ADAPTABLE ANATOMY

Learn about the latest dry granulation innovations available only on GERTEIS® roller compactors. Introducing our cutting-edge In-Line Density Measurement Solution, the new Ultra Small Amount Funnel and the Design of Experiments Software Feature!

PAT: In-Line Density Measurement

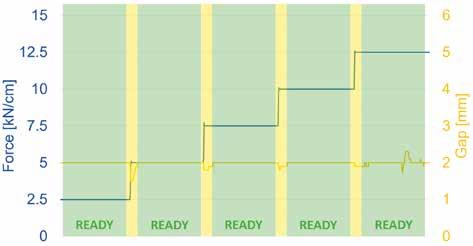

Real-Time Insights: Say goodbye to off-line testing delays. Our system provides instant density measurements during production, allowing timely adjustments and informed decision-making.

High Precision: Accurate density data is key to robust process control. Whether you’re scaling up or down, our system ensures reliable results.

Closed-Loop Feedback: Linking density measurements to process parameters enables dynamic adjustments. Stay ahead of variations and maintain product consistency.

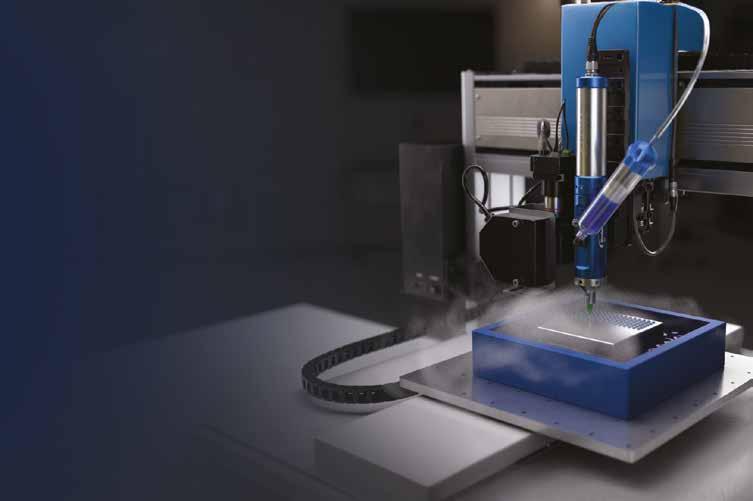

Design: Ultra Small Amount Funnel

Ideal for Small Batches: Process materials with as little as 10 grams of product — perfect for laboratory development and pilot projects.

No Residuals: Almost no product remains in the equipment, making it an excellent high yield small amount option.

Ease of Use: The funnel seamlessly integrates with the compaction unit of the Mini-Pactor, providing the same superior performance you would find in a full scale production machine.

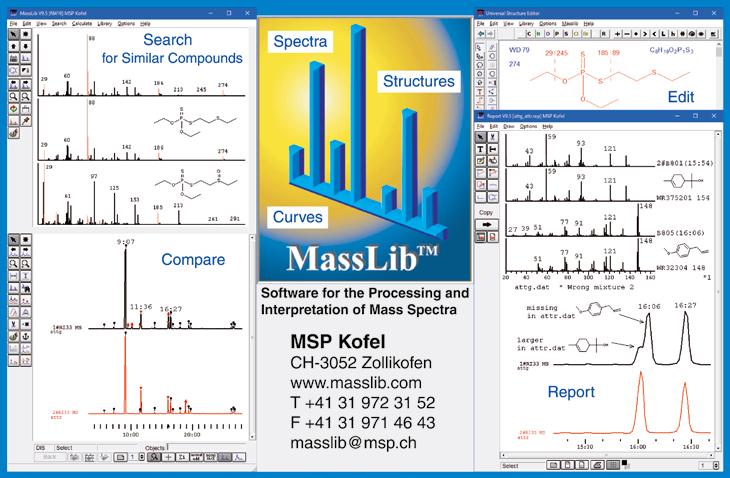

Software: Design of Experiments (DoE)

Efficient DoE Implementation: Design of Experiments is the fastest and most cost-efficient way to create effective experiments. Tap into the power of DoE without the long learning curve.

Built-in Process Support: This goes beyond ordinary DoE software. It guides you on how to make optimal experimental choices, skipping impossible settings to save product and time.

Complete Guidance: From parameterization to execution, the software provides step-by-step instruction and support.

Technology innovations always feature strongly in Eurolab and this issue is no different. Our cover story mixes art and science and explores the work of Dr Richard Arm, an innovator who creates anatomically correct organs for use by students instead of cadavers - one of his techniques deploys a laser sinter to fuse soft rubber particles together using 3D guided geometry. On a more molecular scale, Sino Biological are manufacturing recombinant proteins, read their interesting story on page 32.

Customer relationship management (CRM) in the life sciences and pharmaceutical sector has seen some upheavel since Salesforce and Veeva parted ways earlier this year. On page 12 we interview the CEO of Veeva's partner Conexus about how the split has affected the industry.

Several additional articles look at pipette technology, and with Pipette Enhanced Workflows on page 20, Integra Biosciences tells us how its customer, BioApp Solutions, used the Viaflo electronic pipette to reduce downtime and improve efficiency.

Political decisions are affecting health care practitioners across the globe and in the news round up (page 6) we cover several funding cuts made by the Trump administration in recent months. At the same time, the European Union is pouring money into the biotech industry - perhaps the UK should rejoin as suggested by Zac Polanski (leader of the Green Party).

We preview the upcoming Lab Innovations show on page 55. Do let me know if you're attending and would like to meet - I'll be there and would love to hear your news and views.

Nicola Brittain Editor

Pipette enhanced workflows

How pipette use can enhance high throughput workflows

Curb your waste How best to dispose of single-use pipette tips

Accelerator free gloves Rethinking cleanroom hand protection

update

investigation of gas uptake rates

reagent purity

A look at an advanced line of recombinant

How AI-enhanced DMTA cycles can help with workflows

A look at lab equipment that helps synthesise genomes

A novel approach

An efficient methodology for PFAS

Why DOE automation is a powerful methodology for practitioners

A perspective on managing punch length

How microscopy is used in clean rooms

A look at a 3D stereoscopic

PUBLISHER

Jerry Ramsdale

EDITOR

Nicola Brittain nbrittain@setform.com

CONTRIBUTING EDITOR

Saskia Henn shenn@setform.com

DESIGN – Dan Bennett, Jill Harris

HEAD OF PRODUCTION

Luke Wikner production@setform.com

BUSINESS MANAGERS

John Abey | Darren Ringer

ADVERTISEMENT EXECUTIVES

John Davis, Iain Fletcher, Paul Maher

e advertising@setform.com

CONTACT US...

t +44 (0) 207 253 2545

e mail@setform.com

Setform’s international magazine for scientists is published twice annually and distributed to senior professionals throughout the world. Other titles in the company portfolio focus on Process, Design, Transport, Oil & Gas, Energy and Mining engineering.

The publishers do not sponsor or otherwise support any substance or service advertised or mentioned in this book; nor is the publisher responsible for the accuracy of any statement in this publication. ©2025. The entire content of this publication is protected by copyright, full details of which are available from the publishers. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior permission of the copyright owner.

Boosting skills with automated microscopy

How microscopy is teaching professionals

Meet the deadline

Encouraging submission of applications

A meeting place for lab professionals A preview of Lab Innovations

Setform Limited | 6 Brownlow Mews, London, WC1N 2LD, United Kingdom

ADAPTABLE ANATOMY

A look at the 3D printed body parts created by Dr Richard Arm

In June this year, 484 staff from the US’s National Institute of Health signed a letter criticising the Trump administration for major spending cuts that they said would harm the “health of people across the globe”. The letter argued said the “life and death nature of [the] work” demanded that changes be “thoughtful and vetted.” It continued: “We are compelled to speak up when our leadership prioritises political momentum over human safety and faithful stewardship of public resources.”

The letter went on to list a series of more detailed concerns stating a shared commitment to academic freedom and that the signatories were unhappy with how the halting of

high-quality peer-reviewed grants and contracts had politicised research.

Separately, a federal watchdog found in early August that the Trump administration had broken the law when it terminated 1,800 grants and interrupted funding for the NIH.

According to the Washington Post, it was the fifth time that the Government Accountability Office, a non-partisan legislative agency, faulted President Trump and his top aides for rearranging the budget in defiance of Congress. Between February and June, investigators estimated, the US government had reduced spend on research and other grants by US$8bn year on year.

