Anglia Farmer

News

Delay

Arable

Thirsty crops feel drought impact

Technology

£50m

Sugar

Fen

News

Delay

Arable

Thirsty crops feel drought impact

Technology

£50m

Sugar

Fen

EDITORIAL

Editor:

Johann Tasker | T: 07967 634971

E: johann@ruralcity.co.uk

Design:

Mark Shreeve | T: 01502 725839

E: mark.shreeve@micropress.co.uk

Advertisement production:

Polly Coleman | T: 01502 725841

E: polly.coleman@micropress.co.uk

Callum Hoffman | T: 01502 725840

E: callum.hoffman@micropress.co.uk

ADVERTISING SALES

Danny Lewis | T: 01502 725862

E: danny.lewis@micropress.co.uk

Lawrence Kenny | T: 01502 725860

E: lawrence.kenny@micropress.co.uk

Harvey Taylor | T: 01502 725804

E: harvey.taylor@micropress.co.uk

Anglia Farmer is a controlled circulation magazine published monthly for farmers and growers in the eastern counties. To be included on the circulation list, a farmer must have a minimum of 70 acres of land, or 50 dairy/beef stock, or 50 breeding sows/250 growing stock, or 15,000 laying hens/broiler chickens. Intensive horticulture units are required to have a minimum of two hectares. Subscription is £18 a year (including postage). No responsibility can be accepted by the publishers for the opinions expressed by contributors.

If you no longer wish to receive this magazine, please email gemma.mathers@micropress.co.uk

© Countrywide Publications 2024

Published by Countrywide Publications, Fountain Way, Reydon Business Park, Reydon Suffolk IP18 6DH T: 01502 725800

Printed by Micropress Ltd, Suffolk.

Visit our website for all the latest farming news

Good politicians know when to change their minds – and aren’t afraid to do so when the time is right. Especially when mounting evidence suggests that doggedly pursuing a policy will harm the very people it was designed to protect.

This is the challenge facing the government after a cross-party group of MPs recommended that Chancellor Rachel Reeves delays plans to impose inheritance tax on farmers – and comes up with a more appropriate tax proposal instead.

The recommendation to delay is striking because the Environment, Food and Rural Affairs Committee includes seven Labour MPs. Without their support, the commitee’s call for a delay wouldn’t have seen the light of day.

It provides the Chancellor with an off-ramp –an opportunity for the government to back down with dignity on its controversial proposal to levy 20% inheritance tax on farming assets worth more than £1 million from April 2026.

Should she choose to do so, the Chancellor can cite the advice of her own backbenchers and show that she is prepared to listen and rethink one of

the most damaging policies of Labour’s short time in government.

It is unlikely that the inheritance tax proposal will be scrapped completely. But as the Tenant Farmers Association has pointed out, it is abundantly clear to anyone who has scrutinised the plan that it is not fit for purpose in its current form.

As TFA chief executive George Dunn has argued, the policy must be finessed before it is introduced so that it achieves the government’s stated aim of raising tax revenue and ensure that wealthy individuals cannot “hide” their wealth by buying farmland.

Farming organisations have proposed a number of ways that the government could tweak the policy to achieve its objectives while mitigating against the negative, unintended consequences of its current approach.

Time will tell whether the government will eventually listen. But huge damage will be caused to farming families should it fail to do so. It’s not only the right time for the Chancellor to back down – it’s long overdue.

Johann Tasker Editor

• Vulnerable farmers most at risk

• Tax impact disputed and unclear

• More time to seek proper advice

MPs have called for a year-long delay to government plans to impose inheritance tax on farm assets worth more than £1 million from 2026.

The cross-party Environment, Food and Rural Affairs (Efra) Committee said a 12-month pause “would allow for better formulation of tax policy” and give government ministers the chance to convey a positive longterm vision for farming.

Delaying the plan – due to come into effect from April 2026 – would also protect vulnerable farmers who would have “more time to seek appropriate professional advice,” said the Efra committee.

Rebuild trust

Changes announced in the autumn Budget 2024 were made without adequate consultation – or a proper impact and affordability assessment, said committee chairman Alistair Carmichael MP.

This meant the impact of the changes on family farms, land values, tenant farmers, food security and farmers across the UK was “disputed and

unclear” – with a risk of producing unintended consequences.

Mr Carmichael said: “There is an opportunity here to rebuild trust and confidence in the farming sector and I hope that the government will take our recommendations seriously.”

A raft of announcements – including the sudden closure of capital grants, the closure of Sustainable Farming Incentive scheme and the faster phase-out of direct payments –had left farmers feeling they could not rely on the government.

“The government, however, seems to be dismissing farmers’ concerns and ignoring the strength of feeling evidenced in the months of protests that saw tractors converge on Westminster and up and down the country.”

Poor and confusing

Defra’s communications with farmers have been poor, with confusing and sometimes contradictory messaging, said Mr Carmichael.

He added: “Policies affecting farmers have been announced without due consideration or explanation of their impact or rationale.”

“There has been a lack of adequate consultation

Some 70% of farmers felt optimistic about their rural businesses before the Budget, suggested a March 2025 survey. But that number fell to 12% afterwards, said Mr Carmichael.

“Farmers urgently need clarity, certainty and advance notice of changes – they cannot be expected to rethink their businesses on a whim. It is essential that Defra focuses on rebuilding trust through good-faith communications with the sector.”

A government spokesman said 75% of estates would continue to pay no inheritance tax at all under the plan – while the remaining quarter would "pay half the inheritance tax that most people pay".

Defra is contacting thousands of farmers who were left in the lurch following the abrupt closure of the Sustainable Farming Scheme.

It follows a government decision to reopen the scheme to 3000 farmers who had started an application but not yet submitted it in the two months before the SFI was suddenly closed on 11 March. The farmers had threatened legal action over the closure.

The decision to reopen the scheme came after the group of farmers, supported by the NFU, wrote to Defra secretary Steve Reed to inform him of their intention to legally challenge his decision to close the SFI to new applicants without notice.

New applicants

A notice on the Rural Payments Agency website had assured farmers they would

be given six weeks notice of any intention to close the SFI to new applicants. But the scheme was closed with immediate effect at 6pm on 11 March.

NFU President Tom Bradshaw said: “While it’s good to see an acknowledgement that the decision to close the scheme was flawed, we are disappointed by the constraints imposed which will still leave many farmers unfairly disadvantaged.”

n

n

n

Farmers and farming families worried about the future are being urged to talk to somebody rather than bottle up their feelings.

Suffolk agricultural chaplain Graham Miles says the number of calls he receives from concerned farmers has tripled since the autumn Budget – and a raft of government announcements affecting farming families and businesses.

Challenges include the decision to impose inheritance tax on farming assets worth more than £1 million, the increase in employer National Insurance contributions and the accelerated phase-out of the basic payment scheme.

In his role, Mr Miles champions mental health and wellbeing in the farming community – and encourages farmers to open up about their concerns. He is backing the NFU’s campaign to overturn the government's inheritance tax plans.

“I’m getting calls now every day,” said Mr Miles. “Most of them are about the family farm tax and other aspects of the au tumn Budget. “It’s a very worrying time for farmers out there.”

Mr Miles, a former livestock farmer who lives in Ipswich, highlighted the case of a farmer who declined cancer treatment months before his death due to the strain of facing an inheritance tax bill.

Members of the public will visit hun dreds of farms this month when Open Farm Sunday gets under way on 8 June.

The industry’s annual flagship initiative provides a fantastic opportunity for farmers to develop deeper connections with the pub lic, says event manager Annabel Shackleton, of the Linking Environment And Farming charity (LEAF).

farmers are left feeling this way. Politicians need to fully appreciate the pressures being piled on farmers by some of these new pol icies and work with the NFU and the farm ing community to find solutions.”

The NFU is urging the government to en gage with them on its proposal for inher itance tax to only be applied to qualifying assets if they are disposed of within a sev en-year period after death – so tax is paid only when the money is available.

aims of raising revenue – but avoids penal ising elderly farmers and breaking up fam ily farms. It also makes it unattractive for wealthy people to buy land so they can use agricultural property relief to avoid tax.

