OCEAN POWER

The high-pressure pumps of the HAMPRO® series are used in the Oil and Gas Industries to pump a very wide range of fluids, meet the stringent requirements of the relevant safety and reliability regulations and are characterized by a robust design and careful use of resources.

Our experienced team of experts will be happy to help configure the perfect solution for your individual application.

RECIPROCATING PUMPS TO API 674

- Glycol pumps - Leak test pumps

- Methanol pumps

- Produced water injection pumps

- Sea water injection pumps

Pressure: 50 – 4000 bar

Flow rate: 0,1 – 256 m³/h

Hammelmann GmbH

Carl-Zeiss-Straße 6-8

(0) 25 22 / 76 - 0 pp@hammelmann.de

D-59302 Oelde www.hammelmann-process.com

As we begin to look ahead to 2026, the oil and gas industry stands at a pivotal crossroads, balancing energy security with the urgent need for decarbonisation. Digital transformation is accelerating, with AI, automation and predictive analytics reshaping exploration and production (see page 8 for more). Companies are investing heavily in carbon capture (page 12), hydrogen, and low-emission technologies (page 16) to align with global climate goals. Yet, challenges remain. Efficiency and reliability remain key priorities for the sector (see pages 37 and 44 respectively), as does safety. In our From the Industry feature, we hear from Micropack’s managing director and president on the challenges, learnings and predictions for fire safety and detection (page 46).

As renewables expand, the oil and gas industry is redefining its role in the energy transition. In this issue, we also look at the future of skills, safety and identity in a changing energy landscape (page 64), and new mechanical integrity practitioner training opportunities (page 66).

From page 69, we preview the must-attend events over the next few months for those who like to remain in-the-loop on where the industry is heading and how innovation, digitalisation, and strategy are converging to shape the next era of oil and gas.

Hayley Everett Editor

Transitional tech

How well engineering expertise can be leveraged for the energy transition 22

Sealing the deal

High-performance sliding sleeve seal assemblies for downhole flow control

Backing up barriers

The value of robust barrier technology in long-term plug and abandonment

How

Leveraging

How

Five digital trends influencing pipeline operations

In-house design shift

A new FPSO design for Brazil’s deepwater sector

Sketch to centrepiece

The story behind the Green Pin ROV Pro Shank Hook

From reactive repair to proactive protection

Why forward-thinking operators are adopting fieldready systems from Henkel

Inspection improvement

How furnace inspections with infrared cameras increase efficiency

Precision is paramount

The role of temperature measurement in liquid natural gas export terminals

Preventing unplanned downtime

How load bank testing secures reliable backup power

PUBLISHER

Jerry Ramsdale

EDITOR

Hayley Everett heverett@setform.com

DESIGN – Dan Bennett, Jill Harris

HEAD OF PRODUCTION

Luke Wikner production@setform.com

BUSINESS MANAGERS

John Abey | Darren Ringer

ADVERTISEMENT EXECUTIVES

Paul Maher, Iain Fletcher, Peter King, Marina Grant, David Pattison

e advertising@setform.com

CONTACT US...

t +44 (0) 207 253 2545

e mail@setform.com

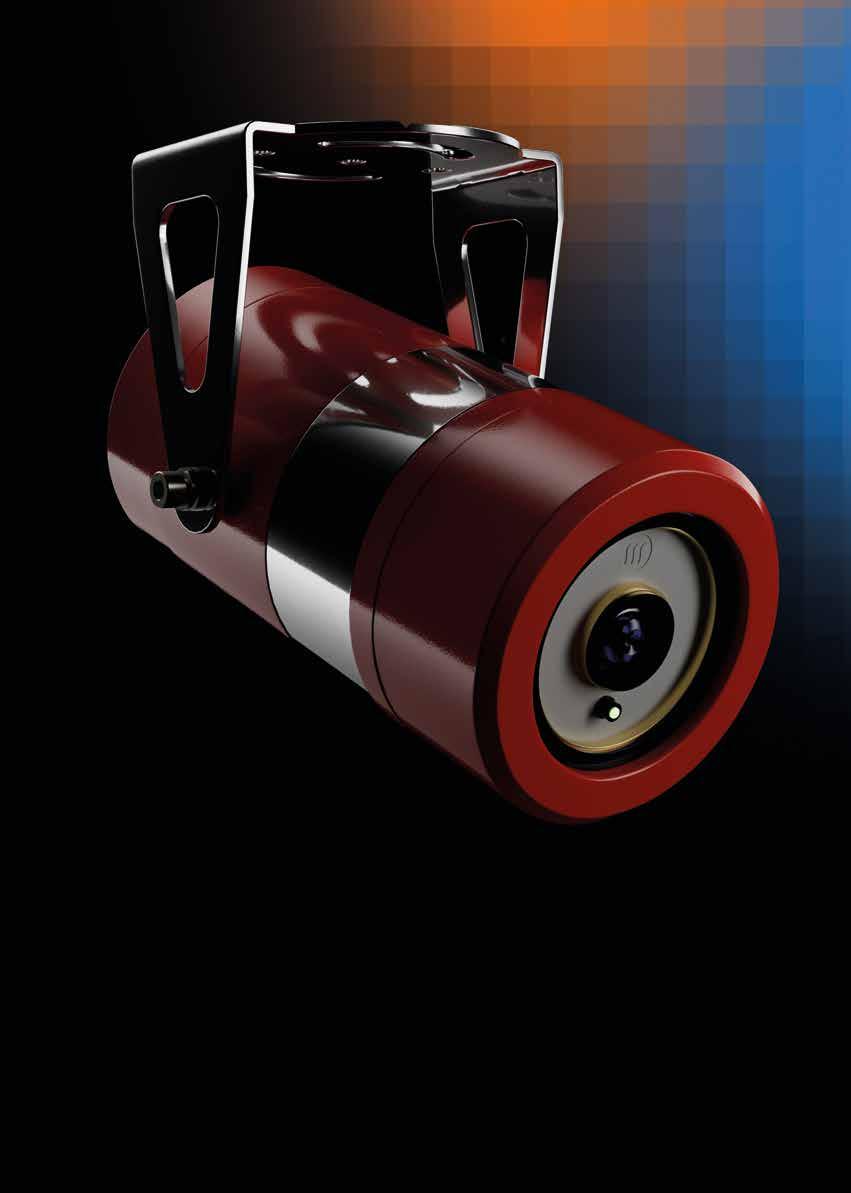

46 From the industry: Graham Duncan

Hear from Micropack’s managing director and president on the challenges, learnings and predictions for fire safety

Smarter and safer

Reducing the hidden risks in lighting and signalling for hazardous areas

FOV validation

The smart solutions revolutionising flame detector field-of-view validation

Field-orchestrated autonomy

Enhancing safety and efficiency in hazardous operations

Legacy library

Why subsea assets need a hybrid approach to equipment

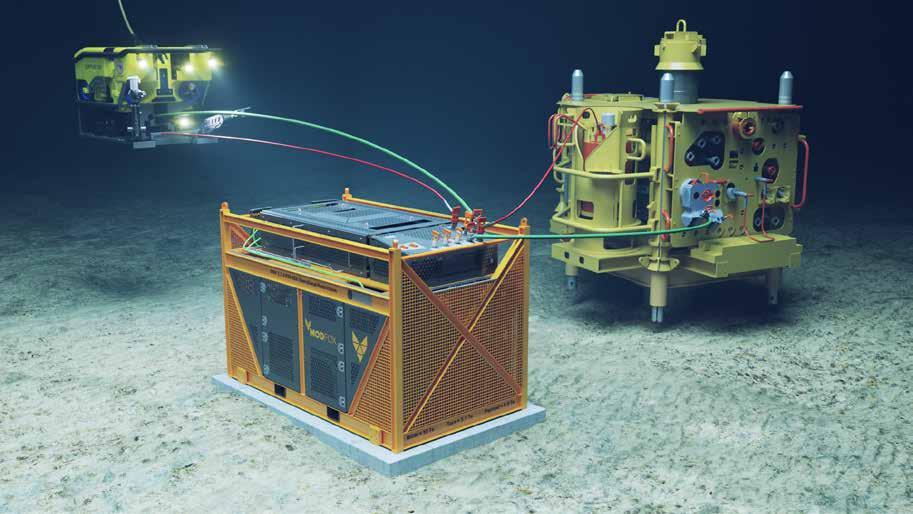

All-electric control

Driving innovation through modular and electric control

Next-gen compression

How next-generation subsea compression technology is boosting recovery at Åsgard

Safer, smarter, connected

The future of skills, safety and identity in a changing energy landscape 66 Mechanical integrity training

The mechanical integrity practitioner training required by industry SHOW PREVIEW

69 Transition under pressure OEEC2025 opens at Amsterdam RAI in November

Innovation beneath the surface

Subsea Expo returns to Aberdeen in February

Join the global energy conversation

ADIPEC opens its doors in November

Setform’s international magazine for engineers is published twice annually and distributed to senior engineers throughout the world. Other titles in the company portfolio focus on Process, Design, Transport, Mining, Energy and Power.

