In the world of super sports cars, there are names that give you goose bumps. Pagani is one of them. Vehicles such as the Huayra or the new Utopia are more than just cars – they are moving sculptures. They express a radical demand for form, function and fascination. But to put such masterpieces on the road, you need partners who share this aspiration. Partners like EROWA.

Here, where passion for every detail lives on, over 700 compo nents are produced per vehicle – many of them from a single block of titanium or aluminum. Take the steering wheel, for example: milled from a solid block, technically perfect, aesthe tically a work of art. «When we show it, hardly anyone believes that it was made by machine – the surface is so flawless,» says Production Manager Antonio Gerardi.

Craftsmanship meets high-tech

But there is more than just high-tech behind this perfection. It is the result of uncompromising thinking that does not leave excellence to chance.

Combining this quality with efficiency and flexibility requires systems that think for themselves. This is why Modena Design opted for the automation solutions from EROWA AG. What looks like rigid technology at first glance is in fact an intelligent partner in the production process.

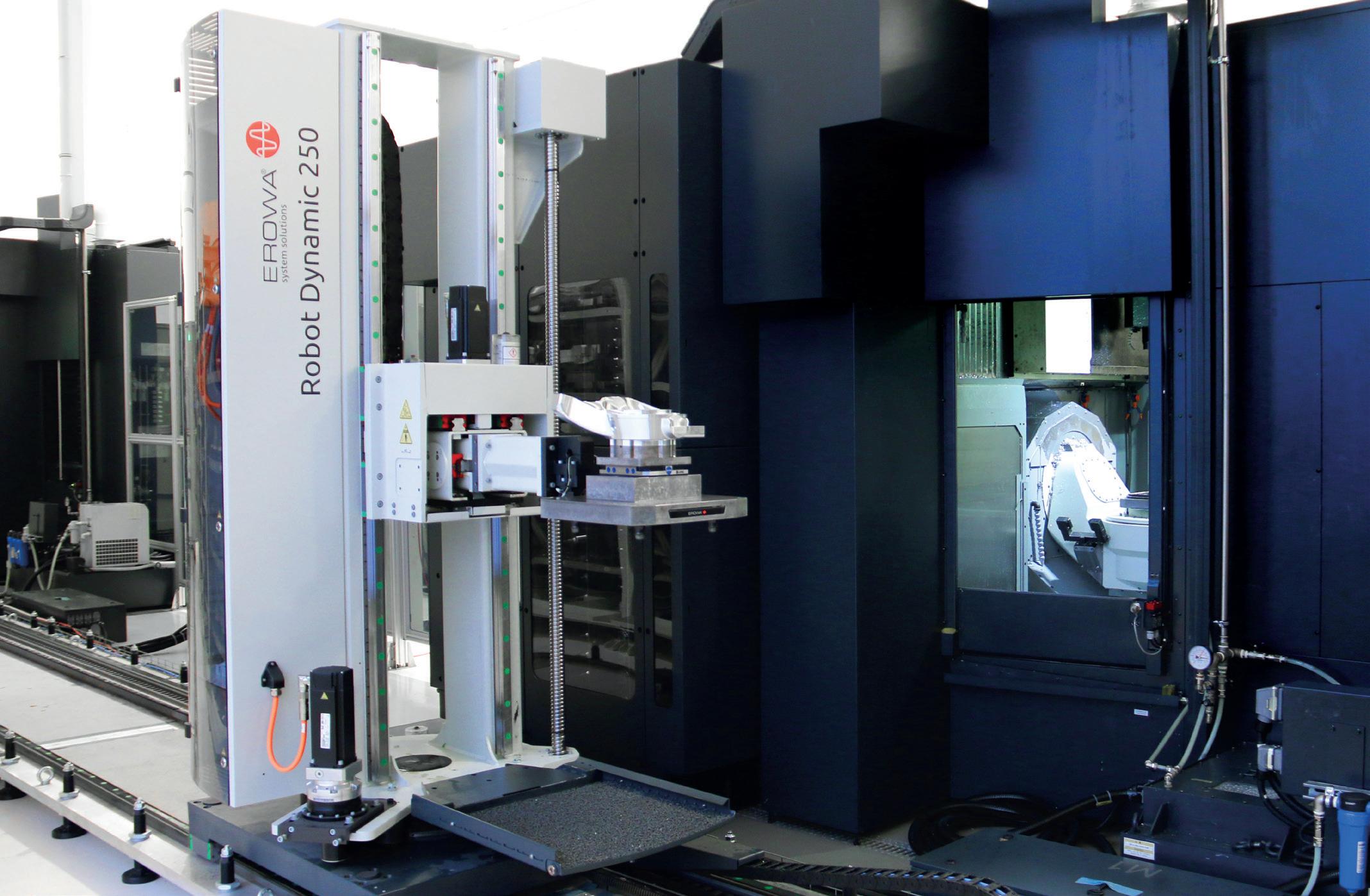

The heart of the system is the EROWA Robot Dynamic 250 Linear, which works in combination with two 5 axis machining centers from MAKINO. The four rack magazines and the central loading station enable fully automatic 24/7 operation – flexible for both individual parts and small batches. Thanks to the MTS and PC210 Combi zero-point clamping systems with pallet sizes MTS 400, PC 210 and ITS 148 mm, workpiece changeover is flexible, fast and reliable – with repeatability less than 3 micrometers.

The result: «over 7,540 machine hours per milling machine in 2024 – with consistently high quality», says Antonio Gerardi.

Automation with soul

But technology alone is not enough. The EROWA JMS 4.0 process control system controls the orders, the EWIS chip system identifies each pallet and the operator always has an overview of capacity utilization and the order situation. Everything is seamlessly linked.

«When excellence is the goal, you need systems that think along with you. Just like those from EROWA.»

Antonio Gerardi, Production Manager Modena Design

for us,» says Antonio Gerardi. «We didn‘t want a standard solution, but a system that would maintain our flexibility –because our production relies on precision in small series and individual parts. This is exactly what EROWA delivers.»

Creating great things together

What makes this partnership special is not just the technology – it is the shared understanding. The will to make the best possible, without compromise. The ambition to not only automate processes, but to perfect them.

Modena Design will produce all milled components for 80 Pagani vehicles in 2025 – in-house, automated, but with a passion that you can feel. Because in the end – it‘s not just metal that‘s shaped – it‘s a feeling. A feeling for precision, for speed, for perfection. And for all those who work behind the scenes to put such dreams on wheels.

Copyright © 2025 - EROWA AG

Pagani S.P.A.

Vill. La Graziosa 41018 San Cesario sul Panaro (MO) Italy www.pagani.com

EROWA AG CH-6233 Büron www.erowa.com