Mr Miles is a qualified Church of England evangelist and unpaid lay minister. He was officially inducted as permanent Bishop’s Agricultural Chaplain for Suffolk by Bish op Martin Sealey in January this year.

Mr Miles added: “My main message to farmers out there who are struggling is that it’s good to talk to someone and not bottle everything up. I am available to talk to 24/7, 365 days a year.

“As a former farmer, I speak their language and I understand the pressures and

“Inviting people on farm, no matter how few or how many, is a surefire way to help put public perception of farming on the right track,” says Mrs Shackleton.

“Our farmers produce nutritious food that we can fundamentally trust by maintaining incredibly high standards, all while working

hard to farm sustainably and safeguard nature. These important achievements deserve showcasing.”

LEAF-certified dedicate at least 15% of their land to natural habitats that help restore ecosystems and strengthen the resilience of the environment and landscape – as well as producing food.

“By keeping farming front of mind, Open Farm Sunday helps foster lasting trust and

the challenges. Being outside the family unit helps as well for anyone who feels like they don’t want to overburden their immediate family with their worries."

To contact Graham, call 07413 683368 or email graham.miles@cofesuffolk.org

appreciation among consumers about the vital role farmers play in producing nutritious and safe food while working in harmony with nature,” adds Ms Shackleton.

“We know we can influence consumer attitudes,” she says. Survey data from last year’s Open Farm Sunday shows that 87% of visitors left with greater trust in British farming, and 91% felt motivated to buy more British produce as a result.

• Lack of rain hits UK cereal crops

• Wheat and barley under stress

• Yield penalties on parched soil

Growers face an earlier harvest with combines expected to roll into cereal crops later this month after the driest start to spring for more than 60 years.

Reservoir levels remain low following the driest March in England since 1961. April received just half its normal rainfall – prompting some farmers to irrigate crops early, including cereals and sugar beet.

AHDB agronomy manager Emma Willis said: “Most cereal and oilseed rape crops were in fair, good or excellent condition at the end of April. A fortnight later and many more were showing signs of stress.”

With some wheat reaching flag leaf stage two weeks earlier than usual, growers on lighter land face an even earlier harvest than 2022, when combine harvesters rolled into barley before the end of June.

Cambridgeshire farmer Martin Lines said: “Every day without rain pushes crop yields backwards. Water

for irrigation is already running low, and farmers are having to make hard decisions about which crops – if any – can be saved.”

A meeting of the National Drought Group – convened last month by the Environment Agency – was told that water companies must do more to cut leakage and encourage customers and businesses use supplies wisely.

The drought group includes Met Office representatives, industry regulators, water companies, farmers and conservationists.

No area is currently in drought –but there is a medium risk this summer without sustained rainfall.

Chairing the meeting, Environment Agency deputy water director Richard Thompson warned: “Drier conditions at the start of this year mean a drought is a possibility and we need to be prepared.”

Farmers growing forage are being asked to assess feed requirements now because of continuing dry weather.

With many cattle and sheep farmers relying on grazing during the summer, and harvesting silage for winter food stocks, now is the time to make plans to help mitigate against poor grass growth.

AHDB senior knowledge exchange manager Katie Evans said: “The lack of rainfall – particularly in the driest regions where it hasn’t rained for weeks – could significantly slow growth, reduce silage yields, and impact grazing availability.”

Although good grass growth rates were achieved on some farms during early May, it was worthwhile farmers assessing both summer and winter feed requirements and building contingency plans, said Ms Evans.

“This might include reviewing silage stocks, being prepared to cut earlier than usual to prioritise feed quality over bulk and considering fastgrowing catch crops for summer or autumn grazing.”

“Rotational grazing can help protect residuals and reduce plant stress, and where pasture supply is tight, using buffer or supplementary feeding early can protect sward recovery later in the season.”

Small decisions now would help to maintain long-term resilience and avoid bigger challenges later in the year, said Ms Evans.

“It’s about being proactive: resting paddocks, avoiding overgrazing, and preserving pasture cover. ”

as working with farmers to help them plan for irrigating their crops.

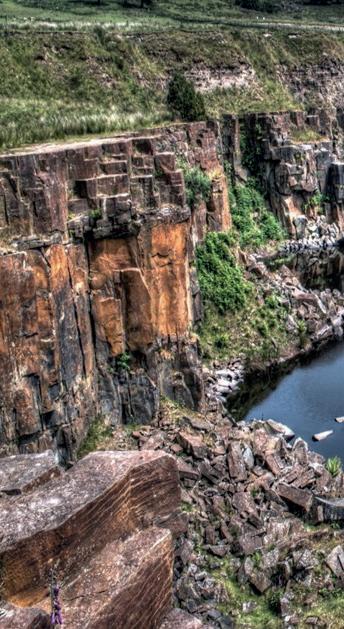

Above: An old bridge is revealed at Baitings reservoir during the 2022 summer drought

The last two years were some of the wettest on record for England, acknowledged Mr Thompson. But he added: “The changing climate means we will see more summer droughts in the coming decades.”

The Environment agency said it was closely monitoring the situation – especially in high-risk locations – as well

Defra water minister Emma Hardy said: Our water infrastructure is crumbling after years of under-investment. Water companies must go further and faster to cut leaks and build the infrastructure needed to secure our water supply.

The government had secured over £104 billion of private sector investment to fund infrastructure improvements, said Ms Hardy.

This included nine new reservoirs to secure future water supply into the decades to come, she added.

• Think about sulphur – not only nitrogen

• Nutrient efficiency at heart of decisions

• Consider decoupling for more flexibility

Growers and agronomists are advised to think more broadly when devising their fertiliaer plans for next season.

A wider view when it comes to organic and inorganic fertilise will ensure crops get the right nutri ents, says Peter Scott, technical di rector at Origin Soil Nutrition.

The need to reduce the carbon foot print of food production and minimise potential environmental issues, means growers need to understand more than ever how to low carbon fertiliser prac tices, he believes.

"Use of inorganic nitrogen fertil isers is the single largest component of the carbon footprint of crop pro duction and any attempt to decarbon ise food production will need to ad dress this."

In a typical combinable crop, 50% of the carbon footprint is related to the production of the fertiliser in the first place and the other 50% is due to in-field emissions.

"But, around half of human die tary protein consumed globally is di rectly related to the use of inorganic nitrogen and in the west, this would be much more. The issue of nitrogen use goes to the very heart of sustain able food production.

"Green ammonia, where the hydro gen element of ammonia comes from water rather than gas, could play an important role in the future with re gard to reducing the carbon footprint of manufacture, but we must also ad dress in-field emissions."

Nutrient efficiency

The pH of soil together with its organ ic matter content and structure plus other considerations such as drain age all impact on emissions, so better management is essential in the future, says Mr Scott.

"One of the biggest things we can do, and one of the most important

ANTLER performed exceptionally in APHA variety list testing in the past 3 tough years. In 2024, extensive farm trials recorded consistent and exceptional yields leading it to be added to the very top of the BBRO Recommended List for 2026 sowing.

With lower bolting and higher sugar content than the market leader BTS1915, it offers better performance with lower risks.

Combine this with excellent seed quality, establishment, a good disease package and the opportunity to buy our proprietary priming and pellet plus a wider range of seed treatments, ANTLER really is the new Monarch of the Fen.

All seed is now sold directly from SESVANDERHAVE

Growers seeking to achieve protein specification in milling wheat are being reminded to optimise nitrogen without overstepping or compromising economic thresholds.

Modern wheat varieties have huge yield potential – but growers must be realistic about whether these can be achieved on their own farms, say two advisers from agronomy company Hutchinsons.

A well-timed application of nitrogen after the flag leaf final-dressing will increase the amount of nitrogen available to crops during that crucial stage of protein development, says crop nutrition manager Tim Kerr.

Without a well-timed late application of nitrogen, crops may struggle to contain enough protein to satisfy yield and quality requirement. The later this dressing is applied then the more influence it will have on grain protein up to ear emergence.

