Very much reflecting the state of play in the oil & gas sector right now, the key theme of this issue can be summarised as 'where old meets new’. Many of the articles in these pages cover technologies that can be described as state-of-the-art without that being hyperbole. And several of them are being applied either to solve problems that are decades old or to revive ageing assets.

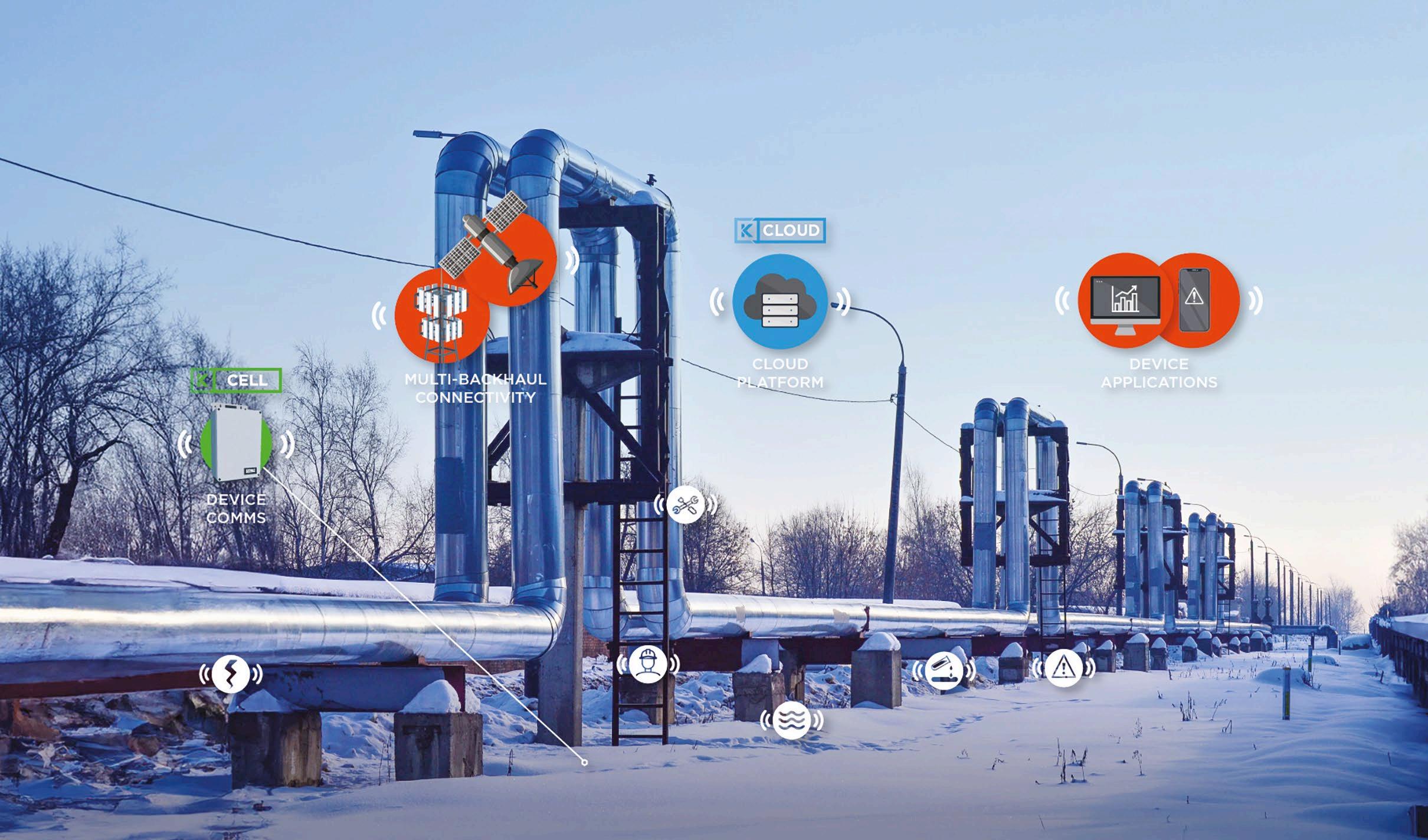

On page 14 we hear from communications technology expert Kevin Quillien, who explains how disparate, established assets can now be joined up to smart networking technologies that aim to futureproof even the oldest oil & gas assets. According to Quillien, “Digitising and digitally transforming this extensive installed base represents a tremendous opportunity to enhance efficiency, safety and sustainability across the sector.”

Meanwhile, our revealing interview with Ekaterina Mezhentseva at coatings expert Jotun (page 10) highlights the staggering costs and impact to the industry of a problem that is undoubtedly ‘old’ – that of corrosion – and details how the ‘new’ (Jotun’s advanced coatings solutions) can help operators deal with this menace.

Further illustrating the ‘old meets new’ theme, on page 34 we have an article that actually has the word ‘old’ in its headline (Old but gold?), in which Michal WozniakowskiZehenter explores whether today’s high-tech operational environment can still benefit from the use of the many decades old T-Card system. Finally, our cover story (page 6) details how new subsea technologies can help overcome old mindsets to develop a greener future.

Louise Davis Editor

Innovative and environmentally friendly technologies for the new underwater

An industry-first deepwater technology that’s able to operate at up to 20,000psi has successfully been deployed

Corrosion is an ongoing headache for operators. However, one coatings expert is aiming to empower the oil & gas industry's efforts to defeat it

for those who manage them. But now, a robust communications network can get these sites better connected

It’s a wrap!

A new composite wrap system for aqueous environments

Rethinking gas quality

Hydrocarbon dewpoint: the gap between theory and reality

22

Digitalisation delivers

A specialist in industrial technology explains how a digital toolbox of solutions can assist oil & gas operators with futureproofing their operations

Blue-sky thinking

How an engineering firm’s customers inspired a gamechanging valve design for major refineries

Guaranteeing gas

Burckhardt Compression boosts European energy security with FSRU compressor overhauls

Boosting efficiency and availability

To avoid unplanned downtime it is essential that vital components work correctly and reliably

New series of Ex command devices

Ex command devices featuring flexible and direct integration 32

Delivering distillation

A new electrified distillation solution aims to improve energy efficiency and enable carbon emission reductions

PUBLISHER

Jerry Ramsdale

EDITOR

Louise Davis

STAFF WRITER

Saskia Henn shenn@setform.com

DESIGN

Dan Bennett, Jill Harris

HEAD OF MARKETING

Shona Hayes shayes@setform.com

HEAD OF PRODUCTION

Luke Wikner production@setform.com

BUSINESS MANAGER

John Abey +44 (0)207 062 2559

SALES MANAGER

Darren Ringer +44 (0)207 062 2566

ADVERTISEMENT EXECUTIVES

John Davis, Iain Fletcher, Paul Maher, Adam Croft

34

Old but gold?

The role of a well-established personnel tracking system in today’s offshore oil & gas industry safety

38 Comfortably equipped

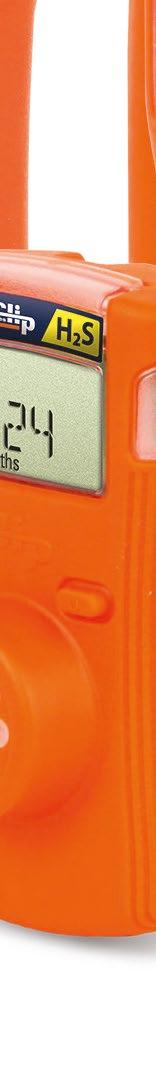

Working in Ex zones does not necessarily mean compromising on user comfort

40 Sophisticated safety software

Mapping safety with precision: the role of fire and gas mapping

50 Powering innovation

How a milestone project has put a new pin on the map for a UK subsea controls specialist

52 Flexible working

How innovative subsea solution providers are meeting industry demands – both here and in other engineering sectors

SHOW PREVIEW

54

Subsea event makes a splash in Scotland

Subsea Expo takes place at P&J Live in Aberdeen, 18 - 20 February 2025

42 Making waves

The subsea engineering trends that are shaping the future of underwater oil & gas operations

46 Subsea pump solutions

Expert support on innovative C02 pumps for subsea oil & gas separation

48 Automating testing

These subsea units shave days off testing times and eliminate human error from the monitoring process 48

Setform’s international magazine for engineers is published twice annually and distributed to senior engineers throughout the world. Other titles in the company portfolio focus on Process, Design, Transport, Mining, Energy and Power.

The publishers do not sponsor or otherwise support any substance or service advertised or mentioned in this book; nor is the publisher responsible for the accuracy of any statement in this publication. ©2025. The entire content of this publication is protected by copyright, full details of which are available from the publishers. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior permission of the copyright owner.

