5 minute read

New challenges in intra-ocular lens metrology

Recent functionalities and computation methods

As the complexity of IOL designs increases, metrology tools must become more and more powerful. Whether they are designed to generate multiple foci or an extended depth of focus, modern IOLs embed complex surface shapes and require ever more accurate metrology tools. By Luc Joannes

Advertisement

Besides the power and MTF benches described in the ISO-11979-2 standard, wavefront sensors are widely used in both R&D and production environments. Besides the instrument used for the raw measurement of the lens, a dedicated data processing and user interface is key for the IOL industry. The Phase Shifting Schlieren, on which the Nimo technology is based, differs from other wavefront sensors methods by its high spatial resolution which makes the measurement of the most complex wavefronts possible and accurate. The present paper introduces the most recent functionalities and computation methods implemented in the IOL-Mentor software application which push the limits of IOL metrology further.

A NEW SYNTHETIC MODEL EYE

The imaging performances of an IOL are evaluated in a lens system called ‘Model Eye’ (ISO-11979-2) accurately positioned in front of a wet cell containing the IOL (figure 1). The Model Eye simulates the power and spherical aberration of the cornea.

Fig. 1: An intraocular lens in the ISO-11979-2 Model Eye. Cornea model (left) and IOL in a wet well (right).

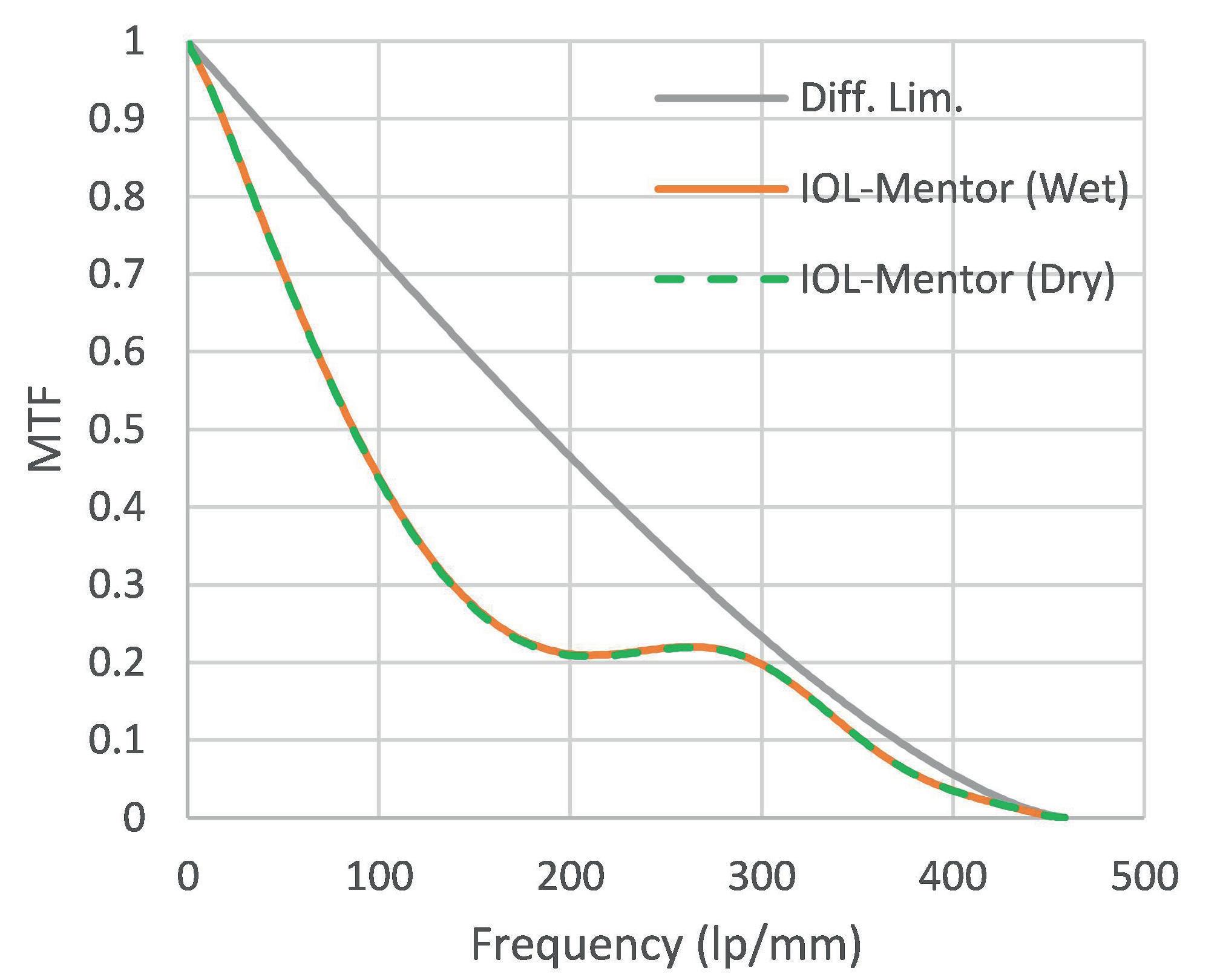

