For over 40 years, the largest mining companies in the world have put their confidence in Richwood’s innovative material handling solutions.

When it comes to solving problems with dust and material containment, Richwood achieves success with engineered passive dust containment systems. Application-specific solutions optimize efficiency through sealed and protected load zones without the need for vacuums, filters or other additional equipment. The reduced wear and tear on equipment and controlled dust and spillage create a safer and more productive work environment. Worry free load zones are designed and built by Richwood every day.

What would it mean for your productivity if dust and spillage issues were eliminated? Contact Richwood today for a review of your application.

Rely on Richwood!

This first issue of International Mining Engineer for 2025 will appeal to those with an interest in managing and operating conveyor belts - an essential component of any mining operation. Two extended pieces explore the systems:: one from Fenner Dunlop (page 40) which looks at the optimum belt material, and another from Martin Engineering (page 24) looking at the structure's configuration. Following the recent US presidential inauguration, it would be remiss not to mention Donald Trump and how his pledges are likely to impact mining in the US. His tenure may also push the industry further down the AI route, as explored in a piece called Trump’s mining promise (page 18).

As everyone working in the industry will be well aware, mining machinery is heavy duty, technically advanced and very expensive. Funds required to finance a project are significant and many operators may not have the requisite cash flow, despite the potential dividends of a project being considerable.

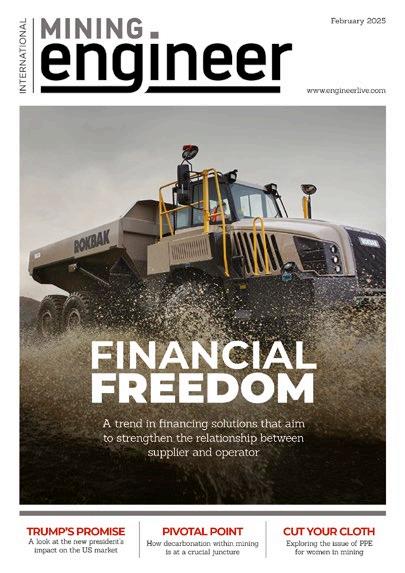

Our cover story, Financial freedom (Page 12), explores Rokbak’s new financing arrangement with West African dealer HMD and the benefits a mine operator might glean from deals of this sort.

The push to boost gender equality in mining is ongoing, and our piece on suitable PPE for women (page 32) looks at a report on the subject and makes the case for producing comfortable wellfitting wearables for women in the sector, thereby enhancing their wellbeing on the job.

Nicola Brittain Editor

16

Streamlined sorting

How XRT sorting technology has helped improve efficiency in a Mexican mine

OPERATIONS MANAGEMENT

18

20

Trump’s mining promise Exploring Trump's impact on American mining

The crucial ingredient Why IoT is the crucial ingredient for the successful digitisation of mining

Conveyor trough angles and skirt wear

The importance of conveyor trough angles for conveyorbelt design

SPECIALIST EQUIPMENT

30 Pivotal point

How mining’s decarbonisation transformation is at a pivotal point

HEALTH AND SAFETY

32 Cut your cloth

Exploring the issue of PPE for women in mining

34 Optimising sulphuric acid production

Boosting sulphuric acid with upgrades and new technologies

38 Alternatives to mining

An IEA report shows how recycling may impact mining activity

40 Breaking new ground

A close up on advances in conveyor-belt fabric

44 Shaft sealing optimisation

The case for double flush inlet configurations in mining operations

46 Size up the impact

Controlling top particle size in coal and bauxite mining

SHOW PREVIEW

48 Expomin Supporting the global mining industry

49 Bauma The European connection

PUBLISHER

Jerry Ramsdale

EDITOR

Nicola Brittain nbrittain@setform.com

DESIGN

Dan Bennett, Jill Harris

GROUP HEAD OF MARKETING

Shona Hayes shayes@setform.com

HEAD OF PRODUCTION

Luke Wikner production@setform.com

BUSINESS MANAGER

John Abey +44 (0)207 062 2559

SALES MANAGER

Darren Ringer +44 (0)207 062 2566

ADVERTISEMENT EXECUTIVES

Paul Maher, Iain Fletcher, Peter King, Adam Croft, Marina Grant Setform Limited, 6, Brownlow Mews, London, WC1N 2LD, United Kingdom

+44 (0)207 253 2545

Setform’s international magazine for mining engineers is published four times annually and distributed to senior engineers throughout the world. Other titles in the company portfolio focus on Process, Design, Transport, Oil & Gas, and Power.

The publishers do not sponsor or otherwise support any substance or service advertised or mentioned in this book; nor is the publisher responsible for the accuracy of any statement in this publication. ©2025. The entire content of this publication is protected by copyright, full details of which are available from the publishers. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior permission of the copyright owner. 48

FINANCIAL FREEDOM

A scheme that will strengthen the supplier / operator relationship

Protect your hydraulic cylinders from abrasive wear and premature failure with Seal Saver.

Seal Saver designs custom-fitted, lightweight flexible protective boots to keep your hydraulic equipment running efficiently in tough mining conditions. Each protective boot is resistant to debris, minerals, abrasions and installs in minutes.

Minimize Rod Scoring

Prevent Chemical Wash Pitting

Protect Cylinder Seals

Four Material Options Including Kevlar & Ballistic Nylon

10 Minute Install - No Disassembly Required

Aramine’s loaders have been designed with advanced energy management and predictive maintenance for a low-carbon future

Electric and battery powered machinery is taking centre stage as mine operators work towards reducing their reliance on fossil fuels. Mining equipment specialist Aramine is one company that has made significant strides in developing electric and battery-powered machinery. Its loaders, such as the L140B and L440B, are engineered for underground mining, where confined spaces and air quality pose unique challenges. These machines address emissions concerns while enhancing operational performance.

The loaders have been designed to be compact and manoeuvrable and so provide efficient navigation

The L440B loader, launched in 2024, exemplifies advancements in battery technology, offering improved autonomy and performance with a 4.6-ton tramming capacity

in challenging terrains. They have also been designed to operate quietly, reducing noise pollution and creating a safer environment for miners. The company explained that the modular energy module at the rear of the machine, allowing battery swaps in under 10 minutes, is one of the most salient features of the loader since it minimises downtime and facilitates the seamless electrification of mining sites.

The L440B loader, launched in 2024, exemplifies advancements in battery technology, offering improved autonomy and performance with a 4.6-ton tramming capacity, according to the company. The success of the L440B loader confirms the effectiveness of the company’s

strategy and drives efforts to expand the product range, supporting mining companies in their goal to lower carbon emissions.

The equipment integrates an energy management system that optimises power usage in real-time. These systems not only reduce energy waste but also extend machinery lifespan by preventing overuse.

Predictive maintenance features are another critical element of the loaders. By detecting potential mechanical issues before they escalate, these systems minimise downtime and repair costs. A spokesperson from Aramine argues that this aligns with the industry’s drive for cost-effective, efficient operations and ensures consistent productivity.

One of Aramine’s most innovative collaborations is with Tysilio, to introduce solar-power stations to remote mining sites. These containerised solar kits deliver 100% renewable energy, enabling the charging of electric equipment without the need for diesel generators. The stations are easy to deploy without extensive groundwork, making them suited to isolated locations. They also help to reduce operating costs and prevent around 100 tons of CO2 emissions annually compared with traditional diesel-powered systems.

Aramine’s initiatives are a ‘win-win for both the economy and the environment’, according to the company. Electric machinery offers substantial savings by lowering fuel expenses and reducing maintenance needs compared with

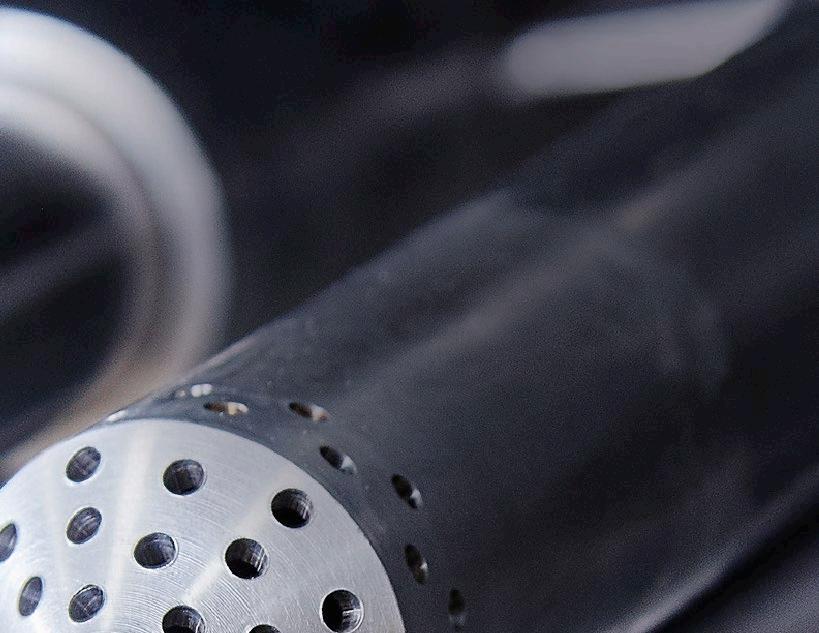

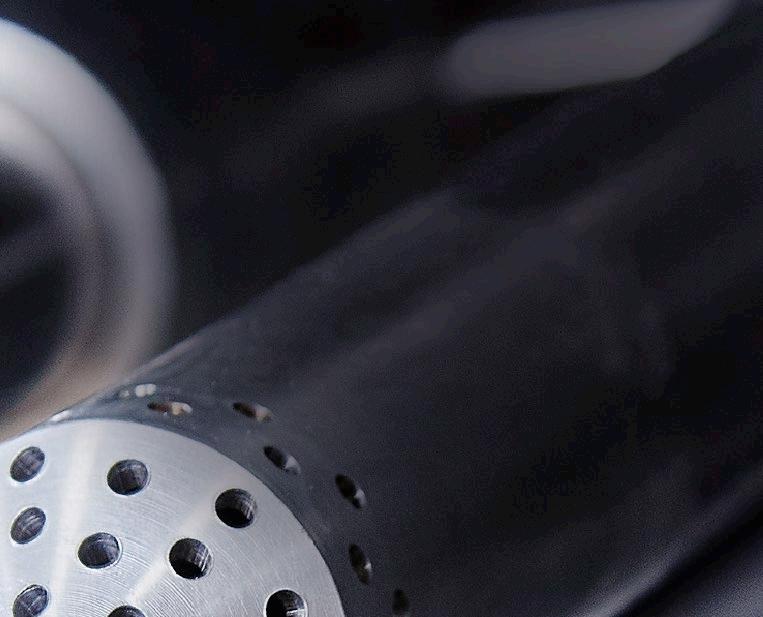

Close-up of the detachable energy module at the rear of the machine, which houses batteries for four to five-hour autonomy

diesel-powered alternatives.