Setform Limited, 6, Brownlow Mews, London, WC1N 2LD, United Kingdom +44 (0)207 253 2545

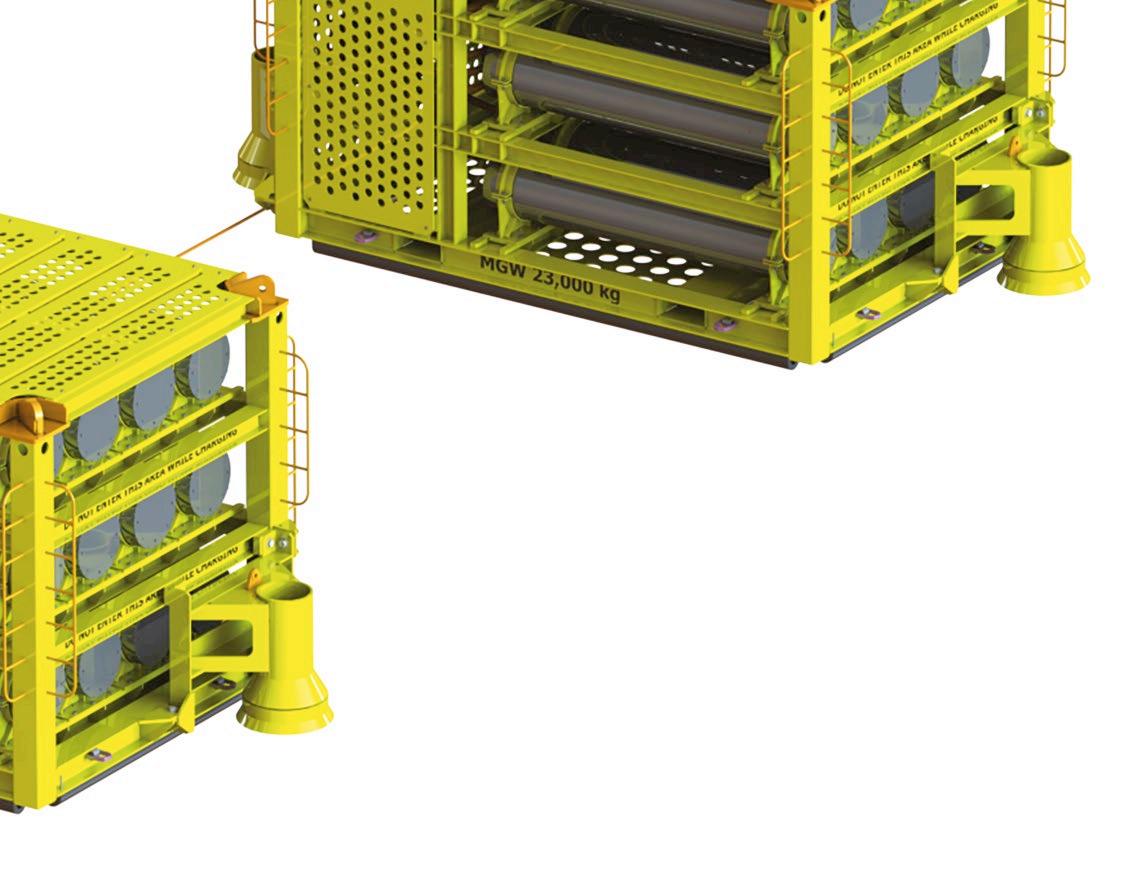

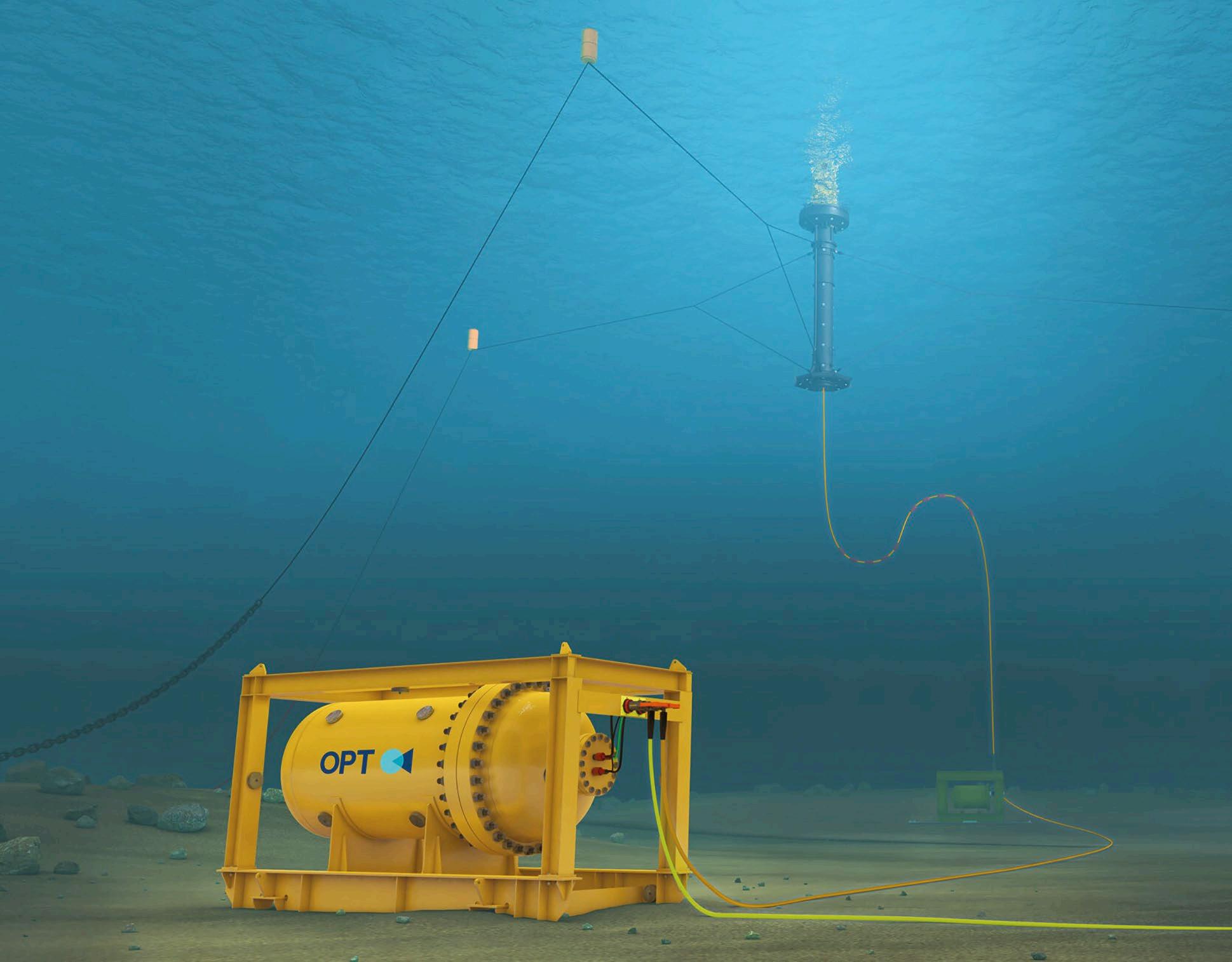

SEA CHANGE

Sustainable and smart solutions for today's evolving subsea sector

A variety of subsea energy solutions can be found in SubCtech’s popular product portfolio

Sören Johannsen discusses innovative and environmentally friendly technologies for the new underwater markets

SubCtech, an expert in underwater technologies, founded in 2010 by applied physicist Stefan Marx (CEO), has grown into a maritime powerhouse based in Kiel, Northern Germany. This medium-sized enterprise, composed of a diverse team of skilled mechanical and electrical engineers and software specialists, is dedicated to nextgeneration R&D, custom project consulting, thorough prototype testing, and high-quality manufacturing according to international standards.

The advantage for the firm’s customers is a safe and reliable field-tested technology that not only significantly reduces CAPEX and OPEX costs, but also considerably reduces the CO2 footprint through less downtime and service calls and longer downtimes. A win-win for industry, the blue economy and the environment.

SubCtech’s Ocean Power products are widely used for applications including offshore oil & gas companies; environmental monitoring stations; subsea applications; and manufacturers of autonomous underwater and surface

vehicles (AUVs, SUVs) as well as remotely operated vehicles (ROVs). The company’s flagship product line, PowerPacks, features advanced Li-Ion battery systems with configurations for basic, subsea, vehicle and custom battery needs, including advanced charging and battery-management systems (BMS). These modular and flexible battery power blocks (SPBs), encased in a custom housing, are suitable for any required ocean depth and designed for a lifespan of up to 25 years.

One of the key factors in the company’s success with its subsea batteries is the excellent reliability and adherence to strict safety standards. The Li-Ion cells as well as the entire PowerPacks undergo rigorous testing to meet UN T38.3, MIL-STD, DNV, and API17F compliance standards, along with further customised requirements. These subsea batteries are specifically engineered for high-capacity, uninterruptible power supply (UPS) solutions for subsea energy production

facilities, capable of operating even in extreme conditions. “Our batteries undergo intensive testing for heat resistance, shock tolerance vibration and EMC to ensure they meet the stringent standards our clients expect from us and heavily rely on,” explains Stefan Marx.

The batteries automatically protect themselves from potential issues, safeguarding the system from damage and ensuring operational safety. They are equipped with features to disconnect in case of over- or undervoltage, over temperature, overcharge, overcurrent or short circuits with a high number of sensors and new KI-based algorithm to eliminate false alarms and detect critical states. Compared with traditional alkali primary batteries, Li-Ion PowerPacks provide robust high-current operation, functioning at sub-zero temperatures able to handle peak currents efficiently and are suitable for long storage or operating times. These attributes make them a superior choice for demanding subsea and offshore applications.

Our batteries undergo intensive testing for heat resistance, shock tolerance vibration and EMC

Recently, SubCtech developed a novel 2MWh subsea energy storage system (ESS), setting a milestone in its commitment to sustainable energy storage solutions. This ESS, with a Technology Readiness Level of 6 (TRL 6 according API17Q), is currently in operational use in the oil & gas sector. The system has proven its value in the field, where it effectively supports the demanding power requirements of offshore operations. SubCtech’s customer, impressed by the ESS’s performance and reliability, recently placed an order for an additional

complete system. This underscores the ESS’s success and the growing demand for sustainable, high-capacity power solutions within the subsea industry.

As the global demand for ocean power products increases, SubCtech has been experiencing rapid growth, supplying products to clients across the world. To accommodate this growth, the company has doubled its workforce to 76 employees and is planning an expansion of its production facilities 2025.

Looking to the future, SubCtech is committed to advancing as a leader

in ocean power solutions as well as ocean monitoring systems. The company is actively seeking strategic partnerships to extend its network and deepen its impact within the international oceanology sector. With continued innovation in subsea energy storage and monitoring, along with a robust commitment to environmental responsibility, it aims to set new standards in sustainable marine technology.

The

SubCtech is a trusted partner in the marine and subsea technology sectors, known for its innovative solutions such as the Li-Ion PowerPacks and the Subsea ESS. These products deliver reliable, field-proven technology that meets the demanding standards of the offshore industry. The recent success of the ESS in operational deployment within the oil & gas sector and the subsequent re-order by a key customer further underscores the effectiveness and reliability of the company’s solutions in real-world applications. As the company continues to innovate and grow, it solidifies its role as a pioneer in sustainable power and monitoring technologies for the marine environment.

