- HÖRL KUNSTSTOFFTECHNIK GMH & CO. KG

Push-the-button measuring, that was our vision

At Hörl Kunststofftechnik, high-tech meets efficiency: state-of-the-art, centrally networked injection molding machines form the core of a highly automated production environment. Intelligent systems control and monitor all processes in real time - for maximum quality, reliability, and speed. End-to-end automation handles even complex tasks in the shortest possible time, ensuring consistently high manufacturing standards.

A conversation with Peter Waldhutter, Measurement Technician at Hörl Kunststofftechnik, about in-process automated quality assurance in serial measurement, modu-lar automation – and why EROWA is the right partner.

EROWA: Mr. Waldhutter, you have been relying on automation at Hörl Kunststofftechnik for years. What was the trigger for the current project?

PETER WALDHUTTER: «The original idea came from our company founder, Thomas Hörl, back in 2017: „Measuring at the push of a button“ – fast, simple, reliable. We wanted an automated quality inspection process that would integrate seamlessly into our plastic parts production, without manual steps in between. The challenge was that most systems on the market were simply too complicated for serial measurement.»

And then you remembered EROWA?

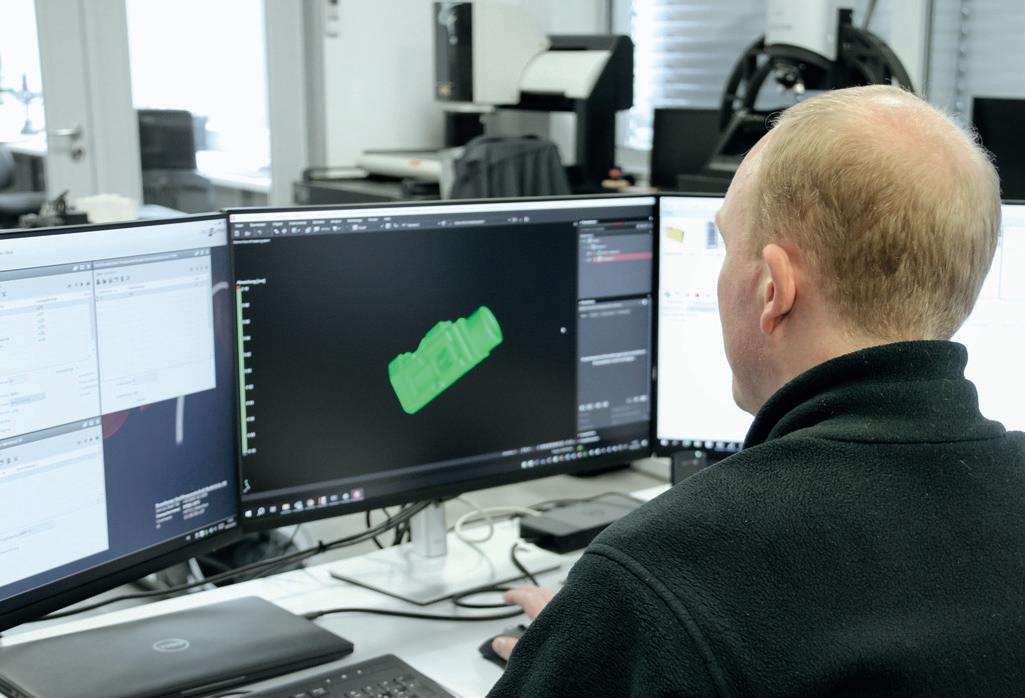

«We already knew EROWA from our toolmaking operations - and that turned out to be a real stroke of luck. The EROWA Robot Dynamic linear robot could be integrated directly without the need for complex special configurations. Combined with the Zeiss VoluMax computed tomography scanner, we created our first fully automated CT measuring cell, featuring both visual inspection and comprehensive dimensional measurement.»

REPORT - HÖRL KUNSTSTOFFTECHNIK GMH & CO. KG

Computed tomography in serial inspection – why take that approach?

«Our plastic parts are often extremely small, with hidden contours. CT offers huge advantages in this regard: it lets us see what would otherwise remain hidden – undercuts, material inclusions, voids. And it does so non-destructively and within just a few minutes.»

How exactly does the process work?

