Technology • Understanding the visual impact of the Stiles-Crawford effect • The importance of poroelasticity in soft contact lenses

Modern modalities require boundless imagination and limitless capabilities. Designed to support the requirements of scleral and ortho-k lens designs, Optimum Infinite’s unique properties offer you the opportunity to push the boundaries of speciality lens design.

32021 (88) ISSN:1386 0194

Fitting Background • Context in contacts Special Topic • New challenges in intra-ocular lens metrology Interview • Lynette Johns NOW AVAILABLE AT YOUR APP STORE Eyepress Fachmedien GmbH Saarner Str. 151, 45479 Mülheim a. d. Ruhr

Hyper Dk Tailored Modulus Inherently Wettable

optimum-infinite.com

Sustainability

The major issues of these times continue to be the corona crisis, the difficulties around global trade and production against a background of sustainability. The optical and contact lens industries are affected differently.

Let's focus on sustainability: Environmental protection is not always easy. Filtering contaminated water leaves a lot of waste that ends up being discharged more-or-less adequately, or at best recycled. Avoiding domestic air travel sometimes costs companies more in employee time and money than traveling by train. Electric cars may save CO2, but battery cell production requires a lot of energy and extraction of the raw materials required is associated with environmental and social problems. The list of such environmental dilemmas is endless.

Often it all comes down to choosing between the lesser of two evils: either in favor of the least harmful raw materials or the comparatively more environmentally friendly process. Does this all lead to nowhere and could we save ourselves the trouble? No! Experts believe that the next ten years will determine what the next 10,000 years will be like for our civilization. Thus there is no excuse for delay! All countermeasures, no matter how trivial they may seem, are important because they all add up in the end.

According to Statista, industry worldwide is responsible for 19% of all greenhouse gas emissions, and transportation for another 25%. The worldwide mass production of spectacle lenses, frames and contact lenses does its bit.

More and more companies that produce in our industry are realizing this. In a recent press release, CooperVision, for example, announced that it would produce its approx. 1 billion disposable lenses per day (!) in a plastic-neutral way in cooperation with Plastic Bank. This means that for every gram of contact lens and blister produced, the same amount of ocean-bound plastic waste is collected.Plastic Bank aims to reduce plastic waste in the world's oceans by building collection

and recycling infrastructures in countries where there is no functioning circular economy.

Bausch + Lomb has also continued to expand its sustainability efforts. The company currently reports to recycle more than 41 million contact lens, eye and lens care materials through collaboration with TerraCycle

Another example: Menicon has long developed a concept of sustainability. One environmentally friendly achievement is the development of their flat pack daily disposable lens. The plastics used in their manufacturing process are approximately 99% recycled. 100% recycled plastics are used for the outer packaging.

And the spectacle lens industry is also showing how this can be done in many areas. For example, the company Zeiss (Germany) claims to be CO 2 neutral by 2025. Essilor is committed to contributing to carbon neutrality, circular economy, worldview, integration and ethics. Emissions from direct operations are to be made CO2 neutral in Europe by 2023 and in other markets by 2025.

There are also more and more sustainable products that address this issue. Be it thinner semi-finished products that use less plastic, products made from sustainable materials, state-ofthe-art filtration systems, creative recycling options for production waste and much more.

But, even though the first step has been taken, most of the journey is still ahead of us.

How is your company doing in terms of sustainability? Write to me with your opinion. ■

SILKE SAGE Editor-In-Chief silke@global-cl.com

3

LETTER FROM THE EDITOR GlobalCONTACT 3-21

– not trivial but not impossible either!

