How perovskite and floating solar panels may mark a step change in energy generation

International Power Engineer has tended to focus less on solar than other forms of renewable energy, in part because we are based in the perennially overcast UK. By contrast (pun intended), parts of China and the US experience year-round sun and both countries are way ahead of the rest of the world in terms of solar capacity. However, this may be about to change. Our cover story, A Bright Future (page 8), outlines interesting developments that allow solar cells to create energy from lower levels of light than was once the case. Perhaps the most exciting is Perovskite being developed by Oxford PV in the UK (among other companies). Although the technology faces challenges such as durability and stability, the early signs are very promising. Because renewable energy tends to come from intermittent sources such as the sun when it shines and the wind when it blows, Battery Energy Storage Systems (BESS) look set to be a crucial component of the green transition. Several stories look at developments of this technology: A safe BESS boom on page 32 explores how these solutions can avoid thermal runaway, while Navigating energy use on page 30 looks at a Bess-asa-Service solution from ABB which promises to make the technology available to smaller players who might not have the funds to invest in storage solutions outright.

The team will be in Aberdeen on 12-13 November for Floating Offshore Wind. Do get in touch if you would like to discuss story ideas or other developments.

Nicola Brittain Editor

convertor A look at Hitachi’s HVDC technology

obsolete to operational A solution to legacy valve problems in power stations

BESS-as-a-Service

PUBLISHER

Jerry Ramsdale

EDITOR

Nicola Brittain nbrittain@setform.com

STAFF WRITER

Lydia Arundel larundel@setform.com

DESIGN – Dan Bennett, Jill Harris

HEAD OF PRODUCTION

Luke Wikner production@setform.com

BUSINESS MANAGERS

John Abey | Darren Ringer

ADVERTISEMENT EXECUTIVES

Paul Maher, Iain Fletcher, Peter King, Marina Grant, David Pattison

e advertising@setform.com

CONTACT US...

t +44 (0) 207 253 2545

e mail@setform.com

How EEMUA provides knowledge and know how

Wind in your sails

An overview of training schemes in the North East and Scotland

Engineering star power

The benefits of nuclear fusion

New jobs in nuclear EDF’s involvement in Sizewell looks set to create new jobs

Offshore in Europe

A preview of the OECC in Amsterdam

All aboard in Aberdeen

A look at the Renewables UK show

ammonia fuel

How to derisk ammonia as a marine fuel

Setform’s international magazine for engineers is published twice annually and distributed to senior engineers throughout the world. Other titles in the company portfolio focus on Process, Design, Transport, Oil & Gas, Energy and Mining.

The publishers do not sponsor or otherwise support any substance or service advertised or mentioned in this book; nor is the publisher responsible for the accuracy of any statement in this publication. ©2025. The entire content of this publication is protected by copyright, full details of which are available from the publishers. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior permission of the copyright owner.

Setform Limited | 6, Brownlow Mews, London, WC1N 2LD, United Kingdom

changing landscape for solar technology

Ball valves from Böhmer have been providing safe shut-off in plants, pipelines & machinery for more than 65 years.

We have always met the challenges of the most diverse applications with the right valve solution. Also in the future Böhmer ball valves keep their product promise: Highest quality & absolute reliability.

www.boehmer.de

A five-year agreement between the distribution system operator Enedis and technology company ABB aims to accelerate France’s SF6free grid transition. The deal, which can be extended to eight years, reflects the strength of the partnership as we as their joint ambition to reduce greenhouse gas emissions from the medium-voltage network infrastructure. The contract was signed and initiated in the third quarter of 2025 but financial terms were not disclosed.

In 2017, ABB and Enedis worked together to pioneer SF6-free alternatives. The partnership led to the first installation of air-insulated switchgear, Unisec V500 (a customised variant of Unisec Air) embedding vacuum circuit breakers in 2021.

Since then, the technology has been validated and incorporated into the operator’s wider network to support new solutions with SF6 gas alternatives in grid switchgear.

Hervé Champenois, chief technical officer of Enedis, said: “This renewed agreement with ABB reflects our shared ambition to reduce environmental impact and support the decarbonisation of the grid while modernising and expanding capacity. By working with partners that share our values, we can make the French electricity system more resilient for the future.”

In its annual report, released last month, the International Energy Authority has revised its figures for global renewable capacity growth downwards compared with last year, owing in large part to policy changes in the US led by the Trump administration. These include the early phase-out of federal tax incentives along with other regulatory changes. In fact, the growth expectations for renewables in the US were down almost 50% compared with last year’s forecast. China’s shift from fixed tariffs to auctions has also impacted forecasts for renewables’ growth in the Chinese market. The central government decided that the country’s solar and windfarms would no longer be guaranteed sales at a fixed price linked to coal benchmarks earlier this year. These adjustments are partly offset by buoyancy in other regions – particularly India, Europe and most emerging and developing economies – where growth prospects have been revised upward owing to ambitious new policies and targets, expanded auction volumes, faster permitting and rising deployment of rooftop solar. Corporate purchase power agreements, utility contracts and merchant plants are also a major driver, together accounting for 30% of global renewable capacity expansion to 2030.

As part of an expanded scheme to fund solar panels for NHS sites, military sites and schools, 34 NHS trusts across England will receive funding from Great British Energy and the government for new solar panels.

These NHS trusts will install the panels at around 70 more sites, from hospitals to mental health facilities.

The NHS is the single biggest public sector energy user, with an estimated annual energy bill of around £1.34bn, which has almost doubled since 2019.

Estimated energy bill savings over the panels’ lifetime could reach up to £65m, according to the government.

The scheme covers more than a third of NHS trusts in England, helping them to power health services with clean, homegrown energy, they will also have the option of being able to sell leftover energy back to the grid.

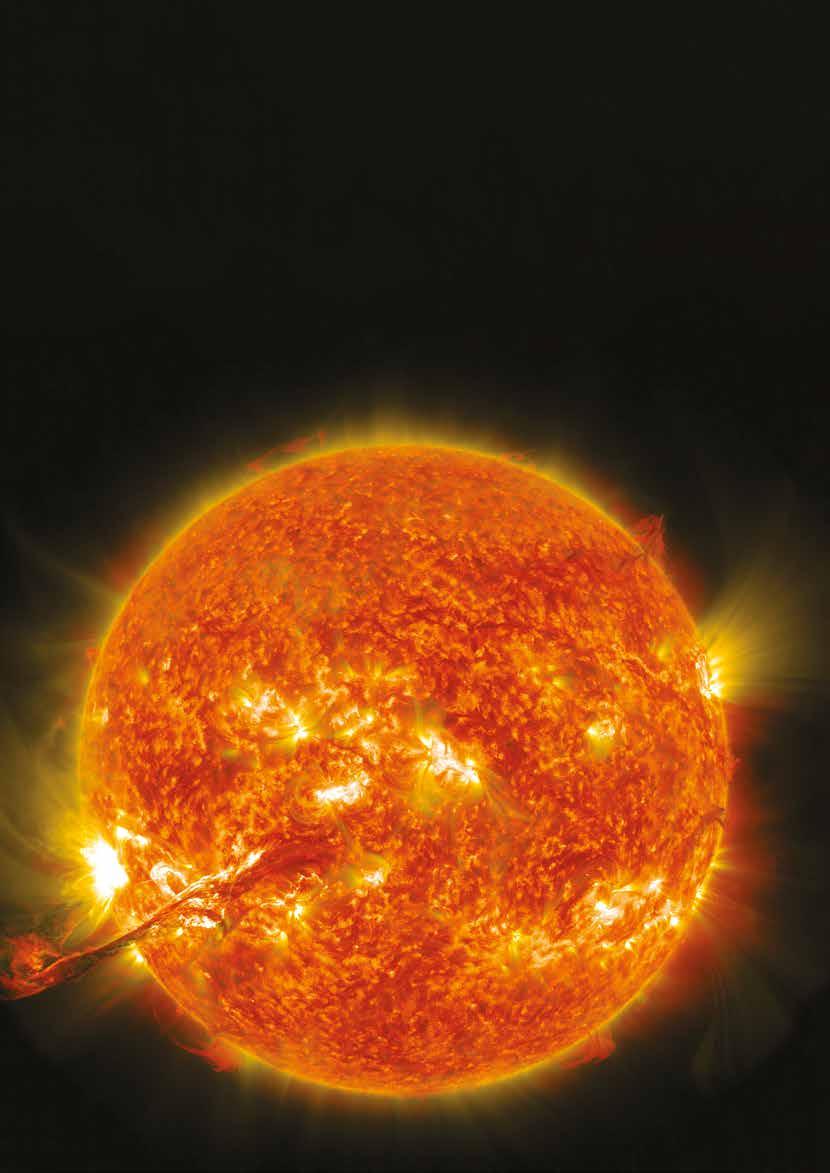

Nicola Brittain looks why those leading the green transition are banking on solar, and how perovskite and floating solar panels are likely to mark a step change in energy generation

Energy from the sun is by far the biggest natural resource available to us as humans.

