EVOLVING LEVs

It’s been a busy couple of months for the transportation industry, with international trade show giants IAA Transportation and Innotrans taking place back-to-back in September. I was on the ground at both events for International Transport Manufacturer, covering the latest product launches, technology showcases and insights from the global transport sector.

This issue highlights some of the latest innovations from the industry, from new traction battery technologies for trains (pages 18 and 24) to fast chargers for electric vehicles (page 21), from novel hydrogen fuel cell technology (page 8) to new-generation digital technologies for rail safety and security (page 40). Also in this issue, we look at innovative approaches to improving the performance of today’s battery cells (page 16) and reducing vehicle weight (page 26). Naturally, autonomous vehicles have continued to generate much discussion at recent industry events, we look at the latest developments in self-driving buses (page 31) and take a deep dive into the technicalities of testing millimetre-wave automotive radar for ADAS (page 37).

This issue's cover story (page 6) takes a look at a new entrant to the L7e vehicle category, offering a versatile and innovative approach to zero emission last-mile deliveries.

As always, our show preview section highlights the upcoming events of note in the industry. November dates for your calendar include AEC2024 in Monaco and Formnext in Frankfurt, while Southern Manufacturing & Electronics returns to Farborough in the new year - more on page 47.

Hayley Everett Editor

– NOVEMBER 2024 –

18

GAINING TRACTION

EVOLVING LEVS

This new quadricycle EV is poised to meet rising lastmile delivery demand

8

H2 GO

Do fuel cells offer a credible alternative to battery electric for heavy goods vehicles?

MATERIALS

13

MIND THE GAP

The advantages of 3D printing spare parts for the rail sector

16 ADVANCING

ANODES

Improving the performance of today’s battery cells

21

24

Introducing an innovative LFP battery solution for freight locomotives

CHARGING AHEAD

This new rapid charging solution holds the answer to long-distance electric travel

PROPULSION PROGRESS

Delivering whole new levels of energy density and fast charging for hybrid trains

The reinvention of stainless steel for lightweight and sustainable vehicles

THE SEARCH FOR EN-LIGHT-ENMENT

How progression in electronics design is helping to reduce vehicle weight

How can autonomous buses revolutionise city transportation?

Accelerating the testing and development of next-gen aerospace materials

Testing millimetre-wave automotive radar for ADAS and autonomous driving

40 ON TRACK

Cutting-edge digital solutions for the rail sector are more vital than ever before

PUBLISHER

Jerry Ramsdale

EDITOR

Hayley Everett heverett@setform.com

STAFF WRITER

Jake Holmes jholmes@setform.com

DESIGN

Dan Bennett, Jill Harris

HEAD OF MARKETING

Shona Hayes shayes@setform.com

HEAD OF PRODUCTION

Luke Wikner production@setform.com

BUSINESS MANAGER

John Abey +44 (0)207 062 2559

SALES MANAGER

Darren Ringer +44 (0)207 062 2566

ADVERTISEMENT EXECUTIVES

Paul Maher, Iain Fletcher, Peter King, Adam Croft

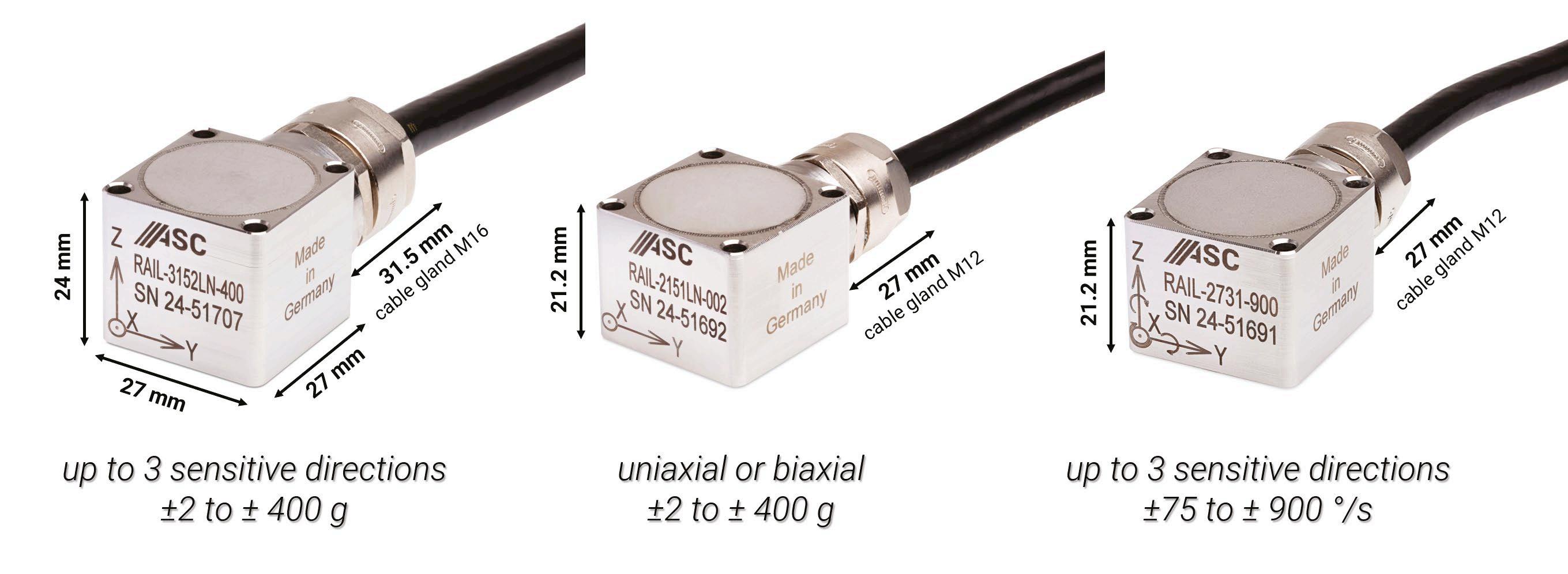

This new sensor series is helping railway operators improve their rolling stock

Exploring new opportunities in IIoT

47 MOBILITY IN MONACO

The AEC 2024 conference by AVERE takes place 13-14 November

IN FRANKFURT

Europe’s largest 3D printing trade show returns to Frankfurt in November

48 HEADING SOUTH

Southern Manufacturing & Electronics will showcase the latest in aerospace, automotive and electronics

Setform’s international magazine for transport is published twice quarterly and distributed to senior engineers throughout the world. Other titles in the company portfolio focus on Process, Design, Energy, Oil and Gas, Mining and Power.

The publishers do not sponsor or otherwise support any substance or service advertised or mentioned in this book; nor is the publisher responsible for the accuracy of any statement in this publication. ©2024. The entire content of this publication is protected by copyright, full details of which are available from the publishers. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior permission of the copyright owner.

Setform Limited, 6, Brownlow Mews, London, WC1N 2LD, United Kingdom +44 (0)207 253 2545

As equipment reliability becomes ever more important in the competitive electronics industry, selecting the right lubricant has become paramount to ensure that your machine components operate smoothly.

Chemours helps our partners anticipate, prevent and solve the most intractable problems through the use of our high performance Krytox™ lubricants. Our lubricants are safe and uniquely compatible with your equipment to extend life, reduce downtime and cut maintenance costs.

For over 60 years, we have considered reliability and performance non-negotiable. That‘s why we are the ideal partner for now and what’s to come.

www.krytox.com

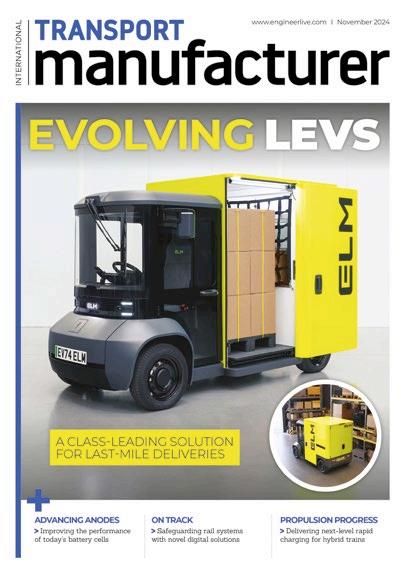

EVOLVING LEVs

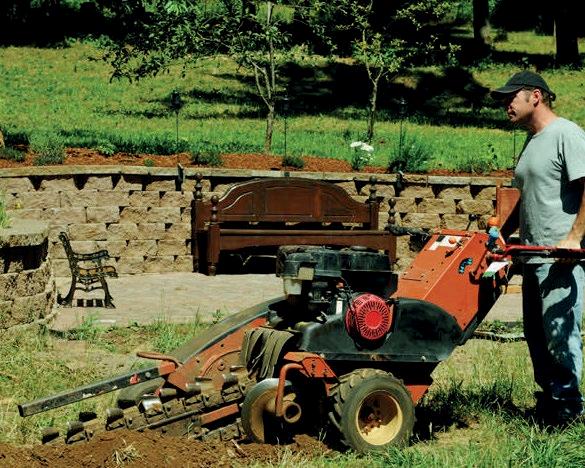

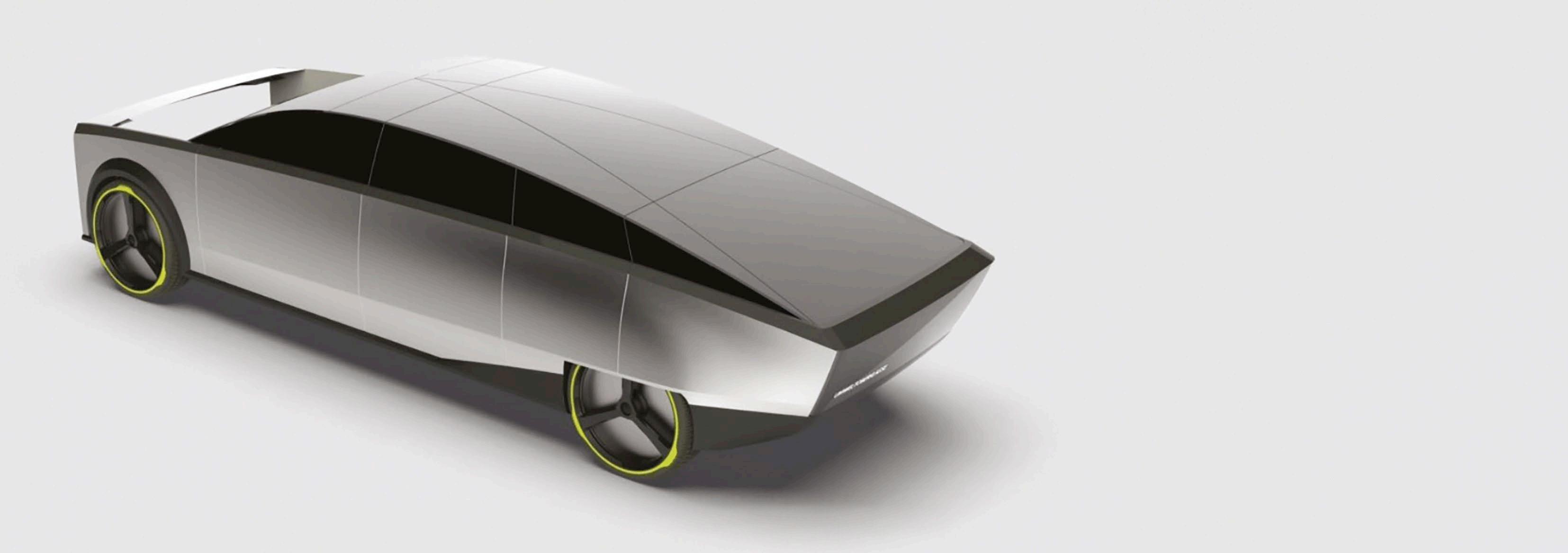

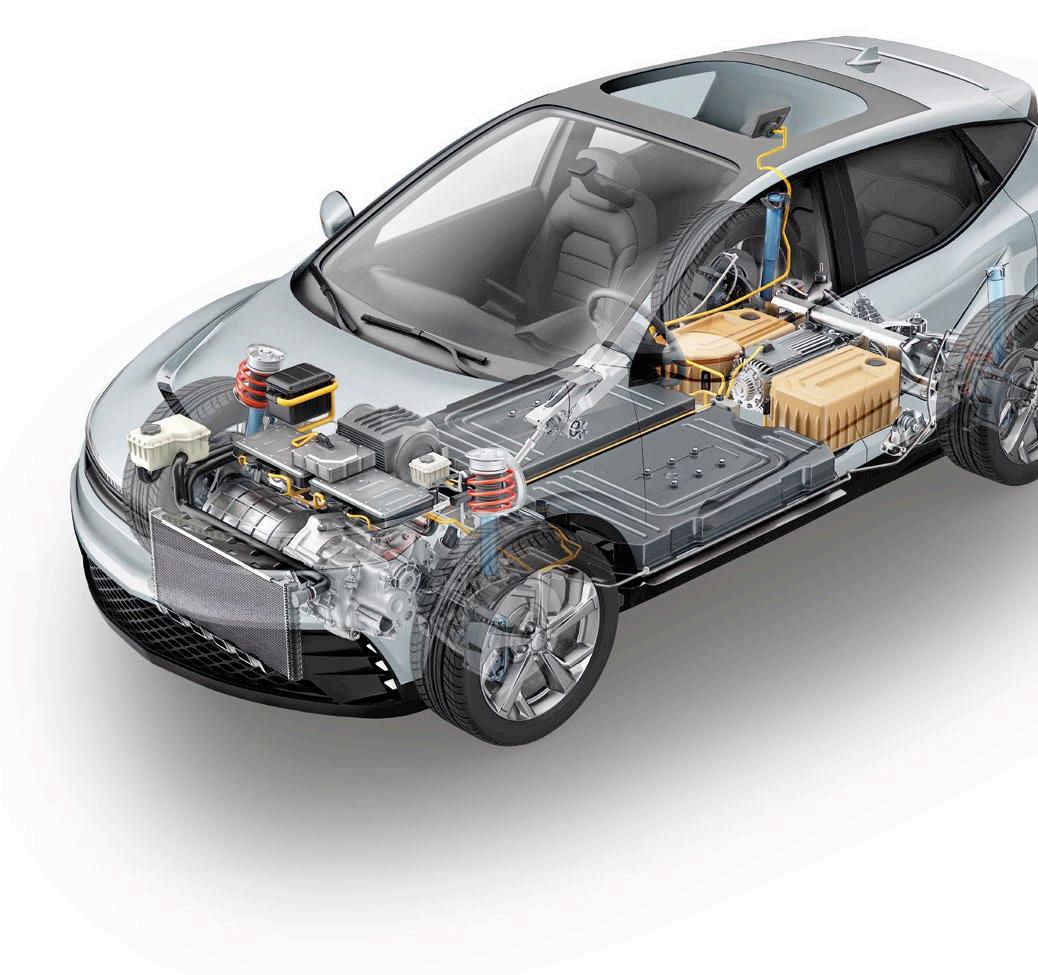

More versatile zero emission vehicles are needed to satisfy the growing demand for ‘last-mile’ deliveries. This new compact yet highly efficient quadricycle demonstrator could hold the answer

With the growth of urban clean air zones and rising online sales, logistics firms and retailers are increasingly seeking greener alternatives for their last-mile deliveries. However, many current zero emission vehicles are falling short in terms of reliability, safety, driver comfort and payload volume, or are simply to large and costly for the task at hand.

Two powerhouses in mobility engineering and design have come together to form a new joint venture that aims to put forward a more credible and efficient last-mile electric vehicle (EV) solution. Under the company ELM Mobility, Prodrive Advanced Technology and Astheimer Design have debuted their electric L7e category quadricycle demonstrator, equipped with a cubic load capacity rivalling that of midsized vans.

COMPACT AND CAPABLE

L7e category vehicles are heavy quadricycles – weighing under 600kg excluding batteries – which are designed to be fuel-efficient and capable of transporting either passengers or cargo. ELM Mobility’s EVOLV quadricycle has been designed to be the most capable, safe and efficient L7e category quadricycle yet. At just 3.24m long, 1.45m wide and 2.15m high, and weighing 850kg with

The compact quadricycle is ideal for last-mile deliveries in urban areas

batteries, the EVOLV features two configurable load areas that provide 4m3 of load space. This is a classleading 60% of overall vehicle volume, says Dr Iain Roche, CEO of Prodrive Advanced Technology.

“The concept is all about efficiency,” he explains. “The vehicle cabin is wrapped around the driver to make it as small as possible in order to be able to optimise volume and usability in the load space. In L7e category vehicles, you have limited mass, so the less you add to the cabin, the more you can add to your load concept behind the vehicle. 99% of last-mile deliveries are completed with a single driver, and the EVOLV’s cabin design allows you to enter the cabin from the left or right, and gives really good wraparound visibility for the driver to improve safety.”

The EVOLV has approximately double the load box volume of other L7e vehicles, and is half the weight of a compact van with a similar load volume, making it the most efficient vehicle in this class both in terms of cost and energy consumption per unit volume of goods per mile. The quadricycle’s design accommodates a 1.6m tall Euro pallet with a 300kg payload in the main load area, which can be accessed on the side via secure self-locking sliding doors, and has a 300mm load bed height. The secondary load area, accessible

through rear ‘barn doors’, provides additional space for a 1.2m tall Euro pallet and 200kg payload.

Astheimer Design’s philosophy revolves around removing everything that is superfluous, and this mantra was carried through the EVOLV quadricycle’s lightweight, robust and simple design.