Taking a Group 1 milling wheat targeting a protein threshold of HFN250, Mr Kerr and farm business consultant Leo Page say growers should pose three pivotal questions around late season nitrogen requirements.

1. What is the likelihood of achieving milling wheat specification?

This is an important starting point and should be based on the historical success of meeting milling spec weight with a particular variety. If regularly or even occasionally achieved, then it would be sensible to follow past nitrogen fertiliser strategies.

If not, don’t apply additional nitrogen, it doesn’t make economic sense. Recommendations also shift with low spring rainfall. If the weather stays dry, later applications of foliar urea at the milky ripe stage will become more important.

Be aware that some milling contracts prohibit the use of foliar urea. Instead, consider forms of methylene urea applied with the T3 fungicide which is now a well-established practice. It is crop safe and reduces the need for extra field passes.

2. Should I then consider a late nitrogen application to push for protein?

Use the protein prediction test to decide whether a late application of nitrogen is needed. Hutchinsons have been using this test since 2019 and Andrew Pitts at Helix National farm uses it routinely for his milling wheat samples.

The test involves digging up 5-10 wheat plants from across a field and then sending off to the lab. Samples can be taken from third week in May onwards. The test retails at £36.50 per sample.

3. How can I calculate the effect of more nitrogen on my break-even costs while accounting for uncertainty and volatility?

Milling wheat requires about 5kgs extra N/tonne of wheat – so a 10-tonne milling crop needs circa 50 kgs extra N than the equivalent feed wheat crop.

Taking into account the reliability of achieving milling spec and the fertiliser product bought, this is an additional variable input cost of £5-6.50/tonne of wheat. This is money well spent when the crop is sold for an additional premium.

Recommendations shift with low spring rainfall. says Tim Kerr

When it comes to crop marketing, says Virgin Money Agricultural Director, Mark Schuurman, we can all learn from our shared experience.

The Value of Shared Experience When it comes to crop marketing, says Virgin Money Agricultural Director, Colin Aitkenhead, we can all learn from our shared experience.

As we head from Spring into Summer, I write this at the end of an almost completely dry April, another persistent weather pattern we would not expect from our traditional temperate climate.

In a period where there are already plenty of headwinds to challenge confidence and optimism, particularly for arable farmers and cereal producers currently, I am taking the opportunity to talk about crop marketing and its potential impact on decision making for the next 12 months.

of focus for me – marketing strategy! I am considering learnings from producers who have been working very closely to the free market and without material reliance on BPS/SFI etc.

For the pig, poultry, dairy, and horticulture sectors the proportion of BPS/SFI has been significantly lower for some time than for our arable and red meat producers. By nature, these sectors continue to be cyclical, but many of these enterprises have a laser like understanding of their cost of production and an agile grasp of their margins, overheads, and bottom-line profit per unit of production. As much as pig, egg, broiler and milk prices vary, these businesses adapt rapidly with market conditions.

For cereal producers, preserving profits demands a marketing strategy that has to be adapted through the year, and this is where I feel focus could be better enhanced. “Do I sell at harvest or later in the season?”… In some cases, storage is not possible or available and so this becomes a moot point, and over time selling off the combine becomes a default option where on average over time, you ‘do ok’.

There is still a sizeable number of farmers who have a fundamentally positive outlook, but with 80 years of subsidised food production now effectively at an end, it has never been more crucial to ensure that resources invested will yield some form of positive return.

Recent conversations highlight one point

With potentially a two-year gap between commencing crop expenditure to when you sell, costs become very disconnected and if the market does not come back to you in Spring, then you can be exposed to added storage costs to compound the problem.

Arable farmers also have this focus, but there is a much greater gap in the relationship between expenditure and market returns for your produce. The sectors above have a crop or produce to sell on daily, weekly, monthly basis, so cashflows are much more predictable and income is more immediately linked to production costs.

As you head into harvest 2025, assuming that the crops are currently planted and awaiting some rain, it seems sensible to start making yield and input assumptions that would indicate where your breakeven point for each crop lies. As assumptions change this can be adapted through the season but will at the very least let you know if you are selling crops at profit or loss.

Of course, the ideal plan is to sell all the crop at the high point in the market, and I hope you do, but working from a known break-even price will make decision making easier, and limit risks of trading deficits. This is particularly important now there is less government support to insulate against a poor year, and a more conservative approach to marketing may be a better long-term strategy.

Every business is different and there is no simple template, but I am confident that using your professional advisors appropriately, and allocating time previously allocated to SFI/BPS will allow you to de-risk, or at the very least make better predictions and minimise the impact to your businesses in low return years.

Virgin Money have huge confidence in our food producers to adapt to what appears to be systemic change in our industry, and as a bank with over 180 years’ supporting in this sector, we base decisions on a long view.

As an agricultural financing specialist with 20 years’ experience, my role involves working alongside customers to help them consider the long-term impact of decisions. It is a privilege to provide experience-based advice to sustain the resilience and agility which I know will define the most durable enterprises over the next decade.

"It’s a combination of all these features that will make it a top performer in the field and one that will help growers not only simplify their management of the crop but also, help produce a profitable crop. "

• Resilience key to consistent yields

• Focus on essential traits

• New Domingos has huge potential

Anewly recommended oilseed rape is said to tick all the boxes by producing consistently high yields across a range of different growing conditions.

Yield potential without the builtin traits needed to give rape optimum resilience and yield stability is not enough anymore, particularly in areas struggling with the crop during recent years, says KWS UK oilseed rape product manager Rory Hannam.

"Strong vigour and a full set of key agronomic traits are now essential for growing oilseed rape in the UK with our new generation of hybrid varieties a significant step forward in future-proofing the crop."

The highest yielding oilseed rape variety specifically on the 2025/26 AHDB Recommended List for the east-west region is KWS Hinsta. It combines the built in traits of TuYV protection and pod shatter resistance.

"The topline figures of 106% for gross output and 46.1% for oil content are also pretty impressive," says Mr Hannam.

These headline figures are eye catching but Hinsta has more to of-

fer, he adds. It's only when you dig beneath the headline figures that the strengths of the variety stand out.

"The RL shows that Hinsta has intermediate resistance to verticillium and our own private trials data would improve on this claim where during inoculated pot tests Hinsta performed as well as a variety classed as partially resistant across a couple of years.

"Pod shatter is an absolute necessity these days as the weather is so unpredictable and we are seeing more extremes in weather patterns.”

Having this built-in trait offers protection against pod shatter to help minimise potential losses when the crop is at its most valuable and after all the hard work has been put in throughout the season.

"It's the same with TuYV protection too. With growers using less, if there was a bad aphid infestation in the autumn having the trait in a variety is the best way to mitigate any risk of infection,” says Mr Hannam.

"Strong varietal resistance to TuYV is the best way to mitigate against this growing threat.”

" Hinsta also has a 7 for Light Leaf Spot (LLS) which again gives it ample protection against this disease which, although largely confined to the North of the country a few years ago, is now a problem in many parts of the country.

"With good standing power, lodging resistance and a height of 155cm, KWS Hinsta has the right type of plant structure to support high yields plus it suits both early and late drilling slots.

Breeder KWS says Hinsta (above) will be a top performer

Underpinning the variety's performance is KWS' commitment to hybrid breeding, Mr Hannam points out. Hinsta is the latest development in our hybrid oilseed rape breeding programme, he adds.

“A full set of agronomic traits is essential

“ It's very much a modern oilseed rape variety and paves the way to a new generation of KWS oilseed rape that packages together the key traits of proven resilience, exceptional yield potential and outstanding hybrid vigour.

"That hybrid vigour is essential in helping a variety power through early season pest threats as well as helping plants get up and away after any adverse weather conditions over winter."

Another new variety KWS Domingos is also ticking all the boxes with an East/West recommendation, a high gross output of 109% and an oil content 45.9%, he adds.

Built-in

traits have big advantages, says Rory Hannam

"Currently a candidate variety, KWS Domingos contains essential built-in traits with a strong disease package including a 7 for light leaf spot and an 8 for phoma.