The publishers do not sponsor or otherwise support any substance or service advertised or mentioned in this book; nor is the publisher responsible for the accuracy of any statement in this publication. ©2025. The entire content of this publication is protected by copyright, full details of which are available from the publishers. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior permission of the copyright owner.

Setform Limited | 6, Brownlow Mews, London, WC1N 2LD, United Kingdom

OCEAN POWER

Innovative and sustainable subsea technologies for marine environments

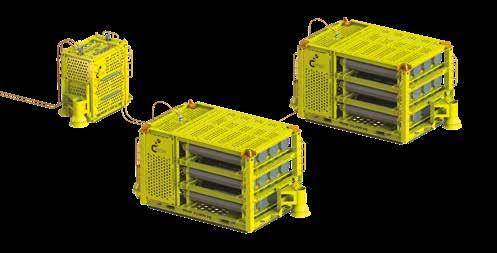

The ESS marks a milestone in sustainable energy storage

SubCtech, a leading provider of underwater technologies founded in 2010 by applied physicist and now CEO Stefan Marx, has grown into a maritime powerhouse based in Kiel, Germany. The company is a member of the Gabler/Possehl Group in Northern Germany and specialises in nextgeneration R&D, custom project consulting, thorough prototype testing, and high-quality manufacturing according to international standards. Customers benefit from reliable, field-tested technology that reduces

CAPEX and OPEX while significantly lowering CO2 emissions.

SubCtech’s Ocean Power products serve offshore oil and gas, environmental monitoring, subsea applications, and autonomous vehicles (AUVs) as well as remotely operated vehicles (ROVs). Its flagship PowerPacks line features advanced LiIon battery systems with modular and flexible configurations designed for

product portfolio encompasses a variety of energy solutions

various ocean depths and a lifespan of up to 25 years.

A key factor in SubCtech’s success is its adherence to strict safety standards. PowerPacks undergo rigorous testing to meet UN T38.3, MIL-STD, DNV, and API17F compliance. Designed for high-capacity, uninterruptible power supply (UPS) solutions, they operate reliably in extreme conditions, as Marx explains: “Our batteries are tested for heat resistance, shock tolerance, vibration, and EMC to ensure they meet the highest industry standards.” These batteries feature automatic protection against overvoltage, undervoltage, overheating, overcharging, and short circuits. Advanced AI algorithms minimise false alarms and detect critical states. Unlike traditional alkali primary batteries, Li-Ion PowerPacks handle peak currents efficiently, operate at sub-zero temperatures, and support extended storage or use, making them ideal for demanding subsea and offshore applications.

These batteries feature automatic protection against overvoltage, undervoltage, overheating, overcharging and short circuits

SubCtech recently developed a groundbreaking 2MWh (extendable up to 6MWh) Subsea Energy Storage System (ESS), marking a milestone in sustainable energy storage. With a Technology Readiness Level of 6 (TRL 6, API17Q), the ESS is now operational in the oil and gas sector, where it has demonstrated its effectiveness in supporting offshore power needs. Following its successful deployment, a key customer placed an additional order, underscoring the system’s reliability and growing demand in the subsea industry.

As global demand for ocean power products rises, SubCtech has expanded its workforce to 85+ employees and plans to increase production facilities in 2025. “Our UN T38.3-certified Li-Ion batteries are transported worldwide via airline cargo, thanks to our professional sales network ensuring seamless service for our customers,” notes Marx.

SubCtech aims to strengthen its leadership in Ocean Power Solutions and Ocean Monitoring Systems. Actively seeking strategic partnerships, the company is dedicated to innovation in subsea energy storage and monitoring while maintaining a strong commitment to environmental responsibility.

As a trusted partner in marine technology, SubCtech’s Li-Ion PowerPacks and pioneering Subsea ESS meet the offshore industry’s most stringent demands. Its solutions significantly reduce CAPEX and OPEX, extend operational intervals, and lower CO2 emissions – a clear win for industry, the blue economy and the environment. The ESS’s operational success in oil and gas and subsequent reorder reinforce SubCtech’s reputation as a leader in sustainable subsea power and monitoring technologies.

Jeremy Angelle explains to Louise Davis how industry demand led to the development of solutions designed for ‘the next frontier’ of offshore drilling

At the end of July 2025, US well specialist, Expro, launched the most advanced version of its Brute Packer system for deepwater wells, the Brute Armor Packer. One aspect of this launch that Jeremy Angelle, vice president of Well Construction, is particularly proud of, is the system’s ability to help users overcome longstanding and tough challenges. “The Brute Armor Packer suite wasn’t just another incremental upgrade,” he emphasises. “It was a direct response to industry demand for high-spec solutions in extreme deepwater environments, particularly for 20k psi-rated wells and large

outside diameter (OD) casing strings.”

Putting this technical evolution into context, Angelle explains: “During well suspension operations, Gulf of America operators follow government regulations that require temporary well barriers to be placed very close to the mudline in subsea wells. This setting depth requirement limits deploying standard equipment deeper in wellbores to counteract increased pressures from reservoirs below. The Brute Armor concept began with a project directly commissioned to address this exact issue for a major operator’s Gulf of America, 20ksi development. Expro was tasked with delivering a retrievable packer system that could be used as a suspension barrier to satisfy regulations and withstand unprecedented downhole pressures that could be encountered in this next frontier of offshore drilling.”

Since that initial project, Angelle reports a powerful ripple effect that nicely illustrates the user demand for such a solution. “Following the successful initial runs, we are continuing to work with the same major operator, but we are also in conversations with other operators that are in the process of planning for their 20ksi projects around the globe. Additionally, we have received other positive feedback that has pushed us to commission projects that push this concept across the other Brute Packer sizes.”

Size is a subject Angelle is often focused on, and he highlights another recent innovation from Expro that demonstrates exactly why size matters. The company has launched a new 20in/22in packer system, which addresses the historical challenges associated with these size retrievable mechanical packer systems. Detailing this development, Angelle says: “Once we started to see successful testing results with Brute Armor, a new question was asked: ‘if Armor can perform in high differentials environments, could this technology handle relatively lower differential pressure, and push the historical limits on seal expansion and retraction?’” The answer was a decisive ‘yes’, as Angelle confirms: “That discussion led to us scaling the technology to

the 20in/22in Brute packer design to specifically address large casing string well suspension applications.” Expanding on this concept, Angelle explains: “Subsea wellheads and blow out preventors (BOPs) have internal clearance restrictions when compared with 22in casing strings that have become very common in subsea well designs. In the past, these clearance issues have been a problem for mechanical packers. Historically, the industry solved the issue using ‘inflatable’ retrievable packer systems. Although these systems have served the industry well, they have technical and operational limitations that a mechanical packer system does not have. That being the case, creating a mechanical packer that could expand enough to meet operator requirements, while not having limitations of the current tool of choice, would give the industry a ‘best of both worlds’ solution.”

When asked to comment on applications of Expro’s new innovations, Angelle says that, “The one thing all these applications – i.e. high pressure, high expansion – have in common is the increased amount of stress put on the elastomer seals.” Because of this, he reveals that Expro is now evaluating, “any – and all – of the industry’s current applications where standard elastomer seal designs are being pushed to the limits.”

And though he can’t confirm specific details on future announcements, Angelle hints: “I can tell you to be on the lookout for two more Brute Armor projects. We are currently wrapping up a development project, for the same major operator, that will result in the release of two new Brute Armor sizes. These sizes will be functional in 14in and 11-1/4in casings with pressure differential ratings above 15ksi and should be released by the end of 2025.”

Looking further ahead, Angelle adds: “Once those packers are released, another area we will focus is the industry’s need for ‘gas-tight’ retrievable barriers. Gas containment is another environment that highly stresses elastomer seals, and we believe our Brute Armor system can provide a solution in that space.”

When asked what is unique about Expro’s technical approach, Angelle says that, “It is driven by innovation with a purpose. It starts with a deep understanding of key trends –spanning geographies, basins, formation targets, and rig designs. What sets us apart is a proven formula that allows us to identify and interpret these trends years in advance, enabling us to anticipate the evolving challenges operators will face in safely and efficiently extracting hydrocarbons.”

He continues: “Leveraging this foresight, we continuously adapt and refine our innovation strategy to maintain a sustainable competitive advantage. This positions us as a trusted advisor to our customers – focused not only on technology, but also on solving their most complex operational problems. From this foundation, we build technology roadmaps that align with real-world needs and deliver advanced solutions with measurable results.”

22in

The value of robust, mechanical barrier technology in long-term plug and abandonment strategies

In today’s increasingly complex plug and abandonment (P&A) landscape, operators face mounting pressure to deploy barrier technologies that ensure reliability, reduce risk, and minimise costly interventions. The Oilenco Pressure Wave Valve (PWV) addresses these challenges with a fully mechanical, intervention-free solution for remotely equalising across installed well barriers.

Designed to be run below standard barriers such as lock mandrels, bridge plugs, hybrid plugs and packers, the PWV avoids the risks associated with conventional pump-open valves, which are often opened by applying pressures above the tested pressure of surface equipment. Instead, it activates via a pre-determined sequence of pressure cycles, configured to remain well below the test ratings of equipment like BOPs.

