First off, happy new year to our readers! As we all return to our offices, factory floors, workshops and design studios, now is a good opportunity to look ahead at what to expect across the engineering landscape for the year ahead. 2024 was all about AI, electrification and sustainability, and 2025 is likely to follow in much the same vein.

Sadly, the climate crisis remains as hot a topic as ever for the year ahead. Innovations in material design are continuing to produce lighter and more efficient parts (page 27), as well as improve the energy efficiency of vital components (page 30). 2025 is likely to bring a greater focus on circular economy processes for new and existing materials (page 32) and see even more ambitious projects to reduce the impacts of climate change on the planet (page 42).

Electric vehicles (EVs) will remain a key part of this endeavour, with novel design approaches to EVs (page 6) becoming more even more vital to increase adoption of the technology. Advances in new battery technologies and designs (page 10) will be important here, as will new manufacturing processes to speed up the production of EV components (page 12).

Industry events (from page 44), such as the upcoming Southern Manufacturing and Electronics show in February, and JEC World in March, will continue to provide crucial technological insights, and knowledge-sharing from across the engineering sector. One thing is key as the new year dawns: We all have an important part to play in the transition towards net zero.

Hayley Everett Editor

16

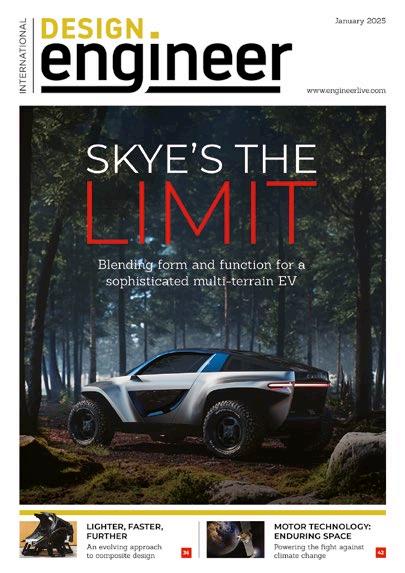

Skye’s the limit

Blending form and function to design a sophisticated multi-terrain EV

Laser-focused

Expelling excess heat from LPBF 3D printing processes

INSTRUMENTATION • ELECTRONICS

18

Discussing the latest innovations in LFP battery design

How a new rapid moulding technology is speeding up production

Oliver Partridge explains why machine shops are 3D printing their jigs and fixtures

Under pressure

How barometric pressure sensors are ensuring accurate and reliable measurement 21

Ultrafast signals

Introducing a new series of ultrafast arbitrary waveform generators

COATING TECHNOLOGY

24 Predicting coatings

Could machine-driven algorithms revolutionise the future of coatings design?

MATERIALS • PROCESSES • FINISHES

27 Stainless steel chic

How stainless steel is continuing to drive the future of automotive design

30 Cool it

TIMs are taking electronics cooling applications to a new degree

COMPOSITES

32

36

Fruitful fillers

How circular economy processes are enabling more sustainable biocomposites

Lighter, faster, further

The UK’s largest automotive vehicle manufacturer discusses the evolution of its approach to composite design

FASTENERS & SEALING

38

Slide on by

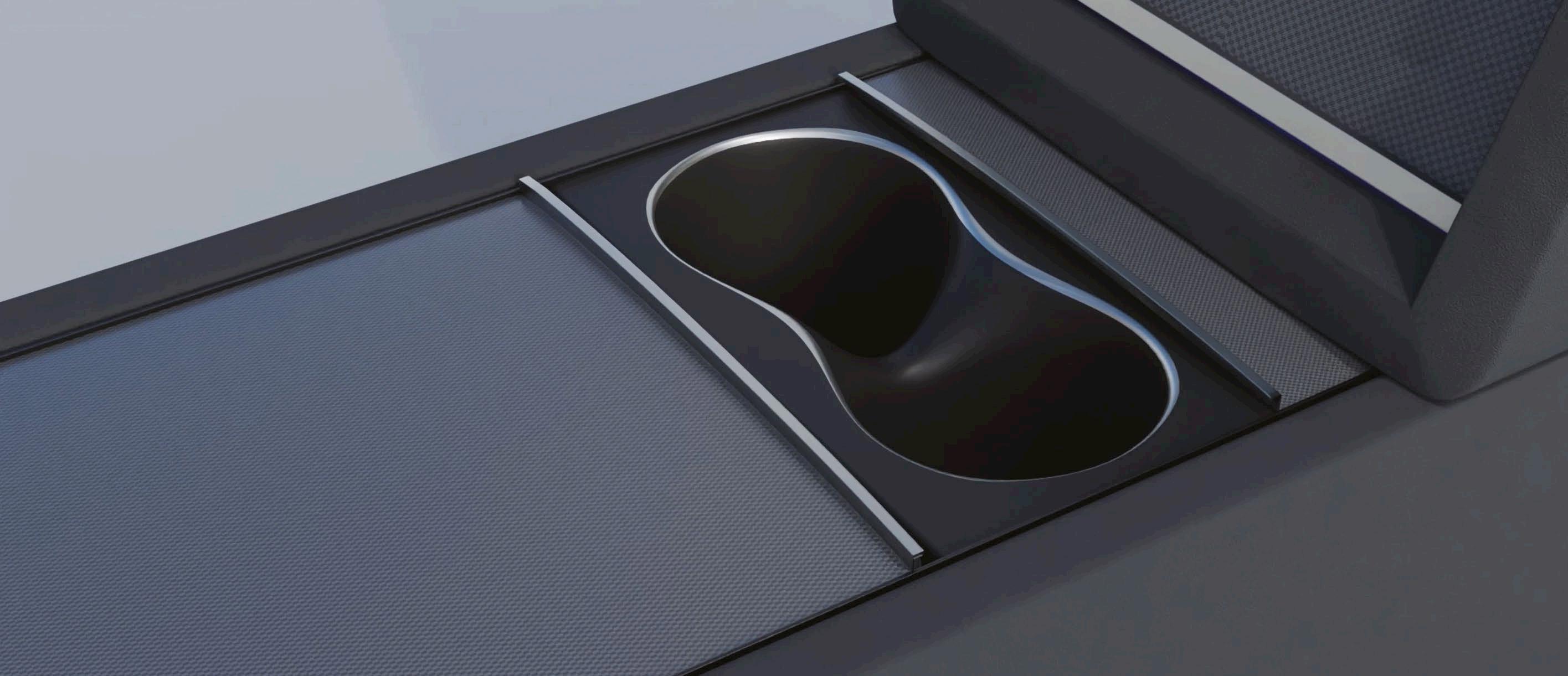

How one small fastener assembly has made a big difference to EV userfriendliness

PUBLISHER

Jerry Ramsdale

EDITOR

Hayley Everett heverett@setform.com

STAFF WRITER

Jake Holmes jholmes@setform.com

DESIGN

Dan Bennett, Jill Harris

HEAD OF MARKETING

Shona Hayes shayes@setform.com

HEAD OF PRODUCTION

Luke Wikner production@setform.com

BUSINESS MANAGER

John Abey +44 (0)207 062 2559

SALES MANAGER

Darren Ringer +44 (0)207 062 2566

ADVERTISEMENT EXECUTIVES

Paul Maher, Iain Fletcher, Peter King, Adam Croft

MOTORS, DRIVES & CONTROLS

40 Prime precision

Looking at the thinnest and lightest slotless motor series yet

42

Enduring space

Dave Walsha discusses how motor technology is powering the fight against climate change

SHOW PREVIEW

44 Composites covered

JEC World 2025 returns to Paris between 4-6 March

45

Flying south for winter

Southern Manufacturing & Electronics takes place in February

Setform’s international magazines for engineers are published quarterly and distributed to senior engineers throughout the world. Other titles in the company portfolio focus on Oil & Gas, Design, Transport, Mining, Energy and Power.

The publishers do not sponsor or otherwise support any substance or service advertised or mentioned in this book; nor is the publisher responsible for the accuracy of any statement in this publication. ©2025. The entire content of this publication is protected by copyright, full details of which are available from the publishers. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior permission of the copyright owner. SKYE'S THE

Setform Limited, 6, Brownlow Mews, London, WC1N 2LD, United Kingdom +44 (0)207 253 2545

Blending form & function for a sophisticated multi-terrain EV

Japanese precision since 1935

Finding the right sensor is like finding the perfect match. With HIOKI current sensors, your application gets the ideal partner. Swipe right for precision and reliability from over 50 years of excellence.

• DC to 10 MHz bandwidth

• 50 A to 2000 A

• ±0.025 % rdg Basic accuracy

• DC to 2 MHz bandwidth

• 2 A to 1000 A

• ±0.2 % rdg Basic accuracy

Ready to find your perfect match? Visit our website:

hioki@hioki.eu www.hioki.eu

A British design and engineering consultancy is making headlines with its novel multi-terrain EV. One of the firm’s key creatives tells Louise Davis how a collaborative approach is paying design dividends

Designers and engineers work hand-in-hand at the consultancy’s offices

Named after its design director, Ian Callum, CBE, Callum is a UKheadquartered consultancy whose scope of work is far broader than many companies with expertise in automotive design. Callum is a design and engineering business that creates its own bespoke and limited-edition products as well as providing consultancy and services to partners and third parties. “What makes us unique is our collaborative spirit. Our team of more than 30 talented experts spans fields from art and audio to motorsport and fashion, creating an environment where ideas collide and innovation thrives. Our approach goes beyond design and engineering; it’s about building stories that ignite curiosity and inspire,” explains Aleck Jones, head of design.

Detailing the type of work the firm is involved with, Jones says that Callum collaborates on both joint and white label projects across automotive, travel, lifestyle and beyond, “always seeking projects that are not only challenging but also fun and meaningful”. On specific examples, Jones notes: “Recent standout projects include a groundbreaking concept car with Nyobolt, featuring pioneering battery technology, and Callum’s

own meticulously crafted whisky and lounge chair, each embodying our ethos of design with a story.”

The consultancy has a wealth of automotive expertise among its team, with staff joining from Jaguar Land Rover, Aston Martin as well as niche automotive specialists and professional motorsport organisations. It’s therefore unsurprising that automotive design is where the firm is finding most work. When asked what the key trends here are, Jones says that, “Naturally, there is a lot of interest in EV design at present and customers are keen to understand the boundaries of what is possible and how creative you can get. We are excited by the opportunities that new technologies offer. For example, in our project with Nyobolt, the company asked us to create a vehicle using its innovative battery technology. This technology paves the way for smaller and lighter batteries, enabling the vehicle to be a desirable drivers’ car.”

Another area of interest for all automotive designers, today more than ever, is materials. On this, Jones observes: “Many customers are starting to think more deeply about sustainable solutions. For others, we

might nudge them down that path, highlighting the business and wider societal benefits. We’ve been looking at everything from recycled denim, coffee, rice and plant fibre plastics.” He adds: “Additive manufacturing is also a fascinating and growing trend. We have a partnership with Stratasys and had 57 3D printed parts on the Jaguar C-X75 bespoke commission.” What’s striking about Callum – and also perhaps reflective of the fact the team are independent designers rather than working in-house for automakers – is that when asked about trends, as well as the abovementioned technical notes, Jones firmly emphasises how the company considers the bigger conceptual picture. “We see the impact of wider culture in automotive design,” he states. “Fashion, for example, certainly has an influence – as does music, art, architecture and today’s culture in general. We take our inspiration from many sources but ‘form follows function’ is a consistent mantra across all projects. We focus on design that is simple but not simplistic; clean and pure but not reductive. Beauty prevails and we must remember that long after the fad has passed, people must live with these designs.”

Given the backgrounds of the team here, people expected a sports car from us, but we wanted to do something unexpected

The biggest illustration of the company’s design ethos can be found in the recently introduced Callum Skye, an eye-catching, multi-terrain EV that certainly looks like its makers had a lot of fun designing it. Indeed, Jones reports that the team had been itching to create such a vehicle for a long time before the Skye was brought to life: “We have always wanted to design, engineer and manufacture our own vehicle – this was a project that’s

constantly been on the radar since we were founded in 2019. Given the backgrounds of the team here, people expected a sports car from us, but we wanted to do something unexpected.”

