Using Connected Intelligence framework linking Key Business Ques�ons for Insights

Price elas�city and its impact on sales

Op�mal alloca�on of spends and budget Inventory planning to have op�mum stock level by loca�on

Capacity constrain monitoring and planning

Logis�cs Op�miza�on and scheduling

Con�nuous metrics monitoring

What-if Analysis, understand impact of compe�tor’s plan

Business planning

Intelligent product manufacturing cycle based on demand forecast

Collec�ng informa�on from various siloed teams

Op�mize promo�ons, por�olio, and Inventory

Assess shi�ing demand trends across channels and prescribe ac�ons

Adapt to capture poten�al change in vendor cost

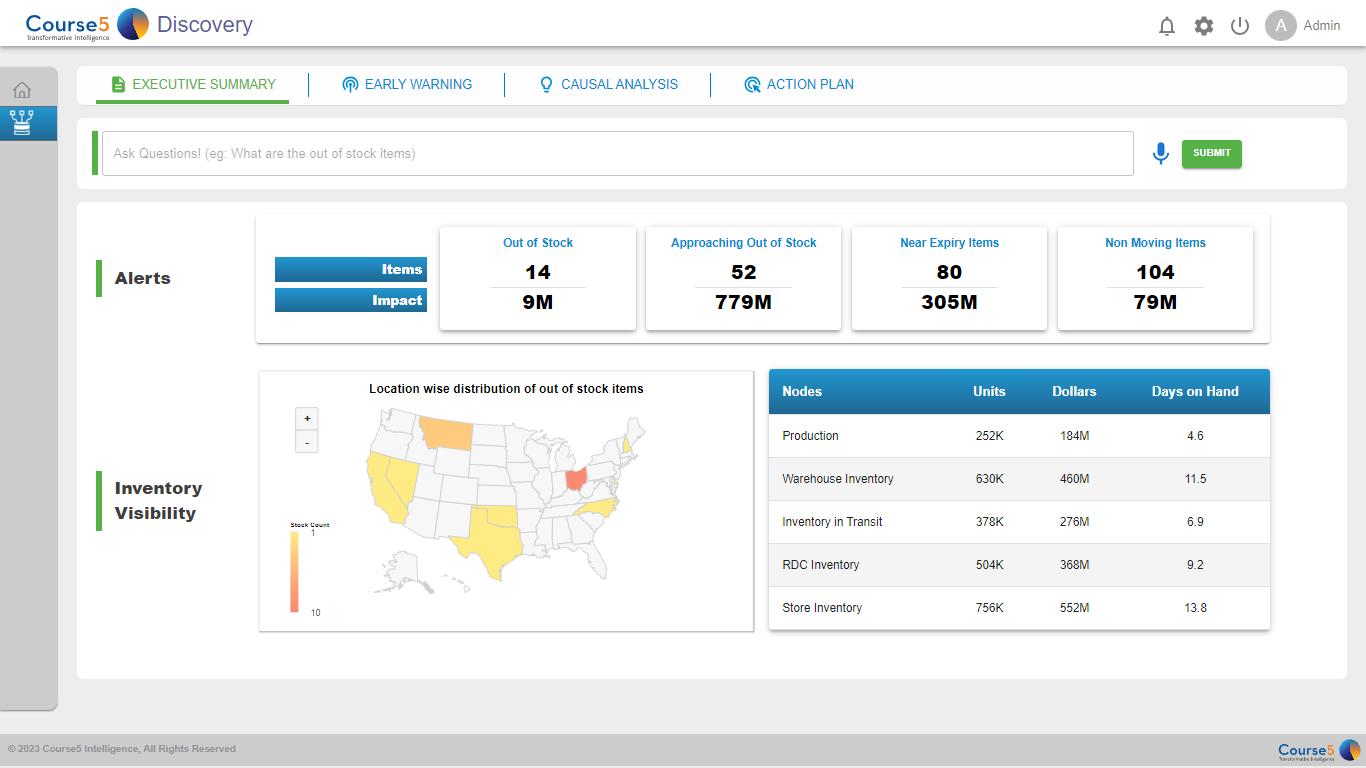

Out of Stock

Reduce Markdown, Damages, Returns

Manage disappearances and Inventory accuracy

Predic�ng poten�al waste

�me anomaly

detec�on Damage propensity

View into pa�erns that drive Waste

Top drivers – planning, shipments, Physical count, Invoice accuracy

Ageing Inventory Management, changeover management Produc�on waste –process, �me and material

