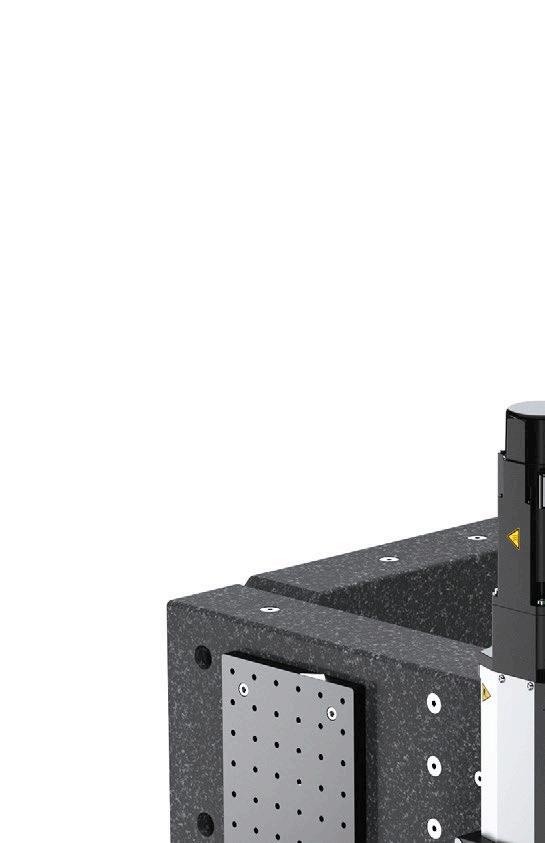

Various Performance Levels for Industrial Applications

building

Flexible building kit based on proven components

Easy to set-up

High-performance ACS controller

Functional safety

Wide range of accessories

Short lead times

See the system live at electronica 2024

November 12 to 15 | Hall A3, Booth 637

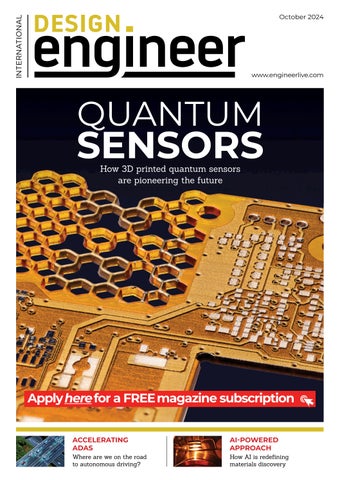

By the time this issue hits desks around the world, the summer period will have well and truly ended for many of us. I’ve spent much of the summer bouncing between trade shows, conferences and other important industry events across Europe, and it’s safe to say that there are several common trends prevailing across all industrial engineering sectors as we head into winter.

Digitalisation is a key one, with many industries continuing to ramp up their adoption of artificial intelligence (AI), machine learning (ML) and simulation. For instance, AI is helping car designers to accelerate ADAS development (page 8), improve data-driven maintenance in manufacturing (page 19) and aid in the discovery of new materials (page 30)

Automation is also high on the agenda for engineering firms, with many realising the benefits of robots and autonomous systems (page 44) within their manufacturing operations. Meanwhile, advanced solutions for vehicle electrification (page 12), variable frequency drives (page 42) and circular economy 3D printing (page 14) are continuing the push towards Net Zero.

In addition, this issue’s cover story (page 6) looks at how 3D printed quantum sensors could revolutionise the med-tech landscape, from controlling prosthetics to aiding locked-in patients.

As always, our show preview section highlights upcoming industry events that are of importance to the design engineering community from page 47.

Hayley Everett Editor

16

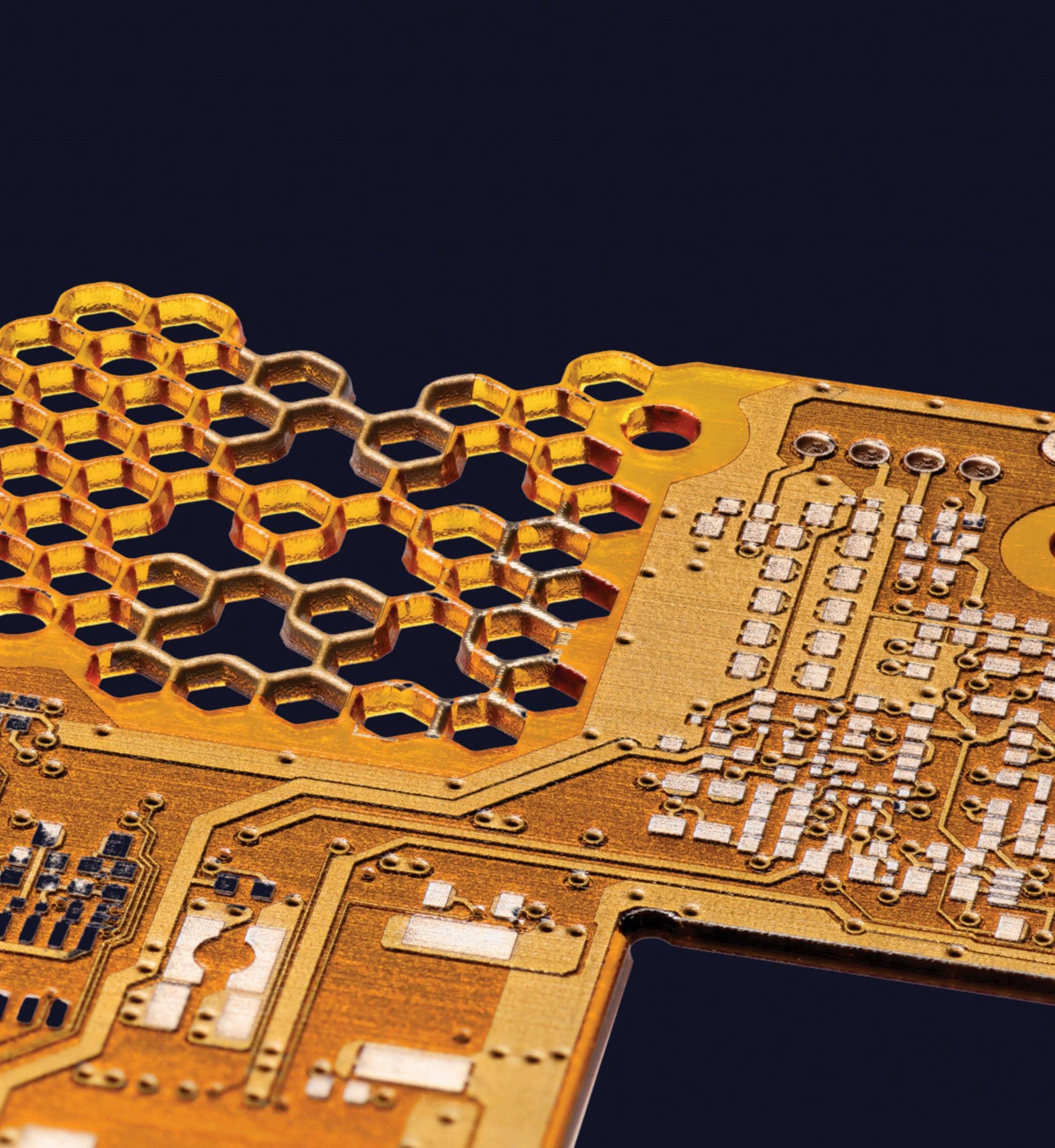

Quantum sensors

How 3D printed quantum sensors are pioneering the future of heterogeneous integration

AUTOMOTIVE DESIGN 08

Accelerating ADAS

Where are we on the road to autonomous driving?

12

Driving electrification

New product launches for the commercial EV market ADDITIVE MANUFACTURING

14

Back of the net

Demonstrating the possibilities of circular economy additive manufacturing

Lattice analysis

How new lattice designs can be fine-tuned to minimise structural defects

INSTRUMENTATION

19

Connected reliability

Digital technologies in manufacturing for data-driven maintenance

22 Gearing up

Considering gear body stiffness for face load factor

24 Layering up

How can the role of advanced thermal solutions revolutionise the design of medical devices?

MATERIALS, PROCESSES & FINISHES

27 Fluoroelastomers: Proven performance

How innovative fluoroelastomers are allowing for uninterrupted supply to customers

30 AI-powered approach

This innovative AI-based materials platform is redefining material discovery

COMPOSITES

33 Pultrusion perfection

The advantages of pultruded composites for bus and coach manufacturing FASTENERS & SEALING

37 Better bonds

How permanent adhesive tapes are solving design engineers’ toughest fastening problems

PUBLISHER

Jerry Ramsdale

EDITOR

Hayley Everett heverett@setform.com

DESIGN

Dan Bennett, Jill Harris

HEAD OF PRODUCTION

Luke Wikner production@setform.com

HEAD OF MARKETING

Shona Hayes shayes@setform.com

BUSINESS MANAGER

John Abey +44 (0)207 062 2559

SALES MANAGER

Darren Ringer +44 (0)207 062 2566

ADVERTISEMENT EXECUTIVES

Paul Maher, Iain Fletcher, Peter King, Adam Croft, Marina Grant

Setform Limited 6 Brownlow Mews, London, WC1N 2LD, United Kingdom

t +44 (0)207 253 2545

40 Crucial cabling

New cable fastening systems provide secure, damage-free cable management

MOTORS, DRIVES & CONTROLS

42 Efficiency drive

How can variable frequency drives help industry to make cost savings?

44 Rallying robotics

47

All about automation

SPS 2024 returns to Nuremberg 12-14 September

Heading south Southern Manufacturing & Electronics takes place in February

48 Formnext in Frankfurt

Europe’s largest 3D printing trade show returns for 2024

Realising the benefits of robots and autonomous systems for UK

Setform’s international magazine for engineers is published quarterly and distributed to senior engineers throughout the world. Other titles in the company portfolio focus on Oil & Gas, Process, Transport, Mining, Energy and Power.

The publishers do not sponsor or otherwise support any substance or service advertised or mentioned in this book; nor is the publisher responsible for the accuracy of any statement in this publication. ©2024. The entire content of this publication is protected by copyright, full details of which are available from the publishers. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior permission of the copyright owner.

42

How 3D printed quantum sensors are pioneering the future

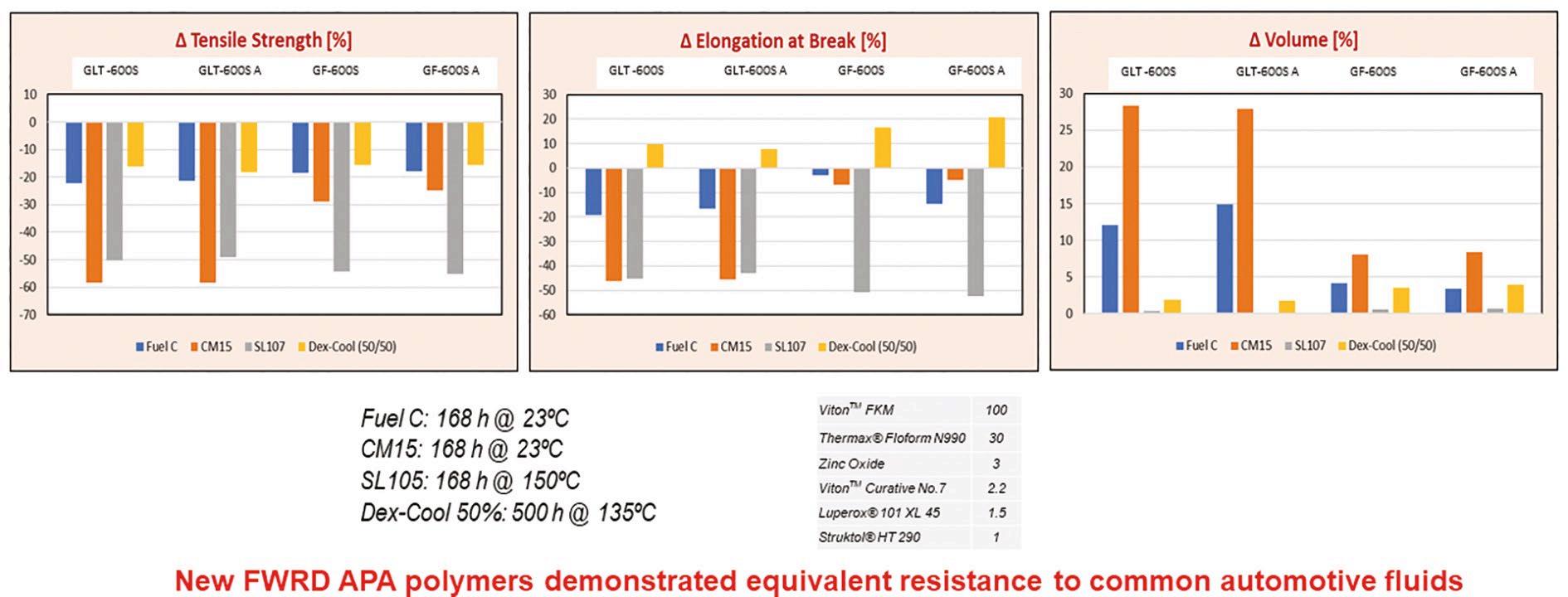

Our process for manufacturing Viton™ FWRD APA fluoroelastomers has been upgraded, by formulating without the use of a fluorinated surfactant. We innovate to meet your performance needs and ensure continued supply, in the face of a rapidly evolving regulatory landscape.

