August 2025

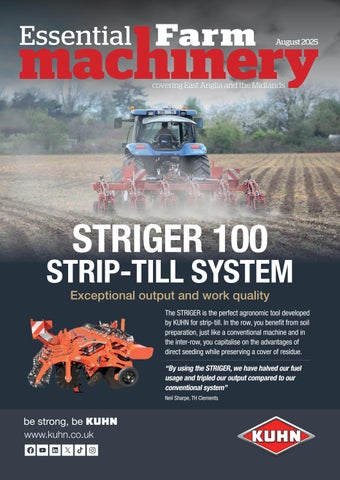

The STRIGER is the perfect agronomic tool developed by KUHN for strip-till. In the row, you benefit from soil preparation, just like a conventional machine and in the inter-row, you capitalise on the advantages of direct seeding while preserving a cover of residue.

“By using the STRIGER,we have halved our fuel usage and tripled our output compared to our conventional system”

Neil Sharpe,

TH Clements

• Over 500 wildfi res this summer

• Simple device helps fight fl ames

• £100m annual cost of farm fi res

Farmers and contractors are being reminded to reduce the risk of field fires at the height of harvest during another dry summer.

The NFU is highlighting the increasing risk of wildfires on farmland and the need for action from government, fire services and local authorities to protect lives and livelihoods.

It follows Met Office warnings that temperature extremes are becoming the norm – with tinder-dry conditions on farms across the country. Parched conditions are putting livestock and crops at risk – and homes and businesses too.

Editor: Johann Tasker | T: 07967 634971 E: johann@ruralcity.co.uk

Advertising sales: Danny Lewis | T: 01502 725862 E: danny.lewis@micropress.co.uk

Advertisement production: Jade Soanes | T: 01502 725840 E: jade.soanes@micropress.co.uk

Firefighters work to extinguish a blazing tractor and baler.

Farmers are ingenious people

Essential Farm Machinery is published monthly for farmers and growers in the eastern counties and the Midlands. It is mailed with Anglia Farmer and Midland Farmer magazines and is also available at selected farm machinery and supplies outlets.

© Countrywide Publications 2025 Published by Countrywide Publications, Fountain Way, Reydon, Suffolk IP18 6DH T: 01502 725800 Printed by Micropress Ltd, Suffolk T: 01502 725800

The National Fire Chiefs Council has reported more than 500 wildfires in 2025, while data from the NFU Mutual shows the increasing cost of farm fires, reaching £110 million in 2023 –an increase of 37% from 2022.

The NFU is asking fire services to invest in a newly developed adapter so fire engines can access water from on-farm water bowsers and tanks once their own on-board supplies have been exhausted.

The adapter has already been adopted by fire services in Lincolnshire and Norfolk.

But in most other counties, fire engine fittings are still not compatible with rural water storage systems, making a farm fire outbreak harder to manage.

Lincolnshire arable farmers Andrew Ward and Rhonda Thompson have first-hand experience of the importance of these adapters when part of their farm went up in flames over the weekend.

Rhonda said: “It was awful to get the call from a neighbour that our poultry manure heap was on fire, which is surrounded by thousands of acres of wheat – both our own and neighbouring farmers’.

“Every minute the fire was unattended added to the risk of it breaking over into the crop, where it would’ve spread quickly to neighbouring farms and been much harder to contain.”

Two fire engines arrived quickly from Nottinghamshire and Lin-

Continued on p7

Norfolk-based self-propelled sprayer manufacturer Sands Agricultural Machinery (SAM) has underlined its commitment to British farmers by moving to a new factory.

It is a key development for the company, which has grown steadily on the site where it was founded 50 years ago at Brumstead near Stalham. Neal Sands and son Thomas say the new factory will enable them to expand production and boost efficiencies.

Following its purchase and considerable investment in redevelopment, the new facility, just a few minutes away, at Catfield, was officially opened in late May, following a move during December-January. One third of the 3.6ha site is under cover, with a number of converted or purpose-built modern buildings.

“We have created a layout which maximises production efficiency, where we can work on six machines at once and unfold 40m booms inside,” says Thomas. “But we also have potential for future expansion.”

There is enough space to extend production by another eight bays if required. The production facilities are complemented by significant investment in new shotblasting and painting facilities with offices, stores and the service department.

“As we make many components in-house, high steel quality is important, which justifies the investment in shotblasting and spray paint facilities, with a large part of that in a new electronic 2K mixing system. This also gives us the ability to strip back,

shotblast and respray used machines where desired.