“The architecture minimises the driver cabin and maximises the load space for improved efficiency, while the skateboard-style chassis enables a full-size pallet to fit inside,” says Carsten Astheimer, the company’s founder and creative director. “At the moment, many small vans used for last-mile deliveries cannot fit a fullsize pallet. Speaking to logistics firms and retailers, many have started to experiment with L7e vehicles, but are dissatisfied with their performance. With EVOLV, everything about the design is fit-for-purpose.”

HIGH UPTIME

The EVOLV has been designed with high uptime in mind. The vehicle’s tight 7.8m turning circle allows for quick manoeuvring in congested streets, while fared in headlights are less likely to be damaged. The vehicle is powered by a 20kWh battery offering ample 100-mile range whilst still achieving a top speed of 50mph, and when equipped with a type-2 connector offers 20-80% charge

time of less than two hours.

“EVOLV demonstrates how our collective innovative design and engineering can push the boundaries of what a last-mile EV can achieve,” Roche says. “With EVOLV, a compact footprint can go hand-in-hand with serious capability and efficiency. The vehicle offers the best of both worlds, injecting versatility without compromise into a logistics fleet.”

SCALING UP

EVOLV was one of 10 recipients selected to receive a share of the UK’s Advanced Propulsion Centre’s (APC) £22.7 million investment in ‘fast-start projects for the accelerated development of automotive products with a potential route to market’. Just one year later, the demonstrator quadricycle has been completed and ELM Mobility has been formed to take the concept into production.

EVOLV offers 4m3 of load space with a combined 500kg payload

cabin’s design gives drivers optimised wrap-around visibility

“Astheimer and Prodrive have a rich history in developing commercial vehicles together, and the idea of developing a purpose-built last-mile delivery vehicle came to us as a result of these projects and insights,” Astheimer adds. “Funding from the Niche Vehicle Network, the APC and a private investor has supported us along the way to this point of proving out the concept by developing an initial prototype to physically demonstrate the vehicle attributes and to get market feedback. ELM Mobility has been created to take the concept to market, and to become an iconic UK brand.” Going forwards, ELM Mobility will take the project into the production readiness phase ahead of certification. Pre-series production vehicles will be trialled by customers, with start of UK production planned for 2028. Prices are expected to start from around £25,000.

The

H2 GO

Do fuel cells offer a credible alternative to battery electric for heavy goods vehicles? This consortium thinks so. Jon Lawson meets the new ICEBreaker

The ICEBreaker is now at MIRAs proving ground in Nuneaton for testing and customer trials

With the Hydrogen Innovation Initiative recently earmarking the hydrogen technology market to be worth up to $1 trillion in the next decade, R&D efforts are set to ramp up in this space, and innovations in fuel cells are at the forefront.

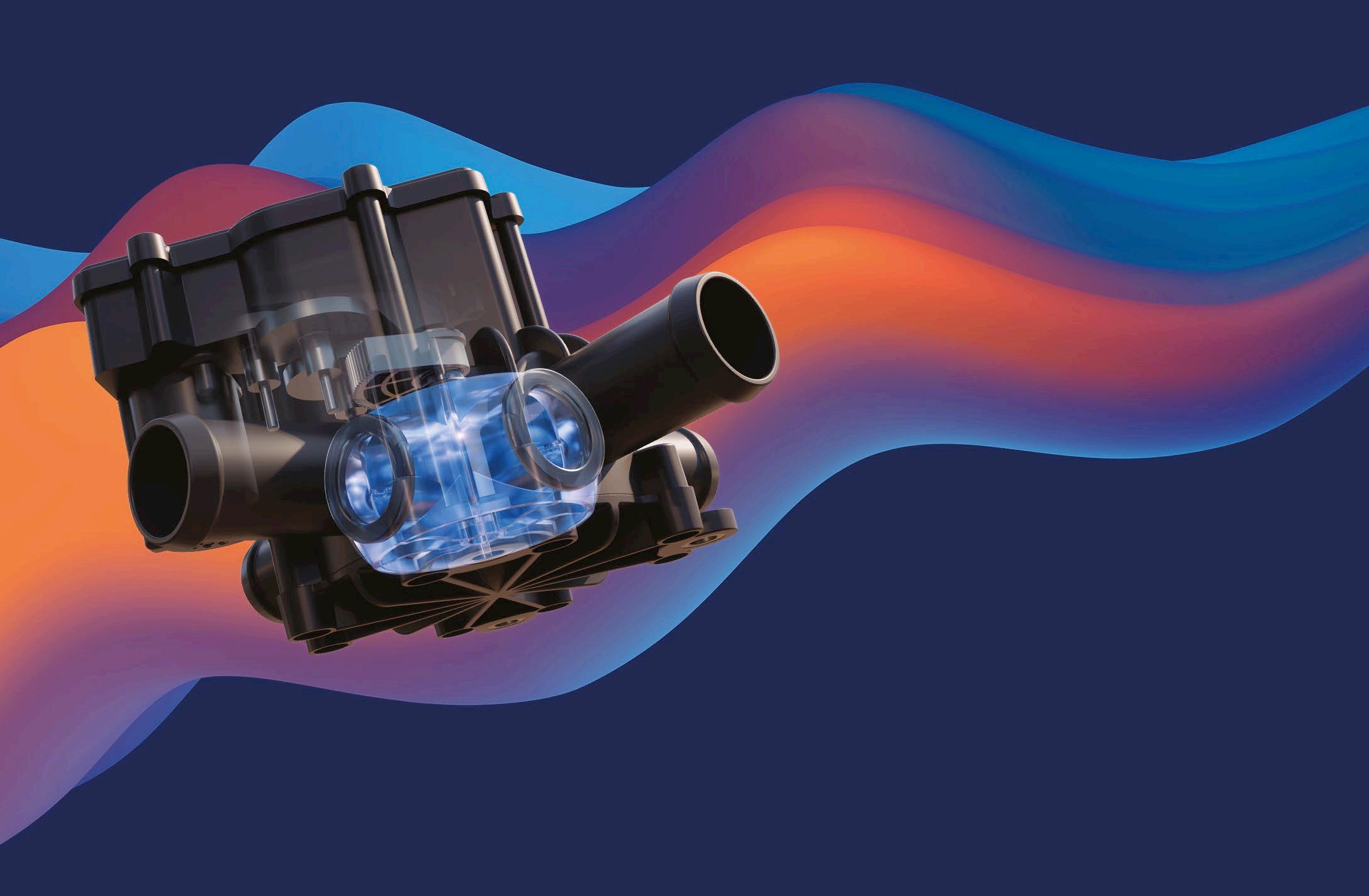

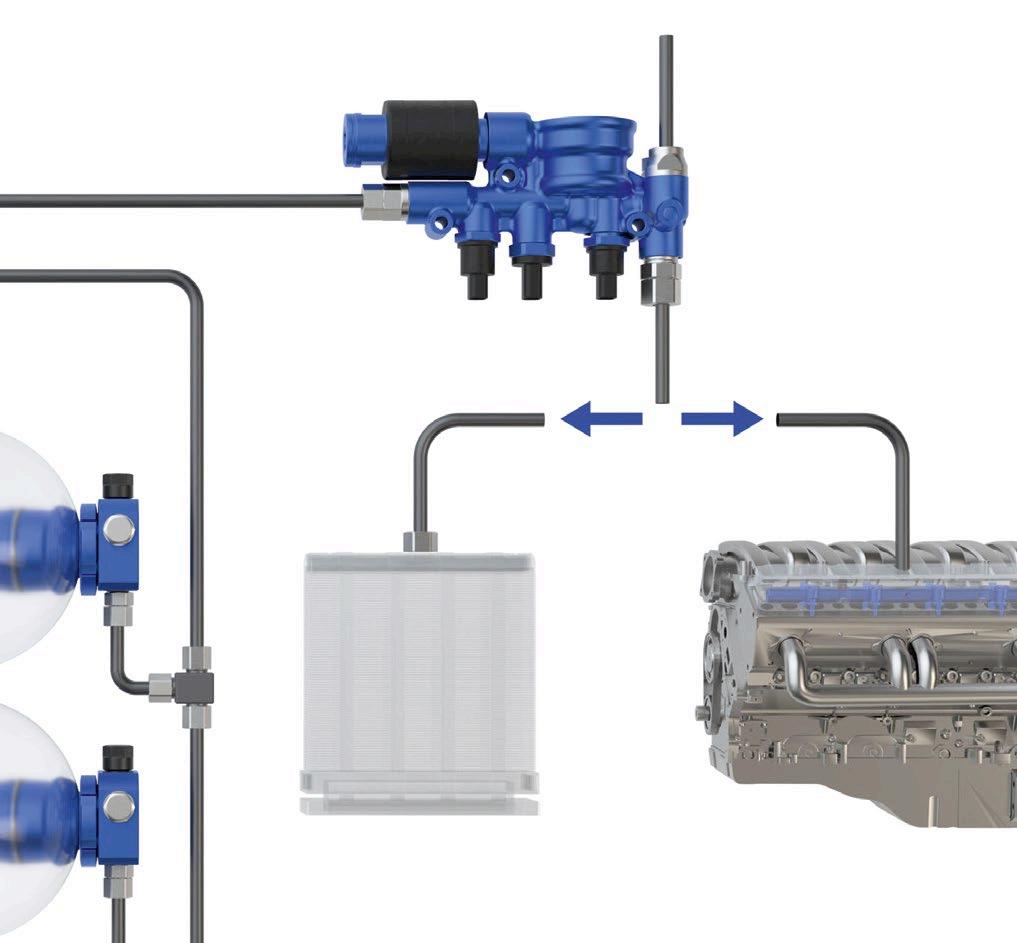

Leading by example, Viritech, Horiba MIRA and Intelligent Energy have teamed up to create a fully functional fuel cell prototype heavy goods vehicle, unveiled to the public for the first time at the Cenex Expo at Millbrook, England in September. The ICEBreaker features a 16kWh lithiumion battery with 400kW charge/ discharge capacity consisting of a pair of Intelligent Energy IE-DRIVE HD100 fuel cells operating in parallel to deliver 200kW each.

The whole thing came together in under 12 months. Greg Harris, chief commercial officer at Intelligent Energy explains, “We were already working on our automotive fuel cell when we were approached at the start of the project, so we could work quickly. Right from the beginning we decided to focus on a fuel-cell strong architecture. These two fuel cells provide the majority of the power needed for the vehicle. Because the transient response is so fast, we can do a lot of the acceleration direct from the fuel cells. The battery just gives a bit of

We want to work with customers on fleet trials and also apply what we’ve learned to other sectors

a boost and does some regeneration, as the fuel cells can’t do this.”

Heat management is crucial for fuel cells, just as it is for pure EVs. This vehicle features a novel system, differing from the conventional circulating liquid glycol via a radiator. Harris continues, “Even with highly efficient fuel cell systems like these, as much heat as electricity is generated. We chose to use evaporative cooling, which has enabled us to have operational benefits like much smaller radiators. We inject liquid water into the fuel cell which removes the heat by evaporating. This is then recovered in a condenser and solves the humidification issue as we are injecting water all the time. This also helps with the packaging.”

Some water escapes through the exhaust, but as water is a by-product of the cell anyway this is easily replaced.

TWIN TIME

Using its modelling expertise, Horiba MIRA has built a digital twin of the truck in order to see if this method can offer up a more efficient approach to vehicle development. “We didn’t want to use the conventional design, build and test approach. Part of the project consists of creating and validating these tools against the test vehicle,” confirms Harris. Post-project, MIRA will develop novel TCO optimisation solutions that will bring forward the point at which FCEVs reach cost parity with ICE which is useful for potential buyers to take into account.

The vehicle is now at MIRAs proving ground in Nuneaton which not only provides a site for testing but will also allow potential customers to inspect and trial the vehicle. “Looking ahead,” Harris says, “We want to work with customers on fleet trials and also apply what we’ve learned to other sectors.”

The ICEBreaker features a 16kWh lithium-ion battery and two IE-DRIVE HD100 fuel cells

This type of fuel cell arrangement may solve some of the problems battery electric vehicles suffer with, such as very heavy batteries and long charge times, but if it is ever to fully compete with internal combustion, the hydrogen fuelling infrastructure must exist. In this case, the ICEBreaker vehicle has a large 700 bar storage tank in order to ensure range. “This is a challenge,” admits Harris. “So far, in the UK at least fuel cell vehicles tend to be operated on a back-tobase principle. In the future, what needs to happen is for the authorities to do what they are doing in the EU, committing to installing a fuelling network by 2030, with stations every 200km or so, which could give hauliers the confidence to invest. We’re still waiting for the UK government to make a similar commitment. That said, there are a couple of interesting projects going on in the UK which will create some hydrogen refuelling capability to support truck trials. These are the HyHaul projects on the M4 motorway with capacity for 30

fuel cell trucks and the ZENFreight project in the north of the UK.” Another obstacle for widescale hydrogen fuelling adoption to overcome is creating the gas in the first place.

Harris says, “Most of the hydrogen today is grey hydrogen, either made from coal or coming from industrial byproducts, and even that doesn’t meet the demand in the UK or in other parts of the world. And it’s not green, it’s producing CO2. The focus now from both an environmental and cost perspective is to use renewables to create the gas via electrolysis. There are some projects being announced now which have received government support, such as the hydrogen production facility in Bradford. These projects will change the UK landscape by offering green H2 at volume and at a competitive cost.”

The ICEBreaker vehicle has a large 700 bar storage tank in order to ensure range

The ICEBreaker fuel cell prototype HGV

The partners developed a fuel-cell strong architecture

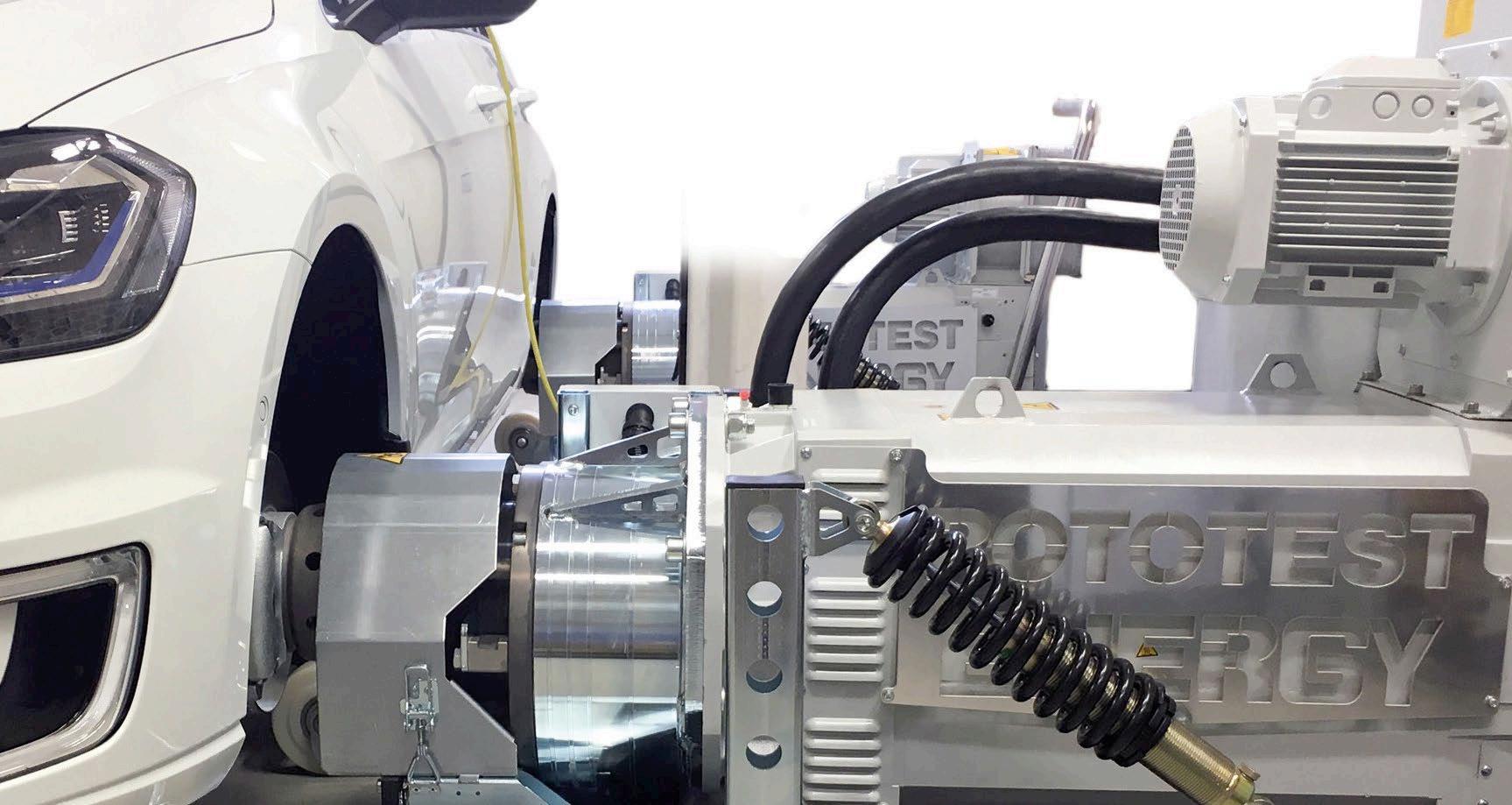

Rethinking Powertrain Testing

Rototest has established a new benchmark for Powertrain Dynamometers. Time optimizing and cost reducing solutions that will advance your R&D into the next decade, providing an unprecedented versatility to meet the demands of tomorrow.