Environmentally, these innovations help mining companies meet increasing regulatory and societal demands for sustainable operations. The company’s transition to cleaner technologies is a significant step toward minimising its environmental impact.

In addition to developing energyefficient machinery, Aramine is exploring ways to extend the lifecycle of its equipment components. For instance, batteries that are no longer suitable for mining operations can be repurposed for secondary uses, such as powering homes or offices.

This approach supports a circular economy, reducing waste and further enhancing sustainability. By coupling battery-powered machinery with renewable energy sources like solar stations, the company says it provides ‘a holistic solution to modernise mining practices’.

The L440B battery-powered mining loader, launched in 2024, with a tramming capacity of 4.6t

Aramine’s Smart Parts e-shop is a platform that aims to introduce a standard exchange system for energy modules, simplifying replacements and reducing costs for customers. This digital service underscores Aramine’s commitment to adapting its long-standing expertise to contemporary needs.

As the mining sector navigates economic and environmental challenges, Aramine remains at the forefront, championing innovations that combine energy efficiency with operational excellence. From pioneering electric loaders to developing renewable energy solutions and circular economy initiatives, the company is reshaping mining for a more sustainable future.

“We are proud to lead the way in responsible mining,” says Marc Melkonian, co-president of Aramine, and in charge of the equipment division. “These innovations are only the beginning. The enthusiasm from our customers inspires us to push boundaries and create more impactful solutions.”

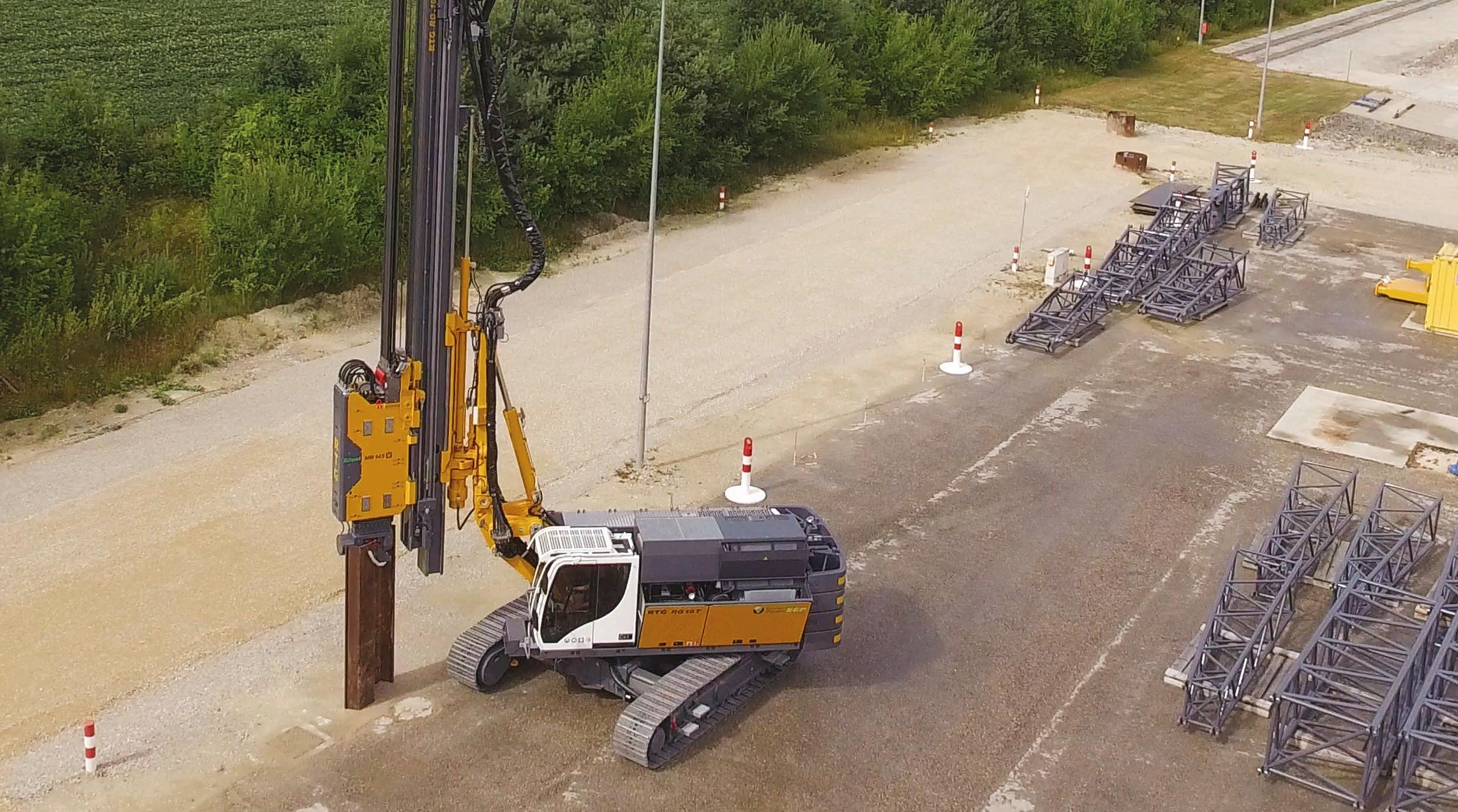

In recent years, inertial sensor solutions have been transforming the capacity, safety and productivity of global industries such as mining, structural engineering, and railway and its sensitive infrastructure (including bridges, tunnels, dams and power stations). In addition, the mobility, commercial vehicle, aerospace, agricultural engineering, transport and general shipping sectors all benefit from innovative sensor technologies, just as much as wind turbine, geothermal and other sustainable energy operators do. For these and similarly demanding applications, the German inertial sensor specialist ASC Sensors has developed a particularly robust range of high precision flexible sensors: the ASC OS series.

ASC Sensors has developed a particularly robust range of high precision, robust and flexible sensors - the OS series

From the benefits realised for these industries in challenging settings, it is a small step to expecting similar advances for the mining industry. This is particularly true since high-precision monitoring, guidance and control systems for drilling, excavation, stabilising shafts or modeling surfaces have been shown to improve results for mining operators. In addition, they will typically help achieve the desired outcomes faster, with less disruptions, overheating, wear and tear and the associated loss of time, effort and precious resources compared with traditional approaches.

MAX CAPACITY, ZERO COMPROMISE: 4.6 TONS, EMISSION-FREE*

Discover the perfect blend between performance and eco-responsibility: the L440B features a fully removable energy module at the rear, containing the LFP batteries & on-board charger. Changing batteries is now quicker than filling the fuel tank.

No changes required to mine infrastructure

Battery swap in less than 10 minutes

4-5 hours autonomy

The largest eshop for mining parts

*while operating

These sensors can also help with the testing of new machinery and component parts, to make them fit for demanding purposes and extend their life, with less investment. When maintenance is required, however, the appropriate sensor system helps predict the optimal point in time – before the occurence of a costly breakdown, replacement or accident.

Mining projects are frequently carried out in locations with extreme geological and climatic conditions, these might include deserts near the equator, polar circles, mountains, the ocean or rainforests. Therefore, beyond their precision and long-term stability, sensors utilised in these demanding settings must also be extremely robust.

As such, the ASC OS series for example, offers highly accurate uniaxial, biaxial and triaxial accelerometers to meet tough measuring tasks while enduring difficult conditions, according to the company. The sensors are based on two proven MEMS technologies and a capacitive operating principle. With available measurement ranges from ±2 g to ±400 g, the LN (Low Noise) models of the ASC OS series provide noise performance from 7 to 400 μg/√Hz. Their high signal-tonoise ratio, in particular, is required to demand the smallest frequencies and amplitudes. The MF (Medium Frequency) accelerometers provide measurement ranges from ±2 g to

±200 g while featuring a wide frequency response range of 0 Hz to 7 kHz (±3 dB), the design is robust with shock resistance of up to 6,000 g. In addition, the integrated electronic circuitry enables a differential analog voltage output of ± 2.7 V (FSO, MF) or ± 4.0 V (FSO, LN) and flexible power supply voltage from 5 (MF) or 6 (LN) to 40 VDC.

With operational temperatures ranging from -40 °C to +100 °C, the ASC sensors feature stainlesssteel housings with protection class IP68 and an integrated cable of configurable length with connectors. This compact, hermetically sealed housing has been designed to make the OS series suitable for tough applications and environments, such as mining or geothermal energy drilling as well as other deep and surface drilling, high-frequency sheet pile vibrating/driving, ramming, pressing, hydraulic hammering, trench cutting or soil mixing techniques.

In all these endeavors, the use of appropriate sensor technology to ensure precise results is of crucial importance. Knowing exact drilling paths or working patterns, and keeping neatly to them, is essential. This is also true of shock and heat resistance, to prevent strong vibrations and high temperatures from skewing measurements and outcomes.

In addition to its own capacitive sensor solutions, ASC also represents highperformance servo quartz-based accelerometers manufactured by Japan Aviation Electronics Industry, Ltd (JAE). These, too, feature high temperature ranges, significant shock and vibration resistance as well as low/ medium measurement ranges. Their resolution of 1 µ g, low noise and long-term stability of scale factor and bias makes them ideally suited for inclination measurement and other highdemand applications in mining and geological drilling, according to ASC.

A partnership with the company means that clients now benefit from the combined portfolio of inertial sensor solutions as well as ‘thorough customer service’ this is conducted through one supplier, which helps to add business value and minimise risks for mining operators and adjacent sectors.

The author, Oliver Stohlmann, is a global communications leader with more than 20 years’ experience of working for several of the world’s premier life-science corporations.

For over 45 years MMD have remained at the forefront of Sizer technology. Combining unrivalled technical expertise, innovation and experience, we develop tailored solutions for a wide variety of materials and applications.

The Twin Shaft MINERAL SIZER™ is a high capacity, reliable and compact machine suited to mobile and semi-mobile systems. The consistent product size and minimal fines generation, together with the ability to process any combination of wet, sticky, hard or abrasive material, has been a successful formula for thousands of surface and underground installations worldwide.

We have developed the Sizer’s range to be able to process harder materials, and delivered solutions for in-pit bulk ore sorting – building upon the Sizer’s inherent efficiency and sustainability credentials.

Learn more about how we can support your operations towards a safe, efficient and sustainable future.

Discover our PRODUCTS +

A new financing solution will help strengthen the relationship between supplier and operator, Nicola Brittain reports

Arecently-signed partnership between articulated hauler manufacturer Rokbak and west African equipment dealer HMD, will provide financing solutions to mining operators in West Africa. This is part of a wider trend towards using such options. The solution is backed by Export Credit Agencies (ECAs) and Private Risk Insurers (PRIs) to West African projects. To date, HMD has introduced the Rokbak brand to Nigeria, Ghana, Senegal, Benin, Guinea and Côte d’Ivoire.