The Greater Manchester Commercial Research Delivery Centre, completed in April 2025, has announced its first vaccine studies.

Three new projects aiming to improve the effectiveness of vaccinations for severe acute respiratory infections have launched in Manchester thanks to support from The National Institute for Health and Care Research (NIHR) Greater Manchester Commercial Research Delivery Centre (GM CRDC).

The three studies are the first to be delivered through the GM CRDC, one of 21 CRDCs across the UK, and aim to recruit patients who have been hospitalised with severe acute respiratory infections (SARI).

The studies will enable researchers to evaluate how COVID-19 and Respiratory Syncytial Virus (RSV) vaccines perform outside of clinical trials and across diverse populations. These studies will provide essential real-world evidence into the

degree of protection vaccines offer against serious respiratory illness, hospitalisation, and ongoing healthcare.

Dr Shazaad Ahmad, a Consultant Virologist at Manchester University NHS Foundation Trust (MFT) and the principal investigator for the studies in Greater Manchester, said:

“Vaccination remains one of the most effective interventions for preventing severe outcomes, reducing hospital admissions, and protecting the most vulnerable. These revaluations will help ensure that vaccination programmes deliver maximum benefit to the populations they are designed to protect”.

In July, the European Union launched a strategy to make Europe “the most attractive place in the world for life sciences by 2030”. This strategy is backed by a annual budget of over €10bn from the EU budget. This strategy will be supported by specific funding for key initiatives, including up to €100m for microbiome solutions and €300m for public procurement of life science innovations like new vaccines and cancer treatments, all managed under cross-sectoral coordination. The strategy aims to ‘accelerate innovation, facilitate market access and build public trust in new technologies’. Alongside the strategy was the launch of the EU Biotech Act which aimed to create a more innovation friendly framework across biotech sectors.

At end of September the European

Council approved conclusions on life sciences and said that it welcomes the European Union’s ambition to become the world’s most attractive place for life sciences by 2030, as outlined in the Commission’s strategy. The council also provided guidance that aimed to unlock the Union’s full competitive potential. The Council encourages full support throughout the value chain from

fundamental research and uptake, stronger research in advanced therapy medicinal products (ATMPs), a leading EU role in clinical trials and a broad approach to biotechnology. It also calls for the use of advanced technologies – such as artificial intelligence and quantum computing – in life sciences, while stressing the importance of developing skills, and attracting and retaining talent.

Leading global manufacturer of primary human cells PromoCell GmbH has announced its entry into the Good Manufacturing Practice (GMP) field. At the 32nd ESGCT Congress in Seville, Spain, PromoCell will showcase its Custom GMP Cell Culture Media Services tailored for clinical applications and further manufacturing in the cell-based therapy industry. PromoCell’s Custom GMP Cell Culture Media Services aim to bridge the gap between research and clinical application, offering Excipient GMP-grade cell culture media manufacturing and expert guidance through the research-tocommercialisation journey.

“We noticed an increasing demand for advanced cell culture media in regenerative medicine and cellbased therapy, and we are pleased to introduce our GMP cell culture medium service portfolio to the life science community at the Congress,” says Dr. Irma Börcsök, CEO of PromoCell. “This launch is a testament to our commitment to supporting customers with our

long-standing cell culture medium expertise from discovery to preclinical, clinical, and commercial manufacturing. The company has made both standard and customised Excipient GMP-grade solutions available and claims to deliver “servicedriven offerings that meet high regulatory standards, empowering scientists to scale their innovations with confidence and compliance.”

Dr Richard Arm, a senior research fellow at Nottingham School of Art and Design, is creating organs to replace cadaver parts. Here Saskia Henn explores the benefits of this practice

Traditionally, cadavers have been one of the main tools for surgical training for medical students, surgeons and trainees, emergency medical professionals, researchers and military medical personnel.

The history of cadaver use in medical training dates back to the first half of third century BC in Greece. Ancient Greek physicians Herophilus of Chalcedon and Erasistratus of Ceos were likely the first to use the dissection and vivisection of cadavers for anatomical learning.

By the 4th century CE, much of cadaver use disappeared owing to religious and social taboos. It did not reappear until the 14th century in Bologna, Italy, and from this point on, became increasingly common.

However, the use of cadavers for surgical training and preparation is flawed and has recently waned in popularity.

The process of cadaver acquisition is complex and preservation is expensive. While anatomically accurate, cadavers lack the same physiological functioning such as blood flow and dynamic responses.

Embalming can help to prevent the organs from descending with gravity. However, the use of hazardous chemicals such as formaldehyde not only poses a risk to users but also contributes to tissue discolouration and stiffness.

“When I first started this research in 2012 I was working with a Belgian surgeon who had designed an implantable device for children with spasticity that helped prevent them from having seizures. I made a torso of my young cousin and reproduced it in materials that were able to mimic flesh and bone, albeit rather simplified. This was used by the surgeon for years to teach other surgeons how to implant his new device, helping hundreds of suffering children around the world.” – Dr Richard Arm

Alternatives to cadaver use have recently been gaining traction. Dr Richard Arm, senior research fellow, Nottingham School of Art and Design, NTU has introduced an anatomically accurate solution that offers many advantages over cadavers.

Arm uses a combination of 3D printing and soft materials such as silicone, polyester polyurethanes and polymer waxes to create lifelike organs.

His interest in art and design began with the Renaissance movement and multi-disciplinary creatives such as Di Vinci and Michelangelo, who were not just artists, but designers, inventors, builders, architects and engineers as well.

“Art underpins all these disciplines, and it’s no different for me,” says Arm. “A broad working knowledge of science, medicine, anatomy and material science are all essential to my work. Understanding the human body, how it works and why, can lead the open-minded artist down a plethora of avenues for discovery and inspiration.”

While often overlooked by decisionmakers in education, the arts contribute to the holistic perspective and lateral decision-making necessary to approach the replication of just one human organ, let alone the complexity of the human body.

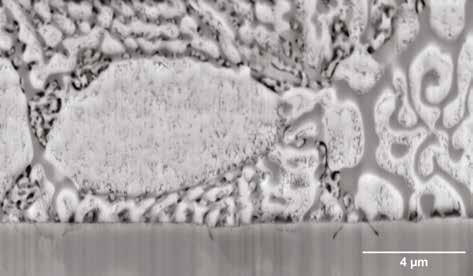

“Human skin is a great example. Resilient, repairable, and compliant, human skin has some unique characteristics that are controlled by its makeup,” says Arm. “Layers, fibre-filled gel membranes and elastic embedded structures are all replicated in the work I do, inspired by nature’s own design.”

Understanding the human body, how it works and why, can lead the open-minded artist down a plethora of avenues for discovery and inspiration

First, a 3D print of the tissue is created based on a patient’s CT scan. This ensures that the blueprints of the anatomical structures are accurate to the training required. This alone could eliminate the difficulties surgeons experience when training for paediatric patients, for example.

Following the creation of the 3D replica, Arm uses soft materials to recreate the elasticity, flexibility and unique characteristics of specific organs.

oesophagus

“We use a variety of materials to simulate living soft tissues,” says Arm. “For example, for complex vasculature that needs interlinked vessels with specific wall thicknesses that would be impossible to cast, we use a laser sintering technique to fuse soft rubber particles together using 3D guided geometry.”

Every aspect of the body is considered, including the way the blood sinks into the body following an incision, rather than puckering upward, as is often seen in media.

“It’s important that any materials we use are compatible with one another, such as PDMS (silicone gels) polymer waxes and thermoplastic polyurethanes,” says Arm, who rarely uses materials straight off the shelf.

“Liquid and solid additives are used in combinations that are essential to change and control the fundamental mechanical characteristics in most materials, to emulate the native biological tissues properly,” he says.

One advantage that Arm’s method has over cadavers is its availability. For

a host of cultural, legal and religious reasons, the availability of cadavers around the world is inconsistent and controversial. In the UK, for example, cadavers are only available as a main teaching method in about 60% of British medical schools.

Arm’s organs are also reusable, portable and independent from any power source. While cadavers must be properly preserved and respectfully disposed of within a certain time frame, these artificial organs can be left out and even transported without being damaged.

Since Arm’s organs are created from scratch with the purpose of mimicking life-like physiological responses, they bypass the complications and costs that arise from preserving cadavers through embalming, which alters the appearance and composition of soft tissue.

The customisable nature of Arm’s approach makes it suitable for a wide range of situations. He has previously assisted in the training of heart transplant surgeons and first responders treating serious chest

trauma that occurs from gun shots, stabbings, shrapnel penetration and road traffic accidents.

