Route complete panels. Ensure that the grain direction is the same for all panels unless specified otherwise.

Use final panel dimensions as per the extrusions that have been installed on the wall.

Tired of reading? Access the training videos using the QR code below

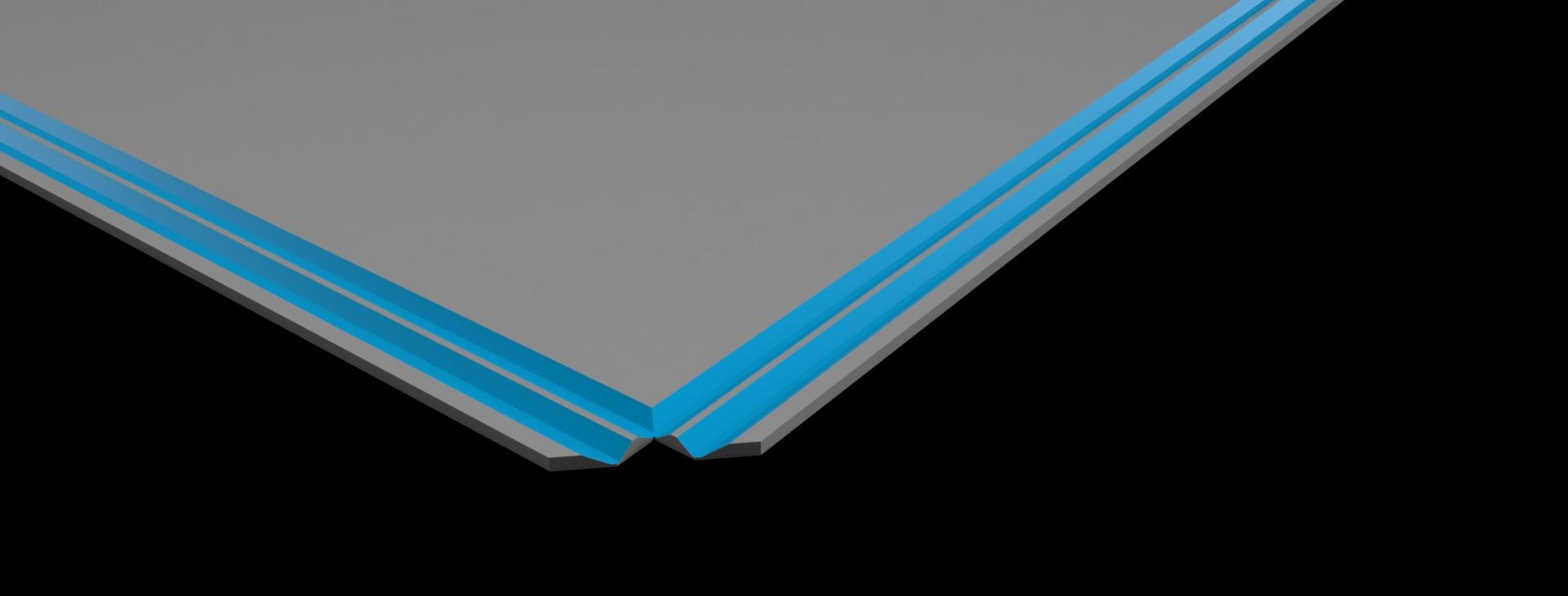

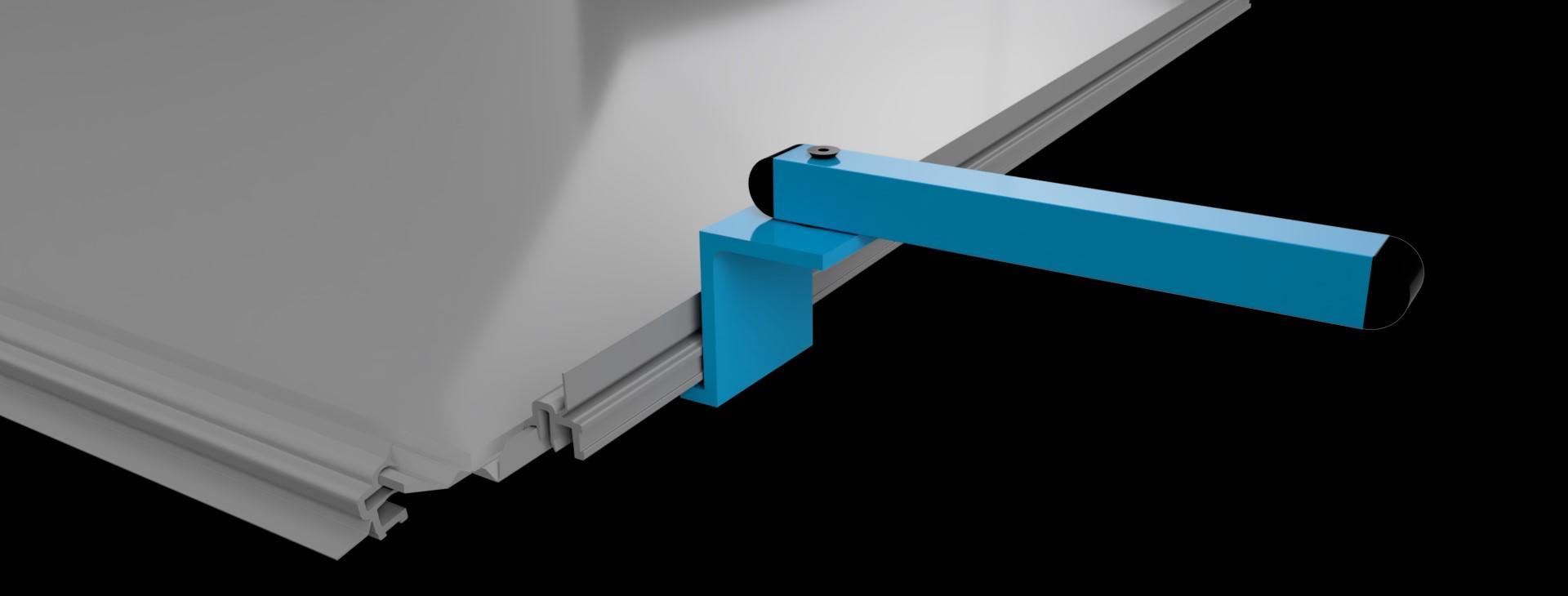

Cut AH-401 Lean Frame Extrusions less than each side. Slide the AH-401 Lean Frame Extrusion onto the edge of the panel, and fold using the AH 410 Lean Folding Handle as pictured.