An industry-first deepwater technology that’s able to operate at up to 20,000psi has successfully been deployed

The US energy giant Chevron has begun oil and natural gas production from the Anchor project in the deepwater US Gulf of Mexico. Anchor production marks the successful delivery of highpressure technology that is rated to safely operate at up to 20,000psi, with reservoir depths reaching 34,000ft below sea level.

“The Anchor project represents a breakthrough for the energy industry,” comments Nigel Hearne, executive vice president, Chevron Oil, Products & Gas. Hearne adds: “Application of this industry-first deepwater technology allows us to unlock previously difficult-to-access resources and will enable similar deepwater high-pressure developments for the industry.”

The Anchor semi-submersible floating production unit (FPU) has a design capacity of 75,000 gross barrels of oil per day and 28 million gross ft3 of natural gas per day. The Anchor

development will consist of seven subsea wells tied into the Anchor FPU, located in the Green Canyon area, approximately 140 miles (225km) off the coast of Louisiana, in water depths of approximately 5,000ft (1,524m). Total potentially recoverable resources from the Anchor field are estimated to be up to 440 million barrels of oil equivalent.

“This Anchor milestone demonstrates Chevron’s ability to safely deliver projects within budget in the Gulf of Mexico,” says Bruce Niemeyer, president, Chevron Americas Exploration & Production. “The Anchor project provides affordable, reliable, lower carbon intensity oil and natural gas to help meet energy demand, while boosting economic activity for Gulf Coast communities.”

According to industry analysts, recent developments in ultra-high-pressure drilling technology – such as the one Chevron is using at its new Gulf of Mexico project – could unlock more

than five billion barrels of known but previously inaccessible oil deposits globally, including more than two billion barrels in the US Gulf of Mexico alone. These figures suggest there is huge potential for future deployments of this novel drilling technology.

The Anchor FPU is Chevron’s sixth operated facility currently producing in the US Gulf of Mexico, one of the lowest carbon intensity oil and gas basins in the world. Chevron’s operated and non-operated facilities in the Gulf of Mexico are expected to produce a combined 300,000 net barrels of oil equivalent per day by 2026.

To reduce carbon emissions, the Anchor FPU was designed as an all-electric facility with electric motors and electronic controls. Additionally, the FPU utilises waste heat and vapour recovery units as well as existing pipeline infrastructure to transport oil and natural gas directly to US Gulf Coast markets.

Ball valves from Böhmer have been providing safe shut-off in plants, pipelines & machinery for more than 65 years.

We have always met the challenges of the most diverse applications with the right valve solution. Also in the future Böhmer ball valves keep their product promise: Highest quality & absolute reliability.

www.boehmer.de

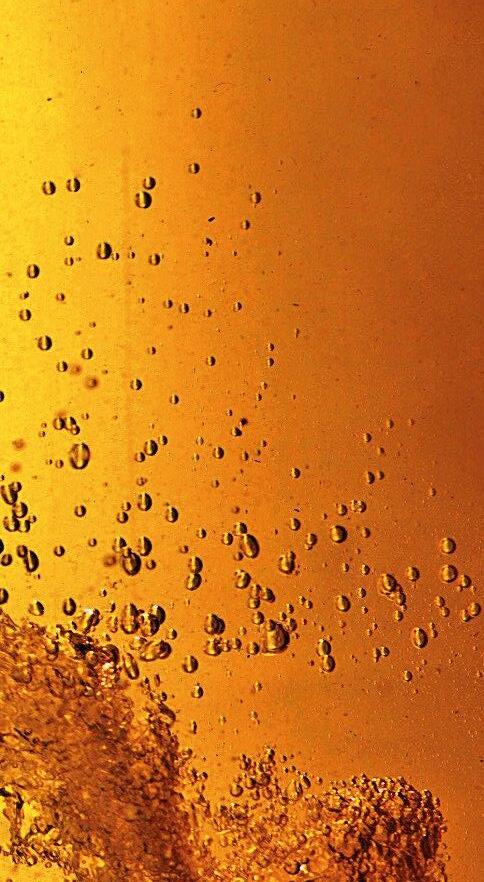

Storage tanks in the oil & gas sector are particularly vulnerable to corrosion due to the extreme environments they are located in

Tackling the costly issue of corrosion is an ongoing headache for oil & gas operators across the world. Louise Davis meets a specialist from a coatings company whose aim is to empower the industry in its efforts to reduce rust

The global cost of corrosion, both in terms of money and the effect it has on the environment, is not talked about enough, according to Ekaterina Mezhentseva, Global Solutions Manager, Jotun Performance Coatings. Determining accurate statistics is difficult for something whose cause, effect and mitigation tends to be a gradual process spanning multiple years. However, Mezhentseva says: “The annual cost of corrosion is estimated at around US$2.5 trillion, which is equivalent to 3.4% of the global GDP, as per data published by NACE in 2013. This does not include the indirect cost related to corrosion, such as downtime and other effects on society – so the total cost is far greater.”

As well as the shocking financial costs, Mezhentseva also highlights a worrying knock-on effect, which is that corrosion is a big source of CO2 emissions globally. “According to the World Steel Association data, steel production represents around 10.5% of total global CO2 emissions. Between 20% and 40% of steel produced today is intended to replace corroded steel. And if we continue the same approach to tackling corrosion, by 2030, as much as 9.1% of the total CO2 emissions will be associated with steel produced to replace corroded steel,” she details.

Although there is still a long way to go in terms of getting the oil & gas industry to limit corrosion, engineering

operators have got considerably better at dealing with it over the years. As in many other parts of the broader engineering sector, Mezhentseva has noticed the rise of a more proactive approach here. She says: “Preventative maintenance is a known approach in corrosion management. Understanding operational and environmental factors affecting steel and causing corrosion and taking actions early enough is a key.”

She adds: “The awareness of corrosion and consequences related to corrosion has been increasing significantly in the industry, and we can see this confirmed in the largescale study related to maintenance in the oil and gas industry that we recently launched.”

Proactive service plans can ensure the application of coatings is swift, planned and causes minimal downtime

Jotun’s survey, which was published in August 2024, collected the views of 1,017 senior professionals in the onshore and offshore oil and gas sectors across 10 countries, exploring the industry’s attitudes to maintenance management and the near-term outlook for the sector. “88% confirmed that they are expecting their businesses to increase maintenance budgets in the next five years. In addition, we see that maintenance including corrosion management is gaining a strategic focus in the industry, particularly driven by sustainability and decarbonisation targets,” notes Mezhentseva.

Putting money aside is one thing; actually tackling the problem is another thing entirely. When it comes to corrosion, there is certainly no ‘one size fits all’ solution. Mezhentseva observes that every project is different: “It starts from understanding the key challenges that both the industry as a whole and a specific operation are facing. Corrosion is a complex issue that requires a certain

level of expertise and experience to manage it efficiently and prevent it from causing damage and downtime. Jotun delivers corrosion expertise and support to the maintenance planning and provides a range of certified and proven technologies in corrosion protection, passive fire protection, and heat- and chemical-resistant coatings.”

In oil and gas environments there’s often a great deal of pressure to keep operations flowing at all costs. Naturally, this means Jotun always emphasises the need for preventative measures. “Operational downtime represents a large cost and safety issue. To maximise operational uptime and avoid unexpected downtime, our main recommendation is always to secure long-lasting or even extended protection that will prevent corrosion even in the most challenging conditions,” she advises. But there will always be some scenarios where treatment or repair work is necessary. “In cases where a shutdown is required

Jotun’s recent report emphasises the growing strategic significance of maintenance within the oil and gas sector. The report’s findings underline the crucial role that maintenance, especially corrosion management, plays in ensuring the safety, profitability, and environmental sustainability of oil and gas operations. The positive news was that respondents confirmed that maintenance budgets are increasing. However, three quarters of the senior decision-makers in the oil and gas industry (74%) said these maintenance budgets are the first to be cut when cost savings must be made. This paradox demonstrates how difficult it is for those in charge of maintenance strategies to plan.

“Effective maintenance is no longer just a technical issue; it’s a strategic imperative that impacts every facet of the industry’s operations, from safety to environmental sustainability,” says Ekaterina Mezhentseva. “Our report clearly shows that the industry is moving towards greater investment in maintenance, driven by the need to meet ESG criteria and ensure long-term operational success, but budgets need to be future proofed to allow for effective long-term maintenance planning.”

More than 400 scientists in Jotun are working closely with the rest of the organisation to ensure we stay on top of product and technology innovations

and the priority is to bring the plant back to operations as efficiently as possible, we support this by providing fast return to service products and solutions.”

To simplify Jotun’s approach in the onshore oil and gas industry, there are several key areas where coatings play a vital role to ensure safety and efficiency at the facility. “Fire protection is one of these areas, as explosions and hydrocarbon fire represent a serious hazard for both people and property, and certified fire protection, such as our Jotachar coating, will delay structural collapse so that people can evacuate the facility safely,” states Mezhentseva.

Corrosion under Insulation, known as CUI, is also a huge threat to safety and operations, and the various and changing temperatures in a facility is causing this challenge. It can be responsible for leaks, fires or even explosions on energy facilities. On this, Mezhentseva comments: “Highperforming technologies, such as Jotatemp, that have been tested and approved for CUI conditions can help

reduce the risk for hidden corrosion under insulation.”

Tank linings are also a part of Jotun’s expertise areas, with close to 70 years of experience within the field. Tankguard is a range of reliable and trusted tank linings that ensure safe and efficient handling, storing and transportation of vital products such as oil, petrochemicals and chemicals.

“Additionally, solutions such as AssetKeeper, our expertise and proactive service programme, is one example of how we support maintenance planning so that downtime will be limited,” explains Mezhentseva.

A recent success story saw the AssetKeeper solution deployed in an oil & gas sector project. Mezhentseva explains: “Showcasing how we work with coating and corrosion assessment, when PPC (Petroleum Pipelines Company) in Egypt wanted us to deliver an assessment on noticeable coatings failures on some of their tanks, we utilised the AssetKeeper tool. Our technical team discovered that the paint

specification used was not suitable for the climate and conditions that the tanks were operating in – with the condition of the coatings being poor after only two years despite being designed to last for five.”