A key advantage of the PWV is its long-term reliability. With no electronics or batteries, it can remain installed for several years. Once activated, it provides large throughbore communication, enabling fluid flow and barrier equalisation without slickline recovery. This makes it particularly valuable in pre-P&A scenarios where barriers are installed years before the full abandonment is completed.

With nearly 100 installations across the sector, the PWV has built a strong track record. One of its most notable operations came during a North Sea abandonment campaign, where the valve successfully opened after 5 years and 9 months downhole – the longest duration recorded for the technology.

Installed as a shallow annulus barrier below a lock mandrel, the PWV was configured with six pressure cycles and a 1,000–3,000 psi opening

window. It was deployed during the pre-phase plug and lubricate stage of a subsea abandonment from a Light Well Intervention Vessel (LWIV) and would act as a primary barrier until a rig could return for the final abandonment.

During initial operations, an unexpected integrity issue caused pressure to build below the valve. As a non-balanced system was selected for the operation, this pressure change could be safely disregarded, giving the operator confidence that only applied pressure cycles would be required to trigger activation.

When the rig returned, the pressure cycles were applied, and the PWV opened as designed – establishing communication and enabling completion string recovery. This

eliminated the need for wireline intervention to recover the installed annulus barrier, delivering significant time and cost savings.

This case highlights the value of robust, mechanical barrier technology in long-term P&A strategies. By combining simple operation with proven reliability, the Oilenco PWV offers operators a dependable solution for reducing intervention requirements and managing well barriers safely –even after nearly six years downhole.

Ball valves from Böhmer have been providing safe shut-off in plants, pipelines & machinery for more than 65 years.

We have always met the challenges of the most diverse applications with the right valve solution. Also in the future Böhmer ball valves keep their product promise: Highest quality & absolute reliability.

www.boehmer.de

The offshore energy industry is undergoing a fundamental shift in how it approaches engineering, risk and operational efficiency. Reflecting this transformation is Acteon, which has consolidated multiple specialist subsidiaries into four integrated divisions. This restructuring positions the organisation to tackle the increasingly complex challenges of offshore oil and gas and renewable energy projects.

The new structure brings together four complementary business lines. Intermoor specialises in mooring and anchoring solutions, providing permanent and rental mooring systems for floating platforms such FPSOs. Menck, the marine foundations division, delivers largescale hammering and drilling capabilities for offshore installations, including a recently commissioned 10-metre diameter drill. UTEC focuses

on site surveys and geotechnical investigations, delivering the critical soil and seabed data needed for engineering and installation. Finally, Acteon’s engineering consultancy arm 2H – branded separately to maintain independence when working directly for operators – brings together 270 specialists from geotechnical engineers to naval architects to manage everything from soil analysis to integrity management. Together, these divisions cover the full lifecycle of offshore infrastructure. “We deal with anything from the seabed all the way to the surface –anything that goes into the water,” says Yann Helle, EVP Engineering at Acteon. “That’s our purpose.”

The largest risks to offshore energy projects aren’t always visible above the waves. According to Helle, seabed and soil conditions represent the single biggest uncertainty in installation and performance. Insufficient geotechnical

data can lead to costly and dangerous outcomes, such as piles unexpectedly sinking during installation or encountering uncharted boulders that halt progress.

This risk is particularly acute in the renewable sector, where wind farms require dozens or even hundreds of installations. While oil and gas wells are typically preceded by extensive coring and soil sampling, the economics of renewables make that level of investigation unfeasible. Instead of 80 soil samples for 80 turbines, developers may take only six or seven, leaving large gaps in understanding.

The result can be costly delays and unpredictable installation outcomes. “Even just two meters to the side, you might hit completely different conditions,” Helle explains. “And when you’re dealing with an area the size of ten football fields, it’s much more difficult.”

To mitigate this, Acteon’s Engineering Business Line is investing heavily

in soil investigation capacity and geospatial intelligence. But Helle argues that the industry also needs to rethink how it specifies and uses data: “There’s a tendency to over-specify data requirements which drives up costs,” he says. “When you really talk to engineers, you often find you can achieve the same outcomes with a more fit-for-purpose approach.”

As such, early collaboration between operators and contractors is essential. By aligning on data needs at the outset, companies can reduce costs and accelerate timelines without compromising quality or safety. This also opens opportunities for new technologies – such as autonomous underwater vehicles (AUVs) and remote sensing – to be deployed more effectively and economically.

Another major theme is the need for better data continuity across the asset lifecycle. Currently information captured during site investigations and installation often gets “lost in translation” between capital expenditure (CapEx) project teams and operational expenditure (OpEx) teams. “We regularly have operators come back to us asking for the design information we already handed over,

Across the board, operators have an opportunity to work more closely with companies like ours to identify the best value, not just the lowest price

because they can’t find it internally,” Helle notes.

Digitising and centralising data from day one can transform this handover, providing operators with a benchmark of asset condition and enabling predictive maintenance, optimised inspections and extended asset life. “Our role is increasingly to help clients unlock the value of the data they already have by making it accessible and usable across their organisation,” says Helle.

An exciting development in offshore design is the rise of minimum facility platforms – lightweight, integrated structures that can be installed quickly and cost-effectively. Originally developed as drillerled solutions, these platforms now incorporate processing systems and other functions while weighing less than 500 tonnes. Minimum facility platforms can save anywhere between $5-10 million per installation and reduce carbon emissions associated with large construction ships. From final investment decision to first oil, Acteon’s platforms can be deployed in as little as 14 months – a crucial advantage when oil prices are low or operators face financial constraints.

“These platforms meet the same legislation as large platforms and can withstand vessel impacts,” says Helle. “Major operators are now seriously considering them, as we can get oil flowing extremely quickly. For an operator, being able to make up their investment in less than two years is a massive advantage.”

Looking forward, Acteon’s Engineering Business Line expects growth from two main streams: small, shallowwater oil projects taken on by new operators, and large renewable projects already sanctioned through 2028. The company is also piloting remote operations rather than spending weeks at sea – a move that could alleviate skill shortages, improve safety, and enhance work-life balance for offshore staff.

Ultimately, Helle sees collaboration and early engagement as the keys to unlocking the next wave of innovation. “Across the board, operators have an opportunity to work more closely with companies like ours to identify the best value, not just the lowest price,” he says. “If we can get that right –data, design, installation – we can deliver projects faster, cheaper and with a lower carbon footprint. That’s the future of offshore engineering.”

Aquaterra Energy, a UK-headquartered offshore engineering specialist, marked its 20th anniversary this year. Over the past two decades, the company has evolved from a niche provider to an international leader in shallowwater engineering, risers and well intervention.

“We were founded in 2005, and this year we celebrated our 20th anniversary,” says Anne Haase, strategy and commercial director at Aquaterra Energy. “We’ve always focused on shallow-water specialisations. Over the last 20 years, we’ve expanded into well intervention, completions, risers and wellhead platforms – specifically for shallowwater environments.”

With 120 employees and £30 million turnover, Aquaterra Energy exports 90% of its services overseas. “We’re a truly international business,” Haase explains. “Our skills are being exported all around the world, and that’s something we’re really proud of.”

Haase oversees the “front end” of Aquaterra’s operations, covering both the oil and gas and the energy transition. She notes a significant cultural shift in recent years: “Having done this for 25 years, I’ve seen a less adversarial approach over the

last five years and less competition between sectors. These industries are increasingly complementary, and there’s a more balanced approach to transition, which I think we will continue to see.”

Key to that approach is carbon capture and storage (CCS) and gas storage, where Aquaterra’s skills can support both decarbonisation and energy security. “CCS is absolutely fundamental for decarbonisation in Western economies,” Haase says. “It’s about using our skills not just for the energy transition but also for energy security, and leveraging UK assets effectively.”

Well intervention is central to Aquaterra’s current work. “Shutin wells are essentially closed off because they’re not economically viable at a particular time,” Haase explains. “Around 30% of wells on the UK continental shelf are currently shut in, particularly in the southern North Sea.”

According to Haase, the North Sea Transition Authority recognises well intervention as a core enabler for low-carbon production: “We believe integration is key to accessing cheap oil and gas produced mindfully. At £12-15 per barrel of oil equivalent in uplift costs, the UK could become far more competitive compared to Nigeria at $48 or the Middle East at $15.”

Aquaterra also advocates for jackup rigs in shallow waters instead of dynamically positioned (DP) vessels. “DP vessels are fantastic for deep water,” Haase says. “But in shallow water, the movement can risk hydrocarbon release or infrastructure damage. Jack-ups are stable, creating a tripod-based platform to safely intervene in older infrastructure.”

This approach is supported by advanced riser and pressure-control technologies, which Aquaterra engineers to reduce risk. “These systems have to be highly designed and engineered to handle high pressures and temperatures,” Haase says. “They form part of the primary well-control envelope, reducing hydrocarbon release risks and improving safety.”