A beautiful yet practical multiterrain EV certainly fits the brief for ‘unexpected’. How hard was it to create such a vehicle? “For both design and engineering, a key challenge we faced was balancing the multitude of different requirements,” Jones reveals. “We wanted to take

a product design approach, but of course functional requirements –particularly given what we want it to do – had to be met.

“Our car design background is perceived as sleek, low-slung cars, but that obviously wouldn’t work for such a capable vehicle. So, it’s a balancing act - Skye is an authentic multiterrain vehicle; it has to perform.”

Jones again flags up the merits of the firm’s collaborative approach in tackling those challenges. He says:

“We are all based in the same office, so designers and engineers can work hand-in-hand to ensure all aspects focus on simplicity and integrity to meet the demanding functional targets of traversing various terrains, while still being a joy to drive around town or on the open road.”

And Jones is confident that the team has achieved its ambitious goals. “A key element for Skye is the concise yet dramatically proportioned exterior. It’s clearly designed to function off-road. Purposeful yet beautiful, it’s a sophisticated design that has a presence,” he asserts.

“We have the striking accent loop around the car, intersected by a strong horizontal structure, flanked by organic forms both front and rear. Ultimately, we think it is paired

down to a level of necessity and understatement: minimal mass, maximum capability.”

The Skye made its debut in May 2024 and Jones says the team has been delighted by the reception it’s received both from industry peers and potential buyers – “so much so, we’ve started accepting deposits.” The feedback so far has focused on the vehicle’s versatility: “It can seamlessly fit into the lives of a broad portfolio of customers. Some examples of how buyers say they intend to use the car include as a yacht tender at a port, on a ranch in California, and to buzz around Kensington!”

Aside from the Skye, the

consultancy is busy on other automotive projects and recently revealed a new bespoke commission.

“It’s the transformation of one of the Jaguar C-X75 stunt cars from a Bond movie into a luxury hyper car to enjoy on the road. It’s been a huge undertaking – over 1,000 hours in the bodywork alone! People love it and we hope it will lead to more bespoke commissions shortly,” explains a delighted Jones. He also hints of other ‘ambitious and unexpected’ projects in the pipeline, saying that, “We’re working with some great partners right now and obviously we are hugely ambitious with our own projects. It’s fair to say we’re only getting started.”

We have the striking accent loop around the car, intersected by a strong horizontal structure, flanked by organic forms both front and rear

Part of the collaborative approach at Callum also extends to supporting the incoming generation of new designers and engineers. The firm is keen to provide new opportunities for young talent and makes a point of stating that the knowledge transfer goes both ways. Callum’s ‘Next Generation’ initiative involves supporting new talent through placements, paid internships and working with highly respected universities.

Co-founder of Callum, Ian Callum, ensures that everyone is given the opportunity to work on all design elements of major projects. “Young people are crucial to a business such as ours,” he says. “Younger members of the team bring energy, curiosity and ambition to our projects. There’s a brightness and a sense of novelty that forms ideas that we might not have thought of.”

And the support is ongoing, too: “We want a team of designers to reach this level of competency faster as our business grows and they can become active channels of the business. We see both our placements and full-time jobs for these young designers as the start of a longer-term partnership.”

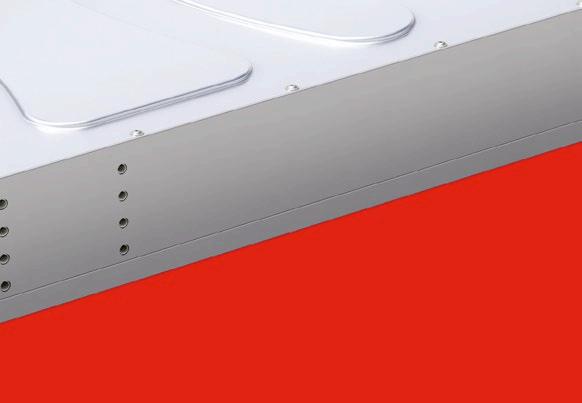

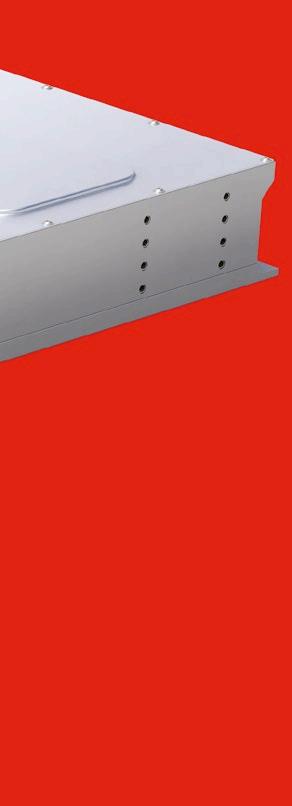

Back in September, BorgWarner debuted a series of new product launches at IAA Transportation, aimed at improving the sustainability of commercial transport. Through the launches – and backed by more than a century of expertise in the sector – the electrification and mobility solutions manufacturer is poised to further accelerate innovation within the electric vehicle (EV) market.

One particularly exciting advancement from the company is its innovative design approach to Lithium Iron Phosphate (LFP) battery packs, says CTO Harry Husted.

“LFP brings several advantages, the first being cost,” he says. “The availability of lithium, iron and

LFP’s higher cycle life is a considerable benefit for commercial vehicles

phosphate is a lot higher than the chemistries in many existing batteries, such as nickel, manganese and cobalt, which are rare and therefore expensive. So, LFP brings a fundamental cost advantage as it reduces the cost of the battery pack.”

But the lower price point isn’t the only benefit, Husted adds: “The other advantage with LFP is its higher cycle life, which is a considerable benefit for commercial vehicles. With our battery pack design, we have a faster charging rate, so we’re able to achieve the required energy density while also charging the battery faster than the technology we currently have today. So, those are three key advantages of LFP and the reasons why we’re heading in that direction with our new generation of battery packs.”

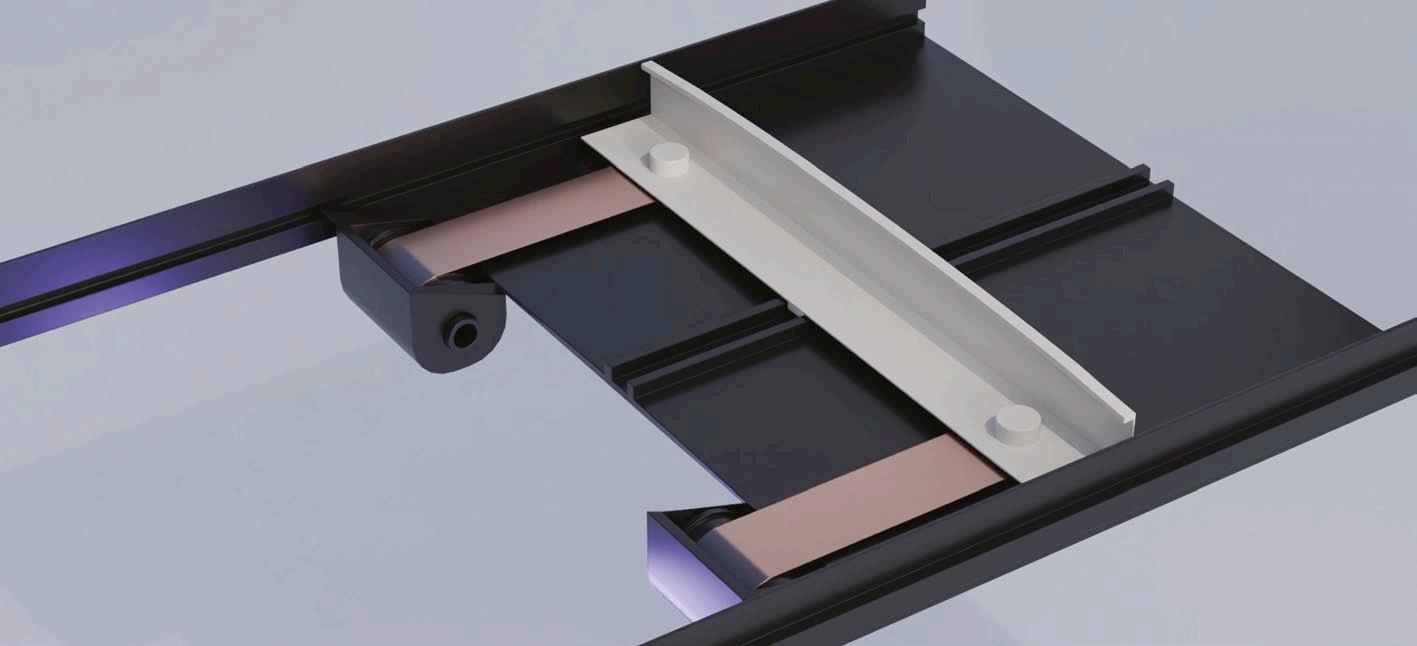

Focusing its attention on LFP has required BorgWarner’s approach to battery pack design to evolve. “For us, it’s about designing the battery pack to be able to package a completely different type of cell,” Husted explains. “The cells we’ve been used to using are small, cylindrical cells which we package a lot of, and now for LFP we’ve had to change our design to use what’s called a blade cell. Blade cells are very long and very thin – you can’t just stack them together like layers in a sandwich, so we had to change our design paradigm for the battery pack.”

In February last year, BorgWarner announced a strategic partnership with FinDreams Battery, a subsidiary of BYD Company Limited, for the rights to localise the production of LFP battery packs for commercial vehicles in Europe, the Americas and select regions in Asia. Through the agreement, FinDreams will supply BorgWarner with its LFP blade cells and some production equipment for battery pack assembly, while BorgWarner handles the design of the battery packs.

“What’s really nice about the blade cell is its form factor,” says Husted. “It’s very thin yet holds a lot of energy, so you get this very tall, thin cell structure that needs less complication

around it in the battery pack to be put together. What this means is when you pack them together, you don’t need to put structural components with them, they become somewhat structural themselves, so you can pack them very tightly. At the cell level, LFP cells have a lower energy density than nickel-manganese-cobalt equivalents, but because they can be packaged together more tightly you regain that density at the battery pack level. For cooling, we simply attach a cooling plate on the bottom of the pack, which is very space efficient.”

In terms of vehicle compatibility, the firm’s LFP battery packs will be suitable for the full spectrum of commercial transportation vehicles, from small last-mile delivery EVs up to HGVs. “LFP is currently being used in passenger vehicles, in heavy-duty commercial vehicles, and our focus is really on the commercial vehicle side,” Husted says. “We’re able to apply the battery packs to light, medium and heavy-duty vehicles due to our ability to create different form factors for the battery packs. A big part of this is packaging, as different vehicles have different form factors.”

Husted continues: “One form factor we have is called the flat pack, which has a very low height of 14cm. This was designed to be packaged

underneath the floor of a transit bus, for example, which is something we hadn’t been able to do in the past. Meanwhile, you look at a medium or heavy duty truck and that form factor isn’t necessary – those vehicle manufacturers want a box that sits next to the frame rail. So, we took that same battery pack and basically folded it up into a cube, which allows us to apply it to trucks. Because we have these different packaging variants, we’re able to cover a wide range of vehicles.”

This flexibility is important, Husted says, as the company identified a trend toward vehicle manufacturers wanting to offer different battery pack sizes in the same vehicle. “Our packs come in 50kW blocks, meaning you can add capacity as you go,” he explains. “Manufacturers don’t need to just buy one big battery pack, instead they can take a more modular approach which helps the market to offer different battery solutions.”

Husted says BorgWarner’s goal is to put its LFP battery packs into production by the end of 2026, with the hopes of building this area up to form a “major chunk” of its business in the future.

How can this new rapid moulding technology speed up production?

