A term that’s been bandied around the manufacturing industry for some years – sustainability in design engineering – is now shifting from an afterthought to a core design principle. Modern engineers are integrating lifecycle thinking, material efficiency, and circularity into every stage of product development—reducing environmental impact while enhancing performance and value. Advances in digital tools such as AI (see our cover story on page 6 for more), additive manufacturing (page 10), and simulation (page 26) now allow teams to optimise components for minimal waste and maximum durability.

Beyond compliance, sustainable design drives innovation, resilience, and market differentiation. As industries transition to net-zero targets, design engineers are uniquely positioned to lead by embedding sustainability at the heart of technical decisions, shaping a more responsible and future-ready engineering landscape. Our special feature on sustainable design (page 24) reflects this sentiment, as does our roundup of the latest green innovations within the fastening and sealing space on page 40. In this issue, we also report live from the factory floor of ABB’s net-zero Vaasa facility, where the company has expanded its range of SynRM motors to plug efficiency gaps in industrial motion (page 42).

Sustainability will also be a core topic of conversation at industry events over the next few months. For previews of what else to expect at SPS, Formnext and Advanced Engineering, flip to page 51.

Hayley Everett Editor

6

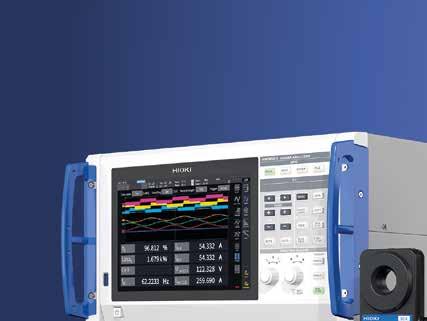

INSTRUMENTATION • ELECTRONICS

The road ahead

How the AI-powered drivetrain of the future will be developed using technologies emerging today

AUTOMOTIVE DESIGN

8

Future of battery tech

How designers can meet the performance and compliance demands of next-generation batteries

ADDITIVE MANUFACTURING

10 Legal landscape

Marks & Clerk’s updated whitepaper delves into the latest in technological evolution and IP in 3D printing

12

The role of radar in modern sensing and the benefits of sensor fusion

15 Sensor standards

How updated standards are changing the game in sensor positioning

19 Keeping commercial aircraft connected

How the 1553B standard is providing a data backbone for modern avionics

22 Raising the bar

How Piezocryst’s GaPO4 sensors are enabling reliable turbine performance

SPECIAL FEATURE: SUSTAINABLE DESIGN

24 The path to low-carbon manufacturing

Exploring the role of quality management in decarbonising the manufacturing industry

MATERIALS • PROCESSES • FINISHES

26 Hidden flaws

How molecular imaging is revealing hidden flaws in plastic electronics

30 Advances in a material world

Dr Aphrodite Tomou explains how Goodfellow continues to move the needle on the supply of advanced materials and metals

COMPOSITES

33 Excelling in efficiency

How GFRP composite tubes are helping to enable more efficient geothermal energy storage

36 Recyclable resins

Unlocking the future of sustainable composites in green energy

FASTENERS & SEALING

39 Small but essential Precision engineered check valves for demanding applications

42

40 Going green

Recent innovations driving sustainability in fastening and sealing technologies

MOTORS, DRIVES & CONTROLS

42 Transforming industrial motion

Reporting live from Vaasa, we explore how ABB’s expanding SynRM motor portfolio is helping to plug efficiency gaps

SKILLS ZONE

48 Training the next generation

Rounding up the latest initiatives transforming engineering education SHOW PREVIEW

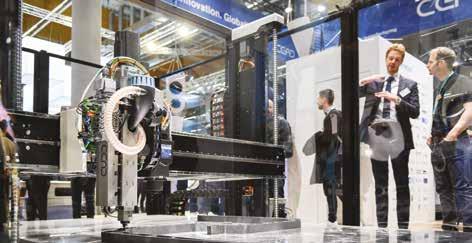

51 Bringing automation to life

SPS returns to Nuremberg 25-27 November

Returning to the AM capital

The ‘fAMily’ will meet in Frankfurt 18-21 November

Engineering’s next big leap

The 16th edition of Advanced Engineering takes place at the NEC 29-30 October

PUBLISHER

Jerry Ramsdale

EDITOR

Hayley Everett heverett@setform.com

DESIGN – Dan Bennett, Jill Harris

HEAD OF PRODUCTION

Luke Wikner production@setform.com

BUSINESS MANAGERS

John Abey | Darren Ringer

ADVERTISEMENT EXECUTIVES

Paul Maher, Iain Fletcher, Peter King, Marina Grant, David Pattison

e advertising@setform.com

CONTACT US...

t +44 (0) 207 253 2545

e mail@setform.com

Setform’s international magazines for engineers are published quarterly and distributed to senior engineers throughout the world. Other titles in the company portfolio focus on Oil & Gas, Design, Transport, Mining, Energy and Power.

The publishers do not sponsor or otherwise support any substance or service advertised or mentioned in this book; nor is the publisher responsible for the accuracy of any statement in this publication. ©2025. The entire content of this publication is protected by copyright, full details of which are available from the publishers. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior permission of the copyright owner.

Setform Limited | 6 Brownlow Mews, London, WC1N 2LD, United Kingdom

THE ROAD AHEAD

Developing the AI-powered drivetrain of the future

inverter is one of the building blocks of ZF’s Select platform

Reduction gears are essential for high-speed electric drives

An e-mobility expert tells Louise Davis how the AI-powered drivetrain of the future will be developed using technologies emerging today

When contemplating the future drivetrain, Dr Otmar Scharrer says that one thing in particular is becoming apparent: “The major trend is to include more parts and more features within the drivetrain,” he begins. Interestingly, he also firmly acknowledges the enabling role of AI in allowing companies such as ZF, where he is head of development for electric mobility, to respond to this trend. “There is nothing without AI: the future will be shaped by AI-based control of the electric drivetrain,” Scharrer emphasises.

Following a long career with the likes of Mahle, General Motors and AVL, Scharrer joined ZF in 2020. He describes his work today as being focused on “smart platforms for smarter mobility; a neuronal approach to powertrain innovation”. And, as Scharrer explains, this work can be illustrated by three recent advances from ZF that fall under this banner.

The first innovation is the Select e-drive platform, wherein ZF addresses the market for pure electric drive

technology. Scharrer describes this as “an inverter platform for volatile markets” – which is a good indicator of how ZF’s approach to future tech is being informed by current geopolitical and supply chain issues.

The new platform is designed as an all-in-one solution, comprised of modular kits for e-machines, power electronics, reduction gears and control software for e-drives. Clearly defined interfaces between components and the overall system simplify integration and production. The platform’s modular construction kits have been designed in a way that

There is nothing without AI: the future will be shaped by AI-based control of the electric drivetrain

ensures ZF can develop commercially attractive complete systems and play a leading role as a component supplier. Integrating four functions in one product reflects an important trend in drivetrain evolution. Ultimately, states Scharrer: “This high level of integration is a gamechanger for the next generation of charging solutions. And the smart combination of electric drive and brake is the future.”

The second future-focused launch from ZF is a new thermal management system, TherMaS, which the company says increases range by up to 10%. Highly efficient thermal management systems can extend the range of battery-electric and plug-in hybrid vehicles without the need for more expensive drivetrains or larger batteries. “The battery of an electric car in particular is very sensitive when it comes to its ideal operating temperature. It feels most comfortable between 15 and 25°C,” explains Scharrer. The ambient temperature

therefore has a major influence on the effective range of an electric vehicle. This is because on extremely cold or extremely hot days, the thermal management system is under greater strain, which leads to higher power consumption which can almost halve the available range. “Improving thermal management is therefore of great benefit to both the manufacturer and the driver,” observes Scharrer.

As another highly integrated system, ZF says that TherMaS is lighter and smaller than comparable variants, yet is more efficient and cost-effective. Using propane as a refrigerant results in better cooling performance, as well as a smaller and lighter system design. Commenting on this trend for smaller, lightweight solutions, Scharrer says simply: “Anything that can be left out will be left out”.

The third area of focus for Scharrer and his team is in hybrid solutions, where their interest lies in adapting to market dynamics by delivering greater flexibility. As the market for electrified passenger car drives evolves rapidly and hybrid solutions regain momentum, ZF is expanding its portfolio to meet growing demand. “Our approach here is illustrated by our new hybrid transmission concept ‘8HP evo’ with improved efficiency and performance,” details Scharrer. This concept is based on ZF’s successful eight-speed automatic transmission. The new 8HP evo offers efficient and flexible performance for

various hybrid platforms. From the outset, the current generation was designed according to the modular principle to support both conventional combustion engines and hybrid models. With the 8HP evo concept, ZF has improved the electrification and efficiency of the transmission. Improvements to the electric motors and power electronics are the main contributors to this – including software-side function updates that further exploit the potential. “The experience gained from our pure e-drive solution has been incorporated into these upgrades to our established benchmark product,” notes Scharrer.