The imaging performance of the IOL is evaluated through the Modulation Transfer Function (MTF), at a specific aperture diameter (in the IOL plane) and for a given spatial frequency. The asphericity of the cornea model can be adjusted to match the manufacturer’s requirements. To measure the MTF, a traditional lens bench takes both the cornea model and the IOL into consideration whereas wavefront sensors can measure the wavefront of the sole IOL. The contribution of the Model Eye can later be computed via numerical simulations. This capability has two major advantages: in R&D, from a single IOL measurement, multiple Model Eye configurations can easily be simulated and compared; in production environments, the measurements are more consistent as they are not affected by the variability of the position of the IOL with reference to the cornea model. Ultimately, and this is non negligible, wavefront sensors and synthetic model eyes make it possible to measure IOLs in air and afterwards compute their performances in-situ and with the contribution of the Model Eye. A straightforward method for the numerical simulation of the effect of the synthetic cornea on the MTF consists in summing the wavefront of the IOL and the wavefront the synthetic cornea generates in the IOL plane. This method, referred as ‘paraxial’, is valid for small apertures and when both the IOL and synthetic cornea have low aberrations, but it rapidly shows its limitations if these conditions are not met. To overcome this problem, Lambda-X has developed a ‘nonparaxial’ ray-tracing method (patent pending) that is valid without restrictions on the amount of spherical aberration in the system. In contrast to the paraxial method, this non-paraxial approach accounts for the focusing effect of the Model Eye and therefore for the incident light entering the Model Eye not