Learn more about our testings solutions at www.rototest.com

MIND THE GAP

By adopting 3D printing technologies and high-performance materials, rail vehicle manufacturers can achieve significant cost savings. Jake Holmes explores the advantages of the additive manufacturing spare parts market for the rail sector

The upkeep and maintenance of railways and rail vehicles can cause significant downtimes, resulting in loss of revenue and high costs for rail operators. Having effective systems that can prevent downtime and improve the speed of maintenance is therefore crucial. Additionally, all rail vehicles – whether a tram, passenger train, high-speed train, freight train, or subway – require precisely designed and tested parts made of certified materials.

This is where 3D printing has been making its mark for several years,

enabling rapid prototyping, tooling, and spare parts for wear and tear components production according to industry standards.

Railway assets tend to have a lifetime range of 20 to 40 years for electrical and mechanical systems, meaning rolling replacements and upgrades are an absolute necessity. This is a significant cost to an operator, as on average rolling stock makes up 30% of lifecycle costs for a high-speed train – matching energy consumption costs (30%). By integrating 3D printing into their operations, rail companies can implement improvements that

result in substantial time savings and reduced maintenance of rolling stock costs.

CERTIFIED MATERIALS ARE KEY

The rail industry has very specific fire safety rules and standards which describe how the materials used in rail vehicle construction should act when exposed to fire. Materials used in rail vehicles for the European market, for instance, must follow the rail standards EN45545-2 to protect passengers and staff against onboard fire risks.

Using 3D printing for spare rail parts can bring down costs and reduce downtime

MATERIALS

Numerous 3D printing materials have been developed in recent years to comply with the standard. These include high-performance polymers, such as PEKK and PEKK-A by 3D printing filament manufacturer Kimya, and ULTEM 9085 by chemical manufacturer Sabic. Such ‘open market’ materials have already been widely used across the rail sector to deliver safe products while minimising production and compliance costs.

ULTEM 9085 is widely used in the rail, aerospace, and automotive industries, as its properties meet the requirements of the most demanding industrial applications. The combination of high chemical and temperature resistance, and flexural and tensile strength makes the material an attractive option for the rail industry. Moreover, it’s easy to machine and offers low flammability and toxicity.

Fused Filament Fabrication (FFF), as well as Selective Laser Sintering (SLS), are 3D printing techniques often used in the industry due to their ability to produce parts with highperforming thermoplastic qualities. SLS is a powder-based 3D printing technology that fuses material layers into a final part using lasers, while FFF is a material extrusion process, building an object by depositing melted material layer by layer.

SPARE PARTS ON TRACK

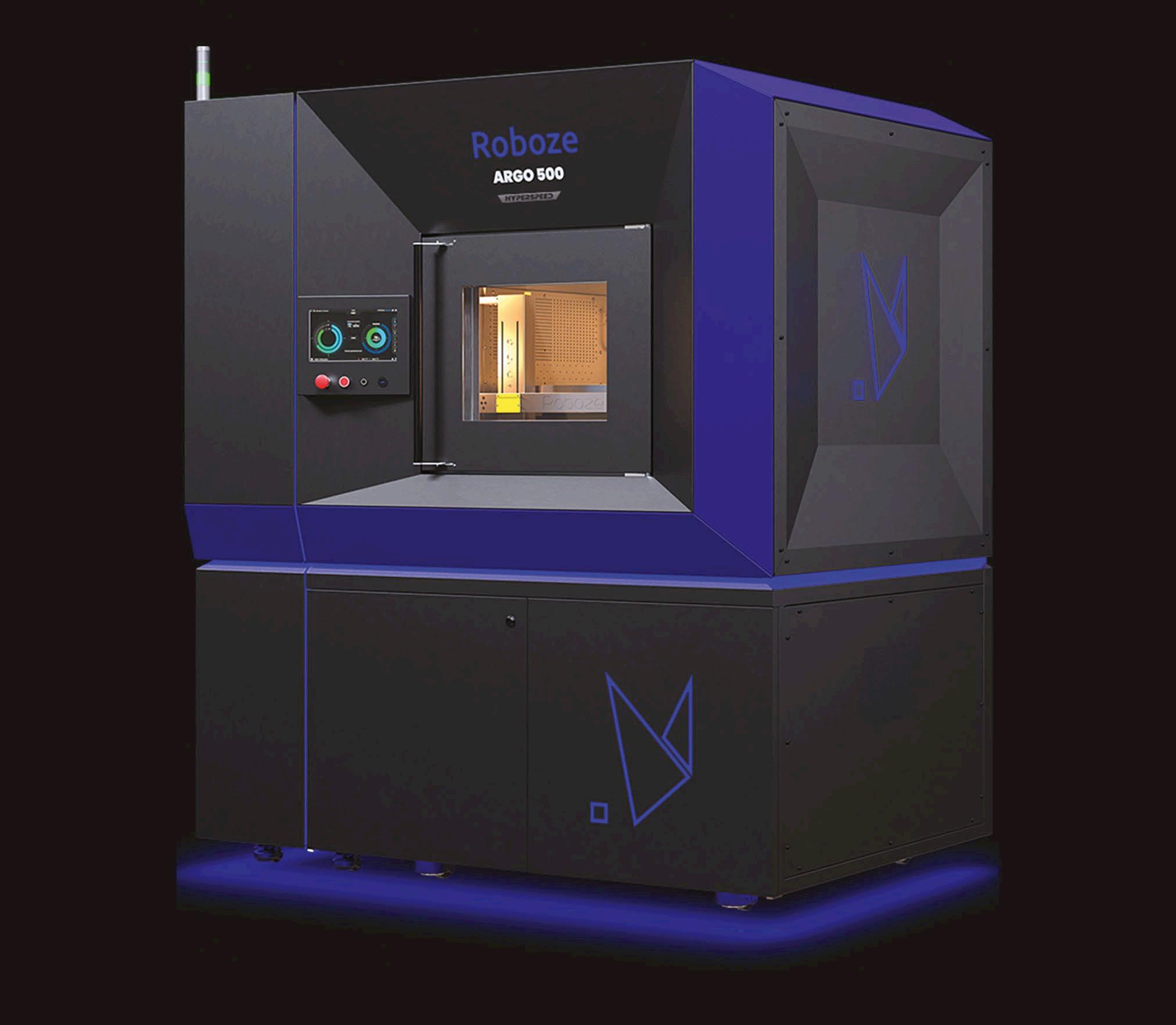

3D printing company Roboze delivers on-demand, just-in-time manufacturing of spare parts to the rail sector, reducing costs associated with storage and pre-ordering for operators. 3D printing allows several components to be integrated together, enhancing the original design of a component rather than merely replacing it.

In suitable applications, Roboze can replace metal with high-performance plastics, reducing weight by 50% which leads to lower energy and fuel consumption. The environmental impact of the overall rail vehicle is also decreased, as more lightweight components require less material during production. Roboze’s ‘digital warehouse’ contains digital blueprints of spare parts. So, only when a part is required is the blueprint sent for printing and the part produced. This process cuts cost and manufacturing times, while reducing the spare part inventory requirements for rail operators.

In terms of 3D printed materials, Roboze uses polypropylene for flapper replacements on train toilets due to its wide chemical compatibility, low weight, and impact resistance. The company replaces toilet drain pumps using Carbon PA because of its strong mechanical properties compared to

aluminium AA1050A. Meanwhile, low FST evolution, UL94-Vo at 1.5mm and 3mm or 0.059in and 0.118in makes ULTEM 9085 a suitable material for 3D printed armrest replacements.

ARMED WITH AM

Kimya – the additive manufacturing (AM) division of technology company Armor – provides 3D printing materials and services for the rail industry. Kimya entered the railway parts arena in 1982 when a supplier ordered a small batch of polymer parts through its manufacturing service. The original mould no longer existed, so the parts had to be redesigned from scratch using a PEKK filament developed in-house at the research and development centre. 3D printing the protective covers using PEKK led to cost savings and reduced lead times.

No digital twin or mould was available for reference, so a single paper plan was used by engineers and an original part was made using PVC as a prototype. A PEKK SC version was able to be printed using the PVC plan and could be applied to end-use. The custom PEKK SC filament was used due to its ability to resist high temperatures, up to 260°C, as well as flame retardant capabilities, abrasion resistance, and chemical resistance.

ON THE RAILS

Many rail companies have turned to 3D printing in one form or another in recent years to fulfil their spare parts supply, enhance component design or improve the environmental footprint of their rail vehicles.

German railway company Deutsche Bahn, for instance, has taken advantage of 3D printing using Gefertec’s 3DMP technology. The process creates near-net-shaped metal blanks using wire as a raw material at fast speeds and has a build-up rate of 600cm3 per hour, making it suitable for steel, nickel-base, titanium, or aluminium. Gefertec’s technology boasts cost savings of up to 60% with nearly 100% material utilisation, borderline eradicating waste. The company uses 3yourmind software to enable digitising logistics.

Additionally, Gefertec’s technology has been deployed for the production of wheelset bearing covers for class

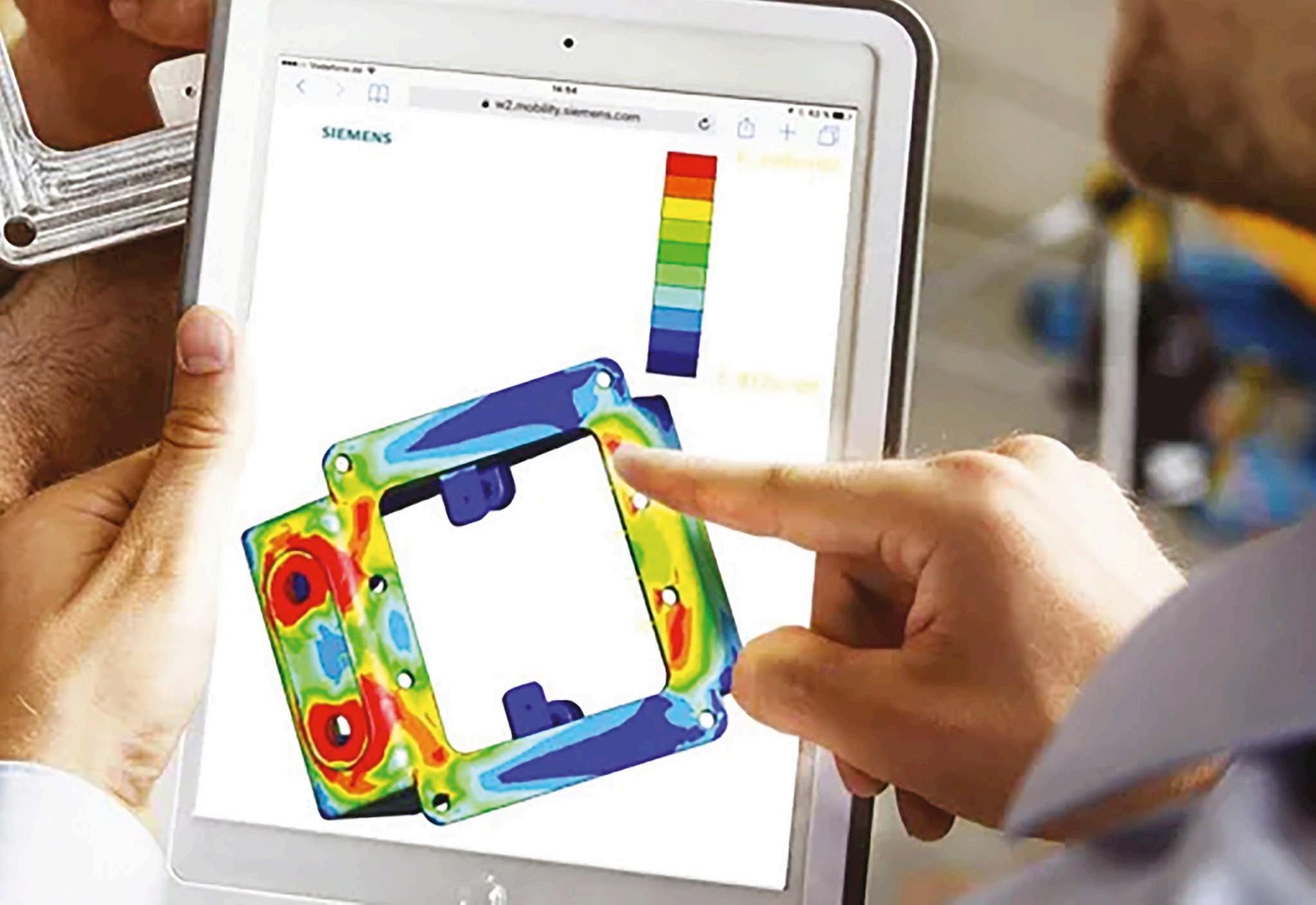

Designing and optimising rail spare parts in Siemens Mobility’s CAD programme

294 locomotives. The component was essential to the vehicle’s safe operation as without it, lubricant could leak from the wheel causing damage to the bearings. Despite this model being over 50 years old, the Arc605 from Rolf Lenk, a German machinery manufacturer, produced a replacement piece for the locomotive. The original cast for the wheelset bearing cover measured 374mm in diameter, 78mm in height, and weighed 11.5kg, taking up to nine months for delivery.

Gefertec’s arc605 system only requires eight hours to produce the component, rather than the nine-month lead time previously. The German federal railway authority’s materials laboratory tests consistently found the product to be of high quality.

Elsewhere, rolling stock manufacturer Alstom has also taken full advantage of 3D printing’s capabilities for its trains, with over 150,000 parts being manufactured this way. This process has seen a massive scale-up from its first introduction in 2016 when 3D printing wasn’t being used to produce parts for the company’s rail vehicles. Alstom now produces 40,000 pieces a year through 3D printing, both spare parts

and new designs.

Polymers, ceramics and metals are the main focus points of Alstom’s 3D printing capabilities. Fire and smoke-compliant materials, EN45545 for Europe and NFPA130 for North America, are available within Alstom’s 20-strong validated polymer portolfio. Meanwhile, aluminium, stainless steel, high-performance steel and titanium are available for metal printing. This range of materials allows the company to produce a wide array of products for rail companies, such as a

headlamp case for a high-speed train in France, a part in a soft material to be installed into an air conditioning evacuation tube for a Spanish metro, a jig to ease screwing holes in car body shells in Germany, and a bogie steel cover in the Nordics.

PRINTING THE FUTURE

Using 3D printing for train repairs and spare parts can bring down costs and reduce downtime. Economically, 3D printing has massive advantages, as there is no minimum order required as well as no warehouse needed for spare part storage. Per unit, costs rise using 3D printing, but the total cost actually drops for replacement pieces as only small orders are required. The breakeven mark for plastics is roughly 2,000 parts, whilst metals is 200. Additionally, less scrap material is produced using 3D printing methods whilst they also use less energy, as only the quantity required is produced. Each tonne of CO2 produced in the future may come with associated costs, at which point 3D printing will provide a more CO2friendly alternative to traditional manufacturing.

Looking ahead, 3D printing’s influence on the locomotive industry may stretch wider than just rail vehicles, as novel ‘Printfrastructure’ technology has been deployed in London on the construction of the HS2 railway line. Concrete has been ‘printed’ on-site using computers, rather than being transported as slabs, in order to build the infrastructure of the new train lines.