According to British physicist Helen Czerski who was presenting at the New Scientist Live show earlier this month [pictured) the sun delivers 343 watts per square metre (or 173,000 terawatts) at any one time. This is significantly greater than geothermal energy (generated by the earth’s hot core) at 15.4 gigawatts (GW) of electricity at any one point or tidal energy which is even less than geothermal energy by a factor of 12. Similarly, wind energy, although important for a blustery little island like the UK, only generates the potential for 71,000 GW at one time.

It is no surprise then that use of solar power is leaping ahead of use of other renewable energy resources – and solar PV is the most widespread of these.

A report called 2025 Trends: Renewable Energy and Solar Research from Rated Power estimates that 593 GW of solar panels would be installed globally in 2024, an impressive 29% surge compared with 2023.

Industry confidence also remains high, according to the report, with the US, Spain, China, and Australia, alongside Brazil and India, expected to be the 2025 growth markets.

Most solar energy currently comes

from photovoltaic systems. These are made up of photovoltaic cells that capture sunlight which is absorbed by semi conductor material and converted into direct current (DC) electricity. Excess energy can be stored in batteries or sent back to the electrical grid.

There are many innovative ways in which this technology has developed, or is likely to develop, here are some of the most promising:

Major markets such as the US, China and Europe all have ambitious green targets meaning the sector shows no signs of slowing down

Although the technology itself is not new, making the traditional PV solar panel float will require significant engineering prowess. It’ll be worth it thought, such modules promise high yields and would benefit from the cool water.

In fact, technology company RWE has developed a floating PV plant at the company’s Amer power station site in the Netherlands. Here, 13,400 solar modules with an installed capacity of 6.1 MWp generate electricity. The cells are anchored to concrete blocks placed at the bottom of the lake, each weighs 4.6 tonnes. There are clearly high installation costs making it more expensive than traditional PV systems. Grid connectivity and infrastructure present considerable challenges to this technology since the modules are likely to be situated offshore.

N-type TOPCon (Tunnel Oxide Passivated Contact) technology is likely to become mainstream any time soon (see box out). Such modules work by using a thin layer of silicon oxide which acts as a barrier, while a layer of highly doped silicon improves electrical conductivity. They are more efficient, have lower degradation and better performance in heat than traditional PV cells. They can also be two sided.

Quantum dot (QD) solar cells are a next-generation PV technology with the potential for higher efficiency and lower cost than traditional cells. They use tiny spheres of semiconductor material measuring about 2–10 billionths of a metre in diameter. They dramatically increase the efficiency of converting sunlight into energy because of their ability to generate more than one bound electron-hole pair, or exciton, per incoming photon. Today’s solar cells produce only one exciton per incoming photon, but the ‘multiple exciton generation’ (MEG) effect of quantum dots promises more energy from each photon. In addition, varying the size of quantum dots effectively ‘tunes’ them to respond to different wavelengths of light. As quantum dots get smaller, the light spectra they absorb will shift to the blue, which represents a shorter wavelength and greater energy.

Although Perovskite cells are still in the development stage, prototypes look to be significantly more efficient at converting more of the solar spectrum into energy than PV cells at approximately 47% versus an upper limit of around 33%; they also contain low cost materials - synthetic perovskite is manufactured from bromine, chlorine, lead and tin. The product is versatile and can be made for use in flexible displays, wearable clothing and even tents! Finally perovskite can operate in low light conditions. Companies developing the technology include Oxford PV and Saule Technologies in Poland.

China is way out in front with utility scale capacity of 880 GW at end of 2024 according to the IEA. However the move from fixed feed-in tariffs to auction (from June this year is likely to create some uncertaintly for investors.

The United States is the second biggest producer with 239 GW of installed solar photovoltaic and concentrated solar power capacity at the the end of 2024.

India is a big player in this market with 97.38 GW of solar power.

The UK has around 18 GW as of early 2025, with the UK government data confirming this figure.

Major markets such as the US, China, and Europe have ambitious green targets meaning the sector shows no signs of slowing down. Advamces in storage and inverters are also improving reliability and efficiency. If current trends continue, solar energy may soon become a consistent and dependable

Solar technology is developing in many innovative ways

source that is ready to power national energy infrastructures, sustain zerocarbon cities, and anchor renewable portfolios in energy markets.

For more information visit: www.IEA.org

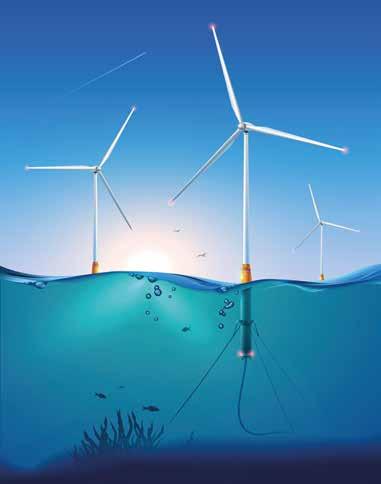

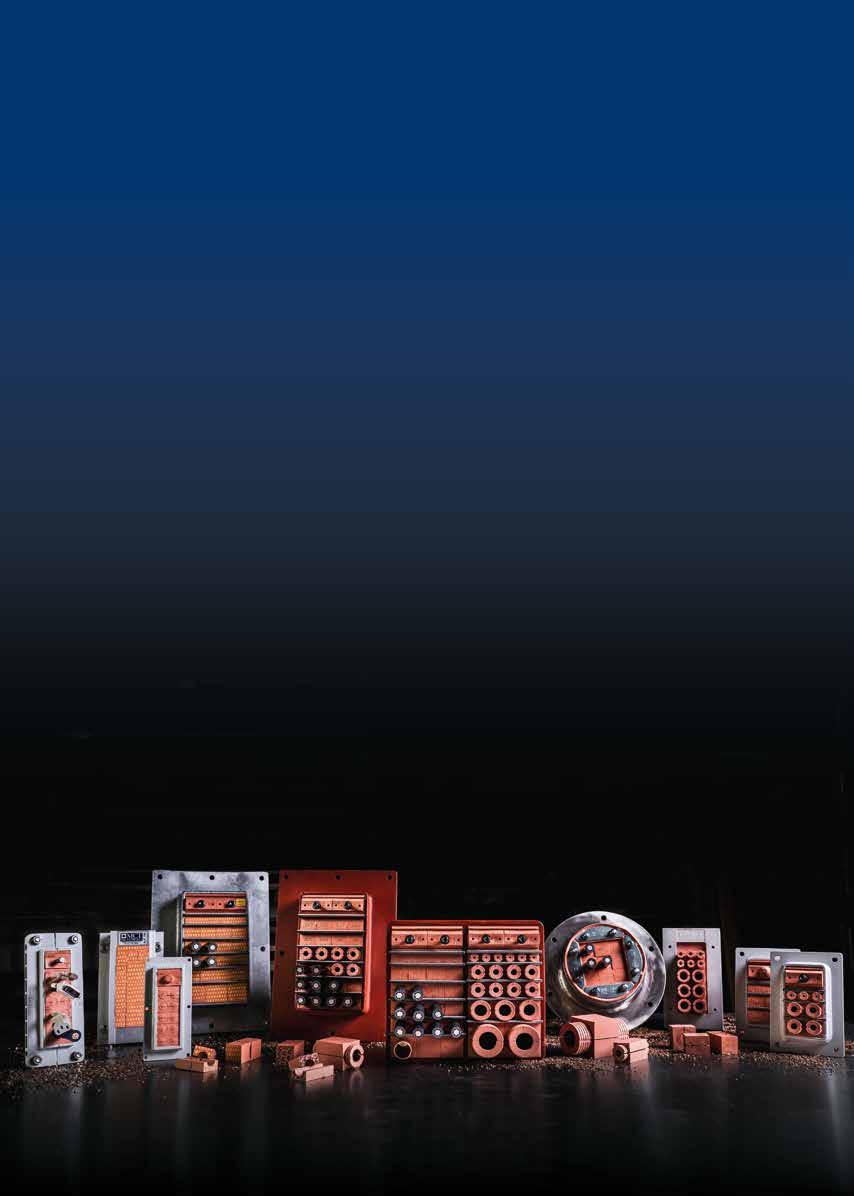

Floating offshore wind technology is powering ahead, and here we explore the critical part that sealing specialist Roxtec has to play in its succesful deployment and operation

The UK government is anticipating that 5GW of electricity generation will come from floating offshore wind by 2030, as part of its broader ambition to reach 50GW of total offshore wind capacity by that year.

Delivering the right sealing solutions for deep-water floating wind farms, which have to withstand extreme weather conditions, including high winds and waves, as well as the corrosive marine environment, is vital.

Roxtec, a long-established sealing solution provider for offshore wind, is playing its part in the development of the floating technology, working in close partnership with other companies in the field.