An additional highlight of ZF’s hybrid approach can be found in its electric range extender systems

Dr Otmar Scharrer, head of development for electric mobility

for battery-electric platforms. The company is currently working on the next generation of these systems; the electric Range Extender (eRE) and the electric Range Extender plus (eRE+). Both variants are a highly integrated design that is flexible in terms of performance, electronics architecture, 400 volts or 800 volts and semiconductor type. The eRE combines an electric motor as a pure generator with an integrated inverter and a planetary gearbox. The system is controlled by ZF software. The eRE+ also has an intelligent clutch and a differential. This allows the electric motor to be used not only as a power generator, but also as an additional secondary drive, which enables manufacturers to temporarily use electric all-wheel drive without installing an additional electric motor. Power can be scaled for both models. “This modular platform approach allows us to respond to dynamic market and manufacturer requirements,” comments Scharrer.

In terms of how these drivetrain developments will be brought to market, Scharrer acknowledges that the future will likely be the same as the present: new technologies join the market in the premium segment and then gradually get rolled out to the mass market as they become cheaper. “I think the art of engineering will now be to connect these two worlds. To be as cost efficient as the compact class but to be equipped with features from the luxury sector,” Scharrer comments.

As electric vehicles (EVs), light means of transport (LMT) and industrial applications accelerate the demand for battery innovation, engineers and manufacturers face dual challenges: how to meet tightening regulations while pushing the boundaries of performance and reliability. A new wave of regulatory updates and AI-powered testing technologies is reshaping the battery development landscape.

This article explores how upcoming European Union (EU) battery regulations are driving compliancefocused design decisions, and how the integration of artificial intelligence (AI) in battery testing is enabling faster, smarter and more robust development cycles.

The introduction of the EU Battery Regulation 2023/1542 marked a significant shift in how batteries are designed, labelled and tracked across

How

designers can meet the performance and compliance demands of next generation batteries in preparation for updates to the EU’s battery regulations

their entire lifecycle. Effective as of 2023, the regulation enforces stricter controls on environmental impact, raw material sourcing, labelling and digital traceability.

“The EU launched its New Batteries Regulation to help ensure that future batteries have a low carbon footprint, use minimal substances and require fewer raw materials from non-EU countries,” explained Stephen Holland, quality, health & safety, environmental manager at Accutronics, an Ultralife company, in a recent thought piece. “The regulation is all-encompassing, covering everything from raw material sourcing to safe disposal.”

One of the most immediate implications for manufacturers is the requirement for CE marking and detailed labelling. Since August 18, 2024, all batteries must display a CE mark, and by August 2026, additional information including weight, category, origin and hazardous substance content, must also be clearly marked.

In his article, Holland notes

the challenge this poses for manufacturers: “If manufacturers are now required to list information as extensive as extinguishing agents, the label size will inevitably need to increase, even if the product stays the same. For example, many of our products come in a standard size, so we will need to rethink how we can present this information while complying with the updated guidance.”

Perhaps the most forward-looking element of the new regulation is the mandatory battery passport, accessible via a QR code, for LMT, EV and large industrial batteries (≥2 kWh) starting February 18, 2027. The digital passport will contain up to 28 pieces of information about the battery’s specifications, compliance and lifecycle.

“The QR code must be visible, highcontrast and indelible, either printed or engraved on the battery itself – or, if size prohibits, on the packaging or documentation,” Holland says. But

the details on implementation remain indistinct: “The current guidance is still vague on how the new QR requirements will be implemented… including what will be purely accessible, accessible only to notified bodies, and so on.”

This push for digitalisation aligns with a broader trend towards batteries no longer being considered just hardware, but data-rich assets that require traceability, intelligent testing and lifecycle insights. This is where AI comes in.

As battery systems become more complex and regulatory scrutiny increases, traditional methods for testing and designing batteries are no longer sufficient. Recognising this, Monolith, a leading AI software company for engineering teams, has partnered with UK-based battery testing firm CamMotive to revolutionise how EV batteries are

By August 2026, additional information including weight, category, origin and hazardous substance content must be clearly marked

tested and validated.

“Our partnership with Cam Motive has the potential to make EV battery development faster and more efficient,” says Dr Richard Ahlfeld, CEO and founder of Monolith. “Training machine learning models with robust, real-world date is what makes AI truly effective.”

At the core of the collaboration is a hybrid modelling approach which combines physics-based simulations with machine learning techniques to detect anomalies during battery testing. This enables engineers to identify complex failure modes that might be missed by traditional rulebased methods.

“Monolith’s AI technology allows us to use our state-of-the-art test facility more efficiently while generating higher-quality results,” adds Bruce Campbell, director of CamMotive. “The insights we gain through this collaboration will help us detect potential issues earlier, streamline workflows, and enable our engineers

to focus on delivering valuable data analysis for our customers.”

Using Monolith’s AI-powered Anomaly Detector and Next Test Recommender tools, CamMotive is already exploring how AI can reduce the need for physical testing by identifying likely points of failure before they occur. In addition to saving time, this shift in approach aligns directly with the regulatory demand for digital traceability and earlier fault detection.

Monolith’s platform allows engineers to reuse and learn from historical test data, enabling faster development cycles without compromising quality. “The platform analyses and learns from this information, using it to generate accurate, reliable predictions that enable engineering teams to reduce costly, time-intensive prototype testing programmes,” Ahlfeld says. By integrating Monolith’s AI with CamMotive’s real-world battery datasets, both companies aim to produce higher-quality insights and scalable testing strategies. This integration supports Monolith’s mission to halve product development cycles by 2026, which could be a gamechanger for companies facing tight timelines and strict regulatory scrutiny.

The combination of regulatory pressure and digital innovation is reshaping the battery development landscape. While companies like Accutronics are ensuring compliance with increasingly complex regulations, Monolith and CamMotive are pioneering how AI can streamline testing and validation.

“Device manufacturers can keep their production on track and adapt their processes ahead of time,” Holland says. “By working with an experience battery partner, you can stay ahead of the curve.”

As the industry looks towards 2026 and beyond, success will depend on a myriad of factors. Next-generation battery design will need to take into account compliance, traceability and intelligence, whether through clearer labelling, digital passports, or AI-driven test validation.

Materials innovation continues to underpin much of 3D printing’s growth

Marks & Clerk’s updated whitepaper delves into the accelerated rise of 3D printing, its technological evolution, and the intellectual property landscape in 2025

Since the publication of Marks & Clerk’s 2020 whitepaper ‘3D/IP: Intellectual Property in an Age of 3D Printing’, the additive manufacturing (AM) landscape has undergone transformative change. With adoption surpassing expectations and regulations beginning to catch up, 3D printing has moved from a specialist tool to a global production force, reshaping industries, supply chains and intellectual property (IP) frameworks along the way.

When Marks & Clerk released its original analysis in 2020, the 3D printing market was projected to reach $3.1 billion. However, the sector hit close to $12 billion that year alone according to the Protolabs 2024 Trend Report, and the industry is now on track to reach a significant $57.1

billion by 2028 – well head of previous forecasts for 2050.

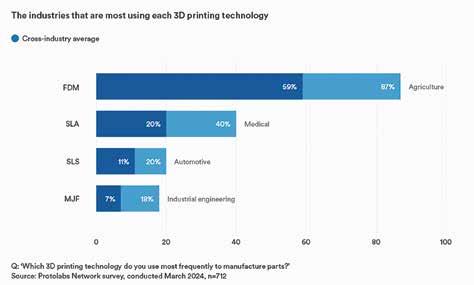

According to Marks & Clerk’s updated whitepaper, this explosive growth has been driven by broader industrial acceptance, significant material advancements and declining costs of hardware. Notably, sectors not traditionally associated with advanced manufacturing – like agriculture – are now among the highest adopters of 3D printing. In fact, 87% of agricultural businesses reported increased 3D printing usage in the past year, compared to a 70% average across sectors.

AM has evolved from a prototyping tool to an enabler of functional, end-use production across critical sectors. Early adoption in automotive, aerospace, and medical

industries has continued at pace. The European Patent Office (EPO) 2023 report confirms that health, transportation, and energy sectors dominate international patent filings. Applications range from custom implants and prosthetics to precision aerospace parts and energy-efficient turbines.