Jake Holmes finds out…

The Polymorphic 28k moulding machine

Many companies are turning their attention to the growing benefits of additive manufacturing, especially for custom solutions or just-in-time manufacturing. Through additive manufacturing, companies can reduce costs and material waste by producing only what is needed, and also save on storage costs. Many train manufacturers have been utilising another great benefit: the ability to produce products instantaneously, cutting lead times from potentially months to just a few hours. This reduces downtime and increases productivity.

Meanwhile, manufacturers within the aerospace and automotive industries often rely on large, complex, and unique equipment for machining. Having the technological ability to quickly produce specific tools reduces the need for stockpiling single-purpose tools in the warehouse.

Traditional machinery can be space-consuming and require multiple fixtures, vices, and jigs. Having a range of single-purpose

machinery can also be expensive and inefficient. This is where additive manufacturing has its benefits, as the same machinery can be repurposed for different applications. Fyous, a British innovative moulding systems developer, is poised to further disrupt this area with its recently launched Polymorphic rapid tooling technology.

Designed to reduce the amount of machinery and tools required in the factory, Fyous’ system can create moulds 14 times faster than traditional additive manufacturing, allowing much faster production. Moulds can be produced almost instantly using this new technology, reducing lead times and allowing factories to have access to custom tools almost instantly.

Fyous’ PolyMorphic 28k forming machine is composed of the machine itself, the pin tool and the firm’s 3D CAD software. The moulding process itself takes approximately 20 minutes, roughly 14 times faster than

3D printing processes for similarsized pieces. Workholding increases productivity and efficiency by reducing the time it takes for time set up between moulds.

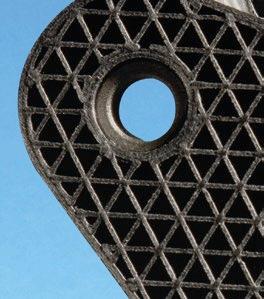

The machine then vacuums the material around the pin to create the final mould. The tightly packed pins raise or lower to the correct level to create the mould, shaping the material with each pin. The pin tool in the forming machine is infinitely reusable, with the 3D CAD model forming the 28,000 densely packed pins into a tooling shape. The strength of the pin tools makes them well-suited to holding metal for machining.

The pins boast an accuracy rate of up to 0.1mm, being able to withstand up to six tonnes of pressure once locked into place. These capabilities make the pins well-suited to vacuum forming, composite layup, composite bonding, and moulding polyurethane products. Each pin part is roughly the same size as a shoe box and can be used together to create large moulds for multiple applications.

Joshua Shires, co-founder at Fyous, says: “The only input is a 3D CAD model of the part to be held, from which we can produce tooling that holds the part perfectly.”

With a pin tool, manufacturers can reinsert it into the forming machine to create a new mould, resulting in no waste for pin production. The mould does not need to be kept, but only the 3D CAD model must be retained.

“Failure to use optimal work holding is not only inefficient, expensive and timeconsuming, it can result in slippage, safety risks, and increased chance of damaging parts,” Shires adds.

The ability to make cost-effective tooling at a rapid pace could be a large step forward for industries such as aerospace and automotive, however these sectors are not the sole beneficiaries as the technology can be applied across a wide range of industries.

For example, Fyous’s technology could be used to produce diabetes care products for the NHS and the broader medical industry. The NHS currently spends almost £1 billion per year on diabetic foot care across 4.9 million diabetics in the UK. Doctors can use the Fyous app to scan the feet of diabetes patients, generating millions of data points that are then used to create custom moulds for trainers.

One industry that may have not expected to use this technology is confectionery. Using the moulding process, users can create customised chocolate. Using the 3D CAD

app, companies can leverage the Polymorphic process to form moulds for pouring liquid chocolate into. This allows companies to create bespoke chocolates for customers, providing personalised products.

Moulding processes are faster than additive manufacturing for creating custom chocolate moulds. Previous methods would allow corporations to create custom chocolate moulds in factories, whereas the increase in moulding speed now offers the potential for customers to purchase customised chocolates on the shop floor using scans they took on the Fyous app.

More than ever complex pieces of machinery are required, and with today’s global economy, there is no capacity for downtime. Both companies and government infrastructure are increasingly seeing the benefits of

paying higher initial costs to ensure high productivity, reduced lead times, and quicker repair times. The rail industry is starting to fully embrace this technology change as the impact it has on service is sizeable.

Shires says: “We can now see for the first time a way to realise the ‘made-on-demand’ model of consumer product manufacturing. The possibilities are limitless, and we are very excited to be right at the heart of this revolution.”

Fyous’ Polymorphic moulding technology now takes the advantages of additive manufacturing to new heights. Previously, the benefits of additive manufacturing’s timescales were largely confined to warehouses and manufacturing centres. Now, the ability to scan and produce a mould in under an hour opens this technology up to more applications closer to the end-user.

Why machine shops are 3D printing jigs and fixtures, and how they are tough enough to do the job

In the past aluminium has often been the material of choice for prototypes, jigs and fixtures, and welding fixtures due to its low cost, ready availability and ease of machining. However, when you take into consideration the associated tooling costs, set up and manpower required it can often make low volume or complex machining using aluminium too expensive.

Now that 3D printing has matured, it is widespread and has many applications across all industries. Not all 3D printers are made the same though; there is huge variation in the technologies used. Some rapidly print plastics for prototyping, others use UV light to solidify resin to micron accuracy, and others use lasers to directly sinter metal powder. These are just a few examples, and there are dozens more with different pros and cons. No one 3D printer can do everything, so it’s important to choose the right technology.

Strength has long been a challenge in 3D printing, however, as a result of material properties. To extrude a material from a nozzle it typically has to be brought near to melting point. This can be achieved with plastics, but metals require other methods (though there are ways of extruding metal filament without extreme heat). Very often, materials that can be easily melted and shaped do not have the best strength characteristics.

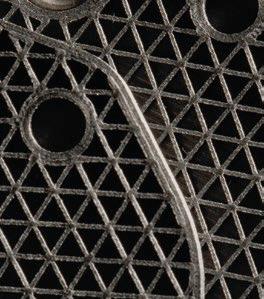

Composites are the solution to this problem, and Markforged has developed unique continuous fibre reinforcement (CFR) technology into its 3D printers to make it a reality. A secondary nozzle extrudes and cuts to measure a second continuous material, such as carbon fibre, Kevlar, or fibreglass. This continuous fibre is “ironed” into the base material, and the resulting parts have a better strength to weight ratio than aluminium. These materials are less costly than aluminium, and manufacturing the parts in house overnight eliminates the costs and lead times associated with outsourcing. These factors make 3D printed parts an attractive alternative to aluminium. In machine shops there is an additional challenge in the form of coolant, which can quickly corrode aluminium and other metals. Because the basic Markforged filament materials are nylon based,

they have excellent chemical resistance properties that allow them to survive coolant in CNC machines.

In a case study with DANA Incorporated, 3D printing workholding fixtures and die sets with Markforged reduced the cost of the company’s tooling by 70%, and reduced lead times by 90% in factories across seven countries. In another example, ISS Aerospace used Markforged’s 3D printers from Mark3D to create carbon-fibre reinforced UAV and drone parts that are lighter and stronger than aluminium. With the ability to rapidly replace damaged parts and create one-off designs, ISS Aerospace has built a strong aerospace business based on 3D Printing.

Oliver Partridge is at Mark3D. www.mark3d.co.uk

Aerospace Sensus L 3D printed UAV

How engineered plastic cooling towers are helping to expel heat from laser powder bed fusion 3D printing processes. Words by Greg Rankin

Additive manufacturing (AM) is booming.

According to a recent report from Persistence Market Research, the sector is expected to double in size by 2028 to exceed $15 billion. Traditionally, AM consisted of turning plastic resins into prototypes and low-volume parts. Now, the industry is expanding to include a growing list of metals that can be processed on sophisticated 3D printers. However, along with these advances comes a new challenge: managing excessive heat loads.

Utilising plastics in AM requires relatively low temperatures, often under 300°C. With metal, however, the print media can reach temperatures ranging from 1,100-1,400°C. To mitigate the heat, cooling towers are increasingly being employed to cool the process water down. This is exactly the challenge that the GE Aerospace AM facility in Ohio, the US, recently encountered.

“The aviation company was working on a state-of-the-art approach to manufacture aircraft parts utilising laser 3D printers,” says Steve Coppock, consulting engineer at Armour & Associates. The Ohio-based company designs, installs and commissions HVAC and processing cooling systems. “The engineering firm brought us in to help with the cooling system that was required to chill the water used in the processing of these parts.”

From lightweight designs, rapid prototyping, and now increasingly used for low to medium-volume components, AM is still in a fledgling state with an incredible amount of untapped potential.

At the GE Aerospace facility, which has been the focus of important R&D work for the company, the laser printers are used for components that require complex geometries or exceptional precision. While lasers

themselves are not hot, the heat produced when the photons come in contact with metals can be significant.

“The facility was looking for a cooling tower that would provide some longevity and would not require a lot of maintenance or repairs,” explains Coppock. “We had been having a lot of success with cooling towers made out of engineered plastic and recommended them for this application.”

Made of high-density polyethylene (HDPE), engineered plastic cooling towers are corrosion-proof, offer exceptional durability, require significantly less maintenance, as well as an easier and quicker installation.

The first tower at the GE Aerospace facility was installed in late 2022 and after a successful debut, a second tower was added a year later to increase production.

“The Delta cooling towers have been

a good fit for this facility, and with the 20-year warranty they are covered for the next two decades,” says Coppock.

Delta Cooling Towers pioneered the engineered plastic cooling tower design in the 1970s. The seamless one-piece shell has no joints, seams, panels, gaskets, bolts, fasteners or caulking like conventional towers. The models selected were the Paragon series which each have a cooling capacity of 250 tonnes.

“They really appreciate that that towers are environmentally friendly as well,” adds Coppock. “They don’t require

as much water treatment chemical, you lose less water from drift, and your energy savings can be significant.”

Another issue for any end user looking to add or replace a cooling tower system is the potential noise it generates. At the GE Aerospace plant, the towers are between two buildings which could have created significant echo reverberating throughout the industrial park. To combat the issue of noise, the engineering firm decided it would be best to elevate the towers so that they sit closer to the roofline of the buildings.

“The towers look great sitting up on those platforms, but in hindsight, we may not have even needed to raise them up above ground level because they run whisper quiet,” Coppock explains. “When you’re standing there, literally, the only thing you hear is the water running through.”

The towers also came with variable frequency drives (VFDs) which allow the fan speed to vary so that the units do not run at max RPM except when necessary. Depending on the application, this alone can result in significant energy savings. In fact, an independent report by the New

York Power Authority estimated almost a 40% decrease in electrical consumption when using the VFDs on Delta’s cooling towers.

HDPE cooling towers can deliver additional cost-saving benefits with a quicker, simplified installation. While getting a typical cooling tower up and running can take several weeks or more, the engineered plastic designs are factory assembled, enabling an installation process that can often be completed in as little as a single day with a smaller crew.

“That installation was basically plug-and-play,” says Coppock. “Don’t get me wrong, there’s some wiring and piping to do, but nowhere near the scale that it takes to put in a stainless steel, galvanised, or even a fibreglass tower for that matter.”

The savings did not end there for GE Aerospace. Coppock estimates that the two new cooling towers have greatly reduced the company’s expenses on costly water treatment chemicals and because they are being well maintained, they have essentially eliminated downtime related to processing temperatures

The sensors undergo a rigorous testing process

How barometric pressure sensors are ensuring accurate and reliable measurement within industrial applications

Simply put, barometric pressure is a measurement of the air pressure in Earth’s atmosphere. While scientists and engineers have been using traditional mercury-based barometers to measure barometric pressure since the 1600s, today’s technology has since evolved. Capacitive pressure sensors are now widely used within industrial manufacturing applications to detect pressure changes by monitoring fluctuations in electrical capacitance.