Over the last few years, asset financing has seen significant market growth, with companies embracing the opportunity to procure essential equipment required to maintain competitiveness. The number of businesses in the financial leasing industry in the UK grew 1.3% per year on average over the five years between 2018 and 2023, while helping commercial businesses, nonprofit and government organisations acquire the equipment they need is now a US$1tn industry in the US according to the Equipment Leasing and Finance Association.

Rokbak’s financing scheme will be used to fund solutions for the company’s ADTs, the RA30 and RA40, which have proven “a strong fit for West Africa’s challenging landscapes”, according to the company. The main applications for Rokbak’s products in the region are mining, quarrying, infrastructure and general construction projects.

Financing solutions like these are a practical way of financing a project when a company’s credit is weak or the project is too large. They can also help reduce the financial burden of fleet expansion with affordable

interest rates, extended repayment periods and structured payment plans tailored to meet the demands of mine operators. This support is particularly valuable for projects requiring multiple ADTs or complete fleet solutions, allowing growing businesses to enhance their capabilities with highquality equipment.

The scheme will be offered in addition to rental options where a company doesn’t want to take on the total cost of ownership.

International Mining Engineer asked Paul Culliford, Rokbak’s regional sales manager for EMEA & LATAM what had driven the move into West Africa. Culliford said: “If you look at Nigeria alone, the mining sector is estimated to have 44 types of commercially viable minerals worth an estimated US$700bn. So it’s a huge market in general at the moment. Rokbak is just starting out in the area so it’s all quite new to us.”

Such financing solutions also strengthen the relationship between operator and supplier as Culliford explained: “Once the haulers have been provided, the customer will benefit from after sale services with parts and maintenance.” He continued: “This will include telematics providing a customer with a deep understanding of how the machine is operated. This information might include hours of operation, the time its working and idle and the maintenance periods of the machine. The customer will also be provided with various things like fuel costs and downtime.” He concluded: “The customer is looking for the overall productivity of the machine, not just the actual machine itself.”

Paul Douglas, managing director of Rokbak said of the scheme: “The availability of flexible financing opens up new opportunities for customers across West Africa to access dependable Rokbak machines.

Financing solutions are particularly valuable for projects requiring multiple ADTs

Together with HMD’s local expertise, we are helping businesses to take on major projects with the right tools and resources.”

The offer of financing backed by ECAs and PRIs is just one element of Rokbak’s long-term growth strategy in West Africa. The company is also working hard to strengthen local partnerships, increase brand visibility and provide operator training programmes.

“We see huge potential for Rokbak in West Africa,” Culliford concluded. “Our aim is to be more like a partner than a suppplier; we are commited to establishing a lasting presence in the region.”

The number of businesses in the financial leasing industry in the UK grew 1.3% per year on average over the five years between 2018 and 2023

New models from hauler manufacturer Komatsu promise increased fuel efficiency and improved torque

Hauler manufacturer Komatsu has launched a new generation of wheel loaders, the WA475-11 and WA485-11. These models come equipped with new technology and offer ‘great performance, efficiency, and operator comfort’, according to the company.

The Dash 11 generation wheel loaders are fitted with a Komatsu diesel engine characterised by high torque in the low-speed range. The engine is combined with a Komatsu-designed hydro-mechanical-transmission (HMT) which enhances performance, power reserves, fuel efficiency and ease of operation for transport and loading tasks.

The WA475-11, for example, demonstrates a 14% improvement in fuel efficiency over its Dash 10 predecessor, while the WA485-11 benefits from a 29% increase in fuel efficiency compared with its predecessor the WA480-8.

Thanks to a constant variable gear ratio, the engine always remains in an efficient fuel zone. Variable speed control makes it possible to individually adapt the machine’s maximum speed to the requirements of the job site. The adjustable variable traction control effectively limits wheel spin in difficult ground conditions.

Compared with its predecessor the WA480-8, the WA485-11’s payload and bucket capacity have been upgraded too. All machine components have been adapted to a permanent payload of 8,800 kg and can be increased to 9,300 kg in an aggregate handling variant, which helps reduce the number of loading cycles required depending on the vehicle size.

The new wheel loaders have advanced emissions control systems, which meet EU Stage V standards. In addition, the well-proven Komatsu exhaust

The optimised Z-bar linkage offers up to 20% more lifting power and a higher production rate of tons per hour

system includes a diesel particulate filter (KDPF) which, together with the Selective Catalyst Reduction (SCR) system, further reduces NOx emissions using AdBlue. These technologies, in conjunction with the particularly lowemission combustion, mean the diesel particulate filter need only be replaced every 8,000 hours; this interval can be extended even further by using particularly low-ash engine oils.

Another new feature is the variable power control, enabling the lifting speed to be controlled independently of the accelerator pedal.

The optimised Z-bar linkage offers up to 20% more lifting power and a higher production rate of tons per hour. Good lifting speed and machine stability help to increase productivity, especially in tight V-shaped loading applications. In addition, the hydraulic response time and the tipping or lifting speed can be adjusted to specific application requirements.

A spacious cab offers all-round glazing and has an interior noise level of just 70 dB(A). The heated rear window is angled, which effectively prevents dirt from sticking on the rear screen. The lever console has a new command control switch and is adjustable on a 5-way axis for each operator. The increased internal air pressure prevents dust and other particles from entering the cab. For easy and safe entry and exit, both machines are equipped with a rearhinged door, angled steps and large handrails.

A magnetic separator can help mine operators identify and remove tramp metal in the early stages of a project

Tramp metal exists in all mining and quarrying operations and the problematic contamination is difficult to avoid. The nature of mining and quarrying - extracting ore and aggregate using large heavy equipment - results in a wide variety of tramp metal contaminating the mined material. Such metal needs identifying and removing before potentially causing costly damage to processing equipment (such as crushers, screens, and conveyors). Additionally, for many mining operations there is a maximum metal contamination content in the mined ore specified by the endcustomer (especially in coal supplied for power stations).

Understanding the source and nature of the tramp metal is the first stage in the process of effective removal. The definition of ‘tramp metal’ is any item of rogue metal not naturally present in the mined ore or quarried aggregate. Such contamination includes digger teeth, pit props, blasting caps, nuts and bolts, and metal originating from the wear and tear at the process plant.

The nature of the rock, the process, and the tramp metal dictates the optimum metal contamination solution. The two technologies commonly used in mining and quarrying operations to prevent processing plant damage from tramp metal contamination are magnetic separators and metal detectors.

Magnetic separators parse magnetically-susceptible tramp metal (e.g., steel and iron), automatically removing the problematic contamination from the rock. Selection of the optimum magnetic separator design for any given application is determined by the process and material specifications.

Whereas magnetic separators find and remove tramp iron, metal detectors focus on identifying all metal contamination. The detection of metal occurs through the disturbance of a magnetic field produced by a metal detector’s coil. Detection of the presence of tramp metal sends a signal to the remotely located control.

On receiving the signal, the control either stops the conveyor and initiates an alarm; sets off a diverter gate to reject a batch of material; or turns on the following overband or suspension magnet.

In many large volume mining operations, stopping the conveyor is not an option. In such installations, a section of metal-contaminated ore diverts into a collection area, where the rock is either manually checked for metal or sent through a separate secondary system for tramp metal location and removal.

The removal of tramp metal is often critical since damage to crushers, screens and conveyors disrupts and even stops production, at a huge repair and downtime cost. Failure to meet end-customer specifications for tramp metal content, especially in coal-fired power stations, may result in costly financial damages or even the rejection of shiploads of material.

Exploring how XRT sorting technology helps to keep Koura’s Las Cuevas operation efficient

Koura Mining Operations has chosen Tomra Mining’s XRT sorters, The COM Tertiary XRT and the COM 1200 XRT to help remove waste from their feed at the Las Cuevas fluorspar mine in Mexico. The operator will also benefit from the support of Tomra’s Mining’s Applications and Service teams. Commissioning of the new sorters is planned for early 2025.

Koura supplies high-purity metspar and acid spar products from the Las Cuevas fluorspar mine in San Luis Potosí, Mexico, one of the world’s largest and most productive fluorspar sources. Koura has agreed to install two X-Ray Transmission Tomra Mining (XRT) sorters at the mine with a view to significantly reducing silica and calcium carbonate content in their run-of-mine material to improve processing efficiency and increase the quality of their fluorspar product.

Koura is responsible for over 20% of global fluorspar supply and the partnership reflects a decade-long relationship built on ‘advanced

technology and dedicated service,’ according to the company. Koura also uses Tomra’s Color sorters at its San Luis Potosí processing plant and the Las Cuevas mine to remove calcium carbonate waste from its fluorspar feed using sensors. Tomra’s XRT sorters were installed in late 2024 and are due to begin operating imminently. The company expects them to reduce costs and environmental impact through minimised water and chemical consumption.

The sorting of fluorite is relative to the end use of the concentrate: MET Grade requires fluorspar to have a grade of 80-85%, with less than 5% silica and carbonates. Acid-grade fluorspar should have a grade of above 95% with less than 1% of carbonates and silica. A combination of sorting and flotation yields these grades, and in most applications, sorting or some type of preconcentration is a necessity. Most fluorspar mines in the world

are seeing their grades dropping below 40%. Tomra sorting can raise these grades to close to 80% in most applications with a considerable removal of carbonates and silica, and without the need to consume high volumes of water. Additionally, the benefits will be also realised during the flotation process, with lower costs due to the preconcentration.

Fernando Romero-Lage, Latin American sales manager from Tomra said: “We count on production-ready machines in our full-scale pilot plant testing warehouse, and we can precisely evaluate the suitability of sorting in any mining application. We apply different sensors to improve the grade without detriment to the recovery of the mineral: X-ray transmission, laser, optical, induction, and near-infrared. After testing for sensor suitability, we proceed with a full-scale test and we can guarantee the performance of the machine after these tests.”

TOMRA XRT technology recognises

and separates fluorspar from carbonates and silica based on its specific atomic density. The sorters use a cutting-edge X-Ray module with Duoline sensor technology to measure spectral absorption information. TOMRA Sorting’s proprietary high-speed X-Ray processing unit uses the data to produce a detailed “density image” of the material. The result is a high level of purity in sorting materials, irrespective of size, the degree of moisture or surface pollution present. In addition to these higher X-ray detection capabilities, TOMRA XRT sorters benefit with the addition of Obtain, a deep learning technology that enables precise detection and classification of individual particles, even when clustered. It brings single-particle precision and higher-throughput sorting, according to the company.

For further information visit: www.tomra.com

Drilling down several thousands of meters requires high-tech tools and equipment. Equally crucial is the appropriate sensor technology, to keep to the exact drilling path for precise results. So are shock and heat resistance to prevent strong vibrations and high temperatures from skewing measurement outcomes while drilling through the rock strata.