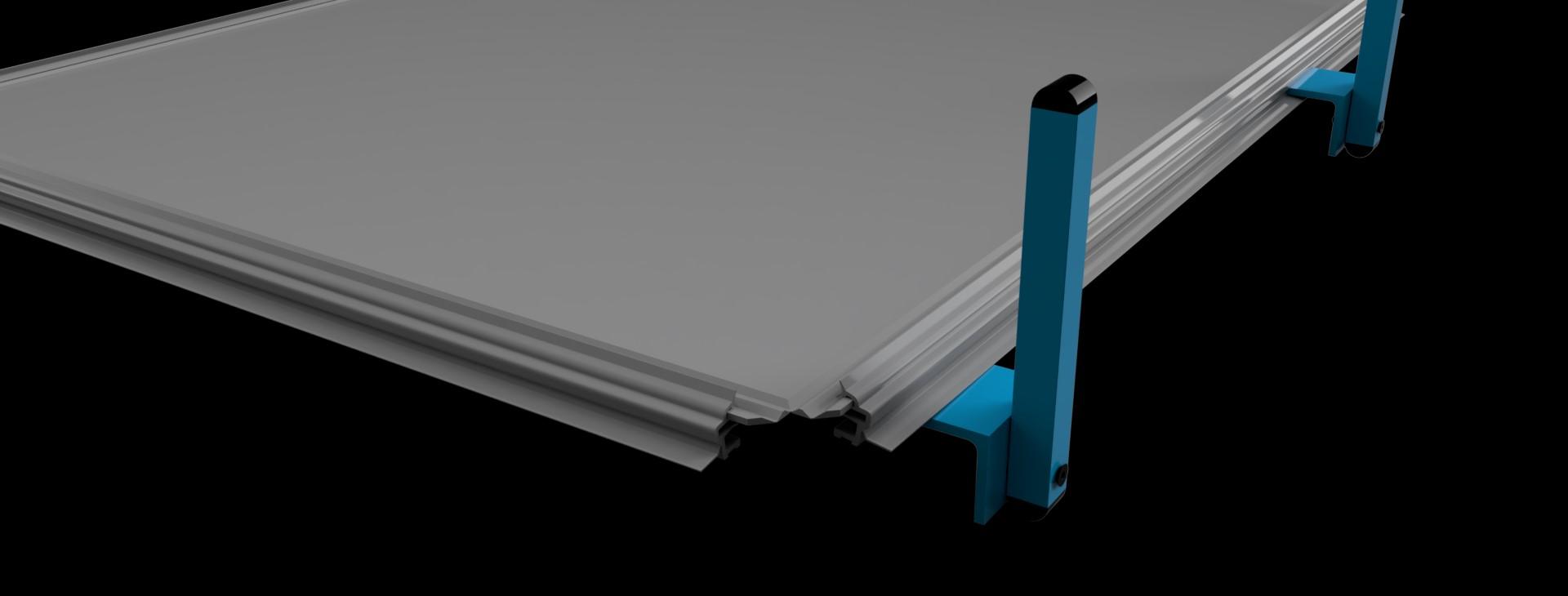

Repeat step 2 on all sides of the panel. At each corner, slightly bend the fastening flange, and fasten the extrusions to each other with a #10 self screw as shown.