3D printed rail components by Alstom

Roboze’s Argo500 3D printer

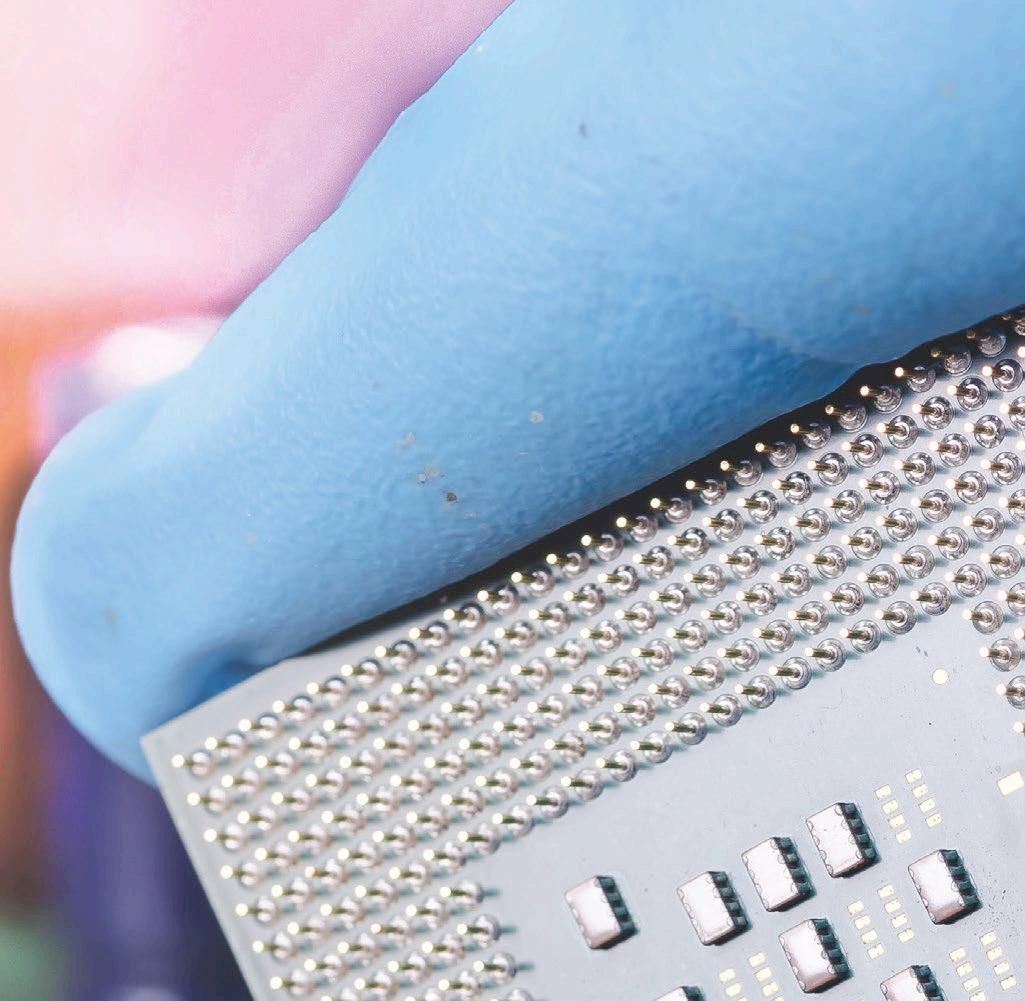

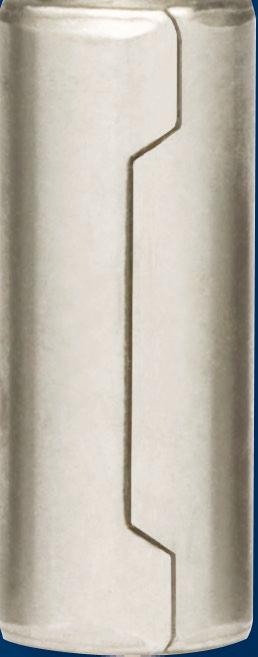

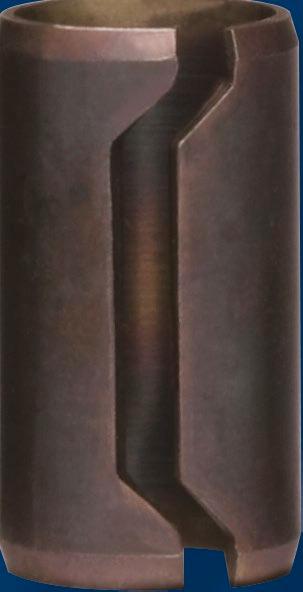

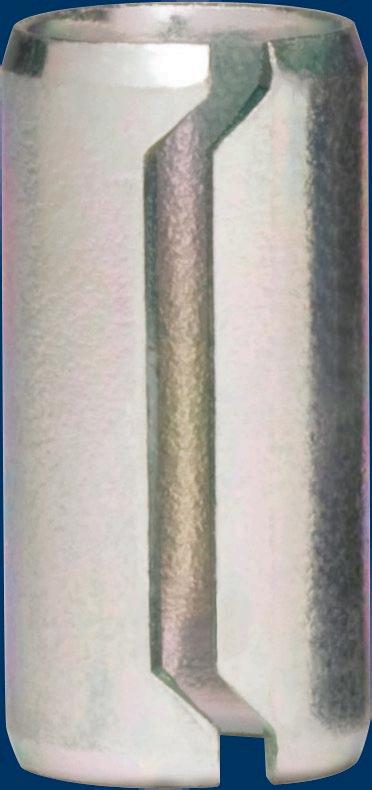

ADVANCING ANODES

Improving the performance of today’s battery cells has so far seen significant advancements to the cathode. However, this company has been directing its efforts towards improving the anode, with impressive results…

Within a battery cell, the anode is the negative or reducing electrode that releases electrons to the external circuit and oxidises during an electrochemical reaction, facilitating the flow of electric charge. While the anode is a vital subcomponent of today’s battery cells, recent development has largely focused on improving the efficiency and capabilities of the cathode, leaving untapped opportunities on the anode side according to LionVolt CEO Kevin Brundish.

“The cell, and therefore the battery, is only as good as either one of

the components, and so the anode has started to trail,” he says. “The mission of our business is to boost the performance of today’s cells. By taking out a graphite anode and replacing it with our lithium anodes, we can get 1.5 times the energy density compared to cells today, which is a very big step change. This enables things like electric flight to become more realistic and is applicable to the consumer electronics market, too.”

OPPORTUNITY AWAITS

LionVolt is an innovative battery scaleup company focused on developing a

3D electrode technology that can be applied in next generation lithium-ion, sodium-ion and solid-state battery cells.

“There are three core outlets for our technology, as we see it,” Brundish continues. “Lithium anodes can be put in today’s liquid cells to boost performance, but they are also viewed as a core component of a solid-state cell as well, and everything in between. Liquid, gel or solid, our anode can be applied to all of these bases.”

Lithium offers 10 times the energy of current anode materials, meaning the potential performance benefits for today’s battery cells are huge. However,

The company has been ramping up its manufacturing capacity over the last year

introducing lithium comes with its challenges, as Brundish explains: “One of the downsides is that if you try to use lithium straight off, it doesn’t have a great cycle life or fast charging speeds. How this has been dealt with by nearly everyone else is that they’re looking at how to adapt the electrolyte to manage those deficiencies. We, on the other hand, have been addressing this at the lithium metal positioning, bringing in a 3D architecture which is the core of the business, and which gives us lots of surface area and very thin films. Typically, the thinner the film, the faster it charges.”

LionVolt’s 3D architecture overcomes the limitations of lithium to enable fast charging rates, but there is a byproduct benefit too. By its nature, the ultra-thin film also has a good lifetime, meaning the company has overcome the two foundational limitations of lithium in a wide range of products.

“We’re drawing on manufacturing techniques in other scaled industries, like photovoltaics, like semiconductors. So, we’re looking at drawing those techniques into the battery world, and the advantages that those bring,” Brundish says. “We see ourselves as working on a complementary angle to those who are working on the cycle life side of cells. We think we’ve solved the challenge of fast charging lithium, and that enables it to be practically applied into a much wider market space.”

PLANES, TRAINS AND AUTOMOBILES

Long-term, LionVolt sees its anode solution being dropped into the existing battery cell supply chain for many different industries.

“The beauty of working on a high energy cell is that it can be applied to lots of different markets,” Brundish says. “The same core product can be built up or down into bigger or smaller batteries, depending on what the end use is, and what we do is very deployable. If you were putting our technology into a plane, for instance, you’d just have to build much bigger batteries using the same product. We’re already working with companies in the vehicle space, but for now it’s about building that scale up. In terms of markets, we’re working in parallel with everybody, but recognising that the needs of each sector differ slightly. Some favour early adoption,

An efficient and repeatable manufacturing process is key

and some prefer a longer-term rollout. But we are working with all sectors –aerospace, electric vehicles, HGVs and so on – and we see ourselves being deployed in all those markets.”

NEXT-GEN ANODES ARE TRENDING

While the general trends of more energy, lower weight and volume, and faster charging still remain as important now as they were decades ago, there are some interesting developments taking off in the cell development space.

“We’re seeing the articulation of solid-state as a solution to some of the safety issues, as well as delivering very high performance products,” Brundish offers. “This has been a market desire for some time, although the practical time frames to deliver this are still being looked at. We want to accelerate this, because we solve some of the core challenges. Additionally, liquid-base cells have been in use for a long time and we’ve arguably had a very stable and safe product for years, but now we

want more from it. So of course, there’s the question of whether we can get this. And so, we are seeing a trend on nextgeneration anodes that could really deliver on those market trends of fast charging, good life and improved safety. The anode forms a very important part of this picture.”

So, what are the next steps for LionVolt on this journey? “Where we’ve been up until now is focusing on the innovation side and demonstrating the technology can deliver all of the above,” Brundish adds. “Over the last year, we have ensured that we have a manufacturing capacity that is sufficiently large and efficiently repeatable, which means we can now build those cells and provide them to our clients in 2025. Our innovation is now being embedded in a product that our clients can evaluate and start to consider designing into their products.”

GAINING TRACTION

Introducing an innovative battery solution for freight locomotives based on LFP chemistry

Forsee Power specialises in sustainable and secure battery systems for commercial vehicles, light electric vehicles (LEVs) and rolling stocks. At the recent Innotrans trade show in Berlin, the company shared its market data and outlook for battery electric propulsion in Europe, an area that is showing promising potential for sustainable transportation.

“In Europe, we have averaged only 57% of the rail tracks electrified by catenaries which, considering the CO2 emission targets we have in Europe, proposes very significant potential for battery electric trains in the future,” says Phillipp Mack, global sales and marketing director for railway applications at Forsee Power. “If you look in terms of the market for energy requirement and install base, by far the trade locomotive market momentum will lead this due to its high energy demand.”

LFP FOR FREIGHT LOCOMOTIVES

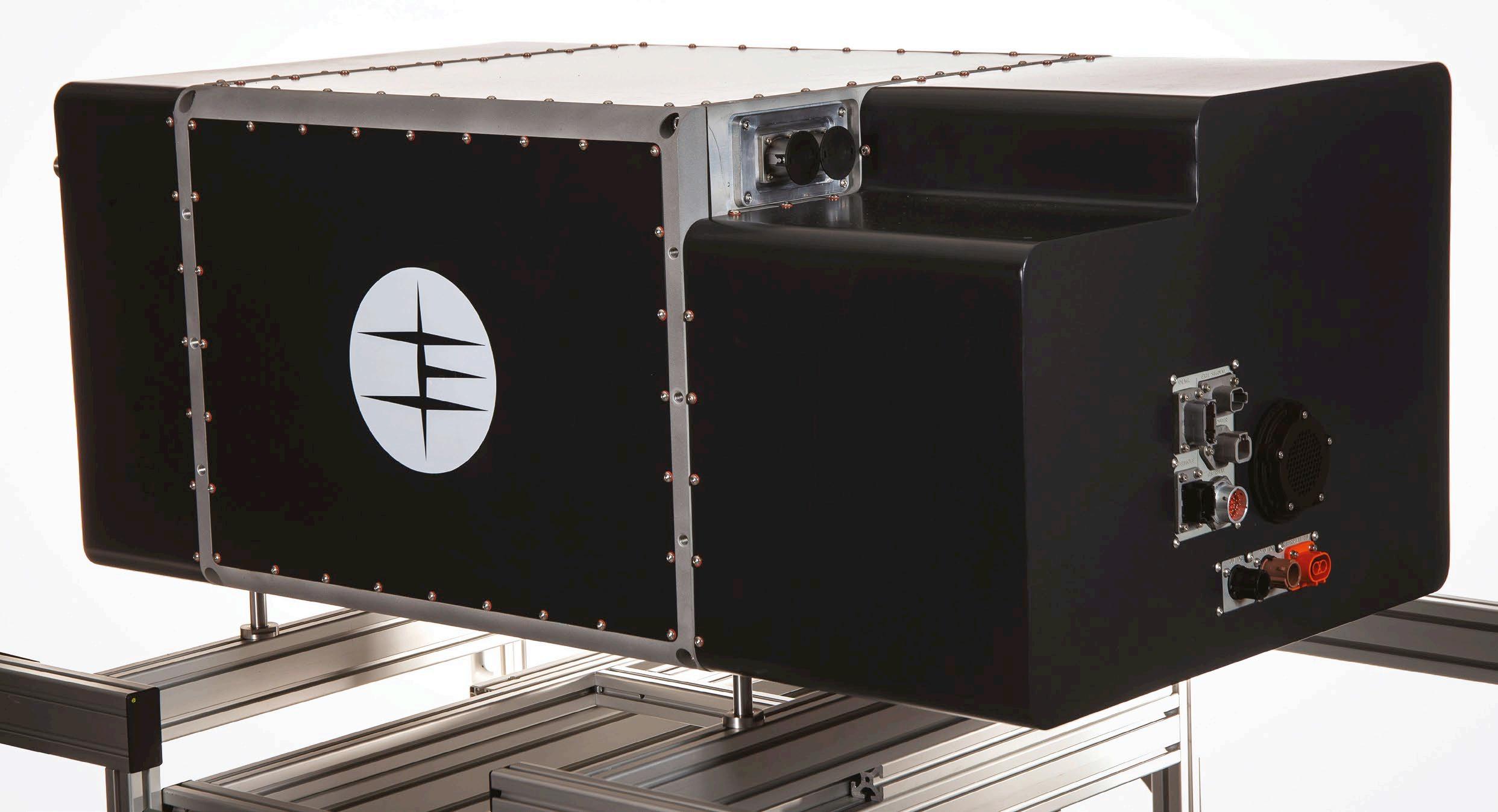

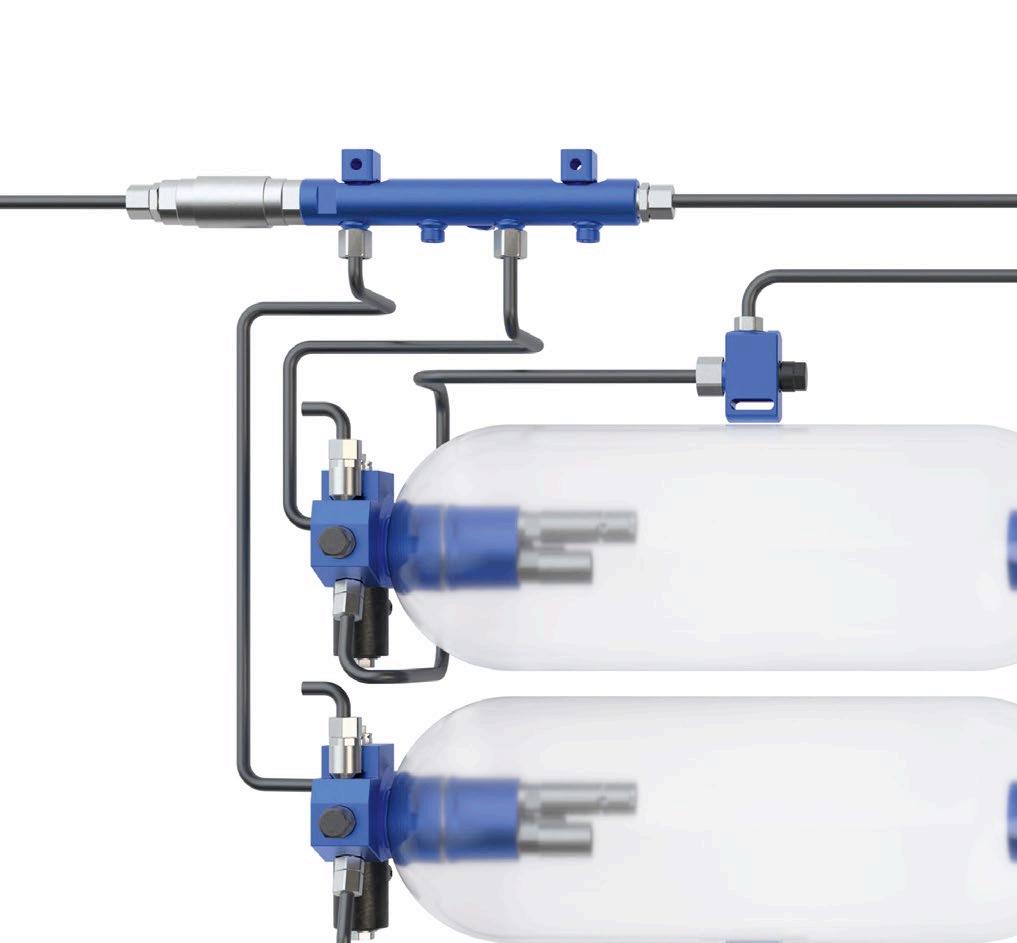

Typically, locomotives operate on a DC link voltage of 1500V, requiring a complex, costly and heavy converter due to batteries typically operating at 750V. To overcome this challenge, Forsee Power has developed the Zen

LFP 1500V high-energy battery pack based on lithium iron phosphate (LFP) chemistry.

The modular system is intended for service, freight transport or passenger transport locomotives, with its high energy storage capacity offering flexibility on portions of nonelectrified tracks, without catenaries.

“LFP is much more cost efficient than traditional LTO chemistry largely used in battery electric quantum applications,” Mack explains. “The solution includes a fully integrated battery operating at 1500V, eliminating the need for complex and costly DC-DC converters.”

The Zen LFP 1500V battery pack offers high energy and power density, making it a cost-effective and efficient solution for freight locomotives. With a specific energy of 194 watt-hours per kilogram, energy density of 240 watt-hours per litre, and power density of 313 watts per kilogram, the battery pack is designed to meet the energy density requirements of freight locomotives by providing a flexible and scalable solution. The battery pack also meets all railway certifications for fire and safety, ensuring a low total cost of ownership for operators and providing a long lifespan of 6000 cycles.

“With the LFP technology, it is possible to design and build multi megawatt-hour systems for locomotive applications,” Mack adds. “We believe this is the solution for the future of electrification in long distance freight locomotive applications.”

Made up of 55kWh modules, the system can be used to create 330kWh 1500V branches (six modules in series) and multi-megawatt-hour systems. These battery systems can be recharged by catenaries via inmotion charging, a stationary charger, or through energy recovery during braking phases.

