By Jay Nachman CEG CORRESPONDENT

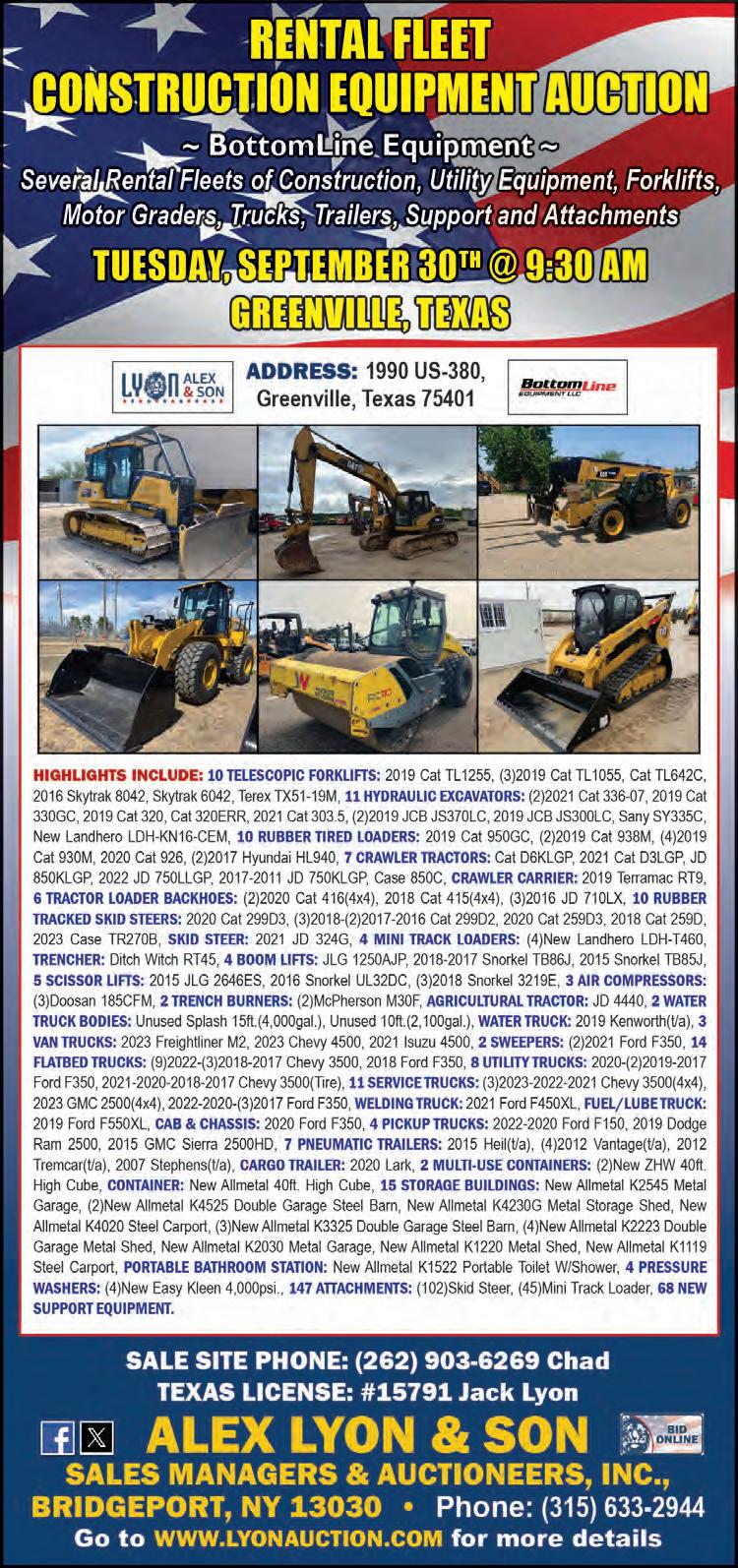