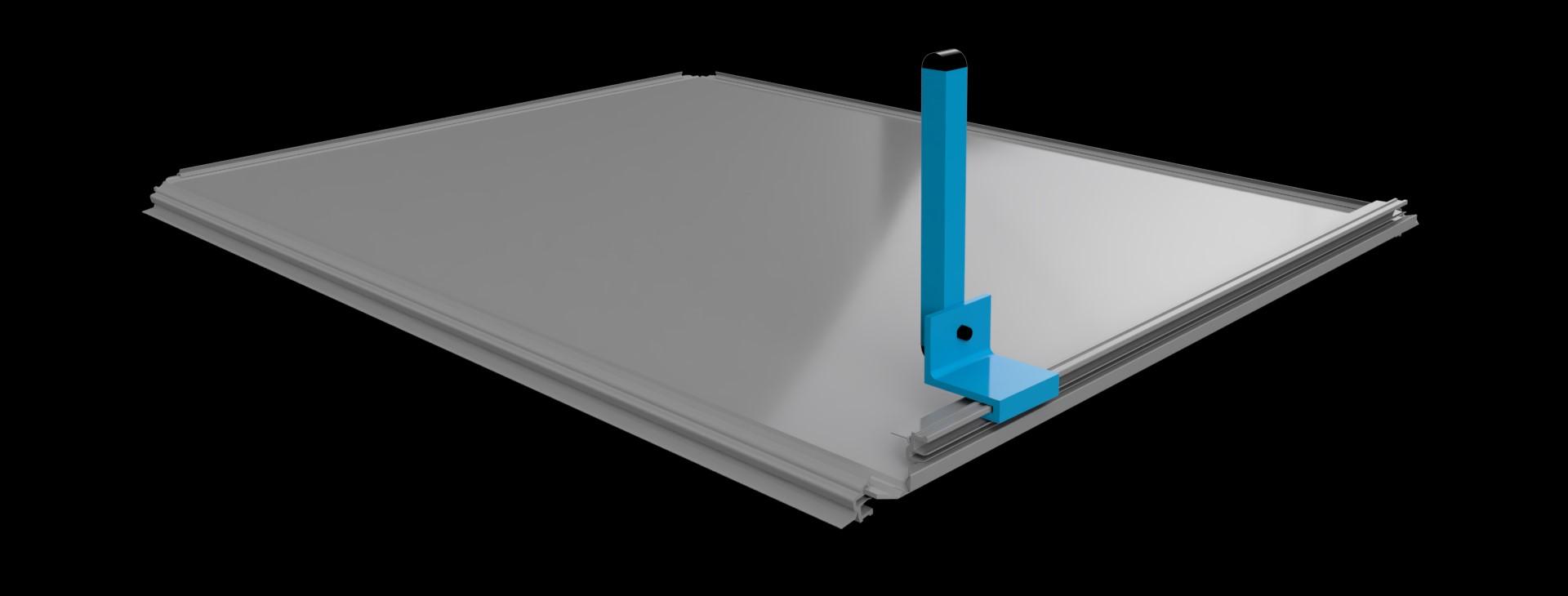

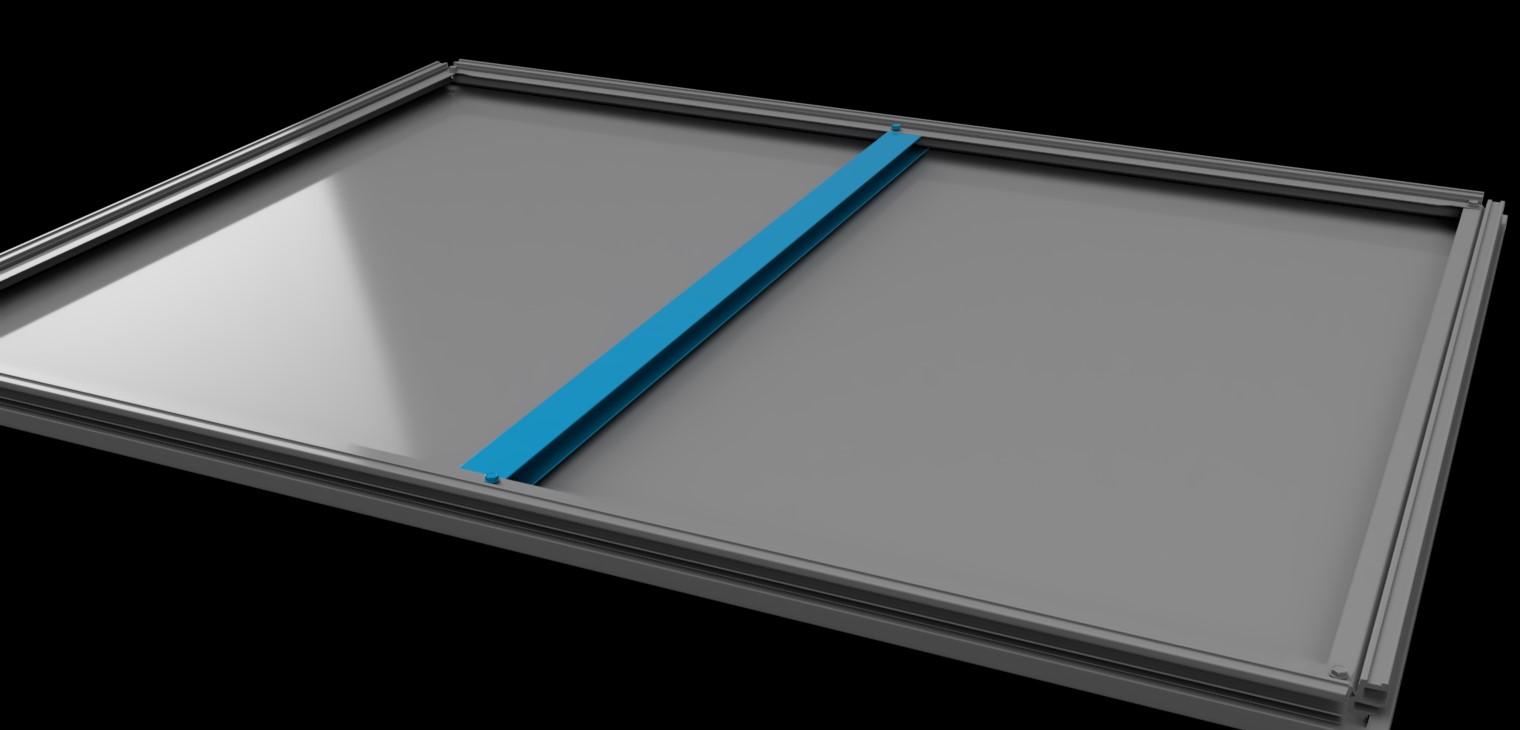

Clean surfaces and turn AH-406 stiffener under both AH-401 frame extrusions. Fasten stiffener to the perimeter extrusions with a #10 self-tapping screw in opposite corners as shown, then add structural caulk on both sides and tool it in.

No need to miter corners for AAMA 508 panels

Only 4 fasteners per panel (not including stiffeners)

Fully tested to NFPA 285, AAMA 508, and AAMA 509

Only double-return system that allows you to get a 60” panel out of a 62” wide sheet