Additionally, new frontiers have emerged. 3D printing is increasingly used in construction (including experimental lunar habitats), fashion, and even food production. Sustainability has become a driver of innovation, with companies exploring recycled feedstocks, including ocean plastics, for consumer goods. Perhaps the most disruptive trend is the decentralisation of manufacturing. 3D printing enables production at the point of care (e.g. hospitals and pharmacies), on-demand part replacement (e.g.

The industries that are most using each 3D printing technology. Image via Protolabs

military and motorsport), and even fabrication in outer space. The European Space Agency and Airbus have tested a metal 3D printer aboard the International Space Station, successfully printing components in microgravity.

Materials innovation continues to underpin much of 3D printing’s growth. In 2020, polymers dominated, and while metal 3D printing hasn’t overtaken them yet, the metal AM market is now growing at nearly 30% annually, compared to 13% for polymers. This reflects increasing demand for high-performance materials tailored to specialised industrial applications. Additionally, blended materials and composites are being developed to meet stringent production needs, enabling more complex parts with better performance characteristics. These advances are expected to trigger further sector disruption and fuel patent filings in the years ahead.

As the cost of 3D printers decreases and their capabilities improve, production locations are changing, the report suggests. From localised print farms to in-house hospital fabrication, AM is becoming a core component of decentralised, just-intime production models.

In healthcare, for instance, custom

orthoses, prosthetics, and even personalised pills, are being printed directly in pharmacies or hospitals. In the automotive sector, companies like Babcock International are using 3D printing to rapidly produce replacement parts for military vehicles, often within days. Formula One teams now rely on in-house 3D printing for fast, lightweight prototypes and components.

The decentralised and digital nature of 3D printing creates major challenges for IP enforcement. A key concern highlighted in Marks & Clerk’s 2020 report was the proliferation of digital twins – 3D files that can be shared online and used to replicate protected designs without authorisation. Since then, the IP framework has begun to evolve. In 2022, the EPO clarified that software files used to operate AM devices – such as G-code – can be patentprotected, offering creators some resource against digital infringement. However, simpler 3D printing geometry files are still more difficult to protect under traditional IP law. Major strides have been made in design law, however. As of May 2025, the European Union (EU) updated its registered design legislation to explicitly include digital and non-physical products. The new definition of a ‘product’ includes items materialised in digital form, enabling IP holders to take action against unauthorised sharing of 3D print files.

Explosive Market Growth: From $12B in 2020 to a projected $57.1B by 2028.

Wider Adoption: Beyond aerospace and healthcare, 3DP is growing in agriculture, fashion, food, and construction.

Advanced Applications: Space-based printing, personalised medicine, and defence readiness illustrate the power of AM.

Legal Progress: The EU now recognises digital product forms under design law; the EPO allows patent protection of AM software.

Global Innovation: China leads in patent volume and materials innovation; Canada shows steady sectoral growth with strong government support.

This legislative change represents a critical advancement, particularly for designers concerned about file sharing in the 3D space.

According to the report, innovation in 3D printing is occurring across the globe, with China showing rapid growth in patent filings – from 2,000 in 2019 to over 5,500 by 2023. Chinese IP focuses heavily on new materials, multi-material systems and domain-specific applications such as aerospace and medical devices. Hong Kong, though smaller in scale, is becoming a hub for commercialisation and R&D collaboration.

Canada, meanwhile, is experiencing steady growth in 3D printing innovation, particularly in aerospace, automotive and medtech. Government support is strong: Federal initiatives like Ngen and IP-focused programmes such as Elevate IP and IP Ontario are providing funding for both R&D and IP strategy development. Canadian firms are contributing to cuttingedge technologies such as adaptive manufacturing – a blend of 3D printing and precision machining.

As 3D printing technology becomes further embedded in global manufacturing ecosystems, the importance of clear, adaptive IP frameworks is rising. For innovators, designers and manufacturers alike, staying ahead means embracing new materials and methods, as well as securing the digital rights that will ensure competitive advantages.

Sensor fusion enhances safety and performance in complex environments

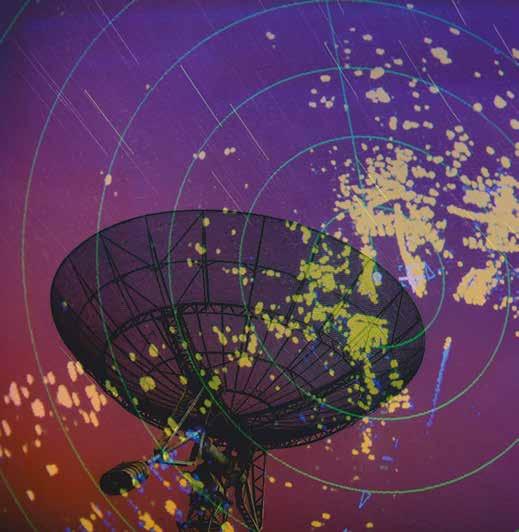

Radar has become an essential part of modern sensing systems

Dr Damien Clarke explains the role of radar in modern sensing and the benefits

In today’s rapidly advancing technological world, radar has become an essential part of modern sensing systems. Its robustness and reliability in challenging environmental conditions, such as fog, rain, snow, and darkness, make it an indispensable component across many industries.

Radar technology is recognised for its unique capabilities, particularly in applications requiring continuous, long-range, and accurate detection. However, radar alone cannot always provide a complete picture. This is where sensor fusion, integrating radar with cameras and lidar, emerges as

a powerful solution. Combining these different modalities allows systems to compensate for each sensor’s limitations, resulting in a more complete and reliable understanding of the environment. As Dr Damien Clarke from Plextek explores…

Radar functions by transmitting radio waves and analysing their reflections from surrounding objects. This process enables the detection of an object’s distance and relative velocity. Since radio frequency signals can operate in adverse weather and low visibility,

radar maintains its performance where optical sensors might fail. Radar systems are also capable of detecting motion, estimating speed using the Doppler effect, and classifying targets through unique micro-Doppler signatures caused by movement patterns like walking or rotating wheels. MIMO (MultipleInput Multiple-Output) radar, a more advanced form often developed for compact platforms, uses multiple transmitting and receiving antennas to estimate direction as well as range and speed. By processing signals from different antenna elements, MIMO systems can perform

beamforming to determine target direction more precisely. When implemented at millimetre-wave frequencies, these systems achieve high angular resolution within small form factors, making them suitable for applications like automotive safety and drone navigation.

Despite these strengths, radar technology does have limitations. Its spatial resolution is typically lower than that of optical sensors, making it harder to distinguish between closely spaced objects or identify fine details. Radar may also face difficulties in classifying certain objects, and its performance can be affected by multipath reflections in cluttered urban environments. Furthermore, while a MIMO radar can estimate a single (i.e. horizontal) angle, more complex antenna arrays are required to measure vertical angles as well.

To overcome these challenges, radar is often integrated with other sensors. Sensor fusion allows for a combination of radar with cameras or lidar,

offering a more complete situational picture. When radar is fused with a camera, the system gains the advantage of combining radar’s robust motion and distance sensing with the camera’s rich visual information. This is particularly useful in applications like autonomous driving, where the camera can read signs and traffic lights, while radar provides accurate detection of moving vehicles even in poor lighting.

Fusing radar with lidar adds another dimension. Lidar provides highly detailed 3D spatial information but can struggle in harsh weather or with low-reflectivity surfaces. Radar, which is not affected by these limitations, complements lidar by offering longerrange detection and better reliability under varied conditions.

The ultimate approach is to integrate radar, camera, and lidar into a unified sensing system. This tri-sensor setup leverages the

Sensor fusion allows for a combination of radar with cameras or lidar

strengths of all three: radar’s range and speed detection, the camera’s object recognition, and lidar’s spatial precision. This fusion enhances safety and performance in complex environments and is especially valuable in mission-critical systems such as autonomous vehicles and space exploration.

Sensor fusion does present challenges, including hardware complexity, power demands, calibration requirements, and realtime data processing. However, these difficulties are outweighed by the substantial benefits.

As radar technology evolves and artificial intelligence improves sensor data interpretation, these integrated systems will become increasingly capable. Sensor fusion is not merely a practical enhancement but a necessity for achieving robust, safe, and intelligent sensing in modern applications.

