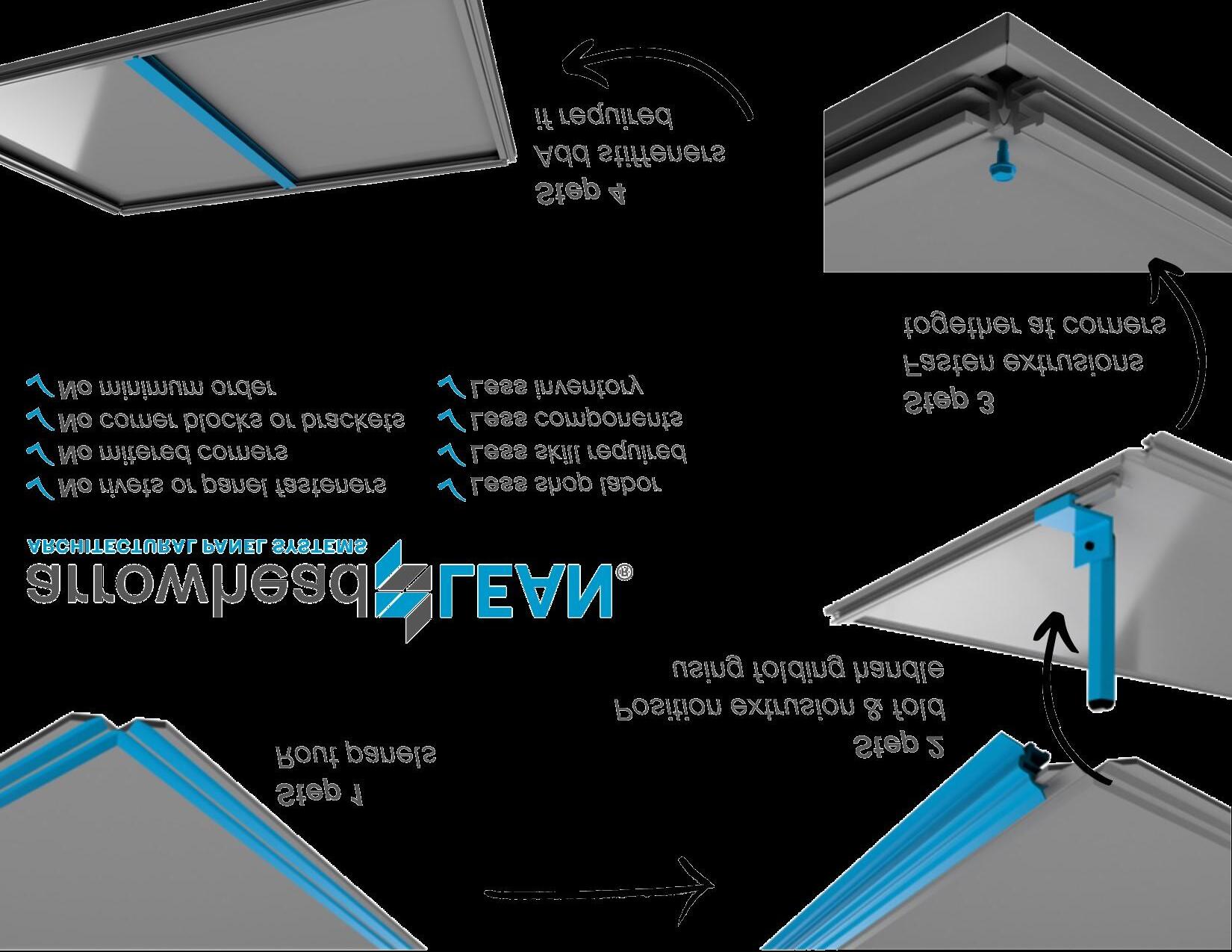

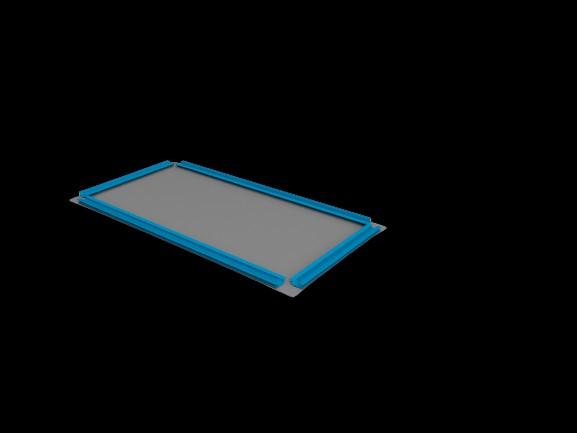

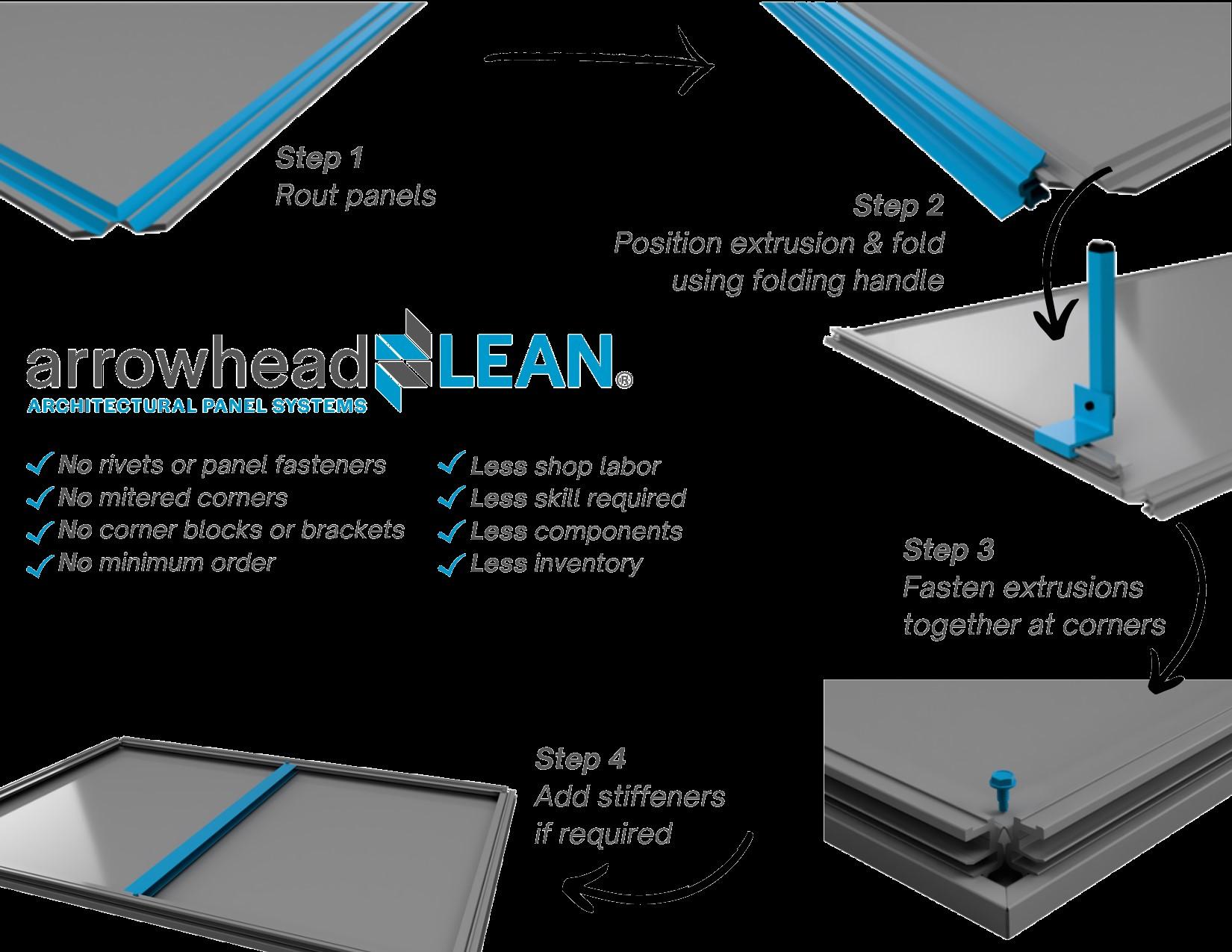

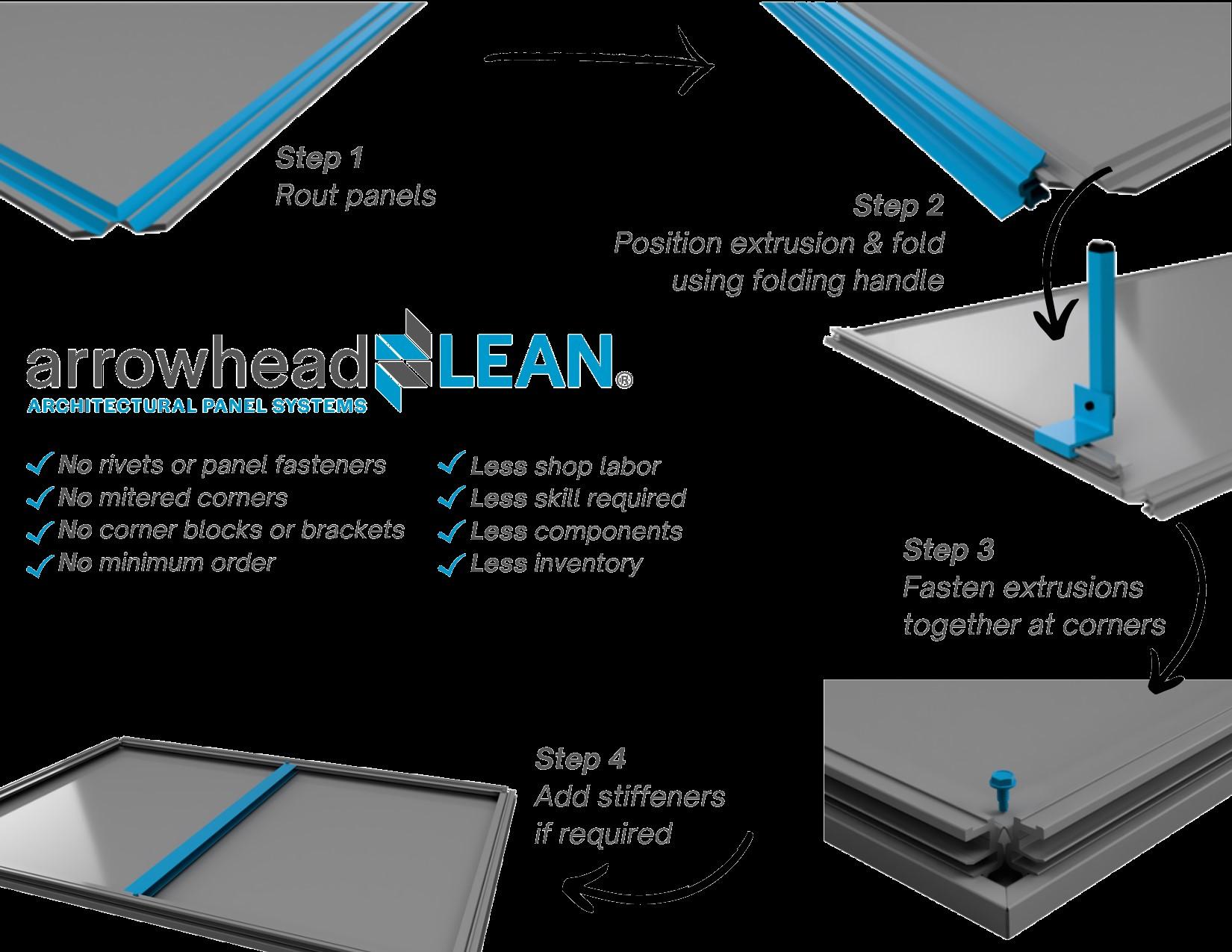

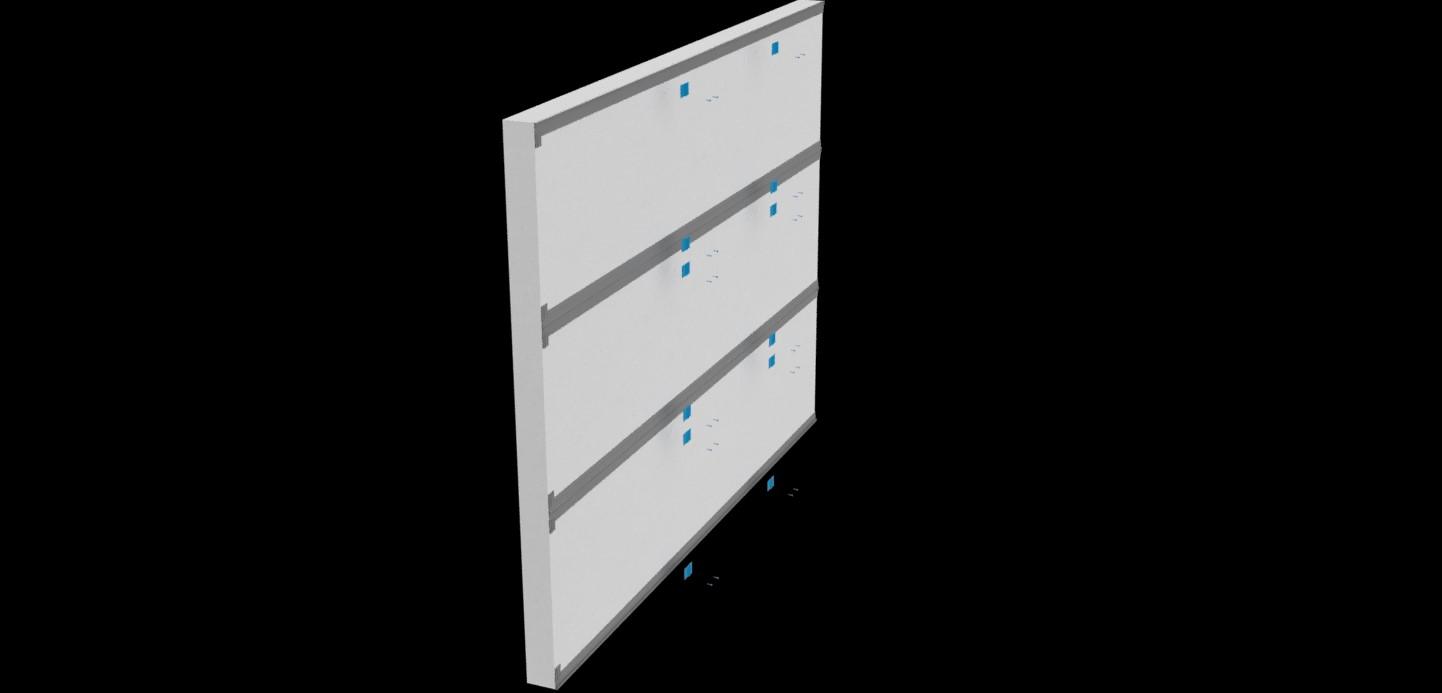

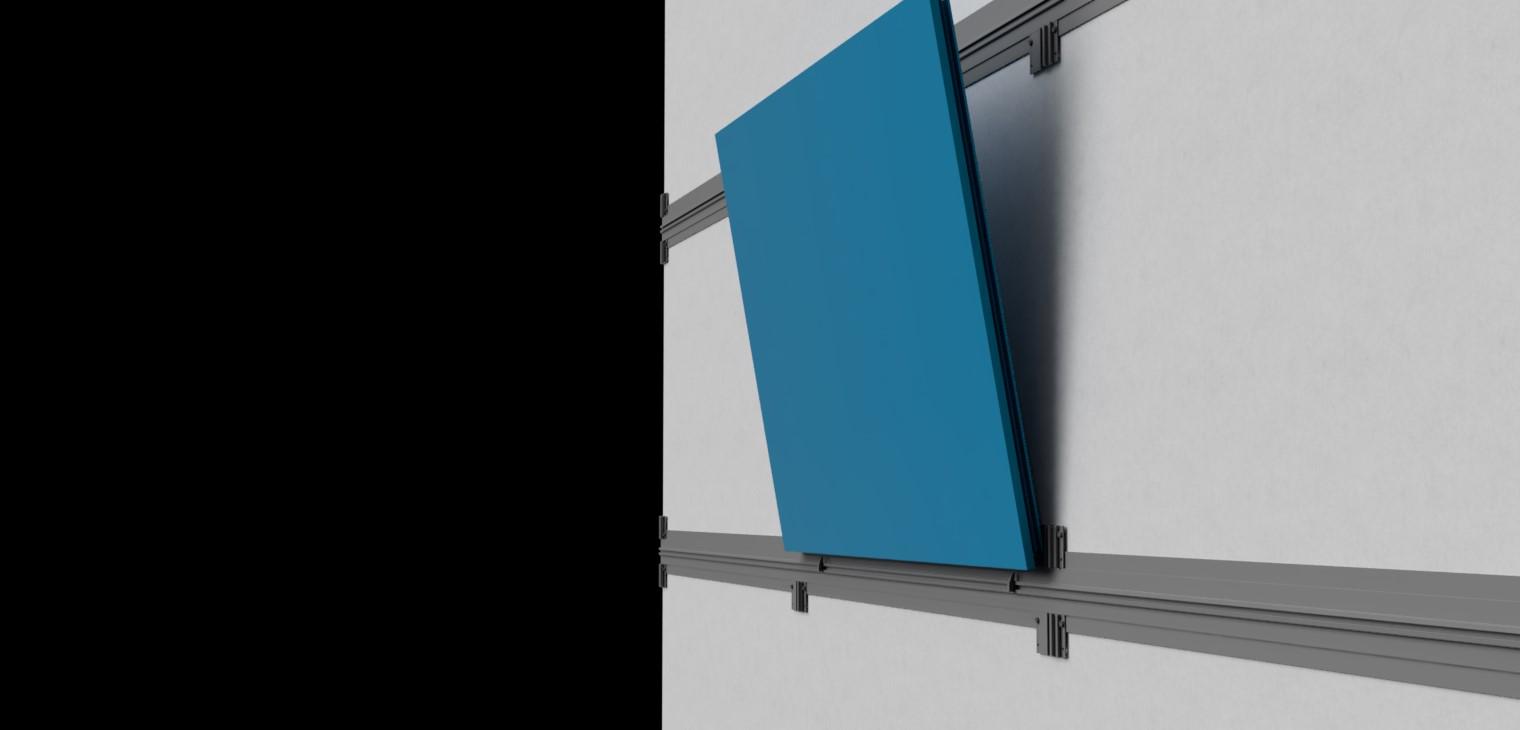

Arrowhead is a non-sequential metal panel installation system that is engineered to increase productivity and capacity without increasing overheads.