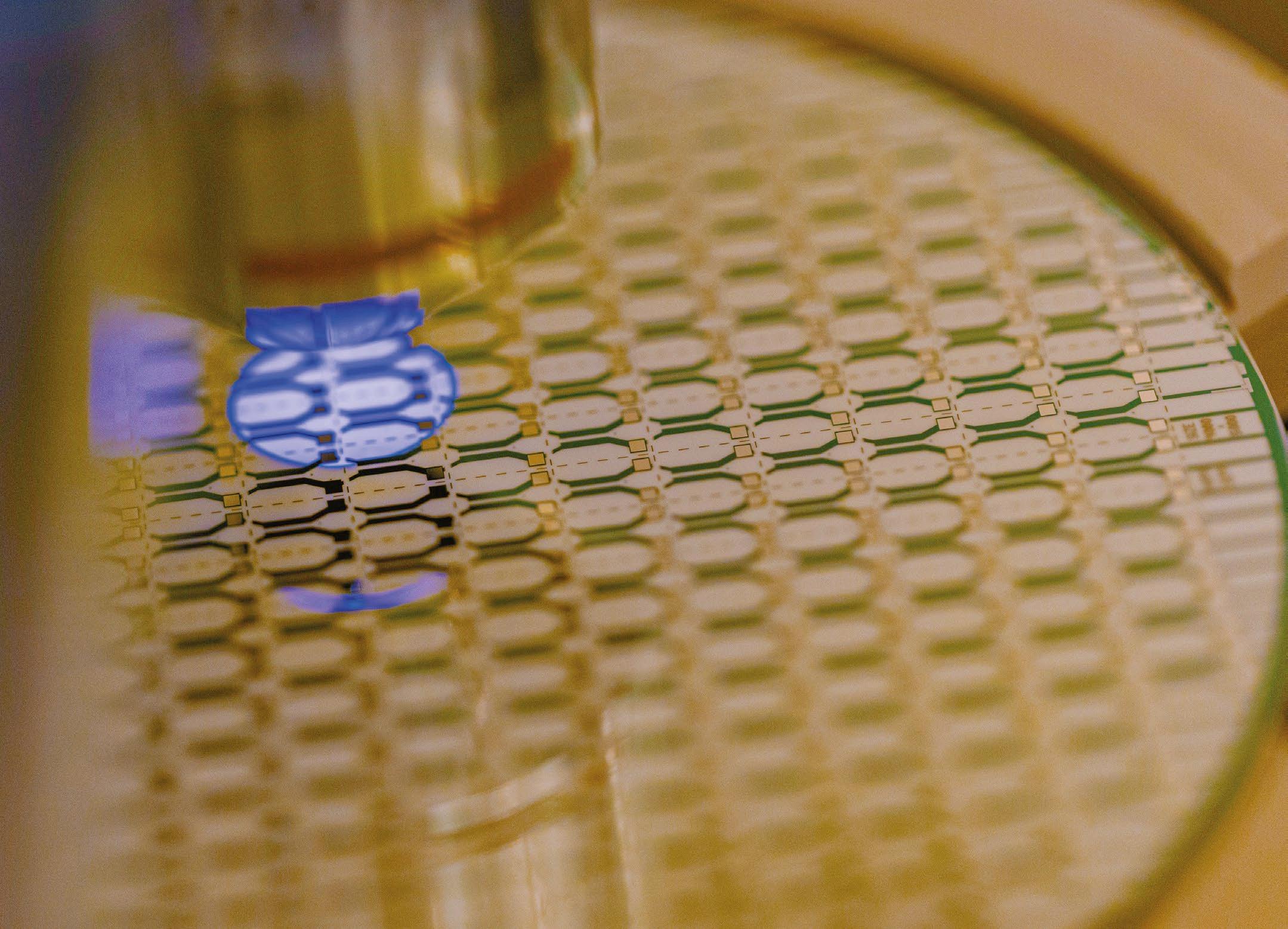

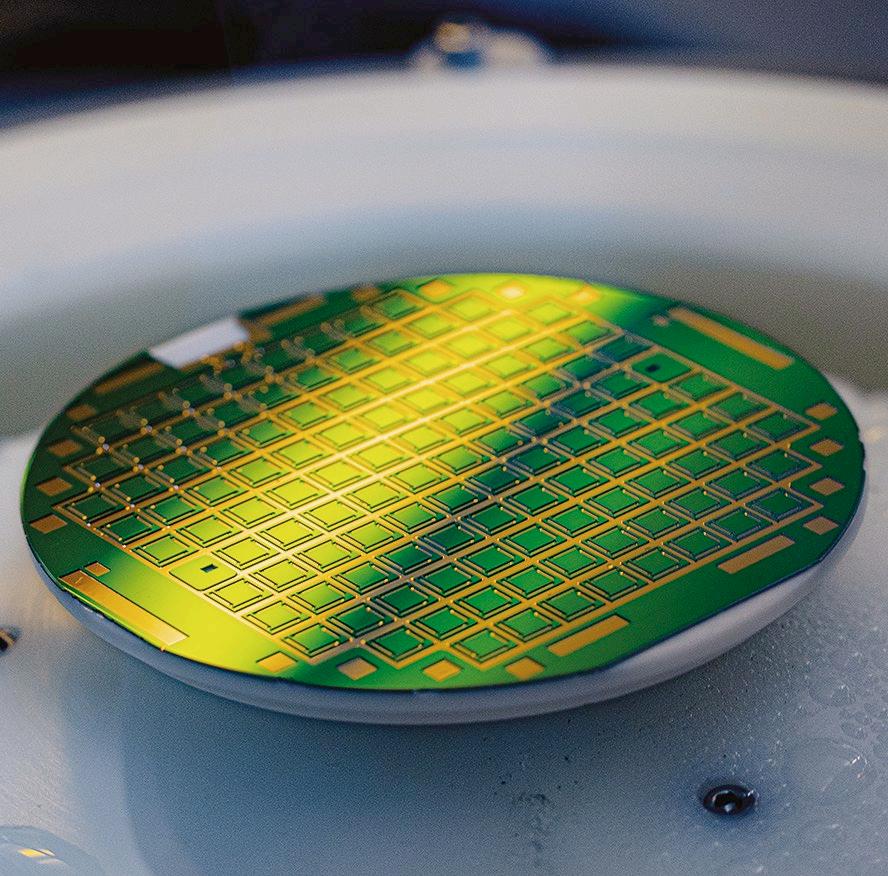

“In various manufacturing processes, maintaining optimal pressure is essential for ensuring product quality and consistency,” says Jing Lin, product manager, sensors, at Vaisala. “One such example is the semiconductor industry. Our PTB210 and PTB330 barometers are widely used in semiconductor production equipment and are deployed by global leading coater suppliers.”

A coater is equipment used in the photolithography process to apply a thin and uniform layer of photoresist onto semiconductor wafers.

“The air pressure within these systems directly influences film thickness, making precise pressure measurement crucial,” Lin continues. “Vaisala’s barometers have been integrated into coaters to provide accurate air pressure readings, thereby ensuring high product quality.”

First introduced in 1985, Vaisala’s Barocap pressure sensors are developed and designed in-house for barometric pressure measurement applications. In the 40 years since, the sensors have been optimised for various applications in which accurate and stable measurement is required.