Improve near term forecast accuracy based on short term market events

Promo�onal demand assessment and impact of strategy change

Product lifecycle management

Differen�ated replenishment programs

Analyze external factors e.g. Economy, weather, demographics

Pricing and Promo�ons by segments

Changes in product Mix and assortment plan

Proac�ve stocking of product shelves to ensure launch success

Op�mum replenishment planning to have right inventory for promo

Forecast valida�on and review

Ra�ngs/ Reviews based product characteris�cs

Sales cannibaliza�on analy�cs

Review capacity plan

unexpected order surge/ drop management

Tailor service agreements and policies to improve profitability

Supplier segments and reliability analysis

Freight op�miza�on based on segmented logis�cs planning

Customer priority se�ng for fulfillment, order alloca�on and order promising

Cost to serve analysis

define tailored supply chain strategies to maximize customer value proposi�on

Alloca�on of ATP by customer priority

Address penal�es –overstocking/order delays

Improve on �me delivery by genera�ng reliable quote

Inventory re-balancing based on demand/ supply change

Op�mize last mile delivery/logis�cs

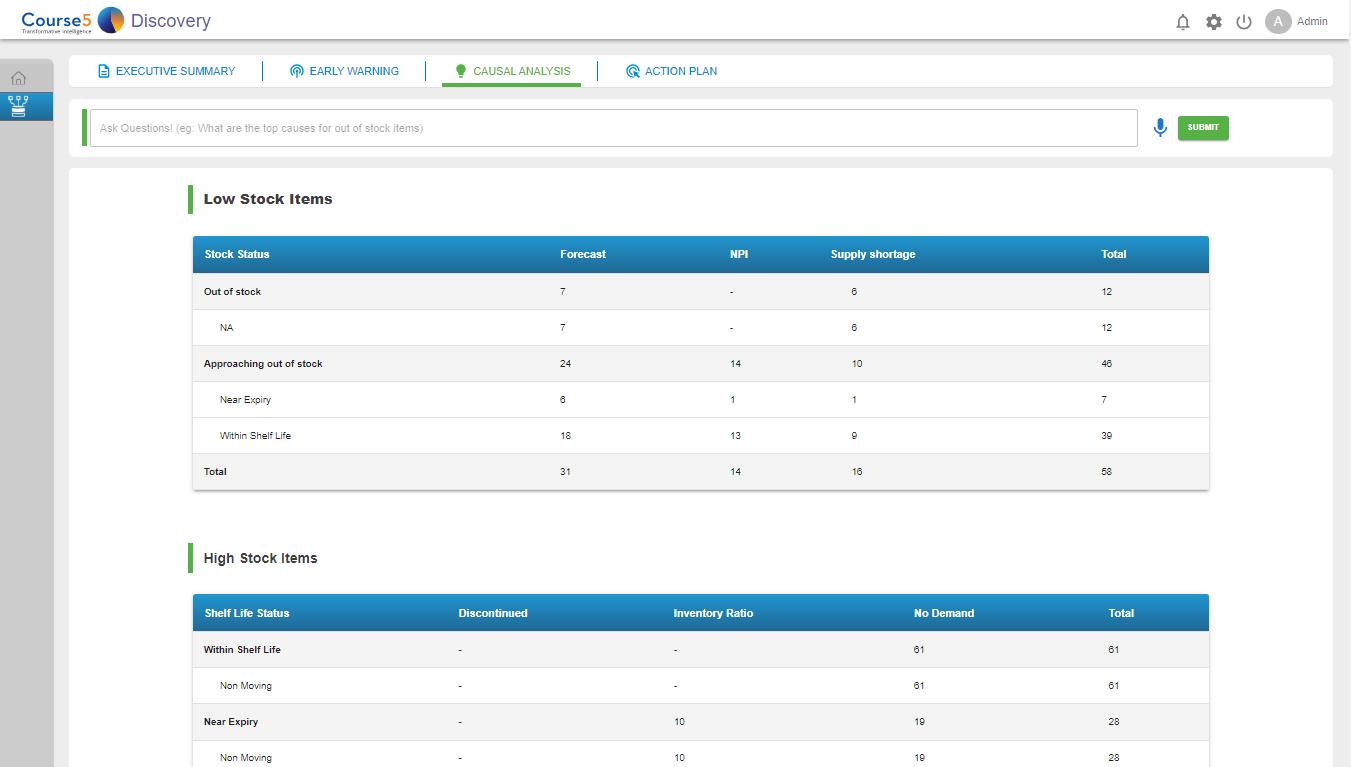

▪ Order Priority - 348 SKU's were priori�zed for delivery to other channels. Check with delivery loca�on on possible root causes.

▪ Order Pa�ern - Unexpected order surge observed across 223 SKU's compared to regular pa�ern. It suggests higher inventory requirement and forecast adjustment.

▪ Order vs Forecast - Higher forecast error observed across 268 SKU's. Check system forecast and adjust according to order velocity.

▪ Others - Out of the orders received, 14 SKU's are discon�nued, 8 SKU's are not in assortment, 44 SKU's have incorrect case pack.