While Arm has several projects underway and still under wraps, he has already begun manufacturing his own manikins and organs at NTU with the help of his research assistant Andrea.

“The reason for us manufacturing our own models rather than licencing our technology is to help drive down inflated prices of surgical models because we want everyone to be able to afford them, not just the privileged few,” says Arm. “We also want to improve and control the quality of the currently available models by designing and building everything in-house.”

Arm’s manikins and organs are available for purchase through NTU’s catalogue of products.

Lowest plunger force.

This familiar lab tool is anything but ordinary. With INTEGRA's SWITCH you choose; pipette manually or 'SWITCH' to repeat dispense mode and gain productivity while enjoying the lowest plunger force possible. SEE IT IN ACTION >

Akshay Kapadia CEO of Conexus Solutions

In this Q&A, Akshay Kapadia CEO of Conexus Solutions talks about the Veeva and Salesforce split and how the Veeva platform meets the specific CRM requirements of the healthcare sector

Why was the split between long-time collaborators Veeva and Salesforce such a big deal for life-science companies?

The Veeva and Salesforce relationship has been a defining force in life sciences customer relationship management (CRM) for more than 15 years.

When Veeva launched in 2007, it built its CRM on Salesforce’s Force. com platform, designing it specifically for the processes and compliance requirements of life sciences companies. This was a pivotal shift that helped move the industry away from traditional on-premises installations and toward a cloud-based, SaaS model. Veeva’s product was an excellent fit for life sciences, and its adoption accelerated quickly. It captured approximately 80 percent of the market in a decade.

The product now sits on a Veeva designed architecture. For the first time in years, organisations are able to choose a CRM and platform that have been designed specifically for their needs as healthcare specialists. It’s a moment of disruption, but also a chance to reimagine what CRM can deliver – not just as a sales tool, but as a driver of intelligent customer engagement.

What does the life sciences industry need from a CRM that might differ from a standard CRM?

The pharmaceutical and life sciences (P&LS) industry has fundamentally different needs from traditional retail or B2B industries when it comes to CRM. These differences are deeply tied to the way the industry operates, the regulatory landscape, and the

unique roles of its stakeholders. Here are some of the key distinctions:

1. A complex selling model: In most industries, the customer who is sold to is also the one who pays for and uses the product. In pharma, the model is far more complex. The healthcare provider (HCP) is the one who ‘sells’ the product they prescribe but doesn’t buy or consume it. The patient consumes the product but typically doesn’t pay for it. The payer (insurance or government) covers the cost, but neither prescribes nor uses the medication. This dynamic creates a multi-layered engagement model that standard CRMs aren’t built to manage.

2. Regulatory compliance requirements: Standard CRMs operate in relatively

Clients want to see measurable results –whether that’s faster approvals, improved field performance, or more efficient content management – they’re looking for service partners who align with those goals

low-regulation environments. In contrast, pharma companies must comply with stringent regulations such as FDA guidelines, HIPAA, the Sunshine Act in the US and GDPR in the EU. Every interaction must be documented, auditable, and compliant –from data capture to content delivery.

3. Sample management:

Sample distribution is a tightly regulated activity in pharma. Reps must collect detailed information, including physician licenses (SLNs), digital signatures, and maintain a chain of custody for each transaction. State-specific laws also apply. Standard CRMs don’t typically have the rigor or built-in processes to support this level of oversight.

4. Field activity tracking:

While standard CRMs offer basic

activity logging and lead tracking, pharma field teams require much more. They need tools for call planning, frequency tracking, capturing detailed call notes, recording product discussions, and tracking the use of approved CLM (Closed Loop Marketing) materials –all while staying compliant.

5. A specialised field force structure:

Pharma field teams are diverse and highly specialised. Unlike traditional models where territories are often geographic, pharma teams include sales reps, Medical Science Liaisons (MSLs), Key Account Managers (KAMs), and Field Reimbursement Managers (FRMs), each with distinct responsibilities and reporting needs. CRM systems must support these nuanced roles and coordinate

interactions across the enterprise. When Veeva launched its CRM in 2007 on Salesforce’s platform, it was purpose-built to address these complexities. It offered life sciences companies a tailored solution right out of the box – something Salesforce itself never provided as a native offering - that has changed with Veeva’s new platform.

Conexus is a service provider that implements and optimises Veeva’s cloud-based software for companies in the life sciences industry. It was built specifically to serve pharmaceutical and life sciences companies. The company understands the unique challenges these organisations face, especially emerging and mid-sized companies. What are customers asking for now that they weren’t say a year or two years ago?

There’s been a noticeable shift in what life sciences companies are prioritising in their service partners. A few years ago, the focus was often on finding experts for a specific application or functional area. Today, customers are looking for broader, more integrated support – they’re looking for partners who can work across the complete Veeva ecosystem, from commercial to clinical to quality.

Another significant shift is in the way value is measured. Traditional time-and-materials models or fully dedicated support teams are giving way to outcome-based models. Clients want to see measurable results –whether that’s faster approvals, improved field performance, or more efficient content management – and they’re looking for service partners who align with those goals.

And of course, AI is at the forefront of many conversations now. What we’re seeing is a growing demand for practical enablement – companies aren’t just looking for high-level strategy or experimental use cases.

Micro-Epsilon’s Glenn Wedgbrow provides insight into how the company’s high precision sensors are used in the medical, biotechnology and pharmaceutical sectors

Medical technology, the pharmaceutical industry and biotechnology are sectors in which sensors and measurement technology are increasingly being used to improve quality and efficiency. MicroEpsilon offers measurement solutions for these industries to solve numerous tasks. Here is a selection of successful projects that help illustrate the range of possible applications.

Stents play a critical role in the treatment of cardiovascular diseases. To ensure their functionality, precise adherence to the diameter is crucial. Optical micrometer sensors from Micro-Epsilon perform diameter checks and wire inspections of the stents during and after production, ensuring the highest level of quality assurance. The shadow cast principle even allows transparent materials to be measured accurately.

The thickness of medical technology products can be measured using confocal chromatic sensors. The confocal sensors measure the wall thickness of transparent materials such as tubes, membranes and balloons, from just one side and deliver accuracy in the micrometer range. Uniform wall thickness is essential for the durability and function of tubes. The sensors measure the thickness without contact

and so ensure consistently high quality during production, as they have no influence on the material.

The confocalDT sensor series from Micro-Epsilon defines the standard for maximum precision and dynamics in confocal chromatic measurement technology. Owing to a wide range of sensors and interface options, this series is suitable for various measurement applications in medical technology. The confocalDT systems are characterised by their fast measuring rates, which are specially designed for dynamic measurement tasks. Dynamic control of the exposure of the CCD line in the controller continuously adapts to the colour and reflectivity changes of the measuring object, which significantly

Draw-wire displacement sensors are used for position monitoring, for example, when moving patient couches or taking measurements in computer tomographs

In medical technology, the colorSENSOR CFO is used, for example, for the colour detection of interior parts such as headrests for couches, packaging control and for sorting medical components by colour, such as closures or labels

optimises the measurement accuracy even at high speeds. With sensor sizes starting at a diameter of just 4 mm, the confocalDT systems enable easy integration even in confined installation spaces. The availability of models with a 90° angle also reduces the required installation depth, which facilitates installation in complex machine arrangements. The measuring systems offer different aperture angles, whereby models with a large aperture angle or a high numerical aperture enable a particularly small light spot as well as excellent lateral (X-Y) and vertical (Z) resolution. Even the smallest of details can be detected with extreme precision.

Draw-wire displacement sensors are used for position monitoring, for example, when moving patient couches. Sensors with potentiometer output are used for tasks that require medium accuracy. Draw-wire sensors with absolute or incremental encoders are used for high precision measurements such as those required in computer tomographs.

Draw-wire sensors provide an effective solution for measuring displacement, distance and position with an impressive measuring range of up to 50,000 mm. These sensors are particularly well suited for use in hard-to-reach places, which makes them indispensable in many industrial applications. They enable accurate measurements even under demanding

DIAGNOSTIC DISPENSING SOLUTIONS

Precision in Every Dispense, Accuracy in Every Test

• Bond medical device housing

• Dispense and freeze reagents for later use

• Highly precise uid volume accuracy and repeatability at ±1%

conditions. In addition, they are characterised by simple, quick and flexible installation, which makes them ideal for various applications, including customer-specific configurations.