Internal testing, as well as customer testing, have confirmed Viton™ FWRD APA fluoroelastomers made using our new process at a commercial scale production plant, have comparable performance to the current grades.

viton.com

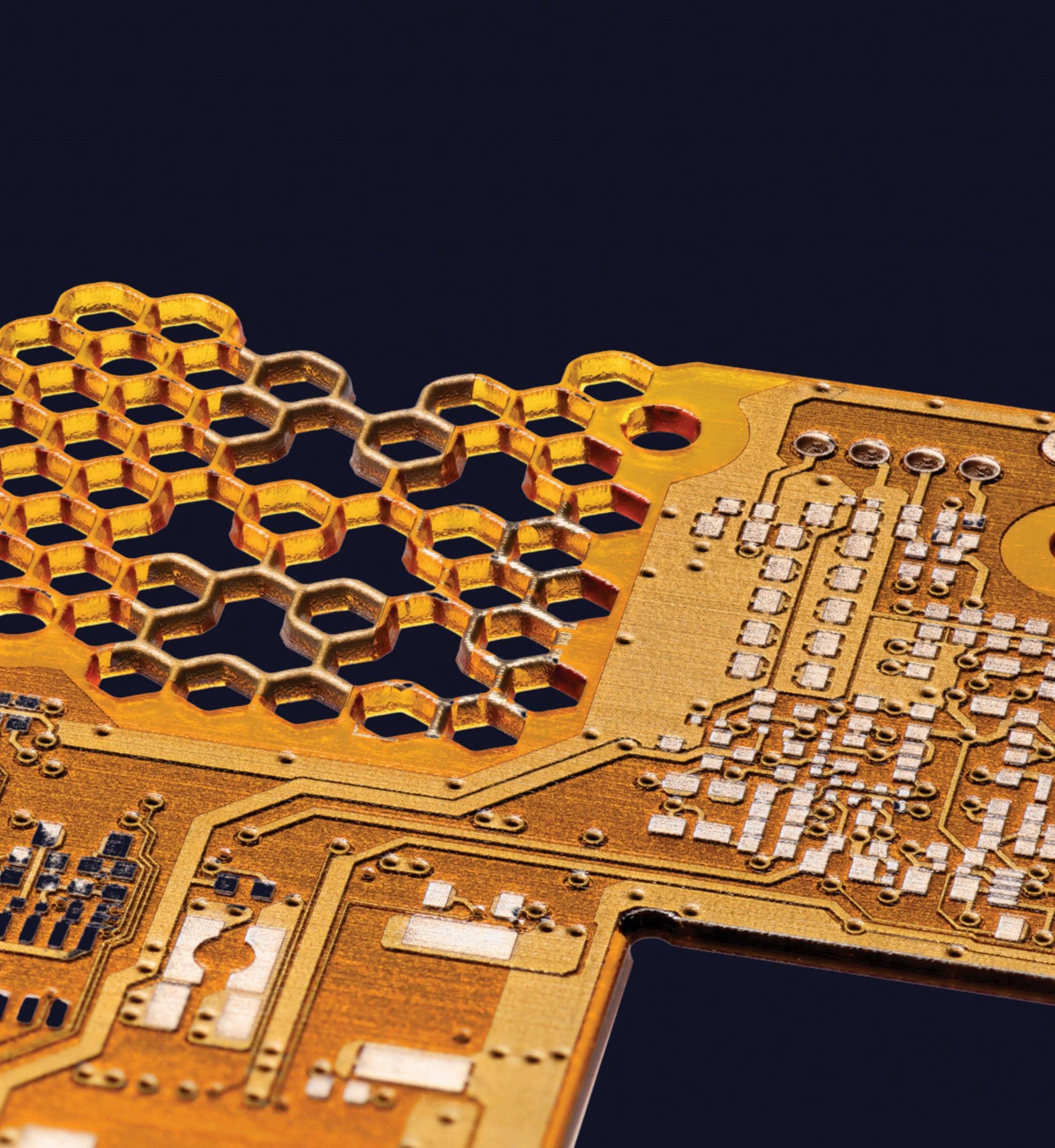

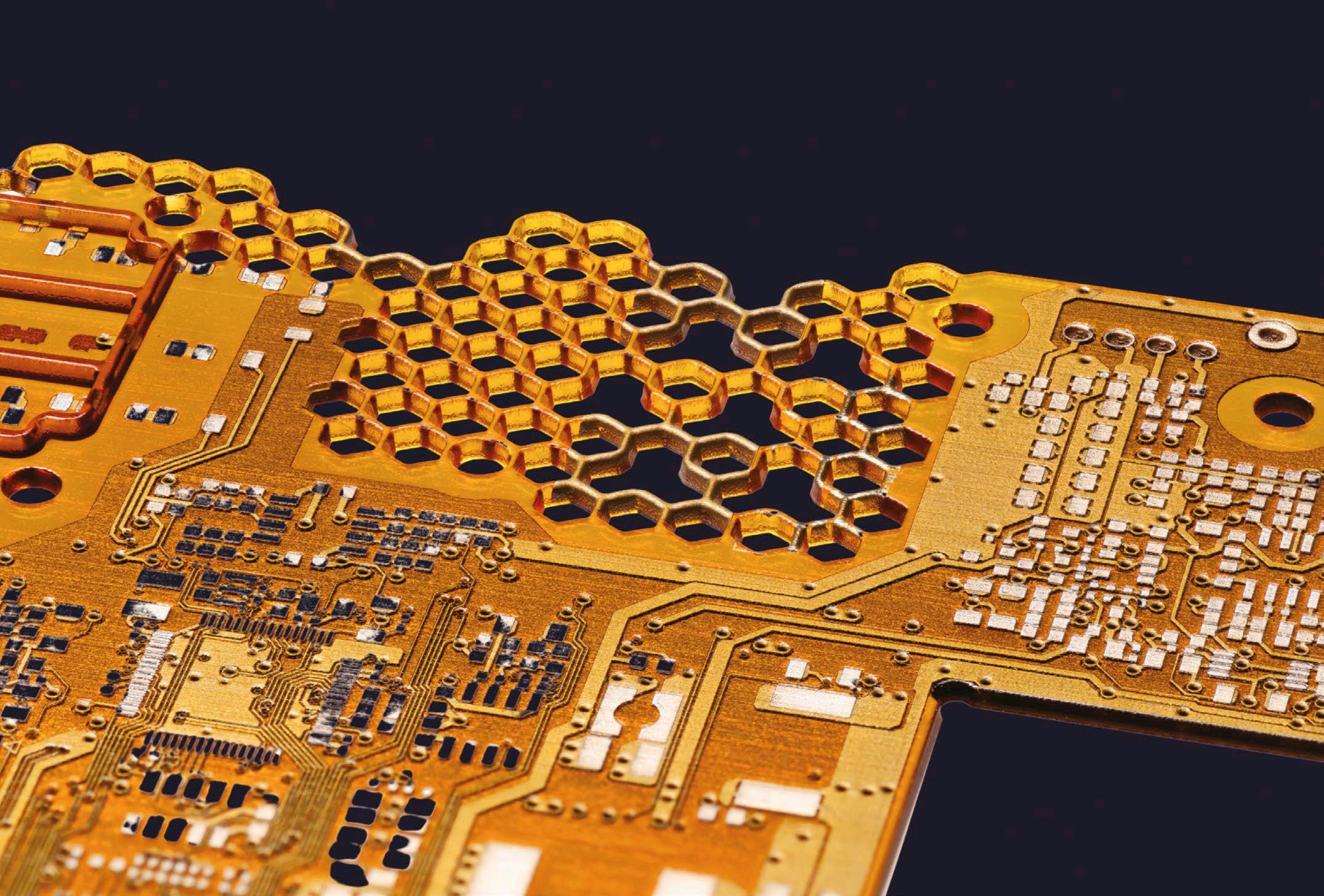

How 3D printed quantum sensors are pioneering the future of heterogeneous integration

Heterogeneous integration enables the development of free-form 3D electro-mechanical designs

In the burgeoning field of quantum sensing, technological advancements are pushing the boundaries of what is possible. A prime example is the development of sensors based on nitrogen-vacancy (NV) centres in diamond, which have the extraordinary capability to measure the minuscule magnetic fields generated by neural currents in muscles and the brain. Despite their potential, the current limitations in size and cost are significant barriers to widespread adoption.

Heterogeneous integration using 3D printed electronics presents a transformative solution, promising to revolutionise the scale, cost, and scalability of these quantum sensors, with applications ranging from controlling prosthetics to aiding locked-in patients.

3D printing has revolutionised various industries by enabling rapid prototyping and costeffective manufacturing of complex

components. In the realm of quantum sensors, 3D printed electronics can integrate multiple materials and functionalities into a single device. This capability is crucial for the development of compact and affordable quantum sensors.

Heterogeneous integration in the context of electronics development refers to the assembly of different types of materials and electronic components into a single system. For quantum sensors, this means combining the diamond substrate housing NV centres with other essential electronic components like readout circuits, signal processors, and wireless communication modules. 3D printing technology enables this integration by precisely depositing particles of different conductive and dielectric materials, layer-by-layer to form complex structures that traditional manufacturing methods cannot achieve.

With the rapid advancement of

sophisticated 3D printing technologies, heterogeneous integration now enables the development of freeform 3D electro-mechanical designs and intricate 3D line and spacing configurations. This technology also supports the implementation of true twisted pair transmission line routing and tridimensional routing, effectively minimising loss generators.

Moreover, the miniaturisation and condensation of devices are particularly invaluable for the creation of nextgeneration electronic systems. These capabilities allow for unprecedented flexibility in designing and manufacturing quantum sensors, paving the way for innovative applications and improved performance.

The DragonFly IV by Nano Dimension exemplifies the cutting-edge in 3D printed electronics, specifically tailored for creating sophisticated PCBs and electronic components. Additively Manufactured Electronics (AME) using the DragonFly IV eliminates many challenges associated

The shift towards 3D printed electronics is democratising access to advanced research tools

with traditional PCB manufacturing, which involves over 70 steps, while allowing for innovative designs and new classes of parts.

Key technical specifications of the DragonFly IV focus on trace width, signal and plane layer thickness, via diameter and reliable printing materials.

The shift towards 3D printed electronics is democratising access to advanced research tools. Institutions like the University of Stuttgart and QSens are leading the way by adopting these technologies, highlighting a broader trend. The ability to produce sophisticated electronic components in-house allows universities and research labs to innovate more rapidly. This autonomy from traditional manufacturing constraints means faster design iterations and experimentation cycles, fostering a more dynamic and responsive research environment.

Quantum sensors integrated via 3D printing hold immense potential in various applications. In medicine, these sensors can be pivotal in developing advanced prosthetics controlled by neural signals, providing a significant qualityof-life improvement for amputees. Furthermore, for patients with conditions like locked-in syndrome, these sensors could enable new forms of communication by detecting and interpreting brain signals.

The future of 3D printed quantum sensors is bright, with ongoing research focusing on improving material properties, resolution, and integration techniques. As these

technologies mature, we can expect a new era of quantum sensors that are more compact, cost-effective, and widely accessible, paving the way for innovative applications across various fields.

The integration of 3D printed electronics with quantum sensors based on NV centers in diamond marks a significant leap forward in sensor technology. This approach not only addresses current limitations in precision, noise reduction, size and cost but also opens up new possibilities for advanced applications in medicine and other fields. As 3D printing technologies continue to evolve, the future of quantum sensing looks increasingly promising, heralding a new age of innovation and accessibility in scientific research and practical applications.

Dr. Rafael Del Rey is director of global application engineering at Nano Dimension. www.nano-di.com

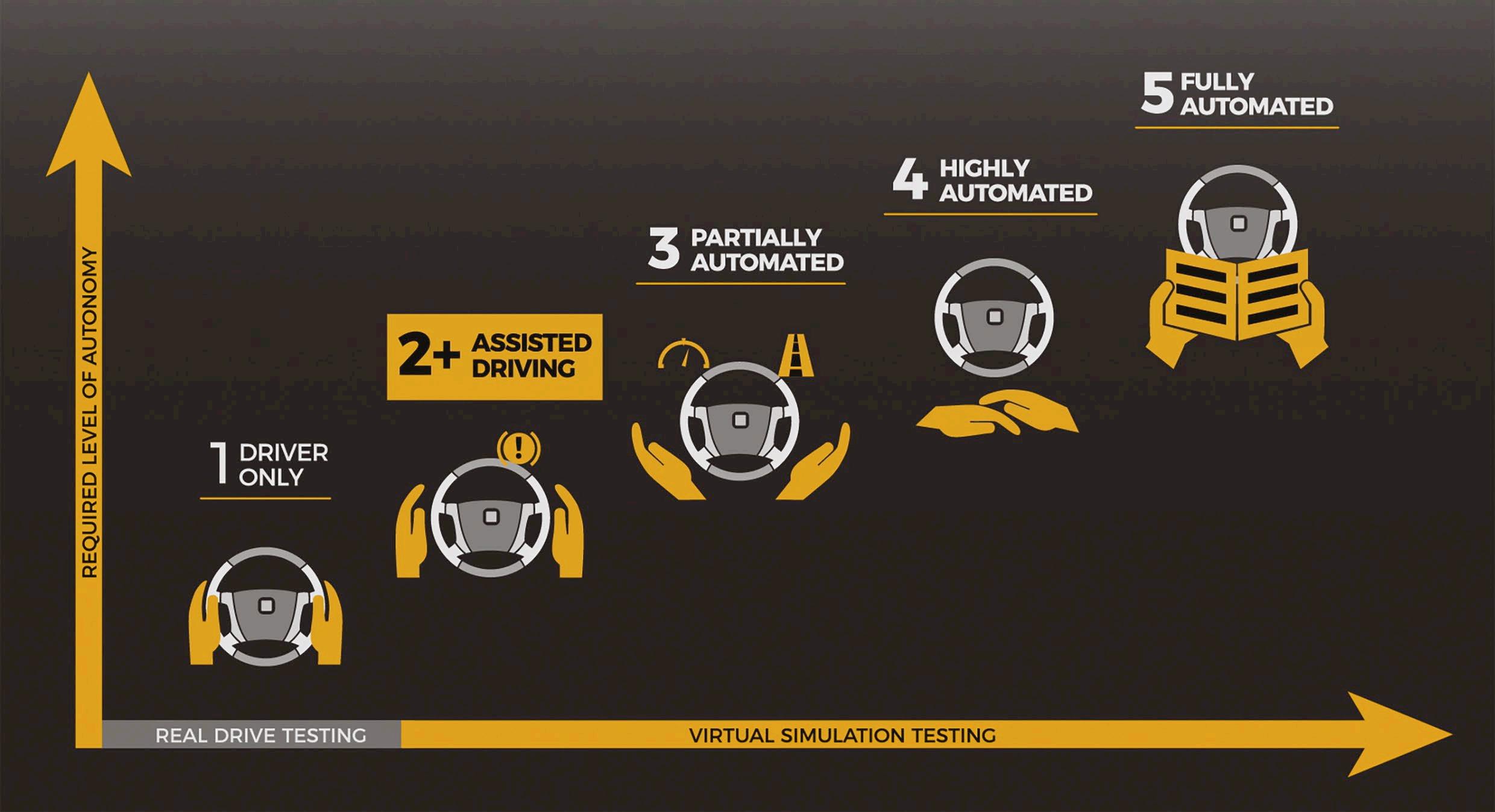

Fully autonomous vehicles could have up to a billion lines of code

Regulatory hurdles, semiconductor shortages, geopolitical disruption; these are just some of the challenges currently facing the automotive industry. To adapt, many OEMs are rerouting investment to develop and deploy advanced driver assistance systems (ADAS) that are equipped with hands-off and eyesoff driving technologies for shortterm returns.