The company’s Zen LFP 1500V battery pack is designed to address the challenges of battery electric changeover in freight locomotives, offering a cost-effective and efficient alternative to traditional diesel trains. By integrating powerful and durable batteries such as this, trains can efficiently store and release electrical energy, optimising their energy performance and reducing emissions.

The Zen LFP 1500V battery pack

Charging forward to the next generation of e cient transportation

Our high-voltage eFan ensures e cient cooling in all-electric heavy-duty trucks.

CHARGING AHEAD

Fast chargers are critical in supporting long-distance travel for battery electric vehicles and alleviating range anxiety. This new rapid charging solution is speeding up the transition

Fast chargers enable quick recharging of battery electric vehicles (BEVs) and, as the adoption of BEVs grows, the availability of fast charging infrastructure is becoming increasingly important. Recent figures from the European Automobile Manufacturers’ Association (ACEA) state that there are approximately three million BEVs on EU roads, with around 75,000 public fast chargers available This translates to a ratio of roughly 30 BEVs for every fast charger, and when counting plug-in hybrid EVs this ratio rises to about 52 cars per fast charger. As the number

of EVs grows, expanding this network of fast chargers will be vital to meet the evolving demands of EV users.

In response to this challenge, Borgwarner, a global manufacturer of electrification and mobility solutions, has introduced its new DC fast charging system to the commercial EV market. Debuted at IAA Transportation Hanover in September, the charging station is described by chief technology officer Harry Husted as an “excellent solution for rapid charging.” International Transport Manufacturer caught up with Husted during the show to find out more.

SPEED IS KEY

The DC fast charger has a scalable power range of 120kW up to 360kW, making it suitable for fast charging commercial vehicle depots and public and high traffic areas. The conversion from AC to DC voltage happens within the charging station’s power electronics to deliver DC directly to the battery, which substantially reduces charging times.

“The unit is fully integrated in one package,” Husted explains. “It features two charging guns meaning you can charge two vehicles simultaneously, and at 360kW, it’s very high-power. This puts it front and centre of the

The DC fast charging station

Harry Husted, chief technology officer, Borgwarner

market for what people are asking for today in terms of fast charging.”

Borgwarner’s DC fast charging stations are specifically designed to handle the high energy demands of commercial and passenger vehicles that often have a need for fast charging ‘on the go’, with its scalable power options able to meet a wide range of depot and charge point operator needs. This means the charger is not only well-suited to the passenger car market but also caters to larger commercial vehicles too.

“We offer the ability to start at 120kW and then you can work your way up to the power level you need,” says Husted. “If customers don’t need the maximum 360kW, they can reduce the price by opting for a lower power level which provides them with greater flexibility.”

THE COMPLETE PACKAGE

“At high power, charging cables can become quite heavy,” Husted continues. “We designed the fast charger with integrated cable management to improve ease of use and counter the cable’s weight, while providing enough cable length to

easily reach the charging point on the vehicle. The charger is also one unit, so it is easy to install and has an integrated large full-colour display screen, built-in current monitors and payment interface.”

The charging station is designed to provide a more convenient and streamlined user experience due to quick turnaround time and higher power input. To meet the requirements of different charge point operators,

Borgwarner can simply change out the plug on the handle. The charger uses a standard protocol on the backend, making integration into various infrastructures and regions easy.

THE IMPORTANCE OF INFRASTRUCTURE

According to Husted, establishing a reliable, widespread charging infrastructure network is key to supporting viable, long-distance travelling for BEVs. Last year, Borgwarner announced a $20 million investment to accelerate the development, manufacturing and testing of its EV products and charging infrastructure equipment, including battery modules and packs, DC fast charging equipment, and microgrid control and operations, in its Auburn Hills, Dearborn, Hazel Park and Michigan facilities.

“Infrastructure is expensive to install, and sufficient energy supply has to be available in the location that you’re in,” Husted says. “Infrastructure is a really important aspect as we move forwards. You need to have quick and efficient permitting, the right power needs to be available where you are on the map, and getting power distribution to the required site is crucial. There’s also long lead times for some of the electrical components in the system, like switch gear, the big circuit protection and disconnected elements, and transformers. We all want to go fast, but there are some aspects that impact how quickly we can make things happen. However, charging products are becoming more widely available, so we’re going to start seeing installation timing and cost becoming bigger factors.”

Looking ahead, Borgwarner is well placed to continue driving innovation forward in the commercial EV sector, Husted says: “Our approach has been to have a balanced portfolio that we can manage going forwards. We feel good about our role for the foundational part of the business, and on the electrification side. We’re continuing to monitor and move with the market as we go.”

The DC fast charger on display at IAA Transportation

The charger features a large full-colour display

Charge Ahead:

Teflon™ Fluoropolymers

Drive Electric Vehicle Performance and Efficiency

Experience unmatched versatility and performance. Teflon™ fluoropolymers deliver superior chemical and thermal resistance, optimizing automotive performance and unlocking innovation.

PROPULSION PROGRESS

This

new traction battery is delivering whole new levels of energy density and fast charging

As reflected in Innotrans 2024’s theme “The future of mobility,” the global rail market is poised for steady growth due to rapid urbanisation, rising road congestion and favourable eco credentials over other forms of transport, like air travel. As such, the railways of the future are starting to take shape, with electrification offering the promise of zero-emission trains. But to meet this challenge head on, new and existing networks must be able to adapt to evolving technologies in order to maintain efficient and sustainable transportation networks. ABB has been an active technology leader in the rail sector for more than a century, offering the market

for hybrid trains

innovative solutions to speed up its decarbonisation journey. When it comes to rail infrastructure, the key focus areas are DC and AC traction power supply applications.

“ABB is at the forefront of supporting efforts to decarbonise the global rail industry by developing cutting-edge traction systems and solutions through intense research and development,” says Edgar Keller, president of ABB’s Traction Division. “Our commitment to reducing energy consumption and introducing cleaner, more efficient technologies further supports the creation of a more sustainable rail industry, helping to meet ambitious global sustainability targets.”

GROWING TRACTION

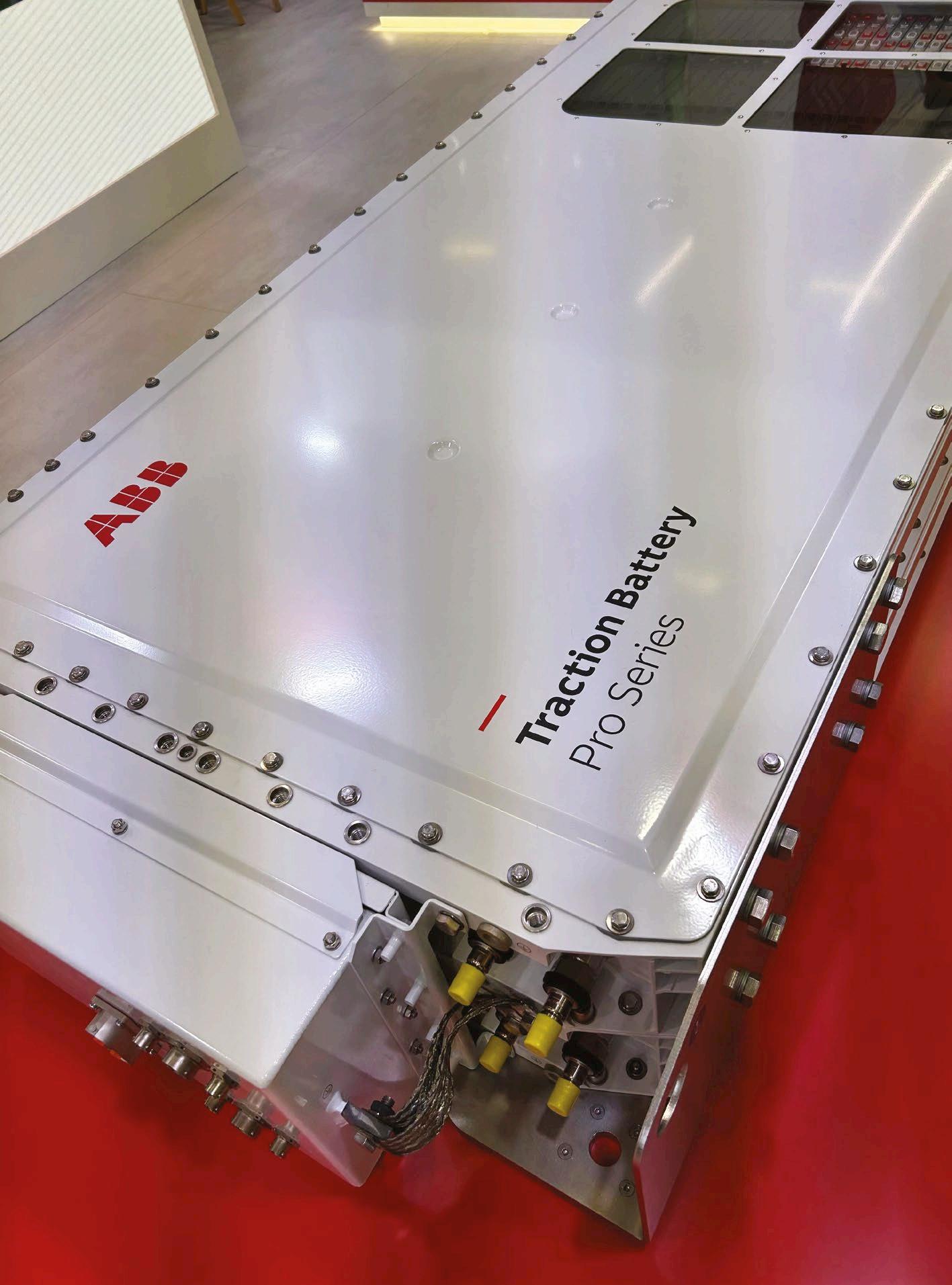

The latest advancement in this area from ABB was debuted at the Innotrans show in Berlin. The company launched the third generation of its Pro series traction battery, designed specifically for demanding hybrid and fully electric rail applications. The innovative battery pack is the latest addition to the company’s extensive traction battery family, designed to offer a range of benefits from scalability and modularity to enhanced energy density.

“This new design is still modular and flexible but is even more compact, and has a higher energy density than previous generations,” says Keller.

“Charging to 80% is possible in just 10

Passenger comfort is a key consideration for hybrid trains

minutes, and the battery is capable of enabling crucial regenerative braking which is a key element in hybrid trains. When there isn’t the time or ability to refuel the diesel tank, you can charge the battery through braking and use the energy again for acceleration. We see this as a big advantage.”

Alongside its rapid charging capabilities, the new traction battery provides a long lifetime with over 20,000 cycles. The Traction Battery Pro’s fast charging element also yields significant fuel savings for hybrid trains, thanks to an accompanying high-performance lithium-ion based onboard energy storage system.

“We have proven that you can achieve more than 30% fuel savings - depending on the network – which equates to around one in three trains running for free,” Keller explains. “From a comfort perspective, this is also a benefit for passengers as there is low noise levels, acceleration is smooth, and there are no fumes or emissions in tunnels, and so on. The passenger can feel like they are on a fully electric train, despite being on a hybrid one. The new battery is able to charge and discharge very fast with limited losses, and can also operate in very low temperatures. The compactness of the battery also allows for more space for passengers.”

The new generation of the Traction Battery Pro is engineered to provide both modularity and scalability to operators, as well as best-in-class performance. The battery is also designed with high levels of safety in mind, and features enhanced energy density in a compact design.

Combined with ABB’s efficient propulsion system and advanced digital tools, the entire system is optimised for better performance.

According to Keller, the battery’s capabilities will help to bridge the time before hydrogen – or something better – becomes more available to take decarbonisation to the next level.

“There’s much hype around hydrogen, but many are realising that this will take time,” he says. “It’s expensive, especially if we’re talking about green hydrogen, and it will take a huge effort to bring this through. And then there is the question of transportation, it’s not like diesel that you can fill up in a

We have proven that you can achieve more than 30% fuel savings - depending on the network – which equates to around one in three trains running for free

Traction Battery Pro series at Innotrans 2024

tank, it’s more complex than that.

So, today we need to bridge the time until we have sufficient green hydrogen infrastructure. This is where hybridisation of diesel trains is key, especially with the fuel savings we are able to achieve with the Traction Battery Pro.”

Alongside applications in hybrid trains, ABB is also exploring the use of traction batteries in trams which can run without catenaries for short distances, in a bid to improve infrastructure flexibility. According to Keller, the near-term focus should be on efficient solutions that meet the increasing demand for public transport, without overloading the grid.

“Regarding electrification, everyone

is talking about the electric car, but the railway has been electric for 100 years - this is nothing new for us,” Keller adds. “Now, it’s a question of balance; what you can run with batteries, when does it make sense to have a catenary on top, and so on. It’s an evolution, and we certainly should not wait for hydrogen fuel to change everything as it will not happen overnight. Electric technology is available today, and there is huge potential in these projects to improve the sustainability of rail.”

For more information visit: https://new.abb.com/railway

The

STAINLESS STEEL SUPERIORITY

Stainless steel has been the old faithful of the automotive industry for decades. Continuous reinvention has kept the material relevant during the rise of electric and hydrogen fuel cell vehicles, offering crucial lightweighting and sustainability advantages

The company’s stainless steel enables the design of next generation vehicles using lightweight yet strong materials

From the 1936 Ford Deluxe Tudor sedan to the 1967 Lincoln Continental, stainless steel has long been the material of choice for iconic car models the world over. Since the material’s birth in 1912 with the patent V2A, stainless steels have progressed to meet the evolving demands of the automotive sector, from corrosion and thermal resistance in the 1900s, to the formability of complex geometries at the turn of the millennium. Now, in 2024, the material is being optimised to improve crash safety, lightweighting and environmental sustainability within today’s vehicles.

DESIRABLE PROPERTIES

Gone are the days when stainless steel was pigeon-holed as being too heavy and cost-intensive for automotive manufacturing. Diverse grades and advanced production techniques have

enabled the material to evolve to suit the requirements of current vehicle applications, from car bodies and structural components to intricate design elements.

Thanks to its unique durability, low maintenance and resistance to corrosion, stainless steel is a strong and economically sustainable material for a wide range of demanding applications, whether for electric, hydrogen or combustion engine vehicles. This has been made possible by redefined stainless steels from the likes of Outokumpu, which offer automotive manufacturers high crash energy absorption, thermal and corrosion resistance and formability, alongside a combination of strength and reduced weight.

“We are producing stainless steels with a chromium content of at least 10.5%, which delivers a chromium oxidised layer on the surface to

Circle Green stainless steel achieved 95% recycled material content last year

provide added durability and corrosion resistance,” says Stefan Lindner, technical sales manager mobility and transport at Outokumpu. “We are offering a material that can really last forever in terms of material supply, as stainless steel is 100% recyclable, but also in terms of significantly extending component and overall vehicle lifetime.”

LIGHTENING UP

Although stainless steel is denser than aluminium, its adjustable strength allows for thinner components, which can offset the weight difference. Outokumpu has developed a new generation of nickel-free austenitic manganesechromium materials for structural vehicle components, with a particular focus on crash-relevant and safetycritical parts. The company’s Forta H-Series – available as Forta H500, Forta H800 and Forta H1000 – offers a yield strength Rp0.2 ≥ 1000 MPa in combination with high elongations at fracture in order to open up new opportunities in lightweight engineering and design with steel.

The Forta H-Series’ unique alloy system, microstructure and hardening characteristics combination gives the material great potential for lightweight engineering. When combined with special manufacturing processes like hydroforming or roll-forming, the stainless steel grades enable new designs for lightweight parts. Where mild steels are still used, weight savings of as much as 40% are

possible, while functional integration helps to reduce the number of parts within a component or vehicle.

Safety improvements go hand in hand with the Forta H-Series’ lightweighting benefits, as material thickness can be reduced while crash performance is improved. The stainless steel’s hardening properties means it can absorb the impact energy without failing and transmit this energy to surrounding parts, even in welded areas.

Cost-efficient industrial processes are critical to component manufacturing, with high processability an essential factor. Outokumpu’s Forta H-Series is notable for its excellent processing characteristics and reproducibility, enabling it to fulfil the very highest quality standards.

SUSTAINABILITY AT THE FOREFRONT

As well as the sustainability advantages delivered to vehicles by lightweight stainless steel component design, it’s important to ensure the material’s supply chain is ticking the green credential box, too, Lindner says.

“We want to create real change in terms of sustainability,” he explains. “We consider our own scope one and two emissions – the direct emissions from our facilities, indirect emissions from the purchase of electricity, mining, transportation and distribution – alongside the scope three emissions of our total supply chain. It’s really important that we as a material

We are offering a material that can really last forever in terms of material supply, as stainless steel is 100% recyclable

manufacturer start the process of collecting that data to inform and improve our operations, considering raw materials, manufacturing processes, joining processes and corrosion protection. We have already integrated a circular economy for our stainless steel Circle Green, achieving our highest recycled material content ever of 95% in 2023 and reducing 12 million tonnes of CO2 emissions.”