The Arrowhead® metal panel installation systems are designed to simplify the process of fabricating and installing metal composite and solid aluminum plate panels. There are three distinct panel systems within the Arrowhead® brand, and are all compatible with each other.

Arrowhead® panels can be installed in any order using two methods of installation. The grid method is the fastest, as it eliminates the need to level and shim each panel, while the clip method is designed to reduce materials without compromising the nonsequential characteristics of the system.

• Most traditional, yet versatile system

• HVHZ Compliant

• Minimum 1” panel return

• Compatible with Vitrabond® and Vitraplate®

• Fast and simplest fabrication

• No rivets, corner brackets, or mitered corners

• 5/8” panel return

• Compatible with Vitrabond®

Arrowhead is in stock at our warehouse in Connecticut and available for immediate delivery to anywhere in North America or Canada.

Shorten your project schedule by up to 50% by reducing stages in the drafting process and eliminating re-verification of field measurements.

• Clean, modern look

• Coped and hemmed 4mm panel return

• Compatible with Vitrabond®

Easily remove and replace damaged panels without compromising the quality, fit, or integrity of the system.

Arrowhead eliminates the need for laser scanning as final panel measurements come directly from the grid.

Panels can be installed in any order, which reduces the risk of being stalled by other trades on-site.

All Arrowhead systems use the same mounting components, allowing for varied panel types and depths in the wall design.