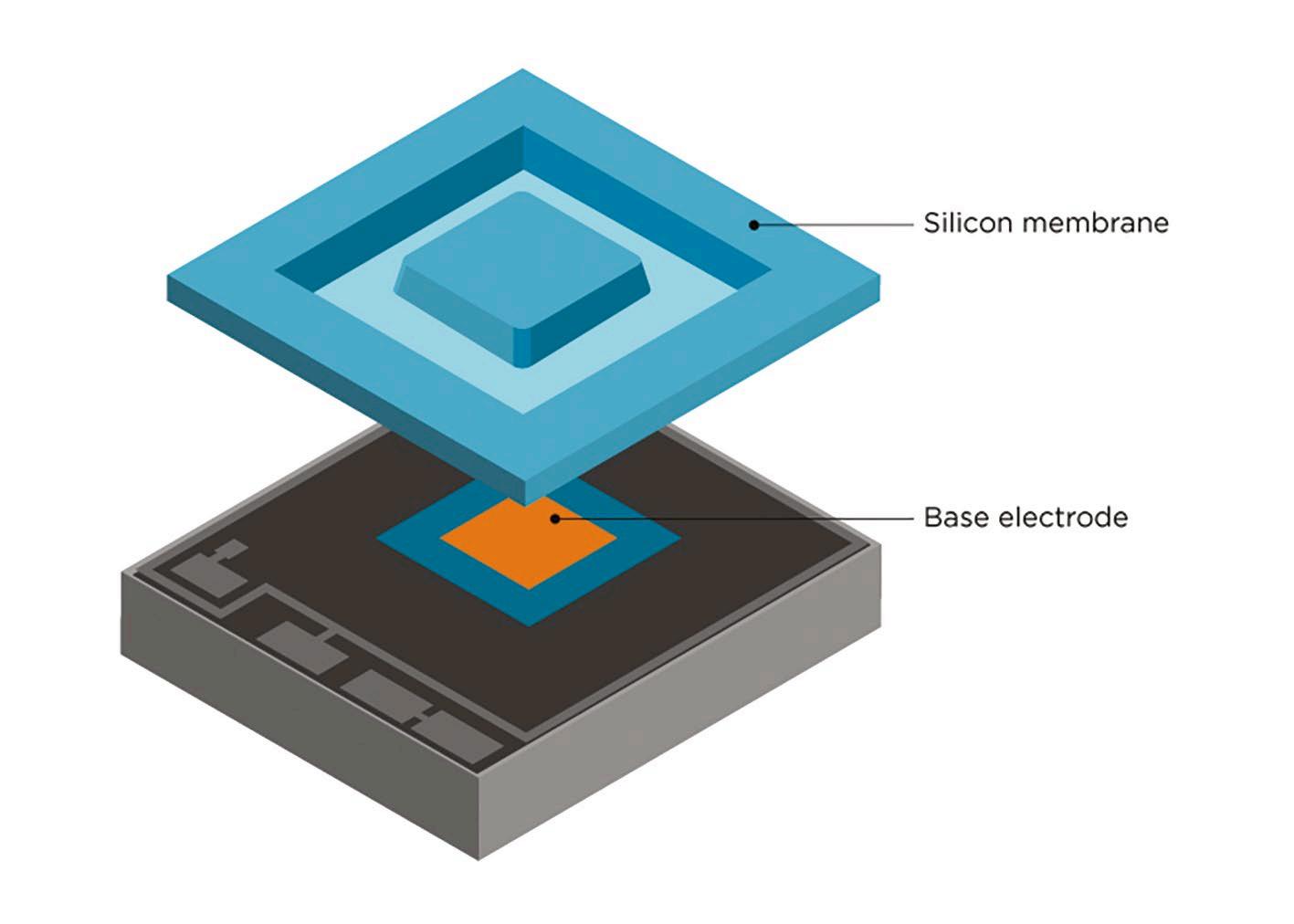

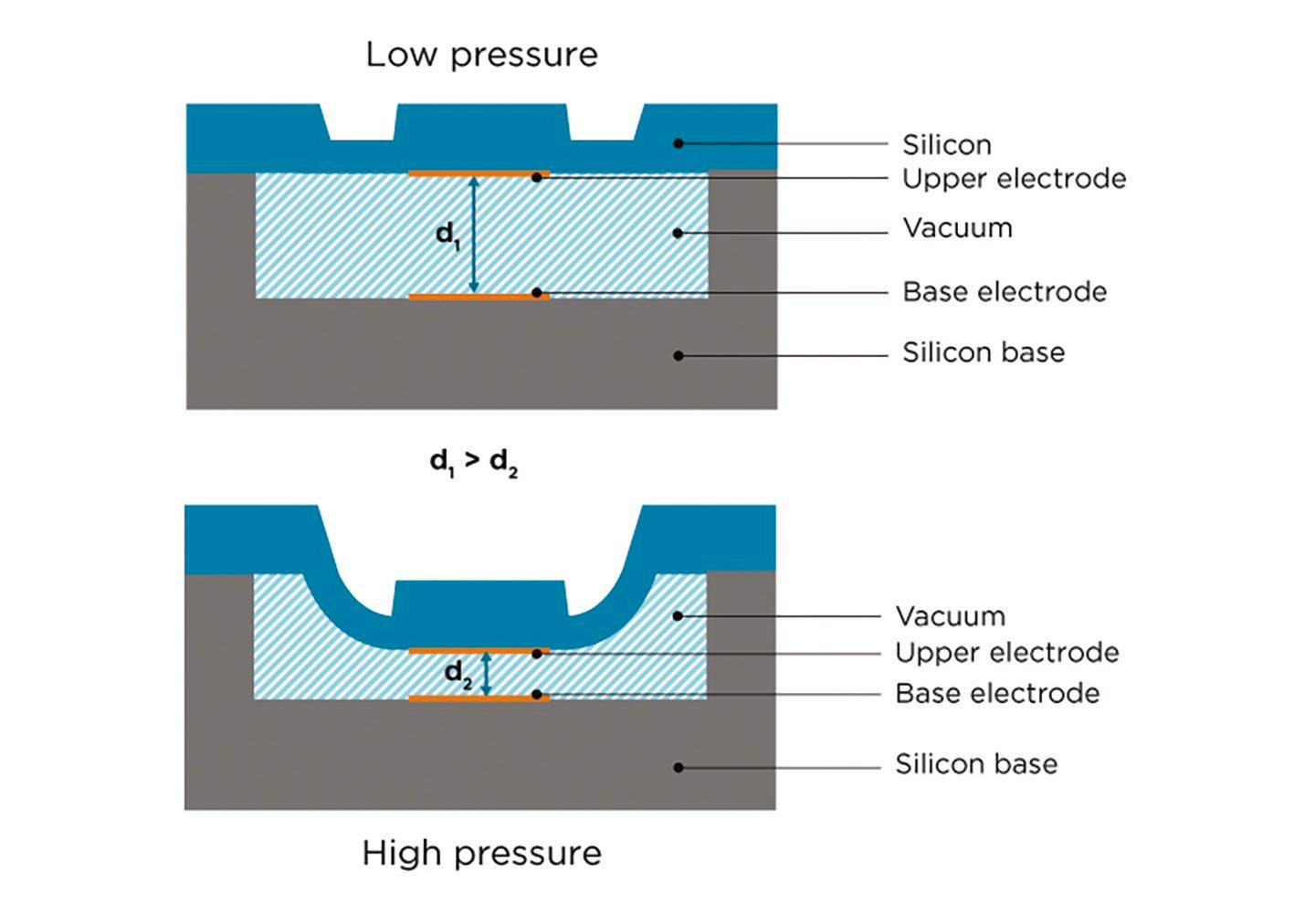

“The structure of Barocap is

very simple,” says Lin. “It is a micromechanical sensor that uses dimensional changes in its silicon membrane to measure pressure. As the surrounding pressure increases or decreases, the membrane bends, thereby increasing or decreasing the height of the vacuum gap inside the sensor. The opposite sides of the vacuum gap act as electrodes, and as the distance between the two electrodes changes, the sensor capacitance changes. The capacitance is measured and converted into a pressure reading.”

The sensor combines two powerful techniques for barometric pressure measurement: the capacitive sensor principle, and the use of single crystal silicon as the sensor material. “The Barocap sensor’s properties – good elasticity, low hysteresis, excellent repeatability, low temperature dependence, and superior long-term

The structure of the Barocap silicon capacitive absolute pressure sensor

stability – are the result of its singlecrystal silicon material,” Lin explains. “The capacitive structure gives the sensor its wide dynamic range and provides a built-in mechanism for overpressure blocking.”

To ensure high quality, the Barocap sensor is manufactured in Vaisala’s own cleanroom, where every assembled barometer goes through a thorough factory testing process covering wide temperature and pressure ranges.

“With the rigorous testing process, we can guarantee high accuracy as well as long term stability over wide and changing environmental conditions,” Lin adds. “This is essential for devices working in harsh outdoor conditions and demanding industrial applications.”

According to Lin, the company’s traceable calibration system also contributes to Barocap’s high performance: “Every Vaisala barometer is individually calibrated in the factory and the measurement

The capacitive structure gives the sensor its wide dynamic range

results are traceable to the international system of units (SI) through national metrology institutes like NIST USA and VTT MIKES Finland, or via ISO/IEC 17025 accredited laboratories.”

Vaisala’s Measurement Standards Laboratory (MSL) is an ISO17025 accredited calibration laboratory and it maintains traceability and provides high quality calibration services for pressure, temperature, humidity and CO2 concentration.

The lifespan of semiconductor equipment is typically between 10 and 20 years. “Vaisala barometers are extremely stable with typical annual drift of less than 0.1hPa, ensuring accurate and reliable measurements throughout their operational life,” Lin says. “Based on our experience, Vaisala’s barometers generally last between 15 to 20 years in the field, significantly reducing maintenance requirements.”

such as humidity and temperature. Vaisala combines pressure, humidity and temperature transmitters such as PTU300 to measure inlet air so that air density, humidity and temperature can be considered.”

The company’s Barocap sensors can also be applied within large marine vessel engine control and emissions optimisation, where the ship engine’s intake air is measured in real-time to optimise the engine performance. “In marine applications, an accurate, robust and reliable instrument that can tolerate harsh conditions such as high humidity and salinity, corrosion and vibration, is crucial,” Lin adds.

The company’s Barocap sensors are not only suited to applications on Earth, as International Design Engineer has previously reported. The Barocap sensors are installed on NASA’s Curiosity and Perseverance rovers, and are still sending data back from Mars after 10 years of operation on the Red Planet.

Aside from semiconductors, another important application area for barometric pressure measurement is the automotive industry, where Vaisala’s pressure instrument is used to measure the inlet air of combustion engines.

Lin explains, “This is an important part in the process of defining engine efficiency and emissions. Car manufacturers are simulating the engine’s performance in different conditions, including altitude simulation and other environmental factors

Looking ahead, Lin says the company plans to continue investing heavily in its research and development activities: “Pressure measurement is one of our core technologies and we will continue our investment in this area to maintain our technology leadership. There are plans to renew our barometer product platforms in the future. For example, the Indigo 500 series transmitter is our latest industrial-grade robust transmitter with modular plug-andplay design and smart sensor features. There will be more exciting new products coming soon.”

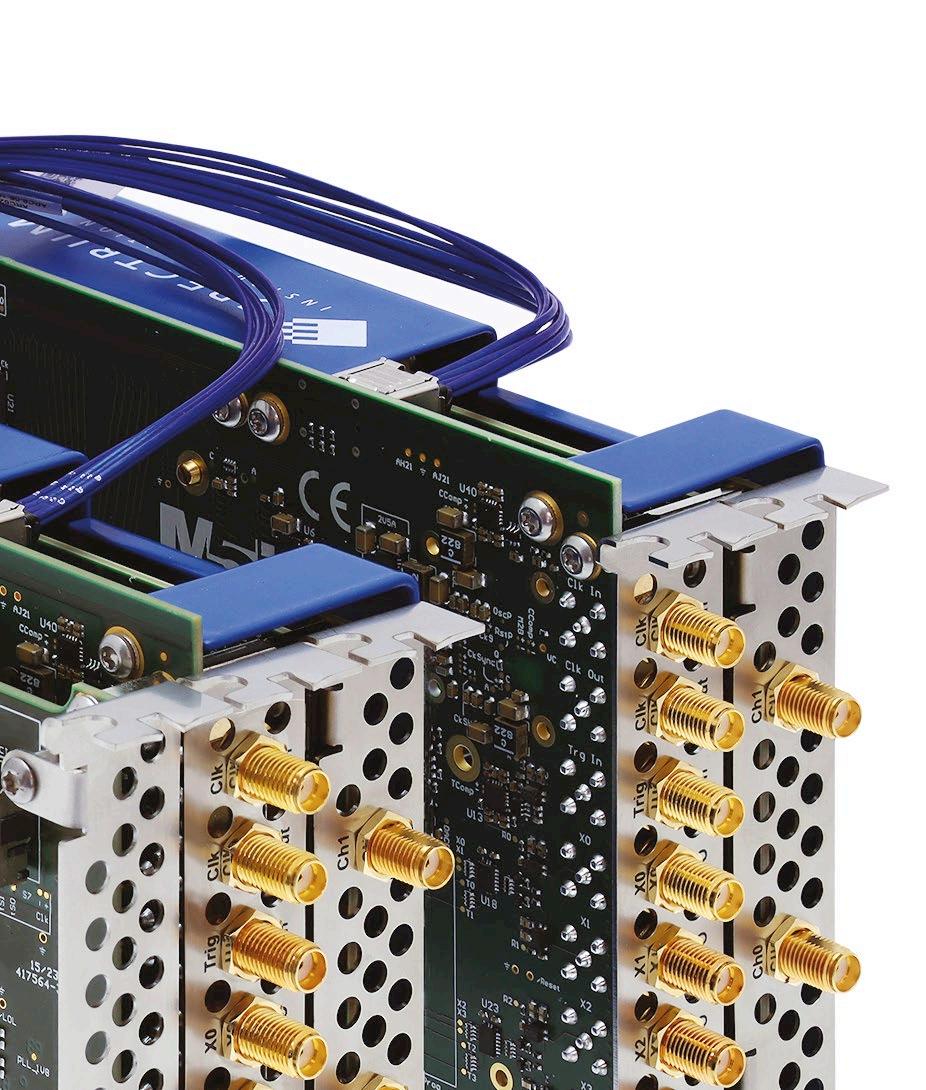

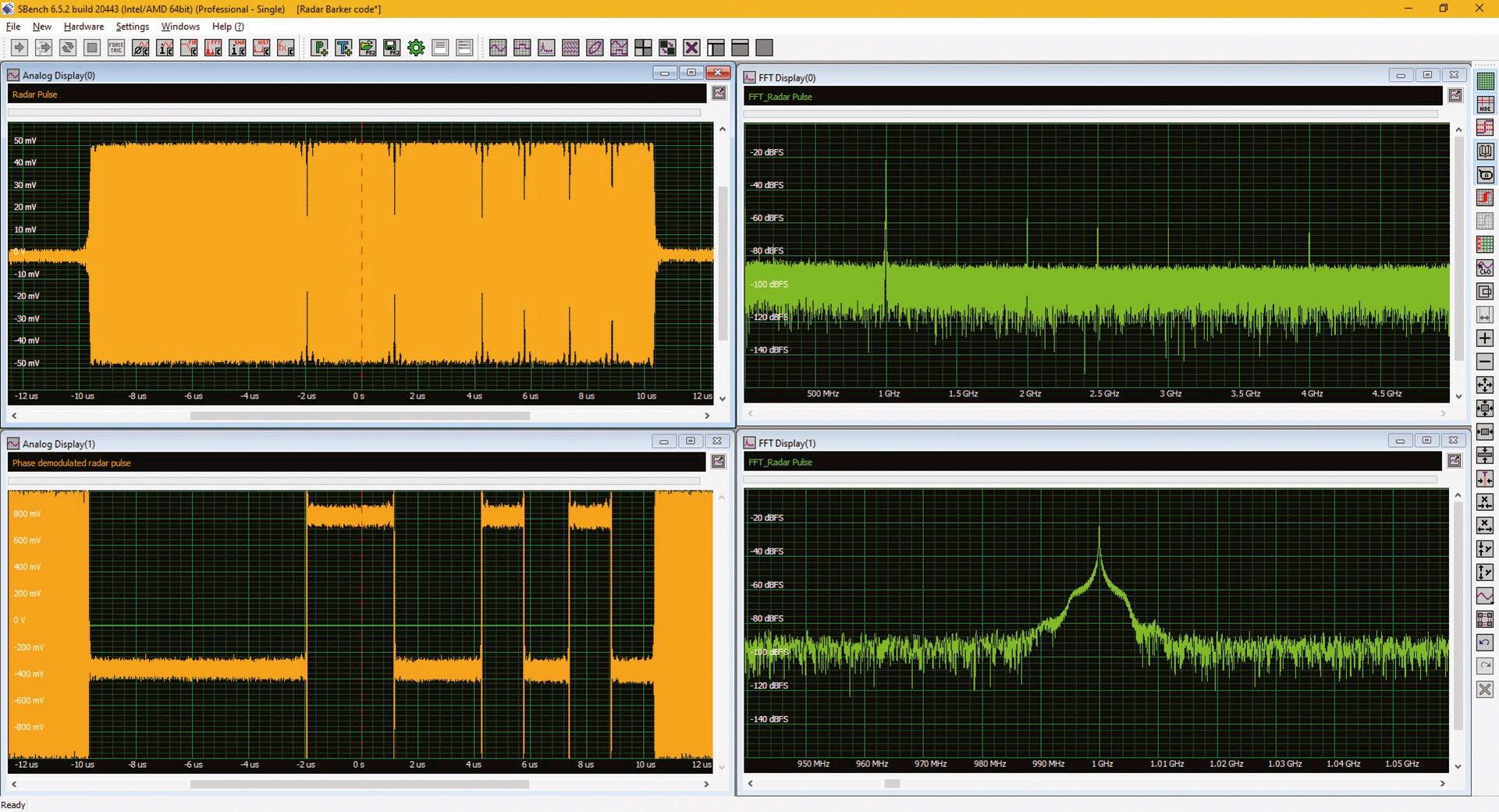

The brand new 10GS/s AWG with 16bit (rear), designed on the same M5i platform like the already established 10 GS/s digitizer series with 12-bit (front)