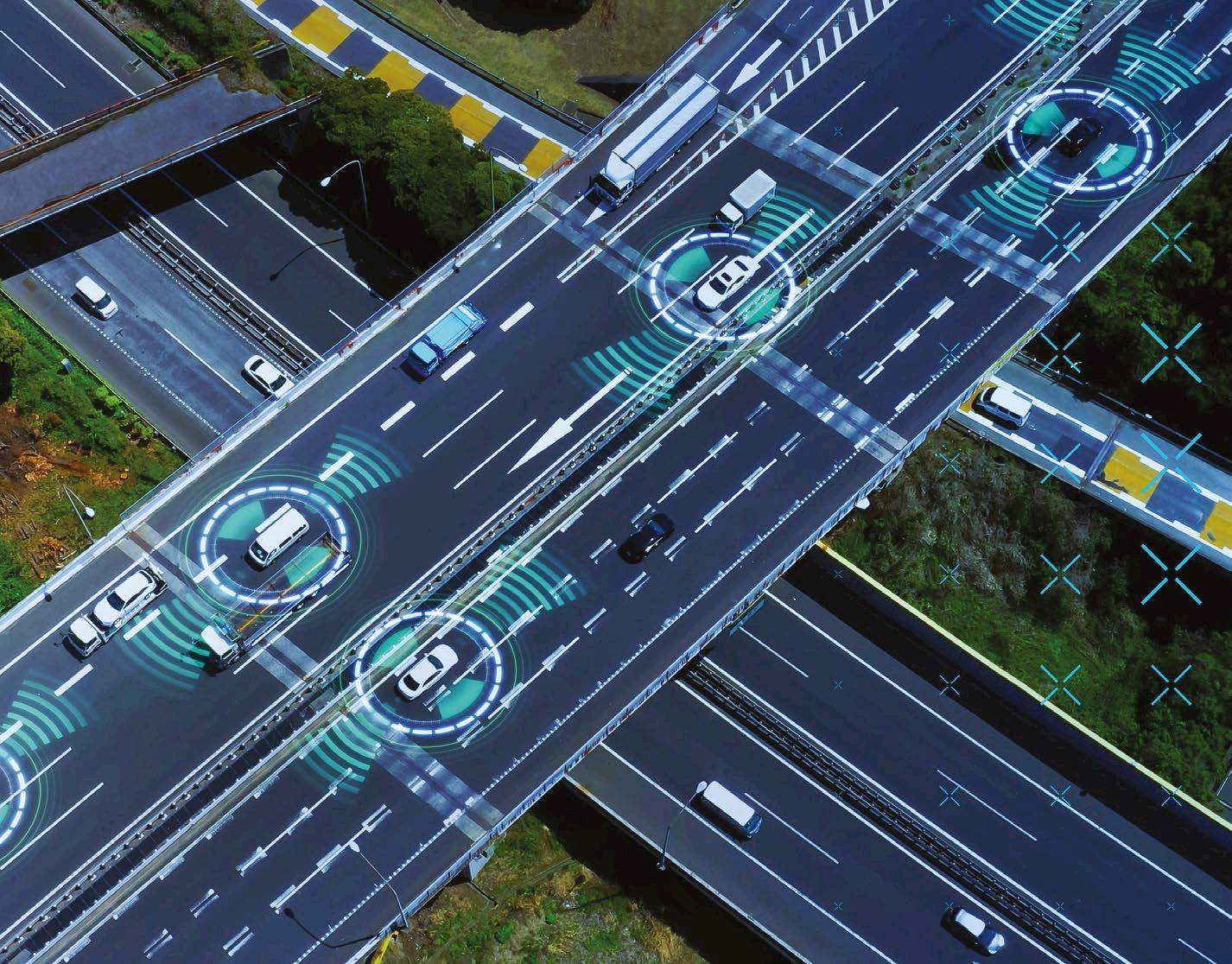

While ADAS may have begun as a premium feature in executive cars, increasing interest from both consumers and safety regulators has driven a surge in adoption across all vehicle classes. As such, there has been a whole host of innovation in this area of late, from cameras and control units to radar and lidar systems, GPS and mapping data, to Human-Machine Interfaces (HMIs) and connectivity.

In this article, two leading developers of ADAS hardware, software and systems share their insights into the market and what they believe will be the next step on the path towards autonomous vehicles.

“With increasing levels of complexity in ADAS/AD systems, it is becoming nearly impossible to thoroughly test and validate designs with traditional methods,” says Emmanuel Follin, senior manager, product management at Ansys. The company’s Autonomous Vehicle Simulation software supports the development, testing and validation of safe automated driving technologies while saving time and money for OEMs.

He continues: “An example of this is physical road testing, which is extremely expensive and timeconsuming. As a result of these obstacles, virtual validation via simulation is gaining more traction than ever before. Especially with higher levels of autonomy, trusted, high-fidelity simulation tools are becoming a mainstream component of the autonomous industry’s manufacturer’s toolbox.”

According to Follin, another major trend is incorporating AI into ADAS design. “AI can coordinate vehicle

connectivity, allowing vehicle information to be shared via highspeed wireless networks,” he explains. “AI also facilitates ADAS and AV perception using large amounts of data intelligence that is collected by sensors during drive time. This information guides system safety by improving system perception, helping ADAS vehicles respond to a variety of driving scenarios. One more area where AI/machine learning is making a profound impact is in the annotation of real-world driving maps and ground truth sensor data – this leads to robust perception outcomes and enhanced safety.”

This insight is echoed by Suraj Gajendra, vice president of products and solutions of Arm’s Automotive Line of Business. Over the past three decades, Arm has become a global computing platform, with more than 70% of the world’s population using products based on the company’s technology. Together with its automotive partner ecosystem, Arm provides OEMs with the processor IP, tools and software solutions for

Safety is the main purpose of

automated driving and softwaredefined cars.

“AI has unlocked new capabilities for every industry, and we’re seeing its impact on ADAS and autonomous driving,” Gajendra says. “Driverassistance packages incorporating AI are helping to improve road safety and the autonomous driving experience, but they also require significant compute and performance. These demands are becoming more complex and costly to address with monolithic chips, which has sparked the industry to explore new approaches to building silicon such as chiplets. Chiplets allow the stacking of multiple semiconductor dies, leading to denser silicon design that can increase performance and lower power consumption. This approach is helping address the unique and specific challenges of the automotive industry, enabling more innovative ADAS features.”

According to a study by the National Highway Traffic Safety Administration, an estimated 94% of serious car accidents are caused by human error. With statistics like this in mind, it’s important to consider how eyes-off and hands-off technology

could potentially influence driver behaviour in the future.

“Safety is the main purpose of ADAS software – it was developed to help reduce traffic accidents through automated detection, navigation and avoidance features,” Follin says. “ADAS helps improve a vehicle’s awareness of its environment and aids its ability to respond to environmental factors within milliseconds, which helps heighten driver safety. Sensor technology (lidar, radar and cameras) plays a huge role in this, as different sensors work together to inform the vehicle of outside factors like pedestrians crossing the street, other

vehicles occupying blind spots, and lane departures. ADAS can reduce driver stress because of the way it improves comfort and convenience and responds to outside variables.”

AVxcelerate Autonomy, Ansys’ end-to-end safety-driven toolchain, embodies this approach, combining statistics and simulation at scale to perform sensitivity and reliability analysis that is critical for the development of ADAS functions. Essentially, the platform enables car manufacturers to develop safe workflows for SAE L2/L2+/L3 signoff processes and homologation. Leveraging expansive scenario

AVxcelerate Autonomy statistical reliability analysis

variation management capabilities combined with physics-based sensor models, the toolchain ensures the accuracy and realism of simulations in order to effectively test autonomous systems.

“Advanced in-vehicle technology brings many positive benefits to driver safety,” Gajendra agrees. “Advanced technology in ADAS systems – some of which are already in vehicles today such as automatic braking or lanekeep assist – can help make decisions to manoeuvre the vehicle a certain way on behalf of the driver to prevent an accident. As this technology becomes more advanced, we will see better accuracy in the alert systems and ADAS decision making.”

Despite the rapidly increasing capabilities of today’s ADAS systems, plenty of challenges remain regarding their development. “The growing sophistication of ADAS and autonomous driving features means greater code complexity,” continues Gajendra. “Today’s advanced vehicles already require 100 million lines of code, and it’s expected that fully autonomous vehicles will have up to a billion lines of code. To meet these growing software challenges, at Arm we are working with the automotive industry through collaborative

initiatives like SOAFEE and the Autonomous Vehicle computing Consortium to enable open-standards architecture and accelerate automated and assisted driving systems.”

Arm recently introduced new technologies to accelerate vehicle development cycles while powering important functions throughout the car, including autonomous driving and critical real-time safety features. The company has also deployed its leading-edge Armv9 and Neoverse V3AE technologies to the automotive sector with the aim of bringing “server-class performance” to autonomous and ADAS workloads.

“In addition to the software, ADAS requires performant, power-efficient hardware for the software to run on top of,” he adds. “Most importantly, this compute must have safety built in from the ground up that meets stringent safety certification requirements. It will be crucial for automakers to ensure their software foundation is built on safe, power efficient and performant hardware to keep up with the ongoing technological advancements of autonomous driving.”

According to Follin, however, navigating the complex rules around regulatory compliance is perhaps the biggest challenge for manufacturers. “There is an exponential increase in complexity in ADAS/AD systems with

rising levels of autonomy,” he says. “Obtaining regulation compliance for an SAE L2+, L3 level autonomy system is a lengthy, complex and extremely costly process to endure for manufacturers. It has been estimated that around eight billion miles of road testing are required to meet the necessary safety compliance. To achieve such an astronomical number with real world driving is a nearly impossible task and demands a sophisticated solution. Additionally, establishing the highest levels of safety is dependent on evaluating millions of unforeseen, critical edge cases that mimic real-world driving scenarios that can be potentially hazardous to drivers.”

With all this in mind, what are the next steps on the path towards fully autonomous vehicles?

“As AI and software requirements of software-defined vehicles increase, so does the need to get to market with technology solutions much faster,” offers Gajendra. “To do this, our partners need specialised silicon that allows them to power modern vehicle applications and do so without increasing costs or time to market. We are continuing to enable our partners with new types of silicon, including the Arm Compute Subsystems (CCS) for automotive, which we expect to deliver in 2025 to help reduce the risk of designing specialised silicon while allowing the industry to hit the performance and power requirements of today’s vehicle applications.”

According to Follin, “achieving higher levels of autonomy will require enhancements to existing features and the integration of sensor fusion techniques, greater reliance on AI-driven decision-making, and robust communications capabilities like Vehicle-to-Everything (V2X). With the collaboration of engineers, automotive manufacturers, technology developers and drivers, ADAS will continue improving road safety and the overall driving experience until fully autonomous driving becomes a reality.”