Mezhentseva says that following Jotun’s reporting and guidance on how to proceed with repairing, the technical team created a new paint specification that considered the requirements PPC had (as well as the extreme conditions) to ensure durability and performance.

The coatings specialist is not content to sit back and revel in such accomplishments, though.

Mezhentseva reports that across the entire company there remains a drive to deliver even greater progress in its mission to banish corrosion.

“More than 400 scientists in Jotun are working closely with the rest of the organisation to ensure we stay on top of product and technology innovations,” she reveals. “This has been at the core of the company since its inception almost 100 years ago, and the teams in our seven R&D centres are excited to showcase new innovations in the coming months.”

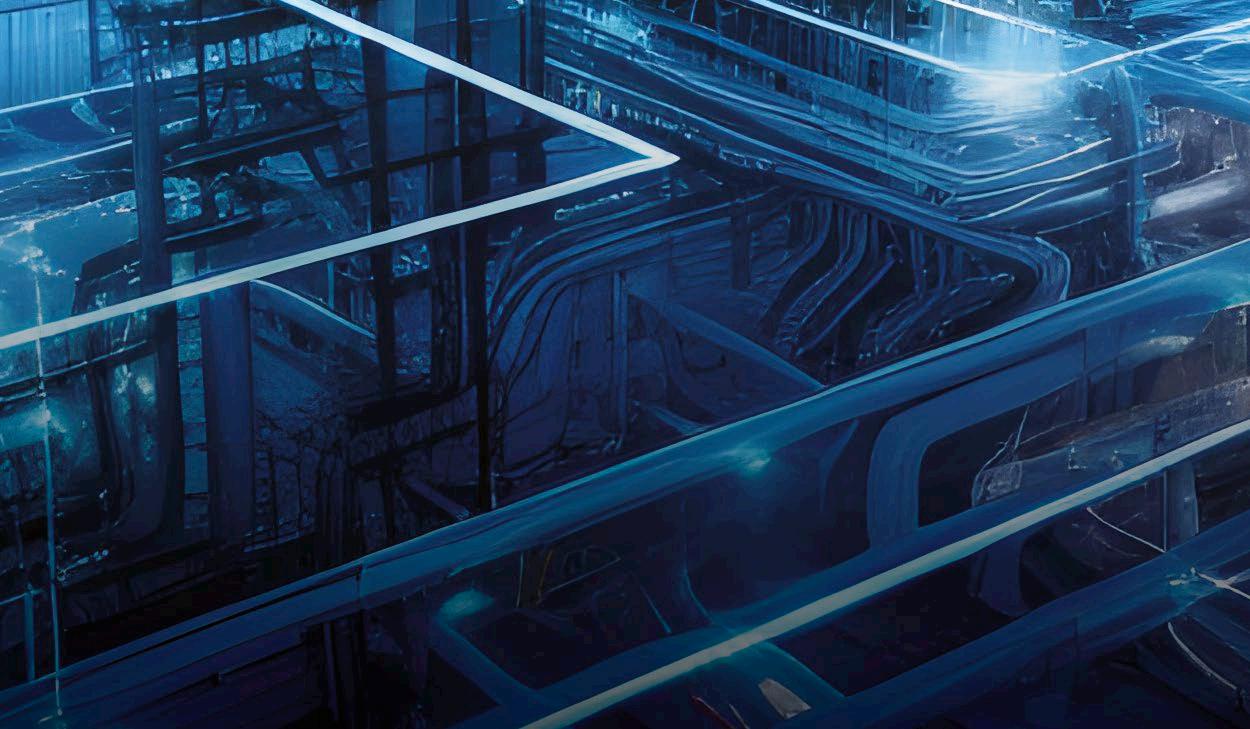

Digitally linking oil & gas assets has long been an issue for those who manage them. Tech innovator Kevin Quillien explains to Louise Davis how a robust communications network can get these sites better connected

According to Kevin Quillien, the Co-Founder and CTO of the UK-headquartered communications company, Krucial, one of the biggest challenges facing oil & gas operators today is managing a vast network of ageing producing assets distributed globally.

“These assets – such as wellheads and transport networks, – are often located in remote, hard-to-access areas, which complicates efforts to modernise operations,” Quillien explains.

“Digitising and digitally transforming this extensive installed base represents a tremendous opportunity to enhance efficiency, safety, and sustainability across the sector.”

Quillien formed Krucial partly to enable operators to take advantage of that opportunity: the company’s

drop-in infrastructure enables the digitisation of assets anywhere on Earth, even in locations with no power or communications, such as offshore platforms or remote desert sites. Quillien notes: “By leveraging wireless ATEX-certified devices, our technology is a low-risk, cost-effective option for large-scale retrofitting. It avoids the complexity of rewiring, bypassing on-site equipment, or obtaining recertification and approvals.”

Krucial’s hybrid communications platform, Krucial Connect, ensures secure and reliable data transmission under any conditions. “This provides operators with confidence in their ability to implement advanced solutions, such as remote monitoring

systems and digital twins,” details Quillien. “These tools facilitate continuous insights and predictive maintenance, driving better decisionmaking and extending the lifecycle of critical assets.”

The solution is simple to deploy and can be remotely configured and managed, eliminating the need for regular on-site visits: “This makes it an ideal choice for operators looking to modernise their ageing assets efficiently and effectively,” states Quillien. Ultimately, the tech innovator believes that Krucial can make a massive difference for the better: “It empowers oil and gas operators to overcome the challenges of ageing infrastructure, unlocking the full potential of Industry 4.0 to modernise their operations.”

By leveraging wireless ATEXcertified devices, our technology is a low-risk, cost-effective option for large-scale retrofitting

Krucial’s drop-in infrastructure enables the digitisation of assets even in locations with no power or communications

When asked what type of applications the platform can be used for, Quillien cites vibration monitoring at an above ground installation (AGI) as a prime use case. “Without monitoring, changes in vibration profiles can lead to catastrophic failures, endangering personnel, the environment, and operational uptime. By deploying ATEX-certified wireless sensors supported by Krucial Connect, operators can automate vibration monitoring, receive early warnings of potential issues, and take proactive measures. This reduces environmental and safety risks while improving operational efficiency.”

Krucial is not the only solution in this market, but Quillien certainly believes it has the edge over other

offerings. On this, he comments: “Existing automated monitoring solutions are often constrained by vendor lock-in, focusing on a limited set of parameters dictated by the specific technology, sensors, and software of the provider. Krucial recognises that comprehensive monitoring of critical assets such as pipelines or AGIs needs to span multiple domains (such as vibration monitoring and leak detection) and bring together a wide variety of technologies from across different vendors to optimally meet the needs of different sites and customers.

“Built on a secure open architecture, Krucial Connect is compatible with a wide range of devices on the ground and transfers data seamlessly and securely to any data analytics

“Like many other sectors, the oil & gas industry has a real need for continuous monitoring of critical assets spread across vast territories,” notes Quillien. “Deploying automated remote monitoring solutions makes this essential monitoring more cost effective and provides more, better quality data on which to base decision making, improve safety, and meet regulatory and reporting requirements.”

Krucial Connect provides a private drop-in network to digitise any location on Earth. “This means operators can deploy the system on a site and benefit from continuous and autonomous data transfer from hundreds of sensing devices across a 15km range, from any location,” details Quillien.

The solution is off-grid capable with multiple inbuilt power options including renewable energy sources and sends data via multibackhauls across cellular or satellite, depending on what is available. Quillien adds: “The solution is robust to extreme environments and ensures data continues to flow through storms or power outages.”

platform, digital twin or AI on the cloud. Once spec’d to meet the needs of a client, the solution is easy to set-up and can be deployed with no specialist skills required. Deployed in mere hours no matter the site location, clients gain access to critical data from a wide range of devices monitoring parameters ranging from leak detection, pipe erosion and vibration monitoring,” he details.

Quillien reveals that Krucial is currently engaged in several projects across the oil & gas industry, with a focus on asset retrofit and preventative maintenance, “as those are the use cases in which Krucial stands out from other solutions”. He notes: “The platform serves as a versatile tool for digital solution integrators – enabling them to deploy without having to make as many compromises as possible for their customers, the end users. Customers are getting increasingly frustrated by the lack of consistency in digital solutions and are demanding ‘single panes of glass’ for their operations –this means integrators need to find ways of having all the technologies they need deployed, even from different vendors and manufacturers, all work together in a comprehensive and consistent manner. Krucial Connect is one such solution,

integrating elegantly across devices and business systems to enable resilient, digitisation at scale.”

The energy sector has a solid reputation for embracing modern solutions and Quillien has observed companies being more eager to digitise their operations than in some other markets he works in.

“The oil & gas industry certainly seems to be progressing at a quicker pace than others in the engineering sector and operators are more open to adoption of cuttingedge technologies such as digital twins. Stringent environmental regulations and pressure to work more sustainably has opened the door for advanced monitoring technologies to support compliance, preventative maintenance strategies to avoid disastrous issues such as leakages in pipelines all in which help operators work more efficiently and sustainably.” But, he notes, “Although there is a growing appetite for modernisation, particularly driven by sustainability goals and stringent environmental regulations, operators often prefer solutions with a proven track record in the field. This cautious approach can create hurdles for introducing newer capabilities and technologies.”

Further complicating the

situation is that legacy systems, often designed decades ago, lack the digital infrastructure and compatibility required for integration with Industry 4.0 solutions such as IoT or AI. “Consequently, no matter the desire to integrate modern technology, its adoption is often blocked by operators not wanting the costly or time-consuming job of replacing entire systems of ageing infrastructure,” confirms Quillien.

“This is where Krucial Connect shines: negating the need to replace entire legacy systems by offering a drop-in remote monitoring solution enabling wireless data transmission via a robust communications infrastructure, allowing operators to reap the benefits of automated monitoring and digital twinning,” he adds.