Haase sees opportunities in new shallow-water markets like the Middle East and Nigeria alongside CCS, and believes that the 2030 net-zero goals will require realism and collaboration. “We all need to develop a sense of balance and a common commitment to move toward the transition with our eyes open as we phase out oil and gas for the things it should never have been used for,” she says. “Oil is far too precious to be used for single-use plastics. It has its place, but we must use it wisely.”

There is enormous variety in the precision components needed to support the Oil and Gas industry. Drill collars, liner hangers, stress joints, blowout preventers, pump joints, completion systems, measurement while drilling, fluid assembly ends, sucker rod, artificial lift, drill pipe and new designs coming as the industry innovates.

UNISIG has machine models that drill holes with a depth to diameter ratio from 10:1 to over 400:1. On-center drilling and off-center drilling are common applications for gundrilling and BTA deep hole drilling. Our standard machines are designed around the needs of our oilfield customers.

UNISIG machines, engineered and manufactured in the USA

Oilenco design, manufacture and engineer specialised well intervention tooling for the global oil and gas industry.

• Safety valve management and refurbishment

• Safety valve remedial solutions

• Scale remedial packages

• Remote opening well barriers

• Bespoke fishing solutions

• Wellhead maintenance tools

• Downhole support solutions

oilenco.com

Mike Byrne – well technology manager at Elemental Energies

Elemental Energies is positioning itself at the forefront of well engineering for the energy transition, building on decades of expertise across oil and gas, carbon capture and geothermal projects. Although new to the company, well technology manager Mike Byrne brings deep sector knowledge and a clear vision for how technical skills can accelerate low-carbon initiatives.

“I’ve been with Elemental Energies for just under two weeks,” Byrne says. “But my team and I have joined an organisation we know very well. Many of us worked together previously at Senergy Wells, which was acquired into Elemental Energies, so it’s like coming full circle. We’re new, but it feels like meeting old friends.”

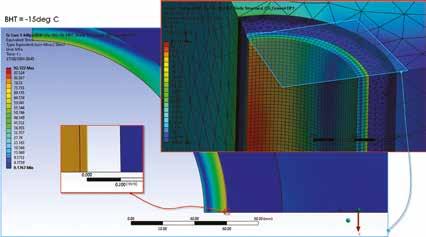

Elemental Energies’ integrated consulting model spans subsurface, production technology, facilities, and well technology. Byrne’s group provides specialist consulting support to oil and gas operators worldwide, focusing on highly technical disciplines such as geomechanics, computational fluid dynamics (CFD), and finite element analysis (FEA).

“These are very specialist processes we’ve developed over many years to support the design of new and existing developments,” Byrne explains. “We’re applying them not only to oil and gas but increasingly to carbon capture and storage (CCS).”

Byrne believes one of the biggest opportunities for Elemental Energies is transferring oil and gas well expertise to CCS. “One of the messages we’re putting out there at the moment is that they’re just wells,” he says. “There’s a lot that’s the same between oil and gas wells and carbon capture wells, but there are also some things that are different and more challenging.”

He will shortly embark on a Society of Petroleum Engineers Distinguished Lecture tour titled ‘Carbon Capture and Storage Wells: The Same, but Different.’

“In oil and gas we’re dealing with hydrocarbons or water injection,” Byrne explains. “Now we’re looking at CO2, which has different properties and different challenges. But there’s

actually a lot of oil and gas expertise that’s directly applicable to CCS - why people like me have transitioned into this space.”

Despite the similarities, Byrne stresses that CCS brings unique technical risks. “Across the world there are two main types of CO2 storage: saline aquifers and depleted hydrocarbon fields,” he says. “Both have specific challenges.”

For saline aquifers – deep underground rock formations saturated with brine – the challenge lies in injecting CO2 without destabilising the reservoir. “We’re adding pressure into a system and need to understand what that pressure will do, where the CO2 will go, and whether precipitates or scale will form,” Byrne says.

Depleted fields pose a different set of risks. “These are at low pressure after decades of production,” he explains. “Injecting CO2 at high rates can create very high velocities, leading to erosion. CO2 is an unusual compound, its behaviour as a solid,

liquid, gas or dense phase is complex. It can be useful for injection, but it presents challenges for temperature, pressure and flow assurance.”

Integrity is the biggest issue. “We’re talking about hundreds or thousands of years of containment,” Byrne says. “It’s no use injecting CO2 if it comes back to the surface in five years. We do a lot of work with geologists and geomechanics specialists to confirm that the store is sealed. Many stores also have old ‘legacy wells’ drilled decades ago which could become escape routes. Managing these vintage wells is critical.”

While Byrne’s focus is on well technology, he highlights decommissioning as a key growth area for Elemental Energies. “From a geomechanical point of view, we get involved in subsurface design for decommissioning – calculating how deep and how many plugs need

to be placed so that wells are sealed forever,” he says. “Our company is involved much more extensively in the wider aspects of decommissioning. It’s vital work, even if it’s not glamorous. There are thousands of wells to decommission in the UK alone.”

He notes that Norway is now looking to the UK as a model. “I was in Norway last week,” Byrne says. “They’re starting to become more aware of the decommissioning challenge, and it’s one area where they point to the UK and say, ‘You’re way ahead of us.’”

Elemental Energies is also eyeing opportunities in geothermal wells. “It’s an area where we see significant potential for growth and improvement,” Byrne says. “There are a lot of deep geothermal wells that haven’t had the engineering attention they deserve.

The geothermal industry has had a failure rate of 40–50% for drilled

Prediction of cement-casing debonding under cold injection conditions using CFD-FEA

wells - unacceptable in oil and gas. We can bring considered engineering to improve that success rate.”

Beyond the technical aspects, Byrne sees a changing relationship between operators and the service sector. “Many of the big oil and gas companies we once thought of as impenetrable – Total, Shell, ExxonMobil – are now looking outward for specialist expertise,” he says. “That’s why Elemental Energies was built: to mirror the technical capabilities of the large operators so they can outsource entire work scopes if needed. We’re already seeing this shift happen, especially in large-scale decommissioning projects.”

Byrne warns of a looming skills shortage across oil and gas, CCS, and geothermal. “Oil and gas isn’t as attractive to graduates as it used to be,” he says. “But there’s a big future in these industries. If you don’t have the skills, it doesn’t matter what your ambition is, you can’t deliver it. This is a really challenging, interesting area, especially with all the new technologies and disciplines emerging. We need young people to join.”

For Byrne, the excitement lies in applying proven engineering tools to new problems. “Carbon capture presents new challenges. If you’re surrounded by people who are good at problemsolving, who enjoy modelling and engineering, it’s the perfect situation. Even at my level of experience, it’s a chance to learn new things.”

At KED-Seals Ltd, we are at the forefront of material technology, specialising in high-performance elastomers and thermoplastics. From concept to delivery, we design and supply advanced sealing and connector solutions for the world’s most demanding applications.

Whether in the depths of oil & gas wells or the heart of chemical processing plants, our components deliver unrivalled durability, reliability, and precision under high temperature, high pressure and harsh fluid & gas media.