During pharmaceutical tablet production, different concentrations of active ingredients influence the tablet colours. The ACS7000 colour measuring system from MicroEpsilon precisely detects subtle colour differences, which enables the composition of the active tablet ingredients to be continuously checked during production.

colorCONTROL ACS7000 is one of the most advanced inline colour measuring systems in the world. The measuring system not only recognises reference colours by comparison, but also identifies individual colours clearly from their coordinates in the colour space. Owing to its very high measurement speed, the colorCONTROL ACS7000 is suitable for applications where colours and shades must be examined on-the-fly and to very high accuracies. The high measuring accuracy means the system is also used in laboratories. Different sensor models are available to suit various measurement tasks.

There are numerous other applications in medical technology where colours are measured with high precision in order to automate and accelerate processes while maximising the level of quality. The colorSENSOR CFO is a highly developed controller, specially designed for precise colour detection tasks. This series impresses with its high colour accuracy and modern interfaces, combined with intuitive user guidance. CFS sensors are connected to a controller with integrated fibre optic cables and can be specially configured for different measurement tasks.

In medical technology, the colorSENSOR CFO is used, for example, for colour detection of interior parts such as headrests for couches, packaging control and for

The highest standards of quality and repeatability apply in medical and pharmaceutical technology. Sensor products from MicroEpsilon are used in a wide range of measurement tasks

sorting medical components by colour, such as closures or labels. It offers a high measuring speed of up to 30 kHz, making it ideal for dynamic processes. Fast output of measured values (Lab/ XYZ) up to a frequency of 500 Hz and a large colour memory enable the management of different test batches with extraordinary precision, with a colour accuracy of ΔE ≤ 0.3.

The controller is also characterised by a robust aluminium housing and IP65 protection rating, which makes it particularly resistant to environmental influences. Customerspecific calibrations are also possible in order to meet specific requirements in medical technology.

For more information visit: www.micro-epsilon.co.uk

To ensure the functionality of stents, precise adherence to the diameter is crucial

The revolutionary FLEXI-FLOW™ Mass Flow & Pressure Controllers are ideally suited for applications in the analytical and biotech market. The compact, lightweight instruments allow easy integration in (portable) devices. Their versatility is second to none:

• Manufactured from non-toxic high grade LDPE

` Shatterproof and safe to use

` Inert to prevent sample contamination

• Responsive control for ease-of-use & reliable performance

• Low-affinity surface for complete sample delivery

• Available sterile or non sterile to suit your application

• No mould release agents used during manufacturing

Samantha Ogles, product manager at Alpha Laboratories, provides insight into simple transfer pipettes as designed for today’s scientific and medical fields

Despite the rapid advancement of technology in scientific fields, the simple plastic transfer pipette remains an essential tool in research, industrial and clinical laboratories, for the easy and safe transfer of liquids. Evolving from the traditional glass Pasteur pipette and rubber bulb, first used in the 1940’s, modern polypropylene single piece pipettes, such as the renowned, high quality Pastette, remain a convenient and cost-effective solution for an extensive range of liquid handling applications.

These disposable transfer pipettes have been developed to meet the demands of various scientific and medical applications. Available in a variety of sizes and styles, they are designed for the controlled transfer of liquids in general liquid handling and also more specialised procedures. They provide precision, safety, convenience, and versatility. Sterile and non-sterile options cater to both

general laboratory use and sensitive applications in microbiology or medical environments. In clinical environments transfer pipettes have many functions, from handling a variety of patient samples, small volume drop work, to preparing slides for analysis. The fine tip and controllable bulb make them ideal for dispensing into sampling cups, without creating bubbles that can disrupt the efficiency of the analyser. They have multiple uses in blood sciences. The narrow stem fits tubes and donor bag tubing and

allows calibrated transfers through graduations and controlled drop size.

Bob Jones of the Department of Microbiology and Infection Control at Victoria Hospital, Kirkcaldy has been using Pastettes since the 1980s, after moving on from homemade glass ones (quite a tricky and dangerous practice). He says “Working in a microbiology laboratory, transfer pipettes are used in abundance for many things. Jumbo Pastettes are ideal for removing sediment from early morning urine for TB examination. Fine Tip Pastettes are

used for filling cell counting chambers with CSF. The serology section is probably the biggest user, transferring serum and plasma from centrifuged blood containers into tubes and vials.”

For self-test and Point of Care (POC) diagnostic kits, where users may not have experience of exact volume pipetting, there are disposable pipettes that will dispense a precise measure of liquid. They offer foolproof simplicity – simply squeeze

the upper bulb to fill and squeeze again to dispense the exact volume required for the test.

Pastettes are extensively used in cell culture laboratories for transferring culture media, reagents, and cells between containers. Their disposable nature eliminates the risk of cross-contamination between samples. In stem cell research, where delicate cells are handled, the flexible tips of Pastettes help ensure that cells are not damaged during transfer. There are even bulbless aspirator Pastettes that can be used with all types of Pipette Aid devices to aspirate and dispense media and reagents. They are ideal for drawing off media from culture flasks and are safer to use than traditional glass or polystyrene pipettes. Being flexible and soft they also protect the cell cultures. They offer the best choice for delicate and valuable cell lines and are a ‘must have’ for work with infectious and hazardous materials.

Even in industrial research and testing laboratories Pastettes are a valuable tool for tasks such as sample preparation for: LC, GC, HPLC, TLC using 1ml auto sampler vials. Robertet, a leading supplier of fragrances, flavours, and natural raw materials, uses transfer pipettes in the applications laboratory, where they formulate trial batches of fragrances that are under development. They work to very precise formulations, occasionally using up to 70 different raw materials for each trial batch. These components are often very expensive, and they cannot afford to waste any, so the accuracy of dispensing is essential. They have found that the 1ml graduated Pastette provides the precision needed for this task.

So, while your laboratory may continue to be enhanced by the addition of increasingly sophisticated equipment, there will always be a place for the multipurpose, humble plastic pipette.

Tom Bentivegna from Integra Biosciences explains how the company expands bioanalytical capabilities with high throughput liquid

BioApp Solutions – based in Leeds, UK – is a specialist provider of training, consultancy and analytical support covering all aspects of bioanalysis. The company was established in 2015 to address the market gap for lab-based bioanalytical consultancy, and to train the next generation of analytical chemists. Unlike officebased consultancies or high throughput laboratories, BioApp draws on decades of combined experience in leading contract research organisations (CROs) to tackle complex challenges that larger organisations may be unable to address owing to their scale or focus on volume. Its clients range from start-ups requiring guidance on establishing new workflows to major pharmaceutical companies seeking tailored, innovative bioanalytical solutions.

BioApp provides expert consultancy services across the full bioanalytical workflow, from exploratory and regulated bioanalysis to method development, validation and biomarker strategies. The company also offers flexible outsourcing options that help sponsors adapt to shifting priorities, manage costs and accelerate research timelines, offering dedicated

full-time equivalent and instrument access, applications support, and comprehensive data interpretation. Its laboratory services focus on earlystage, non-regulated work, combining robust analytical method development with expert project management.

BioApp moved out of the incubator lab it had initially used into its own dedicated CRO facility in 2021 to dramatically expand its analytical

capacity and incorporate mass spectrometry capabilities. This enabled the team to provide a broader spectrum of bespoke sample analyses, as well as offer early-stage method development, workflow optimisation and validation services in house. When establishing its new laboratory, the team was keen to invest in automation products that would suit its workflows, as manual pipetting in high throughput formats can be repetitive, labour intensive and prone to errors, particularly when working

with large batches in 96 well plate format. Tasks including sample dilutions and mixing and extracting supernatants after centrifugation can be time consuming to perform by hand, increasing the risk of variability between operators and placing strain on staff.

The BioApp team was already familiar with Integra’s Viaflo 96 handheld electronic pipettes, having investigated multichannel pipettes for a consultancy client several years earlier. Instruments from several brands were trialled by 20 of the client’s analysts over a week, and Integra’s solution was unanimously preferred for its intuitive design, robustness and minimal downtime. This experience – coupled with BioApp’s policy to invest only in proven, established technologies –made the Viaflo 96 the natural choice for its laboratory. BioApp therefore selected the Viaflo 96 with a 96 channel pipetting head and 300 μl automation Griptips pipette tips to streamline repetitive manual pipetting tasks and boost productivity.