Roxtec’s track record as a global sealing specialist within the oil and gas sector can easily be adapted to floating offshore wind clients

Several global frontrunners are already generating electricity. For example, the 25 MW WindFloat Atlantic project, the world’s first semi-submersible floating offshore wind farm, off the coast of Viana do Castelo in Portugal, celebrated five years of operation earlier this year.

In addition, electricity production has steadily increased each year, reaching 86 GWh in 2024, and it stands as a model for commercial scale floating offshore wind energy.

Principle Power, a leader in the technology, asked that Roxtec sealing solutions help with the foundation designed for the project.

Those solutions were needed to cover low-voltage, high-voltage, and fibre optic cables; cables in multicore or trefoil formation and cables with varying bending radius and thickness, entering columns or passing through steel bulkheads.

The collaborative work of Roxtec and Principle Power led to a standardised solution flexible enough to meet the individual needs of each cable within the same penetration.

The work provided Principle Power with a library of options ready for deployment. It also used the Roxtec Transit Designer software to specify the various seals, considering the cable properties and required protection for each penetration.

The software allows hundreds of cable and pipe transits to be ‘designed in’ to a project in just a few minutes, simplifying product selection as well as the entire process that surrounds cable and pipe transits.

Seth Price, vice president of technology and innovation for Principle Power, said: “Roxtec is among the internationally recognised sealing specialists, with track-record and experience within oil and gas that can be adapted to the floating wind sector.

“We have been laser-focused on every detail of our technology to ensure quality, fabrication efficiency, and reliability. Applying standardised solutions that are readily available in the industry, like Roxtec seals, has proven to be successful.”

He added: “This type of solution will be instrumental for upcoming projects as we optimise technology for commercial scale and aim to deliver reliable cost-competitive solutions to project developers.”

Spanish headquartered Saitec Offshore Technologies also specified Roxtec cable seals for its innovative SATH floating wind turbine concept –a unique floating platform for offshore wind turbines suitable for shallow and deep waters.

A fully watertight sealing solution for the offshore environment was

required. Seals for partitions and cabinets also had to be openable and removable in case more cables or ducts needed to be installed.

Roxtec’s proven offshore performance and customised solutions proved invaluable to the development project. Its round seals and rectangular and compact cable and pipe transits were used to seal off cable ducts for low-voltage and medium-voltage cables, as well as closing off refrigeration ducts from the exterior offshore environment.

Seals of different sizes were used for marine type power cables and pipes. Roxtec also created a customised sealing module to help Saitec seal flat cables.

Aitor Sanz, offshore wind MEP manager at Saitec Offshore Technologies, said: “We need offshore environmental protection of the internal equipment and cabinets of the wind turbine generator at the transition piece and other areas of the floating platform.

“We developed an excellent collaboration with the Roxtec team and we believe that their watertight solution will have a great performance in harsh offshore conditions.”

Rob Cullen, decarbonisation

technical manager at Roxtec UK and Ireland, says the projects highlight how the business is well positioned to deliver solutions that work for floating offshore wind energy projects as the drive towards commercialisation quickens.

He says: “Since 2002, Roxtec has been a leading supplier to the wind power industry, participating in over 130 large-scale projects. Today our cable and pipe sealing solutions can be found in more than 90 per cent of wind farms worldwide.

“It is that level of expertise and technical know-how, coupled with our partnership approach, that will be vital for companies as they work to deliver floating offshore wind farms in harsh conditions.”

Roxtec was founded in Sweden in 1990. It is now the global leader in the manufacture of innovative cable and pipe transit systems and is active in more than 80 markets with a turnover of more than £271million (US$364m).

Roxtec’s products are designed to seal cables and pipes, and are used to protect people, buildings and equipment from multiple hazards

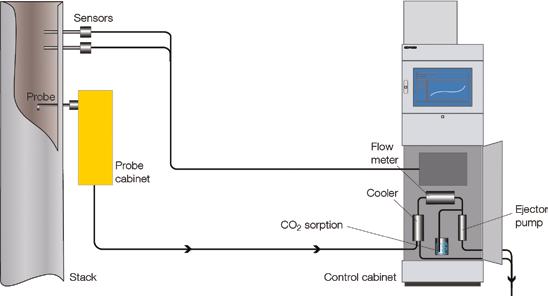

Bengt Löfstedt from Opsis takes a look at the EU’s emissions trading system and how clever sampling of CO2 can help operators using mixed fuels for energy production reduce emission permits costs

The European Union’s greenhouse gas (GHG) emissions trading system (the EU ETS or just ETS) became effective in 2005. It has evolved ever since and continues to do so. It is claimed to be the world’s most comprehensive system for controlling GHG emissions and is thereby also an important tool to cap global warming and fight climate change.

Operators under ETS must monitor their GHG emissions to ambient air, report these emissions to relevant authorities, and acquire and hand over the corresponding number of emission permits to these authorities.

Emission permits are issued by the EU and largely made available to the operators on an open market where the permits can be bought and sold. The EU controls the total number of new permits being issued, thereby also controlling an increasing share of the GHG emissions.

ETS currently applies to well over 10,000 entities within the EU, active in many types of large-scale industries. This includes for example power generation, refineries, steel and aluminium production, cement industry, glass manufacturing, and pulp and paper production.

The GHG list includes carbon dioxide (CO2), methane, nitrous oxide, and a few fluoride compounds. However, for most types of industries it is so far only CO2 emissions that are covered by the ETS so this article will focus on CO2 from here on.

There are various methods to determine CO2 emissions. For example, the flow of incoming fuel and raw materials can be monitored then multiplied by standardised emission factors, often different for different

industries, fuels, and other materials, giving the emissions in tonnes of CO2 per year.

Another approach is direct measurement of the flue gas flow and its CO2 concentration emitted to the ambient air. The CO2 emissions in weight-per-time unit is given by the product of the measurands.

Emission permits are made available and traded on the European Energy Exchange, EEX. They are commodities with a spot price that changes with supply and demand. A permit to emit one tonne of CO2 currently (2025) costs around €60-80.

The revenue received by the EU for the sale of emission permits is distributed among the member states and goes straight into the respective state budget.

There are many cases where ETS is not applicable or has limited impact. For example, since CO2 generated from biomass fuels does not add to the net greenhouse effect, facilities burning biomass do not have to acquire and

hand in any emission permits.

Another exemption is waste-toenergy plants. However, from 2024, installations for the incineration of municipal waste are obliged to monitor and report CO2 emissions. By mid-2026, the EU commission will present a feasibility study of the inclusion of municipal waste incineration installations in ETS. It is envisaged that full inclusion will apply from 2028.

Individual EU member states may also introduce stricter regulations than the core ETS stipulates. Some waste-to-energy facilities in some EU countries are already subject to ETS under national laws and regulations.

The exemption for biomass fuels also applies to cases of mixed fuels with both fossil and biomass origin. Notably, this is the case at many waste-to-energy facilities incinerating municipal waste, although that type of industry is generally exempted from ETS within most parts of the EU. Mixed fuels can also be used in other contexts, for example at cement manufacturing facilities.

Emission permits are issued by the EU and largely made available to the operators on an open market where they can be bought and sold

Operators liable for ETS or ETSlike legislation and using mixed fuels need to acquire and hand in emission permits for the fossil share of their CO2 emissions, but only for this - the biomass fuel share is exempt. The easiest way to establish the biomass fraction is then to rely on a standard fraction number published by competent authorities.

However, it is also possible to measure the actual biomass fraction by means of CO2 sampling and subsequent carbon-14 analysis. This works as follows: if the fuel is fresh biomass only, the carbon-14 content is effectively the same as for living

The operating principle of a CO2 sampler. Isokinetic sampling takes place at the probe. A fixed fraction of the sample flow is led into a sorbent where the CO2 is captured. After a set sampling time, the sorbent material is sent to a laboratory for carbon-14 analysis. Illustration: Opsis AB

organisms. If the fuel is fossil, the carbon-14 content is zero owing to natural decay. A value in-between reveals the biomass share.

Sampling and subsequent analysis of biomass CO2 come with a price tag but the savings through less need for emission permits can still be notable. Let us look at an example.

Roughly speaking, one tonne of mixed household waste gives rise to about one tonne of CO2 emitted to the air. Further, a mid-sized waste-toenergy facility consumes in the range of 100,000 tonnes of waste per year, so let us use this in the example. Let us also assume that the standard biomass fraction determined by the authorities is 50%. The operator of the facility in the example must then acquire and hand over 50,000

emission permits per year.

With a permit pricing of say €70 per unit and setting aside any free permits that in some cases can be granted, the example operator has a cost for its fossil CO2 emissions in the range of €3.5m per year.

Now, if the operator can prove just a single percentage unit higher biomass fraction than stipulated by the standard, the cost saving through reduced need for emission permits would be 0.01 x €3.5m = €35k per year. That should cover the costs for amortisation of sampling equipment, labour, and subsequent CO2 analysis, and might still give a net saving on the bottom line. For a larger plant and/or one with more biomass CO2, the savings can be huge.