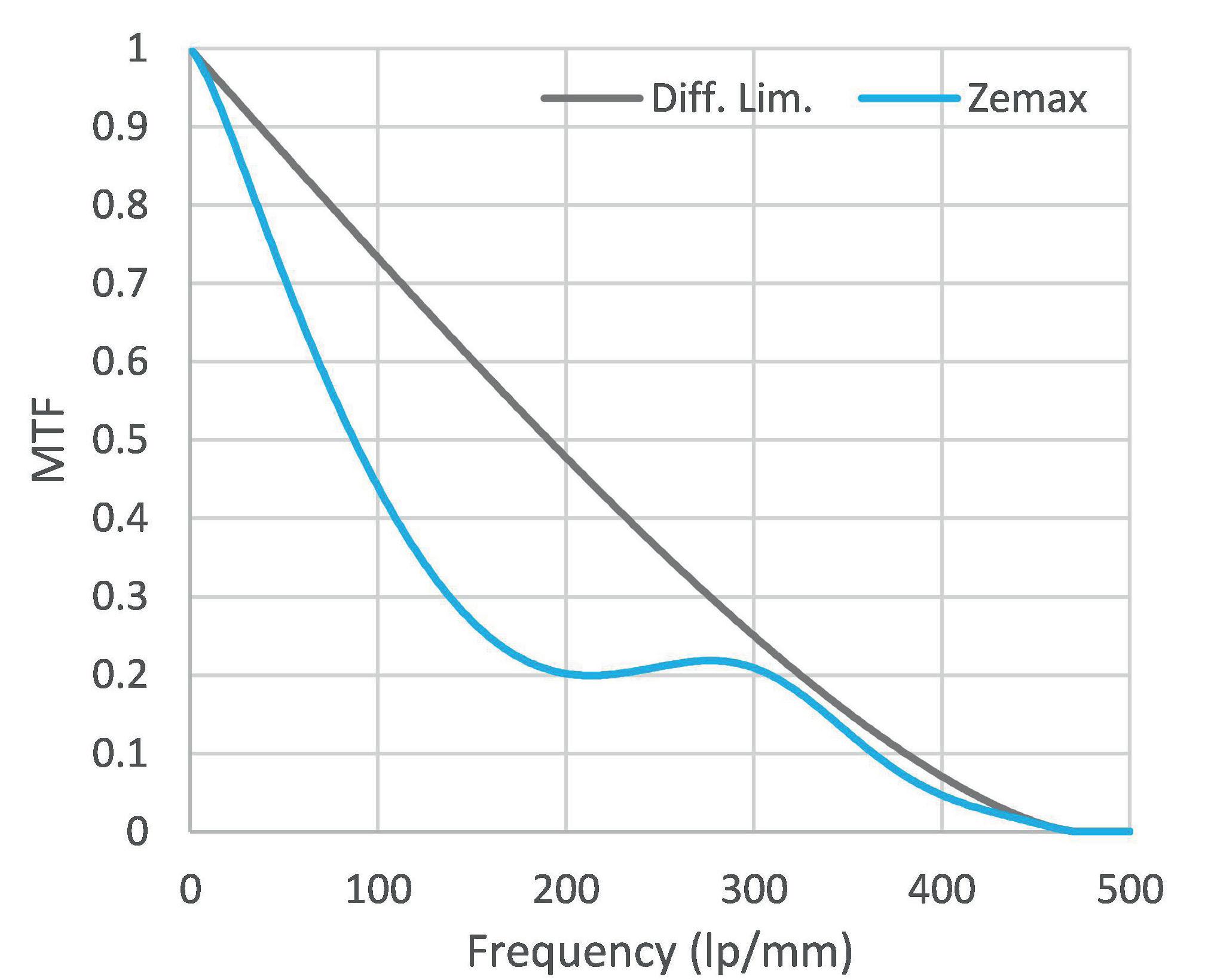

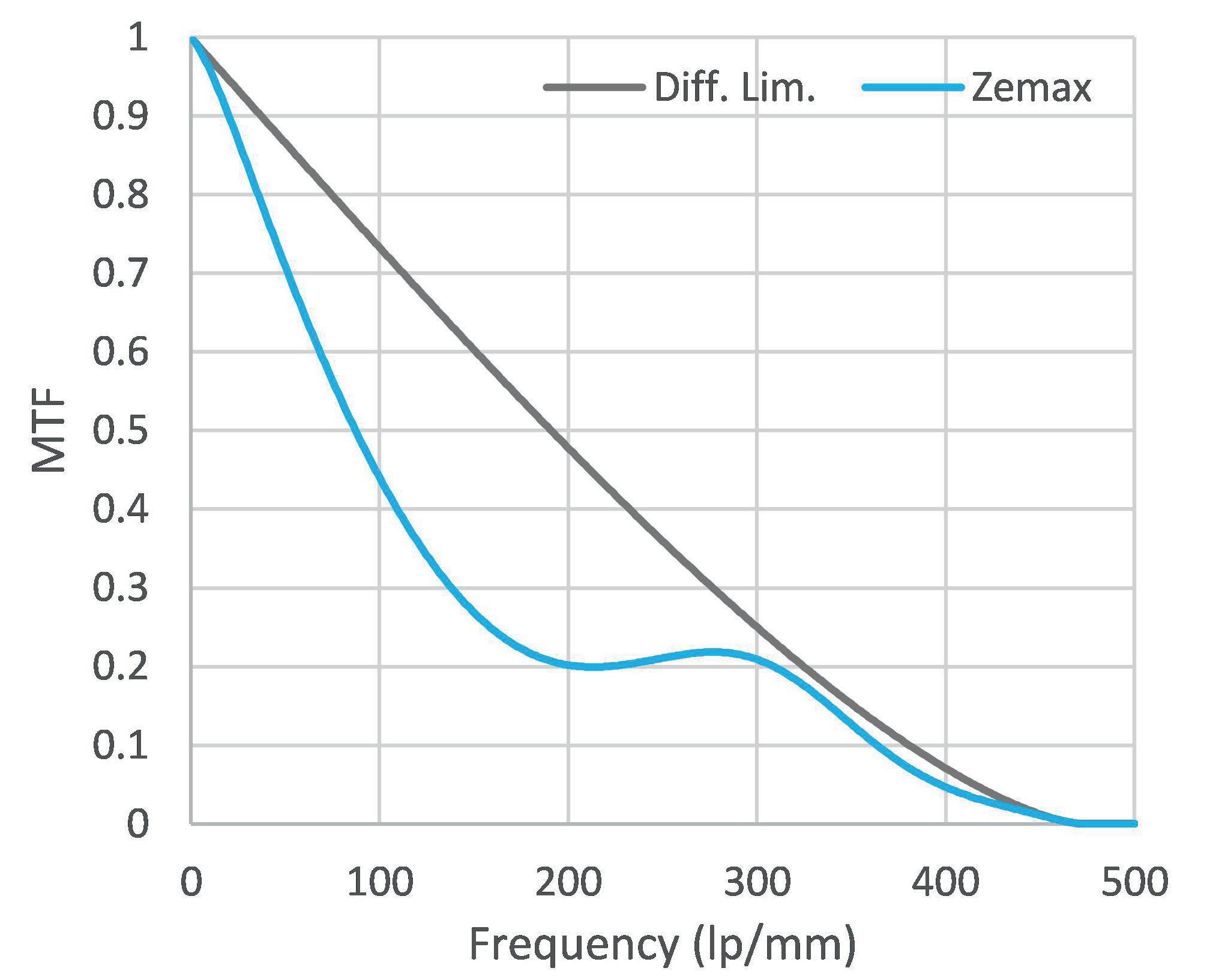

Fig. 2: LB1157 simulated on Zemax Fig 3: LB1157 processed on the Non-Paraxial Model Eye of IOL-MENTOR

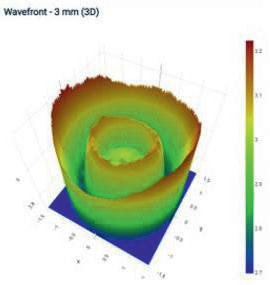

Fig. 6: An EDoF IOL captured by IOLMentor and Nimo. Fig. 7: Complex wavefront of the EDoF lens.

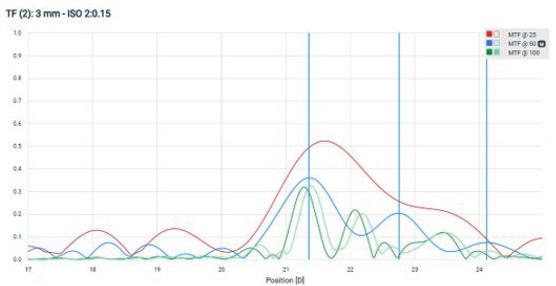

Fig. 8: Measured through-focus MTF on the EDoF IOL. The aperture diameter is 3 mm and frequencies are 25 lp/mm (red), 50 lp/mm (Blue) and 100 lp/mm (Green). Power, cylinder and addition are calculated from the MTF peak positions at 50 lp/mm.