The Viaflo 96 allows the BioApp team to set up entire 96 well plates in seconds. The pipette is used for a range of applications – including sample loading during supported liquid extraction protocols –contributing to significant time savings and improved productivity. Pipetting protocols can be preprogrammed, enabling precise control over cycle numbers and aspirate/ dispense speeds, ensuring each liquid handling step is performed consistently. Eliminating manual errors and inter-operator variability leads to more reproducible results and helps safeguard the mental and physical wellbeing of staff by reducing monotonous, repetitive tasks.

BioApp also selected single- and multichannel Evolve manual pipettes with a range of volumes, from 2 to 300 μl, for handling smaller sample numbers and lower volumes,

particularly during tasks such as spiking samples with known analyte concentrations in preliminary studies. Having multiple pipettes dedicated to specific applications reduces the risk of cross-contamination, adds flexibility and ensures redundancy, helping to overcome throughput limitations. Integra’s ECO rack Griptips pipette tips – which fit securely without leaking or falling off – further enhance productivity, as they are colour matched to the pipettes, allowing staff to quickly select the correct tip without interrupting workflows. This streamlines daily liquid handling tasks and supports sustainability by reducing tip wastage and associated plastic waste.

Reliable liquid handling tools are essential for maintaining productivity, safeguarding data quality and meeting project deadlines in bioanalytical research and development. For a small, highly specialised team working to tight schedules, dependable

equipment minimises the risk of unplanned downtime and ensures that complex workflows can be carried out efficiently from start to finish. BioApp’s suite of Integra tools enables consistent, reproducible pipetting, supporting a variety of method development and sample analysis tasks. They will also play a critical role in helping BioApp to expand its in-house analytical and method development capabilities, diversifying its client base and adapting to evolving industry needs.

Reliable liquid handling tools are essential for maintaining productivity

The single-use pipette tip, an unavoidable consumable in modern biological and chemical research, presents a significant and growing global environmental challenge. While essential for precise liquid handling and preventing cross-contamination, their sheer volume generates a staggering waste stream. Estimates suggest billions of tips are discarded annually, contributing to plastic pollution and resource depletion.

The environmental impact extends beyond mere landfill accumulation. These tips, often made from polypropylene, a petroleum-based plastic, require substantial energy for production. Furthermore, their disposal, particularly incineration, releases harmful greenhouse gases and potential toxins. The reliance on single-use items fosters a linear ‘takemake-dispose’ model, unsustainable in a resource-constrained world.

The sheer volume of discarded pipette tips contributes significantly to the global plastic waste crisis. As highlighted by sources such as the Babraham Institute, laboratory plastic waste is a very large contributor to the overall plastic waste problem. Studies have shown that items like pipette tip boxes make up a very large percentage of laboratory plastic waste. (Babraham Institute).

This waste can persist for centuries,

breaking down into microplastics that contaminate soil and water, posing risks to wildlife and potentially entering the human food chain.

Efforts to mitigate this impact are gaining momentum. Autoclaving and reusing tips, while feasible for some applications, raise concerns regarding accuracy and sterility. However, innovations in biodegradable and reusable pipette tips and packaging offer promising alternatives.

Research into bioplastics derived from renewable resources, such as polylactic acid (PLA), presents a potential solution. Though challenges remain regarding cost and material properties, advancements in biopolymer technology are paving the way for more sustainable options.

Furthermore, implementing robust recycling programs within laboratories is crucial. Closed-loop systems, where used tips and packaging are collected, processed, and repurposed, can significantly reduce waste. Education and awareness campaigns are also vital to encourage responsible consumption and promote sustainable laboratory practices.

In the meantime, a shift towards a circular economy in laboratory consumables is imperative. This requires collaboration between

researchers, manufacturers, and policymakers to develop and implement sustainable solutions. This includes encouraging the development and adoption of reusable or biodegradable pipette tips and packaging as well as supporting manufacturers who prioritise sustainable production and packaging. As seen from Alpha Laboratories, there is a push to use recycled and recyclable materials in the production of the FastZAP pipette tips that are designed with a minimal amount of packaging while preserving product quality.

The environmental cost of scientific progress cannot be ignored. By embracing innovation and adopting responsible practices, the scientific community can minimise its environmental footprint and contribute to a more sustainable future.

References: U.S. Environmental Protection Agency. (n.d.). Sustainable Materials Management: Non-Hazardous Materials. Retrieved from epa.gov

The journey and impact of a pipette tip - Babraham Institute: https://www.babraham.ac.uk/blog/pipette-tips

Rizan, C., & Hankemeier, T. (2021). Towards sustainable analytical chemistry: A critical review on greening liquid chromatography. Analytical and Bioanalytical Chemistry, 413(16), 4065–4085.

Arnott, J. T., & Pilon, L. (2020). Environmental life cycle assessment of single-use and reusable laboratory plasticware. Journal of Cleaner Production, 258, 120677.

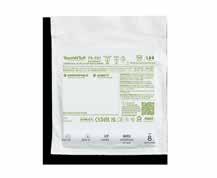

In this article Jo Fabb from safety specialist manufacturer Ansell encourages us to rethink cleanroom hand protection

Working in a cleanroom is like completing a long, detailed puzzle – it requires focus, patience, and stamina. When gloves aren’t designed for lasting comfort, discomfort can set in quickly, leading to skin irritation, loss of concentration, and potential contamination risks. That’s why glove materials and formulation are so important.

For a long time, natural rubber latex gloves were everywhere – in labs, cleanrooms, and hospitals. But they came with a big downside: Type I latex allergies. These happen when your immune system overreacts to proteins found in natural latex, causing reactions that can be serious – like hives, swelling, difficulty breathing, and in extreme cases, anaphylaxis. This type of allergy is an immediate hypersensitivity reaction mediated by the immune system’s antibodies.

That’s why many places switched to non-latex gloves, like nitrile or neoprene. This change helped cut down on latex-related allergic reactions. But here’s the thing: even without latex, some people still

experience skin problems when wearing gloves. Why? The answer lies in the chemicals used to make the gloves stronger and more durable.

Even if you’re using latex-free gloves, you might still run into issues – especially if you have sensitive skin. That’s because many gloves (especially nitrile ones) are made using chemical accelerators. These are

Many gloves are made using chemical accelerators

ingredients like thiurams, carbamates, and mercaptobenzothiazoles (MBTs) that help ‘cure’ the glove material during manufacturing, so the gloves stay stretchy and strong. Accelerators are commonly used in glove manufacturing to speed up the vulcanisation process, making production more efficient.

But for some people, these chemicals can cause what’s known as a Type IV allergy, or allergic contact dermatitis. Unlike latex allergies, this type of reaction doesn’t happen right away. It can show up hours or even days after wearing the gloves. The symptoms are usually redness, itching, dryness, and blisters. Because the reaction takes a while to appear and looks like other common skin conditions (like eczema), it can be easy to miss or misdiagnose. Estimates indicate that more than 13 million workers in the US are potentially exposed to chemicals that can be absorbed through the skin. Contact dermatitis can also result when chemicals are absorbed through a worker’s skin. Contact dermatitis is one of the most common chemically induced causes of occupational illness, accounting for 10 to 15 percent of all occupational illnesses at an estimated annual cost of at least $1bn.1

Allergy Prevents Type I allergy

Prevents Type IV allergy protection from latex proteins from chemical accelerators

Material Synthetic (nitrile, vinyl, or others)

Potential No latex protein, but may

Nitrile without chemical accelerators

Free from both latex proteins allergens contain chemicals and chemical accelerators

Ideal for

Typical usee cases

Those with latex sensitivity

Frequent glove changes

Those with sensitivity to glove chemicals

Long-duration wear (e.g., healthcare) (e.g., cleanrooms, labs)

GLOVE COMPARISON

SUMMARY: LATEX-FREE VS. ACCELERATOR-FREE NITRILE

Choosing the right glove depends on the type of allergy risk you’re managing. Above is a simple breakdown to help you understand the key differences between latex-free and accelerator-free nitrile gloves.

Just as the industry shifted to latex-free gloves to protect against Type I allergies, today’s leading manufacturers are responding to

Type IV sensitivities with acceleratorfree nitrile gloves. These gloves have gained widespread popularity among users owing to their performance, quality, and skin-friendly formulation.

Accelerator-free nitrile gloves are made without chemical accelerators in the manufacturing process. They use the same raw materials as standard nitrile gloves but follow a slightly modified formula that excludes these accelerators. As a result, they offer a safer alternative for users with sensitive skin or chemical allergies. These gloves eliminate common chemical triggers while maintaining the integrity, cleanliness, and compliance standards demanded

Estimates indicate that more than 13 million workers in the US are potentially exposed to chemicals that can be absorbed through the skin

An image showing the impact of chemical accelerants vs no chemical accelerants

by critical environments such as cleanrooms, laboratories, and pharmaceutical facilities. Additionally, their low-risk composition makes them a better choice for both users and the environment.