And Quillien is optimistic that these benefits will be achieved on a larger scale in the very near future. “While the sector’s digital-first mindset is accelerating adoption, there remains a substantial opportunity to modernise processes that still rely heavily on manual intervention. By addressing the challenges of legacy infrastructure and delivering proven, low-risk solutions, Krucial is well-positioned to help operators unlock the full potential of Industry 4.0 innovations,” he concludes.

The high-pressure pumps of the HAMPRO® series are used in the Oil and Gas Industries to pump a very wide range of fluids, meet the stringent requirements of the relevant safety and reliability regulations and are characterized by a robust design and careful use of resources.

Our experienced team of experts will be happy to help configure the perfect solution for your individual application.

RECIPROCATING PUMPS TO API 674

- Glycol pumps - Leak test pumps

- Methanol pumps

- Produced water injection pumps

- Sea water injection pumps

Pressure: 50 – 4000 bar

Flow rate: 0,1 – 256 m³/h

Hammelmann GmbH

Carl-Zeiss-Straße 6-8

(0) 25 22 / 76 - 0 pp@hammelmann.de

D-59302 Oelde www.hammelmann-process.com

Application of composite wrap system in submerged environment

For over 16 years, the composite wrap system, Belzona SuperWrap II, has been applied throughout multiple industries to restore the strength of holed, weakened and corroded assets. Now, the R&D Department at Belzona Limited has honed the capabilities of this technology so that, with the new epoxy resin, Belzona 1984, this technology is now optimised to be applied in aqueous environments.

One of the key experts behind the development of the new surfacetolerant composite repair system, Ian Wade, technical services manager, explains that, “The Belzona SuperWrap II compliant system already features three resins designed for different application and service temperatures. Belzona 1984 is the latest development in this system, engineered specifically with surface tolerance in mind. This resin can be applied directly to damp, wet and underwater surfaces without the need for abrasive blasting.”

Wade adds: “Once cured, Belzona 1984 resists temperatures of up

to 50°C and can be applied in temperatures ranging from 5°C to 40°C. The system can be applied as a composite wrap, pad, plate or patch, depending on the application requirements.”

The new system has undergone rigorous testing and is fully approved for compliance with ISO 24817 and

ASME PCC-2 standards. These tests used samples that were applied and cured underwater in artificial seawater, representing the worst-case and most aggressive environments. Compliance with these standards demonstrates how the system is optimised for use in a variety of challenging environments, making it a welcome addition to many a maintenance engineer’s repertoire of repair solutions.

To apply Belzona SuperWrap II to ISO/ASME standards, applicators are required to complete a rigorous training programme at one of Belzona’s 16 training centres located worldwide. By thoroughly equipping applicators with the skills and expertise to successfully apply the composite wrap system, this ensures that an excellent standard of application is maintained.

To uphold this standard, every two years, the company’s Corporate Belzona SuperWrap II Trainer Committee conducts a mandatory audit of all trainers, facilities and internal staff. Upon successful completion of the audit, Belzona SuperWrap II accreditations are then renewed. Again, this process is designed to ensure a consistently safe and successful application of the composite wrap system.

As industries continue to ratchet up their carbon mitigation measures in line with the netzero by 2050 pathway, the use of polymeric repair and protection technology offers a real boon for maintenance engineers. The process of replacing damaged assets incurs a hefty carbon footprint, not to mention considerable financial expenditure. With polymeric technology, engineers can successfully bypass the carbon- and cost-intensive process of replacement, and instead rehabilitate their assets and protect them against future damage. Now, this can be achieved even in the most challenging application environments thanks to the surface-tolerant epoxy resin, Belzona 1984.

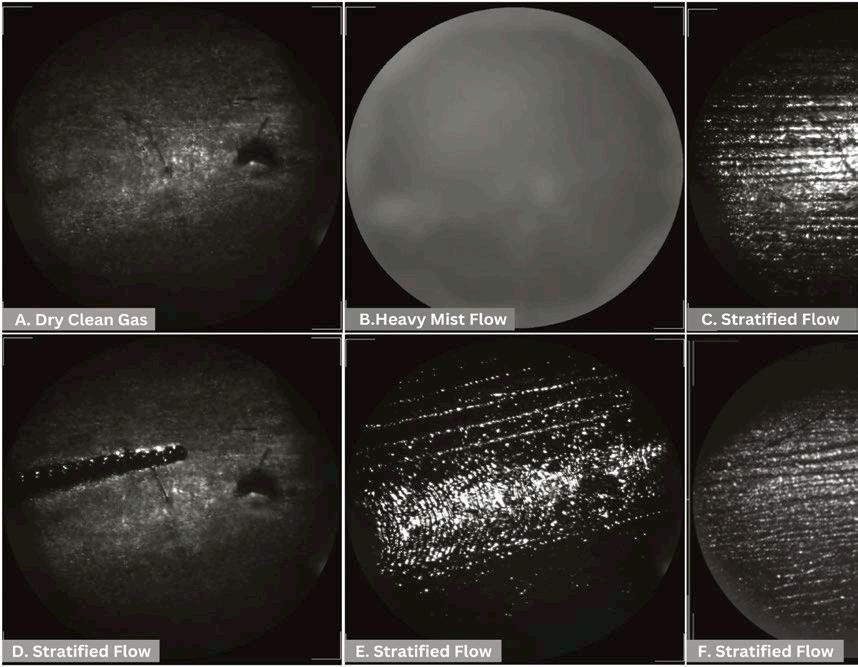

Hydrocarbon dewpoint: the gap between theory and reality. By

Paul Stockwell

For decades, hydrocarbon dewpoint has served as the industry’s standard for determining gas “dryness” in natural gas transmission and distribution. However, recent findings are suggesting that relying solely on hydrocarbon dewpoint is not enough to ensure dry gas. Widely variable results across dewpoint measurement methods highlight a significant accuracy gap that leads to undetected liquids in pipelines. This variability introduces risks to operations, making a case for advanced tools to provide a more comprehensive approach to gas quality.

Traditional hydrocarbon dewpoint is a key factor in gas sales contracts, determining if natural gas supplies meet the “dry gas” criteria essential for safe transmission. Even small volumes of liquids – mist or stratified flows of hydrocarbons – can cause operational challenges downstream. When these go undetected, they can lead to equipment damage, costly disruptions and inefficient operations. Unfortunately, variations in dewpoint calculation methods can create uncertainty about the true condition of gas in the pipeline, with temperature results for a single gas mixture sometimes spanning up to 186°F (103.6°C)[1]. This inconsistency is a growing concern for gas suppliers and end-users alike.

To bridge this reliability gap, the industry must now look at advanced visual monitoring technologies. LineVu, a pioneering pipeline camera system, offers real-time visualisation of gas flows inside high-pressure pipelines, allowing operators to detect actual liquid presence directly. Unlike hydrocarbon dewpoint measurements, which provides only inferred data about liquid formation based on pressure and temperature calculations, LineVu delivers a live view inside the pipeline. This live video feed enables operators to spot liquid mist, stratified flows, and small volumes of natural gas liquids (NGLs) that traditional

measurements fail to report.

The financial implications of undetected liquids are significant. Operators may unknowingly pass substantial liquid volumes through custody transfer points, resulting in high maintenance costs and reduced equipment lifespan. For example, an unobserved liquid presence at just 0.1% of the gas volume in a 100MMSCF/D pipeline could result in over 10,000 gallons of lost NGLs daily, translating into millions in annual revenue losses.

Liquid carryover in “dry” gas pipelines can lead to severe operational impacts in gas turbine power stations. The presence of compressor oils, or glycol can block fuel nozzles, causing imbalances and downtime.

In many cases, combining hydrocarbon dewpoint with LineVu’s real-time video data is proving invaluable. LineVu cameras, installed at standard tapping points along pipelines, enable operators to gain precise insights into the actual gas conditions. This level of transparency supports operational decisions,

ensuring that pipelines truly meet quality standards and reducing risks of liquid-related failures. Additionally, with real-time monitoring, any deviations in expected gas quality can be addressed immediately, protecting downstream applications from contamination and unplanned downtime.

As the gas industry faces increasing demands for accuracy and operational reliability, visual monitoring is becoming a critical tool for modern gas quality management. Technologies like LineVu are validating other gas analysis and flow measurements, providing a comprehensive view that safeguards both operators and endusers from the higher costs and risks of unobserved liquid carryover.

Paul Stockwell is Managing Director of Process Vision. www.processvision.com

References [1] Embry, D.L., May, E.F., (2024, September 17-20), Increase LNG Profitability by Early Identification and Mitigation of Solids Formation from North American Pipeline Gas [Paper and presentation], Gastech 2024, TX, USA.

A specialist in industrial technology explains to Louise Davis how a digital toolbox of solutions can assist oil & gas operators with both managing and futureproofing their operations

According to Sue Quense, Chief Commercial Officer at AVEVA, digitalisation is key to achieving decarbonisation for energy companies and the energy ecosystem. “Our solutions are already helping minimise emissions, manage carbon use and support the transition to a lower carbon future,” says Quense. “For example, by providing real-time energy data and supporting improved operational and design decisionmaking, we are helping hundreds of companies cut their energy consumption and emissions.”

Quense says that oil & gas customers choose AVEVA’s software to optimise existing operations and lower the current carbon footprint, but also to be ready to incorporate future changes. “Key solutions include engineering software, the PI system and our open data platform, Connect,” Quense explains. Expanding on these solutions, she adds: “Our software tools enable oil & gas customers to improve production planning for

refineries and petrochemical plants; deliver higher asset utilisation and reliability from critical assets; introduce or improve carbon-aware planning that allows visibility and management of Scopes 1, 2 and 3 emissions; and collaborate better with partners, customers and suppliers through robust data management using Connect.”

When asked about real-world applications of AVEVA’s solutions, Quense describes how they are being deployed to improve both everyday operations such as refining tasks, and longer-term emissions reductions goals. “Among our oil & gas customers, Neste, the leading producer of renewable diesel and sustainable aviation fuel based in Finland, uses AVEVA Unified Supply Chain software in the cloud to provide international teams with central data intelligence. In this way, the company reduces emissions from conventional refining and also optimise production

of renewable diesels (biofuels). Our solution works across 80 sites to support optimal decision-making around supply and distribution, production planning and scheduling – saving €3 million,” cites Quense. “Another example is Fortescue Future Industries, which uses our digital design and simulation tools in the cloud to optimise the performance of new hydrogen production plants.”