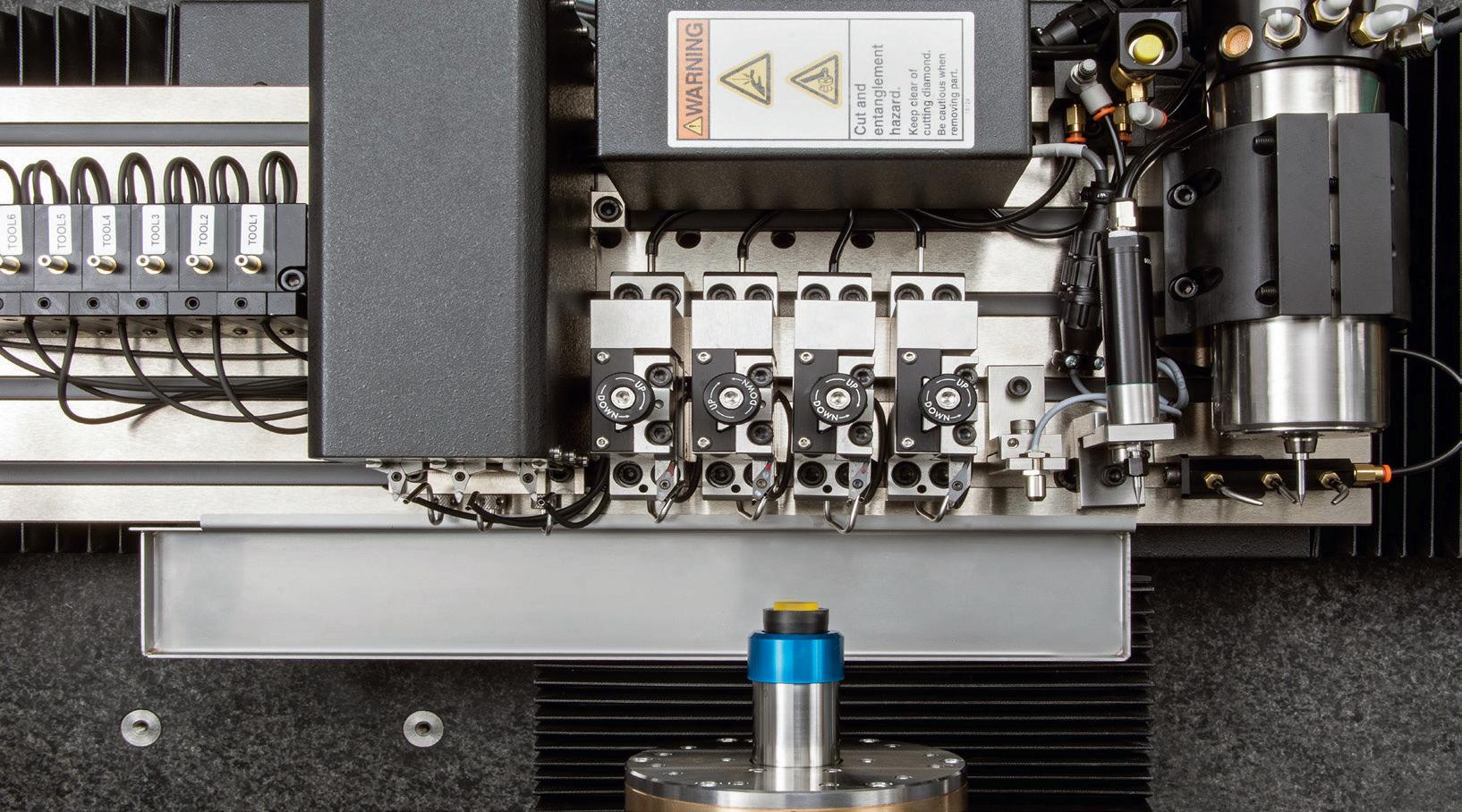

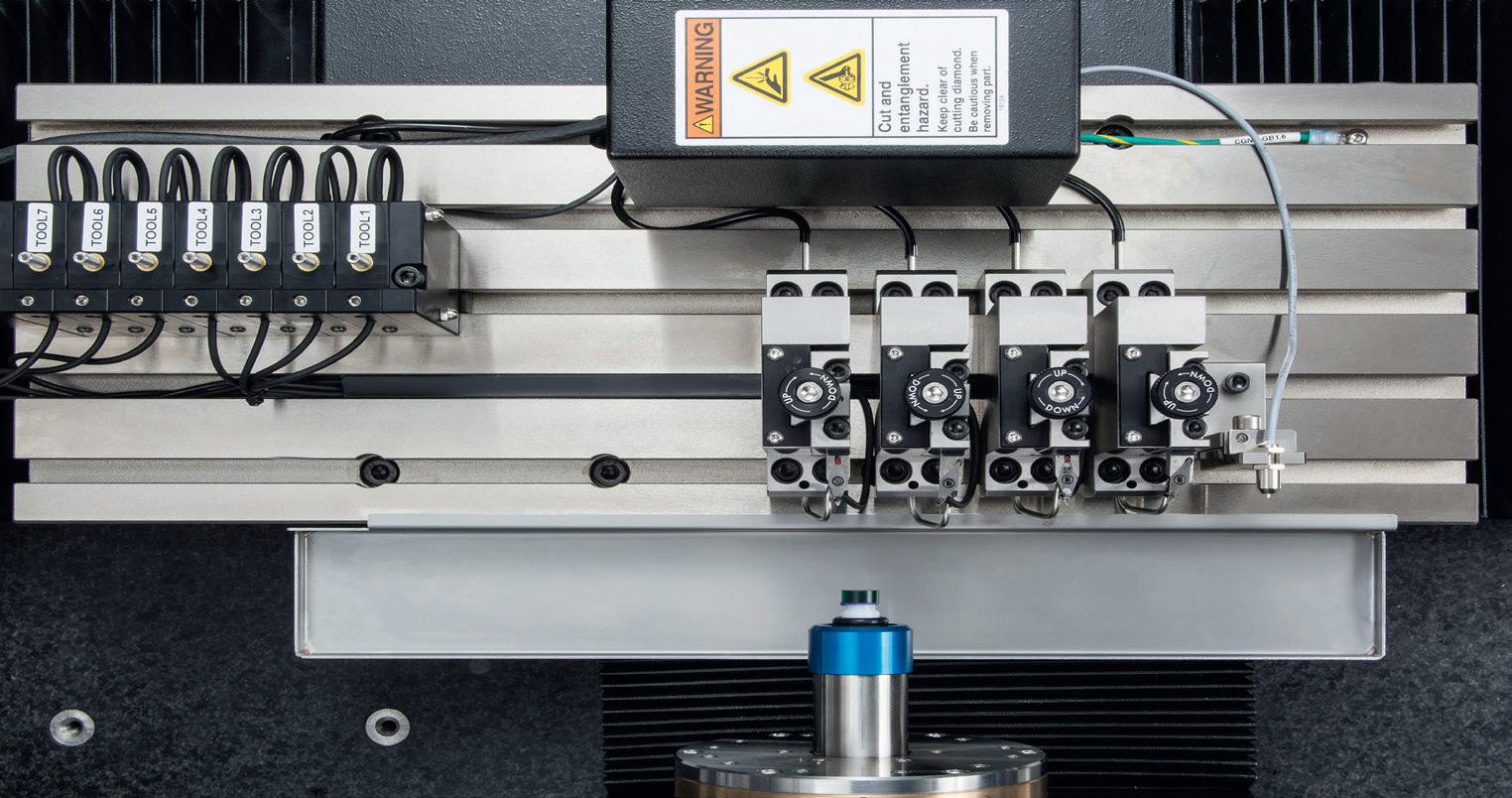

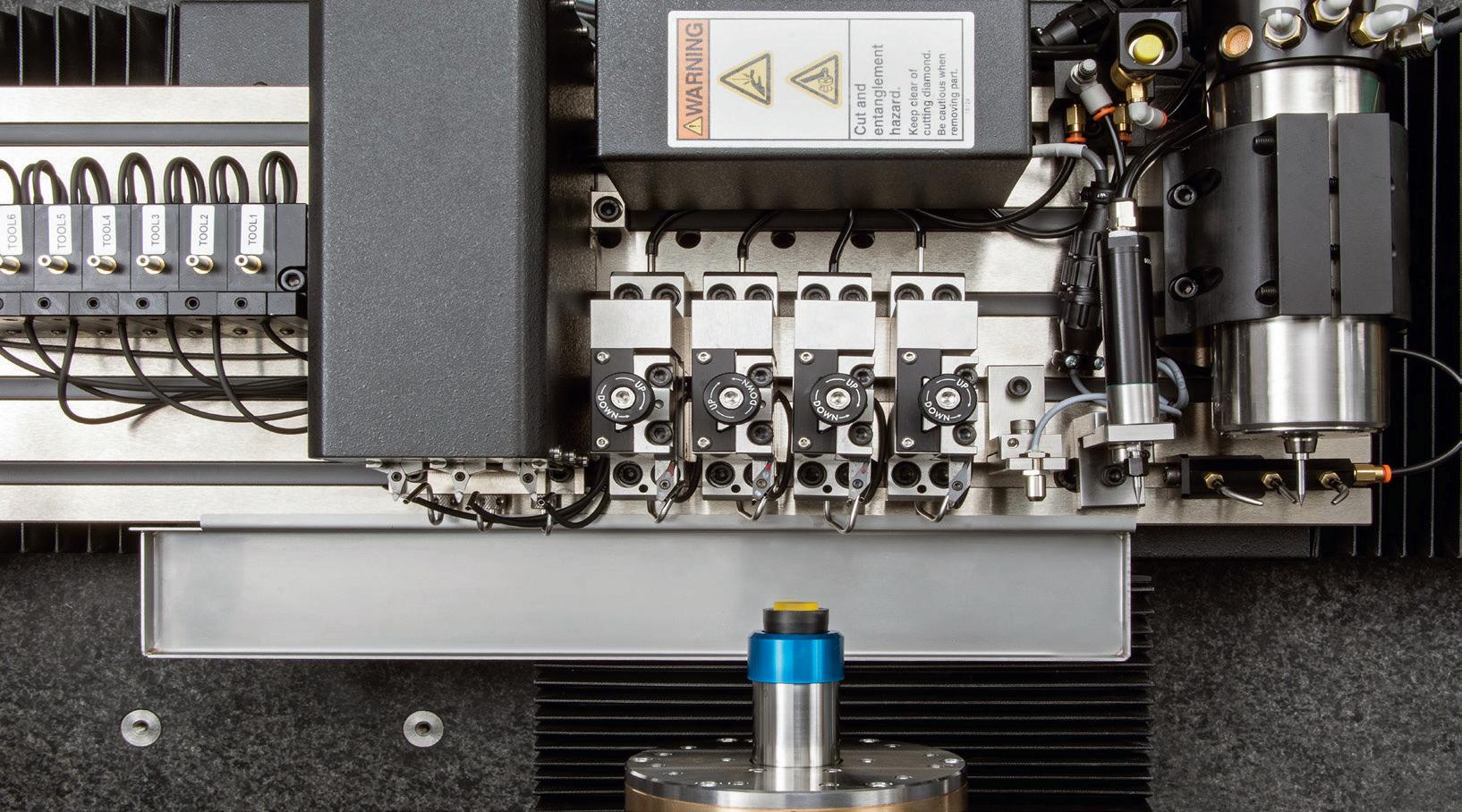

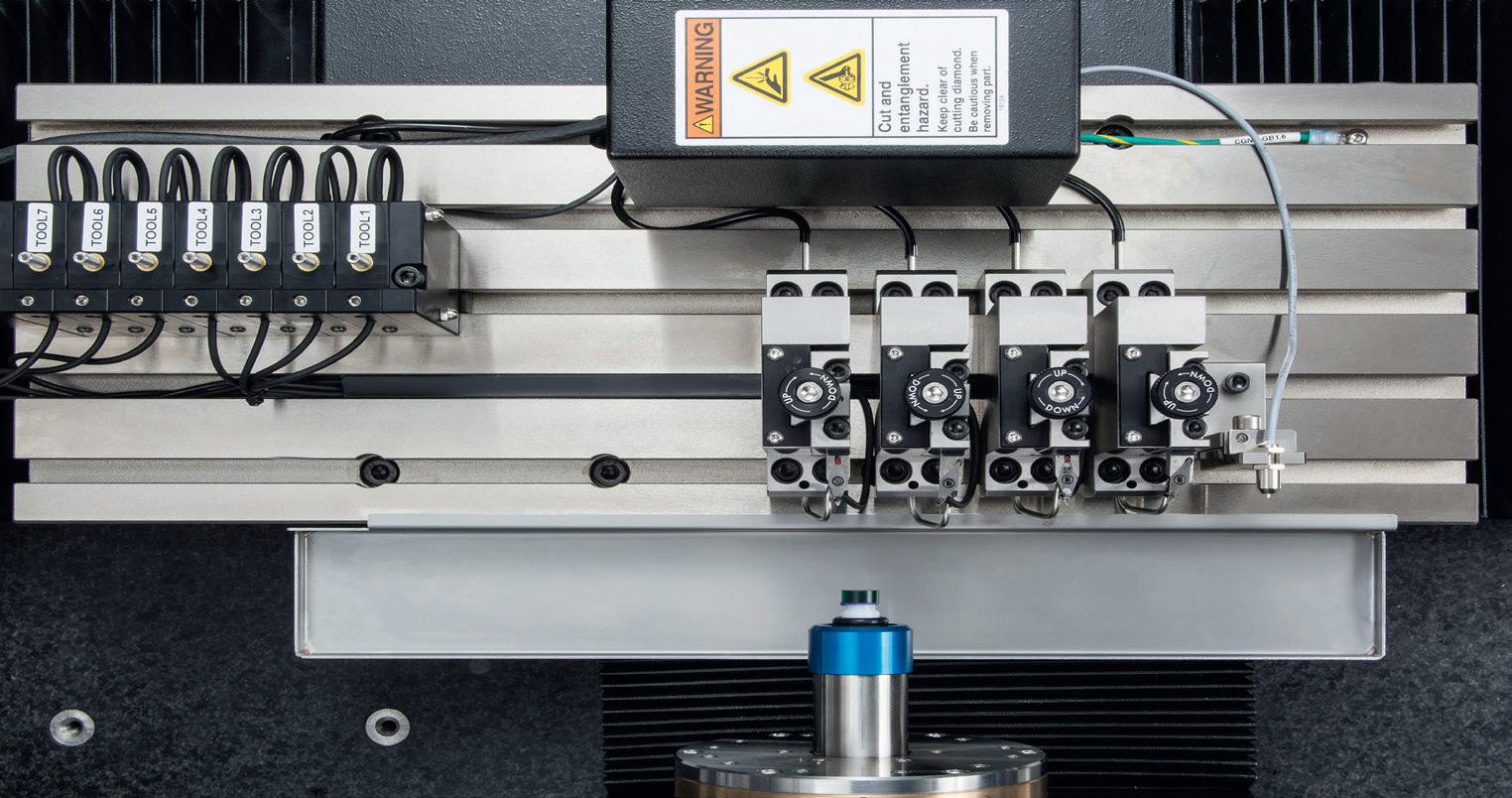

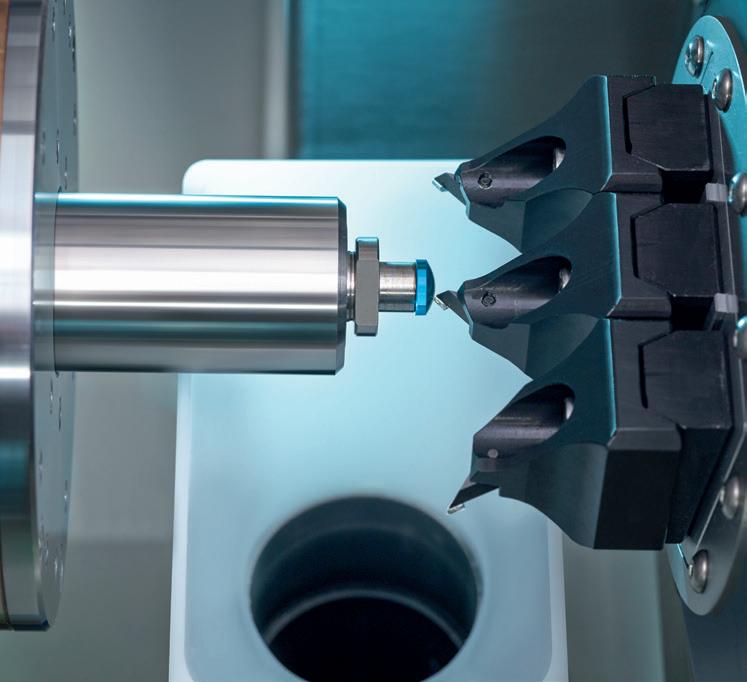

ULTRA-PRECISE AND ECONOMICAL MANUFACTURING OF CONTACT LENSES AND IOL

UPC 100 Vision // UPC nano

Highest surface accuracy and quality meet unprecedented productivity.

The compact and fully featured UPC 100 Vision is optimized for highly dynamic diamond turning of complex freeform surfaces like polish-free IOLs, mold inserts or complex contact lens designs.

The UPC nano is the most affordable and compact machine with on-board freeform capabilities and an optional laser for manufacturing high-quality contact lenses at maximum cost-efficiency.