When it comes to protecting workers who wear gloves for extended periods, skin health is just as important as barrier protection. Accelerator-free nitrile gloves offer a solution that helps reduce these risks while maintaining the high-performance standards expected from nitrile.

The benefits of accelerator-free nitrile gloves include:

• Reduced risk of allergies

• Uncompromised barrier protection and film permeation properties

• Environmental sustainability

• Compliance with regulatory standards

• Versatility in applications

For more info on free nitrile glove solutions click the QR code below.

For more information on free nitrile glove solutions scan the QR code Sign up to Ansell’s newsletter

For more information visit: www.ansell.com

A team from Biotech Fluidics provides details of a practical investigation of gas uptake rates through different tubing types connecting an inline degasser and liquid pump in precision fluidic systems

Inline vacuum degassers (see Figure 1) are vital components within many types of equipment for laboratory analysis, including liquid chromatography, HPLC, UHPLC, ion chromatography, and mass spectrometry. Similarly, degassers are also critical constituents in fluidics systems used in immunology, haematology, in-vitro diagnostics, and semi-conductor manufacturing. In all these fluidic systems, inline degassers serve the role of silent guardians of precision and reliability by removing dissolved gases that could form bubbles which would disturb the fluid flow or recording of

The experiment set up

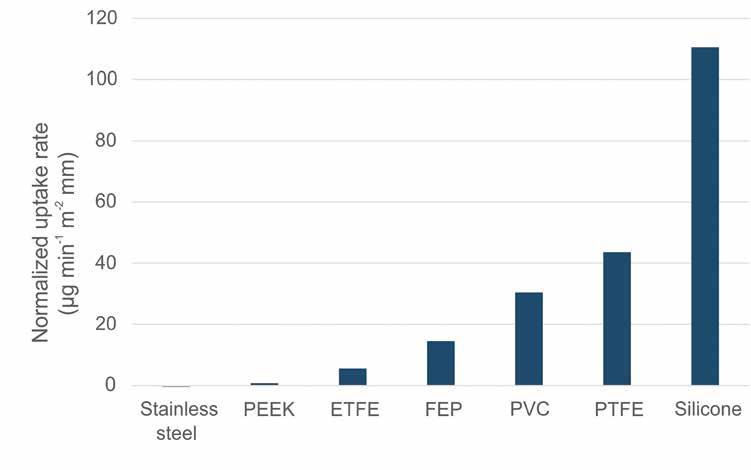

To compare materials across different tubing dimensions, we calculated gas uptake rate normalised to 1.0 mm tubing wall thickness

measurement signals. Inline degassing is consequently considered the most efficient and convenient ways to eliminate troubles with bubbles [1].

An aspect that often may be overlooked, however, is the choice of tubing interconnecting the units throughout the fluidic system [2]. If the gas permeability across these flow lines is high, the influx of gases into the liquid could even nullify the benefit of the degasser and thus risk

that the output shows poor precision and low accuracy. The factors that would be expected to influence to which extent this re-gassing could occur are the material properties, residence time, tube wall thickness, and exposed surface area.

To investigate gas permeability, we conducted an experiment that continuously determined the changes in oxygen levels after passing different transfer tubing that were placed between a degasser and a withdrawing piston pump. The investigated tubing materials were polyetheretherketone (PEEK), polytetrafluoroethylene (PTFE), fluorinated ethylene propylene (FEP), and Ethylene tetrafluoroethylene (ETFE), all which had the same length (1 m) and outer diameter (1/16”), but varying inner diameters of 1.0 or 0.75 mm. Additional tubing materials, with other dimensions were also included, namely stainless steel, silicon and PVC (Tygon).

The content of Table 1 summarises the tested tubing materials and their dimensions plus recorded oxygen uptake through the walls of these flow paths. The increase in oxygen levels

Conditions: Levels of dissolved oxygen were continuously monitored before and after passing though tubing of the stated materials and dimensions, using two optical oxygen FireSting-O2 OXFLOW flow-through sensors. The liquid was air-saturated tap water, withdrawn at 0.2 mL/min from a 1 L bottle at room temperature (24 ± 2 °C) using a Bishoff Compact HPLC pump, via a DEGASi Classic inline vacuum degasser that reduced the oxygen levels to 1 ± 0.3 ppm before entering the tubing to be tested. Values for difference of dissolved oxygen were collected after 25 minutes equilibration for each setup and represent the average during 20 seconds. Uptake rates were calculated by dividing the measured difference in oxygen concentration with internal liquid volume and tubing outer surface area, multiplied by residence time and wall thickness.

ranged from almost 7 ppm down to slightly negative values; the latter likely indicating the uncertainties in the present measurements. It was obvious from the recorded oxygen levels that thicker tubing walls significantly decreased the amount of penetrated gas. To compare materials across different tubing dimensions, we calculated gas uptake rate normalised to 1.0 mm tubing wall thickness. To allow quick comparison of gas uptake rate for different tubing materials, data from Table 1 was averaged for the different materials and plotted in a bar graph, see Figure 2.

The choice of tubing material did have a strong impact on the amount of gas that entered into the liquid flow path, thereby counteracting the benefits of degassing. Tubing wall thickness was also shown to be an important parameter to minimise re-gassing. Silicone tubing showed particularly high tendencies of liquid re-gassing, followed by PTFE and PVC (Tygon) tubing. These types of tubing

materials are therefore not suitable for precision fluidic systems other than in limited sections since their high gas permeability risk resulting in bubble formation even if an inline vacuum degasser is installed.

Although stainless steel tubing displayed zero gas permeability and PEEK only slightly higher, their rigidity and cost might limit the applicability in several applications. The tubing material that best met the criteria of low gas permeability, high flexibility, biocompatibility, and

The tubing material that best met the criteria of low gas permeability, high flexibility, biocompatibility, and chemical inertness, was ETFE

chemical inertness, was ETFE which displayed almost eight times lower gas uptake than PTFE tubing, and five time less than PVC tubing. A good compromise would also be FEP tubing which has limited gas permeability combined with an attractive price.

For more information visit: www.biotechfluidics.com

References

[1] “The Evolution of LC Troubleshooting – Degassing”, LCGC Europe, Dec. 2023, 36 (10), 397-401.

[2] Tubing Materials. https:// biotechfluidics.com/products/ tubing/ (accessed 2025-09-18)

Authors:

Dr. Magda Nyström, Product Specialist, Biotech Fluidics AB, Onsala, Sweden.

Anders Grahn, Chairman & Founder, Biotech Fluidics AB, Onsala, Sweden.

Dr. Tobias Jonsson, Diduco AB, Umeå, Sweden.

An expert from CN Bio explains how preclinical testing is transformed with Organ-on-a-chip technology

At the core of the FDA Modernization Act 2.0 (2022) was the acceptance of data derived using New Approach Methodologies (NAMs), like AI, in-silico tools and Organ-ona-chip, into regulatory filings. At the core of their subsequent roadmap to reduce animal testing in 2025 is an actionable phased strategy to reduce, refine, and ultimately phase out routine preclinical safety testing in animal studies in favor of a NAMsbased approach by encouraging and incentivising their use.

Since then, funding initiatives across the US and Europe have arisen to build research facilities, set up universal standards, train, develop and accelerate the adoption of Organ-on-a-chip (OOC) technology – also known as microphysiological systems (MPS).

Companies that have embraced OOC technology have the early advantage. They utilise it to improve the efficiency of their workflows by addressing gaps where traditional in-vitro assays are not physiologically relevant enough, but animal use is less suited owing to inherent interspecies differences. Some have widely adopted the approach, others have dabbled, many are yet to get started. But there’s no doubt that the field is gaining momentum!

If you ask AI what is at the core of Organ-on-a-chip (OOC) technology, it lists “microfluidics to perfuse cultures, 3D cell culture, dynamic mechanical cues and the integration of multiple cell types, enabling users to create labgrown mimics of human organs and tissues that behave and respond to drugs, toxins, or disease in a way that is more physiologically relevant than traditional 2D cell culture or many animal models”.

While this is true, there are many OOC technologies available and each is different. When the time’s right to modernise your workflows with OOC, it is important to match each system’s core strengths to your needs before choosing. Incorporating any new approach into your workflow takes time, so choose a solution whose core design prioritises ease of setup and use, helping you onboard quickly and sustain momentum.