Our Expertise

PP Custom-engineered seals & connectors

PP High-performance materials tailored to harsh environments

PP Application-driven innovation

PP Rapid prototyping & global supply capability

When failure is not an option, KED-Seals Ltd delivers performance that

l Controlled Shot Peening

l Laser Peening

l Keronite PEO

l Thermal Spray Coatings

l Dry Film Lubricants

l Organic and Inorganic Coatings

l Parylene Ultra-thin Conformal Coatings

l Superfinishing

l On-site Processing

l Material Testing and Analysis

l NADCAP, ISO 9001:2008, ISO 13485, AS9100 Rev D

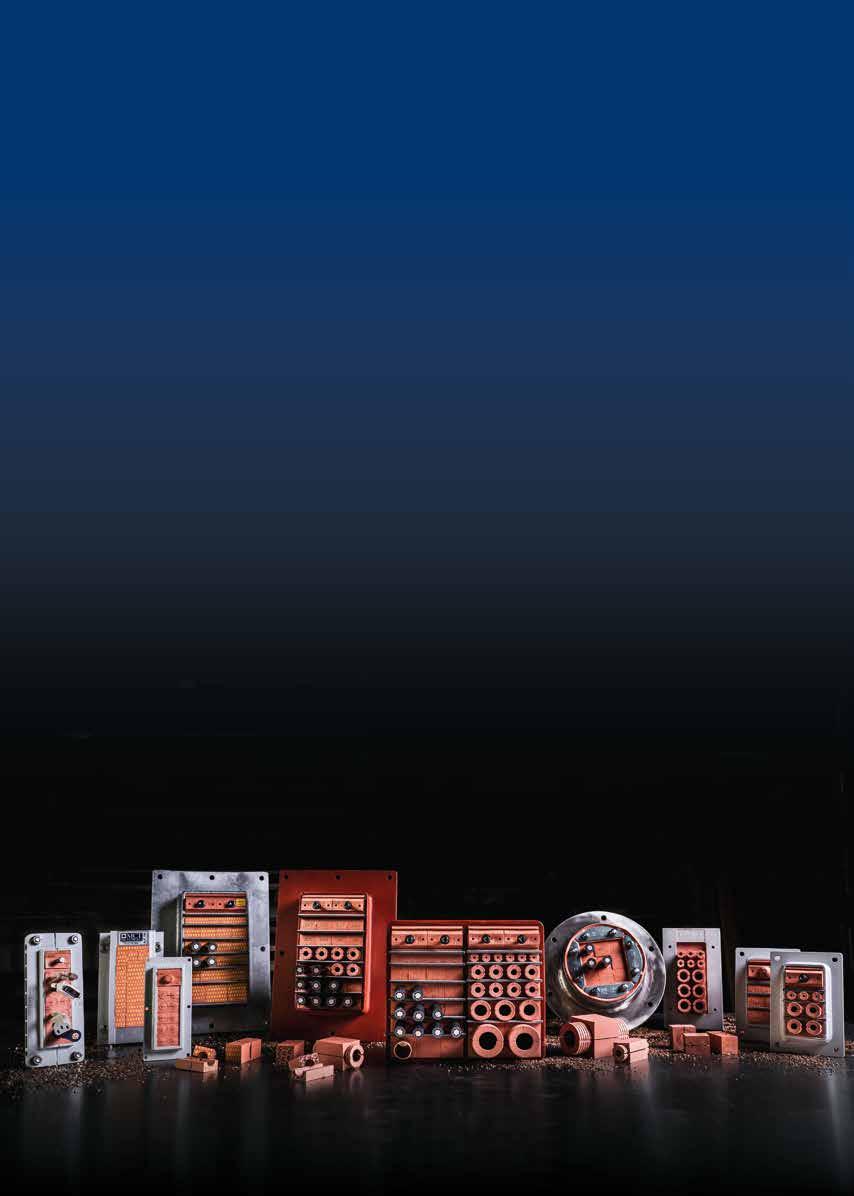

Offshore oil and gas platforms represent some of the most complex and hazardous industrial environments. Every aspect of their design, from structural engineering to electronic control, must account for the constant risk of ignition. Among the many safeguards in place, electrical connectors play a critical role. These components must deliver reliable power and data transmission while eliminating the potential to generate sparks, even under faulty conditions.

The offshore environment is defined by vibration, humidity, salt-laden

air and rapid pressure fluctuations. These conditions accelerate material degradation and increase the likelihood of electrical faults. Even seemingly minor issues, such as saltwater ingress or internal condensation, can lower insulation resistance and heighten the risk of arcing.

Compounding the challenge, offshore platforms concentrate equipment and cabling in confined areas. Connectors are widely used in junction boxes, motor control centres, instrumentation panels and subsea assemblies - locations where energy and environment intersect. As such, they are natural candidates for rigorous engineering designed to mitigate ignition risks.

The defining characteristic of explosion-proof connectors is their ability to contain internal ignition. If a spark occurs inside the housing, the connector is engineered to ensure that combustion cannot propagate into the surrounding atmosphere. This containment is achieved through flameproof (Ex d) construction, typically involving cast or machined housings with precision-engineered flame paths. These geometries cool and quench hot gases before they can escape. Flame paths are calculated against factors such as pressure rise, flame temperature and gas composition, requiring exacting levels

of manufacturing accuracy.

Hermetic sealing provides an additional barrier. Whether through glass-to-metal seals or epoxy compounds, these techniques isolate electrical contacts from the external environment, preventing flammable gases from entering the connector body while withstanding pressure cycles and chemical exposure over years of use.

Explosion-proof design is not universal. Offshore systems typically require a balance between multiple protection strategies. Intrinsically safe (Ex i) designs are common for low-voltage instrumentation and sensor networks, where circuits are engineered to operate with energy levels too low to ignite flammable gases.

By contrast, flameproof (Ex d) connectors are better suited to higherpower applications, including motors, pumps and lighting, where the focus is on containing potential ignition within the housing. Selection between these approaches depends on zone classification, power requirements and system architecture.

Offshore connectors must withstand corrosion, galling and fatigue from vibration or repeated coupling. Materials such as 316L stainless steel offer long-term corrosion resistance, while anodised aluminium balances conductivity and durability. Advanced designs also incorporate polymer sealing systems and highperformance ceramics, which improve strength-to-weight ratios and extend operational lifetimes in subsea or deepwater conditions.

Before reaching the field, explosionproof connectors undergo stringent certification processes under ATEX and IECEx schemes. Testing covers pressure containment, ingress protection (often IP66 or higher), corrosion resistance, thermal cycling and impact resistance.

Traceability is integral to compliance. Manufacturers must document every stage of material sourcing, production and inspection, enabling operators to verify certification at the individual part

level. This traceability not only supports regulatory audits but also simplifies maintenance planning across large-scale offshore assets.

Connector technology continues to evolve alongside the digitalisation of offshore operations. Smart diagnostics are being embedded into housings, allowing sensors to detect moisture ingress, overheating or contact degradation before failures occur. Hybrid designs that combine power and data in a single sealed unit are reducing the number of connection points, simplifying system architectures and improving reliability.

Recent designs illustrate the trajectory of innovation. Explosionproof connector series developed for ATEX and IECEx Zone 1-rated environments combine high current capacity with robust flameproof shells and quick-disconnect couplings, balancing safety with ease of maintenance.

Similarly, advanced cable glands engineered for both armoured and unarmoured cables are ensuring reliable sealing against moisture and gas ingress while accommodating diverse cable sizes. These developments highlight the importance of system-level safety, where every interface contributes to overall explosion protection.

In offshore oil and gas, the risk of ignition is ever-present and the consequences of failure severe. Explosion-proof connectors are not passive components but engineered safety barriers within a wider ecosystem of ignition prevention. From flameproof housings and intrinsic safety principles to advanced materials and diagnostic capabilities, they are evolving to meet the demands of increasingly automated and high-performance operations.

The Series 1275 Subsea Control Valves are a new and fully qualified range, designed, engineered and tested at our Brighouse facility in the UK.

Key features include:

- Specialist trim technology to suit all applications

- Repeatable and dependable operation

- Enhance wear resistance

- Backlash removal

- Highly accurate

- Power efficient

MANUFACTURING SUBSEA VALVES SINCE 1984

KOSO Kent Introl has over 35 years’ experience in the subsea industry manufacturing a range of Control and Choke Valves for the world’s largest energy companies.

Ian Gravill shares fresh insights into high-performance sliding sleeve seal assemblies for downhole flow control

Downhole completion equipment must operate under high pressures, elevated temperatures and in chemically aggressive environments. Sliding sleeve seal assemblies are key components in intelligent completions, zonal isolation and flow control, enabling operators to selectively open or close communication with reservoir zones.

The effectiveness of these valves depends largely on the seal assembly design, which ensures controlled actuation and prevents leakage during closed or partially open states. The challenges for sliding sleeve seals are they must pass ports on the mandrel during differential opening, which can result in seal failure due to erosion and mechanical damage.

Typically, the seal assembly must be designed to withstand the following:

• Differential pressures up to 15,000psi

• Temperatures in excess of 175ºC

• Crossing ports under differential pressures up to 5,000psi

• Fluid compatibility with hydrocarbons, H2S, CO2, brine, acids, and stimulation fluids

• Resisting erosion during opening/ closing of the sleeve

• Surviving multiple open/close cycles over the life of the well

• Low pressure gas testing

The seal geometry of choice is a Bidirectional Spring Energised Seal (SES) assembly consisting of primary SES, with secondary sealing provided by PTFE/TFM vee rings and PEEK vee rings offering support and protection whilst passing ports. A central PEEK double female adaptor is incorporated to provide stability to the complete assembly. Filled PEEK buffer rings

are generally included within the seal assembly and are important in diffusing the pressure and protecting the seal components from erosion and damage.

The SES is the primary seal which incorporates a spring to provide static loading to the seal lips for reliable low pressure 200psi gas tests. The lips are designed with a unique geometry to ensure they pass the ports without being damaged. PEEK hat rings are used to support the axial load created by the pressure and to protect the SES sealing lips.

The PTFE/TFM and PEEK thermoplastic materials are compatible with the aggressive fluid environment, so there will be no chemical degradation of the seal components. Many PTFE/TFM compounds are available, but typically proprietary filled compounds are used to provide the strength and ability to better resist damage whilst providing a good seal. Depending on the pressure, temperature and running clearance, the hat rings and the female adaptors will be virgin, glass or carbon-filled PEEK.

Regarding hardware, slots are preferred to holes as they offer the possibility for maximum seal contact area with the mandrel. Slots should be radiused with shallow lead-in angles, precision machining, and the seal surfaces finished to 8μ-inch to optimise seal performance.

All high-performance seal applications are different and consideration of seal geometry, material selection and hardware design are essential. Working with reputable seal suppliers with design experience and knowledge of critical downhole applications is the key to reliable sealing solutions.

Ian Gravill is general manager at KED-Seals: www.ked-seals.com

Offshore oil and gas installations have always been complex. Today, the digitalisation of operations and rising electrification add a new layer. Platforms that once relied mainly on mechanical systems now contain thousands of kilometres of cabling for automation, control, and safety. These advances improve efficiency but introduce a critical challenge: maintaining fire, gas, and watertight integrity in structures carrying unprecedented cable volumes. Penetrations through bulkheads and decks, often treated as minor details, can become weak points if not engineered to the same rigour as other safety systems.