Many software vendors are selling products into the oil & gas sector, but Quense feels there are several ways that AVEVA is a unique presence here. “Our customers can count on us all along the lifecycle of their industrial assets: for the design phase, our engineering tools have been proven in the rigorous, complex environment of oil & gas for decades; our SCADA systems are solid allies to run operations efficiently; and finally, for asset optimisation, our customers trust PI systems for data management and use our simulation and asset performance management software,” she states. “Having worked in the oil

& gas sector for decades, we know the industry well, which positions us to innovate and develop software tailored to the needs of the industry. We are a pioneer in industrial AI with our predictive maintenance software used in oil & gas for almost 20 years now.”

Quense attributes part of this success to the fact the firm sees the bigger picture: “We provide industrial intelligence through Connect, our open and agnostic cloud data platform, to facilitate the transfer of information throughout our customers’ ecosystem. With advanced analytics and real-time visibility and insight tools, we empower customers to optimise their operations while transitioning to sustainable practices. Connect demonstrates our commitment to innovation, enabling the radical collaboration needed for industrial transformation and the energy transition. Our global partner ecosystem ensures a seamless implementation and support throughout the customer’s asset lifecycles.”

The oil & gas sector doesn’t exactly have a great track record on emissions, but Sue Quense feels that digital tools can make a big impact in cleaning up the energy industry. “As a technology partner to some of the world’s largest oil & gas leaders, we work in diverse ways to help drive lower-carbon strategies,” states Quense. “This means helping them ramp up on renewables and realise their full GHG emissions abatement potential through operational efficiency gains and pioneering carbon capture and sequestration design,” she adds.

With advanced analytics and real-time visibility and insight tools, we empower customers to optimise their operations

All of AVEVA’s work centres around data, and in the oil & gas market, collecting accurate and reliable industrial data has always been critical to assess and measure petroleum volumes and quality in real-time, and to satisfy the demand in a timely manner with real-time inventory status updates. “Now that the sector has a crucial role to play in contributing to a lower carbon world and in facilitating the switch to lower carbon energy, industrial data is even more prominent to help benchmark, measure and improve sustainability metrics,” believes Quense. Most sustainability challenges demand new technologies, scalable solutions and partnerships to drive change at a systemic level: “This all converges on digitalisation, which explains why the sector invests significantly to leverage the full potential of data. It’s the best way to ensure the optimal use of the world’s resources and for organisations to achieve both

sustainability and profitability goals,” she observes.

Like most industrial sectors, oil & gas is also gradually embracing the application of AI. Commenting on this, Quense says: “Energy companies use AVEVA AI-infused solutions for many things: 3D modelling and process design to accelerate and optimise engineering cycles, operators’ support, predictive maintenance aimed at reducing planned and unplanned downtime, process optimisation, and to drive safety and cost reductions.

“We’ve observed that AI can increase productivity up to 25%, enable 10x faster decision making and generate millions of dollars in productivity savings. Overall, machine learning, AI and predictive maintenance are used in the oil & gas sector to extend the life of industrial assets.”

Quense also points out the merits of AI when it comes to sustainability efforts, saying that it helps drives carbon efficiency and efficient use of resources. Proffering two key examples here, she says: ““In Spain, REPSOL has used software optimisations (Romeo + AI) to cut emissions by 20%. In the US energy sector, Duke Energy saved US$1 billion in 10 years through better preventative maintenance of its turbines using just one type of AI. US$25 billion could be saved in the next decade in North America if all energy actors do the same.”

Quense reports that some big-name energy players are taking the lead when it comes to efficiency and sustainability. “Recently, ExxonMobil, one of the largest integrated fuels, lubricants and chemical companies in the world, selected AVEVA to work on a project that contributes to tackling the global challenge of meeting the world’s energy needs for sustainable fuels,” she reveals. “Indeed, although the necessity and urgency of climate action is intensifying, the need to transport people, goods, and services isn’t vanishing. The global population will continue to rise and with it so will the need for transportation and the demand for energy. That’s why Exxon Mobil is charting a new path with Exxon Mobil Renewable Diesel (EMRD), a proprietary process technology designed to help biofuel

The production of biofuel has different constraints than for the fossil fuel

Refineries can reap many benefits of digitisation, including reducing their harmful emissions

producers enhance renewable diesel production while meeting stringent product specifications.”

Quense explains that the production of biofuel has different constraints than for the fossil fuel: “For instance, sustainable fuel producers must meet advanced cold flow specifications while maximising yield, they need to optimise different variables in the renewable diesel production process such as operating temperatures which requires advanced, customisable simulation tools. The design and optimisation of each phase of the biofuel production process is incredibly complex and requires sophisticated simulation technology. That’s why ExxonMobil chose AVEVA Pro/II Simulation to develop EMRD.”

Detailing this solution, Quense says that AVEVA Pro/II Simulation is a steady-state simulator that optimises plant performance by improving process design, running operational analysis, and performing engineering studies. She notes: “Using this simulator, ExxonMobil had the advanced simulation tools it needed to simplify the process. The company reduced model-building and computation time and improved its fundamental understanding of how the

model works and how its components interact while ensuring that the renewable diesel it produces meets the properties of conventional fuel.”

ExxonMobil plans to invest approximately US$17 billion in lower-emission fuel initiatives by 2027 and will incorporate the EMRD technology into Imperial’s Strathcona renewable diesel unit. “The refinery will use locally sourced canola oil as feedstock to produce an expected 20,000 barrels of fuel a day, which will make Strathcona the largest renewable diesel facility in Canada. Once operational, estimations suggest this new facility could help the Canadian transportation sector reduce its greenhouse gas emissions by approximately 3M metric tons per year,” Quense says.

And what about AVEVA: where will the software giant be setting its sights next? “Our product roadmap includes automation control, design reliability, visualisation of complete value chain and capital project lifecycle through different lenses such as sustainability or profitability. We will also continue to infuse Gen AI in our software for design, predictive and prescriptive analytics, to support the workforce of the future,” confirms Quense.

„How do you avoid costly process shutdowns due to the entrained gas in liquid flows? Use KROHNE OPTIMASS flowmeters with Entrained Gas Management“

Entrained Gas Management EGM™ allows our flowmeters to safely maintain operation over a wide range of gas volume fractions and complex flow conditions. e.g. 2-phase or through transition from liquid phase to a gas phase and back.

David

Hopper

Applications and Electronics Manager Coriolis mass flowmeters

Expertise you can trust – Safety solutions by KROHNE Learn more: krohne.link/egm-safety-uk

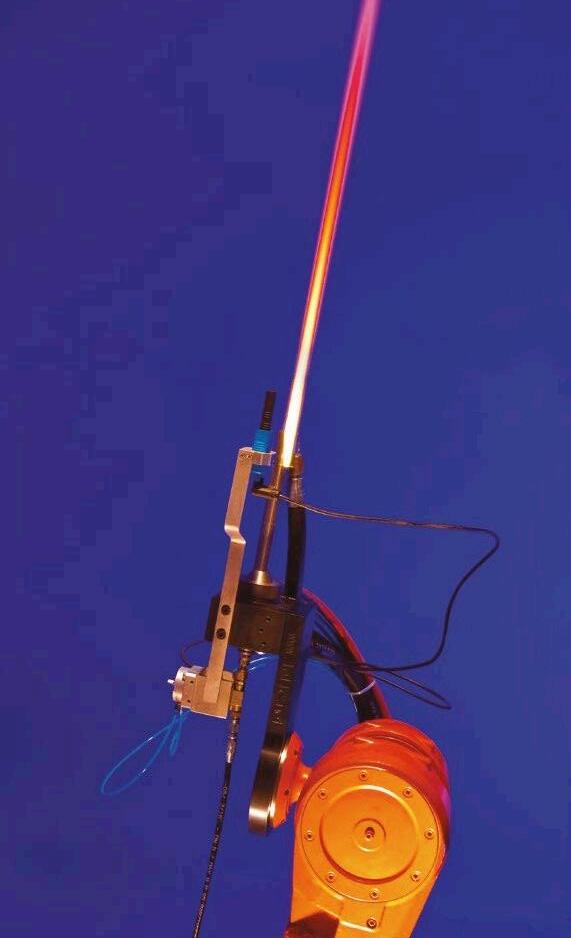

l Controlled Shot Peening

l Laser Peening

l Keronite PEO

l Thermal Spray Coatings

l Dry Film Lubricants

l Organic and Inorganic Coatings

l Parylene Ultra-thin Conformal Coatings

l Superfinishing

l On-site Processing

l Material Testing and Analysis

l NADCAP, ISO 9001:2008, ISO 13485, AS9100 Rev D

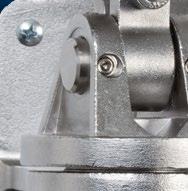

Ali Zandieh Shirazi details how an engineering firm’s customers inspired a game-changing valve design for major refineries

Cracking is essential for converting long alkanes into shorter, more useful hydrocarbons. Thermal processes were originally used for this work, though nowadays, virtually all cracking is done using catalysts. The latter process is preferred because it generates greater volumes of highoctane-rating gasoline and other valuable by-products. However, fluid catalytic cracking (FCC) is also hazardous without due care, especially during turnarounds when the risk of flash fire and injury is particularly high.

In recent months, engineering expert IMI has examined this area closely with customers, developing a breakthrough engineering solution that minimises turnaround risk and drastically reduces the time it takes to bring a refinery back online.

It’s critical to isolate a refinery’s reactor and main column during a shutdown procedure. If this is not done correctly, flammable hydrocarbons will flow into the air side of the FCC unit, creating highly volatile conditions. But this is not the only concern.