Remember, the purpose of OOC is to enhance physiological relevance but OOC systems themselves don’t have to be prohibitively complex, they can be plate-based and familiar and utilise

CN Bio’s PhysioMimix Core microphysiological system mimics human physiology

Recombinant Human B7-H3 Protein (ECD, His Tag), Endotoxin-Free Cat#: 11188-H08H-UE

commonly used consumables such as Transwells. So, before you commit, consider the following key criteria:

1. Make sure that you are comfortable handling the consumables for assay setup and sample extraction.

2. Ensure that the system is easy to program. Don’t waste valuable time over maintenance routines.

3. More importantly, make sure you have adequate training and support to get on the right path. New researchers typically need 5–6 weeks to confidently run PhysioMimix Core experiments.

Deborah Lenart, MSc, Charles River, said: ‘Using the PhysioMimix OOC System is really straightforward; with a little practice, any tissue culture scientist can master the skills needed.’ Access to highly characterised and validated assays is key to your initial success. Most vendors provide validated all-in-one assay or model kits, or protocols that enable new users to get to grips with OOC basics fast but rarely does one size fit all. Therefore, to meet one’s immediate and future needs, another core element to consider is a system’s adaptability.

Multi-chip plates are familiar, accessible and customisable

Confocal image of an Liveron-a-chip model of Metabolic dysfunction-associated steatohepatitis (MASH) disease. Blue (Nuclei) Green (Collagen Type-1), pink (αSMA) and red (Steatosis)

Futureproofing also relates to scalability and the cost of OOC experiments. Consider the throughput you will require once OOC becomes embedded as a core technology and ensure this can be met. Explore the cost per chip and options for cost reduction via miniaturisation without compromising data integrity. Ensure you can extract the widest range of endpoint analysis from each experiment to maximise value and remember, the benefits of perfused organ or tissue cultures can also be applied to more cost-effective cell types, such as iPSCs.

So, what are you waiting for?

To enhance preclinical efficiency, physiologically relevant OOC models and assays represent the future, enabling you to gain deeper and more human-relevant insights into drug responses to inform decisions about which candidates to take forward. To future-proof your investment, ensure you have a strong foundation. Look for an intuitive core system that will grow with your research needs so that you can adopt, adapt and scale with ease.

Examples of how PhysoMimix customers have benefitted from its open architecture:

In a recent webinar, BMS described their work incorporating endothelial cells into a Drug-induced liver injury (DILI) assay, whilst scientists at Sanofi have presented their development of a fully immunocompetent DILI assay at conferences.

Others have applied existing Liver-on-a-chip models to a different context of use (e.g. antisense oligonucleotide delivery at GSK (1), progressive human hepatic resistance MIT & Novo Nordisk collaboration (2).

Charles River utilised CN Bio’s core technology to design their own genotoxicity model and assay (3).

Roche initially utilised a single-organ liver model for quantitative drug metabolism studies (4) before progressing to a dual-organ gut/liver model to simulate the process of first pass metabolism in vitro (5).

Learn more about PhysioMimix Core:

1. DOI: 10.1039/D4LC00504J

2. DOI: 10.1101/2025.01.08.631261

3. https://doi.org/10.1016/j. mrgentox.2024.503762

4. https://doi.org/10.1039/D1LC01161H

5. DOI: 10.1039/D2LC00276K

The only Organ-on-a-chip system with validated performance across single-, multi-organ and higher throughput configurations - all in one system!

An expert from biotechnology company Sino Biological explains how the company’s advanced line of recombinant proteins ensures the purity of reagents

In biomedical research and biomanufacturing, the purity of reagents directly impacts the reliability of experimental outcomes and the safety of downstream therapeutic products. Endotoxins are notorious contaminants in protein preparations. Even trace amounts of endotoxin in recombinant proteins can trigger potent immune responses, distort results, and compromise patient safety, especially in sensitive applications such as immunology, cell and gene therapy, and vaccine production. Biotechnology company Sino Biological’s recent launch of ProPure, an advanced line of endotoxin-free recombinant proteins. aims to address this need.

ProPure represents a new industry standard in the manufacture of recombinant proteins with ultra-low endotoxin content. Unlike conventional preparations, ProPure products are engineered to achieve endotoxin levels below the limit of quantification (LOQ). They are entirely produced in the US at Sino Biological’s centre for bioprocessing (C4B) in Houston, Texas. This facility leverages mammalian expression systems and proprietary multi-step purification protocols to deliver proteins with exceptional purity, stability, and biological integrity.

Sino Biological’s ProPure prduct benefits from minimum endotoxin levels during protein production

Endotoxin-free plasmids

Endotoxin-free buffer with filtration

Low endotoxin-affinity plastic containers

Regular clean-in-place (CIP)

Endotoxin contamination can derail sensitive experiments and therapeutic applications in the following ways:

Distorted data: Even low levels of endotoxin can activate immune pathways, leading to false signals in cell-based assays and immunological studies.

Safety concerns: Contaminated proteins used for animal studies or clinical research may induce harmful inflammatory reactions, endangering animal welfare or patient safety.

Regulatory compliance: Biomanufacturing and therapeutic protein production require strict endotoxin control to meet regulatory standards and ensure product safety.

Features and advantages of ProPure:

Ultra-low endotoxin content: Advanced purification techniques ensure endotoxin levels below the limit of quantification (LOQ), surpassing industry requirements and minimising experimental risk.

Mammalian expression systems: These systems, paired with tailored protocols, minimise bacterial endotoxin introduction and yield proteins with native-like post-translational modifications (PTMs), folding, and functionality.

High consistency and quality: The proprietary manufacturing process ensures batch-to-batch consistency, essential for reproducible results in sensitive applications such as immunology, vaccine research, and animal studies.

Customisation options: In addition to standard catalog proteins, ProPure provides made-to-order custom protein development to serve unique research and production requirements.

Made in the US: The US-based C4B facility underscores Sino Biological’s commitment to supporting the worldwide life sciences community with rapid production, reliable logistics, and robust quality assurance.

Sino Biological’s philosophy goes beyond shipping ultra-pure proteins. The C4B also partners with research labs and biotech firms to offer:

Custom protein production: Tailored to meet specific research needs, including production scale, tag design, and formulation.

Fast turnaround: The integration of cutting-edge technologies, strong expertise in recombinant production, and rapid shipping leads to shorter lead times and increased reliability, crucial during urgent projects like pandemic response or immunotherapy development.

Technical Support: Expert consultation and technical guidance improve experimental success.

A strong example of endotoxinfree protein quality is the Human B7-H3/CD276 protein, which achieves over 90% purity by SDS-PAGE and SEC-HPLC. Its purity and correct molecular size (about 60.4 kDa by SECMALS) are confirmed, while its bioactivity is verified by ELISA with an EC50 of 6.7 ng/ mL. This case underscores the importance of rigorous testing for purity, identity, and bioactivity to guarantee highquality, contamination-free proteins for sensitive research.

Fig.1: Premium ProPure endotoxin-free protein

Optimised mammalian expression platforms and rigorous QC ensure high quality and consistency

Customised proteins and antibodies with an approximate two week delivery window.

24 well plates to 25 L bioreactors for your screening to production level protein needs

Advanced equipment and minimal endotoxin during processing

Sino Biological argues that ProPure marks a new life sciences benchmark for the following reasons:

Researchers and biomanufacturers have a trustworthy source for recombinant proteins, enhancing accuracy, reproducibility, and safety.

The launch of the ProPure product line marks Sino Biological’s ongoing investment in both technological innovation and service to the global scientific community.

In today’s landscape of advanced biomedical research and therapeutics, using endotoxin-free proteins has never been more important. Sino Biological’s endotoxin-free recombinant proteins mean researchers and industry professionals can perform at a high standard, bolstering scientific excellence while minimising risk, according to the company. As research becomes ever more sophisticated and regulatory requirements tighten, the innovation heralds a new era of safety, consistency, and scientific integrity for life science applications.

A whitepaper from ACD/Labs examines how AI-enabled DMTA cycles can overcome fragmented workflows in drug discovery and development

Aseries of two whitepapers produced by ACD/Labs discusses how pharma and biotech organisations can leverage automation and informatics technologies to digitalise workflows, empowering faster, robust, and more cost-effective innovation.