The M5i Star-Hub module, mounted on the left card. This option allows up to 8 AWGs or 8 digitisers to be synchronised by sharing a common sampling clock and trigger source

Combining a new series of ultrafast arbitrary waveform generators and digitisers for stimulus-response systems

In March 2022, Spectrum Instrumentation launched the M5i series platform, the first PCIe digitisers to use the full 16 lanes (Gen 3) of the PCIe interface, leading to enormous 12.8 gigabytes per second (GByte/s) data transfer rates. The following year the M5i. xx digitiser family was expanded, with new models offering ultrafast 10 gigasamples per second (GS/s) sampling speed and 4.7GHz bandwidth.

Now, Spectrum Instrumentation has used the M5i platform to design Arbitrary Waveform Generators

(AWGs) that offer up to 10GS/s signal generation. The series, called the M5i.63xx was launched last October. As a consequence, it is now possible to combine AWGs and digitisers, with ultrafast speeds up to 10GS/s, to create Stimulus-Response Systems and Closed-Loop-Setups with cost efficient COTS parts and normal PCs.

Capable of producing waveforms with bandwidths up to 2.5GHz, the new AWGs can turn any suitable PC into a powerful signal generation instrument. Four models make up

the new M5i.63xx series product line. Each one pairs exceptionally high bandwidth with matching digital to analogue converter (DAC) technology. The result is the family of AWGs offering bandwidths of 2.5 and 1.5GHz that output waveforms at rates up to 10, 5 or 3.2GS/s. All the units feature 16-bit vertical resolution, together with programmable full scale output ranges of ±1V (±500mV into 50Ohm). It is a unique combination in a PCIe instrument, with the M5i.63xx series delivering new performance benchmarks for waveform speed, precision and quality.

Built on the M5i series platform, first developed for Spectrum’s ultrafast 33xx digitiser line, the AWGs exploit proven design technology. All the products come with 2 GSamples of on-board memory (8GS optional) and high-speed data transfer using the 16 lane, Gen 3, PCIe bus. This ultrafast bus allows data to be sent to and from the cards at 10GBytes/s. When needed, data can even be streamed directly to the AWG for replay in a FIFO mode; a process that allows almost limitless waveform production.

Both the M5i series AWGs and digitisers are able to stream data directly to and from a GPU if Spectrum’s SCAPP driver package is used.

Waveforms can be replayed in a single-shot or repeated process, while multiple waveform segments can be output using the Multiple Replay mode, optimising memory efficiency. The different replay modes can also be combined with FIFO streaming. Waveform replay can be initiated by

a simple software command or via a trigger event. Trigger signals can be input on two external trigger lines.

Individual cards offer one or two output channels. If more channels are needed, it is possible to connect multiple cards together using the company’s proprietary Star-Hub clock and trigger synchronisation module. Star-Hub allows up to eight M5i.63xx AWG cards to be connected, to create systems with up to 16 fully synchronised channels. Each channel is then driven by a common clock and shares the same trigger. Using Star-Hub synchronised M5i.63xx AWGs, the user can build synchronous systems with output rates up to 16x5GS/s or 8x10GS/s.

For applications that require the connection of AWGs and digitisers,

like stimulus-response or closedloop test systems, M5i.63xx AWGs and M5i.33xx digitisers can be synchronised using direct clock and trigger connections. Digitisers and AWGs are available with matching speed grades of 3.2GS/s, 5GS/s and 10GS/s for easy integration. Using two of the Star-Hubs, one can combine up to eight AWGs, while the other links up to eight digitisers, setting up ultrafast MIMO systems with up to 16 Transmit and 16 Receiver channels of 5GS/s. The AWG-plus-digitiser combination is a powerful setup that can be utilised for a number of dynamic test applications. For example, to determine the frequency characteristics of wideband amplifiers or filters, or testing the response of electronic components and subassemblies under various conditions.

Our worldwide bestsellers

SERIES: M4i.66xx (5 models)

TYPE: PCIe x8 with 16 bit SPEED: 625 MS/s to 1.25 GS/s

CHANNELS: 1 to 4

Multi-tone DDS option available!

Generate almost any waveform up to 2.5 GHz! Continuous streaming from memory, CPUs, or CUDA GPUs!

2.5 GHz bandwidth 10 GS/s output rate 16-bit resolution

10 GByte/s streaming Up to 16 GB intenal memo y Free SDKs for Python, C, MATLAB, LabVIEW, etc.

Our stand-alone LXI/Ethernet-AWGs for mobile or rack use:

Our cost-effective mid-range AWGs with up to 24 V output swing

SERIES: M2p.65xx (14 models)

TYPE: PCIe x4 with 16 bit SPEED: 40 MS/s to 125 MS/s CHANNELS: 1 to 8

Our PXIe variants

SERIES: M4x.66xx (4 models)

TYPE: PXIe x4 with 16 bit SPEED: 625 MS/s to 1.25 GS/s CHANNELS: 1 to 4

SERIES: DN2.xxx (15 models)

TYPE: LXI-Ethernet with 16 bit

SPEED: 40 MS/s to 1.25 GS/s

CHANNELS: 2 to 16

SERIES: DN6.xxx (16 models)

TYPE: LXI-Ethernet with 16 bit

SPEED: 40 MS/s to 1.25 GS/s

CHANNELS: 6 to 48

Professor Yi Qin, department of design, manufacturing, and engineering management at the University of Strathclyde

Could machine-driven algorithms revolutionise the future of coating design? Jake Holmes finds out…

“Those familiar with the mechanical manufacturing sector will know of the great demand for tough metal components,” says Professor Yi Qin from the department of design, manufacturing and engineering management at the University of Strathclyde. According to him, this remains true when it comes to materials for complex engines. For these types of materials, coatings able to prevent the effects of corrosion, oxidations or other potentially damaging factors are crucial.

Qin and his department are responsible for the development of a new computer model which predicts coatings for specific applications for exact circumstances. The programme aims to remove the need for trialand-error testing of coatings for critical applications.

Hot forging dyes have gained popularity for engine moulding and metal components, but if a coating

is removed from this process the product life will be significantly shorter, he says. “Adding coatings is not just a mechanical need,” outlines Qin, “but also a business need, as shorter product lives will result in more expensive repairs and more downtime, leading to less productivity.”

Coatings in themselves are not necessarily a one-stop-shop answer to these concerns, however. Some coatings can contain toxic properties making them unsuitable for certain applications. Qin outlines the term “Green coating” to highlight coatings that do not have these toxic qualities and are safe for human interaction.

Green coating not only has application benefits but also environmental, as these coatings do not add to greenhouse gas emissions. These types of coatings are more sustainable and have the added benefit of being cheaper than counter coating.

The Technology and Innovation Centre at the University of Strathclyde

Qin’s research was made possible through the University of Strathclyde receiving a £600,000 fund from the European Union’s Horizon Europe fund. Being part-funded by the EU allows Qin and his team to access researchers across the continent to

Using the model can result in significantly reduced raw material waste, as the computer can tell the user the exact measurements which are required for making coatings

assist with research and progress the project faster.

“We can also gather all the experts we need from different countries,” Qin says. “Of course, another plus point is through the network, people exchange experience and also learn from each other.”

The team’s computer programme uses a material design approach, creating a design based on a given element. The design determines the properties of coatings. When the intended coating’s scale is completed, the programme will calculate and adjust its structure accordingly, whether for micro or nanoscale applications, or the largest available scale.

At the selected scale, the software can predict protein performance. When processing the coating, the model takes into account the design material to ensure its suitability for the material being applied. The programme can make further predictions on coating layers and identify suitable materials as substitutes after conducting initial coating analysis and making predictions.

This process can create a sample coating. The programme can make

characterisations of this coating, providing the model with an additional dataset to work with. While real-time data is being created, users search the dataset for different resources.

The model uses a massive data set to come to its conclusions. “All our effort goes into the data,” Qin says. “But of course, we need to update the data continuously, because that is what’s important. We use AI and machine learning techniques, and we have some experts in this project to focus on the data quality and also the creative side for the data management and then system, to ensure that there is enough data for us to use for discoveries.”

First, a demonstrator is selected to help create forging tools for forging dyes and cuttings tools. This is typically done for hard-coating proteins, as these tend to be more challenging. Coatings for such materials and tools must be able to withstand extreme conditions such as 900°C heat and dry cutting.

Qin explains: “Then, we go back to look at the product we’re predicting the coating for. Then comes design, then we think about the design alloys or coating, and even improve the

coating processes, and then optimise the coating layers and how they are combined with sub materials.”

The ultimate feature of any predictive computer program is if it works. With a programme that has too many variable outcomes to test them all, there needs to be a robust way of ensuring the algorithm gives reliable results and does not make costly or potentially dangerous mistakes.

“To make sure the model is accurate enough to give results that are reliable, we have a lot of modelling work, but there is also the parallel development,” Qin says. “This will have the validation processes which produce samples, numbers, validation, and maps, to tell us to verify models or improve models. There’s a lot of iterations developed and designed for this project.”

Despite Qin saying AI does not work as fast as people may expect, it is still significantly faster than using trial-and-error testing. The computer programme can significantly cut down lead times as it can assess and predict coating needs much faster than any other method, leading to reduced lead times and higher levels of productivity.

Another benefit of not having to test coatings through trial and error is less waste. Using the model can result in significantly reduced raw material waste, as the computer can tell the user the exact measurements which are required for making coatings. This is of massive benefit to industry, as this reduces the costs of coatings and allows companies to produce more coatings with the same quantity of raw materials.

Safety may also be an unforeseen positive side effect of the programme, as workers are no longer at risk of being exposed to toxic coatings. The programme can now predict what coating combinations are toxic, enabling workers to properly prepare with protective gear or select an alternative coating.

Sustainability is at the forefront of everyone’s mind. Being able to predict toxic substances and therefore avoid producing them will help to reduce greenhouse gas emissions and achieve a net zero status more quickly in the coatings industry.

Stefan Lindner and Markus Buckner explore how stainless steel is continuing to drive the future of automotive

In the race to build safer and more efficient vehicles, material selection could give designers the edge. The International Energy Agency (IEA) expects the global EV fleet to reach 250 million by 2030, and there is more interest in alternative fuels like bioethanol and hydrogen than ever. But even for petrol and diesel vehicles, sustainability is front of mind for a growing number of customers and manufacturers alike. To create new designs and components that satisfy both customers’ expectations and the physical requirements of future transportation, we must go beyond aluminium.