A generation ago, the number of electrical and communication cables on a platform was far lower. Today’s facilities demand advanced instrumentation, redundant control systems, subsea tie-backs, and digital monitoring, all driving cable counts higher. This density creates engineering headaches. Penetrations must accommodate power, fibre optic, and hybrid cables with different diameters and bending radii. At the same time, regulations demand resistance to fire, blast, and pressure. Methods developed for lower volumes and less diversity are increasingly insufficient.

The challenge is not only the number of cables but also late design changes. During project phases, modifications often require new penetrations. Systems must therefore provide flexibility without compromising safety.

Industry standards such as IMO 754(18), IEC 60092, and national offshore rules impose strict requirements on passive fire protection. Penetrations are tested under conditions simulating hydrocarbon fires, explosions, and water ingress. Yet, incidents continue to show vulnerabilities. Fire can spread rapidly along cable routes if seals fail, while compromised watertightness threatens floating stability. For operators, robust sealing is not just about compliance but about risk reduction.

Designers therefore seek solutions that are demonstrably tested, modular enough to handle variations, and maintainable across decades of service.

Recent developments focus on modular sealing systems able to adapt to growing cable volumes without loss of performance. These typically employ pre-engineered blocks and frames, allowing different diameters to be sealed within one penetration.

Key advances include:

• Improved materials: Highperformance compounds able to resist hydrocarbon fire and longterm exposure.

• Simplified installation: Systems designed for straightforward assembly reduce human error offshore and allow later reconfiguration.

• Lifecycle reliability: Designs maintain performance under vibration, saltwater, and mechanical stress. These innovations move the industry away from bespoke, sitespecific solutions toward standardised, test-certified components that give engineers greater confidence.

Modular sealing systems are engineered to deliver certified protection against multiple hazards

Another important trend is the use of digital design tools for penetration planning. With hundreds of transits on a large installation, manual coordination is error-prone. Software now allows designers to model each penetration in 3D, ensuring every cable is accounted for and sealed before construction. Spare capacity can also be tracked, supporting future expansions and retrofits.

The result is better accuracy and fewer costly modifications during commissioning. In an era where overruns face heavy scrutiny, visualising cable management early is increasingly valuable.

The industry’s energy transition adds further pressure. Hybrid facilities combining hydrocarbons with renewables demand extensive electrical integration. Hydrogen, carbon capture, and offshore wind connections all rely on reliable cable and pipe transits. In this context, sealing solutions are not just regulatory necessities. They underpin the resilience of entire installations, safeguarding people and assets against escalating risks.

Operators that invest in proven, modular systems benefit from safety assurance and lower lifecycle costs, since transits can be adapted without wholesale replacement.

As platforms evolve into more digitalised and electrically complex systems, the challenge of managing cable penetrations cannot be underestimated. Once regarded as minor details, they are now central to overall safety.

Advances in modular systems, improved materials, and digital planning tools are helping engineers meet the dual pressures of compliance and operational flexibility. By addressing cable density challenges with the same rigour applied to other safety-critical systems, the offshore sector can create installations that are compliant, resilient, and prepared for the future.

Ola Johansson is communications and media manager at MCT Brattberg. For more information visit: www.mctbrattberg.com

Operators that invest in proven, modular systems benefit from safety assurance and lower lifecycle costs

Offshore platforms are evolving into more digitalised and electrically complex systems

HTL Group’s Danny Peachey looks at five digital trends influencing pipeline operations, from AI-driven monitoring to predictive maintenance

More than three billion litres of water leak from pipes in England and Wales every day. In the oil and gas sector, unplanned outages, including those caused by pipeline failures, can cost operators over £100,000 per hour in lost production. What links both is the same systemic strain: infrastructure built for a different era, now operating under modern pressures. From climate volatility to tighter regulatory controls, pipeline networks are being forced to perform with

greater reliability, efficiency and transparency, yet without fundamental redesign, many can’t.

Faced with these operational and structural pressures, the sector is transforming towards smarter, data-led operations. Real-time monitoring, autonomous inspections and predictive analytics are replacing reactive maintenance and routine checks. Pipeline management is being reengineered around data, automation and machine learning, across oil, gas and water networks alike.

Pipeline operators now deal with thousands of data points every second, from flow rates to vibration patterns, pressure fluctuations to acoustic anomalies. Traditionally, much of that data was stored but rarely used, but AI is changing that.

Where AI is making the biggest impact isn’t in replacing engineers, but in accelerating decision-making. Shell, for example, has deployed AI-driven

predictive maintenance across more than 10,000 assets, including pumps, compressors and control valves, analysing billions of sensor readings to detect early signs of mechanical failure. This helped cut unplanned downtime by 20% and reduced maintenance costs by 15%.

But AI’s applications extend far beyond equipment uptime. In pipeline integrity programmes, it is

increasingly being used to detect leaks, corrosion, and structural fatigue. According to recent research, machine learning models trained on pressure, flow, and acoustic data can pinpoint the location and severity of leaks with high accuracy in controlled test environments, demonstrating their potential for real-world deployment.

For the oil and gas sector, drone inspections now replace foot patrols in remote areas, and submersible crawlers inspect internal welds and detect corrosion at depths that were once inaccessible. As inspection becomes automated, operators can increase frequency, improve resolution, and reduce exposure to confined spaces, all while cutting operational costs.

Digital transformation doesn’t work without live data, and the proliferation of low-power, high-precision IoT sensors has changed how pipelines are monitored, not every few days, but every few seconds.

UK trials have already shown the value, with Ovarro’s EnigmaREACH system, tested across five utilities in 2024–25, reducing average leak detection time by 50%. By deploying wireless acoustic loggers overnight, utilities identified 5-6 hidden leaks per session, many of which would have gone unnoticed using conventional methods.

This is particularly significant in the context of Ofwat’s 2050 target to halve leakage. While legacy SCADA systems provide bulk data at fixed intervals, modern IoT infrastructure

enables near-continuous condition monitoring. And when that data feeds into machine learning platforms, it becomes a foundation for faster, riskbased decisions across the network.

Rather than relying on static models or assumptions, pipeline engineers are increasingly working with digital twins - dynamic, real-time virtual replicas that simulate how an asset is performing under current conditions. Digital twins are now being used to model stress points in ageing steel pipelines, optimise compressor loads, and test emergency shutdown scenarios. The benefit isn’t just better oversight, it is operational confidence. Operators can see in advance how the network would respond under strain, rather than waiting to find out the hard way.

Until recently, most maintenance was either reactive – fix it when it fails, or preventive – fix it on a schedule, even if nothing’s wrong. Both approaches come with cost inefficiencies and risk. Predictive maintenance changes the model entirely. By using sensor data and historical performance patterns, operators can forecast when components are likely to fail, and intervene just before they do.

Equipment failures cost oil and gas firms an average of £115 million per year, with worst-case scenarios exceeding £400,000 per hour.

Predictive maintenance systems, increasingly being adopted on offshore platforms in the North Sea, are helping to reduce this by extending the lifespan of valves, pumps, and control systems.

Where AI is making the biggest impact isn’t in replacing engineers, but in accelerating decision-making

Singapore’s offshore and marine heavyweight Seatrium has unveiled its first proprietary floating production, storage and offloading (FPSO) design – the FLEXHull 1500K-M – aimed squarely at Brazil’s deepwater oil and gas market. The design has received endorsement from the American Bureau of Shipping (ABS), marking a key milestone for the company as it moves to take greater control over FPSO engineering and delivery.

Formed through the merger of Sembcorp Marine and Keppel Offshore & Marine, Seatrium has decades of experience building large floating production units. However, its FPSO projects have traditionally been based on third-party designs. The launch of the FLEXHull signals a strategic shift toward in-house design capability, giving Seatrium more flexibility to integrate engineering, construction, and lifecycle services across future projects.

The FLEXHull 1500K-M is designed to operate in water depths of up to 2,500 metres and features storage capacity for over 1.5 million barrels of oil. The hull is built to accommodate topsides weighing up to 80,000 tonnes,

supporting production rates of up to 120,000 barrels of oil per day and 10 million cubic metres of gas per day.

The design adopts a simplified and modular hull configuration, eliminating the complex bow and stern structures common to earlier FPSO hulls. This approach reduces steelwork requirements, improves build efficiency, and streamlines integration with topsides modules. The modular layout also allows scalability, enabling the same base design to be adapted for a range of field sizes and production requirements.

Seatrium’s move to develop its own FPSO hull is driven by both market demand and long-term strategy. Brazil remains the world’s most active FPSO market, with Petrobras spearheading multiple deepwater developments in the pre-salt basin. Seatrium is currently building five FPSOs for the Brazilian state-controlled operator – P-80, P-82, P-83, P-84, and P-85 –following the successful delivery of the P-78 earlier this year.