ADAS features are becoming increasingly more complex

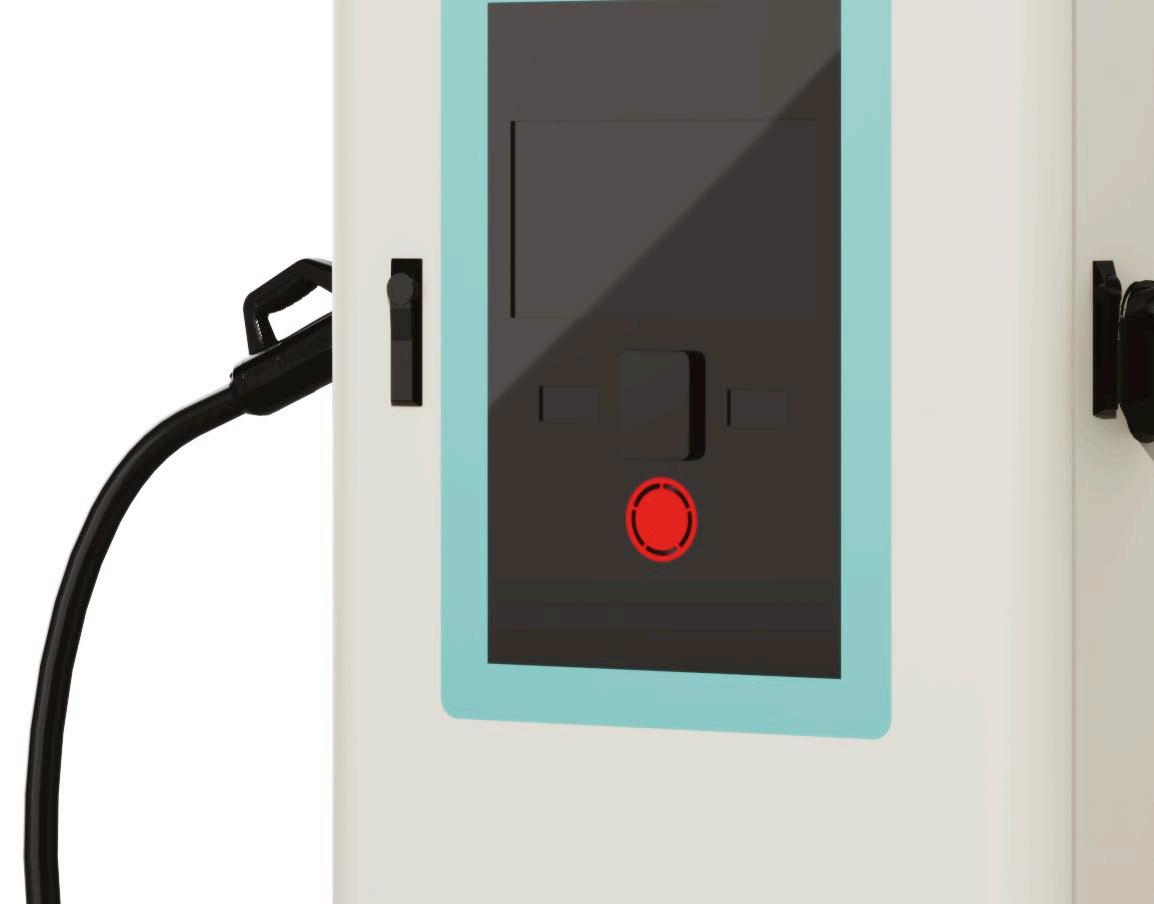

Charging forward to the next generation of e cient transportation

and

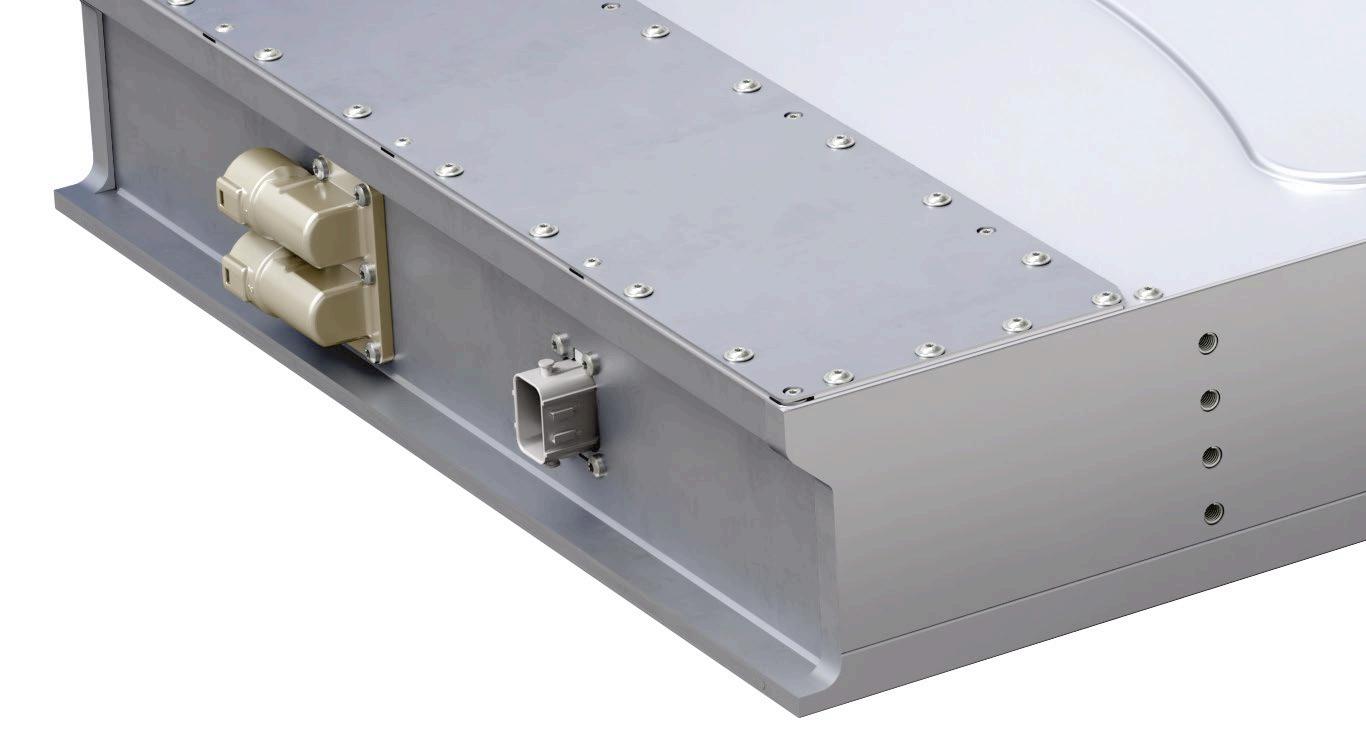

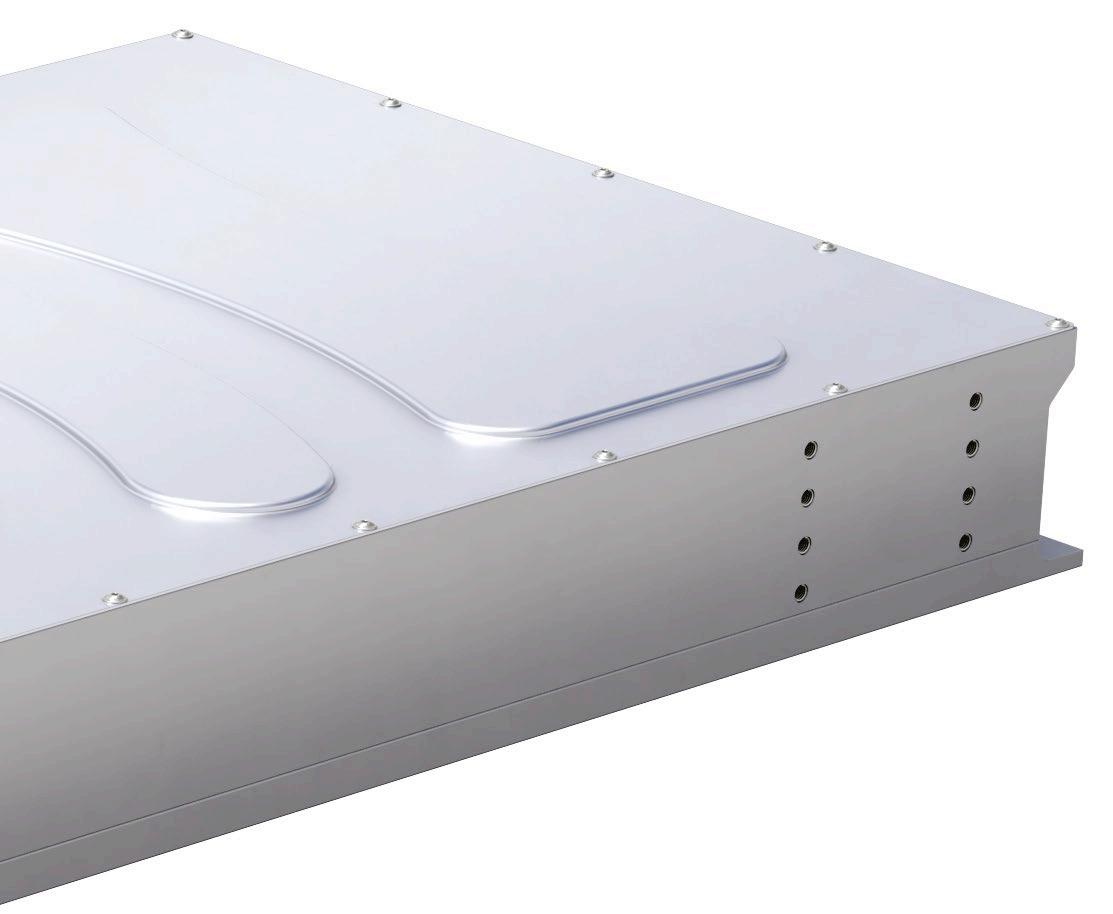

The LFP battery pack

This manufacturer reveals how its latest product launches are set to drive innovation in the commercial electric vehicle market

For more than a century, Borgwarner has been supplying the automotive industry with innovative products for conventional Internal Combustion Engine (ICE) vehicles. Now a global manufacturer of electrification and mobility solutions, the company is continuing to develop advanced products and technologies that are helping to improve the sustainability of commercial transportation. The latest spate of product launches from the manufacturer holds true to this mission, from innovations in Lithium Iron Phosphate (LFP) battery packs and DC fast charging to advanced components for electric powertrains.

In February, Borgwarner announced a strategic eight-year partnership with FinDreams Battery, a subsidiary of BYD Company Limited, to become the only non-OEM localised manufacturer with rights to localise LFP battery packs for commercial vehicles in Europe, the Americas and select regions of Asia Pacific.

“Since the announcement, we’ve

been working hard on our new LFP battery designs and also talking to customers,” says Harry Husted, CTO of Borgwarner. “FinDreams will supply BorgWarner with its LFP blade cells and some production equipment for battery pack assembly. The design of the battery packs is being done by BorgWarner, using some design elements from FinDreams to ensure compatibility with their manufacturing process steps.”

The term ‘blade cell’ refers to its structural design as a long, thin battery cell with side terminals. Husted explains: “The cross-beam-like design of the cell and the terminals on the side of the cell bring benefits in volumetric energy density and electrical interconnection while reducing battery pack assembly complexity. This gives BorgWarner LFP battery packs a competitive combination of cost and performance that we can offer to our customers.”

According to Husted, one of the standout advantages of LFP battery packs is their cost efficiency. “They are less expensive to produce than other lithium-ion batteries, primarily because they do not rely on scarce and expensive materials like cobalt

and nickel,” he continues. “This cost advantage can significantly reduce the total cost of ownership for commercial fleet operators.”

LFP batteries also typically have a longer cycle life, meaning they can endure more charge and discharge cycles before their capacity degrades. “This longevity is particularly valuable for commercial vehicles to deliver improved TCO, long-term reliability and minimal downtime,”

BorgWarner is also making an impact with its new DC charging system, which Husted describes as an, “excellent solution for rapid charging, with a scalable power range of 120kW up to 360kW, making it suitable for fast charging CV depots and also in public and high traffic areas.” The conversion from AC to DC voltage happens within the charging station power electronics to deliver DC directly to the battery, greatly reducing charging times.

“The primary benefit of DC fast charging is significantly reduced charging times because higher power is delivered directly to the battery,” Husted says. “AC chargers run at

The scalable power options of our DC fast charging station offer

a slower rate because the AC to DC conversion step is done in the vehicle’s onboard charger, which is sized at a lower power level. The scalable power options of our DC fast charging station offer flexibility to meet a wide range of depot and charge point operator needs. Our charger is equipped with two output cables to allow two vehicles to charge simultaneously.”

BorgWarner’s DC fast charging stations are specifically designed to handle the high energy demands of commercial and passenger vehicles that often have a need for fast charging ‘on the go’. This makes them ideal for use in depots, and along highways. The charging station also offers a more convenient and streamlined experience for the user due to quick turnaround time and higher power output. The company has already deployed 50,000 of its DC fast charging stations in Asia.

“BorgWarner has long been committed to driving innovation in the automotive sector, and our latest advancements are a testament to that commitment,” Husted says. “Our new technologies are centred on enhancing the efficiency, sustainability and overall performance of commercial vehicles.”

In addition to its LFP battery packs and DC fast charging stations, BorgWarner is also making gains in electric powertrains.

“We are advancing in powertrain electrification with our range of CV inverters and eMotors, which are at

the heart of the propulsion system in electrical commercial vehicles,” Husted explains. “We’ve also focused on thermal management solutions, such as our advanced battery coolers and high-power eFans, which are essential for managing operating temperatures in electric drivetrains, thereby extending the performance, lifespan and efficiency of these systems. These innovations are collectively helping to reduce emissions, improve energy efficiency and lower the total cost of ownership for commercial fleet operators, contributing to revolutionising the commercial transportation landscape and creating a cleaner, more efficient world.”

Looking ahead, Husted believes the pace of technological advancement in battery energy density will be a

pivotal influence on the future of the commercial transportation industry. “The development of batteries that offer higher energy density, faster charging times and lower costs will be key to accelerating the adoption of electric commercial vehicles,” he says. “Secondly, the expansion of reliable and widespread fastcharging networks will be essential for supporting long-haul and highutilisation fleet operations. This will include upgrades to electrical distribution infrastructure in some areas in order to supply power to DC fast charger depots.”