Markus Erdorf explains how the updated standard changes the game in sensor positioning and machine safety planning

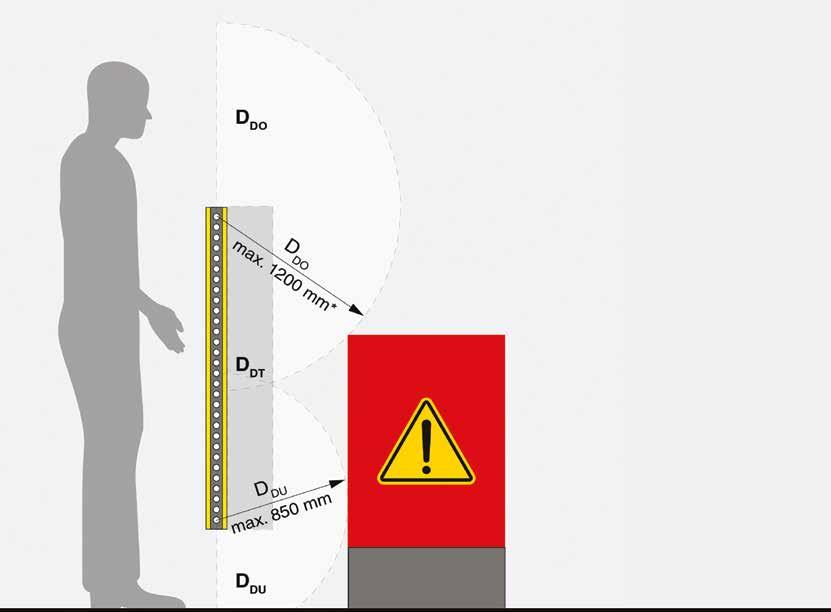

The value for DDO is a maximum of 1200mm and results from the ratio of the upper edge of the protective field to the height of the hazard area

At the end of 2024, the new version of ISO 113855 on the positioning of protecting devices on machines was published. The revised version contains amendments and additions to reflect the developments of recent years and the current state of the art.

The last valid version was published in 2001, around 15 years ago. That’s a long time in industrial automation, and a lot has changed in the meantime. Today, we are dealing with more flexible production systems, more mobile robots, and new operating concepts. The previous standard could only reflect this to a limited extent. We also looked at the incidence of accidents at work and derived normative consequences from this. ISO 13855:2024 is better suited to current technologies because it provides more precise specifications for the calculation of safety distances and,

accordingly, for the positioning of protective devices. It also addresses topics that were missing from the previous standard and adjusts existing values.

The calculation of the safety distance, previously referred to

as the minimum distance, has been revised and extended for the orthogonal, i.e. right-angled, approach of a person. This allows the safety distance to be determined more precisely. Specifically, the range DDS – previously referred to as safety distance C – is now determined on the basis of three criteria: Reaching over, reaching through and reaching under the protective field. The DDU (reaching under the detection zone) has been added and the DDT (reaching through the detection zone) has been extended by a formula. For the parallel approach of a person, the calculation has been simplified by the use of flat-rate values. The Z supplements, which result, for example, from the measurement inaccuracy of safety laser scanners or brake wear on vehicles, have also now been included. Another very interesting topic is ‘distances to safety-related manual control devices’ referred to as SRMCDs in the standards. The distances must now be calculated to

enable installation in a safe position. The introduction of the dynamic safety distance is intended for the future. This makes is possible, for example, to dynamically adjust the safety distance during robot movements depending on external conditions such as speed, braking distance and direction of movement. It has therefore become somewhat more complex to calculate the safety distance. On the one hand, this means more accuracy, but on the other hand it also means more responsibility for the users of the standard.

The Machinery Directive (MD) applies to manufacturers of machinery. This states that only safe machines may be placed on the market. Standards or harmonised standards exist to make this easier to prove. Even though the new EN ISO 13855 has not yet been harmonised, it reflects the state of the art and thus states how machines are correctly safeguarded today. It is therefore advisable to apply the new requirements immediately, regardless of harmonisation, as the MRL also references the state of the art.

Let’s think about a classic in industrial plants: Vertical safety light grids for access protection. In the previous version of the standards, two-beam safety light grids were only permitted

with a corresponding justification in the risk assessment. The use of these devices is now ruled out, as the distance between two beams has been limited to a maximum of 400mm in order to prevent climbing through. In addition, the value to prevent the light grid from creeping underneath has been reduced from 300mm to 200mm. The value against climbing over remains unchanged at 900mm, but these factors mean that at least three-beam safety light grids must be used in future. Manufacturers and operators must pay attention to this when selecting the required safety technology – Leuze offers suitable solutions here with its multiple light beam and safety devices in up to fourbeam versions.

The previous version of the standard did not actually take reaching under into account, only the value of a maximum 300mm of the lowest beam above the reference plane. In this respect, you could easily reach under a protective field with one hand or arm. From now on, the reach for reaching underneath must be determined so that the safety light curtain, for example, can be installed correctly. The now reduced value against crawling under also increases safety.

ISO 13855:2024 now explicitly addresses safety-related manual control

devices, such as SRMCDs. The term is defined more broadly in the standard, but mainly relates to the installation position of acknowledgement buttons. In the past, it simply stated, “the reset device must not be possible to access from the danger zone’ – the distance to a SRMCD – and thus in particular for acknowledgement buttons, must now be calculated. The calculated values may also end the previous discussion as to whether something in unachievable.

Experience here has shown that it is difficult to always know the current state-of-the-art given the large number of standards and directives and their regular revision. And then to also evaluate the machines according to the state-of-the-art. That is why Leuze offers a wide range of services to provide both manufacturers and operators with the best possible support. From simple safety inspections and follow-up time measurements, the complete, safetyrelated assessment of a machine park to the implementation of the safeguarding of a machine, including services and engineering, everything is included. We also recommend our practical online seminars, especially on the new ISO 13855:2024.

Marcus Erdorf is senior safety consultant at Leuze: www.leuze.com

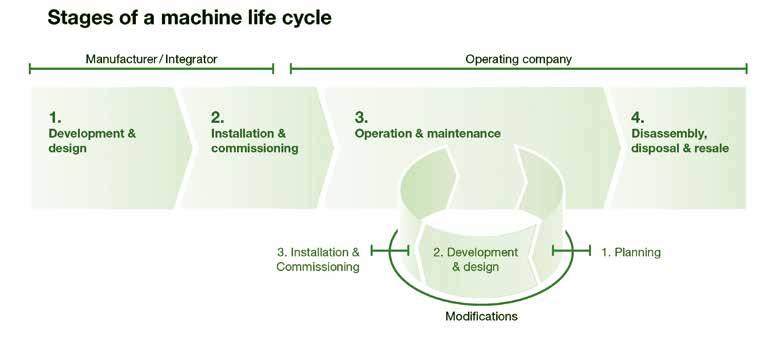

Sustainable machine safety begins with the professional planning of safety systems and extends over the entire life cycle of a machine

engineeringtectosisarecognizedpartnerandhas automotivebeenakeyplayerinthetestingworldfor20years: •Founded2004inGraz,Austria •50engineers/technicians/mechanics •In-houseprecisionmachiningandmanufacturing •4dedicatedengineandbalancingtestbenches •StrongNVHandacousticsexpertisefrom componentleveltovehiclemeasurement

Contactustodayandlettectos “Therefuelyoursuccess! is either a solution or we create one.”

Intel Core i7, XEON, Atom and more

20+ years repair support RUGGED

Temperature -40°C to +85°C

Fanless at full load

8 - 36 / 48 110 VDC

Up to 10Gbit ports

Open frame up to IP 6x

housing

OEM & customized solutions

EN50155 / IEC60945 certified

10+ years availability

How the 1553B standard is providing a data backbone for modern avionics

Commercial aviation relies on robust, deterministic communication between avionics systems. From navigation and flight control to engine health monitoring, these subsystems must exchange critical data without delay or corruption. The MIL-STD1553B data bus standard - first adopted in military aircraft - has proven equally valuable in modern commercial and business aviation, where safety, interoperability, and long-term reliability are paramount.

MIL-STD-1553B defines a dualredundant, time-division multiplexed serial data bus. This topology allows multiple systems to share a

The MIL-STD-1553B

data bus standardfirst adopted in military aircraft - has proven equally valuable in modern commercial and business aviation

common communication pathway while maintaining strict control over message timing and sequence. The redundancy ensures that if one channel is compromised, the other can maintain uninterrupted operation. Its immunity to electromagnetic interference (EMI), combined with proven operation in high-vibration and wide-temperature environments, makes it particularly well suited to the demanding conditions inside an aircraft.