This is combined with vigorous autumn growth and a quick spring growth habit, says Mr Hannam.

"Our internal trials have also shown that in low nitrogen conditions, KWS Domingos has particularly strong nitrogen use efficiency, too,”he adds.

"Taking all this into account, KWS Domingos is an exciting variety to try this autumn – and one to watch in future."

is increasing among growers after an influx of new varieties from breeders

Abreeding revival in both Group 3 and soft Group 4 sectors is helping soft wheats make a comeback on farms.

Back in the day, nearly 50% of the UK wheat area was down to soft wheat varieties – including Claire, Riband, Robigus and Consort. But the percentage declined as those varieties fell out of favour – with only 8% of the total area growing soft wheat in 2024.

That should change with new varieties making soft wheat growing much more attractive again, believes Clare Leaman of NIAB. “We’ve had many years of new biscuit wheats coming, but none of them were a step forward in yield,” she explains.

“And there was such a big gap between them and hard feed wheats, with only a small premium available, that there wasn’t much incentive for growers unless you farmed very close to a biscuit mill.

“That’s now changed with the likes of Bamford, KWS Solitaire and KWS Flute because the yield of those varieties has jumped to be competitive with hard feeds and opens opportunities to a wider range of growers.”

quiring changes to agronomy. Distilling, milling and export markets are all possibilities, depending on location, says Ms Leaaman, albeit at relatively small premiums compared with traditional Group 1 milling wheat.

“Any premium is a bonus, even if you’re not growing it specifically for a market.”

Soft wheat premiums for last year’s crop have been particularly attractive for the past few months, according to soft wheat grower Sam Morris, who has been receiving £28-£30/t, rather more than the typical £10/t.”

Relative scarcity

Part of the explanation for the higher premiums lies in the relative scarcity of soft wheat alternatives, says Mr Morris, plus last year’s challenge with protein content. “This year is almost certainly going to be an outlier, but it’s been welcome.”

tor broke down to septoria as the ‘Cougar’ gene lost its effectiveness.

Market acceptance for a variety from the mill is a key requirement in his variety choice, along with yield. But he will also look at other characteristics to fit his system.

“Our rotation is three wheats on the bounce followed by a double spring break of spring barley and spring beans, which we find works well. So I’m looking for relatively high yielding second and third cereals.”

It’s not just Group 3s which have improved. options for soft Group 4 feed wheats are also keeping pace with hard feed wheats, with the likes of RGT Hexton and LG Redwald all but matching the top-performing hard feeds, such as Champion and LG Beowulf.

Mr Morris, who farms near Royston in Cambridgeshire, has been a long-term soft wheat grower, after switching away from Group 1, when the challenge and higher risk associated with making breadmaking specification became

The beauty of soft wheats lies in the additional market opportunities, without re-

Relatively close to a Whitworth Bros mill near Wellingborough, the typical premium was enough to keep the farm growing soft wheats even through recent difficult years when most of the sec-

He’s also happier to see varieties with better disease profiles available again, following the struggles with septoria.”

Another new variety is soft Group 4 RGT Hexton. It has many attributes, says Mr Morris. “We have a small block of Hexton in one of our fields to see how it performs.”

Clare Leaman: The latest soft wheat varieties have much to offer

Hexton is the top yielding second wheat on the recommended list at 108% of controls. RAGT arable technical manager Andrew Creasy says the variety is very competitive, scoring 105% across all trials.

DTheUK'sFlagshipEvent rivingKnowledge& FInnovationinArable arming

Experience the ultimate event for the UK arable industry at Cereals.

Explore live demonstrations and dedicated zones for agronomy, technology, machinery, business, education, regenerative farming practices and SFI updates – all designed to help you grow your business andyour crops.

Connect with over 450 leading suppliers showcasing the latest innovations, products, and expert advice. From seeds to sprayers, crop varieties to cutting-edge equipment, and fertiliser to finance, Cereals offers a complete one-stop solution.

4Don’tmissthisunmissableopportunitytostayaheadinfarming! 20+ exhibitors|200+ livedemonstrations|600+ cropplots|60+ speakers|17,000+ visitors

• Risk to crops despite dry weather

• Green leaf retention remains key

• How to protect harvest potential

Growers who take action to protect cereal yields against unexpected increases in disease will reap the rewards at harvest.

Risk-modelling shows an increased threat from septoria spores across much of the country following the important flag leaf (T2) timing, says Syngenta fungicide technical manager Jason Tatnell.

Although this spring has been very dry, previous years have shown septoria can be a challenge later in the season – not least because septoria spores are spread by splashes after rainfall.

“You only need to remember 2019 –when June downpours sparked a sudden Septoria onslaught in what had previously been a low Septoria season – to realise this,” says Mr Tatnell.

Syngenta’s new Miravis Plus fungicide technology set new benchmarks in septoria situations prior to its limited launch last season. Mr Tatnell says it has underlined its performance in trials ahead of its increased T2 availability this year.

“The key point to remember about T2 is its purpose is to protect crop green leaf area against disease during the critical yield-building phase.

“There might be 10 weeks between T2 in May and harvest, and every extra day that winter wheat flag leaf green area can be kept above 37%, yield increases by 0.15t/ha.

“For greater yield certainty, the T2 fungicide therefore not only needs to provide powerful disease control but also long-lasting protection.”

In line with this, Mr Tatnell says when new Miravis Plus fungicide technology arrived on the scene last season, it set new standards for yield in septoria situations and in several key barley disease scenarios.

Now, new trials from 2024 in readiness for its increased availability in 2025 have underlined its responses, and should give growers extra confidence, he adds.

“

Long-lasting green leaf areas pay dividends at harvest

The benefits of protection are clear when comparing untreated (left) and treated crops

“Pre-launch trials between 2020 and 2023 showed a Miravis Plus-based treatment delivered in 0.3-0.5t/ha over competitor fungicides, with this performance advantage confirmed in the most recent AHDB fungicide performance results.

A T2 application of Miravis Plus + Era (prothioconazole) in wheat has also resulted in reduction in fusarium head blight and in DON mycotoxin, says Mr Tatnell.

protection

Using Miravis Plus + Era at T2 can make it more likely that a suitable T3 fungicide will keep the crop below a DON threshold.

If rust is a concern, this can easily be targeted by adding Amistar to Miravis Plus + Era,” he adds.

In barley, Mr Tatnell says a Miravis Plus-based treatment

has also given visibly improved green leaf area protection against net blotch and rhynchosporium, while ramularia control has been one of its standout benefits.

“Similar to the trend we’ve seen in wheat trials, results in recent internal and independent trials in barley in 2024 also confirm a yield advantage from a Miravis Plus-based treatment of up to 0.5t/ha over competitors,” he adds.

Potent and long-lasting protection is important, says Jason Tatnell

Lodge Works, Great Ashfield, Bury St Edmunds, Suffolk IP31

Highly recommended for all regions of the UK, this topperforming conventional variety boasts the highest yield. Featuring large pods and abundant seeds, it ranks as the No.1 choice. Developed in Britain specifically for British farmers, its superior yield, vigour, and establishment surpass even that of Campus.

Ajam-packed programme of exhibitions, demonstrations and talks will greet visitors to this year's Groundswell event.

Entering its ninth year, Groundswell provides a forum for farmers and everyone else interested in food production or the environment to learn about the theory and practical applications of conservation agriculture –including no-till, cover crops and improving soil health.

The two-day event will feature talks, forums and discussions from leading international soil health experts. They will include experienced arable and livestock farmers, agricultural policy experts, direct-drill demonstrations and agri-tech innovators.

Aimed at all types of farmers, Groundswell was founded by the Cherry family on their mixed farm in Hertfordshire. Brothers John and Paul Cherry have farmed for more than 35 years, converting to a no-till system in 2010.

“We started Groundswell out of a sense of frustration that no-one was

putting on a summer show to which we might want to go,” says John.

A visit to the fabulous No-Till on the Plains Conference in Salina, Kansas showed what could be done. One of the most striking things was how hungry for information American farmers were about the soil and the ecosystems that lived in them.