Both machines can be easily integrated with an optional automation system.

www.schneider-om.com

INDEX TO ADVERTISERS

Title: Contamac, www.contamac.com

Inside front cover: Bausch + Lomb Inc., www.bausch.com

Page 4: Schneider GmbH & Co. KG, www.schneider-om.com

Page 7: REM Vision Tech, www.remvt.com

Page 9: OPTOCRAFT GmbH, www.optocraft.com

Page 13: K & Y Diamond Ltd, www.kydiamond.ca

Page 15: Optimec Systems Ltd., www.optimecsystems.com

Page 19: LAMBDA-X S.A., www.lambda-x.com

Page 21: Schneider GmbH & Co. KG, www.schneider-om.com

Page 25: Larsen Equipment Design Inc., www.larsenequipment.com

Page 35: AMETEK Precitech, Inc., www.precitech.com

Inside back cover: Efclin, www.efclin.com

Outside back cover: DAC International, Inc., www.dac-intl.com

NAMES TO NOTE

Joannes, Luc 36 Johns, Lynette 26 Kahlert, Marie 33 Kinder, Alina 16

Larsen, Erik 34 Roth, Hans-Walter 40 Vohnsen, Brian 22 van der Worp, Eef 30, 42

LETTER FROM THE EDITOR

3 Sustainability – not trivial but not impossible either!

Silke Sage

INTERNATIONAL NEWS

TECHNOLOGY

16 The importance of poroelasticity in soft contact lenses – pt. 2

Alina Kinder

Understanding the visual impact of the Stiles-Crawford effect

Brian Vohnsen

INTERVIEW

26 Interview with Lynette Johns – Drug delivery in scleral lens wear

Silke Sage

FITTING BACKGROUND

Context in contacts Eef van der Worp

Imaging techniques – case study Marie Kahlert

MANUFACTURING

TOPIC

HISTORY

Hans-Walter Roth

COLUMN

32021 (88) Technology • Understanding the visual impact of the Stiles-Crawford Effect • The importance of poroelasticity in soft contact lenses Fitting Background Context in contacts Special Topic New challenges in intra-ocular lens metrology Interview Lynette Johns NOW AVAILABLE AT YOUR APP STORE Eyepress Fachmedien GmbH Saarner Str. 151, 45479 Mülheim a. d. Ruhr optimum-infinite.com Modern modalities require boundless imagination and limitless capabilities. Designed to support the requirements of scleral and ortho-k lens designs, Optimum Infinite’s unique properties offer you the opportunity to push the boundaries of speciality lens design. Hyper Dk Tailored Modulus Inherently Wettable

10

14

6 All about you & event dates

All about research

All about products

22

33

30

34 Blocking scleral lenses Erik Larsen

SPECIAL

36 New challenges in intra-ocular lens metrology Luc Joannes

40 About the use of the “gel”-contact lens

CONTENT 5 GlobalCONTACT 3-21

42 Under pressure Eef van der Worp NEWS 44 Yellow Pages

All about you

Ten rules for the safe use of contact lenses endorsed by TFOS

The national campaign "Healthy Eyes Are in Your Hands", an awareness project dedicated to contact lenses and their safe use, promoted by the Tear Film & Ocular Surface Society TFOS and supported by ASSOTTICA (the Italian Contact Lens Association), promotes ten rules of correct hygiene and management of contact lenses.

The rules have also been summarized in the educational video "Healthy Eyes Are in Your Hands" in which children are the ones giving adults the indications of correct behavior. This video involves washing and drying your hands before handling contact lenses, never letting the lenses come into contact with water, not sleeping with contact lenses, and disinfecting lenses in a new solution after each use. If you wear disposable daily lenses, it is important to throw them away after taking them off and not reuse them, then follow the manufacturer's instructions and the specialist's instructions. The video campaign is available on the web: https://youtu.be/VdscomrqFsw and has already reached tens of thousands of views. "Contact lenses have a long history, and the materials with which they are made have evolved enormously over the years, thanks to intense scientific research. Today, new synthesis technologies have led to materials compatible with the ocular surface, reaching high standards of safety and comfort," emphasized Prof. Piera Versura, Head of the Ocular Surface Analysis and Translational Research Laboratory, Alma Mater Studiorum University of Bologna. “Unfortunately, we are distancing ourselves from this security mainly due to incorrect behavior. The Healthy Eyes Are in Your Hands Campaign can help you understand and remember that contact lenses are a medical device that we put in the eye, and they need care and maintenance."

CooperVision myopia control research receives Garland W. Clay Award

The American Academy of Optometry has awarded the 2021 Garland W. Clay Award to a team of researchers studying the effectiveness of CooperVision MiSight 1 day contact lenses in slowing the progression of myopia in children (aged 8-12 at the initiation of treatment). The prestigious award is given annually to the author(s) of the most important paper published in Optometry and Vision Science in the preceding five years. The authors of the winning paper, “A 3-Year Randomized Clinical Trial of MiSight Lenses for Myopia Control,” include:

• Paul Chamberlain, BSc (Hons.)

• Sofia C. Peixoto-De-Matos, MSc

• Nicola S. Logan, PhD

• Cheryl Ngo, MBBS, MMed

• Deborah Jones, BSc, FAAO

• and Graeme Young, PhD, FAAO

The Optometry and Vision Science editorial board bestows the annual Garland W. Clay Award based upon criteria including the number of citations in the world scientific literature, impact of vision science, value to the practice of optometry, and relevance to the mission of the American Academy of Optometry. After only two years since publication, the paper about MiSight 1 day contact lenses has been cited over 70 times according to Clarivate’s Web of Science and is the most cited paper in Optometry and Vision Science since 2016.

Optometry and Vision Science Editor in Chief Michael Twa, OD, PhD, FAAO stressed that his publication places a priority on quality evidence-

based publications noting that: “Clinical trial results provide strong evidence that it is possible to slow ocular growth that causes worsening myopia. Research into myopia control is rapidly evolving and effective treatments could do more than improve vision, they may also help lower lifelong risks for glaucoma, retinal detachments, and other degenerative eye conditions.”

CooperVision MiSight 1 day myopia control contact lenses are proven to slow the progression of myopia in children aged 8-12 at the initiation of treatment. Data gleaned from these three years of research laid the groundwork for FDA approval of CooperVision MiSight lenses in 2019. The study, a randomized double-masked clinical trial, demonstrated the effectiveness of MiSight lenses in reducing the rate of myopia progression in children (aged 8-12 at the initiation of treatment) by 59% on average over a three-year period.

CooperVision Director of Research Programs Paul Chamberlain, BSc (Hons.) said, “Our team is grateful to the Optometry and Vision Science Editorial Board and the American Academy of Optometry for recognizing our work. It is very satisfying to know that our research in myopia control is helping age-appropriate children and their parents around the world. And it is truly an honor to be associated with the other pioneering papers that have previously received this distinction.”

Chamberlain and team accepted the Garland W. Clay Award at the American Academy of Optometry’s Meeting in Boston on Thursday, Nov. 4.

6

GlobalCONTACT 3-21 INTERNATIONAL NEWS

Marcus Hughes elected to the BostonSight Board of Directors

BostonSight, a nonprofit eye healthcare organization and research center dedicated to saving sight and improving quality of life for patients, have elected Mr. Marcus Hughes to their Board of Directors. Mr. Hughes is Associate General Counsel at UMass Memorial Health Care in Worcester, MA. He serves as legal counsel to the UMass Memorial Health Care (UMMHC) System and its affiliates, with a primary focus on patient care matters. Prior to his role at UMass, Mr. Hughes was Attorney Fellow, Office of the General Counsel at Partners HealthCare in Boston, and Assistant Corporation Counsel for the City of Boston. Mr. Hughes began his legal career at Choate, Hall & Stewart in Boston. “Electing Mr. Hughes to the BostonSight Board is a tremendous benefit to the organization,” said Sara Yost, BostonSight President and CEO. “He is accomplished in legal healthcare

Johnson & Johnson Vision receives approval in Canada for Acuvue Abiliti 1-Day Soft Therapeutic Lenses for Myopia Management

Johnson & Johnson Vision received approval from Health Canada for Acuvue Abiliti 1-Day Soft Therapeutic Lenses for Myopia Management. Abiliti 1-Day lenses are a new option of daily wear, single-use, disposable lenses that have the potential to slow the progression of myopia and are specifically designed for children who are seven to twelve years old at the start of treatment. “The approval from Health Canada for Acuvue Abiliti 1-Day lenses marks another major step forward in our collaborative efforts with parents and eye care professionals to reshape the future of myopia,” said Xiao-Yu Song, MD, PhD, Global Head of Research & Development, Johnson & Johnson Vision. “Our researchers and scientists specifically designed

matters, including reporting and compliance, which will support BostonSight as we continue to lead in providing expert, compassionate patient care and scleral lens technology globally.” Mr. Hughes received his JD from Boston College Law School and his undergraduate degree from Middlebury College in Vermont where he was a Harry S. Truman Scholar Nominee and part of the New England Small College Athletic Conference All-Academic Team. He has spoken at events of the American and Boston Bar Associations on ethical behavior in the legal profession and operational challenges in responding to COVID-19, as well as written for the American Bar Association on COVID-19 and its impact on healthcare professional licensure and telehealth.

Abiliti 1-Day to be a novel soft therapeutic lens with the potential to slow the progression of myopia in children.”

The company also announced that each annual purchase of an Abiliti product would provide a free comprehensive eye health exam to a child in need through Sight For Kids – a joint program from Johnson & Johnson Vision and the not-for-profit Lions Clubs International Foundation (LCIF). Sight For Kids is one of the largest-known, school-based eye health programs that mobilizes Lions and eye care professionals to provide comprehensive eye health services in low-income schools around the world.

Abiliti 1-Day lenses are expected to be available in select areas of Canada starting as early as this year and expanding beyond in 2022. Parents and eye care professionals who want more information can visit www.seeyourabiliti.com.

Advertisement

Marcus Hughes. Source: BostonSight

Ultra precision CNC lathes for CL and IOL manufacturing Your smartest investment www.remvt.com INTERNATIONAL NEWS

EFCLLIN: PFAS-registry of ECHA: five EU member states have submitted the notification for restriction of PFAS

On 15th July, the five REACH competent authorities – from Denmark, Germany, the Netherland, Norway and Sweden – notified the European Chemicals Agency (ECHA) of their intention to restrict PFAS substances (Registry of Intentions). www.echa.europa.eu/registry-of-restriction-intentions/-/dislist/ details/0b0236e18663449b

Submitting a notification to ECHA’s Registry of Intentions (ROI) is step one of the restriction process – the five competent authorities flag a substance, allowing ECHA to get ready and industry to submit evidence. From this moment, the five competent authorities have twelve months to prepare a restriction proposal and collect all available evidence. All companies who are registered producers or users of the substance will also be notified so they can submit evidence to the

notifier. At the end of these twelve months, the five competent authorities will submit a restriction proposal after which ECHA will launch an open consultation via its website.