In civil aviation platforms, 1553B networks are used to link:

• Flight management and autopilot systems for accurate navigation and efficient routing

• Engine and systems monitoring for predictive maintenance and reduced operational downtime

• Flight data recording for regulatory compliance and safety investigation

• Integrated cabin control systems for environmental, lighting, and service coordination

Its deterministic nature ensures that when milliseconds matter - such as in autopilot adjustments or engine fault reporting - the system provides information promptly every time.

For 1553B to operate reliably, it requires not just compliant cabling but also interconnect hardware engineered for signal integrity and environmental protection. Cinch Connectivity Solutions designs and manufactures connectors, contacts, and cable assemblies built to meet the exacting requirements of the 1553B standard. These interconnects are designed for:

• Controlled impedance and shielding to minimise signal loss and protect against EMI

• Environmental sealing to resist moisture, dust, and contaminants in unpressurised zones

• Rugged construction for consistent performance under vibration, shock, and thermal cycling

Cinch’s product portfolio for 1553B includes high-reliability twinax/triax connectors, terminators, adapters,

bus couplers, and cable assemblies optimised for long service life in avionics environments.

As an authorised assembler and distributor for Cinch Connectivity Solutions, PEI-Genesis configures and delivers 1553B interconnect solutions to match exact customer specifications. Assemblies are built to order, ensuring correct keying, plating, and contact configurations for each application. With extensive connector inventory and in-house assembly capabilities, PEI-Genesis supports short lead times and global delivery which are critical for aerospace maintenance schedules and production timelines. The combination of Cinch’s engineered components and PEI-Genesis’s rapid build-to-order process enables engineers to deploy fully compliant 1553B networks with confidence.

In commercial aircraft, 1553B cabling is typically routed through shielded, twisted-pair harnesses with terminations matched to system impedance. Connector selection is influenced by:

• Location within the aircraft (cockpit, avionics bay, wing, tail)

• Environmental exposure (pressurised vs. unpressurised zones)

• Maintenance accessibility for linereplaceable units (LRUs)

While Ethernet-based avionics networks such as ARINC 664 are gaining adoption for high-bandwidth applications, 1553B continues to play a critical role as a stable, safety-certified backbone. In hybrid architectures, it often handles flight-critical functions while higher-speed networks carry secondary data. With the rise of more electric aircraft (MEA) and advanced health-monitoring systems, 1553B’s predictability, ruggedness, and broad industry support mean it will remain an integral part of avionics integration for years to come.

The enduring presence of MILSTD-1553B in commercial aviation highlights the value of proven, deterministic communication in safetycritical environments. By combining Cinch Connectivity Solutions’ purpose-built 1553B interconnect hardware with PEI-Genesis’s rapid, build-to-order assembly and global supply capabilities, aircraft manufacturers and maintenance teams can ensure long-term reliability in their avionics networks.

The enduring presence of MIL-STD-1553B in commercial aviation highlights the value of proven, deterministic communication in safety-critical environments

• Uses deep learning for high accuracy in complex, variable environments.

• Highly adaptable, learning from new data to enhance performance.

• Thrives in uncertain environments, handling high variability.

• Scalable with no significant resource increase as production grows.

Piezocryst’s GaPO₄-based direct measurement technology offers a combination of thermal stability, hydrogen resistance and long-term reliability

As the energy and aerospace sectors accelerate toward net-zero emissions, hydrogen is emerging as a leading candidate for decarbonising gas turbines and aviation propulsion. Its combustion yields ner-zero carbon emissions, making it an ideal replacement for fossil-based fuels. But hydrogen’s extreme combustion properties – including high flame temperature, rapid flame propagation and complex transient behaviours – create a harsh and demanding environment for pressure sensors used in turbine development and monitoring. Conventional sensors struggle under these conditions, often producing unreliable data due to thermal drift, hydrogen embrittlement and sensitivity loss. This not only limits turbine performance optimisation but also compromises safety and the effectiveness of predictive maintenance strategies.

Enter Piezocryst, a sensor technology company by HBK, whose piezoelectric pressure sensors – based on singlecrystal gallium phosphate (GaPO4) –offer a new standard in direct, highfidelity combustion monitoring for hydrogen-fuelled systems.

Hydrogen’s appeal lies in its clean combustion profile, but this comes with technical challenges. For instance, flame speeds are up to 10 times faster than natural gas, increasing pressure fluctuation rates, while flame temperatures exceed 2,000°C, producing harsh thermal gradients. Additionally, hydrogen embrittlement degrades many common sensor materials over time, and high-frequency acoustic dynamics require sensors to capture detailed pressure waveforms in real-time without signal loss or distortion.

Traditional piezoelectric sensors

using quartz, ceramics or tourmaline fall short under these extremes. Quartz, for example, loses piezoelectric properties above 573ºC due to an α-β transition. Piezoceramics suffer from spontaneous depolarisation (also known as the ‘popcorn’ effect) and exhibit strong pyroelectric interference under thermal gradients. Tourmaline’s high pyroelectric response generates false signals during transient thermal conditions, rendering it unsuitable for precision combustion monitoring.

Piezocryst solves these issues by using GaPO4, a synthetic, single-crystalline material engineered specifically for high-temperature, high-vibration and chemically aggressive environments like hydrogen combustion. The unique properties of GaPO4 include:

• Temperature Stability: GaPO4

maintains a stable piezoelectric coefficient (4.5 pC/N) up to 1,000ºC, with no phase transitions or twinning effects

• No Pyroelectric Effect: Unlike ceramics or tourmaline, GaPO4doesn’t generate false signals during rapid thermal changes

• Hydrogen Resistance: Endurancetested to survive 100 hours in 100% H2 at 500ºC and 3 bar with no degradation in signal fidelity or gas tightness

Where conventional systems use remote sensing setups, such as standoff or infinite tubes, to mitigate the effects of temperature and gas exposure, Piezocryst’s sensors are designed for direct installation on combustor liners. This design strategy aims to eliminate uses such as signal attenuation due to tubing length or condensation, mechanical resonance from tubing variations, and thermal delays and accuracies from indirect measurement. Instead, Piezocryst’s sensors are engineered to provide real-time, unfiltered pressure data that supports advanced combustion tuning, safety systems and predictive maintenance analytics.

In a recent test, Piezocryst’s CP515 sensors were exposed to 100% hydrogen at 500ºC and 3 bar for 100 continuous hours. According to the results, pressure sensitivity remained stable (6.48-6.55 pC-psi) above datasheet minimums, while insulation resistance stayed above 1E+11 Ω, far exceeding the 1E+9 Ω threshold. No mechanical or gassealing degradation was observed after destructive inspection.

This robustness is critical for next-generation hydrogen turbines, which will require long-term sensor operations under severe conditions to validate combustion models, monitor thermoacoustics and ensure safety.

Piezocryst’s sensor portfolio is engineered with both robustness and versatility in mind. Regarding crystal orientation, the sensors are available in longitudinal mode (disc shape) for maximum vibration tolerance,

and transversal mode (bar shape) for increased pressure sensitivity. In terms of miniaturisation, sensor bodies as small as 5mm in diameter are possible, compatible with M5 or 10-32 UNF threads, making them ideal for integration in space-constrained turbine or aerospace environments.

The sensors are also designed to be multifunctional, with select models offering combined pressure, acceleration and temperature sensing, in addition to optional flame detection and ignition monitoring. This reduces sensor count, cabling complexity and system mass.

To ensure every sensor meets the demands of hydrogen systems, Piezocryst employs rigorous in-house testing methods:

• Laser vibrometry: Visualises membrane oscillation modes and detects unwanted resonance

• Thermal cross-sensitivity testing: Assesses sensor response to radiated heat compared with competing materials

• Material endurance trials: Evaluate long-term resistance to hydrogen

Piezocryst’s technology ensures precise hydrogen-powered engine combustion monitoring

embrittlement and dielectric breakdown

For example, GaPO4 sensors showed up to 10 times lower thermal sensitivity than ceramic-based sensors in side-byside comparisons, further reinforcing their reliability under fluctuating temperatures.

As industries shift to sustainable aviation fuel (SAF), ammonia and hydrogen, the demand for highaccuracy combustion monitoring will only intensify. Sensors must be able to cope in extreme, high-temperature, high-pressure, hydrogen-rich environments where the capabilities of conventional materials and designs currently fall short.

Piezocryst’s GaPO4-based direct measurement technology offers a combination of thermal stability, hydrogen resistance and long-term reliability. With over two decades of field experience in harsh conditions, the company is well-positioned to support the future of clean combustion and high-efficiency turbine design.