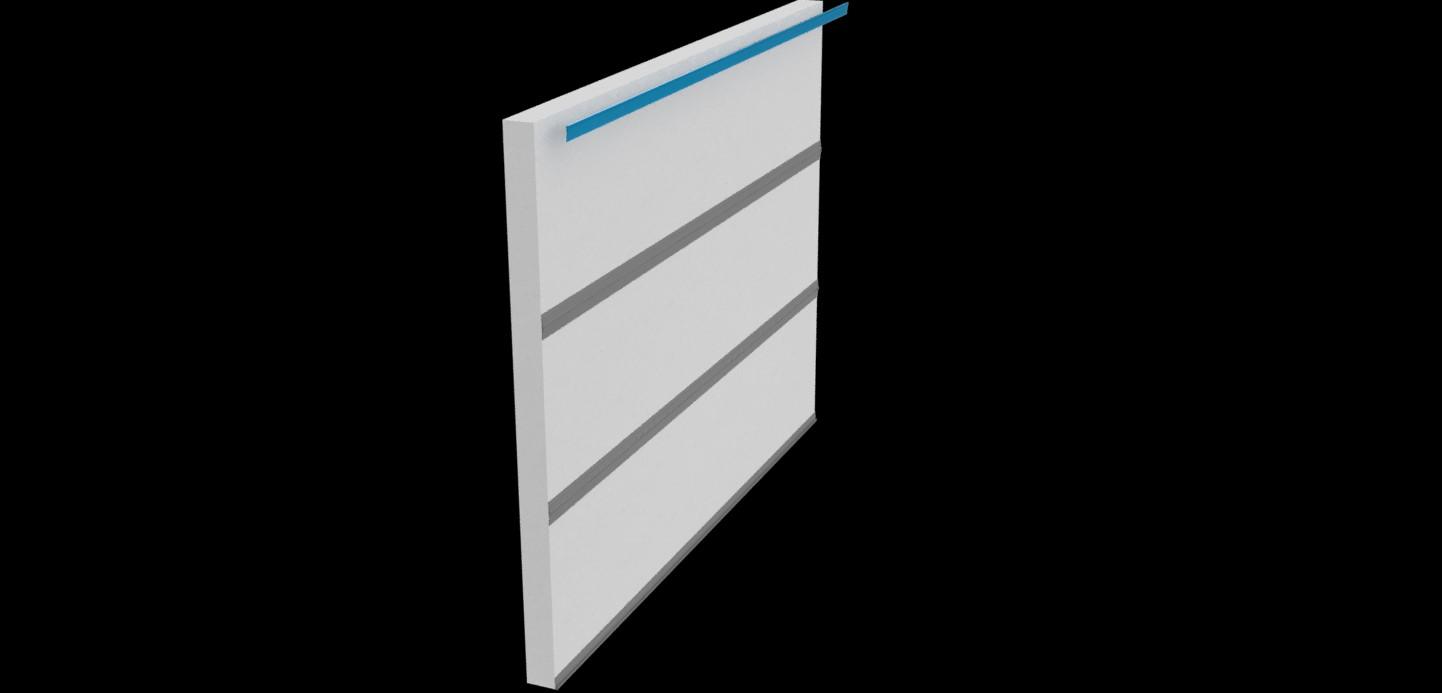

Arrowhead® Flex is a traditional rout panel return. Deeper panels can be fabricated by creating a return greater than

Arrowhead® Flush utilizes a coped achieve 4mm deep reveal. The metal composite material is attached to the perimeter extrusions using 3M level or interior applications.

is designed to reduce the amount of time spent on fabrication, return system that eliminates the need to use any fasteners to connect the perimeter extrusion to the metal composite material. Only 1 fastener is required at each corner to fasten the perimeter

All 3 Arrowhead® panel systems can be installed adjacent to each other using either the Clip or Grid installation methods.

The Grid Installation method can be used to reduce levelling and shimming when installed over a solid substrate or girts, or is used as part of the RapidWrapCI® Wall Assembly.

Step 3

Attach panels in any order, and insert reveal pieces as required.

The Clip Installation reduces the number of components without changing sequential attributes of the Arrowhead® system, by replacing the horizontal extrusions with individual clips. See the manuals below for more details.

PVDF Coating Descriptions Test

ASTM B117 Salt Spray Resistance 5% salt fog at 95°F

Test Result

Passes 4000 hrs. Less than 1/16” avg creepage from scribe. None or few #8 blisters

ASTM D523 Specular Gloss Test Standard @ 60° Varies per finish

ASTM D1308 Alkali Test 10%, 25% NaOH, 1hr No Effect

ASTM D714 Blistering of Paint Test

100% Relative Humidity @ 95°F Passes 4000 hrs.