The proposal will then pass through several technical committees within ECHA who will give their expert opinion. The European Commission will have to decide whether to adopt or not the proposal using ECHA’s expert opinions as guidance. If they adopt it then it will be sent to the European Parliament and the Council of the European Union for their approval, after which it will be published and enter into force.

Over the next few months, ECHA will check whether the five competent authorities’ notification fulfils ECHA’s requirements. If it does, then they will publish the notification on the dedicated website page – the Registry of Restriction Intentions – allowing the public to follow the file’s progress.

CLMA remembers and honors Jo Svochak

Jo began her career in the contact lens industry alongside her husband, Frank Svochak, Sr., a true pioneer of contact lens machining in 1976 when they founded TruForm Optics. After Frank’s passing in 1982 Jo assumed the role as President of TruForm Optics, (1982-2019), and her passion to help people see their world better was made possible through TruForm’s countless contact lens design and machinery advancements throughout her 37 years of service to the industry.

Jo went on to be a pioneer in her own right, as she was the first female to hold the position of President with the Contact Lens Manufacturers Association (CLMA) from 1999 to 2000. In 2013 Jo received the Trailblazers Award, by the CLMA, for her outstanding achievement in product development to the enhancement of the contact lens industry. Since the inception of the Trailblazers Award in 1987 Jo remains the only female to receive the coveted award.

Among Jo’s notable work at TruForm Optics, she was proud of the contributions her late husband, Frank, and her son and current President of TruForm, Jan Svochak, made to advancing the industry forward, and she took great pride in the accolades she was able to see them receive: (1994) Jan Svochak received the Creative Design and Process

Award by the CLMA, for innovation in lens design and manufacturing process to the enhancement of the contact lens industry. (2006) Frank Svochak, Sr., received the Trailblazers Award for outstanding achievement in product development to the enhancement of the contact lens industry by the CLMA.

Jo attended her last CLMA meeting in 2018 and enjoyed the fellowship of her life-long friends and colleagues. Jo was also able to see her son, Jan Svochak, receive the Leonardo da Vinci Award for vision in establishing the focus of the CLMA and dedication to the achievement of its goals. This was a momentous event for the entire Svochak family.

Jo had a zest for life and a personal charm that drew people from all walks of life. Any conversation with Jo was a meaningful and memorable one. Above all of Jo’s career accomplishments and her unwavering dedication to the contact lens industry, her deepest love was being a mother, grandmother, and great grandmother. Jo had a special place in her heart for children, especially babies which always brought the brightest smile to her face.

Naomi “Jo” Svochak, was a compassionate and loving woman, and will be missed by all those who knew her.

8

GlobalCONTACT 3-21 INTERNATIONAL NEWS

Naomi “Jo” Svochak 1937-2021

GSLS 2022 https://na.eventscloud.com/website/22990/home

NCC 2022

https://contactlenscongress.com/?lang=en

EFCLIN 2022 www.efclin.com

ARVO 2022 www.arvo.org

EAOO & ECOO General Assembly www.visiondublin2022.com

ICSC 2022 www.icscmeeting.com

ECLSO Congress 2022 www.eclso.eu

Vision By Design www.orthokmeeting.com

AAO 2022 www.aao.org

IOFT 2022 International Optical Fair Tokyo www.ioft.jp/en-gb.html

Jan 19-22

Las Vegas, NV (USA)

Mar 13-14 Eindhoven (NL)

Apr 28-30 Barcelona/ Sitges (Spain)

May 1-4 Denver, CO (USA)

May 12-15 Dublin (Ireland)

July 29-30 Fort Lauderdale, FL (USA)

Sep 2-3 Paris (France)

Sep 28 - Oct 2 Bellevue, WA (USA)

Sep 30 - Oct 3 Chicago, IL (USA)

Oct 18-20 Tokyo (JPN)

the

please

whether the

takes

Know your quality: Contact and intra-ocular lens metrology made by Optocraft! Tel. +49 9131 69 15 00 email sales@optocraft.de

WEBINARS, CONFERENCES & TRADE FAIRS 2022

(due to

corona crisis,

check via the websites

event

place)

Advertisement

All about research

Studies on contact lens sensors, plastic pollution and the shape of light

A paper published by the journal Matter reports on the development of a new contact lens sensor system for smart contact lenses. The impact of contact lenses, specifically silicone hydrogels, as a source of plastic and microplastic pollution is the focus of a paper by a team of Arizona State University researchers. Further studies take a look at the influence of the shape of light on our vision and present a contact lens sensor for self-monitoring of intraocular pressure.

Ultra-thin sensor for smart contact lenses

In a paper published by the journal Matter, engineers from the University of Surrey together with partners from Harvard University, University of Science and Technology of China, UK National Physical Laboratory, George Washington University and Zhejiang University Ningbo Research Institute report on how they have developed a new contact lens sensor system for smart contact lenses.

The approach uses an ultrathin MoS2 transistors-based serpentine mesh sensor system. The integrated sensor systems contain a photodetector for receiving optical information, a glucose sensor for monitoring glucose level directly from tear fluid, and a temperature sensor for diagnosing potential corneal disease.

According to Dr Shiqi Guo, the first author of this study, the ultra-thin sensor layer is different from conventional smart contact lenses in that it could be mounted onto a contact lens and maintain direct contact with tears, thanks to its easy assembly, high detection sensitivity, good biocompatibility and mechanical robustness. He states that it also doesn't interfere with either blinking or vision.

Co-author Professor Sheng Zhang reports that the contact lens can provide diversified signals from eyes, which could be combined with advanced data analysis algorithms to provide personalized and accurate medical analysis for users.

Another potential that is mentioned in the abstract is that the integrated contact lens sensor system and fabrication strategy could allow for easy incorporation of other functional

10

GlobalCONTACT 3-21 INTERNATIONAL NEWS

components, such as an electrode array for electroretinography, antennas for wireless communication, and power modules for future in vivo exploration. The researchers believe that the system holds promise as next-generation soft electronics for healthcare and medical applications since the in vitro cytotoxicity tests revealed good biocompatibility.

Sources: Abstract of the paper [1], EurekAlert 2021-01-06 [2]

Plastic contact lenses in US wastewater

Arizona State University researchers Charles Rolsky, Varun Kelkar and Rolf Halden have studied the potential of disposable contact lenses as a high-volume pollution source. They conducted the first study to identify contact lenses, specifically silicone hydrogels, as a source of plastic and microplastic pollution. Using sales data and an online survey of lens users (n=416) alongside laboratory and field experiments at a conventional sewage treatment plant, the researchers determined the environmental fate and mass inventories of contact lenses in

the US. Their survey results revealed that around 21% of users flush their used lenses down the drain, a loading equivalent to 44.000±1700 kg y−1 of lens dry mass discharged into US wastewater. The researchers found that biological treatment of wastewater did not result in a measurable loss of plastic mass and caused only very limited changes in the polymer structure, as they determined by μ-Raman spectroscopy. They observed that the lenses accumulated as fragments in sewage sludge, resulting in an estimated accumulation of 24.000 ± 940 kg y−1 of microplastics destined for application on

11

GlobalCONTACT 3-21 INTERNATIONAL NEWS

agricultural soils contained in sewage sludge. Recycling of the contact lenses and their packaging amounted to only 0.04% of the total waste volume associated with contact lens use. In the discussion section of their paper, the researchers mention, that the study featured some limitations in that only 66% of the respondents answered a survey question regarding their age range, thereby reducing statistical power. Another factor is the unknown behavior of contact lens hydrogel polymers

during long-term, multiyear storage in septic tanks which is seen as interesting because an estimated 20% of households in the US use on-site septic systems for wastewater treatment. The team points out that hydrogel as an environmental pollutant through contact lenses could be almost completely avoided by properly disposing the lenses within solid waste. The paper states that at the time of the study, most products in the US contained no recommendations on how to properly dispose of the lenses and their packaging materials. The teams’ research suggests that although contact lenses are a small contributor to the plastic pollution epidemic, their unique chemistry presents a threat to the environment if they are improperly disposed of. They could act similarly to microbeads or microfibers, which are also flushed down the drain.

The shape of light changes our vision

Recent studies have shown that the first stage of vision, the perception of light itself, is extremely fast. But the analysis of this decisive step was carried out on molecules in solution in the laboratory. Scientists from the University of Geneva (UNIGE), in collaboration with Federal Polytechnic School of Lausanne (EPFL) and the University Hospitals of Geneva (HUG), Switzerland, reproduced the experiment on mice, in order to observe the processing of light by a living organism in all its complexity. This non-invasive study shows that light energy alone does not define the response of the retina. Its shape – short or long – also has an impact on the signal sent to the brain to form an image. This discovery, published in the journal Science Advances, opens up a new field of research into vision, diagnostics and possibly new curative possibilities. In the eye, the first stage of vision is based on a small molecule – the retinal – which, on contact with light, changes shape. When the retinal alters its geometric form, it triggers a complex mechanism that will result in a nerve impulse generated in the optic nerve. This process takes some time between the moment the eye perceives the light and the moment the brain decodes it. Physicists looked at the retinal to see how long it took to switch its shape. They isolated this molecule in a cuvette and subjected it to laser pulses to test its reaction speed. To their great surprise, the molecule reacted in about 50 femtoseconds.

To study this first stage of vision in detail, the scientists called on biologists, notably Ivan Rodriguez and Pedro Herrera, professors at the UNIGE Faculties of Science and Medicine, respectively, who placed a contact lens and performed an electroretinogram

on mice. When the light hit the retina, they were able to observe an electrical voltage at the cornea, thanks to an electronic amplifier. Their results showed that this stage took place with the same extreme speed as when the molecule is isolated.

The team continued the study by varying the shape of the pulses over time. Changing the shape should not induce any variation in the response of the retina because until now it was thought that only the number of photons captured by the eye played a role. But this was not the case. This result could be explained with the help of computer simulations performed in the group of Ursula Röthlisberger from EPFL.