For further insights around how you might benefit from CO2, sampling contact Opsis.

For a larger plant and/or one with a higher share of biomass CO2, the savings can be huge

www.opsis.se

Self-lubricating plain bearings are set to conquer offshore wind turbine construction, according to Thomas Dittert from Oiles. Here he explains why they outperform other types under high mechanical loads

The question of the best possible bearing system for wind power technology components is likely to occupy designers and developers once again at this year’s Offshore Energy Show in Amsterdam (previewed on page 48). Among other things, it is aspects such as friction and wear minimisation that allow self-lubricating plain bearing solutions from Oiles to play an increasingly important role. In addition, the maintenancefree machine elements support the realisation of compact wind turbine designs and have proven to be both economical and environmentally friendly. When it comes to slow rotating, oscillating or linear movements under high mechanical loads, plain bearings from this internationally renowned manufacturer are a good choice.

In addition, Oiles plain bearing solutions are finding more applications in green energy. While they have been the preferred bearing system for plant engineers in hydro technology and hydraulic steel engineering for decades, designers and developers of offshore renewable power are now also discovering the advantages of the technology. This is often triggered by the problems that conventional rolling bearings cause in the operation of modern offshore wind turbines: where longer downtimes, frequent impact loads and low speeds are the order of the day, rolling bearings quickly reach their technical limits. This results in increased maintenance and repair costs, both being fundamentally unacceptable given the already complex maintenance of offshore wind turbines. Added to this is another aspect that is a knockout criterion for the ecological balance of any green energy application: dependence on an external lubricant

supply, which always poses a potential environmental hazard.

The decision to use self-lubricating Oiles plain bearings frees both the designers and operators of wind turbines from these problems. The plain bearings from this manufacturer can be used wherever slow rotating, oscillating or linear movements must be performed under high mechanical loads. Specifically, the bearings are made of special alloys or innovative composite materials and can be used, for example, in gearboxes, in the adjustment units of pitch and azimuth systems, and in mooring connectors. Thanks to their compact design, they can be easily

integrated into the structures and support the implementation of weight- and material-reduced designs. In practice, their tribological advantages ensure low-friction and efficient plant operation. Above all, however, because they are selflubricating thanks to their structurally integrated solid lubricants, they do not require any external lubricant supply. In addition to the positive ecological effect and maintenance-free operation, this means that the cost of a centralised or decentralised lubrication system is completely eliminated.

A new RSTX 100 remote control from Auma is a convenient yet highly capable way to operate actuators on site, saving staff time and effort when at work

The RSTX 100 gives full access to all important tasks related to Auma actuators. Its large, high resolution colour display shows the entire communication, including the actuator’s response. With a Bluetooth range of up to 20 metres, operators can operate valves, view actuator status and change settings without climbing ladders or entering confined spaces, even when the actuator’s own display is out of sight.

The RSTX 100 is robust yet ergonomic and easy and intuitive to use, even when wearing gloves. The unit is ATEX- and IECEx-certified as intrinsically safe (Ex ia) for use in potentially explosive atmospheres.

The RSTX 100 remote control works seamlessly with any Auma actuator in the current range: Profox, Tigron, and SA and SQ with AC 01.2 controls. Users can therefore operate different Auma actuator types in their plant in the same intuitive way, speeding up daily work and reducing the need for training.

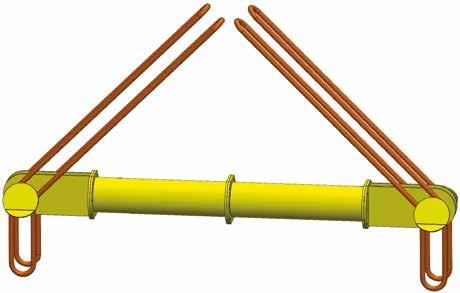

As a specialist in (custom) engineered lifting solutions, Slingsintt recently introduced two standardised products: the Modular Spreader Beam and the Multi-Purpose Lifting Beam. The company shared a Q&A with the young engineer who led the development, Unai Erro (pictured right), to provide insight into the thinking behind these products. Supported by senior engineering staff, this also marked Unai’s first project within the organisation.

Q: WHAT PROMPTED THE DEVELOPMENT OF THE MODULAR SPREADER AND MULTI-PURPOSE LIFTING BEAM?

Not every lifting operation calls for a fully customised solution. In many cases, a well-designed, standardised tool can handle the job just as well. We also wanted to create something versatile, something that could be used across different lifting scenarios without the long lead times, associated (design) costs or added complexity of custom designs. We wanted to develop something that would make life easier for our clients. That’s really where the idea started.

Q: WHAT ARE THE ADVANTAGES OF THE SLINGSINTT’S MODULAR SPREADER AND MULTIPURPOSE LIFTING BEAM COMPARED WITH SIMILAR PRODUCTS ON THE MARKET?

We wanted to push the limits of what is available in the market. Compared to similar products, our beams offer higher load capacities. The Modular Spreader Beam handles up to 110 tons with lengths up to 24 metres and the Multi-Purpose Beam supports up to 100 tons and is being developed for lengths up to 25 metres. We also

An engineer from lifting solution specialist Slingsintt provides insights into his considerations and workings when creating two of the company’s new beams

developed a dedicated transport beam for the Multi-Purpose Lifting Beam to simplify handling, storage and logistics.

Q: WHAT DID THE R&D JOURNEY LOOK LIKE FROM CONCEPT TO FINAL PRODUCT?

We began with a thorough analysis of industry standards and a review of competitor products. We explored multiple design concepts and assessed their feasibility through simulations and engineering calculations. After evaluating the options, we determined that the selected designs offered the most effective balance of performance, versatility, and manufacturability.

Q: HOW DID THE TRANSITION FROM PROTOTYPE TO PRODUCTION GO AND WERE THERE ANY CHALLENGES?

The transition for both beams proceeded smoothly. The only issue encountered was with the Multi-

Purpose Lifting Beam where there was a minor misunderstanding that led to a misalignment in the hole placement, which was quickly resolved.

Q: HOW ARE BOTH BEAMS CURRENTLY BEING RECEIVED IN THE MARKET?

Initial market response for both beams has been very positive. The prototype of the beam was successfully tested at a client site, which led to multiple quotation requests. Since then, multiple units have been sold.

Q: ARE THERE ANY FUTURE PLANS FOR THESE PRODUCTS?

We’re planning to stock both the Modular Spreader Beam and the Multi-Purpose Lifting Beam. And we’ve added a Solidworks extension that automates the design phase. Since lifting point distances often vary per customer, the tool allows us to quickly adjust configurations based on load limits and beam length. It instantly generates both 2D and 3D models, significantly reducing design time and speeding up production. The extension could also support features like automated first-price quotations, giving clients a quick cost estimate and streamlining the sales process.

The Slingsintt modular spreader beam

The UK’s plans green transition plans are ambitious, however grid connection issues are a big challenge. Here we provide insight into these, and how IDNO Vattenfall plans to address them

The UK government wants to reach 95% clean energy by 2030 and this admirable goal and the ongoing green transition has seen a proliferation of clean energy projects launched.

There are currently 217 offshore wind farm projects as well as dozens of onshore wind farms; 198 active hydrogen plants planned with 24 currently in operation. Nuclear, another clean energy source, has seen the government invest in projects like Sizewell C and develop small modular reactors (SMRs) with companies like Rolls-Royce. These initiatives aim to boost energy security and meet climate goals by creating a ‘golden age’ of clean power, according to the UK’s energy secretary Ed Miliband. All promising stuff, however

connection delays threaten to thwart the transition, with an old, overwhelmed grid and network; a backlog of projects waiting for connection; and many unviable projects clogging the pipeline.

Much is being done to address these challenges, not least the establishment of the National Energy System Operator (NESO) in October 2024 which has introduced reforms to replace the old non-prioritised system with milestone and gated processes. This is helping to prioritise viable projects over those that are less well engineered.

The energy regulator Ofgem has approved initial funding of £24.2bn for 2026/27 to 2030/31, part of a wider

£80bn investment program.

The National Grid Group plans to invest around £60bn over the next five years to scale up infrastructure projects in both the UK and US. Projects include upgrades to substations as well as new builds and the construction of new high-voltage power lines.

The UK’s total electricity demand is expected to rise by 50% over the next ten years and double by 2050, driven in part by the rapid growth of energyintensive data centres.

The upshot is that many developers are stuck in the queue, able to generate energy but with no way of sharing this with the grid. As such

Vattenfall, an Independent Distribution Network Operator, has launched a new consultancy service to support them through grid connection challenges.

The product, called The Simple Grid Consultancy service, has been designed to help developers of sub2MVA projects who need answers to critical questions about power availability, grid viability, and likely connection costs.

The company will provide access to grid specialists, project managers, and engineers, who will help navigate feasibility studies, Point of Connection (PoC) applications, cable routes, mini-tenders for contestable works, and legal support for land rights. All will be designed to reduce risk and remove friction from the process.