As part of this shift, we’re looking to redefine the role of stainless steel. It’s currently viewed as a specialist material solely for exhaust systems, but it’s underappreciated as a versatile option for many other areas of automotive design. In this article, we explore the advantages of stainless steel in the factory and on the road, with a focus on its formability, durability, safety, and recyclability.

Flexibility is the cornerstone of modern vehicle design. Whether for visual appeal or mechanical necessity, stainless steel allows for intricate and complex geometries without compromising structural integrity. Its diverse grades have adjustable ductility and hardness, often eliminating the need for multiple materials in a single project.

By optimising mechanical properties through temper rolling and strain hardening, a single stainless steel grade can achieve specific outcomes suitable for different

automotive applications. For instance, crash boxes, door-side impact beams, and EV motor components benefit from the material’s combination of rigidity and elongation. Folding techniques enable engineers to form origami-like structures that minimise material usage and simplify assembly.

With over 320 grade-surface combinations available, stainless steel surfaces can be aesthetically appealing without requiring additional coatings or treatments — as seen in vehicles like the Tesla Cybertruck and the iconic DeLorean, which incorporate them into both exterior and interior design.

Stainless steel has incredible longevity, even in the most demanding environments. Unlike carbon steel, which typically requires protective coatings, stainless steel is inherently corrosion-resistant and can selfheal via chromium oxidation, which reduces maintenance needs.

This resilience is particularly crucial for safety-critical components such as EV battery enclosures. EV battery trays made of stainless steel not only withstand the test of time, but also heat. Some stainless steels can endure temperatures of up to 1250°C for over

Stainless steel is inherently corrosion-resistant and can self-heal via chromium oxidation, which reduces maintenance needs

10 minutes with minimal deflection, significantly exceeding aluminium’s threshold of 660°C. This could provide crucial time for rescue teams to respond in cases of battery fires.

The high strength of stainless steel also enables the use of thinner sheets, reducing weight while maintaining performance. In one simulation involving buses, the use of highstrength stainless steel reduced total weight by nearly a ton.

High elongation properties combined with strain-hardening techniques allow stainless steel to absorb high crash energy, reducing the risk of injury to occupants during collisions. Whether it’s a race car, a bus, or a tractor, the material’s behaviour under impact can be precisely tuned to align with specific design needs. While its advantages in exhaust systems are well noted, stainless steel’s corrosion resistance extends to use in fuel tanks. With the increasing diversity of synthetic and biochemical fuels available, it ensures performance without the risk of leaks or failures caused by material degradation. For a completely different

perspective on safety, the anti-bacterial properties of stainless steel are of particular interest in a post-pandemic world. As car-sharing and automated taxiing services become more prevalent, materials that are inherently hygienic make a strong case.

Materials that promote sustainability across both the production and lifecycle of a vehicle are needed to make a deep impact on emissions. Aluminium is light and easy to transport, so its on-road emissions appear low. But it has faced criticism due to the carbon intensity of mining and refining bauxite, as well as the lower availability of recyclable aluminium scrap.

Stainless steels boast much higher recyclability, with European stainless steel stock having a staggering 85% average recycled content. With a production volume of around 1.9 million tons, Outokumpu achieved a recycled content of 95% in 2023. Outokumpu’s Circle Green goes even further, being made of up to 100% low-emission raw materials such as scrap and produced entirely

with renewable energy sources. This creates an unparalleled sustainability profile. With transparency on emissions across scopes 1, 2, and 3, vehicle manufacturers utilising Outokumpu’s materials can confidently communicate their reduced environmental impact to customers.

New types of vehicles — consumer cars, agricultural machines, public transport, and the new ways to power them — will require new ways of thinking. Stainless steel has the potential to change the game with its unmatched sustainability and sheer performance. A future of sleek vehicles that are not only aesthetically unbounded, but safer, stronger, and made with 100% recycled content and renewable energy, is within reach. If there ever was a time to shake up the traditions of the automotive industry, it’s now.

Electronics cooling is crucial in ensuring that electronic devices operate at their optimal capacity. In addition to averting system failure, proper cooling helps to extend the lifespan of electronic devices by preventing components from overheating and burning out, while maintaining their performance.

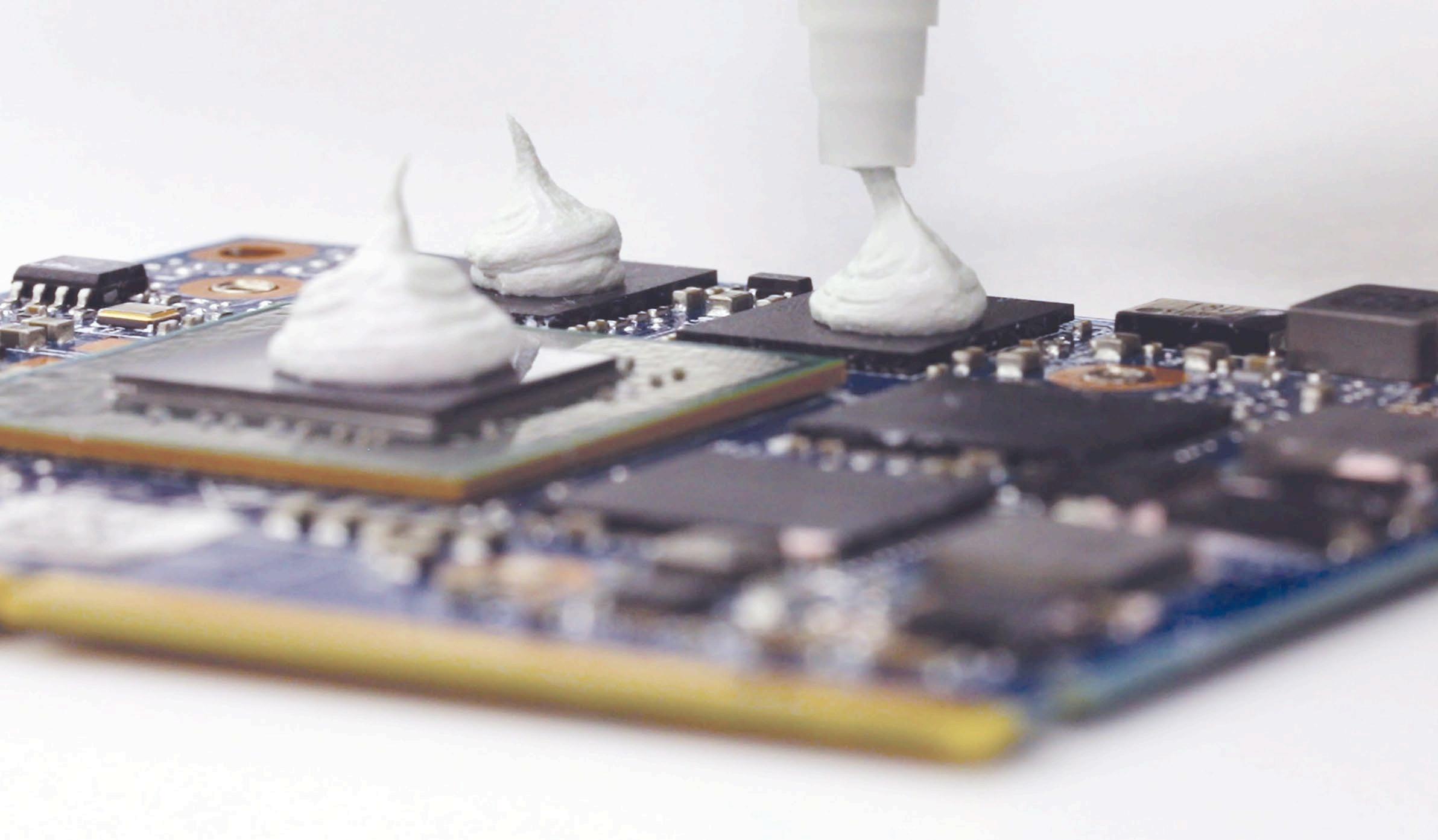

Thermal Interface Materials (TIMs) are designed to aid heat transfer and dissipation within electrical components by filling the gap between contact surfaces, therefore reducing thermal resistance and enabling more efficient cooling. In recent years, TIMs have continued to evolve, driven by market needs for high thermal conductivity, lower thermal impedance, new applications and lower costs.

The Chomerics division of Parker Hannifin Corporation has been active in this space for some time,

releasing its latest trio of TIMs in November at Electronica 2024. During the show, the motion and control technologies manufacturer showcased its new thermal cure-in-place (CIP) material, gap pad and dispensable gel products. Designed to maximise thermal management performance in demanding applications, the TIMs are capable of overcoming key industry challenges such as oil bleed, vertical tackiness and the limitations of hardcuring dispensables.

TIMs work by transferring heat away from electronic components and other heat-generating devices, and can also perform gap-filling duties in certain applications. One case in point is Parker Chomerics’ new Therm-a-Form CIP 60 cure-in-place material and thermal gap filler, says Phillip Ables, global product manager, DLM, in Parker’s Chomerics division.

The Therm-a-Form CIP60 cure-in-place material

The Therm-a-Gap 80LO high-performance thermal gap pad

“Our cure-in-place material allows manufacturers to assemble components for a more conforming fit,” he says. “In different applications, this can potentially reduce stress as well as improve the contact and reduce contact resistance between components. While being soft, the material has excellent adhesion properties. Additional benefits include a load deflection force design, flexibility, automated dispensing and assembly for higher throughput manufacturing.”

With its high 6W/m-K thermal conductivity, Therm-a-Form CIP 60 not only provides an appealing alternative to hard-curing dispensable materials in electronics cooling applications, but also offers an improvement over standard application methods associated with thermal gap filler pads.

“There are two components with the material: Part A and Part B,” Ables

says. “As the two components are dispensed they are mixed in the nozzle tip and dispensed on a substrate that connects a heat generating source to a heat spreader allowing for heat the be drawn.”

As a two-component material, Therm-a-form CIP 60 has an excellent flow rate and is dispensable in high volumes. The material offers vibration damping characteristics to meet the demands of challenging operating conditions, and requires no premixing or weighing of components. These properties make the material particularly suitable as a thermal fill material in applications requiring heat transfer in challenging or irregular geometries, such as cooling multi-height components on a printed circuit board (PCB).

Elsewhere, the material’s combination of high thermal conductivity, flexibility and easeof-use make it a good fit for use in automotive e-mobility systems such as converters and inverters, automotive infotainment systems like panel displays, head-up display (HDU) units and automotive advanced driver assistance systems (ADAS).

Also on display at Electronica 2024 was the company’s new Therm-aGap 80LO high-performance thermal gap pad, designed for applications where the aesthetic or manufacturing issues of silicone oils are a challenge. The compressible thermal elastomer features very low oil bleed and migration characteristics and offers a typical thermal conductivity of 8W/m-K. The pad is engineered to conduct heat in gaps between a heat-generating surface like a semiconductor or battery and a heatdissipating surface.

“The Therm-a-Gap 80LO pad was developed to be a highly reliable and long-term solution for missioncritical and high-performance electronics in nearly every market segment, including advanced computing, defence electronics, telecommunications infrastructure, and automotive,” says Ables. “LO in the product name stands for ‘Low Oil’, indicating the very low silicone oil bleed and migration properties of this gap pad. The pad has a

TIMs are essential for heat transfer away from electronic components

hardness of 60 Shore 00 and exhibits excellent stress relaxation over time, with a nearly 90% reduction in compression force after just one hour. It is designed to impart minimal stress on components such as integrated circuits and provide physical protection such as vibration dampening while maintaining effective thermal contact where conformability in gaps or rough surface texture is a concern.”

The third new TIM from Parker Chomerics is a high-performance dispensable thermal gel suitable for use in automotive sensors and devices, telecommunications modules, battery and energy storage systems (BESS), industrial electronics, and many other such applications. The single-component Therm-a-Gap Gel 75VT offers 7.5W/m-K typical thermal conductivity and vertical tackiness for use in demanding and mission-critical applications.