“Production efficiency has been boosted with the installation of six overhead cranes, plus smaller workbench units, while magnetic technology helps move large steel sheets, reducing the need for forklifts.”

Considerable investment has also been made in environmental and energy-saving features – rainwater is harvested across the buildings, feeding two 25,000-litre tanks, and most roofs feature solar panels.

The parts department for machine construction and supply to customers is now under one roof, with a six-tier stacking system and full computer organisation. Some £2.6m of stock comprising 26,000 lines was moved from the former premises.

The new factory is a key development for Sands Agricultural Machinery

Currently the plant produces approximately three machines every month, but this is expected to rise to four. Some 4,000 Sands SAM sprayers have been built in just over 50 years, and can be found across the UK and Ireland, and as far afield as New Zealand.

Neal Sands built his first self-propelled sprayer in the early 1970s. Neighbours requested similar machines, and the first production Sands self-propelled sprayer was launched to the farming public at the Royal Norfolk Show in 1975.

The current Sands range comprises models from 3,000-6,000 litres capacity with steel boom widths from 24-40m. Sands provides a full retail and support service, with after-sales, servicing and a trade-in route to a replacement machine.

Triton is now accepted as the goto direct and conventional drill for extending the drilling window in catchy conditions whilst increasing yields through deep soil release. The Triton uses the patented self cleaning side presses to close the seeded slot in all conditions. As one heavy soil farmer said ‘If the field will hold the tractor the Triton will drill’ The Triton gives the grower the ability to grow the most profitable crop sequence which is vital in the current climate.

Continuous Winter Wheat with occasional early drilled spring wheat for grass weed control is the most profitable simple low cost cropping solution.

Please call us to discuss why we are so sure of this ‘rotation’ and why the Triton is essential to getting the spring wheat tillering by mid March to ensure a yield more akin to to winter Wheat and less vulnerable to spring seed bed drought.

• Top performance out in the field

• Easier to navigate in tight space

• Specially designed for operators

Slurry and digestate management specialist Tramspread has introduced a compact single-axle version of the popular Contractor Trailer engine-driven pump unit.

The trailer carries everything needed for an umbilical spreading system with a self-contained engine-driven pump unit, compressor for blowing out the drag hose, hose spool carrying cradle and storage for tools, couplings and sundries.

The new introduction fills a gap in the range for a more compact version, combining the same ability and performance with reduced dimensions to make it easier to navigate through narrow and uneven gateways and in awkward yards.

“The twin-axle Contractor Trailer is ideal for most of our customers, but we are quite aware that access can be limited in some areas,” explains Tramspread managing director Terry Baker.

“We always aim to support our customers with products tailored to their specific needs, so we have developed a compact and manoeuvrable trailer which still incorporates all of the well-

The new machine is designed for tighter spaces

liked design features but carries one hose reel rather than two.”

The first contractor trailers were made for Tramspread’s own contracting division in 1998. These early single-axle models were later replaced with twin-axles. All models are designed as a purpose-built unit rather than converted from a trailer chassis.

The new single-axle version can be fitted with a 175hp or 238hp sixcylinder FPT engine, Bauer, Doda or Cri-Man pump, compressors of 140 or 180CFM output and optional GSM or radio type remote control systems with associated high-tech features.

The 900-litre fuel tank has been repositioned underneath the engine and pump, and as always considera-

ble thought has been put into operator convenience with suction and delivery hose connections at low level.

The 1000m hose spool is loaded into its cradle from the front and quickly and easily secured with pins – no straps are needed. The sprung axle is fitted with 50k rated 435/50R19.5 tyres and air brakes.

The drawbar is configured to allow the towing tractor to carry a dribble bar in the linkage, allowing one operator to move an entire umbilical system. Total chassis length is 6.3m, which is over 2m shorter than the twin-axle model.

The full-range of options can be fitted, including a suction hose transport kit, sponge ball (pig) launcher and the new 360-degree camera which was introduced earlier this year.

Continued from p3 colnshire and, fortunately, the Lincolnshire fire engine was carrying the adapter.

“I dread to think how bad it would’ve been if the firefighters didn’t have access to our on-farm water stores and neighbours’ water bowsers and tankers. Sadly, that’s the situation facing most farms across the country without this adapter.” NFU vice president Rachel Hallos said: “One of our members worked with his local fire service to develop an adapter specifically for rural are-

as, then managed to secure funding for all 48 fire engines in Lincolnshire to be equipped with it.

“Farmers are ingenious people. These adapters have been instrumental in minimising the impact of farm fires on livelihoods, and I believe it should be a non-negotiable for all fire engines across the country to invest in.