“A lot of the speakers were describing some fairly radical farming ideas and techniques and their audiences were lapping it up,” says John. “We thought that if the good people of Kansas were ready for this, we sure as hell ought to be ready in Europe.”

Groundswell continues to go from strength to strength – welcoming almost 8,000 visitors last year. This growth reflects increasing interest in regenerative agriculture – and the benefits of such systems in terms of carbon sequestration and flood prevention.

“Despite these other interest groups, Groundswell remains a show for farmers, by farmers. We aim to explore ways of working with nature

Groundswell tickets are on sale for £108 including VAT (single day) and £162 (both days) – with discounts for students and group bookings of 10 or more.

The two-day event takes place on 2-3 July at Lannock Manor Farm, near Hitchin, Hertfordshire. As well as field demonstrations and static exhibitions, the show includes speakers across nine different stages.

Similar to last year, alongside ‘first principle’ sessions for those at the start of their regenerative journey, the event includes a series of extended advanced sessions for those keen to dive deeper into the science and practical applications of regenerative farming.

For full details, visit groundswellag.com

to grow food in a profitable way,” explains Paul.

The event goes from strength to strength

“As the new saying goes: resilience is fertile – and profitability is one of the key factors that makes your operation resilient. It’s all very well regenerating your soil, but if you are not making money while you do it, you won’t be doing it for long.”

One of the most world’s most influential regenerative farmers will address this year’s Groundswell event, which takes place next month in Hertfordshire.

Gabe Brown, a pioneer of the soil health movement, will deliver a series of headline talks at the two-day festival. The best-selling author of the book Dirt to Soil owns and operates Brown’s Ranch in North Dakota with wife Shelly and son Paul.

Mr Brown will join more than 250 speakers and over 8,500 farmers who are expected to attend the regenerative agriculture festival – which takes place on 2-3 July at Lannock Farm, near Hitchin.

The Brown’s 6,000-acre ranch near Bismark, North Dakota showcases a remarkable diversity of crops and livestock. It is this integration which Mr Brown attributes to the regeneration of natural resources on the ranch.

Through innovative soil health practic-

es, the family have created a thriving agricultural ecosystem and annually welcome over 2,000 visitors, leading to Gabe being named as one of the twenty-five most influential agri-leaders in the USA.

Mr Brown expressed his delight at being asked to speak at the worldwide renowned festival. “It is the world’s premier event for regenerative agriculture, and so it’s an honour to join such an inspiring lineup of speakers. I’m looking forward to connecting with fellow soil health enthusiasts and expanding my network in this field.”

swell provides a forum for farmers, growers, and anyone interested in food production and the environment, to learn about

generative farming systems. It’s not all about learning. The

of pints poured every year in the Earthworm Arms Bar. Also confirmed as a speaker at the event is author Didi Pershouse, whose Land and Leadership Initiative is used in 95 countries, including in

"Our goal isn't endless expansion, but rather creating a meaningful gathering where farmers, scientists, consumers, and anyone else who’s interested, can genuinely connect around regenerative practices."

There will be 300 exhibitors on site, and over 200 sessions, along with 30 demonstrations and 20 safaris. “We believe it’s this dynamic approach that makes the event – there really is something for everyone.”

Travelling to the event from New Zealand is Jules Matthews, a coach and educator who applying regenerative practices to beef and sheep farming to reach optimum animal

“At a time when there is so much uncertainty, concern and dissonance in our world, I think it is vital we continue to come together to learn from one another and foster hope

Groundswell also promises a timely appearance for author, podcast host, and founder of The Transition Network, Rob Hopkins, as his new book ‘How to Fall in Love with the Future’ is released in the run-up to the event. Previously voted as one of the UK's top The Independent, Mr Hopkins said he was thrilled to be speak-

Athought-provoking seminar series hosted by the Agriculture and Horticulture Development Board will take centre stage at Groundswell 2025.

The AHDB will host five seminar sessions on its stand each day – encouraging farmers and the wider community discuss the importance of independent, data-driven solutions for nature-based farming.

Each seminar will last about 30 minutes, with times and locations clearly displayed at key locations across the Groundswell site.

This session will tackle ways regenerative farming practices can shift the dynamics of weed management.

With the first case of glyphosate resistance confirmed in Italian rye-grass on a Kent farm earlier this year, the need to proactively manage herbicide resistance risks has never been greater, says the AHDB.

This seminar will unearth lessons from Strategic Cereal Farm East, including results from studying the farm’s weed seedbanks and assessments of non-chemical control – and a debate on the latest herbicide resistance management tactics.

In the race to meet environmental and climate targets, the focus on offsetting others' environmental footprints

often overshadows a critical truth: food production is the ultimate nature-based solution.

This session challenges conventional narratives, arguing that natural capital investment on-farm is not just an environmental nicety but a business-critical strategy to secure resilient and sustainable farming businesses for decades to come.

Join the debate about whether natural capital markets can build resilience or if they risk becoming distractions from or threats to the long-term survival of UK farming businesses.

sustainability

Discover how innovation is providing a brighter future for farming and food production.

Hear directly from farmers and supply-chain leaders about game-changing developments in genetics, technology and supply chain efficiency – from farm to fork.

Experts will be on hand and on stage during both days

Learn about the pivotal role of genetics in advancing farming practices and how consumer marketing campaigns give consumers greater confidence in the quality and sustainability of food farmed in the UK.

This session will showcase AHDB initiatives including EnviroBeef, EnviroCow, Let’s Eat Balanced and the Recommended Lists.

Session 4: From run-off to resilience – land management for clean water

Farmers are under pressure to deliver food and protect natural resources, including waterways.

This session will dig into the latest developments in soil health monitoring and management. It will explore the innovative and practical ways that reduce nitrate and phosphate leaching risks and improve a farm’s bottom line.

Speakers and experts will discuss the unique approaches required in regenerative systems.

from on-farm trials

A panel of experienced farmers and researchers will discuss ways to turn data into decisions.

They will explore how farmers can ensure that trials produce meaningful results, what data should be collected to make informed decisions and how insights from individual farms can be shared to create broader industry change.

The panel will draw on the experience of farmers who have used data to shift their management approaches and researchers who assist in on-farm data collection, knowledge exchange networks and understanding leverage points for uptake of sustainable food production in the UK.

Soil is at the heart of the Groundswell event

New for this year, the AHDB will host a cover crops and herbal leys workshop in the Earthworm Arms marquee at Groundswell.

AHDB and the Cover Crops Guide steering group will be digging into the practical aspects of species selection, establishment, grazing, nutrient dynamics and biodiversity.

This will be done with a strong focus on financial return and practically realising the benefits to farm rotations. The AHDB tipi is located at stand C40 in the demonstration field.

Grain cooperative Camgrain says it remains well-placed to remove ergot from cereal crops this summer – after winning praise for the way it helped growers deal with the problem last year.

The farmer-owned storage and processing facility invested some £500,000 in colour-sorting machines after ergot made an aggressive comeback during the 2024 growing season which brought ideal conditions for the fungus to thrive across the UK.

Many farmers found themselves facing unprecedented levels of ergot contamination. The black, hornshaped fungal bodies – toxic to both humans and livestock – meant thousands of tonnes of grain risked being downgraded or rejected outright.

Caused by the fungus Claviceps purpurea, ergot infects the flowering parts of cereals and grasses, replacing grain with dark sclerotia.

“It was a brave and proactive move

The presence of ergot renders grain unsafe for consumption if left uncleaned. For arable producers, it’s not just an aesthetic issue – it’s a food safety concern. Ergot is toxic and its presence results in severe financial penalties and rejected loads.

With grain arriving at Camgrain stores showing contamination levels rarely seen in recent decades, the chal lenge last harvest was stark: how to clean large volumes of affected crops without passing the cost of losses back to farmers.

Camgrain chief executive Simon Willis says: “Ergot was present in about two-thirds of all wheat intake – and at unprecedented levels.