Launched last month, the consultancy comes at a time when it seems that access to electricity is the main issue delaying UK construction projects. According to global professional services company Turner & Townsend’s latest report,

grid delays are now on par with planning as a leading risk for the green transition, with councils in areas such as West London, Swindon, Oxfordshire and Cambridge already reporting stalled developments owing to local capacity shortages.

“Grid access has become the new bottleneck,” says Stewart Dawson, managing director at Vattenfall IDNO. “We’re seeing growing frustration from developers trying to do the right thing, moving quickly to decarbonise,

electrifying operations, and scaling renewables but then unable to connect to the grid. Our new service offers developers a package of support, expert technical advice, and strategies without locking them into expensive, long-term engagements.”

Prioritise grid connections: Grid connection should be a core strategic consideration for developers.

Engage early: Developers must engage with grid operators early in the process to secure realistic connection dates.

Integrate energy resilience: Projects should incorporate energy resilience into their designs from the outset.

Consider alternative solutions:

- Phased connections

- On-site power generation

- Using existing infrastructure where possible

- Developing on brownfield land with existing cables

Navigate the connection queue: Managing the connection queue is now essential for project success.

As a UK-based manufacturer with over 50 years of experience, KOSO Kent Introl designs and supplies Control and Choke Valves to energy markets around the world. With deep engineering expertise and proven performance in the most demanding environments, we’re ideally placed to support the industry’s transition towards cleaner, more sustainable energy, onshore, offshore and subsea.

We engineer and supply high-performance valves built to withstand some of the world’s most demanding service conditions.

Our detailed records of every valve and component we’ve ever supplied allow us to help you plan and implement a strategic approach to valve asset management.

With extensive in-house facilities and a responsive service team, we ensure your valves are maintained safely, effectively with minimal downtime.

We support your investment throughout its lifecycle with genuine OEM spares, ensuring continued performance and reliability.

As your asset’s life progresses, we can review, engineer and install suitable upgrades or replacement internals to keep your process operating at peak performance.

Using in-house Laser Powder Bed Fusion technology, our additive manufacturing team can design and produce complex components quickly and with exceptional precision.

Retrofit specialist from Sulzer Peter Irlam explores whether pump retrofits can boost profitability and efficiency in ageing power plants

As extreme heat pushes cooling demand to new highs, gas power is proving essential for keeping the grid stable and flexible.

This trend is becoming increasingly common, as countries turn to gas to meet soaring demand and fill critical gaps in the energy mix. Last summer, powerful heatwaves in India increased gas demand by 32% between May and July as higher cooling needs drove electricity use, according to the IEA. Meanwhile in Brazil and Colombia, limited hydropower output caused by extreme droughts similarly increased

gas-fired power. Then over winter, slow wind speeds in Europe led to a sharp decline in wind power output with gas generators bridging the gap by increasing output by 80% year-on-year. Despite playing a critical role in grid balancing, many gas generators are faced with an uncertain future. A mixture of environmental pressures, geopolitical tensions, a competitive global gas market and increasing renewable power generation are presenting increased risks and opportunities. In addition, over the past decade, many gas power plants have been required to switch from

baseload to backup generation where flexible operation requires faster and more frequent start-ups to respond to fluctuating grid demand with an enhanced focus on competitiveness and profitability.

Amid a changing environment, one area where power plant operators still have control is the efficiency of their power plants. For those plants built in the 1990s and 2000s, the possible energy efficiency gains may be especially large owing to improved equipment

and plant designs. In earlier plant designs, equipment such as pumps was oversized right from the start.

For example, safety regulations require a boiler to be pressure tested periodically beyond their typical operating limits to ensure the correct function of all protective equipment. The corresponding pumps must be deliberately oversized to facilitate this. As a result, more than 99 percent of the time, those pumps are throttled, leading to significant energy waste. In other cases, pumps have become oversized owing to changing operating conditions and most have deviated from their best efficiency points because of age-related deterioration.

According to a recent research conducted by Sulzer, nearly 40% of the pumps in fossil-fueled power plants ran outside of their preferred operating range for more than 80 percent of the time. It is estimated that these inefficiencies lead to hundreds of thousands of dollars of energy wasted with significant carbon emissions each year, depending on pump type and operation regime. The energy efficiency improvement potential is especially high for BB3 pumps – the workhorse of many mid-sized power plants – with over 50 percent of those analysed capable of saving $50,000 or more annually.

Many operators have put energy efficiency projects on hold in order to prioritise baseload power. It can be difficult to schedule in additional projects when a typical shutdown is already tightly choreographed with people and projects all needing the same resources – from cranes to workshop space. However, when it comes to retrofitting pumps to improve energy efficiency, many implementations can be completed while the plant is operating.

Sulzer has performed over 60 retrofit projects on power plants alone from its UK-based location. For example, an East of England power plant’s hot gas path components had reached

the end of their life. The replacement gas turbine had an increased exhaust gas temperature which created an opportunity for additional energy recovery from the steam cycle. To take advantage, the boiler feed pumps needed to be uprated.

Rather than replacing, the operator chose to modify the existing pumps. To achieve a 20% increase in heat while accommodating onsite constraints, Sulzer designed a bespoke hydraulic using first principles with a larger diameter. Stage casings were modified to suit, and customised wear parts were fitted. All other major components were retained. With minimal downtime and no changes to the pump’s footprint or interface, the package of works resulted in an increase of 74MW in corrected net output and a 2.9% increase in cycle efficiency.

While gas-fired electricity generation will continue to play a critical role in grid balancing, the landscape is becoming increasingly competitive putting pressure on operators to find new ways to improve profitability. Improving pump efficiency is a huge untapped opportunity within the power sector. With many power plant pumps found to be running outside of their preferred operating range, hundreds of thousands of dollars and hundreds of tonnes of carbon could be saved a year with a bespoke retrofit solution.

Nicola Brittain asks Laura Fleming, country managing director, Hitachi Energy UK & Ireland, about the company’s role in the offshore wind industry as well as the challenges faced by the sector

Manufacturer of HVDC technology Hitachi is playing a key role in the energy transition. In this Q&A Hitachi Energy UK & Ireland, country managing director Laura Flemming explains the crucial role of these transformers and the importance of planning and integration of players in the supply chain.

Q: WHY ARE HVDC TRANSFORMERS SO IMPORTANT FOR GRID TRANSFORMATION AND WHAT DO THEY REPLACE?

High Voltage Direct Current (HVDC) technology and the transformers that come with that solution allow us to transport electricity over longer distances with fewer losses than would be the case with AC (alternate current) solutions. This is needed because of the increase in renewable energy generation from offshore wind - much of this is from wind farms situated quite far off the coast.

The turbines generate AC power, this is collected in the sub station offshore and transformed into DC which is then transported onshore to another substation where it’s collected again in DC, transformed back to AC and put into the grid. So many of the projects in the North East of Scotland are generating energy used in London and the Midlands, and so the power generated in Scotland needs to be transported to the demand centres a long way away.

The big change that we see as we decarbonise is that traditionally the generation sources were built close to the demand centres. Switching to renewable, that paradigm is shifting because the power stations need to be located where we can generate energy.

The way that we’re using energy and electricity is also changing. There is a great deal of electrification happening. Electricity demand is predicted between now and 2040. This is because we’ll be using fewer fossil fuels, but also day to day energy use will be electricity.

A key challenge is the aging grid. It hasn’t been upgraded since the mid 60s and 70s. Now we need much more centralised planning not just around the current demand but the likely electricity demand over the next ten or 15 years.

PLAY INTO THIS?

Yes, so the government started off the planning process with the Holistic Network Design. This is an initiative by the National Grid (now part of the National Energy System Operator (NESO)) to design a strategic offshore and onshore

Fleming is leading Hitachi Energy’s UK and Ireland division

electricity network to support the UK’s clean energy goals, as detailed in its Beyond 2030 publication. This started to plan out to the mid 2030s. Every year now we will see an additional strategy plan coming on top of that. There will also be a Strategy Energy Network Plan released next year that will determine strategic regional and local energy network classes. This is starting to give us the visibility we need.

There are a lot of good plans and there is a recognition that we need to move into action. Ofgem and NISO have been very helpful in terms of allowing customers to access the supply chain particularly for long lead items. The HVDC technology is highly sought after and takes years to manufacture, so changes made by OFGEM and NISA allow customers to place advanced orders, this is very helpful.

Marketing around the successful projects to get the public on board is crucial since public support will be essential to this transition.