The scientists observed that the eye did not react in the same way depending on the shape of the light, even though the light energy was identical. They also discovered that the eye’s reaction differed according to the order in which the colors were varied, for example as in a temporal rainbow, even though they follow each other extremely quickly. The retina believes that there is more or less light depending on the shape of the light, while the energy is similar, and therefore sends a stronger or weaker current to the brain depending on its response. This research is published in Science Advances, DOI: 10.1126/sciadv.abe1911.

Source: UNIGE [4]

12

Source: Nationwide Mass Inventory and Degradation Assessment of Plastic Contact Lenses in US Wastewater. [3]

GlobalCONTACT 3-21 INTERNATIONAL NEWS

Artist's view of femtosecond laser pulses arriving in an eye. Image: UNIGE Xavier Ravinet

Contact lens sensor for self-monitoring of intraocular pressure

A collaboration of researchers from different departments at Michigan State University, USA, has published a paper on a wireless, passive sensor that is capable of continuous monitoring of the change in the curvature of cornea caused by intraocular pressure fluctuations. It sits inside a customized, planar and circular doughnut-shaped contact lens. According to the abstract the sensor consists of a constant capacitor and a variable inductor in the form of a stretchable, closed-loop, serpentine wire that serves as both the sensor and the antenna.

Referenzen:

The abstract reports that the sensor shows a pressure responsivity of 523 kHz per 1% axial strain on a pressurized polydimethylsiloxane membrane and 35.1 kHz per 1 mmHg change in the intraocular pressure of a canine eye. Testing for stability showed unvaried characteristics after repeated cycles and parasitic movements. Predictable influences of temperature and humidity on the sensor response were verified experimentally and can be canceled out using real-time calibration with temperature and humidity sensors to integrate with a reader device. The researchers are convinced that the design has potential clinical applications.

Source: Abstract of the study [5]

[1] Guo S, Wu K, Li C, Wang H, Sun Z, Xi D, Zhang S, Ding W, Zaghloul ME, Wang C, Castro FA, Yang D, Zhao Y. Integrated contact lens sensor system based on multifunctional ultrathin MoS2 transistors. Matter. 2021 Mar 3;4(3):969-985. DOI: 10.1016/j.matt.2020.12.002. Epub 2020 Dec 30. PMID: 33398259; PMCID: PMC7773002.

[2] https://www.eurekalert.org/pub_releases/2021-01/uos-sub010621.php

[3] Charles Rolsky, Varun P. Kelkar, Rolf U. Halden. Nationwide Mass Inventory and Degradation Assessment of Plastic Contact Lenses in US Wastewater. Environmental Science & Technology 2020 54 (19), 12102-12108. DOI: 10.1021/acs.est.0c03121

[4] University of Geneva (UNIGE), 28.04.2021

[5] Hossein M., Kouhani M., Wu Jiajia, Tavakoli Arman, Weber Arthur J., Li Wen. Wireless, passive strain sensor in a doughnut-shaped contact lens for continuous non-invasive self-monitoring of intraocular pressure. Lab Chip, 2020,20, 332-342. DOI: 10.1039/C9LC00735K

Ultra Precision Diamond Tools DAC Optoform Moore Nanotech UPL Precitech Nanoform REM Vision CONTACT LENS AND IOL

Advertisement

www. ky diamond.ca

GlobalCONTACT 3-21 INTERNATIONAL NEWS

All about products

Contact Lens Metrology – upgrade your existing NIMO-TR1504 to the latest CLE-MENTOR software.

When it comes to contact lenses Metrology, CLE-MENTOR offers the most advanced software solution in terms of data integrity and integration. At the very core of the program, its user management options and its compatibility with the FDA CFR21 part 11 guidelines enable the protection of any data along with the traceability, warranties and full audit log.

Every NIMO-TR1504 currently in operation is compatible with CLE-MENTOR. Therefore, anyone can benefit from the new features of the program such as a powerful API offering unlimited possibilities of custom integration in your production workflow and a complete integration with FocalPoints, or the Secondary Aperture option dedicated to the control of segmented and decentered optics.

In addition to its optimised processing, new features and improved ergonomics, CLE-MENTOR offers a measurement time divided by two, reducing the cost while massively increasing the efficiency. For even faster measurements, NIMOevo associated to CLE-MENTOR reduces the measurement time of a lens to less than one second.

Depending on the use of the software, the R&D or the Production mode will meet the requirements and help achieve quality as well as improve the speed of the diagnosis.

Learn more about the software and its compatibility with your existing setup - visit our website: https://ophthalmics.lambda-x.com/cle-mentor/ - sales-ophthalmics@lambda-x.com

Gas Permeable Lens Virtual Education Series

Bausch & Lomb Boston Materials has introduced a virtual educational series on GP Materials. The program is a three-part webinar series that takes a deep dive into the importance of material selection in RGP Lens fitting.

Maria Walker, OD, MS, FAAO, FSLS, hosted Episode One: Selecting Gas Permeable Lens Materials, where she discussed the science that goes into GP material development. This episode provides an in-depth review of Boston materials, including their indications, quality, and manufacturing process.

In Episode 2; Susan Resnick, OD, FAAO, FSLS turned our attention to Gas Permeable Material

Selection for Scleral Lens Design. Here, she takes a closer look at Boston XO and Boston XO2 by highlighting her own case experience in her practice. Coming up in November 2021, the next episode will focus on Gas Permeable Material Selection for Overnight Orthokeratology. For more information on Boston Materials Webinar Series, to register for an upcoming program, or to receive on demand access to past recorded webinars, visit Fit-Boston.eu www.bausch.com

14

GlobalCONTACT 3-21 INDUSTRY NEWS

Optimum Infinite - Infinite Possibilities

Developed to meet the performance needs of modern modalities, Optimum Infinite offers hyper Dk (180 Dk), a tailored modulus and excellent wettability. These unique properties provide an ideal material for scleral and orthokeratology lens designs, offering laboratories an opportunity to push the boundaries of lens design and manufacturing. Optimum Infinite changes the paradigm so you don’t have to compromise when using hyper Dk materials. Contamac’s expert R&D chemists have rewritten the rules on hyper Dk materials, providing limitless capabilities for specialty lens designs. For more information on Optimum Infinite, contact your Contamac representative, or visit www.optimum-infinite.com. www.contamac.com, sales@contamac.co.uk

SortStation IOL: Inspection of intraocular lenses in production

OptiSpheric IOL PRO 2 offers fully automated IOL measurement. It is completed with WorkStation IOL and integrated SortStation IOL. This workplace is the best choice when it comes to carrying out all the steps upstream and downstream of the measurement in a simple, fast and safe process. It includes loading the sample holders with optimal illumination that makes it easy to ensure the ideal positioning of the lenses. Moreover, the lenses can safely be sorted after the measurement: Test results are automatically transferred to the display and made visible directly at the location of the samples. The fulfillment of the pass/fail criterion is displayed in a red/green color scheme and the reliable assignment of each lens is enabled. www.trioptics.com, info@trioptics.com

Advertisement

INDUSTRY NEWS

The importance of poroelasticity in soft contact lenses

Evidence of the pore space of a silicone hydrogel contact lens as transport path for pore diffusion and molecular diffusion – Part 2

Scleral lenses, hybrid lenses or Ortho-K: To ensure safe use of these types of contact lenses, the main focus is on the oxygen permeability of the plastic material of the lens. The metabolism of the cornea and the limbus should suffer as little irritation as possible. The aim of this article is to explain how this transport mechanism occurs and why it is so important. By Alina Kinder

Little is currently known about the pore space in silicone hydrogel contact lenses. The creation of artificial pores or pore space can occur in various ways. The contact lens material is a copolymer, produced by polymerization of a number of different monomers.

In the production of copolymer plastics, the type of structure and properties of the plastic are influenced by admixtures. The type of polymerization can also be used to control the size of the pore space. The cooling rates [19] of the individual manufacturing processes – whether they are produced by shape casting, centrifugal casting, or turning – are important for pore space design. Furthermore, changing pressure conditions during solidification of the plastic mass can lead

to pores and pore spaces. With the turning process, the plastic material is supplied in solid form, permitting the design of the pore space to be controlled to a certain extent. The polymer manufacturing process does not lie within the sphere of influence of the contact lens manufacturer but rather that of the material manufacturer.

In addition, it may be assumed that the first hydration, which transforms the contact lens material from a solid state into an amorphous or viscous structure, allows the actual pore space to develop or be formed. [20] During this process, soft contact lenses undergo a one-time increase in volume of approximately 30% which may correspond to the cavity volume.

Thus the cavity in soft material, resulting from pore diffusion

16

GlobalCONTACT 2-21 TECHNOLOGY

and molecular diffusion, seems to be shaped differently from that in porous solids. It needs to be considered whether the Dk or Dk/t value really is always the same in the different hydration states. [21] When addressing this issue, it should also be clarified whether the Dk/t value needs to take account of the particular state of the aggregate.

Fig. 3: SEM (Hitachi SU3800) photos of the surface of an Efrofilcon A (silicone hydrogel material).

Small Inset: Efrofilcon A before hydration; the surface shows surface damage from the blade.

Large Inset: Efrofilcon A after the first hydration; the surface appears to have a porous surface structure.

17

GlobalCONTACT 2-21 TECHNOLOGY

Fig. 4: Poly-HEMA; hydroxyethyl methacrylate polymer. A polymer that inhibits cell adhesion to growth surfaces in cultures. [22]

The type of polymerization and the composition of the individual components of the hydrogel or silicone-hydrogel plastic material are decisive for the material properties, and thus also for diffusion. The production and further development of the polymer material are key challenges for the material manufacturers. The composition of the material determines the wearing conditions of the contact lens on the eye, which are crucial for the health of the eyes. The manufacturing processes of the contact lenses are largely responsible for the geometry, comfort and vision. They are determined by the base curve (BC), the bevel, the size, the mobility and the surface lubricity. This calls for the expertise of the contact lens manufacturer.