AI, the internet of things (IoT) and virtual reality (VR) are helping accelerate the shift towards zero-defects

Simon Francis, group quality director of G&P

Simon Francis, group quality director of G&P, explores the role of quality management in decarbonising the manufacturing industry, and explains how manufacturers can improve sustainability without compromising their operational and financial performance

In June 2025, the UK government published its Advanced Manufacturing Sector Plan as part of the wider Modern Industrial Strategy. The policy paper was designed to strengthen UK manufacturing and help the sector achieve its net zero and clean energy goals.

To align with the government’s new approach to sustainable manufacturing and supply chains, manufacturers are increasingly seeking new ways to decarbonise without compromising performance or cost. Indeed, managing sustainability with economic growth can be seen as a difficult balancing act when, in reality, they very often go hand in hand.

Reducing waste, improving energy efficiency and eliminating unnecessary material consumption are all key aspects of sustainable manufacturing, and are leading examples of decarbonisation pathways that also provide long-term financial benefits. One process with a central, but sometimes untapped, role to play in decarbonising manufacturing supply chains is quality management. However, by reducing process variation and improving product conformity, effective quality systems are proving to

be one of the most powerful enablers of sustainable manufacturing.

Fundamentally, quality management is about doing things right first time. It exists to eliminate errors and rework, alleviate waste forms and ensure consistency. In high-value sectors like automotive, aerospace and defence, even small defects can lead to a significant waste of correction, incurring unnecessary consumption of additional resources, materials and energy. By embedding quality early and consistently across the manufacturing supply chain, companies can prevent the need for activities that unnecessarily consume resources without adding value while also achieving operational, financial and sustainable benefits.

The advantages of operational excellence have been particularly visible in the UK automotive sector. According to data from the Society of Motor Manufacturers and Traders (SMMT), UK vehicle manufacturers have reduced CO2 emissions per vehicle by 61% since 1999, while also cutting water use per vehicle by

around 47%. Furthermore, in 2024 less than 1% of residual material generated by automotive manufacturing was sent to landfill. These improvements were not the result of a single sustainability initiative but of widespread adoption of lean manufacturing, process control and quality discipline, supported by strong Quality Management Systems (QMS).

In aerospace and defence, QMS require organisations to take a risk management approach to quality, integrating supplier oversight, process monitoring and corrective action frameworks into their operations. In doing so, these frameworks help firms reduce non-conformance rates, avoid excessive inventory and go a long way to preventing the need for high carbon logistics or remanufacture.

Digital technologies like AI, the internet of things (IoT) and virtual reality (VR) are helping accelerate the shift towards zero-defects. Realtime quality analytics platforms, IoT sensors and machine learning are enabling earlier detection of process anomalies and quality drift. These

As UK manufacturers increasingly pursue low-carbon strategies, the role of quality mustn’t be understated

systems can give manufacturers the ability to intervene before defects are produced and prevent unnecessary resource use.

Predictive analytics, another datadriven application, can identify the likelihood of future outcomes, reduce unplanned downtime and ensure optimal efficiency. High-speed, AIsupported vision inspection systems, like those utilised by G&P, further support quality control by detecting non-conformities at high levels of reliability and repeatability, reducing the likelihood of defective parts progressing further down the value chain.

In addition, manufacturers are increasingly using digital twin models and virtual manufacturing tools to optimise assembly processes before physical production even begins, improving factory efficiency and reducing both emissions and costs associated with wasteful operations. However, technology alone is not enough. Without clear operating procedures and defined quality checkpoints, even the most advanced technologies can quickly become ineffective. The real gains are made when quality thinking becomes embedded across the product lifecycle, from product design engineering and

supplier development, through the manufacturing process and to lessons learned from warranty.

At G&P, our own experiences reinforce the need to embed quality throughout product lifecycle. Through engineering, inspection and supplier development services, we support manufacturers in preventing the creation of defects or by efficiently controlling and reworking nonconforming products. This helps prevent costs and emissions associated with the additional materials, inventory, production and the transport needed to replace them.

Where components cannot be reworked, G&P’s deconstruction service provides efficient dismantling and recycling of sub-components. This enables manufacturers to accurately segregate materials and maximise resource recovery while minimising landfill disposal.

The sustainability benefits of this full-pipeline approach are apparent. Manufacturers working with a trusted quality partner can reduce scrap and rework activities, resulting in cost savings and significant reductions in

energy and raw material consumption. When applied consistently across suppliers and production lines, these savings can scale rapidly, emphasising the role of sustainability in achieving operational excellence.

As UK manufacturers increasingly pursue low-carbon strategies, the role of quality mustn’t be understated. It’s not simply a compliance activity, but a strategic solution to enable resource efficiency, reduce waste, enhance reliability and deliver lasting value. Government policy may provide the external motivation, and digital tools the means, but quality management provides a framework help bring these strategies to life.

For manufacturers looking to further embed sustainability into their operations, now is the time to assess whether the right quality systems, tools and expertise are in place. Partnering with a trusted quality management specialist can provide the independent perspective, technical capability and data-driven strategies needed - turning quality into a powerful driver of long-term, sustainable growth.

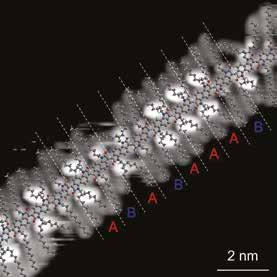

High-resolution STM image showing defects in the polymer sequence and backbone structure

Professor Giovanni Constantini from the University of Birmingham explains how molecular imaging is revealing hidden flaws in plastic electronics

Anew scientific study by the University of Birmingham has uncovered fresh insights into how plastic materials used in electronics are formed, and how hidden flaws in their structure could be limiting performance.

Conjugated polymers are a type of plastic that conduct electricity, often used in applications such as optoelectronics, computing, biosensors and power generation. Thanks to their lightweight and lowcost properties, coupled with their ability to be printed in thin layers onto flexible substrates, conjugated polymers are well-suited for use in next-generation technologies. During the study, the University of Birmingham team investigated a popular method for creating such polymers – aldol condensation –which is praised for being versatile, metal-free, environmentally friendly and scalable. Published in the Nature

Communications journal, the study’s results reveal that this method of synthesis introduces structural defects that could affect how well the polymer conducts electricity or converts heat into electrical energy in thermoelectric devices.

“The aldol condensation process can create defects in the polymer sequences, like missteps in a molecular dance, which can disrupt the flow of electrons through the material, reducing efficiency and reliability in devices,” explains lead author professor Giovanni Constantini. “Our findings could have wide-reaching implications for the development of high-performance, flexible, low-cost electronics and help reduce reliance on rare or toxic metals in manufacturing.”

According to the study, such defects, along with the secondary reaction

pathways that produce them, have not been previously considered because conventional analytical techniques are unable to detect them.

“Much of the success of modern synthetic chemistry is due to the availability of well-established and highly reliable analytical techniques such as mass spectrometry (MS), chromatography, X-ray diffraction (XRD) and what is often considered the ‘queen’ of chemical analysis, nuclear magnetic resonance (NMR),” says Constantini. However, for conjugated polymers, virtually all of these techniques are severely limited.

“The main challenge lies in the intrinsic tendency of conjugated polymers to aggregate,” he continues. “This aggregation (also one of the reasons why they perform so well in solid-state thin films – the basis for devices such as organic field-effect transistors and organic photovoltaics) leads to significant analytical complications. For instance, instead of

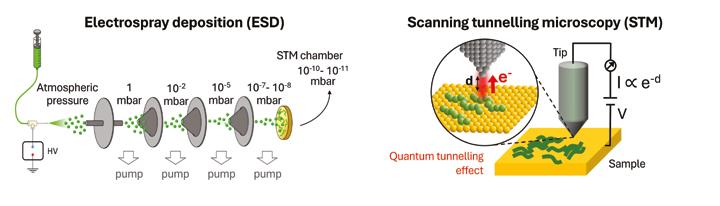

Schematic representation of the ESD process used to transfer conjugated polymers onto atomically flat, clean surfaces under high-vacuum conditions, and of the STM process used to image them with sub-molecular resolution

producing sharp, well-defined NMR peaks that allow clear assignment of chemical species, moieties and their environments, conjugated polymers often yield broad, uninformative signals. We jokingly refer to them as ‘potatoes’ because they cannot be assigned to specific chemical environments, essentially nullifying the analytical power of NMR in this context.”

According to Constantini, MS is equally problematic. “Conjugated polymers are inherently polydisperse in length – and therefore in mass –making it essential to determine their molecular weight distribution. Yet MS tends to overrepresent shorter chains (oligomers) resulting in unreliable distributions.”