IMI’s customers inspired a gamechanging new valve design for refineries

Until recently, isolation of the reactor and main column meant removing a large ring – typically between 40 and 85in in diameter – and installing a plated blind. This blinding location can be found at the reactor overhead vapour inlet to the main column. When this is parted, personnel are exposed to a rich stream of hydrocarbons at 300°F. Site staff work in high-temperature proximity suits and under fresh air for protection. It’s difficult and dangerous work, but also essential for keeping an FCC unit working optimally. Planned turnarounds are necessary for routine maintenance and upgrades across all heavy industries. Without these periods, plants would fall into disrepair and run a much higher risk of downtime, not to mention create much lower-quality yields. Reactors must also be isolated from the main column to deliver sufficient heat to controllably raise the reactor/regen temperature.

Isolation failure caused a major explosion at the Torrance refinery

in California, USA in February 2018. Maintenance preparations inadvertently caused a pressure deviation, allowing hydrocarbons to backflow and ignite in the site’s electrostatic precipitator. The result was an explosion so large it registered a magnitude 1.7 tremor.

Through ongoing consultation with site managers across the world, it became clear that a new approach with easier actuation would offer considerable advantages. During the design phase, IMI’s principal concern was safety. First, it eliminated conditions that could lead to an incident similar to the one seen at the Torrance site. Second, it minimised engineers’ contact with streams of high-temperature hydrocarbons.

However, improving this procedure also had a commercial advantage in the form of effective isolation, which reduces risk and speeds up turnarounds. Quicker shutdowns mean quicker maintenance, allowing customers to recommence production in a shorter space of time. Reducing this window – and ensuring it’s the only downtime that occurs – is critical for running a profitable facility.

The outcome of this design and consultation process has been IMI’s Fractionator Inlet Valve, which allows refineries to run an on/off service.

In the open position, the valve body passage forms a straight tube, so solid particles can pass through without contacting any other part of the fitting. In this position – and when closed – the seat surfaces of the valve body are completely covered.

Safety measures often – and rightly – come at the expense of speed. But with this particular valve, IMI engineers have struck the balance, creating a much safer solution that also delivers distinct commercial benefits.

This project typifies IMI’s collaborative approach to product

The upper section of the goggle plate is also equipped with two separate discs in an internal wedgeball-arrangement. This means one valve will provide a positive/tight shut-off in the closed position. It’s also designed to withstand the extreme conditions common to all refineries. The discs, for example, can be released from their seats without the risk of jamming due to high-temperature changes because the internal wedges form a non-self-locking shape.

To initiate the opening movement, two wedge pieces are withdrawn until their upper faces sit against the stops. The pressure of the process fluid releases the upstream disc from its seat, so no physical intervention by engineers is required.

development, targeting areas where novel engineering can deliver for customers on several fronts.

Ali Zandieh Shirazi is regional maintenance manager, IMI. www.imi-critical.com

This valve’s quick actuation has been transformative and has cut customers’ turnaround times by 36 hours. Upon FCC unit startup, the blind – if required – can also be removed while the reactor and main column are being headed up. The valve will remain in the closed position while manway torquing is completed, and system temperatures are increased. This yields a time saving of 12 hours when compared with current methods.

Floating storage and regasification units (FSRUs) are a cost-effective method to safeguard natural gas supply, and recently, they have proved an effective temporary measure for many European nations.

Helping to support regional energy security, Burckhardt Compression conducted time sensitive compressor overhauls for two FSRUs on behalf of a leading maritime energy firm, ensuring that the revitalised vessels were fully ready to deliver this essential resource.

Although reducing reliance on pipelines is essential for European energy security, many countries do not have adequate capacity at liquified natural gas (LNG) terminals for import, export and storage. Until these facilities are built, offshore FSRUs are functioning as a stopgap, delivering LNG that will power homes and businesses.

When a maritime firm was asked to station multiple FSRUs for European countries, its attention quickly turned to the Burckhardt Compression Laby 5LP250 compressors aboard two of its ships. Featuring a rated power of 2,000kW (2,680hp) and a maximum speed of 509rpm, the unlubricated units suck methane gas in at a pressure of 12bar (174psi) and discharge it at 101 bar (1,465psi). Due to limited operation of these

compressors in the past and vibration issues, the firm wanted the units to be inspected and overhauled as necessary ahead of their deployment. Trusting the superior engineering capabilities and compressor knowledge of the original equipment manufacturer (OEM), the customer contacted Burckhardt Compression to complete the works.

The project presented multiple challenges. First, one of the vessels was due to be operational within three months, putting pressure on the team to deliver on time. Due to limited compressor use, the scope of works was essentially unknown until initial inspections. Having studied the units in detail, Burckhardt Compression engineers discovered issues with the auxiliaries such as the electric motors and safety valves. Furthermore, the anti-vibration pads were rusted, which was placing additional stress on the compressors. Some compressor components also required replacement.

A key reason Burckhardt Compression was selected for the project was its ability to take a holistic approach to the entire compressor skid. This meant that the customer could benefit from a fullservice solution designed to promote the performance and reliability of the complete system.

With the scope finalised, Burckhardt Compression got to work.

Utilising its OEM capabilities and capacity, the team organised express manufacturing and delivery of replacement compressor components for the overhauls. Working with a partner, engineers quickly sourced new anti-vibration pads, while the overhaul of other auxiliaries was conducted with trusted subcontractors. Total oversight by field service representatives ensured the highest safety and quality standards were adhered to during challenging work aboard.

The company completed the works on time, resulting in successful FSRU deployment with no delays. This was possible due to the company’s ‘onestop-shop’ service philosophy, which simplified and expedited all aspects of the project for the customer. New OEM quality components fitted to the compressors ensured the best possible service life.

With energy security a cornerstone of European governmental policy, FSRUs will continue to support countries that are reacting to a previous over-reliance on pipelines. However, the effectiveness of these vessels – and therefore dependable gas supply – is subject to the reliability of onboard equipment. With the full-service capabilities of Burckhardt Compression, FSRU operators in downstream applications now have the holistic support they need to succeed.

To avoid unplanned downtime in plant operation it is essential that vital components such as actuators and valves work correctly and reliably. Plant operators thus need to be able to evaluate the health status of their actuators any time in order to stay alert to maintenance requirements.

Modern digital solutions such as Coralink, the AUMA digital ecosystem, provide the basis for this. Coralink offers a number of smart software modules that allow plant operators to use their AUMA electric actuators efficiently and ensure their reliable and safe operation.

The actuators automatically record extensive operating data, such as number of starts, motor running time, torque, temperatures and any fault codes, giving valuable information on the health status of the actuator. Plant operators can easily read out this data from an actuator in the field by using AUMA’s Ex-rated RSTX 100 remote

control, for example, and subsequently analyse it in Coralink.

The automated analysis and diagnostics of actuator data in Coralink result in a detailed action plan with recommendations for each actuator. Plant operators can plan necessary interventions at an early stage and thus avoid unplanned downtime. Coralink also offers the

option of getting directly in touch with AUMA service experts via actuator-related service tickets.

Coralink is available free of charge in a very comprehensive basic version.

For more information visit: www.coralink.auma.com/en_GB/ service/coralink

Features of a new series of Ex command devices currently being launched by the Steute business division Controltec include flexible and direct integration in machine and plant enclosures within Ex zones 1 and 21.

The Ex ES 97 series is based on the Ex 97 series of position switches. This series is already well established in complex application fields, most particularly explosive zones, and has dimensions to EN 50047.

The switching system of this series (slow action, 1 NC/ 1NO, positive break NC contact) is extremely robust and durable. The separate terminal compartment to ignition protection class Ex e facilitates flexible connection of cables directly inside the terminal compartment

of the command device. Thanks to the compactness of the dimensions (installation diameter just 22.5 mm), the Ex command devices are easy to integrate in the surrounding structure.

The new Ex command devices are initially available in three versions: with a push button, a latching selector and a standards-compliant emergency stop button. All variants are suitable for use in Ex zones 1 and 21 (gas Ex and dust Ex). Additional actuator variants are available on request.

This Ex ES 97 series perfectly complements the Steute Controltec range of command devices for explosive zones. To date, users could choose between the Ex 14 series with connecting cable and the Ex BF 80 in a robust plastic enclosure with a terminal compartment. Now a third option is also available.

For more information visit: www.steute.com/en

A new electrified distillation solution aims to improve energy efficiency and enable carbon emission reductions

Engineering giant Sulzer has recently launched VoltaSplit, its new electrified distillation solution that considerably enhances energy efficiency while enabling the reduction of direct CO2 emissions.

Relying on electricity in lieu of traditional energy-intensive steam boilers, VoltaSplit reduces the direct CO2 emissions of distillation units by up to 90%. This in turn enables process industries to meet regulatory requirements, improve operational performance and reduce their longterm environmental impact.

Distillation is a cornerstone process in numerous industries, yet it is traditionally characterised by high energy consumption. Conventional distillation systems often rely on onsite steam boilers powered by carbonintensive fossil fuels, contributing

substantially to the greenhouse gas (GHG) emissions of refinery and chemical complexes and to the carbon footprint of chemical products, fuels and solvents.

Designed to drastically reduce the energy consumed by distillation plants and the associated CO2 emissions, VoltaSplit has been proven to increase the efficient use of energy and to greatly reduce operational costs by cutting energy requirements up to 20 times compared to traditional solutions such as electric reboilers.

Sulzer’s innovative approach uses electricity as its single power source to run distillation units, enabling process industries to decrease the energy they require. Moreover, it permits them to shift to renewable energy when

available without any major investment in new infrastructure. In this manner, VoltaSplit is setting new standards for distillation by offering a more sustainable and cost-effective solution.

Sulzer Executive Chairwoman, Suzanne Thoma, concludes: “We strive to deliver process solutions that create significant value for our customers. We’re proud to offer a solution that drives efficiency while actively contributing to the reduction of global emissions, both of which are key concerns for industrial operators today. With the launch of VoltaSplit, we aim to speed up the global adoption of transformative technology that enables essential industries to produce at lower costs while saving on GHG emissions.”