“If you calculate and consider that just five pieces of ergot found in a 1kg sample represents 145,000 pieces of ergot in a standard 29t lorry load, then

going to support members and maintain food-grade standards. So, we made the call – early and bold.”

Camgrain placed orders for two Cimbria CTN7 colour sorters – and built a brand-new colour sorting facility at its busiest site in Balsham, Cambridgeshire. The co-op also invested in a fully mobile colour sorting rig for its sites in Kettering and Stratford-upon-Avon.

“It was a brave and proactive move,” says Mr Willis. “If we’d waited, lead times for the machines would have gone through the roof – we’d probably still be waiting for them now.”

Commissioned in January 2025, the new plant brought Camgrain’s total cleaning and colour sorting capacity to over 150 tonnes per hour.

It couldn’t have come at a better time, says Dan Parrott, Camgrain’s head of operations. “We’ve seen more ergot than anyone in the business can remember," he explains.

“We had to move to 24/7 opera-

tions at our East Anglian sites to stay ahead—sorting, cleaning, and removing ergot continuously since harvest.”

The Cimbria CTN.7 machines have exceeded expectations. Designed for high-throughput environments, they use advanced optical sensors to detect and remove contaminants at speed, without damaging the grain.

Their efficiency has enabled Camgrain not only to process ergot-affected grain rapidly but also to reduce costs for its growers in the process –with any operating surplus returned to Camgrain members.

“Because of the speed and success of the new system, we’ve been able to reduce colour sorting charges significantly,” explains Mr Willis.

“Starting with Harvest 2025, our standard member rate for colour sorting will be just £4 per tonne.”

For the 2024 season, where higher sorting charges were initially necessary to recover costs, the co-operative expects to return any surplus directly to members in the form of an exceptional payment this autumn.

“It’s simple: our members are our shareholders,” says Simon. “Any profit we’ve made from helping them remove ergot will be redistributed fairly. That’s the co-operative model working as it should.”

Ergot remains a persistent threat. As climate conditions continue to shift, the frequency and severity of outbreaks could increase.

However, proactive strategies like those deployed by Camgrain are helping to safeguard both farm businesses and food supply chains.

Looking ahead to harvest 2025, Camgrain’s investments ensure that members will not face the same financial burden should ergot strike again.

The infrastructure is now in place, and the business has shown that rapid, decisive action can pay dividends, says Mr Willis.

“We hope for everyone’s sake that this year’s crop is cleaner,” he adds. “But if it’s not, at least we’ve built the capability to deal with it – and deal with it cost-effectively.”

Poor trailer safety is being highlighted as a key contributor to farm fatalities during the busy harvest period.

Farmers and harvest workers are being urged to undertake daily checks and ensure trailers are well-maintained. They should also be serviced and in good condition ahead of one of the industry’s most dangerous times of the year.

“Good preparation leads to an efficient and professional business,” says Jane Gurney, of the Tilly Your Trailer safety campaign.

Being able to prove that kit has been serviced at suitable intervals by a qualified and competent person is important – especially in the event of an accident, says Ms Gurney. Trailers should also be serviced after incidents likely to jeopardise their safe performance.

“Not only is this the legal requirement and helps fulfil your duty of care as an employer, it is critical in lowering the mounting deaths and life-changing injuries within our industry.”

Of 27 people killed in farm accidents last year, nine deaths related to transport, including farm vehicles or machinery, runover incidents, rollover incidents and crush incidents.

Daily and periodic checks on your kit must be performed by the operator who has had suitable instruction, using only the relevant manufacturer’s checks.

These should include frequent checks of the condition of the towing eye. This should not be excessively worn, twisted, misshapen or repaired. A Tilly Pass towing eye measuring gauge is a simple portable device which can be attached to a keyring and used as a good guide to the minimum wear on a towing eye.

Visibility on the road is important to make other drivers aware of your presence, says Ms Gurney. This is especially the case during the busy season and with bright lights and shadows obscuring vehicles and gateways.

Turning onto the road with front weights and bale chutes should be a particular concern, as these protruding have led to catastrophic crashes. Side marker lights and reflective tape are easily available and increase visibility.

Amber flashing beacons should be visible for 360°

Proof of maintenance and risk assessment paperwork

Daily checks correctly recorded by trained operators

Sheeting bulk and strapping flatbeds - understand your 18 inch ullage

Flashing beacons and lights

Understand your trailer speed and weight limits

Developed in 1983 by a group of farmers, Camgrain provides a reliable, safe and secure co-operative grain storage facility to our farmer members.

Developed in 1983 by a group of farmers, Camgrain provides a reliable, safe and secure co-operative grain storage facility to our farmer members.

Looking to diversif y your farming assets and need somewhere to store your grain?

Looking to diversif y your farming assets and need somewhere to store your grain?

We can help with Industry beating drying, conditioning rates and ergot removal enabling access to premium markets.

We can help with Industry beating drying, conditioning rates and ergot removal enabling access to premium markets.

New flexibility on short term storage

New flexibility on short term storage

New flexibility on short term storage

2025 Annual storage + Handling now £9.90 p/t Competitive drying charges

2025 Annual storage + Handling now £9.90 p/t

Competitive drying charges

Competitive drying charges

Reduced Ergot cleaning charges now from £4 p/t

Reduced Ergot cleaning charges now from £4 p/t

Reduced Ergot cleaning charges now from £4 p/t

Arrange your own harvest haulage or pay actual cost to your closest store

Arrange your own harvest haulage or pay actual cost to your closest store

Arrange your own harvest haulage or pay actual cost to your closest store

Special ‘of f peak of fer’ to deal with remaining crop on farm with Ergot issues

Special ‘of f peak of fer’ to deal with remaining crop on farm with Ergot issues

Special ‘of f peak of fer’ to deal with remaining crop on farm with Ergot issues

Please contact the Membership team on 01638 57 2800 option 0 or email us at memberservices@camgrain.co.uk to see how we can help you.

Please contact the Membership team on 01638 57 2800 option 0 or email us at memberservices@camgrain.co.uk to see how we can help you.

Please contact the Membership team on 01638 57 2800 option 0 or email us at memberservices@camgrain.co.uk to see how we can help you.

We proudly serve farmers producing: Wheat | Oilseed Rape | Barley | Oats | Linseed | Rye | Beans | Peas | Organic Crops Join hundreds of like-minded farmers and future-proof your business with Camgrain

With almost 100,000 tonnes of grain storage capacity, cleanliness and biosecurity top the agenda at PX Farms in Cambridgeshire.

Grain storage cleanliness is a key driver for success at PX Farms – which grows and manages some 5000ha (12,500 acres) of arable crops in eastern England.

Founded in 2003 by James Peck when he took on his family farm, PX Farms is now a large business employing 32 full-time staff farming multiple units across Cambridge, Lincolnshire and Hertfordshire.

“We’re an agri-business managing arable land and grain storage for other landowners, but we also specialise in haulage and lettings too,” says Mr Peck, who is managing director.

The farm has steadily grown into an extensive arable business enterprise over the last two decades– but it very much retains the friendly feel of a family farm at its heart.

“When I took on the family farm, there were approximately 300ha of owned land and 60ha of contracted

land,” explains Mr Peck. “We’ve in creased the amount of land we own considerably in the last 20 plus years or so and diversified the business in multiple ways.”

With the capacity to store large amounts of grain, PX Farms works closely with both individuals and mer chants to commercially grow, store and clean grain.

“

It gives you peace of mind

protection is crucial to maintaining the highest standards of grain quality.

cused solely on storing its own crops, but even then, challenges quickly be came apparent.

Continued on p32

James Peck: Keeping the family agri-business feeling while storing almost 100,000 tonnes of grain (above)

With all eyes on crop performance in the field, now is the time for Arable Farmers to prioritise grain store pest protection ahead of harvest 2025. Month’s of hard work can be undone by a hidden pest infestation or missed treatment - compromising grain quality, safety and impacting the market sale value.

Ken Black, Envu account manager, warns: “Insect control is no longer optional. Milder winters have removed the natural chill that kept pests at bay—now, insect pressure in storage is rising fast.”