For the geothermal energy industry, this is enabled by ASC inertial sensor technology. Our portfolio includes high-end JAE quartz-based JA-5 and JA-25 accelerometers particularly suitable for this purpose. In addition, MEMS-based ASC OS-series accelerometers conduct accurate, stable vibration analyses on machines like hydraulic deep drilling vibrators for soil inspection and preparation, to keep them running smoothly and prevent damage.

asc-sensors.de

Measurement While Drilling (MWD)

What will another four years mean for the American mining industry? Saskia Henn reports

So it’s official, Donald Trump has been inaugurated and is back in the White House for another four years. But what does this mean for the American mining industry?

While the US is somewhat dependent on foreign critical mineral supply chains, the mining industry is still very active within the country itself.

Coal is a frequently mined commodity in states such as Wyoming, West Virginia, Pennsylvania, Illinois and Kentucky. Copper is another common material, found in Arizona, Montana, Nevada, New Mexico and Utah. Other minerals commonly found in the US include gold, iron ore, lithium and uranium.

“One of the common misconceptions among policymakers and much of the public is that the country doesn’t have the mineral resources to secure its own mineral supply chains,” said National Mining Association’s (NMA) senior vice president of communications Ashley Burke.

“The US is, in fact, mineral rich but what we have lacked is the focused, coherent policy to turn mineral potential into mineral production.”

This prolific collection of minerals has many Americans pushing for domestic production.

With Trump back in power, mining operators will likely face further deregulation of the mining industry to promote American blue-collar work and independence from foreign supply.

“Deregulation will be central to everything we see, particularly in contrast with the regulatory overreach of the past four years,” said Burke.

One of the countries the US will likely distance itself from is China, which currently accounts for over half of the world’s refining of aluminium, lithium and cobalt, as well as a majority of rare earth metals.

Trump’s decoupling from China will take the form of tariffs on 60% to 100% of goods from the country on top of his proposed blanket tariff on all imports of up to 20%.

This could pose challenges for American mining companies that are still reliant on foreign supply chains, as well as Americans purchasing the

final, likely more expensive, product. However, Trump has been consistent in his belief that American companies should reshore and there will likely be a focus on that.

“Beyond any specific country or threat – we need to focus on building up our domestic mining industry and strengthening our supply chains within them so we can truly fulfil our minerals and energy potential,” said Burke.

Trump will likely pursue deregulation of land and permits, expediting processes where possible to encourage this.

At a Minnesota rally in July, Trump

British-Australian mining company Rio Tinto is a good example of an organisation that is using AI to enhance its business. The company has made headlines most recently because of its collaboration with space exploration company Fleet Space to develop 3D subsurface maps that will advance exploration at the Rincon Lithium Project in Argentina.

Drawing subsurface maps is a particularly useful skill Rio Tinto frequently uses at 98% of its mines with its own technology, the Rio Tinto Visualisation Tool (RTVis).

RTVis allows the company to

Beyond any specific country or threat – we need to focus on building up our domestic mining industry and strengthening our supply chains

vowed to undo Biden’s 20-year mining ban in Minnesota’s Boundary Waters, stating, “I will reverse the Biden-Harris attack on your way of life and we will turn the Iron Range into a mineral powerhouse like never before.”

The US will also need to harness mining technology to keep up with competitors. Artificial Intelligence, for example, is rapidly infiltrating many aspects of the mining industry. A 2024 survey by data analytics company GlobalData showed over 80% of employees at major mines think AI will noticeably impact their mine in the next decade.

visualise surface and subsurface features and collect detailed information about an area. Such visualisation helps achieve better drilling and blast accuracy, reduced explosive use and better waste classification.

AI can also assist in environmental protection, which is becoming a requirement for many mines worldwide. When mining bauxite at Weipa in Australia, Rio Tinto also uses AI to gather data about nearby Palm Cockatoo nests and develop a plan of long-term protection. As the United States hosts a number of endangered species, finding an automated, efficient way to document potential hot spots could save countless resources.

Alistair Macleod, CEO of tech company Ground Control, tells us why the use of IoT is essential for the successful digitisation of mining

In recent years, the global mining industry has experienced an upswing in the commodity cycle, with relatively stable or rising prices. While not yet at the dizzying heights of some super cycles of the past, a sense of cautious optimism has returned. Lessons from the leaner years, when debt accrued and shareholders demanded greater returns, have resulted in stronger financial discipline and steadier attitudes across the sector. Today, the industry appears well placed to withstand challenges such as geopolitical instability, as well as the lingering effects of Covid-19 on global supply chains.

At the same time, however, another fundamental shift is taking shape: the rapid digitisation of mining. Although the sector is often portrayed as conservative and slow to innovate, recent research [1] shows that most mining businesses have either trialled or deployed IoT-based solutions.

Yet for all the excitement, many IoT initiatives stall at the proof-ofconcept stage. According to Alastair MacLeod, CEO of Ground Control, a tech company that uses satellite and cellular technology to connect people and things, “the greatest barrier to success is connectivity.” Here, he explains more.

Stable, continuous data transfer is crucial for fully realising IoT’s potential in mining. Yet in remote regions, conventional networks - be they cable, radio or cellular – can be patchy or non-existent. Historically, satellite alternatives have also been limited by uneven coverage and variable speeds. However, nextgeneration constellations are now reshaping the satellite landscape, promising greater reliability and more consistent performance, even in the harshest locations.

Furthermore, options are now available to utilise networks that bridge satellite and cellular networks, helping to maintain secure data flows under difficult conditions. From early-warning sensors and automated equipment to health and safety wearables, the ability to continuously capture and transmit local sensor readings ensures they can be shared and analysed in real time, no matter where operations take place.

Imagine mines where real-time, robust data is the driving force behind every decision - transforming operations from reactive to predictive. This is a possibility since advanced IoT systems monitor equipment performance continuously, identifying potential maintenance needs long before a breakdown occurs and reducing costly unplanned downtime. Energy usage is optimised through intelligent systems that adapt to demand, minimising waste and lowering operational costs. Supply chains, often burdened by inefficiencies, are streamlined as data-driven insights enable precise inventory management, timely resource allocation, and improved logistics coordination. The result are mining operations that are leaner,

more efficient, and better positioned to maximise profits in an industry where margins are under constant pressure. These advanced capabilities not only enhance productivity but also create a resilient operational model capable of adapting to changing market demands and environmental challenges.

But this isn’t just about efficiency and logistics. Connectivity is rewriting the rulebook on many levels. Take worker welfare, for example. Now, IoT-powered wearables, such as smart helmets and health trackers, are revolutionising safety in remote and hazardous environments. These devices continuously monitor workers’ locations, vital signs, and exposure to dangerous conditions like toxic gases or extreme temperatures. Should an

incident occur, real-time alerts enable rapid response, potentially saving lives. IoT tracking technology enhances this by creating a connected safety net across the site. Real-time location tracking ensures that no worker goes unaccounted for, especially in expansive areas or other operations where isolation is a significant risk. This system provides instant visibility of every team member’s whereabouts, allowing for swift coordination in emergencies, such as evacuations or accidents.

Though the mining industry holds bright prospects for digitisation, the road to full-scale IoT deployment has been anything but smooth. While many companies pursue digitisation to boost efficiencies and reduce costs, a notable number also see it as merely a way to improve safety and ESG

performance. And so despite these promising beginnings, extending IoT across the entire enterprise remains an uphill battle. According to research by satellite service provider Inmarsat, only a fraction of the mining firms that trial IoT technologies successfully scale them throughout their operations. Common barriers include limited capital, interoperability challenges, inadequate digital skills, and, most critically, inconsistent connectivity.

The good news is that these teething problems are not insurmountable. By collaborating with a strategic partner that invests in the right combination of next-generation satellite and terrestrial connectivity infrastructure, while employing a phased technology roll-out, companies can overcome the unreliable network issues that have hitherto hindered progress. Couple

that with an investment into digital skills and training – which may involve upskilling staff, certifications and on-the-job learning opportunities – and you’re on track to build a digital mine of the future set within a culture of continuous learning and innovation.

The mining environment typically involves a mix of legacy equipment and modern IoT devices, creating a patchwork of technology that must work in concert. And while interoperability and integration challenges may occur during the infant stage of a mine’s digitisation, open standards and scalable platforms can allow diverse systems and devices to communicate effectively. By choosing IoT solutions that are modular and easily integrated with existing infrastructure, mining operations can avoid technological lock-in and reduce complexity.

Choosing modular IoT solutions helps prevent technological lock-in

The possibilities of IoT in mining are vast, with potential strategies emerging to overcome persistent challenges. For instance, a remote mining operation could partner with a connectivity provider to establish a multi-network solution. By deploying a combination of satellite and cellular connections, such a mine might achieve a continuous data flow from its machinery and environmental sensors without interruption. This seamless integration opens the door to enhanced predictive maintenance strategies that significantly reduce downtime while enhancing safety monitoring of tailings storage and surrounding ecosystems.

The future of mining hinges on a bold digital transformation. Embracing IoT at scale, backed by resilient connectivity and a culture ready for change, will redefine the industry. With strategic investments in infrastructure and skills, mines will rapidly shift from proof-of-concept to full deployment. As next-generation satellite constellations mature and IoT platforms advance, the entire industry is gearing up for a transformative revolution.