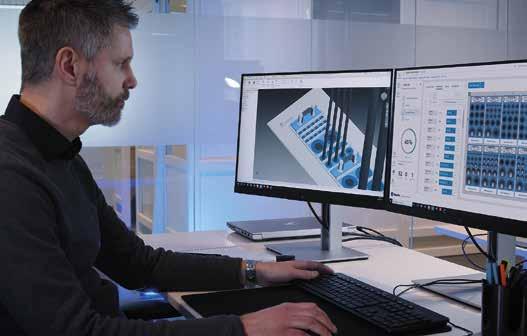

When a legacy valve supplied nearly 30 years ago developed problems on a Main Oil Line application, KOSO Kent Introl’s engineers faced a familiar challenge: an obsolete design, a critical deadline, and no time for long lead times. Here we explore their innovative solution

For more than half a century, Koso Kent Introl has been at the forefront of British valve engineering, supporting the global energy sector from its manufacturing base in Brighouse, West Yorkshire. Founded in 1967, the company has built its reputation on engineering excellence, reliability, and an ability to deliver bespoke control and choke valve solutions that perform in some of the harshest operating conditions on earth. That same commitment to innovation and service was demonstrated when the company was called upon to help solve a

critical issue for a long-standing energy client.

The story began with a valve originally supplied back in 1995. The unit had been performing on a MOL application for decades before operators began to report erratic performance. Early investigation pointed towards internal wear and flow instability, prompting the client to reach out to the original manufacturer for support.

The engineering team immediately set to work. The valve was returned

to KOSO Kent Introl’s UK facility for a full strip-down and inspection. It was during this process that the root cause was identified. The internal trim, of the now obsolete Turbotrol type, had reached the end of its serviceable life.

In normal circumstances, the next step would be straightforward, manufacture and install a new trim. The challenge lay in the fact that the Turbotrol design was long out of production. Standard parts were no longer available, and lead times for a traditionally manufactured alternative would have been far too lengthy for such a critical MOL application.

Rather than treat obsolescence as a barrier, the applications team saw it as an opportunity to innovate. Drawing on extensive valve performance data and experience, they specified a new labyrinth trim designed to deliver equivalent, if not enhanced, flow characteristics compared with the original design. Labyrinth trims are renowned for their precise flow control and ability to manage high-pressure drops, but they are typically produced through disc stack manufacturing. This involves the precision stacking and

Renishaw LPBF machine

bonding of multiple plates to create complex flow paths. While effective, it can also result in significant lead times owing to the intricate machining and assembly required. For this project, time was a luxury the operator did not have.

With the MOL’s performance at stake, the team turned to its in-house additive manufacturing capabilities. Using Laser Powder Bed Fusion (LPBF) technology, the additive engineers were able to design, build, and produce the replacement labyrinth trim entirely in-house, from initial CAD modelling and simulation to final machining and heat treatment.

The entire process, from concept to completion, took just two weeks. That turnaround included the precision build of the trim, subsequent machining operations and post-processing stages such as heat treatment and surface finishing, all under one roof. This rapid response not only restored the valve to full operational performance but also demonstrated how additive manufacturing can transform the maintenance and lifecycle management of legacy assets.

Once completed, the newly manufactured trim was installed

Labyrinth trims are renowned for their precise flow control and ability to manage high-pressure drops but they are typically produced through disc stack manufacturing

during the valve’s rebuild, which was carried out by the service team. The valve then underwent a full flow test to verify the Cv calculations provided by the applications engineers.

The operator’s representative attended the test, witnessing firsthand the precision and performance of the rebuilt valve. The successful test confirmed that the new labyrinth trim met the required performance criteria, validating both the design and the additive manufacturing process that produced it.

The entire manufacture, rebuild and test cycle, from initial investigation to final installation, was completed within the UK using the company’s in-house engineering resources. It was a compelling demonstration of how a well-established manufacturer can combine decades of experience with cutting-edge technology to solve modern challenges.

By integrating additive manufacturing into its operations, the business can now provide faster, more flexible solutions for clients dealing with obsolete components, long lead times, or critical service interruptions. The success of this project has already inspired wider interest, with the operator now citing it as a benchmark example of additive innovation within their UK platform, the first of its kind to be deployed.

For Koso Kent Introl, projects like this reaffirm a commitment to supporting customers throughout the entire lifecycle of their assets. Whether it is restoring a 30-yearold valve to full functionality or developing new designs for emerging energy technologies, the principle remains the same, the company engineers the solution that best serves the application.

BESS -as-a-Service eliminates CapEx costs for customers

A whitepaper from ABB released in partnership with think tank GridBeyond aims to help businesses and organisations transform energy management and reduce carbon emissions

Global electricity demand is projected to surge 75% by 2050. Alongside this, businesses worldwide are facing mounting pressure on grid infrastructure, rising costs, and the challenge of maintaining a reliable power supply. Yet, for many businesses, the upfront costs and complexity of battery storage have prevented them understanding how they might better management their energy use.

The paper called Batteries Without Barriers looks at managed BESS systems or a BESS-as-a-Service model.

This eliminates traditional barriers to entry by delivering profits exceeding service fees from day one, transferring all risks to the provider, converting CapEx to predictable OpEx, and managing the full asset lifecycle.

Stuart Thompson, president of ABB Electrification Service said: “The business case for battery storage has never been stronger. Such solutions deliver immediate financial returns, operational resilience, and the flexibility to adapt to changing market conditions.

With BESS-as-a-Service, the barriers to entry are eliminated: no upfront capital, no technology risk, just immediate access to cost savings and new revenue opportunities. Whether companies are pursuing sustainability goals or simply looking to optimise their energy spend, battery storage delivers tangible value from day one.”

The whitepaper argues that the solution would help reduce costs for customers through peak shaving and demand charge management; market participation via energy arbitrage and frequency regulation, infrastructure savings by avoiding grid upgrade costs, and business continuity through back-up power protection.

As with all ‘as-a-service’ models, however there is a downside. Not least limited ownership for customers and the lack of tailored solutions for more complex needs.

To download the full whitepaper, visit: https://global.abb/group/en

For more information visit: www.abb.com

Prioritise grid connections: Grid connection should be a core strategic consideration for developers.

The global BESS market is forecast to reach US$150bn by 2030, with storage now the critical enabler of renewable integration.

BESS-as-a-Service eliminates CapEx and customers pay a predictable OpEx fee, while the services provider manages performance, maintenance, and trading.

The paper makes the case that financial returns exceed service fees.

AI-driven energy forecasting and optimisation maximise revenue streams through price arbitrage, frequency regulation, and demandcharge management.

By balancing cost, carbon, and continuity, businesses can reduce grid reliance, enhance energy security, and progress toward net-zero targets profitably.

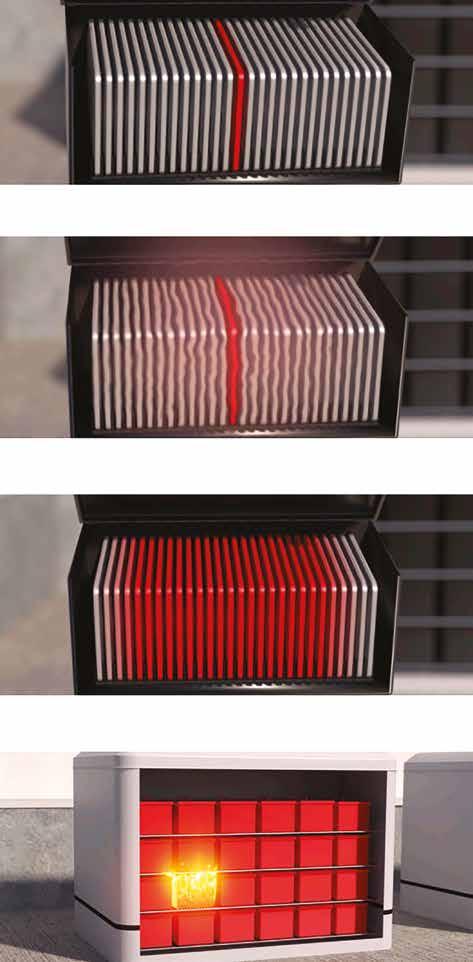

Battery energy storage systems are a critical component of any renewable energy infrastructure but are the safety aspects being fully considered?

The world’s push toward renewable energy transformation continues to charge ahead at full speed. Battery energy storage systems (BESS) are a critical component of renewable energy infrastructure, capturing excess wind and solar power, balancing grids and powering microgrids.

According to S&P Global, the global market for BESS doubled in 2023, reaching 90 GWh of storage capacity. It also means thousands of large-scale lithium-ion battery installations are now operating near homes, stores, hospitals, schools and other populated areas – any of which could be susceptible to battery fires caused by thermal runaway.

Thermal runaway is a violent and unpredictable chemical reaction inside a lithium-ion cell that’s been damaged, overcharged or is malfunctioning for a number of different reasons. Once triggered, the cell’s temperature dramatically rises, releasing more heat and flammable gas and creating an explosive environment.

“The real danger isn’t a single cell catching fire,” said Tom Farrell, principal engineer of test and validation engineering at Fike Corporation. “It’s when that heat cascades into nearby cells, which is known as propagating or cascading thermal runaway. That’s

what quickly turns a small event into a catastrophic one.”