Historically, colder winters acted as natural pest control mechanisms, however the new normal of milder winters are removing one of the natural factors that previously helped reduce pest pressure in grain stores. This shift means farmers must compensate with proactive treatment strategies to limit insect activity and lifecycles. Despite all the hard work growers put into cultivating crops, poor grain store preparation can lead to significant losses during storage.

Ken comments “Grain storage preparation is often the missing piece of the growing season jigsaw, but insect damage in stores can result in losses comparable to pests and diseases in the field. If you don’t get the storage environment as clean and insect-free as possible, you risk undoing all that effort.”

Grain stores should be cleaned out 6-8 weeks ahead of harvest. Remember to:

• Remove dust, debris and old crop residue

• Clean all machinery and handling equipment – even the combine!

• Access all hard to reach areas including roof spaces, underfloor voids, wall junctions, nooks & crannies

• Use insect monitoring traps to assess pest levels

Check every 7–10 days. If pests are present—as is often the case—a grain store protectant should be applied across all surfaces.

One of the most effective treatments for grain stores ahead of harvest is K-Obiol® EC25 exclusive to Lodi UK. Designed for application after cleaning and before new grain is stored, K-Obiol EC25 provides broad-spectrum protection against both primary and secondary storage insects. With up to two months of residual activity, it targets:

SAW TOOTHED GRAIN BEETLE GRAIN WEEVIL

WEEVIL LESSER GRAIN BORER

While K-Obiol EC25 handles structural protection, pairing it with K-Obiol ULV gives full-circle protection by treating the grain itself as it enters the store. This dual defence approach, treating the structure and the crop, provides peace of mind, safeguarding your yield, your revenue, and your reputation. At Lodi UK, we’re committed to supporting farmers with trusted grain storage solutions that are practical, reliable, and backed by years of success in the field.

Contact Lodi UK for advice on application, availability, and how our K-Obiol products can become the most important part of your pre-harvest preparation.

Continued from p30

“Back when I first started out, we had some issues with insects in older buildings, so we soon learned how much hardship grain pests can cause,” explains Mr Peck.

“That experience made us very aware of the importance of thorough shed preparation ahead of harvest.

“Now, we make sure all sheds are cleaned out properly and any potential risks are addressed before new grain comes in.”

He says he’s learned from experience that older buildings with poor ventilation, and those which have previously had issues with insects, are more prone to problems.

Harvest preparation

Mr Peck compares good grain storage protection to taking out insurance on your buildings.

“It's no different from paying for insurance to make sure your shed doesn't burn down – it’s a preventative measure put in place to protect your crops from damage and it gives you peace of mind,” he says.

For protection against grain insects, PX Farms has been using the

grain storage protectant K-Obiol EC25 since the early 2000s for its cleaning and preparation process.

“We’ve been using K-Obiol for many years and it now forms an inte gral part of our grain storage prepa ration protocol,” says Mr Peck.

“All our cleaning is done by a spe cialist team in-house who have all the kit to carry it out.”

He says adequate cleaning is a really important part of pre-harvest prepa ration and can have a big influence on the success of the harvest.

“Once sheds are empty, we thor oughly wash them down and then ap ply the product to the entire fabric of the building,” explains Mr Peck.

“It’s really important that this job is done thoroughly, because grain pests can hide in the cracks and crev ices of buildings, so making sure the product’s everywhere is key to its ef fectiveness.”

Grain protection

At PX Farms protecting the grain as it arrives in the stores is just as im portant as protecting the stores them selves.

“Grain protection requires a combi

Farming 12,500 acres across Cambridgeshire, Bedfordshire/ Hertfordshire and Lincolnshire

32 full-time staff split across three sites, with an additional 19 staff during peak periods such as harvest

Capacity at Scotland Farm in Cambridgeshire to store nearly 100,000 tonnes of grain

12 different crop storage compartments with the ability to store between 8,000 and 25,000 tonnes of crops

Running a fleet of 12 haulage lorries

Accredited laboratory on-site at the Cambridgeshire farm

On-site Grain Hospital removes high levels of admixture and contamination to improve the crop quality

Combinable crop production is a key part of the business

As harvest 2025 edges closer, farmers are being reminded of the importance of prioritising grain store hygiene to prevent costly insect damage.

Ken Black, account manager at Envu, says thorough preparation of grain stores is more important than ever because milder winters no longer naturally suppressing pest populations, .

“Even with a good growing season, poor storage preparation can lead to losses comparable to pests and diseases in the field,” he explains.

Mr Black recommends grain stores are cleaned out six to eight weeks ahead of harvest, with attention paid to hidden areas like roof spaces,

nation of measures and not one measure alone will be the solution,” says Mr Peck.

“We’d previously used a wellknown broad-spectrum insecticide but following its ban in the 2000s, we had to look for an alternative solution for a grain protectant to complement the other work we were doing to keep grain insect-free.”

While protecting sheds with K-Obiol EC25 offers a great defence barrier to damage-causing grain insects, Mr Peck says all incoming grain is also

underfloor ducts, conveyors, and handling equipment.

“After thorough cleaning has taken place, monitoring traps should be used to check for insect activity,” he says.

“If grain pests, such as the grain weevil or sawtoothed grain beetle, are detected, an appropriate chemical treatment should be applied to all surfaces until wet, allowing time for it to take full effect.”

Aadopting a proactive approach to grain storage hygiene can safeguard grain quality and avoid the risk of infestations once new grain is moved into store, says Mr Black.

treated with K-Obiol ULV6.

“This is applied to crops going into store as a precautionary measure – we want to provide a solution to a problem which hasn’t yet occurred,” he explains.

PX Farms has a strong reputation for grain storage which it is keen to uphold, so taking a belt and braces approach makes sense.

“We’ve invested a lot of time and money into protecting grain from damage caused by insects, and it’s absolutely paid off,” adds Mr Peck.

Is game changing wheat Bamford still changing the game? Four experts give their verdicts.

Now in its second year on the Recommended List, Group 3 soft wheat Bamford came through a challenging first full commercial season in 2024.

Bred by Elsoms Seeds, the first year was dominated by serious outbreaks of both septoria and brown rust, as well as tough autumn establishment conditions. So has the variety continued to live up to its hype?

Clare Leaman, NIAB cereals variety specialist

It’s no exaggeration to say that Bamford has revitalised the Group 3 sector and has made the variety decision for many growers who moved over to hard Group 4 feeds a much more difficult one now than in previous years.

To see a Group 3 of Bamford’s overall quality is very welcome, and something we haven’t seen for some time. On agronomics, it has a high, competitive untreated yield –offering a good specific weight and a solid overall disease resistance profile.

Bamford has wide marketability and there were no red flags during a challenging 2024 growing season – so it’s absolutely up there. That said, 2025 is another big year and I think growers will know a lot more by next harvest.

Joe Wood, Wynnstay Group seed manager

Farmers in the west often encounter very different climatic conditions to growers in the east –including higher rainfall that often results in heavy septoria pressure.

Our customers need varieties with solid disease resistance scores supported by a high untreated yield knowing that key sprayer timings may not always be met

current Group 4 feed wheats.

As most of our customers are mixed farmers high straw yields are critical, and, with many of them rolling their own grain on-farm, a bigger, bolder grain such as Bamford’s is much more desirable than a smaller pinched grain.

Although I recognise and respect Bamford’s wide marketability, most of our customers are growing for feed so the emphasis is on yield and how easy the variety is to manage on fields that are often difficult to travel on.

Wheat varieties grown in the west need to be flexible and straightforward to manage, tiller well and, most importantly, not fall over. Bamford has also fully justified its solid scores on resistance to septoria and brown rust.

Ian Davy, national seed sales manager, Agrii Bamford achieved an overall treated yield of 110% to controls in Agrii trials across eight regions last year. On untreated yield it achieved 89% across the 8 trials, very much in line with its official RL rating.