Developing a proprietary hull design allows Seatrium to offer an integrated, standardised FPSO solution that can be replicated across multiple projects. The company aims to reduce its

reliance on external licensors, improve cost competitiveness, and accelerate project execution through repeatable engineering and fabrication processes.

The FLEXHull also aligns with Brazil’s emerging build-own-transfer (BOT) model, in which contractors finance and construct FPSOs before transferring ownership to the operator. By offering a standard moored hull platform, Seatrium can better serve this growing segment while retaining flexibility for global deployment.

Although tailored for Brazil, the FLEXHull 1500K-M is also designed with global deepwater markets in mind, including West Africa and South America’s Atlantic margins. Its scalable, cost-efficient architecture positions Seatrium to pursue future FPSO opportunities in regions with similar operating conditions.

The ABS endorsement underscores the design’s compliance with international safety and performance standards, strengthening Seatrium’s credibility as both designer and builder. With the FLEXHull 1500K-M, the company is positioning itself not just as a fabricator, but as a fully integrated FPSO solutions provider capable of meeting the next generation of deepwater production demands.

The Green Pin ROV Pro Shank Hook is designed for efficient release and retrieval operations

The R&D team shares the story behind the development of the Green Pin ROV Pro Shank Hook

In the June issue of this magazine, Green Pin introduced the ROV Pro Shank Hook; a product that immediately caught the attention of subsea professionals. While the hook’s innovative features were showcased, the story behind its development remained largely untold. Until now.

The Green Pin ROV Pro Shank Hook was not developed overnight. Its origins trace back to 2013, when product manager Emiel van Norel began prototyping ROV hooks. At the time, however, limited production capabilities made it impossible to bring the concept to life. That changed in 2018, with the acquisition of Irizar Forge. The acquisition unlocked access to larger hook designs, paving the way for real innovation in the subsea industry.

They wanted a hook with a latch that locks in a neutral position, so loads would not be lost due to current or misalignment

The Green Pin Pro Shank Hook was built to be intuitive, safe and robust, performing three key functions: retrieving, releasing, and locking. It had to work seamlessly for both ROVs underwater and crew members on deck, while remaining scalable across multiple hook sizes.

The demand for ease of use and reliability came directly from subsea professionals. “They wanted a hook with a latch that locks in a neutral position,” explains product manager Purya Talebi, “so loads would not be lost due to current or misalignment.” Translating that need into a durable, versatile design that could withstand harsh offshore conditions was a challenge, which Royal Van Beest’s team was determined to solve. Innovation, as it turns out, does not

always follow a schedule. “It was four AM, I woke up with this idea and could not go back to sleep,” van Norel recalls. That early-morning spark led to a flood of sketches and a breakthrough in the design process. “I started thinking through every concept we had tried and realised there was one movement we had not explored.”

With help of Dominic Lu, one of Royal Van Beest’s product engineers, the rough sketch was transformed into a functional mechanism. “He did not just draw what I imagined, he added mechanical insights I had not considered,” van Norel explains.

The result was a hook that combines simplicity, safety, and versatility; a product born from creative thinking and multidisciplinary collaboration.

Rather than relying on lab conditions, the team tested prototypes directly in the North Sea, exposing them to mud, sand, and strong currents. These field trials revealed critical issues, from misfitting POM wheels to latch mechanism tolerances that did not hold up. “We learned quickly what worked and what did not,” van Norel noted. While no formal research institutes were involved, the practical insights from offshore and subsea professionals proved valuable.

Materials, coatings, and assembly methods were also carefully reviewed to ensure the hook would be durable, easy to maintain, and cost-effective. Stainless steel was used only for critical components, while the rest of the hook was protected with a coating and designed with rinse-through openings to prevent salt buildup. The mechanism is fully replaceable, allowing the hook to remain operational even if parts fail.

After all these efforts, the final prototype was nearly ready for production, requiring just one minor digital adjustment before moving forward.

The Green Pin Pro Shank Hook has been received with enthusiasm. “Engineers instantly understand how it works; almost no explanation needed,” says van Norel. “It is intuitive and simple, and that is exactly its strength.”

Arnoud Stasse, area sales manager, adds: “The hook is attracting serious attention at trade shows. Everyone wants to know how it works and what it could mean for their ROV operations. And with more exhibitions and webinars planned, we will continue to engage the market.” Stasse also confirms that the first hooks have been sold and are ready for delivery.

Looking ahead, the team is exploring larger sizes and adapting the mechanism for other hook types, as well as optimising existing designs. “The ROV line is evolving,” van Norel says. “We are always improving; for the market and for ourselves.”

Finally, the team is proud of the result and emphasises the

collaborative effort. “It was true teamwork,” says Talebi. “We are open to feedback and eager to keep innovating with our customers.”

The Green Pin ROV Pro Shank Hook will be on display at upcoming industry events such as ADIPEC, and those interested in finding out more about the product can join Green Pin’s online webinar on 18 October by registering at GreenPin.com/academy.

The side-positioned controls offer operators clear visibility of the hook’s mechanism, latch and opening in one view

Highland International’s Dry-Fall Epoxy and Urethane coatings deliver a durable, visually appealing finish

Why forward-thinking operators are adopting field-ready systems from Henkel to safeguard critical storage assets for the long-term

Storage tanks are more than supporting structures; they’re the backbone of safe, continuous, and efficient operations. Yet all storage tank infrastructures face relentless threats from corrosion, mechanical stress, thermal cycling, and environmental exposure. The cost of failure can be catastrophic and is often underestimated.

Across industries, there is extensive consideration in storage tank maintenance, often framed as a choice between reactive or proactive. With growing global emphasis on asset reliability and risk mitigation, the shift toward proactive protection is no longer optional, but essential.

Forward-thinking operators are adopting industry-proven, long-lasting, and easy-to-maintain solutions that extend asset life, ensure compliance,

reduce downtime, and lower total cost. Every storage tank is made up of critical zones: roof, wall, bottom, and surrounding assets, and each face distinct challenges. By applying specialised technologies and integrated protection systems to these areas, it is possible to significantly enhance tank reliability, safety, and service life.

Tank roofs are among the most exposed and failure-prone areas of a storage tank, often suffering from corrosion, coating degradation, and leakage due to weld failures or aging seals. Historically, operators have relied on conventional insulation and underdeveloped epoxy coatings that degrade under UV exposure or trapped moisture. These methods often fail to prevent corrosion

and lack the durability which results in failures and unpredicted maintenance requirements.

Tank walls are vulnerable to corrosion, coating damage, and leakage. These issues can be due to internal or external factors. For internal, it is often a result of chemical exposure or the medium inside the tank, and externally due to environmental stressors such as UV exposure, physical impacts or degradation of previously used coatings. In the past, operators have relied on generic coatings and insulation systems that require extensive surface preparation, or coatings that fail under UV exposure or chemical attack. These methods tend to miss early-stage damage and lack the resilience needed for long-term protection.

Composite repair applied to an outer wall using CSNRI technology restores structural integrity without hot work

Tank bottoms are especially vulnerable to corrosion and leakage due to water settling beneath stored medium, sludge, flooding and contact with moist soil. Condensation and ingress can create corrosive environments, and poor surface preparation and chemical attack often lead to applied coatings to fail. Inspection is difficult due to limited access, and traditional methods could miss addressing corrosion points that can cause unexpected failure.

Application of Stopaq on tank chimes provides a self-healing barrier against corrosion and water ingress

Additionally, cathodic protection systems, if improperly designed or maintained, can fail to prevent corrosion, resulting in long-term degradation and the tank becoming unusable. Historically, operators have relied on underdeveloped coatings and sacrificial anodes, which often do not perform long-term due to installation complexity, lack of monitoring, and inability to self-heal or adapt to field conditions.

Tank surrounding assets can include handrails, stairways, auxiliary zones, pipe supports, flange systems, and emergency systems. These areas are also prone to corrosion and damage due to environments, chemical leaks, and also saline conditions for the tanks in offshore or subsea facilities. Previously, operators have relied on manual inspections and generic coatings which often fail to protect against corrosion, lack real-time visibility, and require disruptive shutdowns for repairs or isolation.

A diverse range of field-ready solutions is essential for proactively maintaining storage tanks. Henkel can provide a comprehensive portfolio of advanced systems, coatings, and digital tools specifically engineered to support proactive

maintenance and ensure long-term protection of storage tanks.

Loctite adhesives, sealants, coatings and repair systems deliver chemical resistance, structural reinforcement and wear protection. Loctite Pulse enables continuous monitoring of leaks, corrosion, and structural integrity facilitating a shift from reactive to proactive maintenance. CSNRI composite repair technologies address localised structural damage efficiently.

For tank roofs, walls, and bottoms, Mascoat solutions are known to provide long-term thermal insulation, personnel protection, and help prevent the risk of corrosion under insulation (CUI). Stopaq self-healing coatings offer surface-tolerant corrosion protection without the need for abrasive blasting. Anodeflex systems can ensure long-term cathodic protection, and liquid coatings and linings from Powercrete, LifeLast, Canusa-CPS, US Coatings, and Highland International provide robust protection against chemical exposure, corrosion, and mechanical damage, both internally and externally.