“They aren’t expensive, yet the cost of a farm fire can be devastating. There are solutions out there, and what we’re asking for today will help tackle some of the key causes and risks of wildfires.”

• Shift to regenerative farming strategy

• Well-maintained kit up for grabs

• Opportunity to make big savings

Amajor farm machinery sale will take place next month – on behalf of Eastern Farms Limited at Somersham, Cambridgeshire.

East Anglian-based auctioneer Cheffins will undertake the sale – hosted on farm – on Wednesday 10 September. With the ability to gross over £2 million in total, it will be one of the most important agricultural auctions of 2025.

The sale has been prompted by a shift toward a new farming strategy, a comprehensive fleet renewal, and a commitment to regenerative agriculture – with Eastern Farms owner Charles Leadbetter deciding to part with nearly half his machinery.

Eastern Farms encompasses some 2700ha (6,700 acre) of arable enterprises and grassland, with some land in Countryside Stewardship and Sustainable Farming Incentive schemes across Cambridgeshire.

The farm has experimented with direct drilling and intends to roll this out across business – reducing establishment costs in order to remain financially viable when growing combinable crops and grassland.

The combination of this move and a fleet renewal policy has shown that a substantial portion of machinery is now surplus to requirements – resulting in 200 lots of machinery and equipment being offered for sale.

Highlights from the sale will include a 2023 John Deere 9RX 640 tractor which has an estimate of £300,000; a 2019 John Deere 9620 RX tractor (estimate £180,000); and a 2022 John Deere X9 1100 combine harvester (£300,000).

Further lots include a 2021 JCB 435S loading shovel (£100,000); two John Deere 6R 215 tractors from 2024 and 2022 (£130,000 and £90,000 respectively) and a 2020 Richard Western GR25 chaser bin ( £40,000).

Mr Leadbetter established Eastern Farms with just 120ha two decades ago. Through strategic growth and innovation, he has expanded the operation significantly, while also building one of the region’s leading agricultural contracting businesses.

“Farming is facing a period of major transition,” said Mr Leadbetter.

Direct drilling and low disturbance cultivations could help protect farmers against rising establishment costs as well as extreme weather and labour challenges. It also delivered stronger returns than conventional methods.

“We are still actively seeking all farm business tenancies and contract farming opportunities, and it is our belief that economies of scale are the way forward for long term sustainability.

“With strong demand and prices in

A sale includes a range of wellmaintained arable machinery

the second-hand machinery market, now is the right time to streamline our fleet and invest in equipment tailored to the demands of sustainable farming.”

Cheffins director and head of machinery sales Oliver Godfrey said: “This sale is a major undertaking, and will bring a series of highly desirable tractors, combines and other equipment to the market.

“

“Charles has been exemplary in how he has cared for his kit, with all of it dealer maintained and kept under cover, and I am sure that the effort he has put into this will be reflected in the prices achieved on the day.”

Second-hand machinery prices continued to grow but still represented a financial saving on buying new, said Mr Godfrey. The sale showed that farmers could still purchase the best in class of machinery to support their farming operations.

“We are delighted to be able to offer these quality machines to the market and are sure that the John Deere 9RXs and the John Deere combine are sure to be of interest for farmers and contractors not just in the UK, but throughout Europe.”

For sale details, please visit www. cheffins.co.uk

Anew universal cultivator extends the Horsch Fortis range with a compact solution for medium-sized farms.

The Fortis LT was specifically developed for standard tractors up to 500 hp and is available in four working widths from 4.60m to 6.75m. The cultivator has the flexibility to be used for shallow tillage to primary soil cultivation at depths of up to 30cm.

It was designed with the increase in tractor power over recent years, harvest residues or catch crops performance and incorporation quality. A special feature sees levelling tools placed close to the last row of tines so soil is directed into the levelling discs.

The combination of a four-bar design, a 27cm tine spacing and an 85cm frame height ensures an enormous clearance for working without clogging at a maximum working depth of 30cm, while ensuring a well-mixed soil flow.

Compared to the proven Fortis AS,

the LT is more compact and shorter. The TerraGrip tine system with large radii on the tine shaft ensures a low horsepower requirement. The chassis can be moved out of the

The Fortis LT can be customised to meet customer requirements

The Fortis LT can be customised to meet individual customer requirements and operating conditions. The MulchMix coulter system, with its range of options, contributes to the flexibility of the machine.