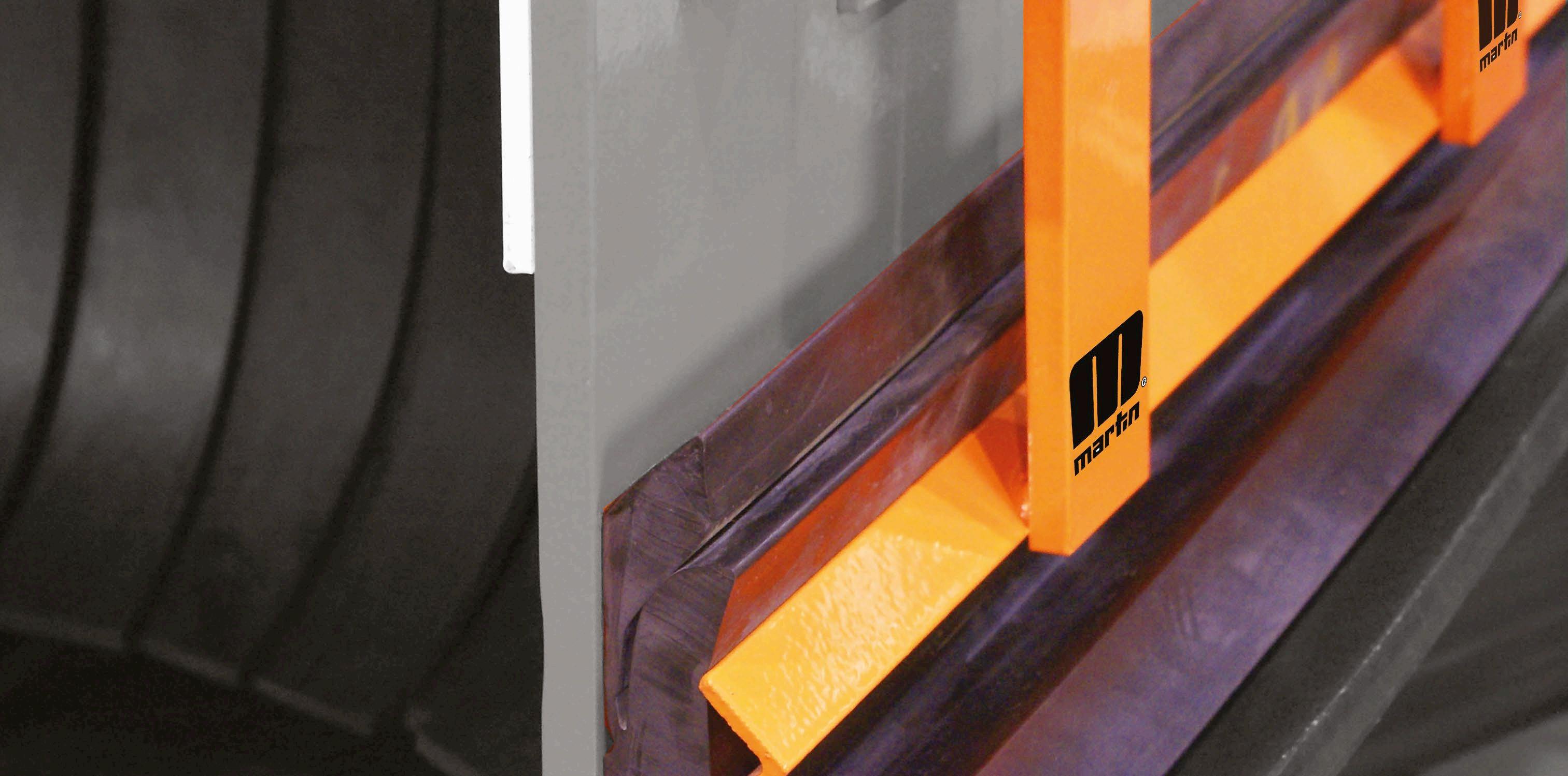

Todd Swinderman from Martin Engineering explores the importance of getting conveyor trough angles right when designing a conveyor belt system

Belt conveyor trough angles are not an arbitrary matter of ‘preference,’ they are based on precise decisions made according to several operational factors. Material size, the way it settles when loaded (angle of surcharge), and how it centres when the full trough angle is achieved are all factors that need to be considered both in the initial design and during retrofits.

The selection of the conveyor belt trough angle is also a compromise between the belt width, the skirtboard width, liner wear, throughput and the desired reduction in spillage. The balancing of these variables is important for reliable and safe operation over the long term. Failure to examine this issue may result in lower capacity, increased liner wear, excessive spillage and belt damage.

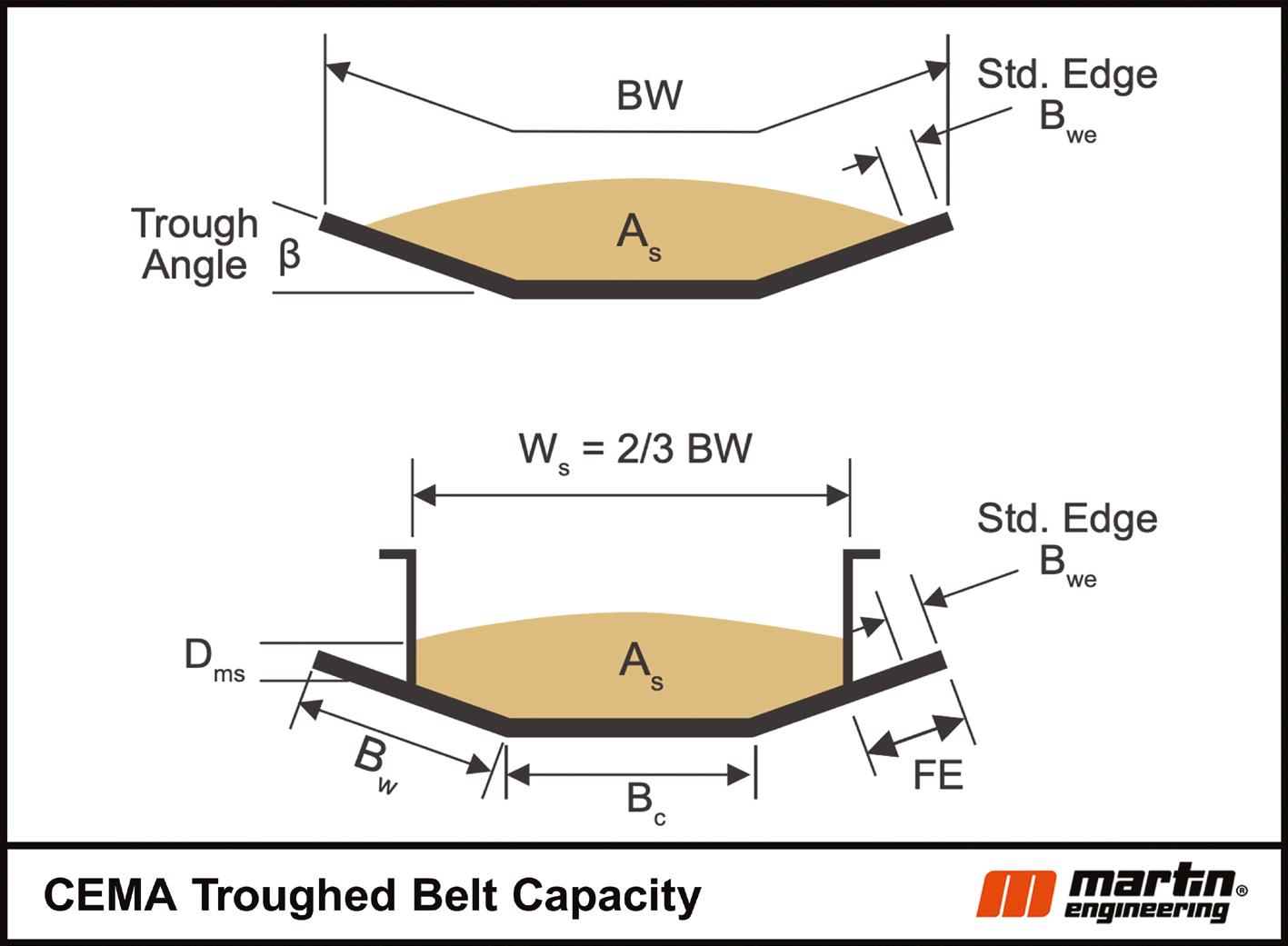

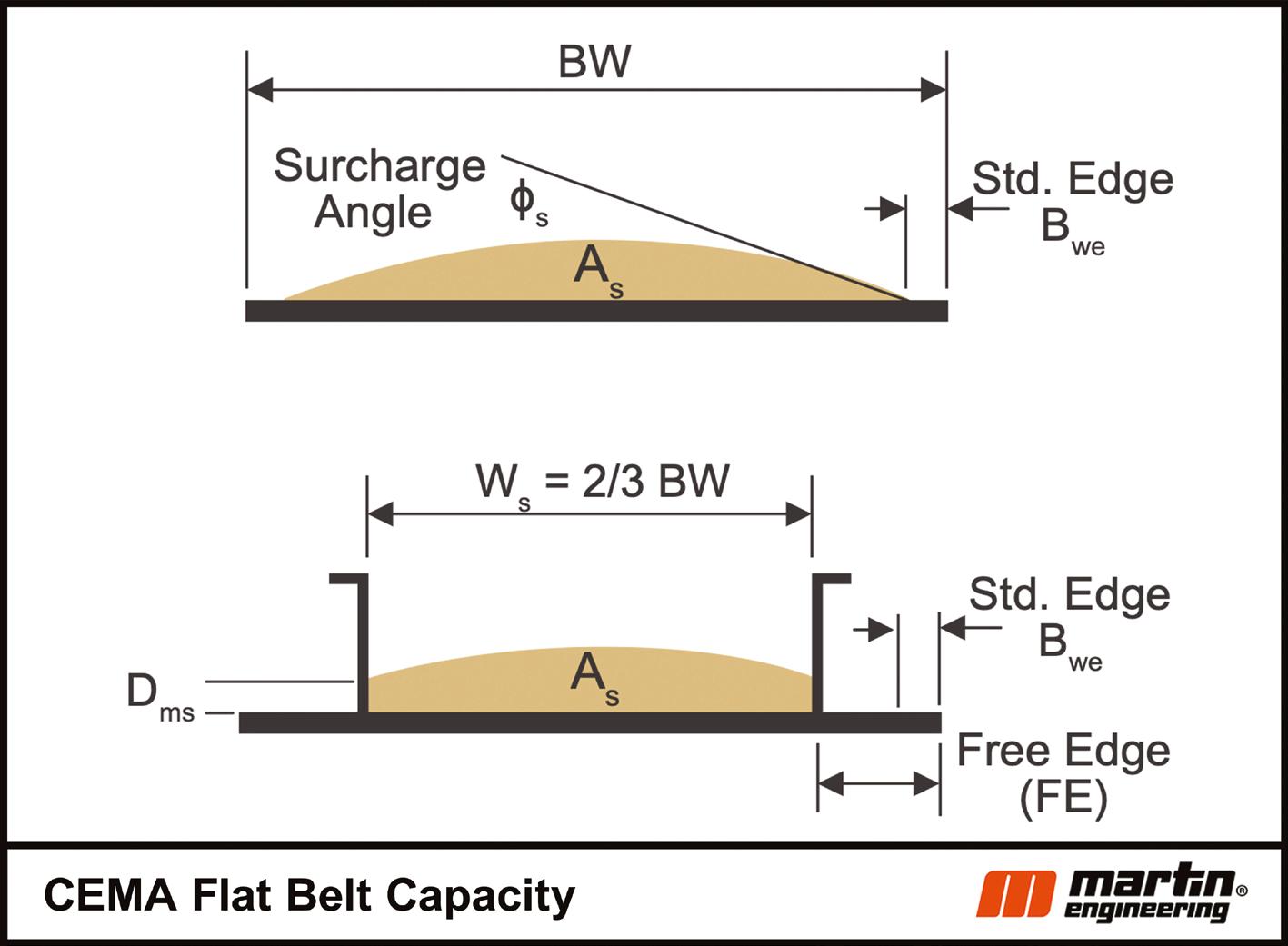

In Chapter 4 of Belt Conveyors for Bulk Materials, 7th edition published by The Conveyor Equipment Manufacturers Association (CEMA), there are dimensionless ratios developed so that any 3-roll idler configuration can be evaluated.[1] The CEMA terminology is being used in this idealised analysis of the loading chute cross-section.