Informatics company ACD/ Labs develops and commercialises software in support of digitalised R&D and has released a new twopart white paper series, AI-DigitalPhysical Convergence: The Future of DMTA in Drug Discovery and Development. The series explores how pharmaceutical organisations can accelerate innovation by modernising the design-make-test-analyse (DMTA) cycle through AI applications and scientific software working in concert with scientists and the physical experiments they undertake.

The papers describe the transformative potential of an ‘AIdigital-physical DMTA cycle’— which can help organisations reduce data preparation time for predictive modeling and AI/ML applications from 80% to zero.

Part one focuses on drug discovery and outlines how digital twins and AI can accelerate lead optimisation, reduce the burden of manual synthesis design, and improve decision-making across exploratory and confirmatory experimentation. By unifying design, synthesis, testing, and analysis, researchers can shorten the path to identifying viable clinical candidates while maintaining scientific rigour.

Part two discusses the implementation of these principles in pharmaceutical development focusing on Chemistry, Manufacturing, and Controls (CMC). Innovations that accelerate pharmaceutical development can significantly reduce the cost of developing an API into a drug product. AI-augmented DMTA cycles enable organisations to implement quality by design (QbD) principles more effectively; leverage design of experiments (DoE) and Bayesian optimisation for iterative and robust design; apply process digital twins for continuous optimisation and regulatory readiness; and improve drug substance characterisation and drug product formulation with higher reproducibility and compliance.

The whitepapers argue that AI can significantly reduce data preperation time for predictive modelling

‘The scientific method is being redefined,’ said Andrew Anderson, white paper author and vice president of innovation and informatics strategy at ACD/Labs. “While many R&D organisations are well into their digitalisation journeys, most continue to operate in fragmented environments that rely heavily on manual data transfer between systems. This creates inefficiencies, increases the risk of errors, and slows down the transition from scientific insight to clinical reality.”

“We’re increasingly seeing machinereadable data being the work product of experiments to help shorten project timelines. Leaders in pharmaceutical R&D are striving to enable collaborations with well-structured data—by their scientists, between scientists and machines, and machineto-machine. In this white paper series, we’re highlighting best practices from the world’s most innovative R&D organisations.”

The white paper series “AIDigital-Physical Convergence: The Future of DMTA in Drug Discovery and Development” is now available for download at acdlabs.com/ FutureofDMTA

From our founding in a former elementary school in 1985 to becoming a global, 100% employee-owned company, we’ve come a long way in our 40year history. We’re proud of our legacy of innovation, our commitment to close partnerships, and our continual investment in the future. Above all, we’re proud of the work we’ve accomplished with you.

Join the celebrations at restek.com/ restek40 A legacy of innovation, a blueprint for the future.

Dr Jakob Maciejko from Nippon Genetics explores how nextgeneration lab equipment supports the synthesis of human genomes

Anew initiative, SynHG (synthetic Human Genome) will develop scalable tools and technologies for synthesising human genomes. This five-year research project marks a bold step forward in genomics. In this article, Dr. Jakob Maciejko, product manager at Nippon Genetics Europe explores recent genomics progress and how modern lab equipment supports cuttingedge research.

Advancements in genomic research have brought the development of nucleic acid drugs (NADs), which regulate and translate nucleic acid functions. These therapies have demonstrated longlasting efficacy in gene repression, replacement and editing.

Numerous studies now discuss the feasibility of NADs in both the prevention and treatment of diseases, the most widely-recognised application of which is the COVID-19 mRNA vaccines

RNA-targeting NADs have gained significant attention in the pharmaceutical industry. Companies from AstraZeneca to Moderna are leveraging RNA-based therapies to address neurological, cardiovascular, genetic and infectious diseases, as well as metabolic disorders.

One particularly active area is oncology. As of January 31, 2024, there were at least 131 RNA-based therapies in clinical trials, with many more in pre-clinical development.

An exciting drug in the pipeline is mRNA-4359, an mRNA drug for the treatment of advanced solid tumours. The first UK patients received the experimental mRNA therapy at

Imperial College Healthcare NHS Trust as part of a phase 1/2 clinical trial in October 2024.

Dr David Pinato, a clinician scientist at Imperial College London’s Department of Surgery Cancer states, “This research is still in the early stages and may be a number of years from being available to patients, but this trial is laying crucial groundwork that is moving us closer towards new therapies.”

Traditional UV-based gel documentation systems, which have remained largely unchanged for over two decades, still dominate despite their limitations. These systems expose lab personnel to harmful UV radiation and can degrade nucleic acid samples, compromising accuracy.

Modern alternatives such as Blue/ Green LED-based systems offer

significant improvements. The LED light is emitted in the visible spectrum and causes no damage for the sample or for the user.

Planet A Foods chose the gel doc system with Blue/Green LED technology from Nippon Genetics Europe as part of their project.

This system provides faster, safer and more precise DNA imaging, crucial in workflows like those at Planet A Foods.

Importantly, these advanced systems are not more expensive. In fact, their lower energy consumption reduces utility costs. Their customisable design, adaptable in complexity and size by Nippon Genetics Europe, makes them suitable for any laboratory, whether large commercial or smaller specialised.

In this article, Dr. Shun-Hsin Liang from Restek details an efficient methodology for direct, simultaneous determination of ultrashortchain, alternative, and legacy PFAS

As interest in monitoring a wider range of PFAS in both potable and nonpotable waters grows, efficient methodology becomes more important. Here, a team from Restek describes a unique approach that provides concurrent ultrashort-chain PFAS analysis along with alternative and legacy PFAS, allowing C2, C3, C4, C6, C8, and alternative compounds to be tested together instead of through separate methods. Results from verification experiments are presented.

Ultrashort-chain, or C2 and C3, per- and polyfluoroalkyl substances (PFAS) are small and very polar compounds that contribute to at least 40% of the total PFAS detected in environmental waters (e.g., rain, river, and groundwaters) [1, 2, 3]. Ultrashortchain PFAS include trifluoroacetic acid (TFA), perfluoropropanoic acid (PFPrA), perfluoroethane sulfonate (PFEtS), and perfluoropropane sulfonate (PFPrS), with TFA being the most abundant and difficult to analyse chromatographically. Current practices for PFAS monitoring do not address the analysis of these newly trending ultrashort-chain compounds owing to their insufficient retention on typical reversed-phase (RP) columns. On the other hand, analytical methods implementing anion-exchange chromatography often show too much retention and poor chromatographic

performance for ultrashort-chain PFAS. The challenge becomes even greater for simultaneous monitoring of ultrashort-chain, alternative, and legacy PFAS in a single method. To overcome this limitation, we used a unique hybrid HILIC/ion-exchange column (Raptor Polar X) to develop a fast and simple LC-MS/MS method for comprehensive analysis of C2, C3, C4, C6, C8, and alternative PFAS. Because the column employs balanced, multimode retention mechanisms, ultrashort-chain PFAS and long-chain PFAS can all be analysed in a single isocratic run. This direct injection method was evaluated by precision and accuracy analysis of fortified water samples, including tap water, river water, groundwater, and water from publicly owned treatment works (POTW, sewage effluent). As demonstrated here, the method provides convenient setup and high-throughput conditions for water testing labs interested in adding ultrashort-chain PFAS analysis to the same workflow used to measure alternative and legacy PFAS.

Because the column employs balanced, multimode retention mechanisms, ultrashort-chain PFAS and long-chain PFAS can all be analysed in a single isocratic run

Chromatographic method:

The chromatographic conditions were as follows.

Column: Raptor Polar X (2.7 µm, 50 mm x 2.1 mm ID [cat.# 9311A52])

Column temp.: 40 ºC

Injection volume: 10 µL

Mobile phase A: Water, 10 mM ammonium formate, 0.05% formic acid

Mobile phase B: Acetonitrile:methanol (60:40), 0.05% formic acid

Time (min) %B

0.00 85

8.00 85

Flow rate: 0.5 mL/min

Ion mode: Negative ESI

Mode: MRM

In a polypropylene vial (used to mitigate background contamination), 250 µL of each water sample was mixed with 250 µL of methanol and 5 µL of internal standard solution (10 ng/mL of 13C2-PFHxA, 13C2PFOA, 13C3-PFBS, 13C4-PFOS in methanol). The vial was capped with a polyethylene cap (again, to reduce background contamination) for injection and analysis.

Calibration standards were prepared by using deionised water (generated by a Thermo Scientific Barnstead E-Pure system) and fortifying it with 14 analytes at a range of 10–800 ng/L. The calibration standard solutions were then diluted 1:1 in methanol following the sample preparation procedure above.