Capable of being individually adapted to changing soil conditions, the angle of the double packers can be adjusted by means of the proven aluminium clips, a system that is unique in this class.

sulting in better consolidation in dry

Lower fuel use, a better tilth and improved soil structure were all demonstrated at last month’s Groundswell event in Hertfordshire

Kuhn Farm Machinery showcased recent trial work on its Striger strip till cultivator that the company says has delivered significant crop establishment savings compared with traditional methods.

With arable margins tighter than ever, the potential to save fuel and other inputs by moving to strip tillage were of interest to many Groundswell visitors, says Kuhn arable product specialist Edd Fanshawe.

“In two trials across the south and east of the UK during 2024, the Striger was evaluated against a two-pass min-till system and a traditional plough and press cultivation, to assess fuel and cost input along with end yield,” he said. In the eastern trial, the Striger cultivation used 8.6l/ha (£6.45/ha), whereas the min-till was 17.7l/ha (£13.28/ha), and the plough and press up at 28.1l/ha (£21.08/ha), says Mr Fanshawe.

The Striger delivered lower fuel use and comparable yields to the other two systems –achieved by burning less diesel and reducing

the number of passes in the field while preserving the soil structure through targeted cultivations.

Kuhn also demonstrated its mechanical weeding range at Groundswell. These included the Tineliner, for weeding young broadacre crops such as cereals; and the Rowliner, for inter-row weeding in maize and sugar beet crops.

Both machines are increasing in popularity as farmers look to reduce inputs, says Mr

Fanshaw. The Rowliner and Rowlink are available for funding in the latest round of grants from Defra’s Farming Equipment and Technology Fund (FETF).

Mechanical weeding can significantly cut spray costs in cereal crops during early growth stages. Growers regularly passing through crops can encourage crop tillering while disturbing young weeds to prevent them outcompeting cereals.

Ex-demo

£11,500

TP 200 PTO Chipper

3yr warranty. Simple, flexible and e cient chipping of branches and trees up to 200 mm in diameter. The obvious choice for park and golf course maintenance and for municipal and agricultural grounds.

£19,995

MultiOne 5.2K Multifunction Loader + 130CM General Bucket 25HP Kubota D905 Diesel Engine, 36 L/ Min Auxiliary Oil, Flow (for attachments) 1,110KGS Max Tipping Load, 2.75 Metres Max Boom Height, 23x8.50-12 Skid Tyres (Can be upgraded) 1,020KGS Gross Weight, Comes with free bucket!

£21,500

TP 176 Chipper

Only 5hrs use! 3yr warranty. Lightweight, high-performance machine, auto start-up, auto-reverse feed, adjustable discharge & advanced monitoring, designed for easy transport & e cient chipping.

£23,995 +VAT

B31-749 Stump Grinder

Comes with free Grinder Guard. No daily maintenance & elimination of V-belts lower operating costs. Enhanced manoeuvrability & stability with counter-rotating tracks & low centre of gravity. 74cm wide!

Stump Grinder

Comes with free Grinder Guard. HWD for e ortless mobility in terrain or up ramps. Turntable design with balanced pivot point & individual wheel brakes. Narrow access walk-behind stump grinder.

FOR HIRE: FSID30 Stump Grinder

Economical 35L diesel engine. This robust machine generates torque at low RPM, minimising noise & increasing comfort.

FOR HIRE: AS Motors Ovis RC RC flail mower for steep, hard-to-reach areas, 23HP engine, 100cm cutting width & stable low-profile design.

£9,995 +VAT

Grasshopper Zero Turn Mower

Ex-demo, very low hrs, excellent condition. 124V. 54” 4XRD cutter deck. 24hp engine. Extra comfortable seat. Fast cutting speed. Still with full manufacturers warranty. Available immediately.

AS Motors 65 4T Mower

£3,950

Ex-demo. B&S Series 3 INTEK 5-speed manual 13HP engine, inclines up to 35°. Powerful, slope-capable mower designed for tough terrain & grass up to 150cm, o ering reliable performance.

FOR HIRE: AS Sherpa 920 2WD Ride-on mower, 90cm cutting width, 27HP engine, designed for mowing dense grass & vegetation up to 1.5m tall.

Farmers and farm workers are being urged to take care after new figures confirming that agriculture remains the UK’s deadliest profession.

In 2024/25 alone, 23 farm workers lost their lives on farms across Great Britain, a grim reminder of the sector’s persistently poor safety record. Nearly half (48%) of the workers killed were over the age of 65.

The stark statistics were released ahead of last month’s Farm Safety Week. An average of 31 lives have been lost on our farms every year for the past 13 years, said the Farm Safety Foundation.