VoltaSplit reduces the direct CO2 emissions of distillation units by up to 90%

• IR3, UV-IR flame detection

• HD cameras & on-board recording

• 5 years warranty

• Highest immunity to false alarms

• ATEXIEC ExFMSIL certified

• Energy transition

• Offshore wind

• Hydrogen

• Energy storage

• Oil & Gas

Michal Wozniakowski-Zehenter discusses the role of a well-established personnel tracking system in today’s offshore oil and gas industry safety

The T-Card system could be incorporated into muster lists

Safety and efficiency of operations are the most important things in the offshore oil and gas industry. The environment is hazardous, full of extreme weather conditions, isolation, and possible high-risk incidents such as blowouts, fires and leaks. Personnel tracking and efficient managing of operations become critical tasks in such an environment. One traditional yet effective method of managing personnel on offshore installations is the T-Card system. This system is not new; it has been in many offshore operations for decades. Like any system, though, there are pros and cons.

The T-Card system is a simple manual system for tracking personnel on offshore installations. It gets its name from the cards in a T-shape that are used in the system. Each card represents a worker and carries the worker’s name, position, and

other useful information. These cards are slotted into a rack or board, often located in some central and accessible place on the installation. Cards can be moved or marked in some fashion to indicate whether the worker is at work, not at work, at some particular worksite, or engaged with specific tasks.

The T-Card system is appreciated for its simplicity and straightforwardness. It does not require advanced technologies or much infrastructure; hence, it is easy to establish and use. One would just move his or her card to the corresponding slot or appropriate section according to his or her current status. In this case, it allows one at first glance to understand who is on installation, their location, and their current activity. This simplicity makes system a popular choice in an environment where electronic systems may not be reliable or feasible because of technological limitations, harsh environmental conditions, or cost constraints.

The main advantage of this system is that it is simple and straightforward. It depends on no electronic gadgets, no internet facility, or any sophisticated software. Hence, under offshore conditions, too, it’s very reliable due to failure resulting from worst weather conditions, faulty equipment, or power failures. The fact that the T-Card System is manual means it doesn’t fall under the increasingly pervasive cyber threats that internet-based systems of the modern age do. Where safety is paramount, such as it needs to be in such an industry, this can be a big plus for a manual system.

The other added advantage is the transparent, on-the-spot picture of personnel during installation. In case of an emergency, such a facility becomes vital for ascertaining the presence and absence of anyone and where they were last seen. This becomes very important in cases of fire, blowout, or abandonment, where every second counts as rapidly

Manual mustering is used to evacuate an offshore installation during an emergency; knowing how many personnel need to be evacuated is crucial for operators

accounting for personnel. The T-Card system can be especially useful in remote areas where digital systems may have limited connectivity or when power is lost.

Yet another point in its favour is that the system is cost-effective. Unlike electronic systems, which demand highly priced hardware and software and require expensive maintenance and training, the T-Card system does not have high initial set-up costs or recurring maintenance expenses. The materials include T-shaped cards and a rack or a board, fairly inexpensive and seldom needing replacement or upgrading. Hence, this proves to be highly economically viable in smaller operations or installations with a shoestring budget.

It is a highly flexible and adaptable system. The system can be tailored to suit particular needs of an installation or operation. Colour-coding of cards, labelling with different information, and various configurations make the card suitable for a specific application in personnel tracking. This, again,

The T-Card system does not have high initial set-up costs or recurring maintenance expenses

enables the adaptability of the system to work in conjunction with other safety and operation management systems, making it more functional in complicated environments.

Though providing certain advantages, the system also entails a few possible disadvantages. The main problem is that the method tends to depend too much on manual entry and human intervention. It would require people to remember card movements and report status changes accurately for the whole system to work. Working in such a busy, highpressure environment as an offshore installation, personnel may forget to update their cards or, worse still, deliberately manipulate the system to suit their convenience. This immediate dependence upon human behaviour introduces the possibilities of mistakes, omissions, and inaccuracies that can so easily defeat the overall system’s effectiveness.

The system also does not scale very well, which is a major drawback. The T Card system might be fairly workable on smaller installations with a limited personnel roster, but in larger installations where hundreds of workers are employed, the system starts to become very cumbersome and laborious to apply. As the number of personnel increases, the administration and maintenance of the card system become ever-more complex. It will involve much time in updating and finding particular cards individually; hence, the system will be less effective and could also affect general operational safety.

Moreover, there are intrinsic limitations in the type of data that the system can show: where electronic systems can support analytics, trend analysis, and automatic reporting, for instance, the T-Card system can present just a static picture of the personnel at any moment in time. It is not able to track the movement over time, analyse patterns, or provide current information in such a manner as to add something new to improvement in decision-making and operational efficiency. This limitation can be a significant disadvantage in an industry where data-driven decisions are increasingly important for optimising safety, productivity, and cost-effectiveness.

Apart from that, another serious drawback is the system’s unsuitability in emergencies when an immediate evacuation or rescue has to be arranged. In cases of emergencies, personnel may not get the time to correct updates on their cards. The result may be chaos and delay in the accounting process for all the personnel involved, and this can have serious consequences if it involves a high-risk environment. In such cases, the inability to have real-time data and possibly the error from a human intervention may severely curtail the effectiveness of the T Card system.

Though the T-Card system presents disadvantages, solutions that can help ease these issues and make the system more effective as a whole are available. The easiest approach would be regular training and reinforcement that informs personnel about the importance of updating their cards correctly. Operators can reduce the chances of errors and omissions by building a safety culture of accountability in which accurate personnel tracking is recognized as playing a very important role. Likewise, regular drills and exercises can instil good habits and ensure that personnel know what to follow in case of an emergency.

Integrating the T-Card system with digital solutions could complement the scalability issue. For example, this can be further developed into a hybrid system whereby the backup or secondary system would be an electronic tracking system with the T-Card system. This will provide the reliability and simplicity of the T-Card system while reaping some benefits from enhanced data capabilities and scalability of digital systems. This will, in turn, enable operators to develop a more robust and versatile solution for personnel tracking by merging the strengths of both systems.

On the other hand, technological advances also hint at possible solutions for the data limitations of the system. One such method could include RFID tags or QR codes on T-cards that allow electronic tracking of movements while retaining the simplicity of the manual system. Personnel would swipe their cards at various checkpoints or stations, thereby recording their movements and activities in real time. The information thus obtained logs automatically and can be analysed for detailed insight into personnel behaviour, operational efficiency and safety performance.

For emergency response, it may be appropriate for operators to develop protocols that do not wholly and entirely rely on the T-Card system for personnel accounting. This could be taken to an advanced level where the system is incorporated with other emergency response tools, such as digital muster lists, automated headcounts, or electronic tracking systems. This would ensure that in case the T-Card system fails or is compromised, there is another mechanism for the accounting of all personnel at speed and within the minimum percentage of discrepancies.

Improvement in its physical design and layout can also help overcome certain disadvantages. Locating the T-Card rack or board, for example, in a central position that is easily accessible could help personnel remember to update their cards. Besides, the cards could be enlarged to become more easily readable or in different colours for distinct roles or departments to

The use of technology in improving communication and coordination is equally important as it would help mitigate some of the weaknesses of the T-Card

reduce any likelihood of misunderstandings in using the system.

In any case, operators may institute routine checks or audits to ensure proper observance and uniformity of the system. The use of technology in improving communication and coordination is equally important as it would help mitigate some of the weaknesses of the T-Card system, for example, the playing of radios, public address systems, or even implementation of tools used in digital communications to remind personnel about card changes or present current updates during any emergency situation to work better

with the system. To reduce some of the issues with the T-Card System, preparation for an appropriate and clear communication scheme should be in order, and all personnel should be informed about it.

Over the years, the T-Card system has proved to be a reliable, lowcost method for personnel tracking offshore inshore installation in the oil and gas industry. This simplicity and ease of use, added to its reliability in hostile environments, render it extremely useful in situations where electronic systems cannot be

used or prove feasible and reliable. However, the system has a host of disadvantages. These include reliance upon manual input, the system not lending itself to scaling up, and the lack of real-time data tracking capabilities.

Knowing these limitations and introducing potential solutions, such as frequent training, hybrid systems, enhancement of technology, better design, and communication, will lessen the identified disadvantages of the system that operators perceive. Inversely, they may maximise their total effectiveness. As the search for offshore oil and gas continues to expand, the balance between traditional methods and modern technology holds the key to maintaining safety, efficiency, and productivity across operations.

The T-Card System, if put into practice effectively, can continue to be a valued component of the overall personnel management approach in the demanding and changeable environment of offshore oil and gas.

Working in Ex zones does not necessarily mean compromising on user comfort, explains Kathrin Geisler

Working in potentially explosive atmospheres and harsh industrial environments is associated with risks on the one hand, but also with restrictions on working comfort on the other. Due to specific requirements the intrinsically safe protective equipment is often somewhat uncomfortable, unwieldy and heavy. Of course, safety and especially intrinsic safety are always top priority. To fulfil all requirements, the i.safe Mobile development team always strives to offer users the best possible user comfort for physically demanding work on site, in addition to the absolute priority of intrinsic safety.

Now there are also many areas in industrial operations in the oil & gas sector that do not belong to Zone 1/21, such as areas in Zone 2/22 or a combination of this and rugged work zones. It is precisely for these transitional areas that i.safe Mobile has now introduced its latest, light and convenient industrial smartphone for zone 2/22. The ATEX/IECEx-certified IS880.2 is a further development of its popular predecessor model, the IS655.2. During development, the company responded to customer suggestions and focused in particular on userfriendliness and product longevity.

The 5.5in smartphone (dustproof and waterproof according to IP68 and MIL-STD-810H) was developed for users who are not only working in Zone 2/22 with just one mobile device in their pocket, but also in harsh outdoor areas or also in the office area of the company. In terms user experience, the smartphone with Android 14 is almost indistinguishable from a normal, more robust smartphone thanks to its reduced weight and manageable dimensions.

A fingerprint sensor was a request from industry users, as facial recognition is often not possible

The IS880.2 is a comfortable, intuitive option for users in the oil & gas industry