Chromatography – typically in the form of gel permeation chromatography (GPC) – also falls short. “It requires calibration using standards (most often polystyrene) which has very different hydrodynamic properties from conjugated polymers,” he explains.

High-resolution STM image of an isolated conjugated polymer synthesised via aldol condensation, displaying sequence defects

“As a result, the mass values obtained are known to be inaccurate. Aggregation in solution can further distort the results.

Constantini adds, “X-ray diffraction, finally, is inherently sensitive to crystalline order. Since most conjugated polymers are only semicrystalline at best, XRD only captures a partial and often unrepresentative view of the material.”

To overcome these limitations, the researchers used a powerful imaging technique called scanning tunnelling microscopy (STM), combined with electrospray deposition (ESD) which allowed them to examine polymers at the molecular level.

“The combination of ESD and STM, which we have developed over the past few years, allows for the characterisation of conjugated polymers at the single-chain level,”

Constantini says. “This method provides sufficient resolution to determine, in many cases, the precise monomer sequence of individual polymer chains with subrepeat-unit accuracy. With this powerful technique, characterising a sample of conjugated polymers becomes conceptually straightforward and intuitive: One can directly inspect the TM images to determine sequence, chain length distribution and assembly behaviour – all through direct visual analysis.”

In practice, however, carrying out these

experiments is technically demanding, Constantini acknowledges: “We are currently one of the few groups worldwide with both the necessary equipment and, crucially, the expertise and experience to perform them reliably. The same applies to the analysis of the resulting data, which is often equally complex.

That said, we are actively working to automate various aspects of both image acquisition and analysis, with the long-term goal of transforming what is currently still a rather ‘exotic’ and technically intensive method into a more mainstream analytical technique. It is a highly challenging and ambitious objective, but one we are pursuing rigorously, particularly through recent collaborations with computer science colleagues to integrate machine learning approaches into the analytical workflow.”

The team studied four different polymers made using aldol condensation, discovering two main types of defects. The first, coupling defects, are like kinks or bends in the polymer chain caused by the building blocks connecting in the wrong orientation or position. The second, sequence defects, occur when the order of the building blocks is incorrect, like having two of the same blocks in a row when they’re supposed to alternate.

However, by adjusting the chemical design and purifying the building blocks before polymerisation, the researchers were able to significantly reduce the number of defects. One approach involved using aldol condensation to

create small, well-defined molecules, which were then linked using a different method – producing much cleaner polymer chains.

“By comparing the four conjugate polymers studied in this work, we found that the final polymer we analysed exhibited fewer sequence defects,” Constantini explains.

“This was also the only polymer for which the monomers were synthesised via aldol condensation, but the polymer itself was formed using a different coupling strategy, Stille polymerisation. As a result, chromatographic purification methods could be applied to the monomers, which is effective for small molecules but much less so for macromolecules. These purification steps evidently removed a significant portion of defective monomers, thereby reducing the overall defect content – specifically the types of defects introduced during aldol condensation – in the final polymer.”

However, this alternative approach introduced a new class of defects associated with the Stille polymerisation mechanism, Constantini admits, particularly homocoupling defects. These were not observed in the other polymers, which had been synthesised directly via aldol condensation.

“There are indeed strategies to minimise or avoid homocoupling defects in Stille polymerisation, and we have been part of an international team led by professor Wouter Maes at Hasselt University in Belgium that has explored such approached,” Constantini continues. “Unfortunately, these methods are synthetically demanding and not always practical. Moreover, despite its widespread use and reputation as a ‘gold standard’ for conjugated polymer synthesis, Stille polymerisation is far from ideal: It involves multiple synthetic steps and requires organostannane precursors, which are highly toxic and environmentally harmful.”

The team’s immediate goal is to further develop the ESD-STM methodology and apply it to obtain statistically representative sequences of entire populations of conjugated polymers. “This would provide a

type of information that has never been available before: A detailed, information-rich, monomer-resolved characterisation of polymer samples at the single-chain level,” Constantini explains. “Such data could offer unprecedented insights into the underlying synthetic processes that generated these samples.”

However, there still remains a large gap between synthesis and meaningful verification of the results: “In most cases, synthetic outcomes are judged solely based on the performance of a device fabricated using the polymer in question. Although, device performance is influenced by numerous factors unrelated to the molecular structure of the polymer batch. As a result, the

actual characterisation of the material remains minimal, and progress in the development of conjugated polymers often relies on trial and error rather than rational design.”

The approach taken by Constantini and his team aims to change this paradigm. “By using ESD-TM to acquire highly resolved structural data – and integrating this with quantum mechanical calculations and kinetic modelling – we aim to establish a feedback loop from characterisation back to synthesis,” he says. “This would, for the first time, enable synthetic chemists to refine their approaches based on detailed, sequence-level information about the resulting materials, thereby enabling a true rational design approach.”

Goodfellow continues to move the needle when it comes to the supply of advanced materials and metals, often involved at the start of some of the world’s biggest innovations. Dr Aphrodite Tomou explains

Agrowing emphasis on additive manufacturing, sustainable materials and cross-sector innovation are set to be some of the main discussion points when the Advanced Engineering Show opens its doors at the end of October (29th-30th). That’s the prediction of Dr Aphrodite Tomou, who heads up the technical department at Goodfellow, a global supplier of more than 170,000 advanced metals and materials and a specialist in certified reference materials (CRM) and expanded analytical services.

Over the last 12 months, her team of material specialists have noticed a definite increase in the use of 3D printing moving beyond prototyping into full scale-production, especially in aerospace, automotive and the medical sectors. They have also seen a rise in demand from designers for green materials like biopolymers, high-entropy alloys, shape memory alloys, reference materials and functional coatings, with buyers now prioritising traceability, sustainability and performance at scale.

“With 9000 delegates set to descend on the Advanced Engineering Show at the NEC in Birmingham, there really is no better place to get under the skin of new applications and, importantly, the materials that will be at the heart of the next innovations,” explains Dr Tomou, who was named as an Exemplar in The Manufacturer’s Top 100 competition last year. “Sectorsincluding fusion, aerospace, medical and battery tech - are all adopting new materials and, importantly for the domestic marketplace, there appears to be a genuine shift towards reshoring and just-in-time delivery. This is being driven by significant supply chain concerns.”

She adds: “Many of the technologies that will define the next 20 years, like quantum computing, hypersonic travel, and clean energy breakthroughs, will depend on materials that didn’t even exist a decade ago…that’s really

Goodfellow’s product range includes metals, alloys, ceramics, polymers, compounds and composites

exciting. What was once science fiction - materials that self-heal, adapt to environmental conditions, or conduct electricity better than copper - are now entering real-world applications. And these materials are no longer hidden enablers; they are strategic assets shaping global competitiveness and I’m sure we’ll be talking about them during the two-day show.”

2025 has been an exciting year for Goodfellow, with the acquisition of Suisse TP and Bureau of Analysed Samples increasing its certified reference materials and analysing capabilities. These deals build on the Huntingdon firm’s 170,000-strong product range, which includes metals, alloys, ceramics, polymers, compounds and composites.

Backed by Battery Ventures, the company has built a strong reputation as a trusted supplier to firms involved in R&D, advanced engineering, space and the scientific sector, with subsidiaries across Europe, North America and China helping it extend its global reach. The material specialist also provides a range of post processing facilities, including rolling, electroplating, sputtering, heat treatment, disk punching/turning and guillotining/sawing.

In addition to exhibiting at Stand R195 at the Advanced Engineering show, Goodfellow will also be one of the main sponsors of the AM2 Forum and will be live recording its latest “Innovation Discussed” podcast direct from Birmingham.

l

l

l

l

l

l

l

l

l

l

l

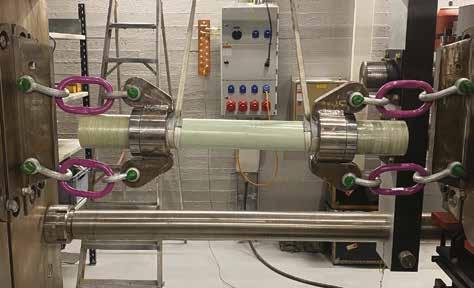

How GFRP composite tubes used in one R&D project are helping to enable more efficient geothermal energy storage

Composite tubes, such as glass fibre-reinforced polymer (GFRP), offer significant benefits in geothermal energy storage due to their corrosion resistance, long lifespan, and ability to be tailored for underground applications. Global composites manufacturer Exel Composites has recently completed a research and development project with geothermal technology specialist QHeat in this area, suppling composite tubes to store excess heat energy at the Lounavoima waste incineration plant in Salo, Finland. The project’s simulations suggest the GFRP tubes can enable plant operators to store 14GWh of heat in underground wells two kilometres down in the granite bedrock.