Farm Safety Week, the annual awareness-raising campaign run by the Yellow Wellies charity brings attention to the dangers farmers face every day when producing food for the nation.

In an industry that accounts for 1% of the working population, farming accounts for nearly 20% of all workplace deaths – this gives farming the poorest safety record of any occupation in the UK.

Nearly half (48%) of all farm worker fatalities were over the age of 65. But youngsters too are affected – including members of the public.

Two of the killed were children –both of whom had accidents while using all-terrain vhicles (ATVs). Being

killed by moving or overturning vehicles was again the main cause of fatality in the industry in 2024/25.

Farm Safety Week brings together voices from across the UK and Ireland to reflect on another heartbreaking year for farming families, with lives lost or changed forever and communities deeply affected.

The charity highlights the need to address an underlying culture of risktaking and complacency. Some 81% of farmers believe ‘complacency’ is a major contributor to having a farm accident while 82% cite a poor ‘attitude’.

Farm Safety Foundation manager Stephanie Berkeley explains: “‘I’ve always done it that way’ is a phrase we hear all too often. Although confidence built over years on the land is a strength, it can also become a blind spot.

“When you start to underestimate the dangers of the vehicles, equipment and animals we know so well, we risk letting routine turn deadly. Experience should guide caution, not excuse it.”

This year, the charity has broadened the scope of the campaign and is working with their antipodean counterparts – Farmsafe Australia – to share stories, learnings and make a joint call for simple changes to save lives.

While the agricultural sector has

long been associated with high rates of injury and ill health, recent data suggests that meaningful progress is being made in improving farm safety.

Historically, the industry has faced alarming figures, with over 23,000 reported cases of long-term ill-health and serious injuries. But there are now signs of a positive shift with the number of long-term ill health and serious injuries falling to 18,000.

Furthermore, according to rural insurer NFU Mutual, the number of farm accident claims in the UK dropped from 937 in 2023/24 to 894 in 2024/25. Though modest, this decline is a welcome indication that safety initiatives are having an impact.

Despite the reduction in claims and injuries, the causes of farm accidents remain consistent and concerning. Incidents involving moving vehicles, falls from height, slips and trips, and trapped body parts continue to dominate the statistics.

Summer and the busy harvest period is a key time for farm accidents

Ms Berkeley said: “Over the years we have seen the attitudes and behaviours around farm safety in the UK and Ireland starting to change but the pace of change is slow. Too slow for the families who have lost loved ones in preventable accidents.

“Too slow for the thousands of farmers living every day with chronic pain, long-term illness, or life-altering injuries caused by the very work that sustains our communities. We cannot accept this as the cost of doing business.”

The Farm Safety Foundation says reducing serious and fatal injuries is only part of the challenge. In the past year alone, these types of accidents cost rural insurer NFU Mutual over £48 million.

Health and safety expert Wayne Owen says farmers need to put the health and safety of themselves and others at the heart of what they do.

“Farming is an extremely important but difficult and challenging job. Complacency towards tasks, and a poor attitude towards keeping people safe and healthy has to change. The responsibility for that change rests with the industry itself.”

Mr Owen is a Health and Safety Executive inspector for agriculture. The HSE will continue to play its part, but recently released statistics show the number of fatalities remains stubbornly high, he says.

“The fact that children continue to be killed on Britain’s farms is also a source of tragedy and sadness and is totally unacceptable. Each farm and each industry leader has a part to play in driving the muchneeded cultural change in farming.”

For more information on farm safety, visit www.yellowwellies.org

Farm unions have joined forces to raise awareness about the dan gers of using all-terrain vehi cles (ATVs) on farms.

With almost 600 farm-related inci dents reported in the last year alone, the NFU, NFU Cymru and NFU Scot land are urging everyone in agricul ture to prioritise safety and reduce the risks that come with their every day use.

ATVs are vital tools on many farms, but every year preventable accidents involving these vehicles cause serious injuries and fatalities. To help farmers keep safe, the unions are urging farmers to remember four measures (see panel).

That’s why we are coming together to send a clear message: safety must always come first.

NFU Deputy President David Exwood said: “Every year we see lives

“No one plans to have an accident and you never know when one might happen. Whether you’re checking livestock or moving around the farm, the risks

ATV safety first

A Always wear a helmet

T Training

V Vehicle & maintenance checks

S Single rider only

are real every time you get on an ATV.” Mr Exwood said it was vital to take life-saving steps like wearing a helmet, completing proper training, being competent and confident in handling the vehicle and carrying out routine safety checks and maintenance.

“Safety must be our first thought and not the last.”