“Gel 75VT was developed to conduct heat away from electronics towards heat sinks or enclosures

and to perform reliably in vertical and/or high vibration applications,” Ables says. “The ‘VT’ suffix in the product name stands for vertical tackiness. During development, Gel 75VT was tested to a number of rigorous long-term reliability tests such as automotive vertical slump testing, high vibration testing, and telecommunications thermal material verification processes. The longterm reliability of Gel 75VT provides confidence for mission-critical applications that rely on consistent thermal performance over many years of continuous operation.”

The gel requires no mixing or secondary curing and is designed for easy application and rework. Taking ease of use one step further, the gel can be dispensed at various bond line thicknesses typically up to 0.16in (4mm) to take up gaps created by assembly or manufacturing tolerance.

Together, Parker Chomerics’ new TIMs are poised to optimise electronics cooling applications across crucial industries such as electronics, transportation and alternative energy systems.

These innovative fibre additives and functional composite fillers are derived from an unusual source: fruit waste. Here’s how circular economy processes are enabling more sustainable biocomposite materials

Founded in 2017, BioPowder is a producer and supplier of high-grade fruit stone powders and bio-based abrasives derived from fruit processing streams. The company pitches itself as a key part in a sustainable supply chain that converts excess organic material from the fruit industry into fully biodegradable ingredients for reuse in other sectors.

Not all plant-based ingredients are automatically sustainable, with renewables often coming from sources that involve industrial farming, and the use of agrochemicals and monocultures. While certain staple food crops such as corn and have been used as raw materials for non-food biomass products in the past, in the context of a growing world population and misallocation of food there needs to be a better solution, says BioPowder co-founder Kathrin Schilling.

“The ultimate goal is to produce end-products that allow manufacturers to generate the minimum environmental impact and maximum added-value in terms of technical properties and sustainable material design,” she says. “Within a bio-based composite, all of its constituents – the resin, fillers and reinforcing particles – can be biobased. Composites with a higher biobased content generally have a lower carbon footprint, specifically as less emissions are generated throughout the entire product lifecycle.”

Backed by decades of experience in the biomass processing industry, BioPowder’s small team takes excess fruit waste and converts it into fully biodegradable ingredients that can be used to form novel biocomposite materials with a wide range of industrial applications.

“We produce sustainable fillers, reinforcing powders and functional additives that composite manufacturers can use in their compounding processes to produce biocomposite materials,” Schilling explains. “To do this, we make socalled ‘performance particles’ from recycled olive stones.”

For centuries, olives have been an essential staple food in the Mediterranean region. Today, olive stones have become a sought-after filler material with added value for ceramics, coatings, composites, polymers, asphalt and bitumen. Besides adding a significant bio-based percentage to existing materials, they have strong binding and texturising capabilities, and have been proven to boost material resistance, tensile strength and lifespan.

“Olive stones are very hard and have very low density – only around a third of the density of conventional fillers,” Schilling says. “When they are incorporated into a bio-based composite, they can add significant strength and stability, while also offering lightweighting benefits

which are fundamentally important for parts and components within the automotive, aerospace or shipbuilding industries, where every gram of weight counts.”

Olive stones can also provide other functional and aesthetic benefits, too. “We can create very unique textures and surface effects such as anti-slip properties,” Schilling continues. “Not only is the resulting material fully degradable, but it is fully compostable in different environments and doesn’t require industrial recycling processes. Also, we shouldn’t forget that olive stones contain certain bioactive compounds that can deliver antioxidant and even antimicrobial properties to materials.”

Schilling explains the processes involved in converting olive stones

into useable biocomposite materials, which begins with the process of creating olive oil.

“When olives are pressed during the olive oil process, a solid residue or paste consisting of pulp shell and crushed olive stones remains,” she explains. “We separate the stones from the paste, as the stones are a hard lignocellulosic material which is truly multifunctional. In the past, it has been used as an alternative biofuel. Then, the stones undergo a process that we call micronisation, which involves drying the raw material and then carrying out several stages of milling, sieving and classification to produce particles in very defined micrometre ranges.”

The biocomposite market is very strict when it comes to particle size, she adds, because this determines the powder’s texture, flow behaviour, density and aesthetics. “When the powder is incorporated into composites, the micron range can have a huge impact on parameters like dispersibility, viscosity, elasticity and surface properties,” Schilling adds. At the end of BioPowder’s complex treatment process, pure, clean olive pit granules remain, which can be transformed into high-grade powders for use as fillers and additives in a wide variety of composite materials.

BioPowder’s whole approach is built on the circular economy concept, which represents a shift from the traditional ‘take, make, waste’ industrial model to a system that operates on the principles of reducing, reusing and recycling.

“Bio-based composites have a lower environmental impact than conventional composites because they are derived from plant-based raw materials, and they can also deliver better technical features,” Schilling says. “Our powders have been incorporated into a wide range of materials and applications as functional fillers, such as within the polyethylene, polypropylene, PVC, polystyrene and PU industries. These materials are often used within injection or extrusion-based manufacturing techniques for hightech parts within the automotive, shipbuilding and aerospace sectors,

Bio-based composites have a lower environmental impact than conventional composites because they are derived from plantbased raw materials

and for biodegradable consumer items and construction parts. The main incentive for these applications is lightweighting paired with high hardness properties, and of course the fact that our powders consist of 100% bio-based content.”

Another key application space is rubber composites, Schilling adds: “Our powders can be added to rubber or thermal plastic elastomer materials to reinforce them with added strength, resistance, or certain surface texture properties. We also have applications within the coatings market, ranging from protective coatings to floorings, to food coatings and bio-based leather alternatives.”

Going forward, BioPowder will continue to emphasise the importance of ensuring that resources are used and reused as efficiently as possible. Schilling concludes: “To be truly sustainable and forward-thinking, there should be a more holistic approach to composite production. There are hundreds of thousands of opportunities to make new types of composites, and the good news is that more and more of these are being derived from bio-based sources.”

How the UK’s largest automotive vehicle manufacturer has evolved its approach to composite design and manufacturing

Built upon two iconic British car brands – Land Rover, known for its premium all-wheel-drive vehicles, and Jaguar, for its luxury cars – Jaguar Land Rover (JLR) is recognised across the globe for its automotive manufacturing prowess. In recent years, the manufacturer has positioned itself as a leader in the transition to electric vehicles (EVs), with Jaguar becoming the first ever brand to offer a premium all-electric performance SUV, the Jaguar I-PACE.

One of the contributing factors behind the company’s success in the electric space thus far has been its approach to material and design, which has seen numerous projects lead to the development of stiffer and lighter vehicle structures for improved EV performance.

“Sustainable mobility is key for a net-zero future with battery electric vehicles (BEVs) playing a central role in this transition,” says Frédéric Sicard, technical specialist composite material and process at JLR. “However, vehicle

efficiency is driven primarily by mass, and BEVs are traditionally heavier than Internal Combustion Engines (ICE), which represent an engineering challenge. Composites can deliver weight-saving solutions compared to metals, but they usually come with a higher carbon footprint (CO2e). To balance vehicle weight, cost and CO2e targets, it is vital to optimise the use of such materials to improve the efficiency and performance of our vehicles, while preserving vehicle safety.”

At the beginning of 2018, JLR initiated the Tucana project – a three-year programme with the aim of making the UK a world leader in low-carbon technology. Leading a consortium of academic and industry partners, JLR sought to accelerate research efforts into advanced lightweight composites with the potential to deliver increased range, greater performance and a more dynamic driving experience for future BEVs.

“The Tucana project’s primary objective was to enable stiffer, lighter and more affordable design to BEVs by using composite materials, taking the rear body structure of a Jaguar I-PACE as an example,” says Sicard. “The R&D project came to a close in October 2021, achieving 30% uplift in torsional stiffness, 30% weight saving, a 65% part reduction and an estimated saving of 4.5 million tonnes of CO2e over a 10year use-phase thanks to the optimised composite design.”

The results of the project were impressive, with the innovative design receiving two awards: The 2021 Composite UK Award for Innovation in Composite Design, and the 2022 JEC World Innovation Award for Automotive and Road Transportation – Structural.

“From a digital design perspective, we used similar techniques and tools used by our engineering colleagues to develop future JLR products while applying these to composite materials characteristics,” Sicard says. “The design was initiated by conducting iterations

of topology and topometry optimisation to determine the optimum load paths. While more than 75 load cases were considered before completion, the optimisation focused on the three most relevant cases, including torsional stiffness and rear crash. As the digital work progressed, a testing and manufacturing campaign was deployed to validate materials and assess the processability and compatibility with JLR paint processes.”

In parallel to this, the digital design was refined with Design for Manufacture (DfM) inputs. “Key features and critical geometries were validated through physical experimentation using demonstrator tooling,” Sicard adds. “Specific tests were also performed on manufactured demonstrator components.”

In February 2021 JLR doubled down on its all-electric business with the launch of its Reimagine strategy. However, the Tucana project in its original concept was not meeting the company’s new sustainability ambitions, Sicard acknowledges: “Through Reimagine, JLR is looking holistically at sustainability and is transforming in an all-electric business,” Sicard explains. “JLR will be preventing the emission of millions of tonnes of CO2e by delivering electric models of all its luxury vehicles by 2030. JLR’s approach to addressing environmental impacts goes beyond tailpipe emissions, aiming to achieve a more resource efficient economy through reducing waste and repeated circulation of products and materials – use less, extend the life of what we have, and reuse wherever possible. With an updated approach to sustainable composites, efforts have been refocused on redefining our materials roadmap, bridging the sustainability and circularity gaps on materials.”

In particular, the company’s composite material roadmap has shifted towards sustainable and circular materials that display highperformance properties.

“The first and short-term milestone is the development of high-performance and low CO2 composite materials,” explains Sicard. “Learnings from Tucana highlighted virgin carbon fibre as the main contributor to the concept

The SOCA project focused on the performance and viability of sustainable material alternatives

As Sicard attests, historically end-of-life management and efficient recovery of composite materials have been challenging.

“In its original scope, Tucana presented difficulties regarding both dismantling and segregation,” he says.

“However SOCA, which aimed at decarbonising the manufacturing of composite components for automotive, offered a viable route to market for reducing the environmental impact of carbon fibre components. The adoption of material derived from SOCA would first target JLR current carbon fibre components with the goal of decarbonising their manufacturing. Then, they would match the end-of-life requirements and the current availability of materials in the supply chain. Longer term, as the supply chain scales up, the ambition is to roll this out on future JLR vehicles.”

The demonstrator showcased how the manufacturing of composite components could be decarbonised

CO2 footprint -or global warming potential (GWP) – therefore, we are looking at materials originating from recycled feedstock, natural fibre, or nonoil-based, as credible opportunities.”

With these circular economy principles embedded, JLR is now investigating technologies capable of reducing waste and energy, or enhancing the properties of these innovative sustainable materials whilst being careful of their compatibility with its final products and business case.

“Our latest Sustainably Optimised Composite Automotive (SOCA) project reused the Tucana design to investigate the performance and viability of sustainable material alternatives,” Sicard continues. “Following the same framework,

we collaborated with partners to manufacture the optimised load path, parts and completed the assembly of two full-scale demonstrators, exhibited at Cenex Expo and the Advanced Engineering Show in 2024.”

According to Sicard, the SOCA project demonstrated that the Tucana CO2 footprint could be improved by around 60% and compete with the original aluminium structure CO2-wise, while remaining lighter and stiffer.

“Results and learnings from projects like Tucana or SOCA are compatible with JLR sustainability and circularity ambitions, compliant with legal requirements and supporting the transition to a net-zero and BEV future, without compromising on quality,” he adds.

Three different versions of the spring and spool mechanism were designed

Jake Holmes looks at how one small fastener assembly has made a big difference to the user-friendliness of electric vehicle components

When people list off electric vehicle (EV) components, they tend to focus on crucial mechanical parts such as the battery, motor and electronic control units (ECUs). However, it can often be the less obvious components that make all the difference in how a customer perceives and experiences a vehicle.