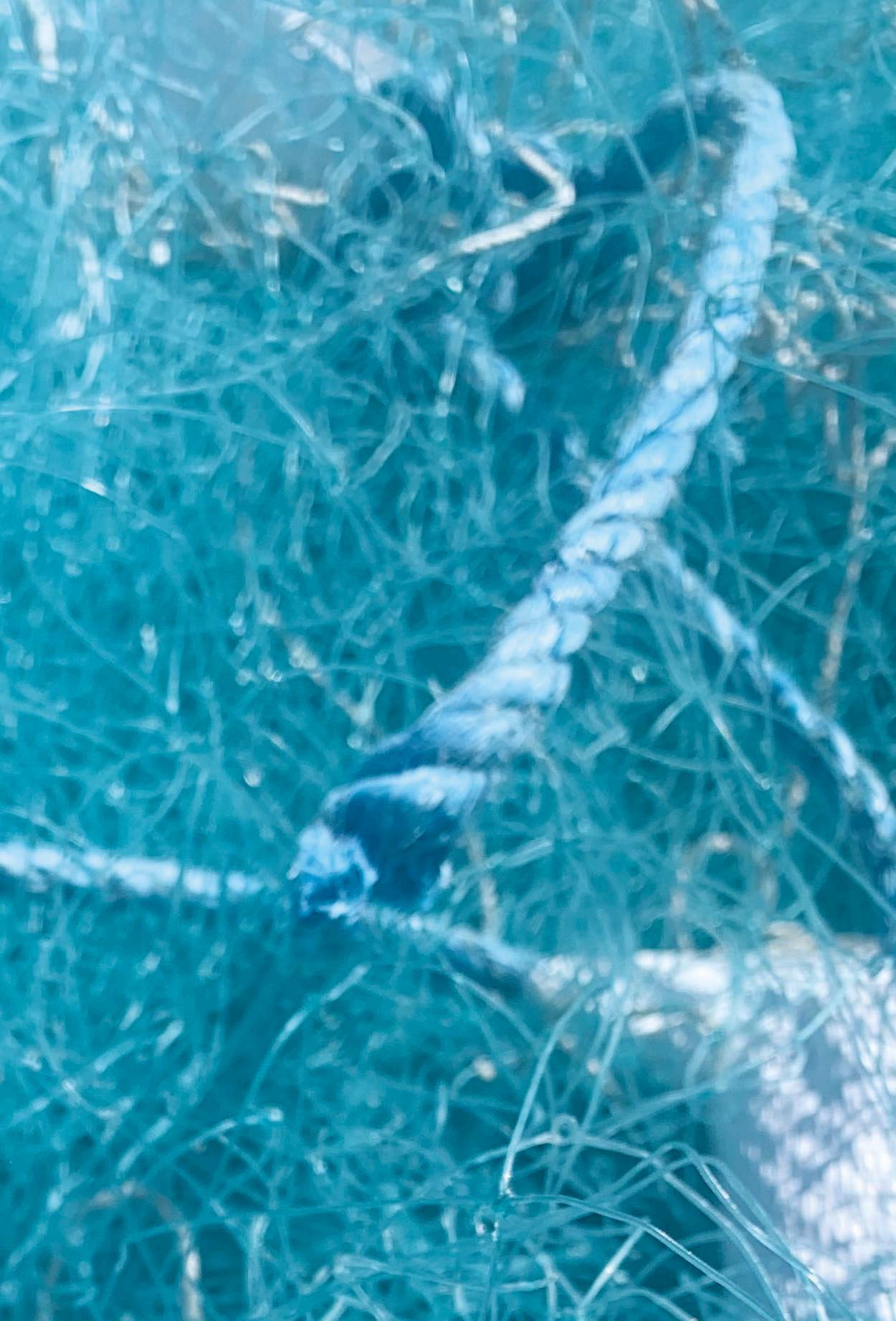

How one company’s mission to tackle fishing net waste is demonstrating the possibilities of circular economy additive manufacturing

t first, tackling waste from used fishing nets may appear to be a niche issue. In reality, though, it’s a global one, with 150,000 to 200,000 tonnes of high value Nylon 6 polymer being consumed every year just in the process of making one type of net. As Ian Falconer, founder of Fishy Filaments, explains, “The majority of these nets are currently buried or burned at the end of their lives, which is generally somewhere between six months and a year. A recent paper by Richardson et al from the Australian science agency CSIRO found that globally around 2% of gill nets are lost at sea, which means that 98% of them get returned to land for disposal. So, that’s many tens of thousands of tonnes of engineeringgrade nylon every year that gets used for a few months then put to waste.”

Falconer first launched Fishy Filaments as a project in 2016, then as a funded company a year later, with the initial goal of commercialising IP that he had developed with strong

potential to make plastics recycling more efficient. The process found its home in the fishing industry, where it can be applied to clean the algal biofilm off used fishing nets.

“We’ve set out to find a way to bring the Nylon 6 contained in those nets back into industrial use,” says Falconer. “Unlike conventional plastics recycling challenges, the logistics of fishing net collection have historically robbed the activity of a means to return value to those at the sharp end, the fishing communities where end-of-life nets accumulate.”

Over the years, Fishy Filaments has been working hard to prove its recycling process, understand the invention and how it can scale, and identify potential markets for the new materials it can process.

“When we launched our MVP, a world-first 100% recycled PA6 filament for 3D printing, it was with the understanding that we didn’t know the

marketplace and little data existed to help us,” Falconer continues. “It ended up winning us the 3D Printing Industry News award in 2021 in a public vote of over 140,000. So, we knew we had a product that could engage with public sentiment, even if it wasn’t an immediate commercial hit.”

Since then, Falconer and his team have been working with hundreds of customers around the world to explore the material’s capabilities, winning multiple global design awards. However, he concedes, “We knew it wasn’t the easiest material to use and its application was really limited to professional or semi-professional customers rather than having a wider appeal in the hobbyist market. Even from the earliest days I had my eye on recycled carbon fibre (CF) as the perfect fit for our recycled nylon and a means to add functionality to the raw recyclate. That idea was shared in principle when the company launched, but it took until 2022 before the product line that became 0rCA was realised.”

0rCA is available as a 10% CF-filled PA in cut strand pellet form

0rCA is short for ‘near Zero (0) recycled CArbon’ and is more of a materials concept than a single product, Falconer says. He explains: “In 2019 we did a Life Cycle Assessment with Exeter University’s Environmental Sustainability Institute for our raw recyclate that returned a fantastic result. It showed that our recycling process could save 97-98% of the carbon emissions when compared to new nylon production.”

The company has since bought its own lab-scale compounding plant to advance the 0rCA project, allowing it to test and optimise new composite production in-house.

The first commercially available variant of 0rCA is a 10% CF-filled PA6 that can be bought as a cut strand pellet or as a 3D printer filament via the company’s global filament distribution partner, Fillamentum.

According to Falconer, the material’s mechanical performance is equal to or better than most other PA-CF materials currently in the 3D printing filament segment.

“It is relatively high temperature –especially compared with PA11 and PA12 – impact resistant, chemically resistant and UV resistant,” he says. “As a materials family our CF10% variant has an estimated carbon saving of 90-95% versus virgin equivalents, so any company that currently uses PA6-CF but wants to slash their carbon impact for a

0rCA facilitates multi-component assemblies via injection moulding, FDM and SLS

particular product, 0rCA can be a drop-in replacement. In filament form, it is stronger than most virgin equivalents too.”

Mono-materiality and corecyclability have been long-term drivers behind developing 0rCA as a family of materials. “The availability and usability of 0rCA across a range of manufacturing, not just additive, means that multi-component assemblies can be built using IMbuilt components as well as SLS and FDM made parts,” Falconer continues. “But at end-of-life, those assemblies do not need to be taken apart for recycling. This is a long-term consideration for designers when working towards compliance for the EU’s circular economy and product safety directives.”

Traceability is a key benefit for companies utilising 0rCA, Falconer adds. “Our base material is 100% recycled Nylon 6 and 100% of it comes from fishing vessels we know. We know where they fish, what species they fish for and their supply chain for the new nets. Few recycled materials have as good a provenance, and few new materials have as open a provenance.”

0rCA is designed for use across multiple manufacturing methodologies, with a designer able to produce an early prototype using Fused Deposition Modelling (FDM), a low-volume

product using Selective Laser Sintering (SLS) and then mass production via injection moulding, all using the same material with the same supply chain. According to Falconer, high performance consumer facing items such as sports equipment, eyewear, and designer fashion are suitable applications for 0rCA, alongside low volume engineering componentry for spares and repairs, vehicle customisation and tooling.

The powder has also been designed to be accepted straight back into Fishy Filaments’ plant as a fractional source material for secondary use.

“This work means we will offer 0rCA as a zero waste 3D printing powder for customers,” Falconer says.

“Fundamentally, the recycled materials sector needs to be more understanding of what designers need rather than trying to get them to fit to what its own technical ability is right now. Recycling needs to be more ambitious about creating value and less about waste management.”

Fishy Filaments is currently in scale-up production with Warsawbased Alpha Powders for 0rCA, and hopes to amass a group of technically competent early adopters to spur on the powder’s development and commercialisation.

For more information visit: www.fishyfilaments.com

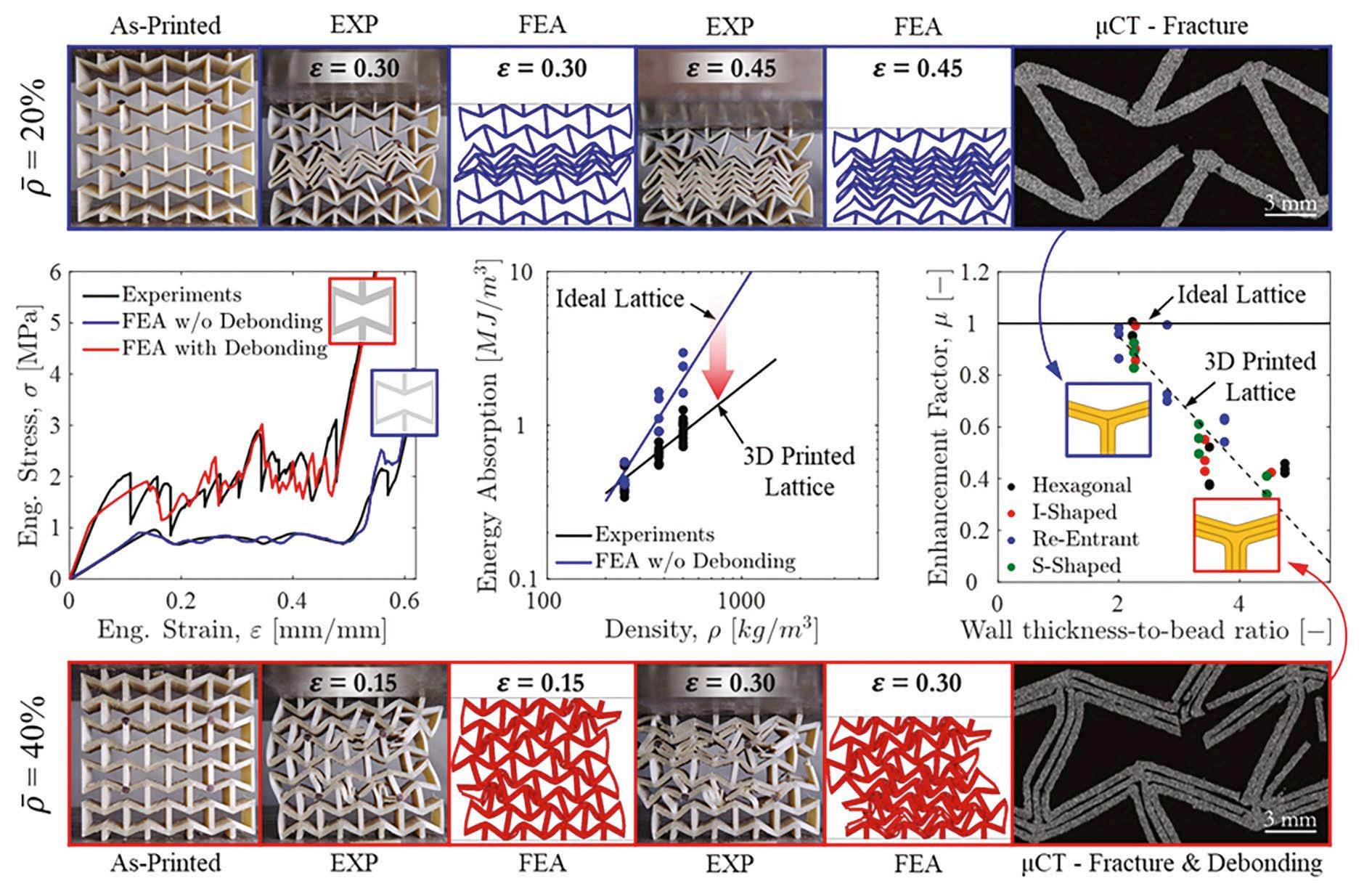

Providing a reliable way to predict how new lattice designs can be fine-tuned to minimise structural defects

The design and construction of lattice materials relies on a delicate balance of structural factors. Researchers at the University of Glasgow have been investigating the deformation mechanisms which cause 3D printed materials to fail under strain, culminating in a new design parameter called the ‘enhancement factor’.

“The enhancement factor tool is designed to bridge the gap between theoretical predictions and the actual performance of 3D printed lattice structures, helping engineers to optimise their designs,” says Professor Kumar Shanmugam, professor of composite materials and advanced manufacturing at the University of Glasgow. “The tool acts as a corrective factor that quantifies the discrepancy between the ideal, defect-free lattice structure and the real, printed version, which may be affected by various factors such as printing defects and deposition strategy.”