Common industry responses often treat BESS fires like any other fire with water or suppression agents, or by just letting them burn. But these methods have proven largely ineffective. Lithium cells burn hotter than most conventional fuels, and water, while helpful for surface cooling, vaporises instantly at impact. Meanwhile, clean agents like FK5-1-12 are effective for adjacent control rooms but ineffective for lithium battery fires as they begin to break down well below lithium fire temperatures.

Recent events highlight the consequences of underestimating these systems. For example, a BESS fire at California’s Moss Landing Power Plant in early 2025 forced the evacuation of over a thousand people, and several other events involving industrial lithium-ion battery fires have occurred with much worse consequences.

At Fike Labs in Blue Springs, Missouri, Farrell and his team have

A Fike team have spent years studying the effects of thermal runaway in various battery types

spent years studying the effects of thermal runaway in various battery types and BESS configurations, all with the goal of solving the thermal runaway problem that was once thought unsolvable. Their work finally led to a breakthrough: a thermal management system that effectively absorbs the heat generated during thermal runaway.

The result would eventually be named Fike Blue, a liquid agent that cools cells fast enough to interrupt the propagation into adjacent battery cells.

“In the test, we only lost six of the 36 cells (after applying Blue), Farrell said. “The ones that were lost were two groupings of three cells: one with the heater applied and the one on the immediate other side. Everything else in the case was unharmed and it drastically reduced the thermal output and off gas that came off the system all the way down to about 60-70 degrees celsius, a far cry from 450 degree celsius in the ‘let it burn scenario’ in the very beginning.”

Thermal runaway events also produce toxic and explosive gases: hydrogen,

methane, ethylene, carbon monoxide and other hydrocarbons. As more cells are affected, the gas volume rises exponentially, increasing both the fire and explosion risks.

That’s why standards like NFPA 855 focus heavily on explosion control and require systems to keep gas concentrations below 25 percent of the lower flammability limit (LFL) through a combined solution of ventilation, gas detection and explosion venting.

Farrell said that this offgassing is one of the leading reasons why he doesn’t recommend letting a BESS experiencing a thermal runaway event burn itself out.

“The ‘let it burn’ philosophy is dangerous,” Farrell said. “You’re releasing massive amounts of toxic gas into the environment and exposing first responders and nearby communities. Instead, if you can stop the propagation, you stop the offgas – and that’s how you make deployment into rural areas safe. Otherwise, we generally recommend that unprotected BESS remain in rural environments away from people.”

Thermal runaway incidents are still rare, but the scale of BESS deployment means these incidents will only increase. Every new installation is a reminder that storage technology can’t scale safely without comprehensive fire and explosion protection.

Today, Fike Labs researchers perform pre-UL 9540A testing on full BESS modules and racks, capturing temperature, heat flux, offgas composition and thermal load data, and also working closely with customer to design custom safety systems which may include Fike Blue, ventilation, explosion vent panels, custom gas detection kits and more.

Their goal isn’t only to help customers pass compliance tests - it’s to help an industry with no signs of slowing down to evolve into safer and more responsible solutions.

www.fike.com

Electronic components in solar PV systems must be permanently protected against heat moisture and radiation, here we explore how potting compounds can help

As energy supplies become increasingly decentralised, the individual components in solar photovoltaic (PV) systems – especially those critical to safety – have to meet increasingly stringent reliability requirements. Live and electronic components for outdoor use, including power electronics, safety switches, junction boxes and connectors, must be permanently protected against heat, moisture, UV radiation and mechanical stress.

Electronics manufacturer WevoChemie argues that its tailored twocomponent silicone potting compounds serve as an all-round solution since RTV silicones are highly adaptable and can therefore be used in the production and long-term operation of demanding PV applications.

PV optimisers, microinverters and safety switches contain compact power electronics and circuit boards that have to run reliably over the long term. The Wevosil 2210x series of silicone potting compounds, specially developed for modern electronics, combines effective heat dissipation with high insulation properties and heat resistance. Their self-adhesive properties support reliable heat dissipation and reduce thermal stress on sensitive components. This is a significant factor in the cost-effective operation of solar PV systems. These reactive RTV silicones have an extremely low Shore hardness and viscosity. As a result, they help to reduce tension, preventing crack formation and delamination on housings, circuit boards and solder joints – even when subject to major temperature changes or mechanical stresses such as vibration. Also, the flame retardant silicone potting

compounds fulfil fire protection requirements according to UL 94 V-0 and can therefore be used in installations near and on buildings or in large-scale industrial systems.

In PV junction boxes, DC and AC connectors as well as cable systems, silicone potting compounds from Wevo ensure reliable sealing against moisture and UV radiation. Integrated bypass diodes – essential for protecting shaded module sections – also benefit from the use of these 2K material systems.

In addition to their hydrophobic properties and high dielectric strength, Wevosil’s products contribute to the longevity of these sensitive

components through their ultra-soft, gel-like consistency. Even under extreme temperature changes, harsh weather conditions and high mechanical stresses, they provide reliable protection – including for components with complex geometries. Low-viscosity, free-flowing two-component silicone potting compounds can be processed efficiently using standard mixing and dispensing systems, according to Wevo. Proven in practical applications, these materials are a good choice for series production of demanding components in PV systems.

We didn’t invent protective coatings, we simply took it to the next level.

Easy-Qote is a self-adhesive corrosion prevention coating applied with minimum surface preparation requirements. Or as we like to say: easy as 1, 2, 3.

For more information visit easyqote.com

Tobias Moss from Drager talks us through some of the challenges and approaches to decarbonising ammonia as a marine fuel

Few developments in maritime decarbonisation are more technically challenging, or more closely watched, than using ammonia as a marine fuel. Carbon-free at the point of use, ammonia holds huge promise, but its success at sea depends on how well crews can control its toxic and cryogenic risks during operations such as bunkering.

While regulations catch up, DNV (Safe Introduction Of Alternative Fuels, Focus on Ammonia and Hydrogen as Fuels, pages 6, 22, 29) says the foundation for incorporating ammonia at scale in maritime operations lies in robust technology and gathering experiences from other industries and experts. For equipment suppliers this includes knowledge about reliable detection, clear alarms, effective respiratory protection, comprehensive training as well as a fast emergency response.

As large-scale deployment begins, experienced partners like Dräger–leaders in gas detection and safety–can help to deliver the proven reliability and trust that regulators, crews, and the public need.

The ammonia’s danger comes from its toxicity and corrosiveness. In fact, when looking at the chemical, DNV says, “...toxicity is the key hazard related to ammonia.” Dräger also highlights how exposure to even small concentrations can irritate the eyes,

Ammonia as fuel holds huge promise, as long as crews can control its toxic and cryogenic risks

nose, throat, and lungs, while higher exposures can be fatal. In addition, the compound is hygroscopic and cryogenic, properties that can cause it to behave unpredictably when released, either rising as a gas or sinking as a cold vapour depending on temperature and humidity. This dual behaviour complicates risk assessment and sensor placement, particularly in confined or partially ventilated areas such as engine rooms or bunkering stations. (Safe Introduction Of Alternative Fuels, Focus on Ammonia and Hydrogen as Fuels, pages 13 & 15).

Fike delivers complete BESS protection – thermal management, explosion control, custom gas detection, system design, testing, and consultancy – all engineered to perform when it matters most. Our solutions meet UL 9540A requirements and safeguard people, first responders, and the environment from the risks of thermal runaway.

At sea, ammonia poses even more unique challenges. Ships operate in changing and often harsh conditions, exposing fuel systems to risks unseen on land. Collisions, groundings, vibration, moisture, and salt all add strain, while limited space makes it difficult to maintain safety distances for equipment or isolate fuel systems from other operations such as cargo handling. (Safe Introduction Of Alternative Fuels, Focus on Ammonia and Hydrogen as Fuels, pages 13 & 15).

Considering bunkering specifically, ammonia’s high toxicity and corrosiveness demand a fully closed and pressurised bunkering system. Transfers must use dedicated equipment that prevents any vapour release, with continuous monitoring to detect leaks immediately. Automated emergency shut-off valves are critical to isolate the system within seconds if a fault occurs.

“All of these considerations are what make it challenging to scale ammonia as a fuel,” says Tobias Moss, Global Business Development Manager for CleanTech at Dräger. His perspective reflects the growing awareness across the industry that regulation alone cannot solve the

problem. While the IMO approved interim guidelines for ammoniafuelled ships in late 2024, they remain high-level and leave many design and operational aspects to risk-based approval under the Alternative Design and Arrangement (ADA) process. (Safe Introduction Of Alternative Fuels, Focus on Ammonia and Hydrogen as Fuels, page 11).

On top of that, comprehensive, mandatory rules under the IGF Code are not expected before 2028. (Safe Introduction Of Alternative Fuels, Focus on Ammonia and Hydrogen as Fuels, page 16). The result is a fragmented regulatory landscape in which early adopters can proceed, but only through case-by-case assessments and close coordination between flag states, class societies, and port authorities.