ASTM D2244 Exterior Exposure 10 years @ 45° South Florida PASS - Max. 5 fade

ASTM D2247 Water Resistance

ASTM D2794 Reverse Impact

ASTM D3359 Adhesion

100% Relative Humidity @ 95°F No #8 blisters

1.5 x metal NOMINAL THICKNESS (Aluminum) No cracking or adhesion loss

Reverse impact 1/16” crosshatch No adhesion loss

ASTM D3363 Film Hardness Pencil Test F - 2H PASS

ASTM D4145 Prepainted Metal Coating Flexibility T - Bend 0 - 2 T - Bend, No pick off

ASTM D4214 Chalk Resistance 10 years @ 45° South Florida Pass - Max. 8 Chalk

Our dedication to fulfilling our customer’s expectations is reflected in our superior quality control system, beginning at the point of specification and continuing through to delivery of our guaranteed products. All activities are carried out in a manner that:

• Uses the framework of ISO9000 Quality Standards to verify the quality of our systems

• Ensures that our products and services are of the highest standards

• Create continuous improvements to our product through the application of the best quality practices

Access the most recent Vitrabond Technical Evaluation report by DrJ Engineering by scanning the QR code.

Vitrabond® complies to AAMA 508 and AAMA 509 when installed with Arrowhead and meets the test protocols TAS201, 202, and 203 in accordance with the Florida building code for high velocity hurricane zone and Miami Dade County requirements.

Standard Test

ASTM E238 Air Leakage of Test Buck (without panel system installed)

ASTM E1233 Cyclic Static Air Pressure Differential (pressure cycling) Cycle Time Lag 0.08 sec max. Cycle Pressure Difference 12.5 psf max.

E331 Static Water Penetration

ASTM E330 Uniform Load Deflection and Uniform Load Structural L/175 of Stiffener Length

AAMA 509 DRAINED AND BACK VENTILATED ARROWHEAD RAIN SCREEN

Standard Test Arrowhead LEAN Results Arrowhead FLEX Results ASTM E283 Air Leakage V1 V3

ASTM E331 Static Water Penetration

AAMA 501.1 Dynamic Water Penetration

Vitrabond® using the Arrowhead Flex system meets TAS 201, 202, and 203 test protocols in accordance with the Florida building code for the high velocity hurricane and Miami Dade County requirements.

VITRABOND

TAS 202 - 94 Uniform Static Air Pressure

TAS 201 - 94 Large Missile Impact Procedures

TAS 203 - 94 Cyclic Winds Pressure Loading

-150 psf)

-150 psf) PASS

-150 psf) PASS

½ Pre-Consumer + Post-Consumer Recycled Content Up to 44.5%

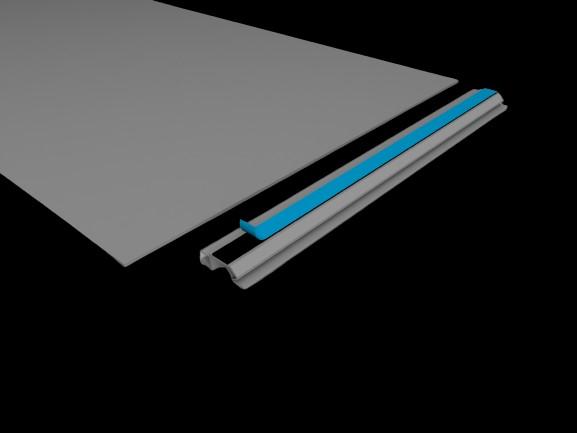

Edgeline is a premium Architectural Grade flashing material, the same quality as metal façade cladding materials.

Fairview’s Edgeline premium metal flashing material is a pre-finished product available in 0.032” and 0.040” thicknesses. Unlike typical flashing material, Edgeline has an architectural grade fade resistant finish that will outperform other flashing products.

When Edgeline flashing materials are used together with our Vitrabond® and Vitraplate® cladding materials on a building façade, they will look the same not only from project completion but also for years to come thanks to their architectural grade coating.

• All Edgeline products are available in the exact color as your building facade.

• Our Edgeline products are high quality, lightweight and easy to install.

• Edgeline materials are easy to fabricate to fit the exact needs of your project.

You can buy your panels and flashing material (flat sheets) from one supplier which enables you to benefit from bundled pricing, one lead time, one delivery schedule and more.

We are always developing and adding to our product range in order to meet the needs of our customers. Below is an outline of what Edgeline can be used for:

A parapet cap is a barrier that forms an extension of the wall at the edge of a roof, balcony , terrace, walkway or other structure.

Our high-performance sill flashing designs enable flashing to be installed prior to framing.