In the context that half of global energy use is for heating, we see the environmental gains that electrification of heating can provide

Prior to installing a heat storage system, the Lounavoima plant released its excess heat into the air during the summer. When ambient temperatures fell to -20°C in the Finnish winter, its emissions increased because of the supplementary oil burners needed to supply heat at peak times. The energy saved by improving the plant’s storage efficiency equates to the heating requirements of 700 detached houses per year.

“60% of all EU heat production comes from fossil fuels, and the remaining 40% is still mostly combustion, like natural gas or waste incineration,” explains Erika Salmenvaara, CEO at QHeat. “In

the context that half of global energy use is for heating, we see the environmental gains that electrification of heating can provide.”

However, this process isn’t perfect, Salmenvaara continues: “Electrification of heating puts significant strain on the world’s ageing power transmission infrastructure, but innovative engineering can help there too. Grid-enhancing technologies are advancing rapidly and, besides, heat pumps deliver up to 600% more energy efficiency than using electricity directly.”

Exel Composite’s R&D department worked closely with QHeat’s engineers to tailor the composite tubes to the job’s specific environmental and performance requirements. The two teams went through several iterations, optimising for sizing, connection methods, and thermal insulation versus mechanical strength tradeoffs. GFRP is well-suited to the pressure and temperature involved with underground applications. The partnership between the two companies focused heavily on the material’s insulating capacity to ensure energy efficiency in heat transfer was as high as possible.

“GFRP offers significantly higher strength than plastics, which alone might provide good insulation but would not be strong enough for this application,” adds Tiina Uotila, technical sales manager at Exel

Composites. “The combination of corrosion resistance, structural strength and thermal insulation makes GFRP a very suitable choice here. In this case, the material provides both insulation and structural benefits without a trade-off.”

“Heat preservation combined with the right mechanical performance was the biggest criterion to satisfy with these pipes,” Uotila adds. “However, we collaborated with QHeat to understand how we could make them easier to assemble and install, and to make sure that we have a defined, sustainable end-of-life route.”

Rather than going to landfill, the pipes will now be co-processed into

cement, where the reinforcement replaces raw materials and matrix replaces fuels.

“I was impressed that Exel Composites’ head designer came on site with us in Salo to see the first pipes installed,” Salmenvaara says. “I also had the chance to visit Exel’s Mäntyharju factory in Finland. Then I understood its expertise, design capabilities, and the quality of its products.”

According to Uotila, “This first project is only the beginning. Geothermal energy has the potential to reduce the reliance on burning fossil fuels or biofuels for heating in many countries, offering a strong contribution to net zero goals.”

This first project is only the beginning. Geothermal energy has the potential to reduce the reliance on burning fossil fuels or biofuels for heating in many countries

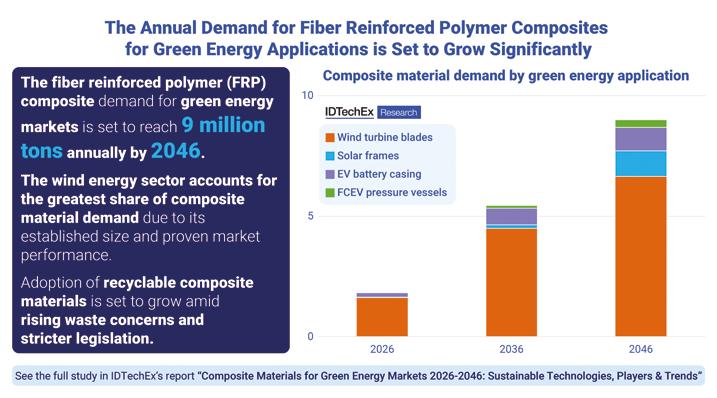

The annual demand for fibre reinforced polymer composites for green energy applications is set to grow significantly

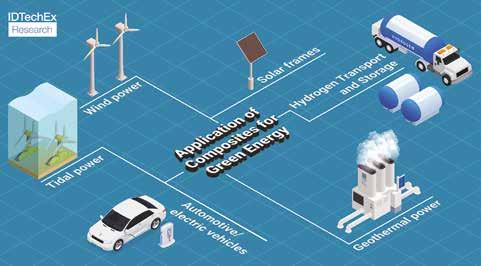

As the global energy transition accelerates, the demand for highperformance, lightweight materials is surging across wind power, electric vehicles (EVs), hydrogen infrastructure, and solar power systems. Composite materials – particularly fibre-reinforced polymers (FRPs) like glass fibre (GFRP) and carbone fibre (CFRP) reinforced systems – have become indispensable in these sectors. Their strength-to-weight ratio, corrosion resistance and design flexibility are enabling critical green technologies such as longer wind turbine blades, lighter EV bodies and pressureresistant hydrogen tanks. However, as usage scales, so does a less discussed issue: the growing environmental cost of composites at end-of-life. Most FRPs are currently incinerated or end up in landfill sites, contributing to an emerging waste crisis and threatening the

long-term sustainability of such sectors. This has intensified the push for recyclable resin systems, which market analysis firm IDTechEx sees as a transformative innovation that could redefine composite lifecycle management and material circularity.

The firm’s recent report Composite Materials for Green Energy Markets 2026-2046: Sustainable Technologies, Players & Trends, investigates the solutions driving sustainability in this space. The findings provide a 20-year outlook, detailed analysis of resin chemistries and technical insight into recycling pathways that could enable truly circular composite ecosystems.

According to the report, the root challenge lies in the thermoset resins commonly used in FRPs. Once cured, these resins form permanent covalent bonds that give them outstanding chemical and mechanical stability.

But this same cross-linked structure makes them impossible to remelt or reshape, locking them into a singleuse lifecycle. Breaking these bonds requires high-temperature thermal processes or harsh chemicals, both of which are energy-intensive and often result in degraded materials. As a result, the majority of composite waste is mechanically shredded into lowgrade fillers, incinerated, or landfilled. This issue is becoming especially urgent as early renewable energy infrastructure reaches the end of its operational life. Wind turbines, for example, are typically designed for 2025 years of service, Now, many of the first-generation blades are entering decommissioning, creating thousands of tons of unrecycled composite waste. Further complicating recycling is the complexity of composite structures. Modern FRPs are not simple two-material systems – they integrate fibres, foams, adhesives, coatings and multiple resin types,

The green energy applications of composites making disassembly and separation extremely difficult. Compounding this, traceability is poor. Few composite products include digital passports or detailed material documentation, making it nearly impossible to identify suitable recycling methods at end-of-life.

To address these issues, the industry is developing new recyclable resin systems designed with end-of-life in mind. These fall into two broad categories: thermoplastics and recyclable thermosets.

Thermoplastics such as polypropylene (PP), polyethylene terephthalate (PET) and highperformance polymers like PEEK soften when heated and can be reshaped and reused, making them inherently recyclable. Companies like Arkema have pioneered thermoplastic composite systems for structural applications. However, thermoplastics face limitations.

“Their relatively lower chemical resistance and susceptibility to creep under long-term load make them less suited for high-demand sectors like wind energy,” the IDTechEx report notes. These drawbacks have limited their adoption in structural green energy components, though continued development is underway to close these performance gaps.

Recyclable thermosets, meanwhile, aim to retain the mechanical advantages of traditional thermosets while enabling controlled disassembly or reshaping. This is

achieved through cleavable bonds or dynamic covalent chemistries. One of the most promising innovations in this area is vitrimers – thermoset materials that allow bond exchange at elevated temperatures without complete depolymerisation. This allows for reshaping or repairing, providing a middle ground between thermosets and thermoplastics. Companies such as Wastlake Epoxy and Techstorm are developing vitrimer systems for applications like wind blades.

Other technologies include cleavable resin systems that break down in specific chemical environments. Notable examples are Swancor’s EzCiclo and Aditya Birla’s Recyclamine, both of which have seen pilot-scale commercial deployment. These resins offer dropin compatibility with conventional manufacturing processes, easing the transition towards sustainability.

However, challenges remain.

“Even with advanced chemistry, recycling often results in downcycled thermoplastics, limiting reuse in high-performance applications,” the report says.

Innovative resins alone aren’t enough, the report states, inferring that recycling infrastructure and techniques must evolve to recover value from these new materials. IDTechEx highlights three main pathways to achieve this:

• Mechanical Recycling: Simple and

While recyclable resin technologies are still maturing, regulatory pressure is creating urgency and opportunity

low-cost but results in reduced fibre length and strength, often used for non-structural fillers