For simplification, the thickness of the belt and skirtboards are assumed to be zero, which is customary in bulk

material conveyor belt engineering. The tolerances this introduces are minimal compared with the normal variations in the material’s bulk density and other factors such as loading and weather which affect throughput. Only one configuration of belt width geometry is studied but the method applies to any belt troughed by three roll idler sets. Similar ratios can be developed for non-standard idlers with more or less than three rolls. The detail of interest is the belt’s Free Edge (FE) that is

available for the sealing system and belt mistracking. [Fig 1 & 2]

The theoretical CEMA crosssectional area that a particular arrangement can convey is called the “CEMA Standard Area” (As). The area is developed using the standard edge distance and the bulk material surcharge angle. The top surface of the Standard Area is a circular arc tangent to the surcharge angle beginning at the Standard Edge Distance, Bwe.

The standard edge distance is calculated through a formula and is intended to prevent material spillage from the belt as it sags between the widely spaced carrying idlers outside the load zone but not to determine the width of the skirtboards. The FE width of the skirtboards should be based first on reducing spillage by having adequate room for a side sealing system and secondly on how much bulk material is rubbing on the inside of the skirtboards or wearliners. [Figure 3]

While holding the skirtboard width ratio constant, the change in trough angle results in decreasing free belt edge as the trough angle increases, while the standard cross-sectional area, As, increases with a larger trough angle. The results for the four common trough angles are shown in Figure 4. The CEMA mistracking allowance is based on the dimensions of the standard CEMA idlers and pulleys.

standard cross-sectional, As, area by 15% and provides recommended ranges of belt speeds for different materials and applications. The best approach is to base the belt width and speed on the life cycle cost and not on the price of installation. When increasing the cross-sectional area or belt speed, confirm that the existing belt, idlers and structure can handle the increased load. The design options of a new system dwindle as the price outweighs the cost.

By applying the traditional 2/3 belt width rule for the skirtboard widths and loading the conveyor at the CEMA 100% full (As) cross-sectional area, designs can stay competitive and efficient. Not applying these principles results in material continuously rubbing on the internal structure walls, prematurely eroding them and causing more spillage. The height of material rubbing on the skirtboards or wearliners is called Dms in CEMA terminology. The theoretical Dms is 40 mm and for the 20-degree troughed belt and Dms is 73 mm for the flat belts used in this article.

In Figure 4, the trough angle affects the free edge and therefore the space for the sealing system. In addition, mistracking becomes problematic for 35- and 45-degree trough angles. A common low-cost OEM sealing system consists of an internal wear liner, a vertical external seal and angle iron clamps. The seal clamping arrangement needs to clamp close to the bottom of the skirtboards to reduce seal deflection. As the trough angle increases, the space available for the clamp decreases, raising the danger of the clamp rubbing on the belt and damaging it.

The external seal is typically a 13mm thick rubber slab. A common problem with OEM sealing systems is the skirtboard and liner are often spaced well above the belt leaving the rubber seal to contain the material pressure. This means the cargo is

continuously rubbing on the liners or exerting pressure on the seal. This prematurely erodes the rubber seal and wearliner resulting in leakage and belt damage. Material trapped in the space between the liner and the seal can cause belt grooving requiring more frequent cleaning and maintenance attention.

The capacity (cross-sectional area x belt speed x bulk density) rises by increasing the trough angle but often this is the only consideration when upgrading. Spreading the distance between the skirtboard walls reduces the available free edge and widening the belt increases the initial price. The solution is often to increase the belt speed while holding the tons-perhour constant. This lowers the crosssectional area needed to convey the same volume at the slower speed.

CEMA recommends reducing the

While a little more spillage may seem to be a minor cost compared with the next wider belt, consider the lifetime of additional cleanup and maintenance costs. Although there are other causes, spillage and wear are directly proportional to the square of the belt speed. There are also labor and replacement component costs, as well as indirect costs associated with more frequent cleaning and maintenance.

Recent projects applying the principle of long-term cost over initial installation price resulted in an increase of 25% to belt life, 40% to idler life, 60% reduction in cleanup. Improving the access to transfer points made maintenance easier and faster which is widely acknowledged to drastically increase workplace safety.

Almost invariably the capacity is expected to increase to meet production demands over the life of a conveyor system. If operators anticipate that production capacity may need to be increased, they should consider future production needs early and factor those into the original design. Rather than derating

Seal the Deal in Record Time with Our High-quality Packing

Experience the power of prompt deliveries! Order today and we will ship your packing the same day, ensuring you get the reliability you need precisely when you need it. On the rare occasion your item is not in stock, trust us to deliver within 14 days, maintaining our commitment to efficiency and quality.

High Temperature and High RPM applications. Chemical applications. Power generation applications including Condensate and Boiler Feed pumps.

An all-purpose workhorse. The go-to product for applications under 500ºF. More

than all of the other PTFE/Graphite packing combinations. Large Hydro-turbine applications. Chemical Slurries.

the conveyor capacity and speeding up the belt, another approach is to change the trough angle. Using the 1200 mm belt width example the capacity increases compared to a 20-degree trough angle are shown in Figure 5.

Figure 5 shows that the FE allowance for the sealing system is probably adequate at roughly 40 mm but if the trough angle is increased to 35 degrees there is hardly any room for a sealing system. So, this is where the balancing act begins.

Common conveyor system adjustments for increased production include:

• Narrowing the skirtboards to increase the height of the material rubbing on the liners

• Different trough angles

• Different belt widths

• Increase/decrease belt speed

One technique that is used is 20-degree idlers in the load zone and then after the load zone transition to 35-degree idlers. The transition must be calculated using the same approach as the transition from the tail pulley to the troughing idlers. This design allows adequate room for belt wander and for a more robust sealing system. The 20-degree configuration gives more room for belt wander and the sealing system. The 35-degree idlers can carry more material. The height of the material rubbing on the skirtboards may cause wear issues. The same concept can be used to help center the load when off center loading causes mistracking in the carrying run.

Making the replacement and adjustment of the seal and liner system easy is important for safety and controlling costs. Mounting the wearliner on the outside of the skirtboards and then placing the seal against the liner does several things. It eliminates the gap, which is the thickness of the skirtboard side wall,

created by putting the liner on one side of the skirtboard and the seal on the other. This gap can catch and hold material and abrade the belt. Conventional systems weld wearliners onto the inside of the skirtboard making adjustments or replacements require hours of confined space entry involving two or more workers. Moreover, it makes the job more difficult, dangerous and timeconsuming than necessary, raising the cost of operation.

The CEMA method using dimensionless ratios can be used to analyse any threeroll idler sets either fixed or garland by substituting the actual dimensions in place of the CEMA standard assumptions. There are many other idler designs available today to address various needs but all can be studied using basic trigonometry. Typically, the center roll of a set is the most heavily loaded. To increase the load capacity the center roll is often made shorter than the wing rolls. Extending the life of heavily loaded idlers for faster belts can be achieved by widening the diameter of the center roll so it rotates slower. Custom and adjustable trough angles are also available which can be used to help center or recenter the load and help reduce belt mistracking.

The selection of the trough angle for a new design or retrofit requires a holistic view. When production exceeds the original design or there is a significant material change, operators must confirm the existing belt, idlers and structure can handle the increased load. What seems to be an adequate trough angle for the carrying run may create excessive wear in the loading zone resulting in more frequent spillage, increased clean up and more regular maintenance. Optimising trough angles and skirtboard widths to allow a robust sealing system is critical to reducing belt wear and damage.

Similarly, having adequate free belt edge to accommodate the sealing system and belt wander along with the idler design to handle the load is the path to lower overall costs.

[1] Belt Conveyors for Bulk Materials, 7th edition, Conveyor Manufacturers Association www.cemanet.org

[2] U.S. Occupational Safety and Health Administration (OSHA), ‘OSHA Safety Pay$ Estimator’, Dec. 2023. https://www.osha.gov/ safetypays/estimator

Complete your belt conveyor cleaning system with Martin's SQC2S™ Secondary Belt Cleaner. It clears away residual material your primary cleaner misses, preventing costly carryback and protecting your entire conveyor system.

The rugged SQC2S™ handles a wide range of belt speeds and sizes and features five specialized blade options that adapt to the belt for optimal cleaning performance. With simple maintenance and reliable operation, SQC2S™ helps create a safer, more efficient workplace while reducing energy costs.

Trust Martin's proven technology to keep your production moving in the right direction.

of

Max Luedtke from ABB finds that mining’s decarbonisation transformation is at a pivotal point

The mining industry is at a pivotal point in its journey towards decarbonisation. As global efforts gain momentum, mining companies face dual responsibilities – supplying the raw materials essential for green technologies while drastically reducing their own carbon footprints. ABB’s recent report, ‘Mining’s Moment’, sheds light on how mining leaders are navigating these challenges and the transformative role technology is playing to make the industry more sustainable. With 2030 targets looming, there is cautious

optimism within the sector, yet 30% are still behind schedule with their decarbonisation goals.

The optimism that exists stems largely from the technologies already available to enable meaningful emission reductions. A majority (70%) of respondents believe significant decarbonisation is achievable with current technologies. Additionally, recent strides in electrification, automation, and digitalisation, tools that are proving instrumental in

Mining companies and partners are collaborating with ABB to create the technologies that will help meet net zero targets faster

reducing emissions, are serving to bolster efforts. However, this confidence is tempered by the reality that 15% of respondents do not believe they will meet their 2030 goals in time, underscoring the urgency for decisive action.

The industry is rising to the challenge, but it’s clear that action must be taken now to maintain momentum and make meaningful progress. The current period represents both an opportunity and a responsibility to align mining operations with global sustainability goals.

Electrification remains crucial to mining’s sustainability efforts. 91% of those surveyed said they consider electrification essential to, or part of, their decarbonisation strategy. Transitioning heavy machinery from diesel to electric power significantly reduces emissions while cutting fuel costs and minimising supply chain risks. Many mining companies are also integrating renewable energy sources to further amplify these benefits.

Digitalisation and automation are equally transformative. By harnessing advanced data analytics and automated systems, mining operations can optimise energy use, enhance process efficiency, and reduce environmental impact. These technologies also contribute to improved safety and precision, making them indispensable for modern mining practices.

An integrated approach to electrification, automation, and digitalisation is believed to be essential for sustainable mining transformation according to 77 percent of mining companies. These technologies are not only available today and constantly evolving in a scalable way but are proving their value across operations worldwide and building a foundation for overcoming challenges to sustainable transformation.

While technology is a critical enabler, the journey to more sustainable operations is not without its challenges. Nearly half of mining leaders (46%) cite operational disruption as a significant barrier to adopting new technologies. To address this, mining companies are increasingly taking an incremental approach, focusing on phased implementation that minimises risk while ensuring steady progress.

Another pressing issue is the talent gap - 70% of mining companies are committed to investing in reskilling and training programs to prepare their workforce for the demands of a more sustainable industry. As mining becomes more technologically advanced, skilled technicians, engineers, and operators are essential to managing and maintaining these systems.