Slab edge covers are used to hide the balcony slab edge. They create a design feature on the facade.

A drip edge is a nonstaining and noncorroding material applied to a roof’s edge to allow water to filter out of the roof system.

Beam wraps provide a variety of solutions to integrate building design elements and enhance the look of a project.

Our J-Channels provide a secure fit and support for aluminum soffit channels.

• Order with Vitrabond® or Vitraplate® to have color consistency on your project

• Most common thicknesses are 0.032” and 0.040”

SOLID/MICA/METALLIC/PATTERNED

ALLOYS

3003 (other alloys may be available upon request)

NOMINAL THICKNESS: 0.020” up to 0.125” (Typical for this application is 0.032” and 0.040”)

Custom nominal thicknesses may be available upon request

WIDTHS: STANDARD: 48”, 60”, 62”

LENGTHS: STANDARD: 122”, 146”, 196”

ALLOYS

CUSTOM: 36” to 62” (+-1/4” Tolerance)

CUSTOM: 100” to 240” (min 20 sheets each)

5005 (other alloys may be available upon request)

NOMINAL THICKNESS: 0.020” up to 0.125” (Typical for this application is 0.032” and 0.040”) Custom nominal thicknesses may be available upon request

WIDTHS: STANDARD: 48”, 60”, 62”

LENGTHS: STANDARD: 122”, 146”, 196”

CUSTOM: 48” to 62” (+-1/4” Tolerance)

CUSTOM: 100” to 240” (min 20 sheets each)

NOTE: Separate sheet widths may be from separate coating runs, and in some cases could results in a perceivable color difference

Edgeline® has no minimum order when purchased from existing inventory unless it is ordered as an Accessory Purchase or a Production Run as described below:

ACCESSORY PURCHASE (Purchased with Vitrabond® or Vitraplate® in the same finish)

When purchased as an accessory product with Vitrabond® or Vitraplate®, there is no minimum order quantity for Edgeline if it is in stock.

When Edgeline® is not in stock as an accessory to your Vitrabond® or Vitraplate® purchase:

PURCHASED WITH VITRABOND® PURCHASED WITH VITRAPLATE®

(Same width as Vitrabond® only) - 200sf

NOTE: Minimum order quantity per color, width and thickness.

PRODUCTION

When produced to order as a stand-alone product, the following minimum order quantities apply:

NOTE: Minimum order quantity per color, width and thickness.

STANDARD TEST

PROPERTIES

TEST STANDARD RESULT

ASTM E136 Fire Performance of 3003 Aluminum ΔT< 86°F PASS

THERMAL PERFORMANCE

ASTM D696 Coefficient of Linear Expansion

13.8x10-6 in/in/°F (Aluminum)

PVDF Coating Descriptions Test Test Result

ASTM B117 Salt Spray Resistance 5% salt fog at 95°F Passes 4000 hrs. Less than 1/16” avg creepage from scribe. None or few #8 blisters

ASTM D523 Specular Gloss Test Standard @ 60° Varies per finish

ASTM D1308 Alkali Test 10%, 25% NaOH, 1hr No Effect

ASTM D714 Blistering of Paint Test

ASTM D2244 Exterior Exposure

ASTM D2247 Water Resistance

100% Relative Humidity @ 95°F Passes 4000 hrs.

10 years @ 45° South Florida PASS - Max. 5 fade

100% Relative Humidity @ 95°F No #8 blisters

ASTM D2794 Reverse Impact 1.5 x metal NOMINAL THICKNESS (Aluminum) No cracking or adhesion loss

ASTM D3359 Adhesion Reverse impact 1/16” crosshatch No adhesion loss

ASTM D3363 Film Hardness Pencil Test F - 2H PASS

ASTM D4145 Prepainted Metal Coating Flexibility T - Bend 0 - 2 T - Bend, No pick off

ASTM D4214 Chalk Resistance

10 years @ 45° South Florida Pass - Max. 8 Chalk

½ Pre-Consumer + Post-Consumer Recycled Content Up to 32.5%

A standard product warranty of up to 20 years is available on coil-coated or coil-anodized Edgeline®, with an extended warranty of up to 40 years available on select finishes.

Our unwavering commitment to quality ensures superior products by following strict ISO9000 standards, guaranteeing consistency and continuous improvement