As part of its sustainability mission, Outokumpu has unveiled its concept for the sustainable luxury car of the future, an innovative platform for automotive suppliers. The concept car will be made out of more than 95% recycled stainless steel, combining sustainability with high-strength and crash-safe materials. With a chassis constructed from folded stainless steel, an extremely lightweight construction would become possible via an easy and cost-efficient manufacturing method. The concept is naturally electric, with batteries integrated into a stainless steel platform. Stainless steel materials would also be used in the vehicle’s other drive technology, such as the bipolar plates of fuel cell systems or the bio-fuel drives like tanks and engines. Overall, the concept is presented as a holistic approach to vehicle safety and sustainability. Whether we will actually see one in the flesh – or steel – in the future though, remains to be seen…

The sustainable luxury car of the future concept

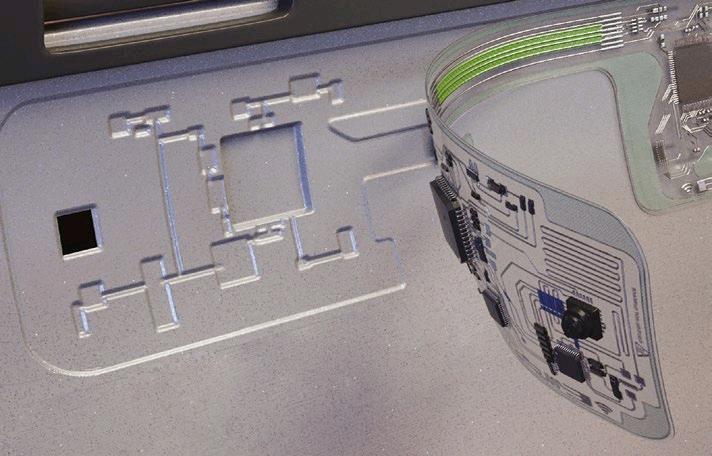

OMSE close-up of Flexihibrid circuit assembly showing components and receptive moulded cavities

THE SEARCH FOR EN-LIGHT-ENMENT

Neil Armstrong discusses how progression in electronics design is helping to reduce

It is a never-ending quest for automotive manufacturers to reduce the weight of the vehicle. Delivering better fuel economy, higher payload capacity, longer battery life and better performance is the nirvana. So, how does the development and progression of electronics impact this mission?

The electronic functionality of modern commercial vehicles is increasing exponentially. The automotive electronics market is growing at a compound annual rate of over 7%. Today’s commercial vehicles

the weight of vehicles

have on average over 100 electronic control units (ECUs). Depending on the complexity of the vehicle and the functionality delivered, this figure can rise significantly. The drive towards electric vehicle technology or hydrogen power will inevitably push these numbers up. Common to most vehicles, electronics control the powertrain, gearbox, differentials, ABS, airbags, instrument controls, body functions, ADAS systems… the list goes on. The growth in the integration of additional electronic aids such as roll and stability control, side wind

assist and load control is becoming commonplace. Irrespective of the electrical architecture, electronics need to be integrated to control these functions. Where they are located has some bearing on the electronic system weight. The balance for the designer is off-setting the number of electronic boxes to be distributed with the weight of additional, or reduced wire harnesses and interconnects.

The overall weight of vehicles is on the rise as additional functions are integrated. Of course, there is also continual drive from suppliers and sensor manufacturers to develop smaller and lighter components, along with a focused approach into lightweighting the electrical harness systems.

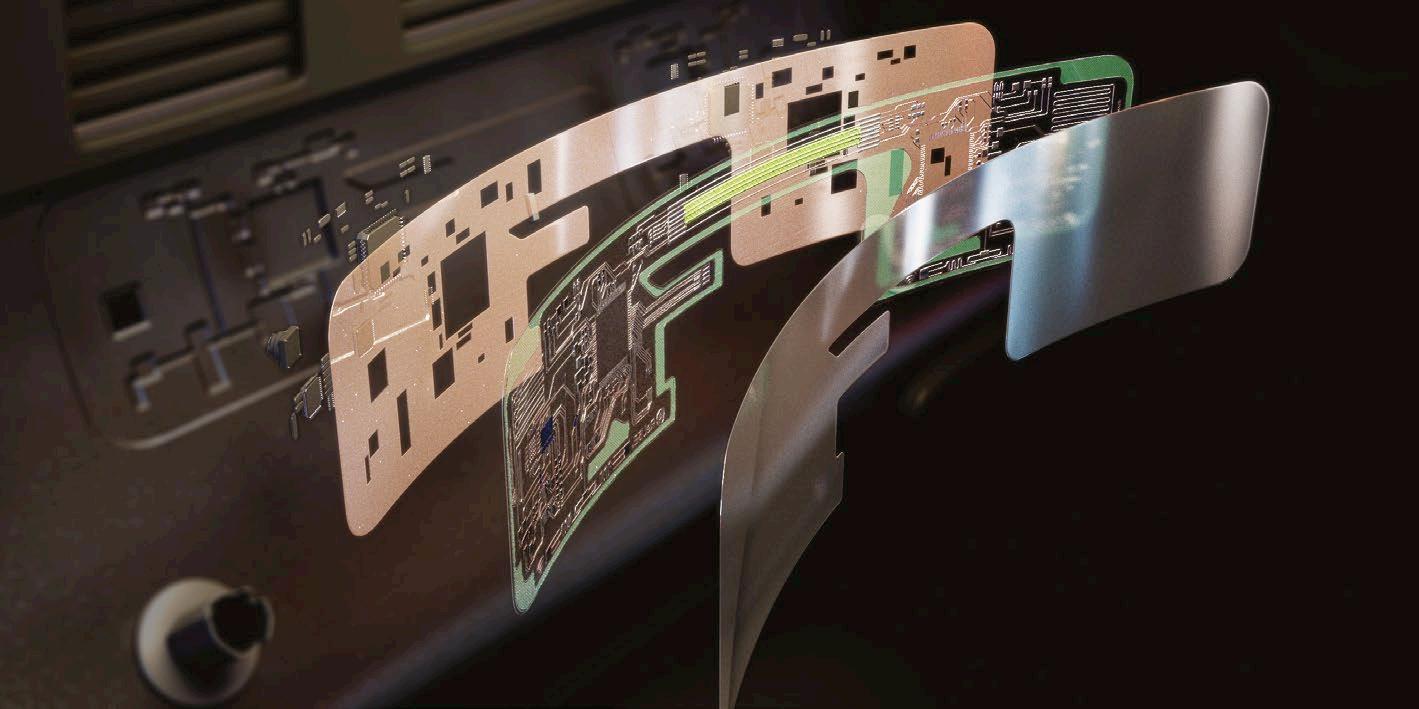

One route being taken to deliver less mass in the electronics is to integrate the component level designs into the mechanical plastic parts used in other areas of the vehicle, i.e. re-purposing plastic mouldings. Often referred to as In-Mould-Electronics (IME) this allows, to some level, low-complexity

Left: Circuit built into car showing components and receptive moulded cavities (close-up) Right: Flexi-hibrid circuit board assembly

printed circuit board assemblies to be over-moulded through injection moulding techniques delivering electronic functionality without the need for a separate protective box. The limiting factor with this approach is that the stresses imposed by injection moulding can significantly limit the type and number of electronic components integrated in this way and mostly requires some level of smaller external box containing the main electronic control functions. This solution also renders the moulded unit non-recyclable as the very nature of the injection moulding process means that it is virtually impossible to recover the individual materials at end-of-life.

For over 25 years, In2tec has been pushing the boundaries in the design and delivery of flexible electronics, dedicating its resources to breaking down barriers in design to solve the most complex problems with pioneering technology solutions. In the case of electronic integration with plastic or composites, the company has taken a more elementary

approach. Rather than moulding ‘in’ the electronics, In2tec utilises its Flexi-hibrid Electronic circuit board technologies and developed OMSE (On Mould Sustainable Electronics). “In simple terms, we take a circuit board manufactured on flexible or semi-rigid substrates and laminate it ‘onto’ sympathetically designed superstructures,” says Neil Armstrong, group managing director. Mark Hudman, chief technology officer at In2tec, adds, “This provides a far simpler single unit that can be moulded with traditional methods and integrates high complexity electronic circuits in an environmentally protected single element”.

Utilisation of real estate is the key value here. Integrating electronics onto superstructures within the vehicle significantly reduces the need for protective enclosures and in design can minimise the connector count. In addition, the ability to use areas of the vehicle not normally associated with electronics allows weight to be re-distributed and the centre of gravities lowered. For

OMSE integrating electronic systems through highly recyclable Flexi-hibrid Technologies

example, taking the seat control ECU (traditionally a plastic box with mechanical fixings housing the control and power electronics packaged primarily in the base of the seat system) and essentially dispersing the electronics onto a flexible substrate and laminating it to the internal seat back moulding reduces weight, and dramatically improves packaging constraints. It changes the whole paradigm of electronic integration and systemically engages both mechanical and electronic, or mechatronic design methodology providing a real synergy.

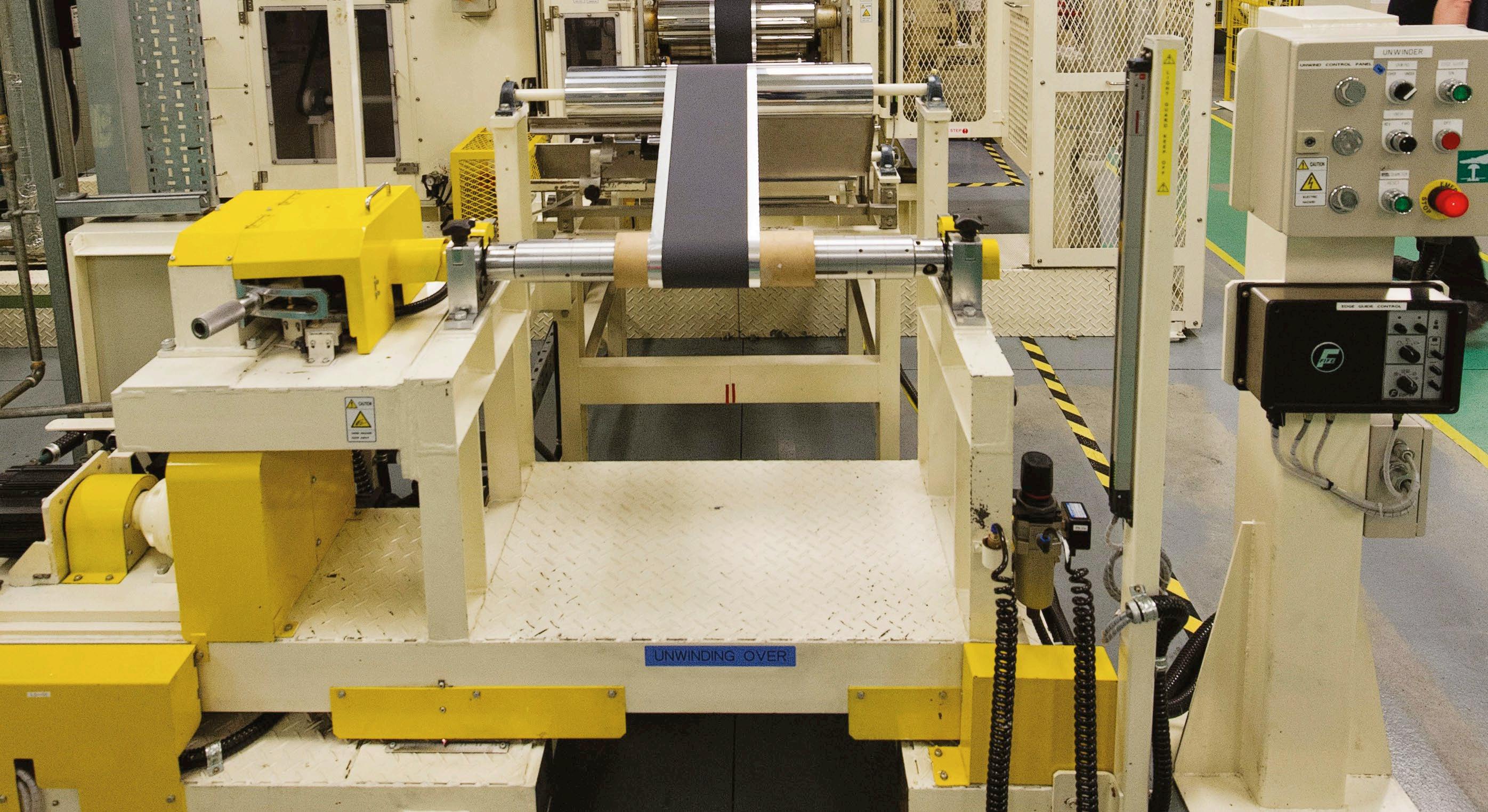

If we think about pushing the boundaries through innovation, Flexihibrid technologies can deliver planar interconnect systems (essentially flat wiring harness applications) with the electronic controls embedded in the wiring systems. Significantly reducing the number of connectors and the re-distribution of harness weight would revolutionise the advancement of traditional wiring harness design. Today, In2tec has already made possible printed flat shielded twisted pair designs through its patented technology, and low current transmission of power and data is delivered and demonstrated. A flat thermoformed wiring assembly with the CAN nodes integrated into the assembly provides a ‘stick and play’ approach to assembling the harness. “Full wiring systems delivering comms and power on flat formed surfaces is our end goal” states Hudman. “Just think if we can produce a wiring harness in the shape of a vehicle floor pan, adhere it simply onto the floor utilising all that real estate and doing so lowering the harness weight by over 40%. These are the predictions we have modelled.”

Electronics now has solutions to fully support and change the paradigms of electronics integration within the boundaries of automotive lightweighting, allowing designers to balance the additional functionality with minimising the weight increase. Maybe the lightweighting nirvana is closer than we think.

Neil Armstrong is managing director at In2tec: www.in2tec.com

Multi-layer Flexi-hibrid circuit assembly, sealed and bonded to inner form of moulded shield

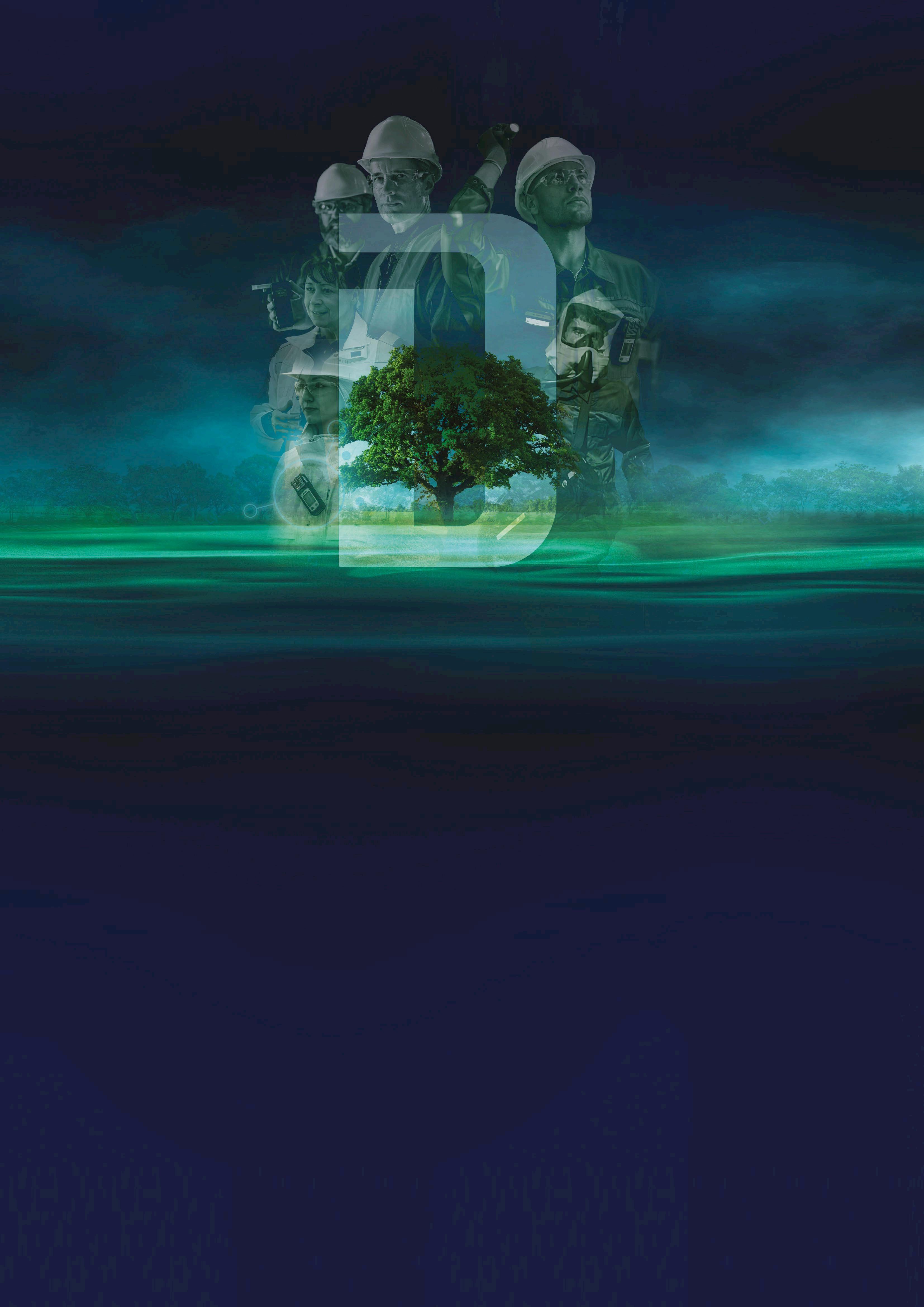

Clean Energy Safety Solutions

—

Supporting a Safer Journey to Net Zero

Dräger, with a legacy spanning over 100 years, is your trusted safety partner in this journey

We deliver comprehensive safety solutions tailored for the evolving clean tech landscape. From gas detection and respiratory protection to service and rental, we’re dedicated to protecting your team and assets in the face of new challenges across various sectors — be it hydrogen, carbon capture, battery production, offshore wind, waste-to-energy, or nuclear We are not just a supplier; we are a partner in your journey towards a safe and sustainable future.