These barriers highlight the need for a comprehensive strategy that balances technological adoption with workforce development, paving the way for a more resilient and innovative mining industry.

The path to decarbonisation requires a balanced focus on advanced technologies and rethinking operational practices. By leveraging key solutions and optimising processes, mining companies can build a more sustainable and resilient industry.

Strategic partnerships and collaborations play a vital role here. The ‘Mining’s Moment’ report found that 71% of respondents view partnerships as crucial to achieving sustainability goals. As part of a successful collaboration, expert integrators play a key role in ensuring

seamless coordination among stakeholders, helping to drive progress efficiently and effectively.

By aligning technological innovation with collaborative efforts, the industry can overcome challenges and create a cohesive roadmap towards decarbonisation.

The mining industry is uniquely positioned to support the global energy transition. Minerals and rare earth metals are critical components of renewable energy technologies, from wind turbines to electric vehicle batteries. This responsibility underscores the need for sustainable practices that align with broader environmental goals.

This isn’t to say the road ahead will be straightforward, but the opportunity to make a real difference has never been greater. Through a combination of incremental progress and bold ambition, the mining industry is poised to play a central role in creating a low-carbon future. This is mining’s moment to lead, innovate, and transform for the better.

To read the report visit: https://new.abb.com/mining/ campaigns/mining-moment

A report from PPE supplier MyWorkwear says that engineering lags other sectors when providing adequate PPE for women. Here we explore why the issue must be addressed

Safety equipment is of course essential for mining engineers, and companies need to ensure they take appropriate safety measures to ensure their staff are protected from mining disasters. The industry is responsible for around 15,000 accidents a year according to a report in the Journal of Safety Research (2023).

In addition to mine safety products such as breathing apparatus, communication and monitoring systems, operators must consider personal protective equipment (PPE). Such equipment includes hard hats, footwear and protective clothing.

Women are underrepresented in the global mining workforce, making up just estimated 8%-17% depending on the geography according to research by McKinsey and Co (2021). Although the women in engineering mining roles are even less represented, there are still significant numbers. More than a quarter of the women mentioned in a 2022 report published by the advocacy group Women in Mining were working as engineers.

Despite this there are still significant issues with adequate equipment. A 2023 survey of 130 women in mining, construction and quarrying conducted by Ground Engineering found that 80% have been provided with PPE that does not fit them in a working environment.

A statement on the IWIM website (IWIM, is another non-profit organisation advancing equity within the sector, reads): “Employers have a responsibility to ensure the safety, comfort, and well-being of everyone in the workplace by providing correctly-fitting PPE.”

Despite this, a new study by personalised workwear and PPE supplier, MyWorkwear, has shown that engineering is still one of the least inclusive industries for women,

and a release from the company states that this might “inhibit further growth of female representation within the sector”.

The study, which also looked at maternity pay, the gender pay gap and menopause, found the engineering sector to be lagging other more inclusive industries for women when workwear and these other issues were considered. In fact, according to its calculations, engineering scored just 32.9 out of a possible 100 points, compared with corporate and business sectors which scored 67.2 out of 100.

Gayle Parker, commercial director at MyWorkwear explained that there is an increasing variety of options available for women within the workwear space: “A variety of PPE items now come in women’s fit, including hi-vis items such as jackets and vests as well as trousers.”

Although there has been much talk about new technologies such as 3D printing enabling increased access to PPE for frontline workers, with companies such as Jacobs, GE Power and Eaton exploring this space, Gayle said: “We don’t believe that it’s technology as such that is driving change, but rather demand and research. Owing to the increase in demand, manufacturers are speaking to women to find out where the issues lie. This understanding is then enabling them to create garments that fit more appropriately while still providing the safety necessary for PPE.”

30% report being behind schedule with their decarbonization goals

Download the report packed with the inputs from 400+ experts

Read data and trends on where, in terms of sustainability, the mining industry is at now, what needs to be done, and where technology can help, all while remaining financially viable.

53% anticipate significant or complete transformation of their operations over the next five years

https://new.abb.com/mining/campaigns/mining-moment

412 mining leaders interviewed

18 countries represented

77% believe an integrated approach to electrification, automation, and digitalization is essential for sustainable mining transformation

How increased output of sulphuric acid using upgrades and new technologies helped an African Copper belt mine improve OPEX and efficiency

Sulphuric acid (H2SO4) plays a central role in industrial applications, particularly in mining, where it is used for the leaching of copper, cobalt, and precious metals. In beneficiation processes, H2SO4 extracts these metals from their ores. Additionally, it supports phosphoric acid production for fertilizers and helps descale equipment to prevent mineral buildup, ensuring machinery operates smoothly.

As global demand for sulphuric acid rises, plants face the challenge of increasing output while minimising operational expenditures (OPEX) and unplanned downtimes. This article looks at a sulphuric acid plant in the African copper belt, where production capacity was boosted from 2200 MTPD to 3000 MTPD. Through targeted upgrades by burner and combustion specialist CS Combustion Solutions, such as ultrasonic nozzles and advanced combustion technologies, major efficiency and cost improvements were achieved.

The plant had multiple efficiency issues that hampered performance:

1. Incomplete combustion:

Traditional pressure atomisers caused large sulphur droplets to pass into the waste heat boiler (WHB) and catalyst beds, resulting in fouling, increased pressure drops, and unscheduled maintenance shutdowns.

2. Frequent nozzle plugging:

Regular nozzle blockages forced production stoppages for replacement. Over US$200,000 was spent in under two years on nozzle tips and guns alone.

3. Pressure drop and overheating:

Large droplet sizes and poor atomisation caused hotspots in the refractory lining. Inappropriate chamber design amplified overheating, leading to structural risks.

Have Questions? Let us know.

www.terrasonicinternational.com/contact

SONIC drilling ensures deep, straight and continuous near-in situ core samples, enabling accurate lithological representation and more statistically significant data.

Terra Sonic rigs drill quickly through all types of overburden and provide clean, stable boreholes.

TSi SONIC Technology is the ideal choice for mineral and aggregate investigations, tailing piles, leach pad drilling and much more.

4. Uneven temperature distribution:

Inefficient combustion chamber dynamics and pressure atomisers caused hotspots on the furnace shell, compromising durability and safety. These issues resulted in elevated operational costs, reduced productivity, and recurring maintenance challenges.

To tackle these problems, CS Combustion Solutions implemented a four-step optimisation strategy:

1. Ultra-sonic nozzle atomisation: Replacing traditional pressure atomisers with ultra-sonic nozzles was a game-changer. Droplet size was reduced from 400 µm to 110 µm, significantly improving sulphur combustion efficiency. Smaller droplets reduced fouling in the WHB and catalyst beds while extending refractory material life.

2. Swirl bodies for enhanced combustion: Swirl bodies were integrated into the combustion system, inducing rotational motion in combustion air. This promoted better flame stability and complete combustion, particularly during startup operations when oil is also burned.

3. Single vector wall installation:

Ineffective baffle walls, which failed to mix combustion air and sulphur properly, were replaced with a single vector wall. This solution ensured efficient turbulence and mixing within the chamber, preventing unreacted sulphur from reaching downstream equipment.