For surrounding infrastructure, applications from GeoTree, Fyfe solutions support structural reinforcement, and AVT provides emergency isolation and maintenance activities without requiring operational shutdowns.

Across industries worldwide, Henkel’s solutions have outperformed legacy methods, delivered longterm durability and engaged in the shift toward proactive maintenance. By enabling smarter monitoring, safer operations, and longer asset life, Henkel empowers operators to prevent failures before they occur. The result is a more reliable infrastructure, reduced maintenance demands, and significant savings in both cost and time – delivering a compelling value proposition for resilient, future ready operations.

Harish Iyer and Sébastien Deregnaucourt are at Henkel, parent company of Loctite, CSNRI, and Seal For Life Technologies. www.sealforlife.com/tanks

Star-Line EX Series

CERTIFIED FOR HAZARDOUS ZONES

ATEX & IECEx approved

EXTREME PROTECTION

IP68, rugged coating, heat & voltage resistant

ANY CONFIGURATION YOU NEED

Power, signal, or mixed; up to1500 A

QUICK, EASY TERMINATION

Save time and effort

CABLE VERSATILITY

Works with multiple standards

HIGH-POWER PERFORMANCE

RADSOK® high-amperage options

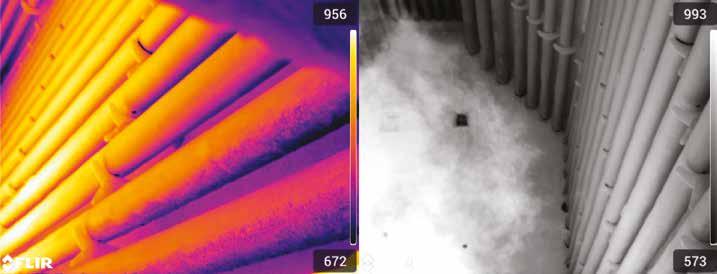

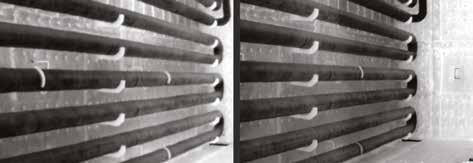

How furnace inspections with infrared cameras increase efficiency, improve safety and reduce costs

Furnaces are the beating heart of refining and petrochemical operations. They provide the high temperatures essential for distillation, cracking, and other core processes. But when they fail, the consequences can be severe. A single day of unplanned downtime can result in losses exceeding $1 million, alongside significant safety and environmental risks.

This reality is driving operators to adopt smarter, safer, and more costeffective inspection methods. Companies like PROtect, under the leadership of Jason Czajkowski, are leveraging the latest infrared (IR) technologies to transform furnace inspections from a reactive task into a proactive, datadriven maintenance strategy.

Infrared inspection technology has evolved dramatically over the last three decades. Early tools such as the Agema 550 and Inframetrics 390 laid the groundwork for remote temperature diagnostics in hazardous environments. Although these firstgeneration cameras were bulky and required extensive setup, they opened the door to non-contact thermal inspections – a critical breakthrough for operators working in extreme heat.

FLIR’s GF309 marked the next big step, becoming the workhorse of the industry. It delivered real-time thermal imaging through flames with improved ergonomics, enabling inspectors to work more efficiently

and safely. However, with a resolution of just 320x240 pixels, the GF309 had limitations when it came to identifying fine anomalies at a distance.

Recognising the need for greater clarity, PROtect transitioned to the

FLIR G609 High Resolution Furnace and Boiler Inspection Camera, a purpose-built system featuring a 640x480 detector. This leap in resolution enables technicians to detect smaller anomalies such as hot spots, coke buildup, or insulation breakdowns earlier and from safer distances.

The FLIR G609 represents the latest stage in the evolution of furnace inspection technology. Designed specifically for high-temperature applications, it is equipped with a re-engineered heat shield, a factorycalibrated furnace lens, and a modern touchscreen interface. These features combine to create a tool that withstands harsh conditions while remaining intuitive to operate.

With its increased resolution, the G609 can accurately measure temperatures on narrow furnace tubes deep within radiant sections — something older models often struggled to achieve. It also incorporates a redesigned cold filter, enabling clear thermal visibility through flames even in the most challenging environments.

According to Czajkowski, these advances add up to more than incremental improvement. “It’s not just clearer images,” he says. “It’s better decisions, faster.” PROtect’s teams can identify issues earlier, keep personnel at safer distances, and plan maintenance before problems become emergencies.

IR inspections provide a sharper thermal image, faster workflow and greater safety

While the G609’s hardware is impressive, its real power emerges when combined with FLIR’s Thermal Studio Pro software. This integration transforms how inspections are planned, executed, and reported. The software’s Route Creator tool allows inspections to be pre-planned with precise inspection points loaded directly into the camera. Technicians follow a defined route, eliminating guesswork and ensuring consistency from one inspection to the next. Afterward, images are automatically organised by inspection point, and professional reports are generated in minutes.

“This combination of camera and software creates a seamless workflow from planning to reporting,” says Czajkowski. Inspectors spend less time sorting data and more time analysing it. That means faster decision-making and more reliable outcomes for clients.

Although Thermal Studio Pro is not yet directly integrated with third-party maintenance platforms, it is designed for flexibility. Images are saved as standard JPEG files and reports export as PDFs – both widely compatible formats that can be uploaded into most maintenance systems. This ensures operators can easily incorporate thermal inspection results into their broader asset management workflows.

By adopting the G609 and an integrated software approach, PROtect has helped its clients significantly improve safety and uptime. Early

detection of anomalies such as burner misalignments, coking conditions, or developing hot spots has allowed plants to schedule repairs during planned downtime rather than responding to emergency outages.

In one instance, the early detection of a developing hot spot prevented a refinery from experiencing an unplanned shutdown, saving hundreds of thousands of dollars in potential losses. This type of proactive maintenance not only reduces costs but also improves safety for personnel, who can now inspect furnaces from greater distances with more reliable data.

Infrared furnace inspections have matured from a niche technique to an essential maintenance strategy. With modern tools like the FLIR G609 and expert leadership from professionals such as Jason Czajkowski, PROtect is setting new standards for asset reliability across the refining and petrochemical industries.

Today’s IR inspections provide sharper thermal images, faster workflows, greater safety, and measurable return on investment. The combination of advanced hardware and smart software creates a holistic solution that reduces downtime, improves maintenance precision, and protects both people and assets.

“We’re not just taking pictures,” Czajkowski says. “We’re delivering solutions that protect assets, budgets, and people.”

As refining and petrochemical plants strive to improve efficiency, enhance safety, and reduce costs, infrared furnace inspections are emerging as a critical tool for achieving these goals. The FLIR G609 represents a step change in capability, enabling inspectors to see more clearly, measure more accurately, and act more decisively.

Captions to go here

By pairing cutting-edge hardware with integrated software, companies like PROtect are redefining what’s possible in furnace maintenance. The result is a smarter, safer, and more cost-effective approach to one of the most challenging aspects of plant operation, an approach that is rapidly becoming the new industry standard.

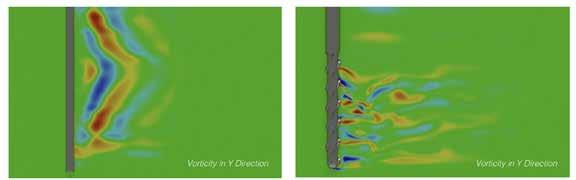

The DHTW breaks up flow and reduces transverse forces caused by the wake frequency approaching the natural frequency of the thermowell. These vibrations, which would cause reduced life and failure due to metal fatigue in standard thermowells, no longer pose an issue with VE Technology®.

OPTIMASS with sensors and electronics MFC 400 for Safety Instrumented Systems

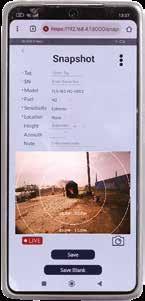

• Using the new OPTICHECK Flow Mobile app on mobile devices or FDT/DTM on laptops commissioning, parameterisation, verification, performance monitoring and application parameters can be managed on-site via a secure Bluetooth® connection (<20 m/65.6 ft) –ideal for inaccessible areas or EX Zone 1

Free OPTICHECK Flow Mobile app for iOS and Android: krohne.link/opticheck-mobile

Helix Thermowell

These

aren’t just off-theshelf thermometers; they are robust, temperature measurement points designed to operate reliably in the harshest of environments

Liquid natural gas (LNG) is a cornerstone of the global energy landscape, and its journey from gas field to consumer is a marvel of engineering. At the heart of this process are LNG export terminals, complex facilities where natural gas is cooled to a frigid -162°C (-260°F), transforming it into a liquid that’s easier and more cost-effective to transport. The success of these multibillion-dollar projects hinges on a single, paramount factor: precise temperature control. Without it, the entire operation is at risk.

At Daily Thermetrics, a company with a long history of providing specialised temperature instrumentation, we have seen firsthand how our technologies have become an indispensable part of

these projects. The value we add goes far beyond simply providing a measurement; it’s about enabling safety, efficiency, and reliability throughout the entire LNG value chain.