SELF-DRIVING BUSES

How can autonomous buses revolutionise city transportation? Jake Holmes finds out

As technology advances and labour markets shorten, autonomous driving solutions for public transportation are becoming inevitable. Eran Ofir, CEO of autonomous driving company Imagry, sat down with International Transport Manufacturer to explain his company’s existing self-driving technologies, as well as the future of autonomous

driving and how regulators can best help introduce these new systems.

HOW DO THEY WORK?

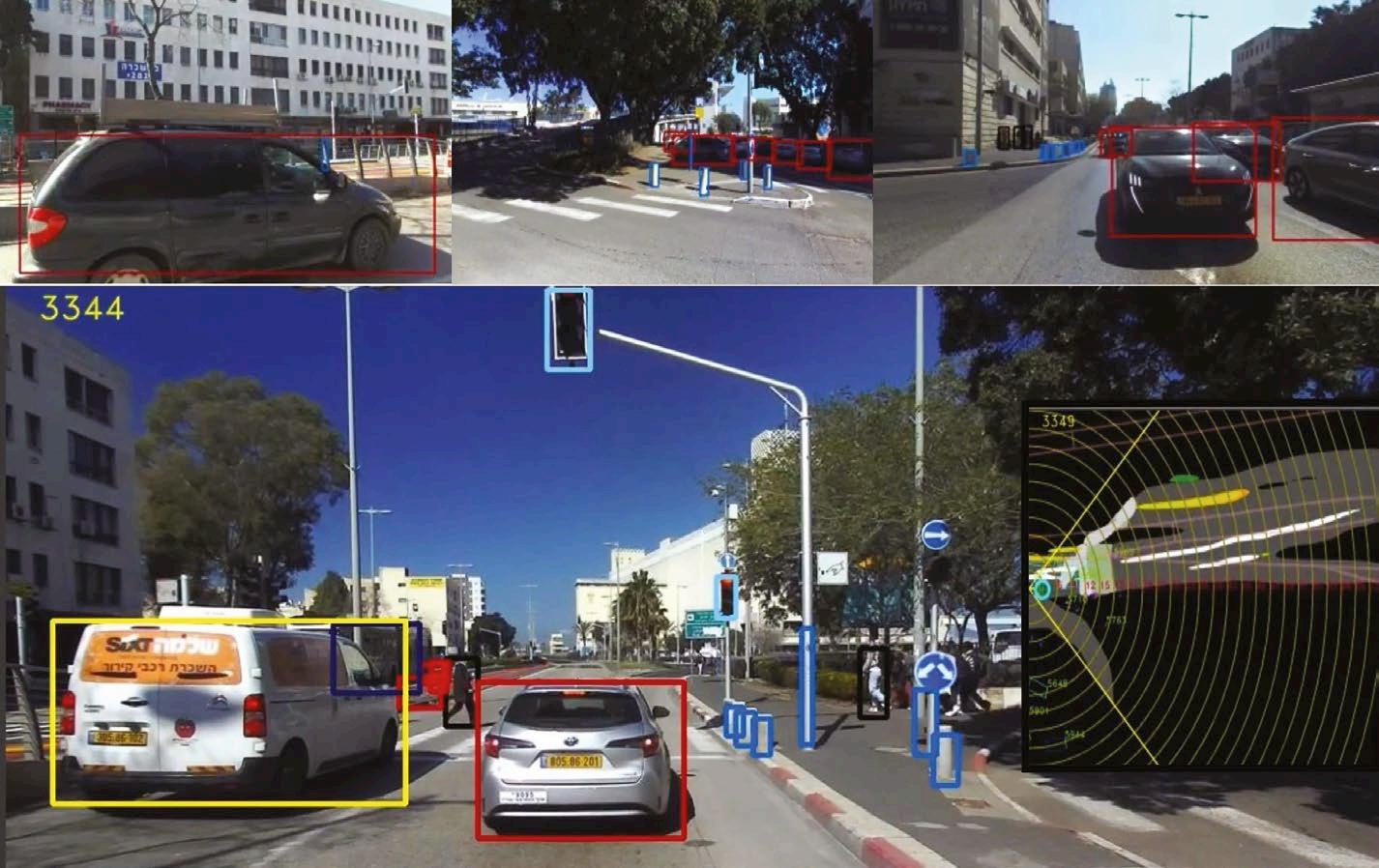

External 3D mapping is a method of capturing locations to provide a digital representation of the world. Although this technology has been used in autonomous driving before, it is not used to drive Imagry’s autonomous buses. Instead, a network of cameras

feed information to the main computer allowing it to create a 3D map. Each camera is tasked with detecting traffic lights, vehicles, pedestrians and any other road-related items.

“We do not use those external HD maps that are provided to vehicles, but instead those that are created on the go,” says Ofir. “The entire system is built out of neural networks and is AI end-to-end. We get the video feed from eight cameras into an array of neural networks where each neural network is responsible for object detection and classification for a different type of object. One is looking at traffic lights, one at pedestrians, and then we build in real time a threedimensional map that represents everything in the surrounding of the vehicle up to 300m and 360°.”

Imagry’s autonomous buses do not use rule-based coding, which is when computers are given specific rules to react to situations, similar to a decision flowchart. Instead, a black box is fed with information from the neural network which learns

The technology enables real-time situational awareness

This technology brings the reality of driverless buses a step closer

by imitation how to drive. Constant improvements can be made through this process, as the computer does not require additional programming to improve its driving.

“Through this, the system learns how to drive better and better, the same way I’m sitting in a vehicle with my daughter instructing her what she should and shouldn’t do whilst driving,” Ofir continues. “The future is mapless. No one can map the world in a resolution of 5cm as it is very costly and it will never be updated enough.”

Unsupervised training gives systems mass amounts of data and lets them lean how to operate through trial and error simulations. This can be risky and can potentially lead to a vehicle developing dangerous driving habits. On the other hand, supervised training of the system involves a person grading the decisions the vehicle makes. Supervised training can ensure

Supervised training can ensure the vehicle learns best practice for driving and safe operation

the vehicle learns best practice for driving and safe operation.

“Because we are not using external maps but instead undertaking realtime processing, our latency, which is the most important parameter of autonomous driving, is shorter and we can respond faster to everything that happens on the road,” Ofir explains. “A system that is receiving external orders regarding how to drive on the road is prone to cyber-attacks by definition. A system that is selfsufficient will respond by itself and will not be prone to any threats from the outside.”

The only external instructions provided to the vehicle are directions, such as from Google Maps, which tells the vehicle where it needs to go, but it does not tell the vehicle what it expects to see on the road. By not using HD maps, the vehicle can detect and adapt to things that will not be

on the map, such as roadworks and parked cars.

Bus detours are possible, as the self-driving features can work in any environment. This can be achieved without needing to provide a route beforehand. When the vehicle decides vision of the road is limited and it cannot conduct classification of objects, the system will not engage and safely stop.

TESTING THE TECH

Imagry tested its AI driver in Frankfurt, Germany. The vehicle had been brought from America and had never been driven in Germany before yet operated on the roads without any issues or hinderance. This was possible possible due to the company’s mapless technology.

Conversion of previous buses to Imagry’s new model is possible, but the steering box must support drive-

by-wire. The driving system must be able to receive commands via its computer for driving. “Apparently, most electric buses do not have electric power steering,” Ofir explains. “An electric bus that was converted from diesel will not have it, as it will have the old power steering. Only electric buses that were born electric will have electric power steering.”

NEXT STEPS

Imagry’s technology brings the reality of driverless buses a step closer, but despite having this technology developed, rolling out may still take some time. This is because sourcing buses and passing regulations remain obstacles for the technology.

HOW LEGISLATION IMPACTS INNOVATION

Imagry assisted in the creation of Israel’s autonomous driving bill and is currently working with German, French and Dutch regulators to create similar legislation. For the autonomous driving system to be activated on the road, the New Car Assessment Program (NCAP) must be passed. Currently, Imagry is so far the only company to pass NCAP for buses.

We are the first and only company in the world that has passed NCAP testing for buses

Ofir says: “We are the first and only company in the world that has passed NCAP testing for buses, meaning in 90 different scenarios of a bus driving between 30-60km/h - where all kinds of things are jumping out in front of the bus, and you have to stop and respond immediately - you have to pass with 100.”

Once the test has been passed, the system can be activated on the road but still requires a safety driver and cannot have any passengers at this stage. This is until UN Regulation 155 around cyber security is passed. This regulation ensures the bus cannot be remotely hacked and controlled externally.

Upon passing UN regulation 115, the bus can now operate with passengers, allowing it to be used for public transport.

THERMAL TESTING

An industrial-scale iso-thermal testing platform is poised to accelerate the development of next-generation materials and process technologies for aerospace

Sustainable air travel has long been the overarching goal of the aerospace industry, with recent advances in sustainable aviation fuel (SAF), lightweighting and efficiency. Now, a new collaboration in advanced engineering and materials science is aiming to further support this mission.

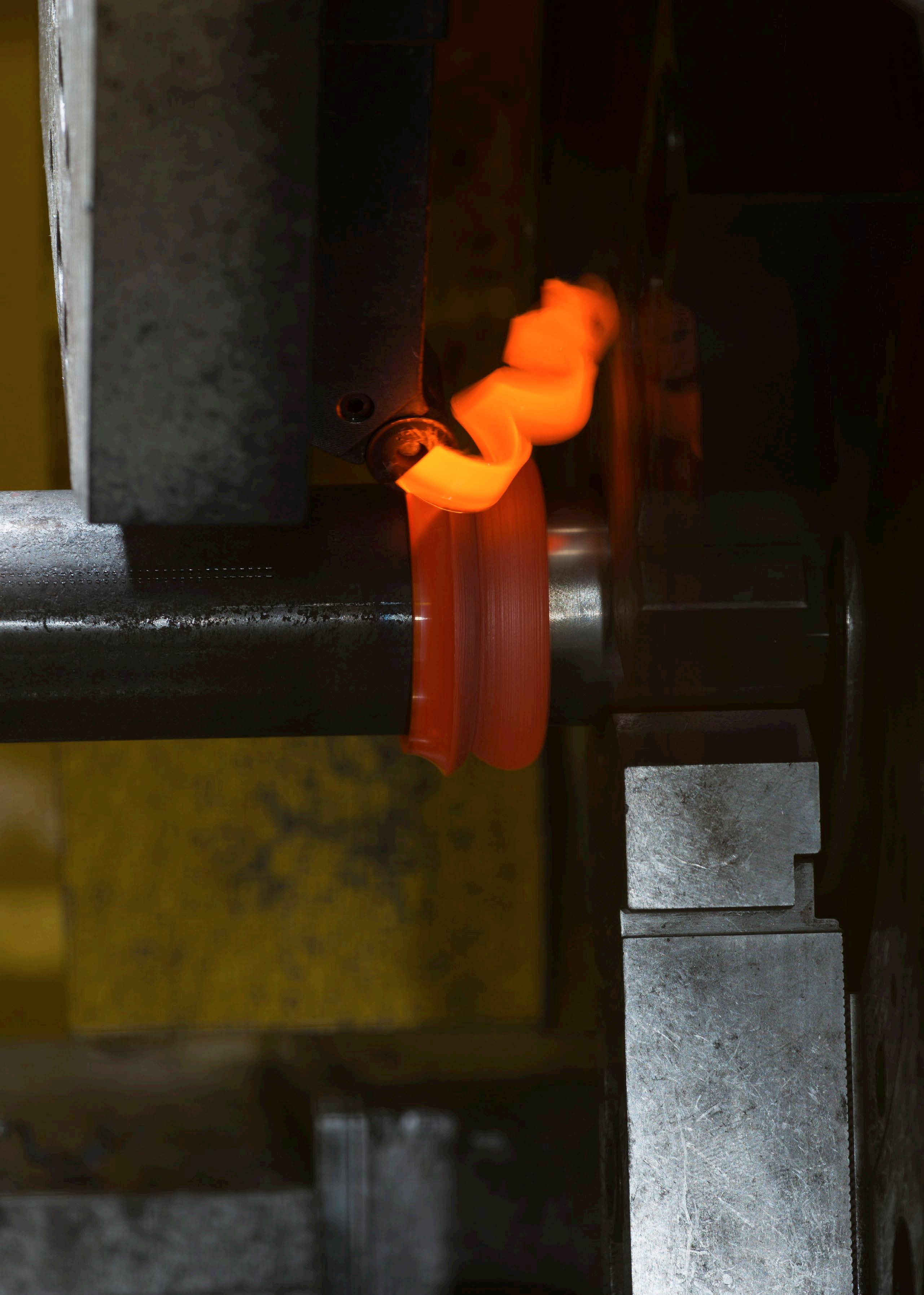

International aerospace firm ATI has joined the University of Strathclyde’s Advanced Forming Research Centre (AFRC) in a partnership that seeks to progress the development of advanced engineering and materials science to support more sustainable air travel. Key to this is access to the AFRC’s pioneering FutureForge facility, which provides an industrial-scale isothermal testing platform. As airlines increasingly focus on sustainability, new metallic alloys that can endure higher temperatures than ever before will be key to allowing jet engines to operate at maximum efficiency and, ultimately, burn less fuel.

“ATI is one of the world’s largest forging houses and a key supplier of high-performance materials to many of our existing members and partners, particularly within the aerospace sector,” says Professor Brad Wynne, director of the AFRC.

FUTUREFORGE

The AFRC launched FutureForge earlier this year, connecting the $75 billion global forging sector with the industry-scale testbed and centre’s expertise. FutureForge comprises a tri-modal 2,000 tonne press offering open die, closed die and iso-thermal forging capabilities, instantaneous data analytics through a state-of-theart control room, two furnaces – one powered by electricity and the other by gas – and a custom-built smart robotics manipulator arm. ATI will now be able to use the platform to derisk the development of new products,

processes and technologies for the aerospace sector.

“Aerospace is a hugely important sector for the global economy and materials science is key to developing the next generation of aircraft engines that can operate more sustainably,”

Wynne adds. “With FutureForge, the AFRC is in a unique position to help develop these kinds of novel materials and offers an industrial-scale testbed like no other.”

FORGING AHEAD

According to Wynne, FutureForge is poised to unlock a valuable opportunity for forging companies to explore modern processes and new integrated digital technologies that could have a significant impact on global aerospace manufacturing.

“With the latest hot forging press of its kind, dedicated solely to R&D, unparalleled connectivity capabilities, and over a decade of experience in materials science, the AFRC is in a unique position to help the forging industry embrace net zero, unlock energy savings, accelerate productivity and ultimately transform and secure this vitally important industry for future generations,” he continues.

The FutureForge is hailed as a “unique facility”, owing to the fact it can capture large amounts of data, enabling true digital twins of data to be developed at scale for the very first time.

“This enables companies to develop an understanding of whether their product is going to perform well in service, therefore giving confidence to the end user to make sure they have the best material for the job,” Wynne adds. And, with the platform’s trimodal offering and multiple furnaces, “industry has the opportunity to compare and contrast the different types of energy source in terms of their productivity, as well as their cost and effectiveness. For the first time, industry can actually do R&D at the industrial scale.

“Through FutureForge, companies will have access to all of the National Manufacturing Institute Scotland (NMIS) capability set from digital through data to lightweighting and all the other amazing capabilities that NMIS has.”

The FutureForge platform at the AFRC

Proven performance with tesa® ACXplus by your side

For years, tesa® ACXplus has been the trusted, high quality permanent bonding solution for challenging applications in the transportation and vehicles industry. tesa® ACXplus acrylic core foam tapes support your need for design freedom and speed, while improving efficiency and productivity.

Setting the standard for precision and quality

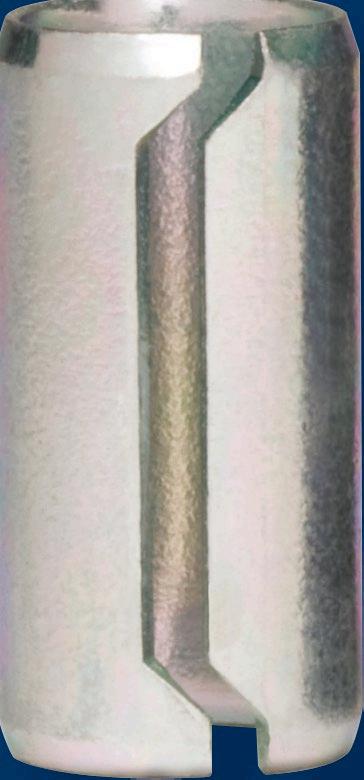

Thompson friction welding machines set standards in terms of precision, dynamics, process control, and manufacturing productivity for the transport industry.

KUKA, as the OEM of Thompson friction welding machines, has the largest subcontract friction welding facility in the UK. Offering in-house testing and on-site metallurgical services with a fully equipped laboratory.

To discuss your requirements, please call 0121 585 0800 or email: frictionwelding. uk@kuka.com thompsonfrictionwelding.co.uk

RADAR READY

Testing millimetre-wave automotive radar for ADAS and autonomous driving

Automotive millimetrewave radar is used to detect people and objects in Advanced Driver Assistance Systems (ADAS) and Autonomous Driving (AD) applications. Typically, sensors to monitor the environment outside the vehicle include radar, cameras and Light Detection And Ranging (LiDAR). ADAS assists the driver in a wide range of driving operations, such as collision warning, automatic braking and parking assist. In autonomous driving, the sensor data is used to control the vehicle automatically.