According to Shanmugam, lattice designs offer many significant benefits for industrial parts, primarily due to their unique structure. “One of the primary advantages of lattice materials is their ability to achieve high specific strength and stiffness, making them ideal for structural applications,” he explains. “Additionally, their capacity to absorb energy makes them suitable for impact resistance and shock mitigation. This versatility enhances the performance of industrial components, particularly in applications requiring both strength and weight reduction.”

Lightweighting is also an important advantage of lattice designs. “The lightweight nature of lattice-designed components is a crucial advantage across industries like automotive, aerospace, robotics and biomedical fields, where reducing weight without compromising performance is essential,” he adds.

Additive manufacturing has emerged as an ideal production technology for developing new lattice designs, however challenges remain. Shanmugam’s team focused on overcoming these issues to produce structures with minimal defects, porosity and dimensional inconsistencies using 3D printing.

“Engineers often rely on established theoretical models to predict stiffness, strength and energy absorption of lattice structures,” Shanmugam says. “However, these models are typically based on ideal conditions or on materials produced through traditional manufacturing methods. When it comes to additive manufacturing, the actual mechanical properties of the printed structures can differ significantly due to the unique challenges of the process.”

The team’s enhancement factor tool is designed to provide a practical means to connect theoretical mechanical properties to those of the actual 3D printed structures. “Engineers can assess the effective mechanical performance of their designs, accounting for the real-world imperfections introduced during the

printing process,” he continues. “This enables them to make more informed decisions about material selection, lattice architecture and process parameters, ultimately improving the performance and reliability of the final product. Moreover, the enhancement factor tool serves as a diagnostic metric for the quality of the printing process.”

By adhering to these guidelines, engineers can design 3D printed lattices that are not only robust, but also optimised for advanced applications, he adds.

“Our research holds significant potential for advancing component design and material development across various industrial applications. In automotive, flawlessly produced lattice materials could revolutionise road safety, in aerospace, engineers could develop more fuel-efficient aircraft, and customised implants made from 3D printed lattice materials could improve patient outcomes.”

Assessing the adoption of digital technologies in manufacturing for data-driven maintenance

AI will be a priority for 93% of respondents in 2024

Also known as “humancentric industry”, Industry 5.0 is seen as the next evolution of manufacturing, integrating the latest technologies such as artificial intelligence (AI), robotics and automation while putting a greater emphasis on the role of human workers. Once thought as futuristic, Industry 5.0 is now progressing rapidly with the advancement of AI. According to a recent AI adoption report by Fluke Reliability, a provider of tools, software and services to optimise asset performance, manufacturers have ambitious plans to achieve Industry 5.0 goals within the next year.

And it’s no surprise that companies are rethinking their maintenance and reliability strategies, driven by macroeconomic challenges, sustainability concerns, supply chain disruptions and the growing skills shortage. With that, comes investment in digital technologies such as AI.

“Our mission is to simplify connected reliability for our customers

so they can keep the world up and running,” says Ankush Malhotra, Fluke Reliability’s President. “But you’ve got to get started - if you haven’t, you’re already late. A lot of our focus is on demystifying AI and to ensure the barriers to start are really small. This is a technology that is easily understandable for the problems our customers solve, and it’s easy to scale up so a customer can start small, get comfortable, improve the ROI and then keep growing. Through our managed service and training, our job is to help them through that journey.”

According to Fluke’s report, manufacturers are already leveraging a range of digital technologies to enhance their operational and maintenance capabilities, however only 8% are currently operating a predictive maintenance strategy. This looks set to change drastically, though, with over 76%

of maintenance managers wanting to shift to predictive or proactive maintenance in the future. The work is starting now, it seems, with over a third of manufacturers already having Industry 5.0 and smart manufacturing projects underway. With many of these projects expected to be complete within 10 months, it’s clear that AI is a priority for 2024 and beyond, with manufacturers investing heavily in the technology.

“The idea of continually improving maintenance and reliability strategies to enhance efficiency and drive profitability certainly isn’t new,” says Malhotra. “However, there’s little doubt that today’s challenging operating environments – coupled with the ongoing shortage of skilled maintenance professionals – is driving the issue higher up the boardroom agenda.”

Perhaps one of the most significant figures laid out by the report is 93% of respondents confirming that the adoption of AI technologies is an organisational priority for 2024, with

the intent to invest 44% of their budget on AI technologies like predictive maintenance and machine learning.

“Having visibility across multiple sites and operations is now critical for c-suite executives – to inform smarter planning, to share inventory and ultimately to help them make group level decisions that really move the needle on key cost drivers,” Malhotra adds. “Is AI driving urgency in many of these conversations? Absolutely.”

Over the past 75 years, Fluke Reliability has helped reliability and maintenance teams to optimise their asset performance with a range of powerful tools, software and services. The company’s Azima DLI brand –acquired by Fluke in 2023 - enables engineers to maximise uptime and demonstrate ROI with vibration monitoring, advanced AI analysis and enterprise reporting. The Azima DLI Diagnostic engine has been trained on 30 years of data and draws from 100 trillion data points across 50 machinery component types, offering a vast wealth of crucial information to maintenance and reliability

engineers. Together with Fluke’s eMaint asset management software and Prüftechnik condition monitoring and alignment devices, Azima DLI’s AI-powered machine health analysis offers engineers a comprehensive platform for implementing an effective predictive maintenance strategy.

“Manufacturing faces many challenges such as supply chain disruption, skilled labour shortages, sustainability, net zero goals, lack of standardisation and so on,” says Malhotra. “But I also think we’re at a unique time in our industry where the opportunities are even greater with all the technologies available, from

Industry 5.0 to predictive maintenance and AI. The message we’re saying to customers is to start small and then scale, demystify AI with training, and make sure that we can be a partner to help our customers on this journey. That’s why we’ve put together these solutions. Our vision is to simplify technology, and make things easy for our customers to understand and implement.”

11 months to complete their current AI technology goals.

10 months to complete their current Industry 5.0 goals.

10 months to complete their current smart manufacturing technology goals.

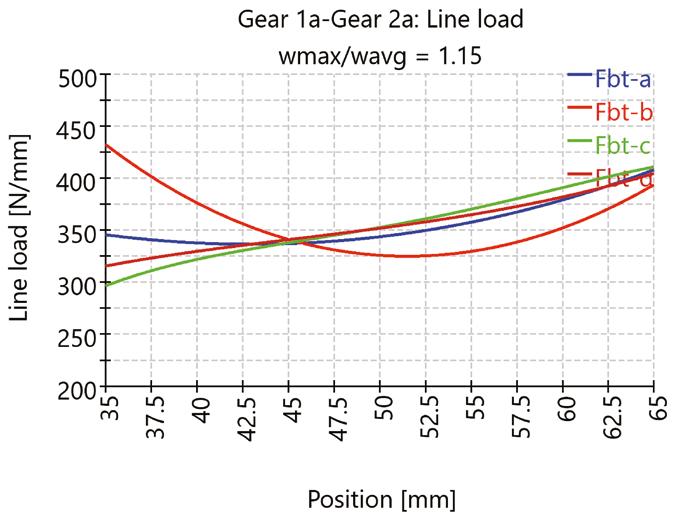

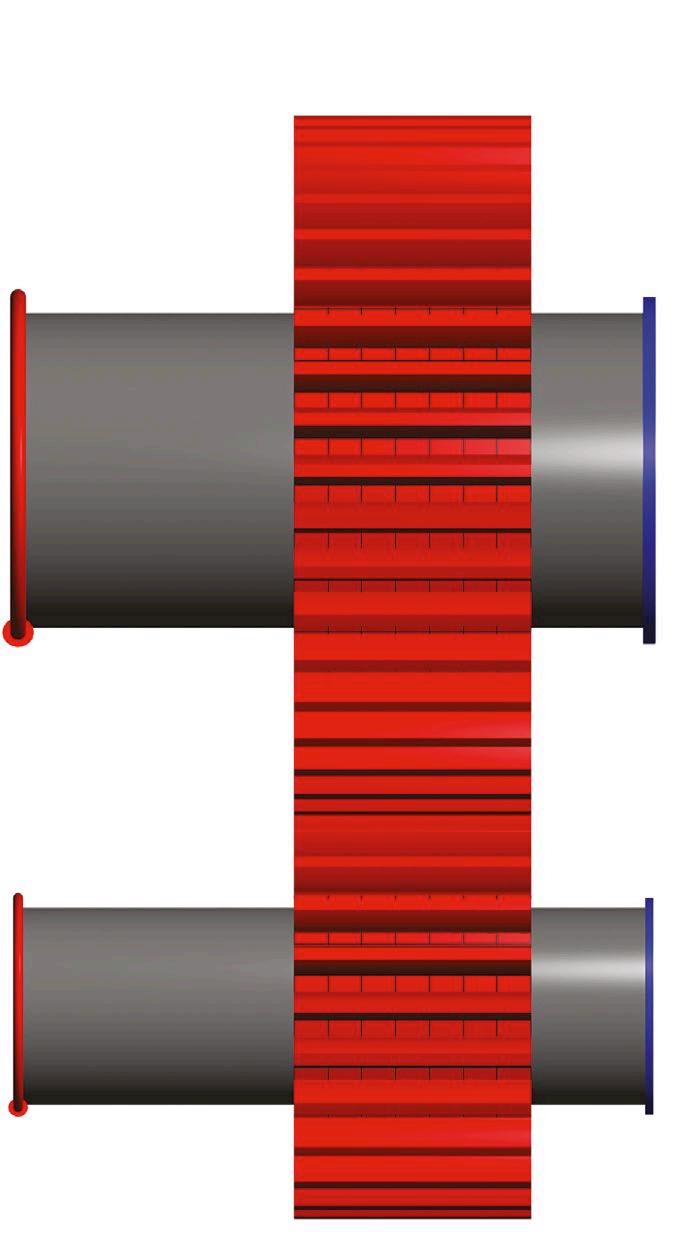

Swiss-based company Mesys develops software for technical calculations in mechanical engineering, with a particular focus on the sizing of machine elements like gears, shafts, bolts and rolling bearings. Here, director Markus Raabe discusses gear body stiffness for face load factor. In gear ratings according to ISO 6336, the face load factor accounts for uneven load distribution along the face width of the gear. Mesh misalignments because of manufacturing deviations, bearing clearances and stiffnesses and shaft bending are considered in this face load factor.

One difficulty lies in the consideration of the stiffening of the shaft by the gear body. ISO 6336-1 provides three values to be used for the calculation of shaft deflections under clause 7.4.3.4. First, it says to use a midway diameter between hub diameter and bore for shrink-fitted gears or other parts, and in this case the root diameter of the gear and its bore diameter might be used. This is reasonable to be used for the calculation of the shaft deflection, because the shaft can deform inside of the gear body and therefore using the outside diameter of the gear might be too stiff. Then, the standard says in the same clause to use the mean value of tip and root diameters for bending deflections of the gears and the root diameter plus 0.4 times module for torsional deformations. It is reasonable to use a mid-diameter of the tooth in the tooth area as the deformations of the teeth determines the mesh misalignment. On the other hand, the stiffening of the shaft will be too large. According to the standard, the first midway diameter is generally used for gears or other parts shrink-fitted to the shaft, the other two diameters shall be used for the deformation in

the tooth area. Some also use the first diameter for the tooth area, which will be too soft.

The MESYS shaft calculation uses a 3D-FEA model for the gear body to combine these two approaches. Results of an example calculation for a gear pair with rigid supports and no manufacturing deviations are shown for four cases. The first case is using the root diameter plus 0.4 times module for stiffening of the shaft (a), the second case is using a midway diameter between root diameter and shaft diameter (b), the third example is using an 3D-FEA model reduced to central nodes on the outer diameter (c) and the fourth model is using a 3D-FEA model with local load introduction (d). Figure 1 shows the line load distribution for the four cases and table 1 some numeric results. Figure 2 shows the gear pair

used for the calculation.

Cases ‘a’/’c’/’d’ show almost the same line load for the gears while case ‘b’ leads to a larger line load. For case ‘a’ the shaft deflection is too small as expected and cases ‘b’/’c’/’d’ show almost the same shaft deflection. Case ‘b’ will suggest a flank line correction in a different direction than the other cases. Using a 3D-FEA model makes it possible to combine the stiffness of the gear body for the flank line deformations with the lower stiffening effect for the shaft deflections. Moreover, different gear body geometries can be used easily as the 3D-FEA model allows variations of the gear body geometry, which is not possible with the beam model of the shaft.

recom-power.com/3dpp

How can the role of advanced thermal solutions revolutionise the design of medical devices?

Manufacturers (OEMs) are increasingly seeking out sophisticated thermal solutions to improve the performance of medical devices. With over two million different medical devices across the global market, according to the World Health Organisation (WHO), the design of these critical devices must be perfect. In this article, Andy Selvy, the chief systems designer at industrial heating technology manufacturer Watlow, delves into the transition from traditional heaters to advanced, layered heating technologies in medical device design.

Thermal management within medical devices, clinical diagnostics instruments and analytical instruments involves the sophisticated control of temperatures to prevent overheating and ensure devices operate within their optimal performance range. Proper thermal regulation is vital because even the slightest of deviations can lead to device failure, diminished treatment effectiveness, or serious risks to user safety.

Effective thermal management is crucial for devices that generate significant heat during operation or that use heat as part of therapeutic treatments. Examples include maintaining body-temperature fluids in dialysis machines and regulating the temperature of surgical tools to avoid tissue damage. This precise temperature control is essential for the success of treatments and the safety of patients.

The introduction of sophisticated heating technologies into medical devices brings a set of complex challenges that must be carefully

managed. Advanced heating solutions must not only provide effective temperature control but also ensure safety, requiring rigorous testing and adherence to international safety standards such as IEC 60601-1-11. This regulatory standard outlines specific safety requirements for medical electrical equipment.