Different cross-links of the polymers with different properties of elasticity and deformability can be created by the various polymerization processes. A preferred form of the long polymer chains is the random coil, which can change its shape dynamically. This dynamic gives rise to the elasticity known in natural rubber. Structural cross-linking occurs when at least four polymers are bonded together. Due to the regular arrangement and repetition of the individual monomers in a polymer it can be called a lattice structure, although the material exhibits amorphous properties. The definition of the Dk value should be adapted to the likely aggregate state. Furthermore, the term poroelasticity needs to be introduced into contact lens optics, because the structural crosslinking and the resulting elasticity cannot be adequately described by Young's modulus (modulus of elasticity) alone. [23,24]

The formation of this cross-linking during polymerization in the polymer material of a contact lens provides soft lenses with a pore space, leading to a corresponding effect on its elasticity. The elasticity of a contact lens is defined only by the modulus of elasticity (Young's modulus). However, in the context of wearing comfort and duration/rhythm, this one physical property is insufficient to fully describe the comfort and deformability during wearing. Thus, to improve wearing comfort, the industry is focusing on the design, surface roughness and coating of contact lenses. Another way to maximize wearing comfort is to modify the structure or composition of the contact lens. An integrated water gradient is designed to make the lens more

comfortable to wear. This allows better wetting of the contact lens and improves stability in the core.

Despite these efforts, no firm prediction can be made about the influence of the contact lens on the supply of oxygen to the cornea and wearing comfort. Not only the geometry of the cornea and the composition of the tear film but also the condition of the eyelids and the effects of the blink are important. During blinking, when pressure or frictional forces act on the surface of the contact lens, there is a momentary change in the cavity structure and oxygen may be released. The pore space of a contact lens is not a static space. On the one hand, particles/molecules that adhere and then detach again permanently change the volume of the pore space. On the other hand, the expansion and composition of the contact lens cavity depends very much on the surrounding conditions. Soft matter is an amorphous material that can be elastically deformed. During a normal blink, a pressure of 10.3 mmHg/ mm2 is exerted; during a conscious blink, pressures of about 51 mmHg/mm2 may be exerted [25] thus deforming the contact lens. Subsequently, wearing comfort appears to improve (as most contact lens wearers will confirm). This material property could well be defined by the magnitude of poroelasticity. It remains to be clarified whether this blinking effectively "squeezes out" oxygen from the pore space. Further, it also needs to be investigated which, or how many residual particles still in the pore space are detached from the pore walls. The blink of an eye can lead to speeds up to max. 20 cm/s. [26] The frictional force of the eyelid triggers shearing forces which act on the surface of the contact lens.

POROELASTICITY

Against this background, further research is required to determine whether the blink of an eyelid is capable of elastically altering the pore space of a silicone hydrogel contact lens to such an extent that adherent molecules can be dislodged. The term poroelasticity is scarcely used in contact lens optics, although poroelasticity well describes the elastic behavior of a porous plastic as well as defining the stiffness of the porous plastic. In fact, poroelasticity would be the material property that can realistically describe the dynamic behavior of a soft contact lens during wear. Current properties used can only define the contact lens in a static state (in the lab). The improvements in vascularization of the cornea observed since the introduction of the silicone hydrogel material have been attributed to the silicone content, and thus to the apparently improved circulation of oxygen. [27] It needs to be investigated whether the change in rigidity of more modern materials has not also improved the durability of the contact surface. Due to the extreme flexibility of the hydrogel material, very strong frictional forces may arise at the contact surfaces, which in turn may stimulate vascularity. [28]

In contact lens optics, the diffusion of oxygen into the tear film

18

GlobalCONTACT 2-21 TECHNOLOGY

is based on liquid diffusion. However, what has been discussed so far suggests that the transport of oxygen through a contact lens is more adequately described by pore or molecular diffusion than by simple diffusion processes.

Pore diffusion and molecular diffusion are processes widely used in physics and chemistry to describe the material property of amorphous bodies. For porous materials, the actual diffusion in liquids or solids does not apply while the diffusion within the pore space is more significant. Pore diffusion takes into account the tortuosity (turns) of the cavity as well as the transport path, which covers a much greater distance than just the material thickness of the contact lens.

Molecular diffusion does not leave out of consideration the interaction between the pore wall and the solute, so that the adsorption processes of the solute particles are included in the diffusion process.

ILLUSTRATION OF DIFFUSION THROUGH A PORE SPACE

The pore space itself now needs to be investigated. As a possible experimental approach, colored liquid can be diffused through the pore space as detached particles. This method of liquid staining can be used to demonstrate the effect of pore diffusion within a contact lens. The existence of cavities in a silicone hydrogel contact lens can be demonstrated by studying the diffusion over time (via video). On the basis of the known diffusion coefficient and the measured time, the Einstein-Smoluchowski equation (1) is used to determine the transport distance, which may be longer than the known center thickness of the contact lens.

D = <x>2/2t [m2/s] (1)

The path taken by the oxygen (dissolved in the tear film)

through the contact lens can be recorded and the time evaluated accordingly. Subsequently, the path length x can be determined via the diffusion constant D, which is known, and the measured time t using the Einstein-Smoluchowski equation.

As oxygen is difficult to dye, physiological saline solution stained with fluorescein can be used as a substitute. The diffusion of fluorescein is an obvious way of investigating diffusion. To measure fluorescein diffusion, the diffusion path of two contact lenses was examined and compared, in order to demonstrate the effect of pore diffusion.

Silicone hydrogel contact lens Efrofilcon A:

• Copolymer of silicone & fluorine and a lactam group N-vinyl pyrrilidone

• 74% water content

• Dk-value of 60*10 -11 ml(O2)*cm2/ml*mmHg*s or a Dk-value of 45*10 -11 ml(O 2)*cm 2/ml*hPa*s (center thickness = 0.266 mm, Ø = 16 mm).

Hydrogel contact lens Filcon II 3:

• Copolymer of MMA and a lactam group N-vinyl-pyrrilidone

• 75% water content

• Dk-value of 43*10 -11 ml(O2)*cm2/ml*mmHg*s or a Dk-value of 32*10 -11 ml(O 2)*cm 2/ml*hPa*s (center thickness = 0.225 mm, Ø = 16 mm).

These contact lenses were not coated and differ merely in their base material which in one case was a silicone material and in the other a MMA-VP material.

To prove that systematic errors can be excluded, a reference group consisting of two very similar hydrogel contact lenses was created.

Metrology solutions for CLE sales-ophthalmics@lambda-x.com - www.lambda-x.com Data integrity and traceability Measuring a contact lens in about one second Advertisement TECHNOLOGY

The reference group consisted of:

Hydrogel contact lens Hioxifilcon B:

• Terpolymer of glyceryl methacrylate

• 49% water content

• Dk-value of 15.8*10 -11 ml(O 2)*cm2/ml*mmHg*s or a Dkvalue of 11.9*10 -11 ml(O 2)*cm2/ml*hPa*s (center thickness = 0.235 mm, Ø = 16 mm).

Hydrogel Acofilcon B:

• Terpolymer of glyceryl methacrylate

• 49% water content

• Dk-value of 15.8*10 -11 ml(O 2)*cm2/ml*mmHg*s or a Dkvalue of 11.9*10 -11 ml(O 2)*cm2/ml*hPa*s (center thickness = 0.225 mm, Ø = 16 mm).

This table clearly shows that the resulting diffusion coefficient Derm – determined over time – appears to be of an order of magnitude less than the diffusion coefficient D of fluorescein dissolved in physiological saline would suggest.

Assuming fluorescein diffusion is conclusive, the pore diffusion in the contact lens made of the silicone hydrogel material is about six times higher than expected; in the reference lens it is about ten times higher. Due to its larger pore space, the silicone-hydrogel contact lens allows faster diffusion than the hydrogel material. In the reference group, the diffusion coefficients found were much smaller, so that the effect of pore diffusion was even up to 50-times greater than anticipated.

As far as is known, Fluorescein diffusion as discussed here has never been used to investigate the mode of diffusion through soft contact lens materials. Thus the aim here is to demonstrate the existence, effects and magnitude of pore spaces in contact lenses.

CONCLUSION

Diffusion path x erm = √(D*2t)[mm] Effect of the pore space x

These contact lenses, too, were uncoated and differed only in the base material. The Dk value and water content were the same. The effect of the pore space x PD can be determined based on the specified center thickness x and the actually measured diffusion path x erm Contact lens Center thickness of contact lens x [mm]

Efrofilcon A 0,266 0,67 2,52

Filcon II 3 0,225 0,73 3,24 Hioxifilcon B 0,235 1,61 6,85 Acofilcon B 0,225 1,65 7,33

Tab. 2: Influence of the pore space based on the increased diffusion path measured (for given diffusion coefficients).

Instead of the assumed diffusion paths corresponding to the center thickness of the contact lenses, 2.52- to 7.33-fold longer transport paths were measured. The Efrofilcon A lens had a shorter path than the Filcon II 3 reference lens, due to the composition of the copolymer material and the resulting different pore space. The control group with the same two hydrogel contact lenses also showed a transport path significantly longer than the actual center thickness of the two contact lenses. The diffusion paths determined for the two contact lenses Hioxifilcon B and Acofilcon B of 1.61 mm and 1.65 mm respectively were very similar due to their similar material composition. When the diffusion constants D and Derm are compared to each other, this results in the effect of pore diffusion EPD.

Contact lens Diffusion coefficient of fluorescein D [m²/s]

Diffusion coefficient determined from time D erm = x 2 /2t [m²/s]

Based on the results, when considering diffusion through a contact lens the concepts of porosity and tortuosity need to be taken into account in order to get closer to a more realistic understanding of diffusion. It is now evident that the concept of diffusion in a liquid on its own is not able to describe the complex process of particle transport.

Two different diffusion processes take place in the two different soft contact lens materials: In the hydrogel contact lens material, diffusion takes places through the aqueous phase, while in the silicone-hydrogel contact lens it is the interplay between pore diffusion and molecular diffusion that is the driving force behind oxygen diffusion.

With diffusion through the water phase in the hydrogel contact lens material, Brownian motion describes the diffusion process, allowing oxygen to diffuse through the contact lens. Random fluctuations of the water molecules are responsible for oxygen flow. The amount of diffusion is temperature dependent.

With the manufacturing process of hydration, the contact lens material undergoes expansion. During blinking, pressure or frictional forces are exerted on the surface of the contact lens.

This causes a brief change in the material structure, enabling oxygen to be pumped clear.

Effect of pore diffusion E PD = D/D erm

Efrofilcon A 0,42*10 -9 6,71*10 -11 6,26

Filcon II 3 0,42*10 -9 4,01*10 -11 10,48

Hioxifilcon B 0,42*10 -9 8,93*10 -12 47,01

Acofilcon B 0,42*10 -9 7,77*10 -12 54,04

Tab. 3: Effect of pore diffusion EPD, when the specified diffusion coefficient D is compared to the diffusion coefficient Derm measured (for a given center thickness).

Poroelasticity can adequately explain this "oxygen pumping" process and should thus be included in the description of the wearing comfort of a contact lens on the eye.