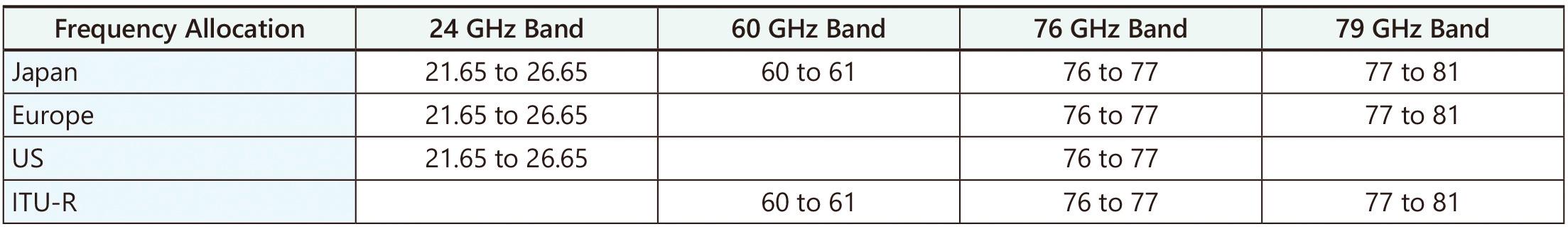

Table 1

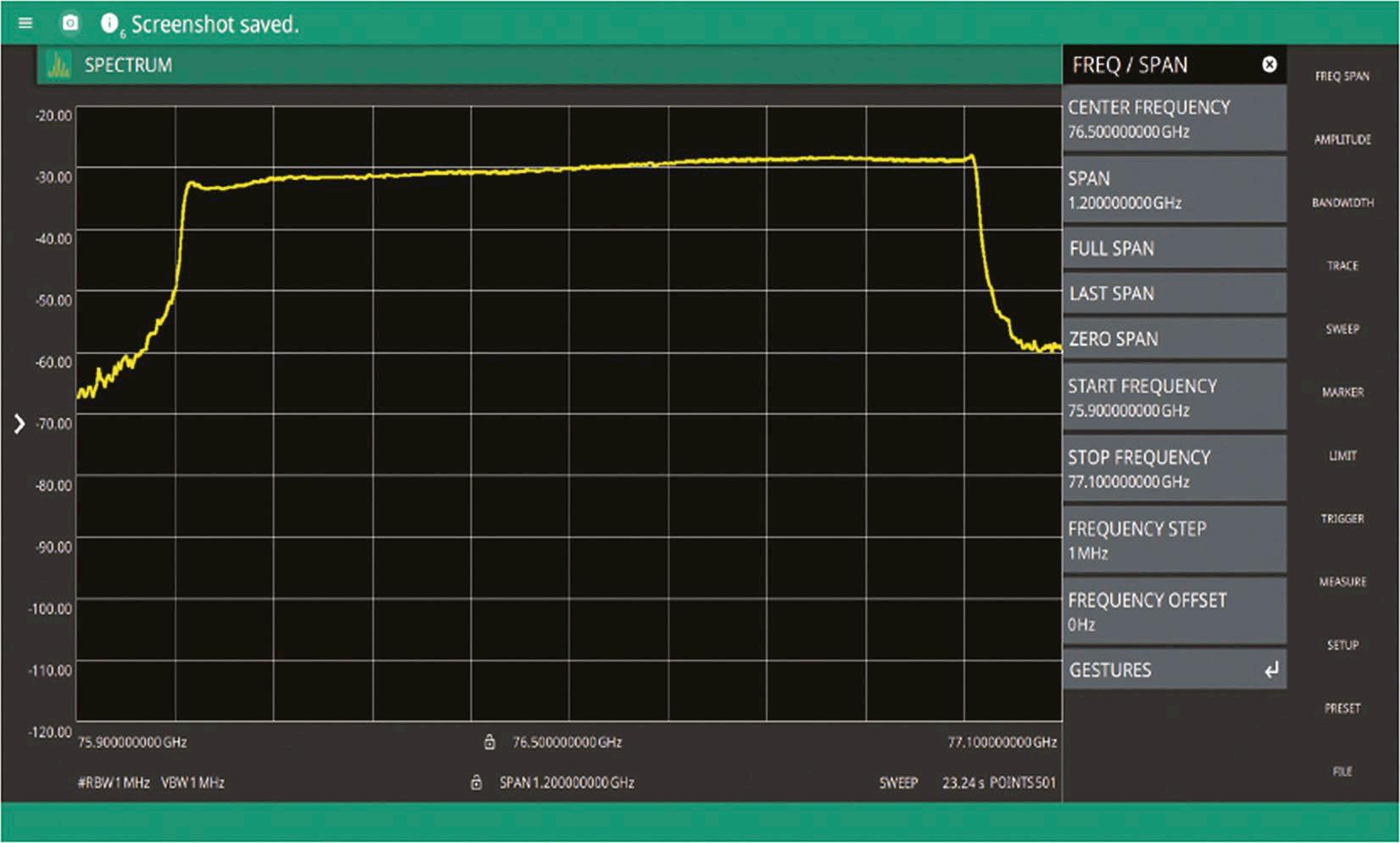

Automotive radar typically operates in the 24 and 76GHz bands. The 24GHz band is used for short and middle-range perimeter monitoring for pre-crash and collision damage reduction, as well as front and rear monitoring. Due to its high resolution, 76-77GHz radar is used primarily to detect obstacles 100 to 200 metres ahead of the vehicle. Radar is also used for interior or ‘in-cabin’ sensing applications. For example, systems that prevent children or animals from being left in cars operate in the 60-77GHz bands. Table 1 shows the automotive radar frequency allocations used in each region.

RADAR METHODS

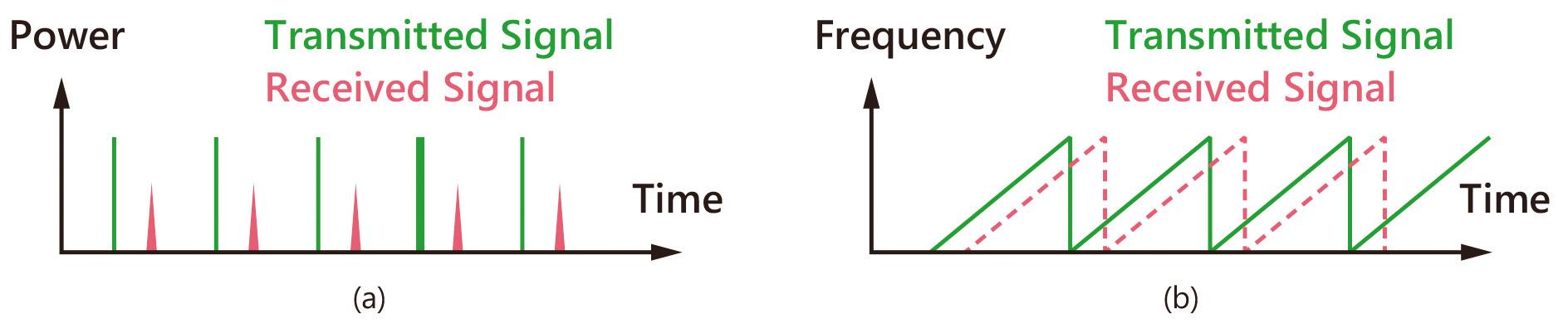

Automotive radar measurements use either the pulse or FrequencyModulated Continuous Wave (FMCW) method. The pulse method measures the round-trip time the radio wave takes from the transceiver to the object and its reflection to come back. The FMCW method transmits periodic radio signals with an increased frequency in a certain period to an object. Here, the transmitted and reflected radio waves interfere to generate a beat signal. By analysing the difference in frequency and other factors obtained from the

TEST, SAFETY & SYSTEMS

beat signal, the distance to an object and its velocity can be determined. Figure 1 shows the signal modulation schemes for automotive radar.

Unlike pulse radar, FMCW offers benefits such as low transmission power and high signal-to-noise ratio. Furthermore, the relatively low response frequency of the transceiver circuit enables a simple design, which reduces costs. Consequently, the FMCW method is widely used in automotive radar.

FMCW BASICS

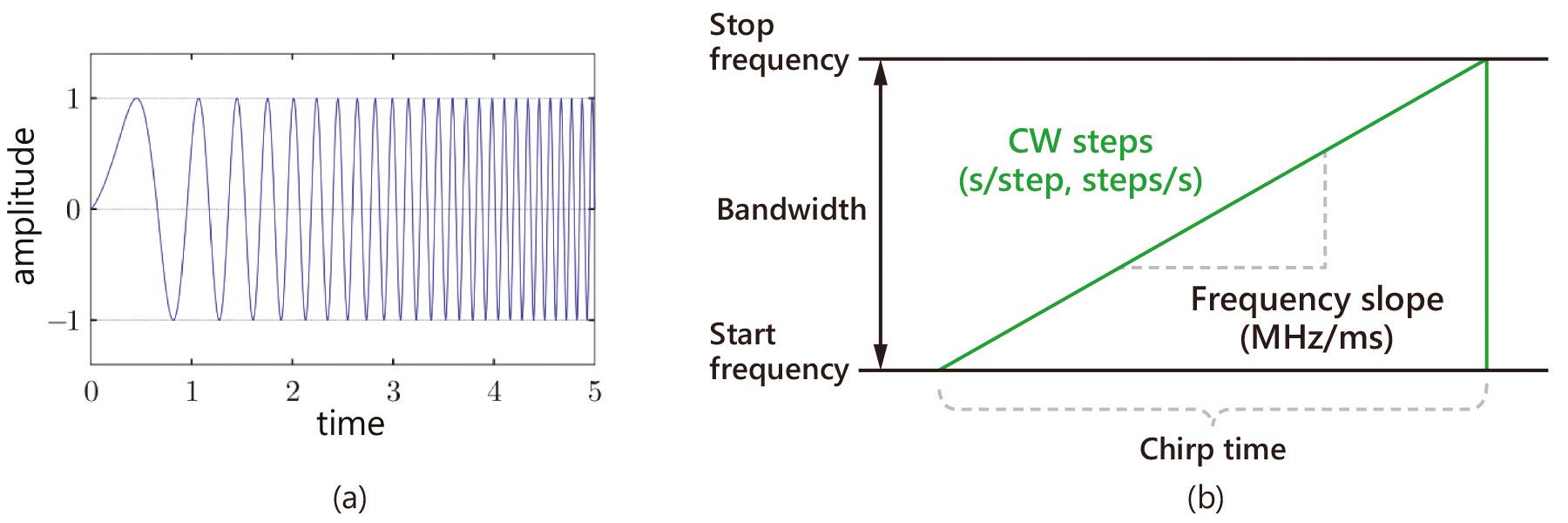

A signal for which the frequency increases linearly with time is known as a chirp, shown in Figure 2 (a), and is key to the performance of the FMCW signal. From the chirp signal shown in Figure 2 (b), with the vertical axis replaced by frequency, the range or distance resolution and maximum distance range are obtained. These are the main performance characteristics of the FMCW radar. The range resolution Dres is expressed by Dres = c/2B = c/2STc, where c is speed of light, B is the chirp bandwidth (end stop frequency - start frequency), S is the chirp slope, and Tc is the chirp duration.

From the equation, the wider the chirp bandwidth, the higher the

resolution that can be detected. For example, the range resolution is about 7.cm for a chirp bandwidth of 2GHz, and the range resolution is about 3.8cm for a chirp bandwidth of 4GHz. The maximum detection range is inversely proportional to the chirp slope S, which represents the rate of increase in frequency. This means that the smaller the chirp slope the greater the maximum detection range. For a fixed chirp duration, a wider bandwidth B will result in a higher resolution. However, this results in a trade-off as the maximum detection range is reduced because the chirp slope increases with bandwidth. This trade-off requires caution when designing automotive radar systems.

Automotive millimetre-wave radar will prioritise detection range or resolution depending on the application. For example, in adaptive cruise control the ability to detect a vehicle at long range is important, while high resolution is not so necessary. On the other hand, collision avoidance requires high resolution as the vehicle needs to respond rapidly to sudden changes at close range.

From the chirp signal, the radar velocity resolution Vres and the maximum detection velocity Vmax can also be calculated using Vres =

/2Tc and Vmax = /4Tc where radar wavelength = c/f

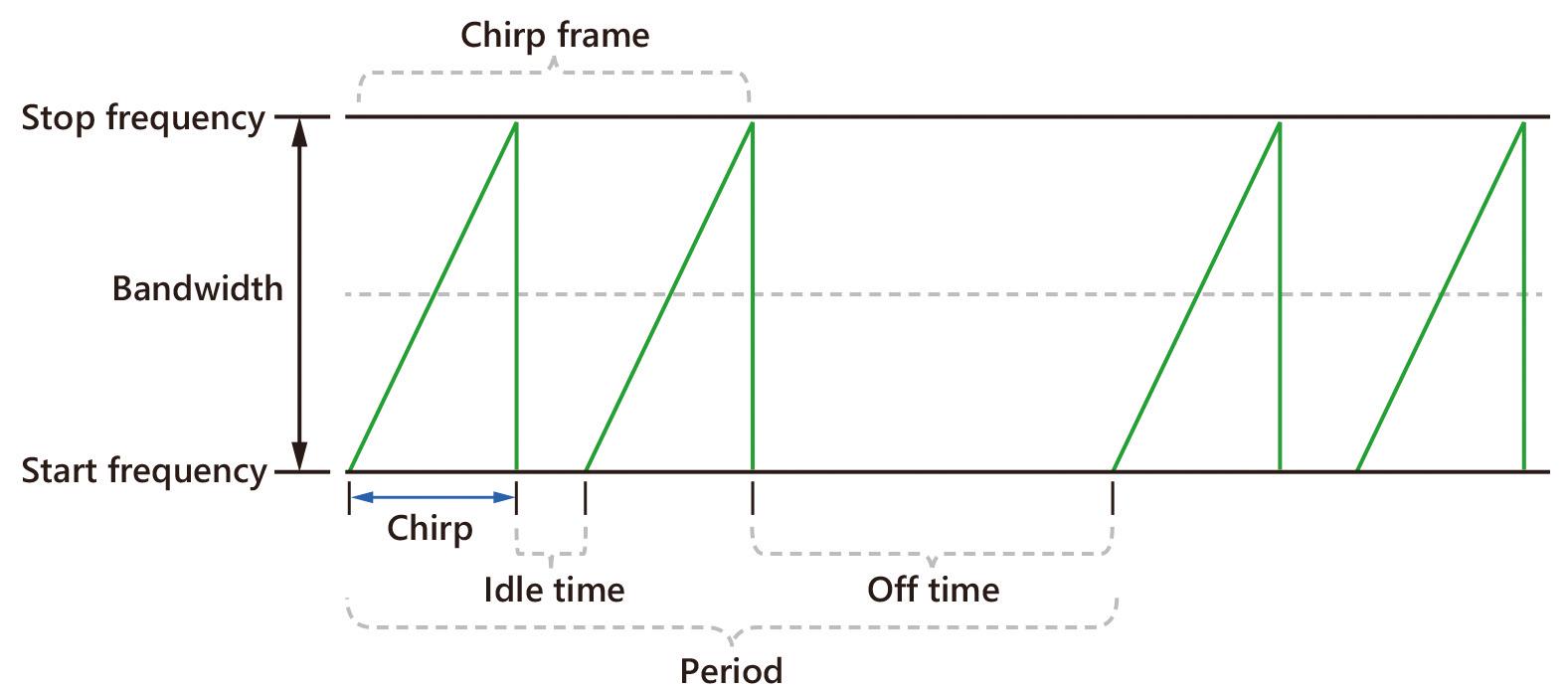

The maximum detection velocity Vmax is inversely proportional to the chirp duration Tc. Reducing chirp duration increases maximum detection velocity. However, shortening chirp duration adversely affects the range resolution. A radar frame comprises a few to several hundred chirps. A chirp frame is depicted in Figure 3

The frame time Tf is calculated by multiplying the number of chirps by the sum of the chirp duration and the waiting (idle) time until the next chirp signal is sent out: Tf = (Tc + Twait) x N where Twait is the wait or idle time until the next chirp is sent, and N is the number of chirps. The reason for using multiple chirps within a frame is to obtain Doppler information from the object to accurately ascertain its velocity. There is also a variable off time between each frame that can be used to improve the power efficiency of the chipset.

FMCW SIGNAL MEASUREMENT

Factors that make measuring chirp signals difficult include chirp frequency changes in an extremely short time, ultra-wideband modulation,

Figure 2

Figure 1

and higher chirp frequency. Often all three need to be taken into account simultaneously.

Chirp signals are usually measured with a spectrum analyser, which is typically used to evaluate transmission characteristics for wireless communications equipment. There are two types of spectrum analysers — swept and real time. The swept spectrum analyser is based on superheterodyne technology where sampling and signal processing are sequentially repeated operations. Where the chirp frequency changes over an extremely short period, the swept spectrum analyser often cannot keep up due to sequential processing, failing to capture some of the chirps. Sections where the chirp is not captured are referred to as blind spots.

The real-time spectrum analyser, which leverages fast Fourier transforms, performs sampling and signal processing in parallel, enabling it to capture short-time changes in the chirp signal. However, the measurement frequency range or