Achieving high thermal efficiency is essential to prevent overheating, enhance energy efficiency and minimise operational costs. This involves optimising heat transfer capabilities, improving insulation and selecting materials that exhibit excellent thermal properties. Each of these factors plays a critical role in the development of safe and effective medical devices.

Furthermore, the development of cutting-edge thermal solutions can be both complex and costly. Manufacturers must balance these factors with the need to produce affordable medical devices. This

balance is crucial to ensure that advanced medical technologies remain accessible to healthcare providers and patients alike. Balancing cost and complexity requires innovative design strategies, efficient manufacturing processes and careful material selection to ensure the final product is both effective and economically viable for the market.

The move to advanced heater solutions is motivated by the demand for medical devices that are not only compact and energy-efficient, but reliable and consistent in operation. Traditional heating solutions have long relied on nichrome element wires embedded within magnesium oxide insulation. These products, such as cartridge and tubular heaters, have been foundational yet come with inherent limitations. They often struggle with heat distribution and

temperature stability, leading to energy inefficiency and environmental risks due to high operating temperatures and potential insulation breakdown. They must also operate at lower watt densities leading to larger physical sizes for the same power level.

Layered heater technology marks a significant leap forward, employing meticulously deposited thin layers of heating elements. These layers, often as thin as a fraction of a human hair, are engineered to achieve optimal thermal performance. By stacking layers with precise control, these heaters provide unmatched temperature uniformity and quicker thermal response times, allowing for precise thermal expansion matching, which is crucial for maintaining structural integrity and functional reliability under varying thermal conditions.

The materials used in layered heaters, such as aluminium nitride or other advanced ceramics, play a crucial role in their performance. These materials are selected for their high electrical insulation and superior thermal conductivity, crucial for safe and efficient operations.

Ultimately, layered heater technology not only represents a significant technological advancement but also a paradigm shift in thermal management that is set to redefine standards and expectations within the MedTech industry. The ongoing push for greater efficiency, miniaturisation and safety points to broader adoption of these heaters.

As medical technology continues to advance, the role of sophisticated thermal management systems will remain crucial. Ongoing innovations in heater technologies promise to enhance device performance, improve patient safety, meet the complex demands of next-generation medical devices and facilitate the development of new and effective medical treatments. Looking to the future, the integration of advanced thermal solutions will continue to be a critical area of focus, promising significant impacts on the future of healthcare technology.

iants for PCIe, PXIe and Ethenet/LXI

One to 32 synchronous channels

Up to 400 DDS sine waves in one system

32 superimposed sine waves in frequency domain

Sine signals between 1 Hz and 200 MHz

Easy generation of sine waves using FPGA-based DDS

Direct programming of frequency, amplitude, phase, frequency slopes and amplitude slopes

Continuous output, only changes need to be sent

Parameter changes in as little as 6.4 ns Produce trains of waveforms, frequency sweeps or finely tuneable references!

for quantum, industrial, medical, imaging, network analysis or communications!

How

Fluoroelastomers are used in a wide variety of highperformance applications for their long-term reliability and resistance to elevated temperatures and aggressive chemical changes. Chemours’ range of Viton fluoroelastomers was first introduced in 1957 to meet the high demands of the aerospace industry, and for the next 65 years became known for their outstanding temperature and chemical resistance. In 2001, Chemours developed specialty types of Viton fluoroelastomers called Viton APA, leading to a step-change in processing and end-use performance. Today, the materials are widely used in the automotive industry and are regarded as a leading sealing technology for emerging markets such as advanced electronics, semiconductors and electric vehicles (EV). Most recently, the company unveiled its newly introduced Viton FWRD APA fluoroelastomers, which enable customers to maintain uninterrupted supply, despite evolving regulations.

Viton APA fluoroelastomers dramatically improve processing characteristics, such as flow, cure and mould release. Because good physical properties and low compression set can be achieved without post-curing, unique production opportunities, such as over-moulding onto plastic inserts or carriers, are realised. Moreover, engineers and parts manufacturers specify Viton APA fluoroelastomers for the most demanding applications due to their ability to maintain performance at high and low

temperatures and their exceptional chemical resistance.

Responding to shifts in the industry, Chemours has innovated its manufacturing process to eliminate the use of a fluorinated surfactant, producing Viton FWRD APA fluoroelastomers without sacrificing performance.

With the growing emphasis on sustainable transportation options, peak performance is required in newer, extreme environments, and Viton fluoroelastomers continue to deliver peak performance under the most challenging conditions.

These specialty materials are used in seals, gaskets and o-rings which are critical applications within automotive, semiconductors, industrial manufacturing, oil and gas and aerospace and defence. Customer qualifications have confirmed Viton FWRD APA fluoroelastomers made using the new process technology have comparable performance to Chemours’ current offerings.

Chemours’ fluoroelastomer portfolio has been evolving to meet everincreasing industry demands since its introduction. This development builds upon the company’s legacy of product innovation, having converted the standard Viton grades to nonfluorinated surfactant technology more than 20 years ago.

Today, the tradition continues, with transition to the new process having officially begun in October 2024. Small quantities of current Viton APA grades continue to be available for a limited time to support customer transition.

Viton FWRD APA fluoroelastomers exhibit comparable uncured and cured properties, as demonstrated in Table 1. Performance of Viton GLT-S grades using the current commercial process and the new, innovative process are representative of the full Viton APA portfolio.

Given the prevalence of Viton APA grades in automotive applications, the automotive fluid aging test is a critical evaluation used to understand the fluoroelastomers’ longevity, stability and overall effectiveness in maintaining intended properties in the presence of common automotive fluids over time. The aging test typically involves subjecting the fluoroelastomers to accelerated conditions that simulate the stress and environmental factors it may experience during use. This accelerated testing helps to predict how each grade will perform while being exposed to these fluids over an extended period to facilitate material selection. The results of automotive fluid aging testing (Figure 1) demonstrate

equivalent performance to current commercial grades.

To confirm processability and flow behaviour of Viton FWRD APA fluoroelastomers, all grades have been tested in compression and injection moulding. For example, injection time has been recorded, and processing was rated in term of mould filling, fouling and release. Viton FWRD APA grades have also been characterised for die swell, shrinkage and surface morphology.

The performance of Viton GBL200S compounds using the current commercial process and the new process are comparable, as shown in Figure 2, and representative of the Viton APA portfolio.

Chemours’ innovative and proprietary technology to produce Viton FWRD APA fluoroelastomers does not use a fluorinated surfactant, demonstrating the company’s commitment to responsible manufacturing. Commercialisation of this technology ensures continuous supply in the face of an evolving regulatory landscape and industry expectations.

In addition to driving process innovation, Chemours has set bold environmental leadership commitments, including aggressive emissions reduction targets: Pledging to reduce Scope 1 and 2 greenhouse gas emissions by 60% by 2030, on a path to net-zero by 2050. The company has also made a specific commitment to reduce emissions of fluorinated organic compounds, a key contributor to greenhouse gas emissions, to air and water by 99% or greater by 2030. The Science Based Target initiative (SBTi) has approved Chemours’ near-term Scope 1 and 2 reduction goal, as well as a new Scope 3 target to reduce emissions by 25% per tonne of production by 2030.

Chemours, Viton and any associated logos are trademarks or copyrights of The Chemours Company FC, LLC.

Ariana Cornwell is product and marketing manager at Chemours. www.chemours.com

Typically based on a trial-anderror approach, materials discovery has traditionally been a slow and resourceintensive process. However, the emergence of artificial intelligence (AI) is turning this on its head, prompting an evolution of research and development techniques for producing novel materials for netzero technologies.

Materials Nexus, a deep-tech company using AI to design novel materials, is an active player in this field. The company’s most recent breakthrough centres around the creation of MagNex, a new rare earth-free permanent magnet, the identification of which was powered by Material Nexus’ AI-based materials discovery platform.

“AI is expected to play a crucial role in developing future materials by revolutionising the traditional materials discovery process,” says Dr Jonathan Bean, Materials Nexus’ CEO. “By enabling a shift from a trial-and-error approach to a designfocused approach, AI can significantly accelerate R&D. It improves R&D techniques by analysing vast datasets and predicting material properties with high accuracy, minimising the need for expensive, time-consuming and resource-intensive experiments. This makes the process more cost-effective, less wasteful and environmentally sustainable.”

The company’s unique technology combines AI with quantum mechanics to accurately and rapidly predict novel, high-performing and sustainable materials. The platform is designed to fast-track the discovery and development of such materials to deliver efficiency and performance benefits to green technologies like wind turbines and electric vehicles

(EVs), which still rely heavily on the mining of rare-earth materials and precious metals.

“Unlike traditional trial-and-error methods, this platform enables an intent-based design process, analysing the entire periodic table to identify and model materials from the quantum level to the bulk scale,” Bean explains. “The platform utilises quantum mechanics for composition prediction and models processing and synthesis techniques, allowing for the rapid identification and production of high-performance materials in months rather than decades. This allows us to not only identify, but also physically produce high-performance materials accurately, significantly speeding up the R&D process.”

Permanent magnets are essential for manufacturing across many vital industries, including EVs, wind turbines, robotics and drones. Demand for rare earth magnets is expected to outpace supply in the coming years, with the use of rare earth magnets set to increase up to tenfold by 2030 in the EV industry alone. However, the rare earth metals required to produce these magnets are vulnerable to several supply chain issues.

To address this, Materials Nexus has used its AI platform to design and create a new rare earth-free permanent magnet, MagNex. Working in partnership with the Henry Royce

Institute and the University of Sheffield, the company deployed its AI platform to identify and analyse over 100 million compositions of rare earthfree permanent magnet candidates that address industry challenges, such as supply chain security, cost, performance and environmental issues. In just three months, the partners were able to design, synthesise and test MagNex – 200 times faster than the development timescale for the current industry standard permanent magnet. MagNex can also be produced at 20% of the materials cost and a 70% reduction in material carbon emissions compared to rare earth element magnets currently on the market.

“MagNex is a significant milestone in the use of AI to design materials of the future which are cheaper, higherperforming and more sustainable than existing options,” says Bean. “AI-

AI is expected to play a crucial role in developing future materials by revolutionising the traditional materials discovery process

The creation of the MagNex rare earth-free permanent magnet powered materials design will impact not only magnetics but also the entire field of materials science – we have now identified a scalable method for designing new materials for all kinds of industrial needs. Our platform has already attracted widespread interest for various products with applications that include semiconductors, catalysts and coatings.”

Going forwards, Bean says the company will continue to develop MagNex for industrial applications.

“MagNex is a demonstration of our platform’s ability to predict a novel functional material based on desired variables,” he explains. “Next steps will be the continued collaboration with industry partners to develop the magnetic material. The platform will continue to support this effort as we look at processing techniques. Further development of the platform will be done simultaneously, building on capabilities across multiple material areas such as semiconductors, superconductors and green hydrogen technologies.”

Without adequate battery protection, EV batteries may experience reduced performance, malfunction or in the worst case thermal runaway events. We provide performance materials for reliable function, safety and best power of battery modules and packs. CHT offers a comprehensive package of solutions for thermal management, lightweight potting compounds, gap fillers and high performance adhesives for assembly and gasketing of battery packs. In addition, we offer customized products to meet your individual design and functional requirements. Benefit from our expertise and experience in silicones.

Transportation vehicle manufacturers face mounting challenges, particularly when it comes to the design of buses and coaches. Growing urban populations have placed higher demands on public transport infrastructure, while the need to adapt to ongoing environmental pressures has prompted engineers to look for electric vehicle (EV) solutions. However, the materials used in such vehicles need to accommodate for battery weight and combat corrosion while improving structural integrity and lowering emissions.

A recent whitepaper from Exel Composites explores the growing role of composite materials in the bus and coach sector. Composite materials are well-suited to meet the challenges of electric buses, as in addition to

being lightweight they also offer excellent corrosion resistance and thermal insulation. According to the whitepaper, continuous pultrusion manufacturing techniques enable the creation of wider, longer and more complex composite profiles at high volume and repeatable quality.

“Composite materials are wellsuited to meet the challenges of this new generation of buses and coaches,” says Patrick Loock, Sales Director Europe at Exel Composites. “The customisation options are built into the pultrusion manufacturing process, reducing lead times for customers. Many might know about the lightweight, excellent corrosion resistance and thermal insulating properties of composites.

“A less obvious point is the ability to make wider and more complex shapes with pultrusion,” he continues. “Fiberglass side panels of up to 1.2m wide and 12m long are possible, whereas aluminium profiles are more limited in size. Having one continuous panel reduces the complexity of assembly and maintenance compared to using multiple pieces. Additionally, using one panel is cheaper overall than manufacturing or buying fixings and attaching pieces together.”

According to the whitepaper, advanced materials such as composites are becoming more accessible and better suited to bus and coach manufacturers’ needs than ever before. Continuous manufacturing techniques such as pultrusion enable large-volume production of highquality uniform panels and profiles for any 2D components, helping

Pultruded composites can provide benefits such as durability and improved structural integrity

manufacturers to meet increased public transport requirements.

“Over the last 20 years, urban growth has really pushed the limits of our public transport systems, especially buses,” Loock says. “As we move towards more sustainable options, advanced materials like composites will be key. They enable companies to tackle the challenges of EVs headon, helping us reduce vehicle weight, extend maintenance lifetimes and improve design flexibility.”

Exel Composite’s pultrusion and continuous lamination techniques enable the creation of custom glass reinforced plastic (GRP) and carbon fibre reinforced polymer (CFRP) composites that deliver several benefits across a wide range of bus applications, including bus roofs, body panels, side walls, skirt profiles, coach profiles, luggage racks and internal coves. According to the company, employing composites in bus manufacturing unlocks numerous advantages, from substantial fuel economy improvements to reduced maintenance costs, in addition to

opening up new possibilities for creative design.