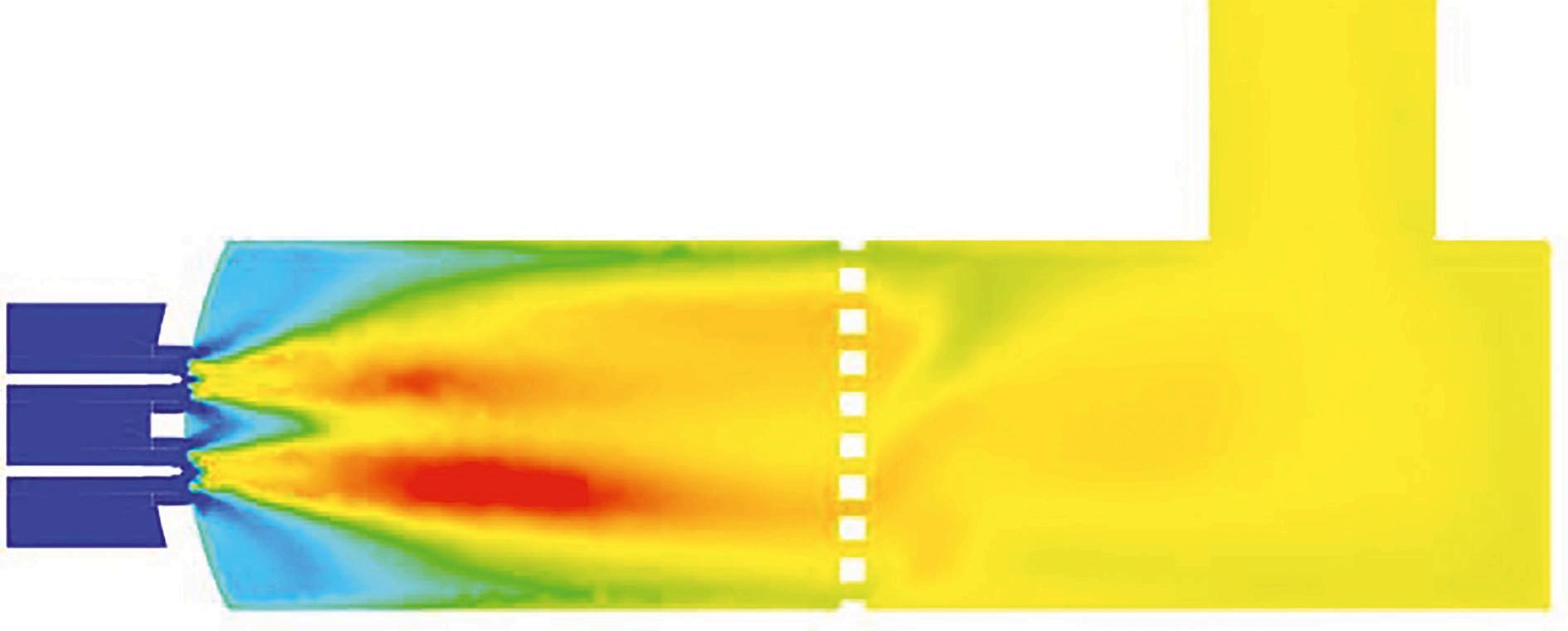

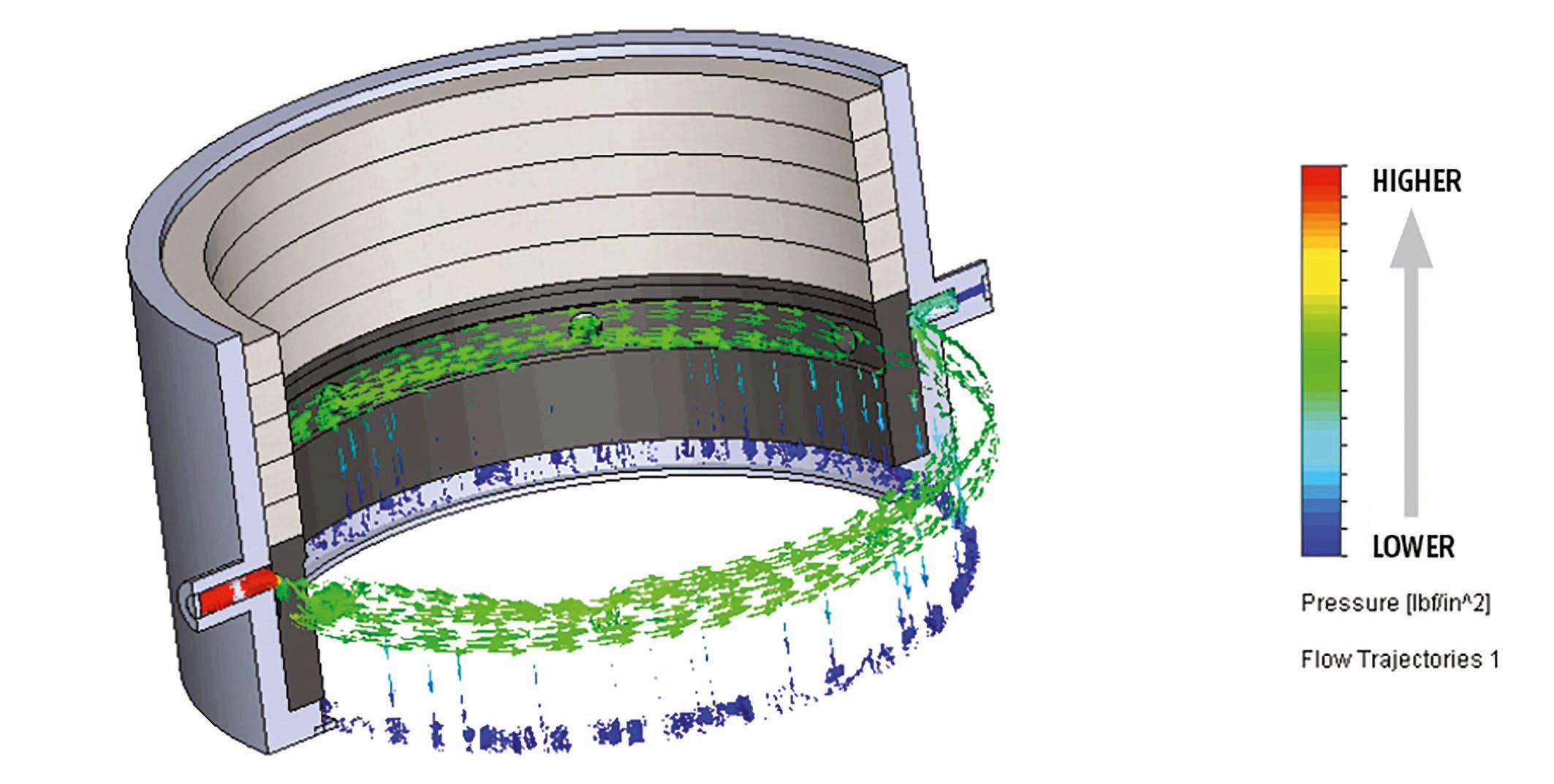

4. Computational fluid dynamics (CFD) study:

A detailed CFD study was conducted to simulate the proposed modifications and ensure optimal performance before implementation. This predictive step was crucial in minimising risks and validating the expected improvements.

The optimisation delivered remarkable improvements in plant operations and efficiency:

1. A production capacity increase of 30%:

The upgrades enabled the plant to achieve 3000 MTPD, incinerating 40 tonnes of sulphur per hour without compromising performance.

2. Improved maintenance flexibility:

Operators could replace sulphur guns during operation, eliminating unplanned shutdowns and increasing plant availability.

3. Enhanced combustion efficiency:

Swirl bodies and ultra-sonic nozzles optimised SO2 conversion rates, leading to complete sulphur combustion with lower emissions. Despite the increased capacity, emissions remained controlled owing to improved efficiency.

4. Pressure loss reduction:

The vector wall and optimised combustion chamber design reduced pressure drops, leading to annual OPEX savings of US$160,000 on blower operations.

5. Hotspot elimination:

Smaller droplet sizes and controlled atomisation angles prevented large sulphur particles from impacting the refractory, extending its lifespan and enhancing furnace safety.

6. Cost savings and downtime reduction:

Unplanned shutdowns decreased significantly owing to fewer nozzle failures and better refractory stability.

The African Copperbelt plant’s success demonstrates the critical role of high atomisation quality in optimising sulphuric acid production. Advanced technologies, such as ultra-sonic nozzles and swirl combustion systems, significantly improve plant efficiency and reliability.

Ultra-sonic nozzles provide a quick and effective upgrade for existing furnaces, reducing droplet size to minimise fouling and refractory wear. The results of this project also emphasise the value of CFD-based studies for validating design changes before implementation.

For plants facing similar challenges, adopting such innovative solutions can increase capacity, reduce operational costs, and enhance long-term performance.

CS Combustion Solutions’ expertise in ultra-sonic atomisation and combustion optimisation helped the plant in the African Copperbelt overcome major operational challenges. By boosting capacity, enhancing efficiency, and reducing OPEX, this case study showcases how targeted upgrades can provide significant benefits in a competitive market.

As sulphuric acid demand continues to grow, plants must adopt similar strategies to remain efficient and competitive while minimising downtime and costs.

You’re looking at the first XNO® powered hybrid vehicle.

Unveiled by Switch Technologies, this pioneering development gives mining operations high performance electrification with a low total cost of ownership.

XNO®, Echion’s uniquely robust anode material, performs in the toughest environments.

www.echiontech.com/landcruiser

Opportunities to boost secondary copper supply are rising

A

new IEA report finds that the successful scale up of global recycling will significantly lower the need for new mining activity

As the shift to a clean energy accelerates, substantial investments in new mines and refining capacity, especially in geographically diverse regions, will be required to produce essential minerals such as copper, lithium, nickel, cobalt and rare earths. However, recycling will also be indispensable to the security and sustainability of critical mineral supply for clean energy transitions.

With this in mind, a new IEA report finds that a successful scaleup of global recycling will lower the need for new mining activity on the world stage by 25-40%. More broadly, it looks at the importance of unlocking the potential of recycling by evaluating the current status of recycling of minerals critical to the energy transition, analysing the prospects for secondary supply, and outlining targeted policy recommendations.

Despite growing policy ambitions, the use of recycled materials has so far failed to keep pace with rising material consumption. In the case of copper, which plays a central role in all electrical applications, the share of secondary supply (including direct scrap) fell from 37% in 2015

to 33% in 2023. Similarly, the share of recycled nickel decreased from 33% to 26% over the same period. The main exception is aluminium, which benefits from well-established waste management programmes and supportive regulations, where the recycled share increased modestly from 32% to 35%.

Despite this, policy momentum is gaining strength, with a surge in new policies and regulations. According to the IEA’s Critical Minerals Policy Tracker, more than 30 new policy measures related to critical mineral recycling have been introduced since 2022. These policies generally fall into four categories: strategic plans, extended producer responsibility (EPR), financial incentives and cross-border trade regulations. Some also include regulatory mandates such as industry specific targets for material recovery, collection rates and minimum recycled content. However, most strategies are not yet comprehensive. Among the 22 countries and regions surveyed, only three had a broad framework that included clear targets, implementation mechanisms, monitoring systems and economic incentives.

As stated, a successful scale-up of recycling would lower the need for new

mining activity by 25-40% by 2050 in a scenario that meets national climate pledges. While accelerated clean energy deployment calls for a substantial expansion of new mines and refineries to meet material demand, it also creates an opportunity for secondary supply to play an increasingly valuable role. In the Announced Pledges Scenario (APS), which reflects national climate pledges, recycling will likely reduce new mine development by 40% for copper and cobalt, and close to 25% for lithium and nickel by 2050. The market value of recycled energy transition minerals is also predicted to grow five fold by that time reaching US$200bn. As a result, requirements for primary materials are likely to begin to decline by this time. Nonetheless, investments in new mines will continue to be essential as supply levels required by midcentury will still be higher than today and existing mines will experience natural declines in output. Enhancing critical minerals recycling will offer substantial financial and sustainability benefits. In the APS, some US$600bn of mining investments will be required through 2040, while achieving net-zero emissions by 2050 will cost around US$800bn. Without an increase in recycling, these costs would both be 30% higher, increasing the burden of mobilising the necessary financing. Recycling will also mitigate

the environmental and social ills that come from excessive mining.

The report argues that scaling up the recycling of end-of-life scrap from traditional industries is essential to alleviate pressure on critical mineral supplies, particularly for copper since there is a supply deficit. By 2035 announced projects will only be sufficient to meet 70% of copper requirements in the APS. However. opportunities to boost secondary copper supply are rising as scrap

volumes are likely to surge from around 2030. Copper scrap availability is expected to grow alongside consumption until then, when it will outpace demand growth. A combination of policies – raising collection rates for legacy applications, mandating recycling, improving sorting systems, and investing in new secondary smelters – can further elevate secondary supply’s contribution.

Mining generates around 100 billion tonnes of waste every year, in addition

to the sizeable amount already existing in active, inactive and closed tailings. The accumulated waste volume is set to increase by almost 90% over 2020 levels by 2030. Reprocessing mine waste, or tailings, can reduce waste generation and mitigate environmental impacts such as water contamination, safety risks and soil pollution. For closed or abandoned sites, it also presents an opportunity for environmental remediation. Previously, the minerals left in mine waste were considered economically unviable, but declining ore quality and future supply concerns are making reprocessing more appealing. For instance, in Chile, the copper content in mine waste with higher grades than primary sources is poised to rise from 1.6 Mt in 2005 to 5.6 Mt by 2050. Realising this potential will require comprehensive waste resource mapping, supporting research and development for new recovery technologies, providing economic incentives, and addressing liability barriers related to mine waste at closed sites.

Conveyor belt expert Leslie David explores advances in the technology and the benefits they afford to industry

In the mining industry, as with many other industries, conveyor belts are critical components that play an essential role. Their reliability and efficiency are essential to success. It is therefore surprising to find that, in a world of continual technological advancement, the basic construction of rubber conveyor belts has not fundamentally changed since 1905 when mining engineer Richard Sutcliffe invented a belt made from layered cotton and rubber. Since those early days, the rubber is now almost entirely synthetic, and the multiple layers of cotton have been replaced by layers of synthetic (usually polyester and polyamide) fabric ply material with a thin layer (skim) of rubber in between each layer. In principle, the heavier the application, the more layers that are used.

This multi-layered carcass structure is protected by an outer layer of rubber. Known as ‘multi-ply’ belts, they are by far the most common type of

conveyor belt. But that is where the new thinking seemed to end, until now.