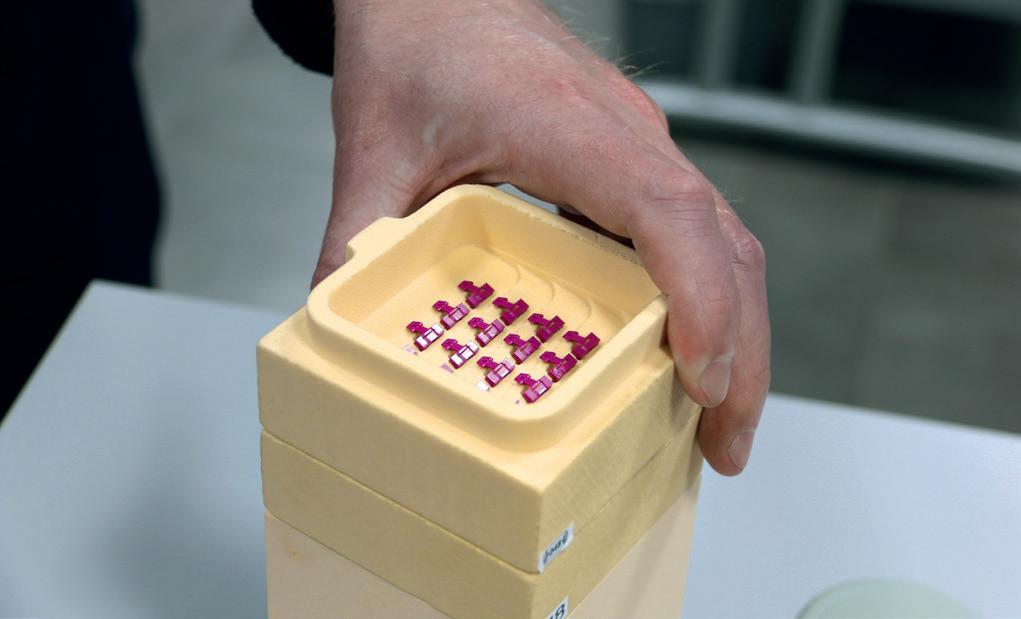

«The workpieces are placed on specially designed carriers developed by us. All information – program, part ID, position – is digitally linked via a barcode. The operator scans the code, places the part into the magazine, and the system starts automatically. Measuring, evaluating, documenting – everything runs seamlessly.»

What convinced you most about EROWA?

«Clearly, it’s EROWA’s openness to our individual requirements. We use our own clamping systems and carriers – which was no problem for EROWA. The magazines remain compatible and modularly expandable. This flexibility is invaluable.»

«The system runs flawlessly; we are very satisfied, including with the service.»

Peter Waldhutter, Measurement technician, Hörl Kunststofftechnik

REPORT - HÖRL KUNSTSTOFFTECHNIK GMH & CO. KG

Were there concerns within the team – especially regarding such highly automated processes?

«Of course. Especially among the measurement technicians, there was some skepticism – CT measurement without “holding the part in hand” was unfamiliar. But as experience grew, so did the trust. Today, everyone appreciates the relief – repetitive tasks are eliminated, and expertise is used more effectively.»

How has this affected your productivity?

«Enormously. Previously, we sometimes had to wait up to an hour for a measurement result – today it takes just a few minutes. Without automation, we would need 40 additional quality assurance specialists. And as everyone knows, those are not easy to find.»

What’s next?

«We’re already planning expansions. The system paid for itself within two years. And we know that with EROWA, we can grow – step by step, building block by building block.»

Mr. Waldhutter, thank you very much for the conversation - and continued success with your “push-the-button measuring” system!

HÖRL KUNSTSTOFFTECHNIK GMBH & CO. KG

Through continuous development, Hörl Kunststofftechnik has evolved from a regional injection molding company into an internationally recognized technology partner for high-precision plastic solutions.

The Milestones

• 1991 - Founded by Thomas Hörl and Alois Hainz as a specialized injection molding company.

• 1999 - Expansion to include an in-house toolmaking department.

• 2004 - Construction of a modern production facility with warehouse and administrative building.

• 2010 - Partnership with Rosenberger Hochfrequenztechnik GmbH & Co. KG; doubling of production capacity and business volume.

• 2013 - Construction and relocation of the injection molding and toolmaking departments to a new, climate-controlled building with visualization of all production equipment.

• 2021 - Climate-neutral manufacturing (Scope 1 and 2).

• 2025 - Full integration as a subsidiary of the Rosenberger Group under the name Hörl Kunststofftechnik GmbH & Co.

Copyright © 2025 - EROWA AG

HÖRL Kunststofftechnik GmH & Co. KG

Lepperding 2, 83410 Laufen (DE) www.hoerl.de

EROWA AG CH-6233 Büron www.erowa.com