Because ammonia is highly toxic, DNV advises shipbuilders to design vessels in a way that the occurrence of leaks is prevented and if they occur, their impact is limited. In the event of a leak, early detection is crucial. Dräger recommends

continuous, multi-point monitoring to spot even trace amounts before they become hazardous. Fixed detectors such as the Dräger Polytron 7000 can detect ammonia at parts-permillion concentrations, providing early warnings well below exposure limits. On ships where ammonia poses an ignition risk, triple-IR flame detectors like the Dräger Flame 1750 H2 are best suited to identify the otherwise invisible infrared radiation emitted by ammonia flames within seconds.

Powered air purifying respirators such as the Dräger X-plore 8000 and chemical suits like the CPS 5800 protect crews from gases, vapours and cryogenic splashes, while portable gas detectors like the Dräger Pac 8000 NH3 continuously monitor air quality to warn workers from dangerous concentrations above exposure limits. Training completes the safety chain. As Moss notes, “Even the best equipment depends on people who know how to use it. Training turns technology into real safety.” Dräger’s marine training programmes combine theory with realistic simulation, preparing crews to manage leaks, shutdowns and evacuations with confidence.

The future of clean shipping won’t be defined by new engines or fuels alone, but by the trust built around them. That starts with safety. Ammonia may offer a route to zero-carbon propulsion, but only if it’s handled with care and precision that is seen in other high-risk industries. In the push to decarbonise, safety isn’t a barrier to progress. It’s the foundation that will make progress possible.

For more on Dräger’s approach to decarbonising ammonia fuel read:

Dräger, with a legacy spanning over 100 years, is your trusted safety partner in this journey. We deliver comprehensive safety solutions tailored for the evolving clean tech landscape. From gas detection and respiratory protection to service and rental, we’re dedicated to protecting your team and assets in the face of new challenges across various sectors — be it hydrogen, carbon capture, battery production, offshore wind, waste-to-energy, or nuclear. We are not just a supplier; we are a partner in your journey towards a safe and sustainable future.

EEMUA is a non-profit membership organisation for companies in the industrial engineering sector

EEMUA’s methods help provide knowledge and know how in industrial engineering via up-to-date training, exchanging experience with peers and more

Energy engineers work to improve the efficiency and safety of companies. Their workloads are increasingly demanding – technology, company, industry, market and political factors frequently prompt changes to the pace and direction of engineers’ everyday activities and longer-term plans. These factors inject uncertainty into acquiring and finessing the right skills for engineers to promote their own and colleagues’ safety and company success. Under intense work pressures it is common for individuals to relegate career below work tasks immediately at hand. Professional development is, though, inter-twined with efficiency, safety, and compliance – and not just over the long-term.

Eliminating complications and uncertainty without losing sight of company objectives and industry requirements is a conundrum that each engineer does not have time to solve. The collective wisdom of industry can help companies and individuals to release wise decisions from complications that have already been encountered by colleagues.

EEMUA is a natural place to seek the industrial engineering community’s collective wisdom because EEMUA is driven by Members on the front line of energy engineering. EEMUA’s not-for-profit status means the association invests all its revenue into sharing practical, ‘how to’ guidance resources, professional networking events, training, and more – that the industry has directly required, specified, developed and verified… ‘by industry, for industry’. EEMUA’s positive relationships with regulators around the world help ensure that its training courses are compliant with the latest legal and regulatory requirements locally.

EEMUA’s Members working on the front-line throughout the world collectively specify, contribute to and verify EEMUA’s ‘how to’ guidance publications – an approach proven effective by engineers for 75 years. Recent guidance updates cover Mechanical integrity of dead-legs in pipework (EEMUA 249); Alarm

EEMUA provides guidance on safety, plant operations and more

systems (EEMUA 191); Definedlife repairs in pressure equipment (EEMUA 250); In-service tank floor inspection statistical analysis (EEMUA 247); Civil, structural and building asset management (EEMUA 238); Inspection, maintenance and repair of above ground storage tanks (EEMUA 159); Application of IEC 61511 to safety instrumented systems (EEMUA 222); and more. This guidance is available to all and is free or discounted for EEMUA’s Members and Associates.

Access to know how is not enough for busy engineers. Keeping on top of

Some of EEMUA’s industry defined, good practice guidance

new and old engineering equipment and materials requires a flow of reliable and readily-used details on the features and properties of the latest materials and equipment; careful guidance on how to use them efficiently and safely; and insights on how to apply current and forthcoming regulations appropriately.

The volume of know how is immense, so the flow of that know how to an individual must be adjustable. The means of delivery also need to be adaptable to suit the current uses of the recipient. Whatever the case, the learning must also provide suitable pathways to future professional development.

An array of learning methods are available through EEMUA: classroom-based courses; e-learning; live online training; and blended learning. Courses are available in multiple languages and set at each

career stage through Awareness, Basic application, Practitioner and Leadership. Certification through robust examination proves the mettle of those who trained and CPD hours prove their attitude and investment.

An important complement to training and guidance manuals are EEMUA’s industry events, all led by industry experts. Readily accessible webinars present updates on new developments. Workshops provide interactive sharing of know how. Specialist seminars dive deep into subjects that matter most to industrial engineers.

Cyber security is another area for which EEMUA provides guidance

The face-to-face seminars and workshops also deliver peer-to-peer professional networking – completing the ‘by industry, for industry’ cycle of demanding, contributing and sharing good practice know how and experience. The next face-toface seminar is the EEMUA Storage Tanks Seminar 2025. Taking place in Ridderkerk, the Netherlands on 27 November 2025 it is open to all and free for EEMUA Members and Associates.

If you share EEMUA’s purpose of promoting efficient, safe and compliant industrial engineering then resources are ready to help you advance your career development with training and professional networking structured for industry and tailored to your needs. Please just ask@eemua.org to make EEMUA’s many practical resources work best for you and your team.

The Aberdeen-based Energy Transition SKills hub has seen considerable funding in recent months

The North East of England and Scotland benefit from high winds, a key source of renewable energy. Here we look at some key regional training initiatives helping to create the workforce of the future

The North Sea around Scotland and the North East is known for its high winds – and hubs in the area are capitalising on this as a means of generating energy. The UK Government’s commitment to 95% clean energy by 2030 recognises that the area is a leader in the offshore energy field but that it needs further investment to continue in this vein. Key programmes have included the Technology, Innovation and Green Growth for Offshore Renewables (TIGGOR) program; support for the Floating Offshore Wind Centre of Excellence and investment in the ORE Catapult, a testing and research programme in the area.

This burgeoning sector has also seen an increase in funding for training initiatives in the region. The Scottish Government has committed to investing a total of £9m over the next three years to the Oil and Gas

Transition Training Fund, matched by £9 million from the UK Government. The funding will provide oil and gas workers with careers advice and funding for training to enable them to move into roles in sustainable energy industries.

Both governments have said they will work with trade unions and industry to develop and promote the scheme and explore opportunities for additional private investment.

The Just Transition Fund and the Energy Transition Fund are two that have already seen £120m from Scottish Government in the North East to support the region’s transition to net zero.

Companies from the North East and Scotland are also committed to re-skilling. Offshore wind specialists Ørsted is an example. It currently partners with two University Technical Colleges in The Humber - Ron Dearing UTC in Hull and Engineering UTC Northern Lincolnshire in Scunthorpe.

UTCs are government-funded schools that work with industry to prepare 14–19-year-olds for the fast-changing landscape of the 21st century workplace.

Created in conjunction with companies and universities, they aim to fill regional talent gaps by training young people in the practical and technical skills they will need to succeed.

“Our investments and partnerships in UTCs are ways of helping young people be work ready,” Rob Howes, lead apprentice specialist at Ørsted, said: “Ørsted is always thinking about the next step, and this includes future engineers. Our investments and partnerships in UTCs are important steps to help young people be work ready.”

The offshore wind industry alone is expected to employ approximately 100,000 people in the UK by 2030, according to a 2022 report by the Offshore Wind Industry Council. With the industry currently employing about 31,000 people – that increase will

require extensive investment with the aim of generating 50GW of offshore wind by 2030.

A planned Aberdeen-based Energy Transition Skills hub has also seen considerable funding in recent months. The Engineering Construction Industry Training Board (ECITB) has awarded £400,000 to support the

project which opened in the summer of 2025. The collaborative venture has involved the Energy Transition Zone, the Scottish Government, Shell UK and North East Scotland College as part of a consortium of private and public investment.

The Hub provides workshops and flexible teaching spaces; equipment reflecting to the latest advancements in the energy sector and showcasing future technologies related to offshore wind, electric vehicles, hydrogen fuel,

and carbon capture and storage. The hub claims to offer expert-led learning and training to ‘ensure students are equipped with the knowledge, technical capability and experience integral to energy transition’. it also offers community spaces for use by local groups and organisations.