When considering diffusion in liquids, the viscosity of the solvent plays a role. The equation below refers to the viscosity η of the solvent and not the viscosity of the contact lens material. An increase in viscosity due to particles in the tear film leads to a slowdown of diffusion. The slowdown is not affected by the viscosity of the contact lens material itself.

20

PD = x erm /x

GlobalCONTACT 2-21 TECHNOLOGY

D = k BT / 6ηπR 0 (2)

k B = Boltzmann constant (1.380649 x 10-23 J/K)

T = Temperature

η = Viscosity

R 0 = Hydrodynamic radius

In the fluorescein diffusion above, the fluorescein dissolved in the reference group needed a much longer diffusion time than expected. Here diffusion occurs through the water content in the hydrogel material. The amount of oxygen diffusion via the pore spaces in the hydrogel material still requires further investigation.

Two diffusion processes play a major role in silicone hydrogel materials. One of these is pore diffusion, where the solvent diffuses through the pore space. The other is molecular diffusion, which takes account of the adsorption and capillary action of the solution in the pore space. The adsorption of solute particles in the phase or boundary layer of the pore walls changes the extent and nature of the pore space. This process is recurrent and thus does not represent a steady state. The capillary action within the pore space leads to different rates of diffusion which in turn affect the diffusion time. Pore diffusion can well represent the processes of diffusion in silicone hydrogel contact lenses. The interaction of pore diffusion through the cavity, and molecular diffusion which describes the diffusion rate through the shape of the cavity with the capillary action in the pore space, can be described by the material properties porosity and tortuosity. In addition, a more realistic insight into the amorphous nature of the polymeric contact lens material is achieved through consideration of the poroelasticity. The deformability of the material and the related development of forces such as suction and pumping forces in this connection should no longer be ignored. n

This is part 2 of this article. Read part 1 in GlobalCONTACT 2021_02 and in our app.

More information on using the GlobalCONTACT app on page 46

References are available on request from the editorial office or are listed in the GlobalCONTACT app.

Alina Kinder (EurOptom, Master of Science (Klin. Optometry)) is a lecturer at the Professional School for Optometry in Cologne (HFAK). She also works as an examiner on the examiner board of ECOO diploma and optometrist (ZVA/ HWK).

Living Innovation

www.schneider-om.com

Design the future with us!

The family-owned SCHNEIDER GmbH & Co. KG is one of world’s leading manufacturers of machines and system solutions in the fields of ophthalmics and (ultra-) precision optics. Known as the pioneer of freeform technology, we set new industry benchmarks by putting a heavy focus on R&D and new technologies.

As a full solutions provider, we offer our customers innovative solutions, ranging from the small individual machine to large and fully-automated Industry 4.0 lens production systems. Our company has more than 480 employees and is located in Germany, the USA, Brazil, Thailand and China.

Join our innovative team and apply for:

Specialist CL & IOL (f/m/nb)

Location: Fronhausen, Germany

Your responsibilities

Take full ownership for commissioning, installation, training, and servicing of our high-tech machines for custom contact lens (CL) and intraocular lens (IOL) production worldwide

Provide high-level customer support and expert training regarding all technical, quality and process aspects

Liaise with customers as well as internal departments to ensure satisfactory customer experience

Collaborate with our specialist departments to support machine optimization and product development

Enhance internal knowledge and transfer skills internally

Perform quality assurance and conformity testing of CL & IOL machinery, this includes the evaluation of lens geometries and surface inspection

Pilot test operation and presentation of machinery

Test and obtain machine acceptance of contact lens machines, including FAT & PDQ

Qualifications

Technical degree or relevant technical diploma/certificate Fundamental knowledge of contact lens or IOL manufacturing processes

Experience in customer support Knowledge of measurement and metrology devices for contact lenses or IOL inspection

Knowledge of analytical troubleshooting of CNC machinery’s hardware and software functionality

Benefits

Interesting and demanding tasks in a highly innovative environment

State-of-the-art workplaces

Flexible working hours Company pension scheme Workplace Health Promotion Numerous perks in a number of shops

High-quality and fresh food offers in the inhouse restaurant

Employee events Join our team to shape the future of the optical industry with us!

www.schneider-om.com/career/

SCHNEIDER GmbH & Co. KG

Biegenstrasse 8–12 D-35112 Fronhausen

Phone: +49 (64 26) 96 96-360 www.schneider-om.com

Advertisement GlobalCONTACT 2-21

22 GlobalCONTACT 3-21 TECHNOLOGY

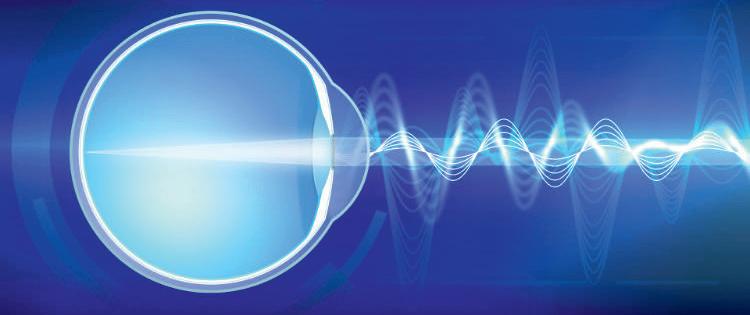

Understanding the visual impact of the Stiles-Crawford effect

The Stiles-Crawford effect (SCE) is a classic of visual optics that remains poorly understood. Discovered by Walter Stanley Stiles and Brian Hewson Crawford in 1932, it is a directional optical effect related to the very elongated shape of photoreceptors. The effect is only observed in photopic conditions and thus it is exclusively a cone photoreceptor effect. It is commonly analyzed for a single pupil point at a time in Maxwellian view corresponding to a single angle of incidence onto the retina. This differs markedly from normal vision through the entire eye pupil.

By Brian Vohnsen

The SCE is normally represented as a pupil apodization. Yet, as it originates in the optics of the retina itself, this approach is invalid, and the SCE provides a much stronger apodization than predicted with Maxwellian view. This has direct implications for vision and refractive optics of the anterior eye. In this contribution, the optics of the SCE is described with emphasis on the fact that photoreceptors themselves are active optical elements that impact vision on par with the optics of the anterior eye.

WHAT IS THE STILESCRAWFORD EFFECT?

Vision is highly sensitive to the angle of incidence onto the retina. This is due to the elongated structure of the photoreceptor cells where visual pigment is distributed in densely packed layers within the outer segments of each cell. The common assumption is that they act like optical fibers by guiding light from the inner to the outer segment of each cell. Yet, there are indications that lensing may also be in play in the high refractive index mitochondria that are densely packed in the ellipsoid between the inner and outer photoreceptor segments. The sensitivity to acceptance angle is described by a characteristic Stiles-Crawford function that resembles a Gaussian distribution in the pupil plane. The peak of the function is because photoreceptors point towards a common point near the pupil center whereas the width of the distribution describes the angular sensitivity of the photoreceptors. Thus, if a single ray of light is incident at a pupil eccentricity of 2.5 mm it will dampen the visual response by 50% and at 3.5 mm eccentricity by 75%.

WHAT CAUSES IT?

Although clearly of retinal origin, the mechanism causing the Stiles-Crawford effect remains elusive. Photoreceptors are believed to act as biological waveguides due to an elevated refractive index. Yet, vision is only triggered when light is absorbed in the outer segments where visual pigments are stacked and gradually renewed within an approximately two week cycle. Excess light is absorbed by the dark retinal pigment epithelium layer beyond the photoreceptors. That waveguiding is the principal cause of the Stiles-Crawford effect is challenged for a number of reasons: (1) foveal cones that are directional have a similar geometry to that of peripheral rods that lack directionality, (2) waveguiding does not describe what happens with the nonguided light, (3) the short length of outer segments allowing only a single or few reflections that may not build up modes effectively, (4) foveal cones are very densely packed very unlike those of individual optical fibers, and most importantly (5) waveguided oblique light would have a larger optical path

Left: The Stiles-Crawford function of the first kind (SCE-I) is usually expressed by a Gaussian pupil apodization with a characteristic directionality parameter of approximately rho = 0.05/mm2 at the fovea. It expressed the angular acceptance curve for the photoreceptors when measured with Maxwellian light at the pupil. Right: It is common practice to add the SCE-I function point-by-point across the pupil when analyzing its effect for the natural pupil size. Yet, this approach is flawed and severely underestimates its combined effect at the retinal plane. The effective truncation with a natural pupil is nearly an order of magnitude higher than with Maxwellian light.

23

GlobalCONTACT 3-21 TECHNOLOGY

Left: Light traverses stacked layers of visual pigments in the outer segments. The total absorption is proportional to the volumetric overlap between the light and the outer segments. For oblique light some light will leak into adjacent outer segments that will absorb the light according to the cone type.

Right: Cones are either isolated or grouped in small patches within the photoreceptor mosaic, whereas rods are grouped in larger patches with highly similar rods. The larger the patch of identical receptors, the smaller is the effective directionality. The plots show calculated SCE-I visibility curves for individual to larger and larger patches of identical outer segments in a hexagonal photoreceptor array. For rods the SCE-I directionality is practically absent.

The wavefront at the pupil has an accompanying wavefront slope at the retina only for even-order Zernike aberrations. For odd-order Zernike aberrations the point-spread function is similarly degraded, but the wavefront is incident along the axes of the photoreceptors and is therefore not attenuated in the same manner by the SCE-I.

trefoil) Zernike aberration orders as only the former has a wavefront slope in the retinal plane. Additionally, the plasticity of the retinal photoreceptors as being able to readjust to maximize light capture over a period of days suggest that they show a certain degree of phototropism like that of sunflowers. This may help understand visual adaptation as an optical mechanism to improve vision even in cases of blur and scattering of light, and ultimately help understand what optical mechanisms trigger and drive myopia in dim light such as indoors with larger pupil sizes.

HOW DO WE TAKE IT INTO ACCOUNT?

in the outer segments and therefore effective visibility should be larger, not smaller. Thus, I have recently argued that leakage of light rather than waveguiding may be the main reason for the Stiles-Crawford effect. This agrees with other reports of crosstalk between adjacent photoreceptors, but also explains why there is a small hue shift for oblique light (the Stiles-Crawford effect of the second kind) as light leaks into adjacent cones containing a different type of visual pigments (there are three cone types: long wavelength sensitive red cones, medium wavelength sensitive green cones, and a small fraction of short wavelength sensitive blue cones) whereas in the case of rods, any leakage into adjacent rods, will flatten the directionality response.