With an untreated yield of 90% Bamford ticks that box. And with a treated yield of 107% in the west, it offers a higher potential yield than virtually all the

With solid agronomics, a wide drilling window and exceptional competitiveness, which enables it to compete against difficult grass weed burdens, it offers growers the triple reassurances of high yield, good quality grain and multiple end markets.

Bamford sold well with high demand coming from virtually every UK region, something which is not always the case. It’s one of our top five best-selling varieties.

Regardless of classification, Bamford is a great winter wheat in its own right and I see no immediate reason for its current popularity to diminish.

David Bouch, head of seed, Hutchinsons Bamford is delivering yields that are as good – if not better, than all the Group 4 feed wheats, holding its appeal and looking set to gain more area with an increased market share.

It’s arguably one of the best winter wheats on the current RL, regardless of classification, and is still a game changer for first-time growers who have only just begun successfully incorporating it into their rotations last autumn.

It can be grown as either a first or second wheat, performs well on all soil types, and during a very bad year for both septoria and brown rust its disease resistance held up very well from customer reports we’ve received.

It also carries the Pch1 Rendezvous resistance gene, widely recognised to be the best in terms of resistance to eyespot and that should enhance its credentials as a second or even third wheat.

With very few agronomic weaknesses, Bamford was one of only two recommended varieties to match or better its four-year average in 2024.

If anything holds it back, it would only be reluctance from growers to go back to a Group 3 following bad experiences from mediocre varieties prior to Bamford’s arrival.

• Auto-drying with remote alert

• Quieter, cleaner and efficient

• Easier to use and to maintain

ABedfordshire grower is reaping the rewards after replacing an ageing PTO-driven grain dryer with a state-of-the-art mobile machine.

Sandy Wade-Gery, who farms with son Will at Bushmead Farm at Colmworth, near Bedford, installed a new automatic electric Mecmar SSI 28T mobile dryer, supplied and supported by McArthur BDC.

“Our old mobile dryer was reaching end of life and we needed to upgrade to an automated solution providing larger capacity and improved energy efficiency,” says Mr Wade-Gery, who grows some 400ha of combinable crops.

The Mecmar SSI 28T stood out for its build quality and its ease of use, particularly the remote access capability of the dryer’s control panel, which sends an SMS notification to the operator when the dried grain is ready to be discharged.

Quieter drying

“There is no longer the need for the operator to be constantly monitoring the dryer,” said Mr Wade-Gery. “The old dryer tied up a tractor and the burners were driven by gas from a bulk tank. It was noisy, and dusty.”

The new electric Mecmar uses diesel from an onboard tank to power the burners. It is super-quiet and has an integrated dust extraction system – two features which mean it sometimes can’t be heard working.

The old dryer was precarious and difficult to maintain, whereas the Mecmar is much easier to look after as the grease points are positioned in one central location beside the control panel.

The Mecmar dryer is fully automatic, streamlining the entire drying cycle. From the field, grain can be tipped directly into the loading auger from the trailer. It can also be loaded with a telehandler via a portable hopper placed over the loading auger.

Using the Mecmar’s control panel which has pre-set drying programmes, configured by the operator at the beginning of harvest, the correct programme is selected so grain is dried precisely to the required moisture content.

Once set, the grain is automatically fed from the intake hopper to the Mecmar and as soon as the mid-level sensor located inside the dryer is covered, the fan and burner starts and drying begins.

When the high-level sensor is covered the loading auger stops automatically. As the grain recirculates within the dryer, the Mecmar’s aspirator, located at the top of the central auger, removes dust and chaff, improving the bushel weight of the crop.

Once grain reaches the target temperature, the dryer then enters a predetermined cooling cy-cle. Once cooled, the Mecmar’s integrated moisture content meter checks the grain to deter-mine that it is at or below the pre-selected target moisture content.

If the moisture check is correct, grain is then automatically discharged.

When the low-level sensor is uncovered and the dryer is empty, the loading auger automatically starts, feeding grain into the dryer so that the next batch begins – making the dry-

The new dryer is light years ahead

ing process as timely and as efficient as possible.

When the operator receives a notification from the control panel that the grain is ready to unload and, if a trailer is in place, he allows grain to be discharged and taken to the store.

“The Mecmar is light years ahead of our old dryer,” says Mr Wade-Gery.

“We wanted a dryer that delivered an auto-mated solution, was efficient, quieter, reliable and would meet our drying requirements well into the future," he adds.

“McArthur’s support, which was a significant factor in our choice of the Mecmar, has been excellent and the whole system fits perfectly with our forward-thinking approach to farming.

“To keep moving forward we are looking at relocating the Mecmar into a dedicated grain store and adding a colour sorter to further enhance how we process our grain”

Working

• Dry spring slows crop growth

• Many crops at different stages

• Strategic approach to weeds

Lack of rain continues to create challenging conditions for sugar beet – with hot weather adding to the challenge of what and when to spray for weed control.

While the dry weather helped growers expedite drilling, with most finished by the end of March, it has slowed crop development and left plants at different growth stages, says UPL head of technical services Stuart Jackson.

“Continuing dry weather coupled with relatively high temperatures is leading to – in some cases – stressed, variable crops and difficult conditions to achieve successful weed control,” he says.

“It’s not in every situation. Where growers were able to get a good seedbed, drilled a little earlier, crops are generally looking healthy, and weed control has been good.”

Drought stress

Emerged weeds are generally pretty tough to control because they are waxed up and drought-stressed, adds Mr Jackson. In these scenarios, we need to load more contact activity into programmes.

“Typical residual mixer partners, such as Venzar (lenacil), are less effective in dry soils, where root uptake is restricted, and should be replaced by more contact-acting herbicides.”

“For example, you can look to add products such as Shiro (triflusulfuron-methyl) and/or Vivendi (clopyralid) to base mixes of Betasana (phenmedipham), plus Bettix Flo (metamitron) + Efeckt (ethofumesate).

A diligent approach is always best for sugar beet weed control

“Emerged weeds are tougher to contro

Tank mixes

Adding oil to herbicide mixes will help pep up weed control, but it can come at the cost of crop safety. Use the forecast maximum temperature on the day of application to help guide decisions, with anything over 21ºC as the cutoff for not adding it into tank mixes. Where growers want to use oil at their own risk in temperatures above 21ºC, rates should be cut to no more than 0.5 litres/ha and spray first thing in the morning or the evening, says

(flupyradifurone), all of which are compatible with the three-way mix of Betasana, Bettix Flo, and Efeckt.

“What we don’t know yet is the compatibility of Sivanto Prime with the bigger multi-way mixes where you add in Shiro or Vivendi. Insyst or especially Teppeki are better options if you’re looking to do that type of bigger mix.

“Obviously, you also need to consider advice around the sequence order of the insecticides, which says to avoid using two sprays with the same mode of action in a row.

“Shiro will be helpful on polygonum

“If crops have flagged or flopped during the heat of the day, avoid spraying in the evening and leave them until the morning.”

Depending on that, it may be the case of spraying the weeds first, waiting for a few days before spraying the insecticide to give more flexibility.

“If you are tank-mixing an insecticide, don’t add oil. However, it may be worth replacing the oil in these conditions with a biostimulant like Vitalroot to help the crop thrive.

With aphids arriving earlier than originally forecast at the beginning of May, many growers might need to tank mix an insecticide with their weed control spray.

The three insecticides available for use are Teppeki (flonicamid), Insyst (acetamiprid), and Sivanto Prime

contact are important

Vitalroot is seaweed extract with phosphorus and potassium. It can be used at 1-2 litres/ha in conjunction with a broadleaf spray programme.

It won’t pep up herbicide activity like an oil, but it will help with crop growth,” concludes Mr Jackson.

Sugar beet growers looking to rationalise herbicide use should consider the pros and cons of alternatives – which may not suit all situations and seasons.

British Sugar’s in-house weed specialist and technical support manager Pam Chambers has been testing different weed control strategies at a site in Yaxley, Suffolk, for two seasons.

The inspiration for her work is the threat of herbicide withdrawals and the need to reduce reliance on chemistry.

Big losses include the loss of desmedipham in 2020 and recently, the European Union recent-