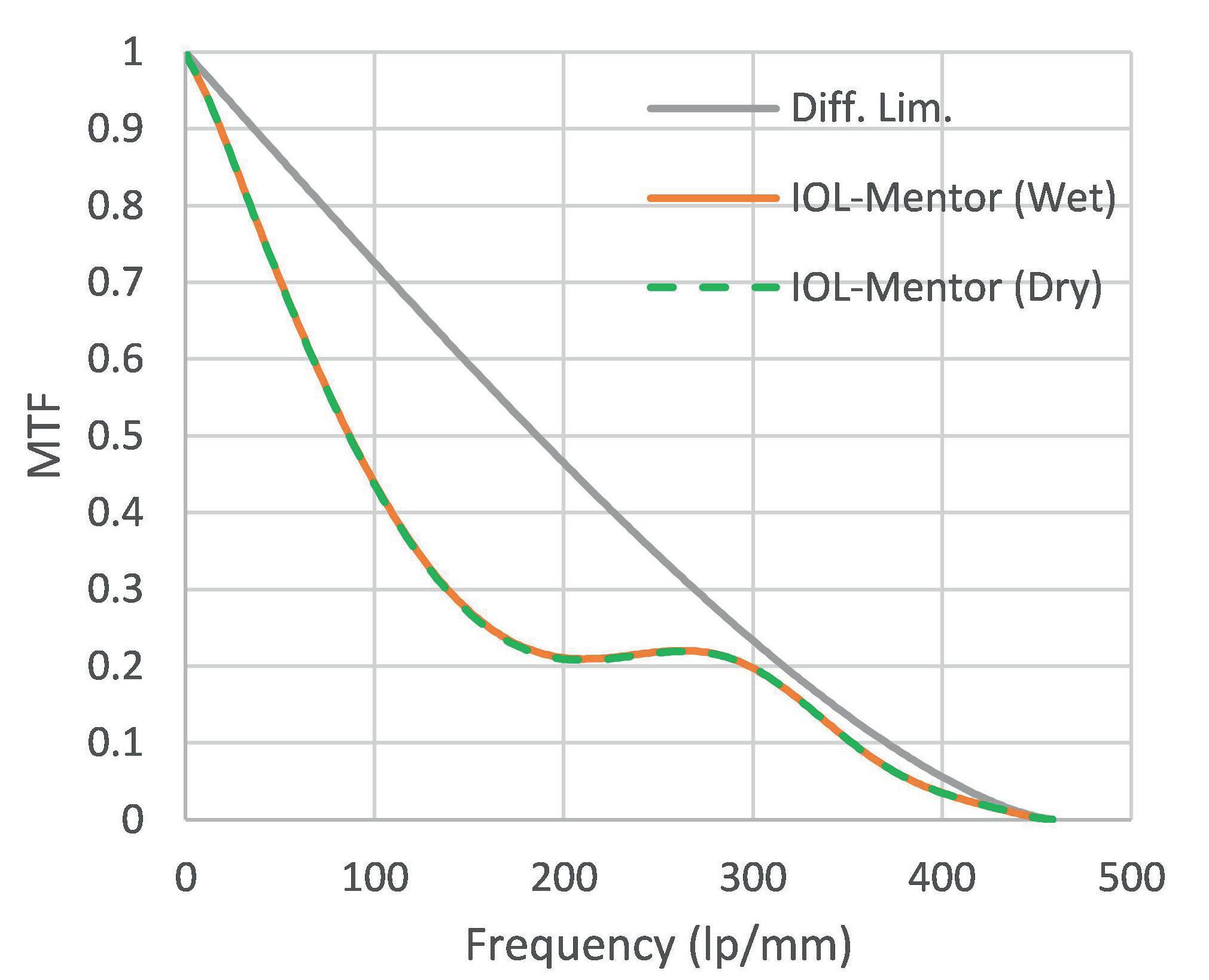

being collimated. In order to apply this method, the refractive index of the lens material and the overall lens geometry need to be taken into consideration as parameters for the measurement of the IOL (or its post processing). The method has been validated against the lens design software Zemax for multiple IOL designs including toric lenses. A first demonstration is given in the simple case of a bi-convex glass lens (Thorlabs – LB1157) which has a power of 100D in air and a center thickness of 2.4 mm. The theoretical through frequency MTF in the best MTF (50 lp/mm) plane for an aperture diameter on 3 mm has been simulated in Zemax (figure 2). Figure 3 demonstrates the accuracy of the Non-Paraxial Model Eye available in IOL-Mentor. The MTF computed from the IOL wavefront measured first, in situ in a wet cell and then in air, perfectly matches the MTF simulated by Zemax. Note that the spherical aberration of the cornea model is chosen to be 0.1 µm but IOL-Mentor allows any value between 0.00 µm and 0.45 µm. IOL-Mentor can deal with any type of lens (biconvex, planoconvex) and any surface geometry (spherical, aspherical, toric, aspherical toric). The method has also been validated for a 1.5 mm thick aspherical PMMA lens and for a large aperture (5 mm). Similar to the previous example, figure 4 is the MTF simulated by Zemax while figure 5 confirms the perfect match of the MTF computed by IOL-Mentor for the lens measured in air and in-situ.

EDOF CHARACTERIZATION

Nimo is also capable of measuring a large variety of extended depth of focus (EDoF) intraocular lenses (figure 6). Complex wavefronts can be captured as long as they do not include a diffractive step structure (figure 7). The through-focus MTF at a given frequency is generally used to extract the IOL power(s) and evaluate the imaging quality. Figure 8 shows the through-focus MTF curves of a commercial EDoF IOL measured with Nimo and computed with the Non-Paraxial Model Eye of IOL-Mentor. The cornea model has 0.15 µm of spherical aberration in this case.

CONCLUSION

The patent pending Non-Paraxial Model Eye implemented in IOL-Mentor opens way to a generalization of the use of wavefront sensors in IOL metrology for both R&D studies and production quality check. Since the IOL can be measured in air and as a single lens, the operation is simpler, more consistent, and beneficial to IOL manufacturers and ultimately contributes to a better vision for the patient. n