WHY DOES IT MATTER?

A careful understanding of the optics of the retina and photoreceptors is vital as it is the last optical element of the eye where images projected by the anterior eye trigger a visual sensation. The Stiles-Crawford effect shows that the angle of incident onto the retina is critical for vision. It also differentiates between even (defocus, spherical) and odd (coma, astigmatism,

Apodization of the pupil with a Stiles-Crawford effect is only valid on a ray-by-ray basis but not for the combined effect of vision through the natural pupil where its effect is nearly an order of magnitude larger with a drop-off in visibility with pupil size being closer to that of a power law and therefore there is a strong preference for small pupils. The time is due to consider the Stiles-Crawford effect rightfully in the retinal plane as only then can we evaluate its true role in vision. n

Brian Vohnsen, MSc, PhD, is a Fellow of Optica (Optical Society) and Associate Professor in optical physics at University College Dublin (UCD) in Ireland. He received his PhD in NanoOptics at Aalborg University in Denmark. His current research spans from advanced optical imaging techniques and adaptive optics to understanding vision with a special focus on the optics of the retina. He lectures both optics and physics, being twice a winner of the UCD College of Science teaching award and chairs postgraduate programs in physics and the physics committee on equality, diversion and inclusion. Contact: brian.vohnsen@ucd.ie

24

GlobalCONTACT 3-21 TECHNOLOGY

Larsen Equipment

In 2004, Keith Parker and I opened Advanced Vision Technologies (AVT). At that time, the economy was going through a very bad recession and as a result, it was impossible for a new business starting up to get a loan. We immediately reached out to Erik and Pam at Larsen Equipment to get refurbished equipment to use in our Laboratory. As AVT’s business grew, we invested in many different pieces of new equipment from Larsen Equipment and this helped us grow into one of the Premiere Labs in the United States. Our success is due in part to Erik and his Team with their state-of-the-art equipment and maintenance of their products. AVT is forever grateful for Larsen Equipment’s support of AVT. It is great to know AVT is working with Industry leaders with the Larsen Equipment and their Team!

Janine Bungo, VicePresident

QUALITY MANAGER: RANDY MINGOY

I have known Erik Larsen since 1992. Since then I have used just about every piece of equipment his company has built. My experience with Erik and the Larsen team has been one of great appreciation as they have always helped me in my needs of fully understanding equipment used to manufacture quality contact lenses. Erik has also been able to engineer any part needed for me even it was a custom part. Erik (Larsen Equipment) has been and still is a pioneer in the contact lens and optical industry, and I am thankful to him for his support over the years.

Randy Mingoy Quality Manager

PRESIDENT: KEITH PARKER

I have had the pleasure of working with Erik since the beginning of Larsen Equipment. The first piece of equipment, a 6 spindle horizontal arm polisher revolutionized our production of GP contact lenses. Through the years, I watched his business grow as he and his team listened to our Industry needs and developed now numerous products not only simplifying many tasks of manufacturing but improving the consistency of quality in our finished products. Innovation has been an ongoing experience of our Company only made possible through the innovation of necessary equipment developed and made available by the Larsen team.

Advanced

Vision Technologies

DIRECTOR OF OPERATIONS: JORDAN GOBEL

There can be a lot of moving parts when it comes to managing operations, so it is key to have reliable precision equipment that assists in overall efficiency. Larsen Equipment delivers just that! I have been utilizing Larsen manufacturing equipment for over 15+ years and have yet to run into an issue they could not resolve. I am a satisfied owner of bladder polishers, edge roller’s and auto-blockers etc. Each one of these units greatly assists in the reduction of rejects and manufacturing waste. Their ability to customize and retrofit specific tools certainly sets them apart from the competition. Larsen stands behind their equipment with a knowledgeable staff that provides exceptional service. Simply put, we are a better laboratory because of our relationship with the folks at Larsen.

Jordan Gobel

Director of Operations/Consultant

Advanced Vision Technologies

Larsen Equipment is a family owned business hosting a team of willing Staff all having the attitude of serving their Customer’s needs. As a Customer, we are made to feel like we have a friend in the business helping us develop a more efficient process allowing our Company to deliver better products for our Customers.

Our success of AVT simply could not have been possible without the help, assistance and dedication of Larsen Equipment. I will be forever grateful for my opportunity to work with Erik and his very capable Staff.

Keith Parker President

Keith Parker President

969 S. Kipling Parkway, Lakewood, CO 80226 Phone: 303-384-1111 888-393-5374 Fax: 303-384-1124 www.AVTLENS.com

25

GlobalCONTACT 3-21 PR-Advert

Drug delivery in scleral lens wear

Interview with Dr Lynette Johns, Harvard Medical School Department of Ophthalmology

Drug delivery in scleral lens wear is still a bit uncharted territory, although talk about this and pioneering work in the field date back at least a few decades. The areas of potential application could be prevention against corneal infection in case of corneal defects, and particularly in case of persistent epithelial defect healing. These defects can be very difficult to re-epithelialize, and it is important to use prophylactic antibiotics, to prevent corneal infection in these vulnerable eyes. Another area of potential application could be the use of medication that prevents neovasculasation in the cornea. These drugs can prevent new blood vessel growth in the cornea. Other areas such as glaucoma medication application are still under investigation. Here, like in general scleral lens fitting, it is the balance between the benefits and the costs (including risks etc.) that need to be considered. Here is an overview of what we know so far.

By Silke Sage

GlobalCONTACT: Which drugs are generally suitable for the administration through scleral lenses?

Lynette Johns: If there is an epithelial defect on the cornea, it may be wise to have an antibiotic present to prophylactically prevent against a corneal infection. One of the antibiotics we use is Moxifloxacin – that provides dual protection against gram-negative and gram-positive microorganisms. Moxifloxacin is a preservative-free ocular therapeutic, which makes it ideal for applying in the reservoir of a scleral lens. Preservatives of topical medications are toxic to the cornea with extended exposure times or dosing in drop form. When preservatives are used in a scleral lens, they can cause dense superficial corneal staining.

GlobalCONTACT: When are they applied?

Lynette Johns: If there is a persistent epithelial defect, then this may be particularly useful. A persistent epithelial defect is a non-infectious focal loss of corneal epithelial cells. Often, they are caused by mechanical trauma, neurotrophic corneal disease, or post-surgically.

Depending on the underlying condition, they can be very difficult to re-epithelialize. Using aggressive lubrication and bandage soft contact lenses is typically needed. It is important to use prophylactic antibiotics as described above, to

26 GlobalCONTACT 3-21 FITTING BACKGROUND

prevent corneal infection in these vulnerable eyes. In extreme longstanding cases the eyelids are sewn partially closed (tarsorrhaphy) in order to heal and resurface the cornea. To prevent this, scleral lenses have been used to resurface corneal epithelial defects.

Drug delivery using scleral lenses was first suggested in a publication in 2000 by Dr. Perry Rosenthal and colleagues.[1] In this retrospective study, 14 eyes with persistent epithelial defects were treated with extended wear of scleral lenses and in some cases, there were prophylactic antibiotics placed in the reservoir of the lens with the saline. Unfortunately, there were four cases of microbial keratitis, but eight eyes completely resurfaced. Moxifloxacin was not used in this study. Later, this same group retrospectively reviewed 20 different cases with epithelial defects where

Moxifloxacin was used in all cases, and 17 eyes resurfaced. There were no cases of microbial keratitis in theses 20 cases using moxifloxacin in the reservoir. 2

I worked with Dr. Perry Rosenthal using extended wear of scleral lenses with prophylactic Moxifloxacin in the reservoir of the lens in many of these cases. It was remarkable to see how quickly and effectively this worked. The protocol for this treatment method was published by Ciralsky et al. in 2015.3

GlobalCONTACT: What is the requirement for these types of scleral lens fitting and how is the drug administered?

Lynette Johns: Basically, a scleral lens is fit as optimally as possible, with the plan to have no scleral lens compression or impingement on the conjunctiva. The lens is filled with preservative-free saline and one drop of moxifloxacin and applied on the eye using the typical method for scleral lens application (head parallel to the floor). The lens is worn on an extended-wear basis for 24 hours and the eye is examined carefully the next day. The lens is removed, photos are taken for comparison, the epithelial defect is measured, and all signs of microbial keratitis are ruled out. The lens is disinfected, and the same process is repeated daily until the defect has resurfaced. In some cases, the epithelium is very fragile and can break down the first night the lens is not worn. We would have patients wear the lens an extra night with the antibiotic to allow the epithelium to “tack down”. In my experience, the majority of corneas would resurface within two weeks. If

27 GlobalCONTACT 3-21 FITTING BACKGROUND

the healing was slow, we would manufacture two lenses for the patient and train him/her on careful application and removal of the lens. When proficient we dispensed both lenses. They would wear them on a “12/12” schedule. Basically, they would wear a fresh lens with the antibiotic in the morning while the nighttime lens is disinfecting during the day, and then remove that lens at bedtime and put a fresh lens in with the antibiotic and then disinfect the daytime lens overnight. When epithelial defects healed, the patients would wear the lenses daily and lubricate aggressively at night. If their lids open at night while sleeping, we would have them tape the eye closed while they slept.

GlobalCONTACT: Are there other potential fields of application?

Lynette Johns: Another medication used in the lens was topical 1% bevacizumab which is an anti-vascular endothelial growth factor (VEGF) medication. VEGF is a prominent factor that promotes neovascularization – new blood vessel growth in the cornea, and this drug can slow down the progression of that process. It has been injected into the eye to prevent retinal neovascularization and also injected into the conjunctiva against corneal blood vessel formation. It also had been used topically to prevent corneal neovascularization. I worked with Dr. Deborah Jacobs who was the first to use this medication in the lens for patients who demonstrated new blood vessel growth that was potentially sight-threatening. This use of 1% bevacizumab is off-label and carries potential risks of poor wound healing, corneal thinning, and ulceration of the cornea. To avoid systemic

absorption, the patients had punctal occlusion. The drug needed to be compounded made-to-order and preservative-free – which is expensive. The lens was worn daily only, and patients removed the lens and reapplied the drop midday for a total of two days dosing in the lens. This treatment continued for three months and was continued based on the discretion of the corneal specialist.4,5 Long-term results ranging from six months to eleven years of 13 patients who used a course of bevacizumab in the lens were reviewed and approximately 90% of eyes had a reduction in corneal neovascularization and approximately 75% had an improvement in best corrected visual acuity.6

GlobalCONTACT: How do you make sure, the dosage is correct?