“Composites are changing how we build transport vehicles,” Loock explains. “Unlike metals, pultrusion lets us create much wider, complex profiles in a single piece, cutting down on connectors. This not only simplifies assembly but also makes it easier to maintain, lowers costs and enhances the overall design.”

He adds: “When it comes to modern transportation, especially in rapidly growing cities, composites offer advantages far beyond just weight savings. Their machinability lets us craft customised profiles that meet today’s demands. This doesn’t just make vehicles lighter; it also boosts durability and eases maintenance requirements, which is vital as population centres continue to expand and demand more from their public transport systems.”

Pultrusion enables large-volume production of uniform panels and profiles

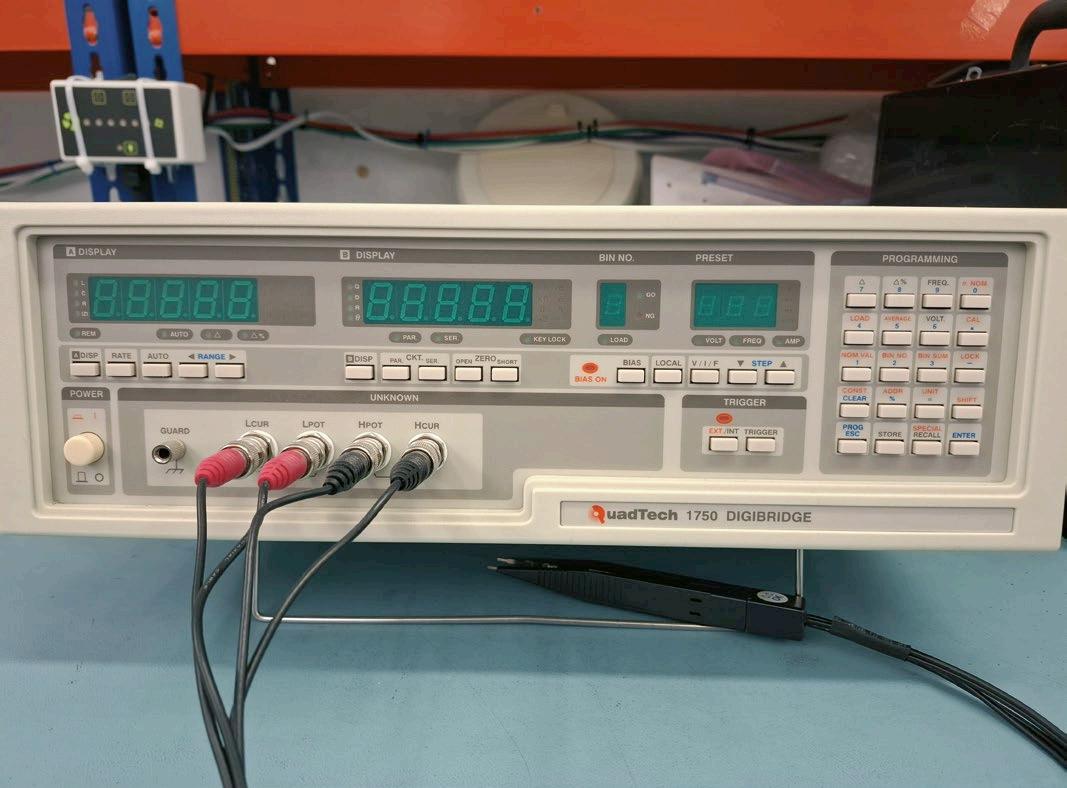

Electronics manufacturing from purchasing to finished product with a personal touch

Contract Electronics Manufacturing

Refurbishments Procurement Prototyping

Final Assembly Upgrades Test/Calibration

Electronic Repairs Box-Builds Cable Assembly

We specialise in smaller batches and products where processes cannot easily be automated

From motorsport to metal fabrication, permanent adhesive tapes are solving design engineers’ toughest

Creating a permanent bond between components is a fundamental engineering challenge, yet conventional methods often force designers to make difficult trade-offs.

For example, screws, rivets and other mechanical fasteners can be visually intrusive. Localised stresses can distort panels and each additional hole is another point of leakage, corrosion or cracking over the life of the product. Welding or bonding with liquid adhesives both provide strong, continuous joints, but each presents manufacturing challenges. Many of these problems are exacerbated by industry trends. In

Tape bonding creates a strong and reliable seal against dust and moisture in a single operation

tesa ACXplus has been used in place of screws and rivets to secure roof panels in HGVs

the transport sector, for example, the drive for greater efficiency is driving demand for lighter structures and components. This often means thinner panels and more difficult materials. Across all sectors, customers prefer products that have a clean, aesthetically pleasing appearance.

One approach that overcomes many of the limitations of older joining methods is the use of adhesive tapes. The new generation of highperformance, permanent adhesive tapes – such as the tesa ACXplus range – are now being used in a wide range of demanding assembly

applications across many industries. Tape can be applied quickly and cleanly, and its immediate handling strength enables short cycle times and straightforward production processes. Tape bonding creates a strong and reliable seal against dust and moisture in a single operation. The unique construction of tesa ACXplus offers several additional benefits. ACXplus tapes have a core of durable acrylic foam, up to 4mm thick as standard. The high density of this foam, compared to polyethylene foam and similar materials, gives ACXplus its superior strength. The foam also has viscoelastic properties that allow the tape to conform to

variations in the shape of the bonded components, ensuring a secure sealing bond even over long splices and large components.

In service, the viscoelastic properties of the acrylic foam allow tesa ACXplus tapes to accommodate movement due to differential thermal expansion. This helps maintain joint integrity during rapid temperature changes, even when the bonded components are different materials with different expansion characteristics. In addition, the foam layer provides excellent vibration absorption. This reduces sound transmission and helps protect components from the long-term effects of continuous vibration.

A leading manufacturer of heavy goods vehicle (HGV) trailers has adopted tesa ACXplus in various widths and formats to improve product durability, appearance and manufacturing productivity. The company is using 19mm and 12mm-wide tesa ACXplus 7812 tape to fasten load securing tracks to the inside walls of its trailers, for example. The tapes replace multiple screws that were previously required to hold the tracks in place. The

change has accelerated production, eliminating a fiddly and timeconsuming task for operatives.

Elsewhere across its product range, the company has introduced tesa ACXplus in place of screws and rivets to secure roof panels, interior kick plates and the exterior aluminium profiles for body reinforcement and protection.

Productivity improvements were also top of mind for a leading global supplier of engineered noise control products when it approached tesa to find a solution to a tricky

manufacturing problem in its range of soundproof doors. Stiffeners, used to provide rigidity to the product, were traditionally spot welded to the inside of the panels and doors. However, this method left surface marks that required extensive sanding and finishing to remove. The quality of the paint around the spot-welded areas was often below standard, resulting in rework and additional costs.

Working with tesa’s application engineering team, the company undertook a test programme to evaluate the use of 19mm tesa ACXplus 7074 in place of spot welding. The programme involved extensive testing on mock panels and doors of various lengths, thicknesses and widths of reinforcement. The performance of ACXplus was tested on original substrates under a wide range of temperature, weather conditions and mechanical impacts. These tests showed that tape offered strong and safe performance, while the reduction in the number of production steps required now saves the company more than 50 hours of manufacturing labour per month.

Permanent adhesives tapes offer an attractive solution to current assembly challenges. Rather than waiting for problems to arise, designers should specify a robust, reliable and efficient alternative at the design stage of their next project.

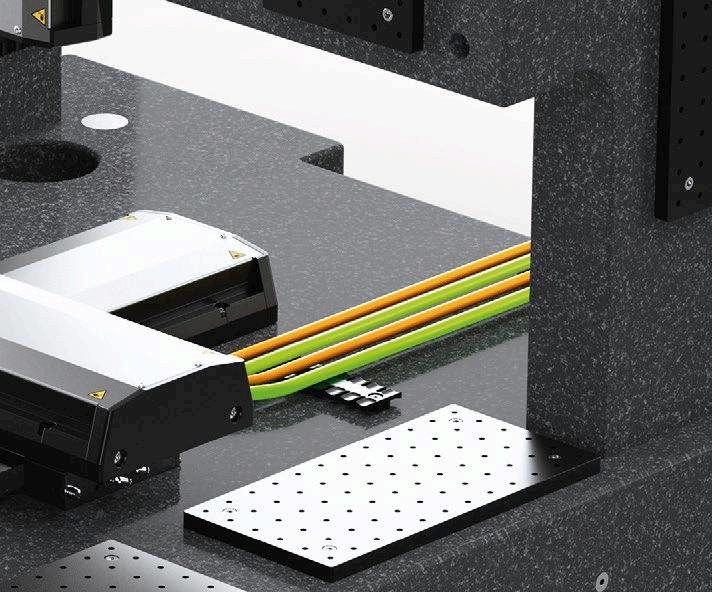

No matter the industry, effective cable management is crucial to maintaining a smooth and safe operational environment. Ensuring cables are properly organised helps to prevent hazards, extend equipment lifespan and minimise clutter on the factory floor. For 65 years, Norelem has been developing innovative products and technologies designed to meet the demanding requirements of machine and plant construction environments. The company’s product range is made up of more than 100,000 products, from aluminium profiles to cross tables and cylindrical pins. Now, the company has launched four new product families of cable fastening systems featuring fastening tape technology, which provides quick, flexible bundling and securing solutions.

“These systems offer significant advantages, with our fastening tape providing constriction-free mounting, preventing damage to cable insulation,” says Marcus Schneck, Norelem CEO.

“Both the fastening base and tape are reusable, enabling flexible reorganisation without generating waste. Additionally, the fastening tape is self-extinguishing according to UL94-V2, and the fastening base meets the UL94-V0 standard, ensuring high safety standards.”

Norelem’s new fastening base and tape system is designed for screw mounting wires, cables or hoses, enabling tool-free removal and insertion. The tape can be opened and closed hundreds of times, while also being suitable for direct mounting with countersunk screws. Described by the company as a ‘practical and adaptable’ solution, the tape is available in widths of 7.5, 10, 20 and 30mm, with lengths supporting clamping ranges from 4-100mm. As a result, the tape allows for easy adjustments and repositioning without

extra tools alongside the customerfocused benefits of cost-effectiveness and environmental consciousness.

For those working with aluminium profiles, Norelem also offers a base with fastening tape designed for mounting on Type I and Type B aluminium profiles. This version can be attached across or parallel to the profile groove with a 45° right turn. Available in widths of 10mm and 20mm and three lengths, the base accommodates clamping ranges from 4-60mm. According to Norelem, the product integrates ‘seamlessly’ with aluminium profiles, providing a secure and adjustable cable management solution for profile-based systems. Additionally, the tool-free mounting options save time and effort, thereby enhancing productivity and ease of installation.

Another of Norelem’s new innovations is fastening tape on a roll made from high-quality polypropylene. This hookand-loop tape roll offers a versatile solution for cable management, allowing customers to cut the tape to any length to fit specific needs. The

repeated use of the tape provides a flexible and sustainable option for organising cables. Available in seven widths, from 7.5-30mm, and in lengths of 15m or 25m, the tape can be easily cut to the desired size to offer flexibility for various applications.

Finally, the company’s new fastening strap features high-quality fastening tape with a welded plastic eyelet, making it easy to bundle and secure cables and wires. At 20mm wide and available in lengths from 170-600mm, the strap provides customers with the ability to choose the dimensions that meet their specific requirements, ensuring convenient and reliable cabling. Schneck adds: “These features mean that our customers benefit from secure, damage-free cable management that is environmentally conscious, adhering to high safety standards, while adding value to our customers by ensuring long-term performance and reliability in various applications.”

Proven performance with tesa® ACXplus by your side

For years, tesa® ACXplus has been the trusted, high quality permanent bonding solution for challenging applications in the special vehicles, rail, marine and metal fabrication industries, plus more. tesa® ACXplus acrylic core foam tapes support your need for design freedom and speed, while improving efficiency and productivity.

How can variable frequency drives help industry to make cost savings as well as secure environmental gains by reducing emissions? Louise Davis finds out

British electric motors and drives expert Invertek Drives has long known that a critical market differentiator for its products is the impact they can deliver in terms of energy efficiency and sustainability. Kes Beech, Technical Manager, says: “Invertek Drives is at the forefront of demonstrating how variable frequency drive (VFD) technology is pivotal in achieving significant cost savings and supporting environmental sustainability across industrial applications globally.”

Beech explains that, “One of the most compelling ways VFDs, such

as our Optidrive range, contribute to cost efficiency is through substantial energy savings. By precisely controlling electric motor speed to match actual demand, VFDs eliminate energy waste prevalent in traditional fixed-speed (Direct On Line) motor set-ups.”

What this translates to in realworld applications is potential energy savings of up to 50% in certain applications, such as pumping and fans/ventilation – a benefit that directly impacts the bottom line for businesses. “Furthermore, the smoother starts and stops facilitated by VFDs minimise mechanical stress

on the equipment, leading to reduced wear and tear. This leads to extended equipment lifespans and decreased maintenance costs, adding another layer of financial benefit,” Beech notes. Another advantage is the precise speed control through VFDs enables process optimisation, leading to increased productivity and potential cost reductions across various industrial operations.

Beech is also keen to point out that the merits of VFDs go beyond financial savings. “The environmental sustainability aspect of VFDs is equally important,” he states. “The reduced energy consumption resulting

from optimised motor control directly contributes to lower greenhouse gas emissions, playing a vital role in combating climate change.

“By enhancing the efficiency of motor-driven systems, VFDs empower industries to decrease their overall carbon footprint and advance towards a greener future.”