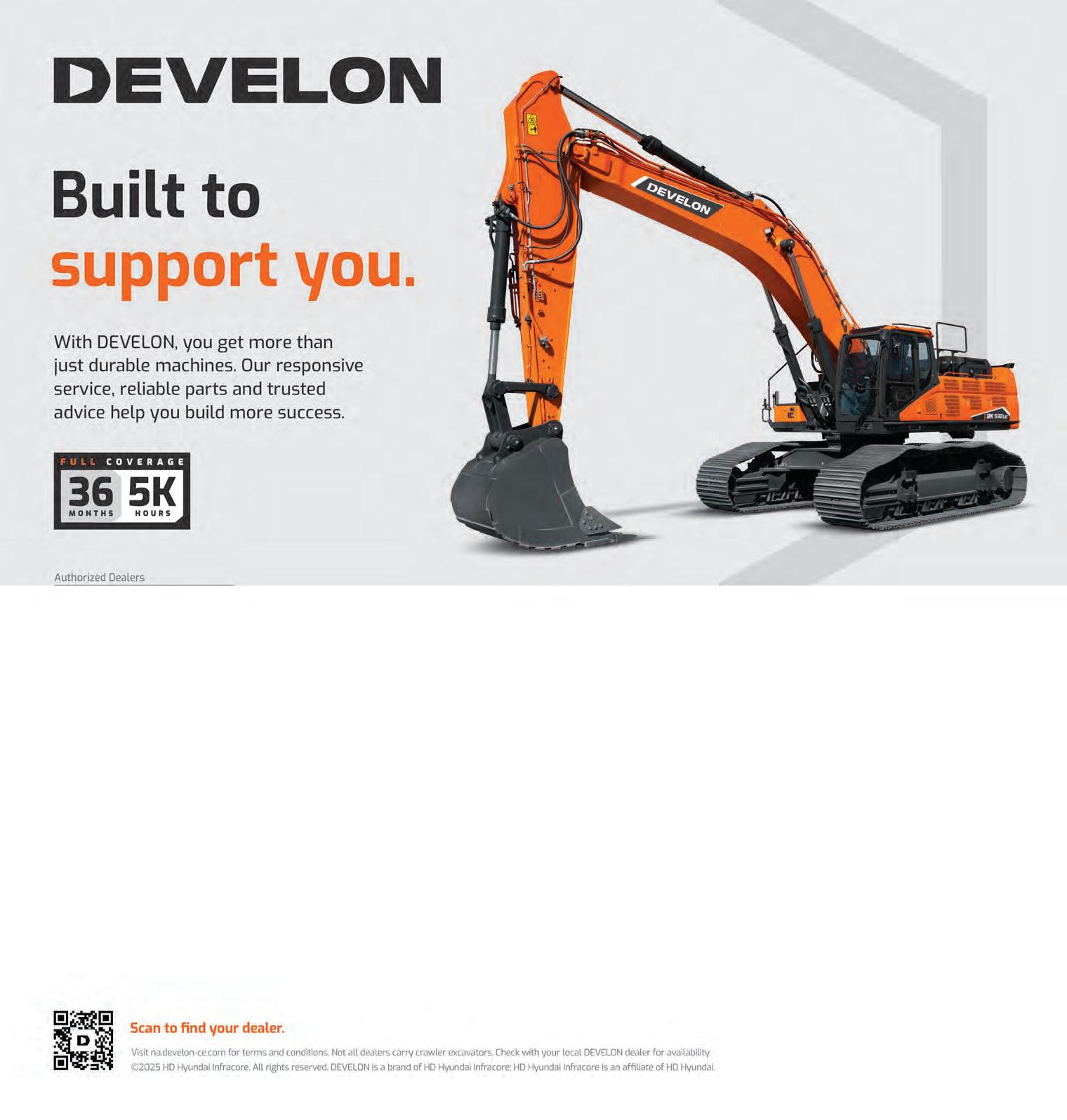

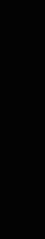

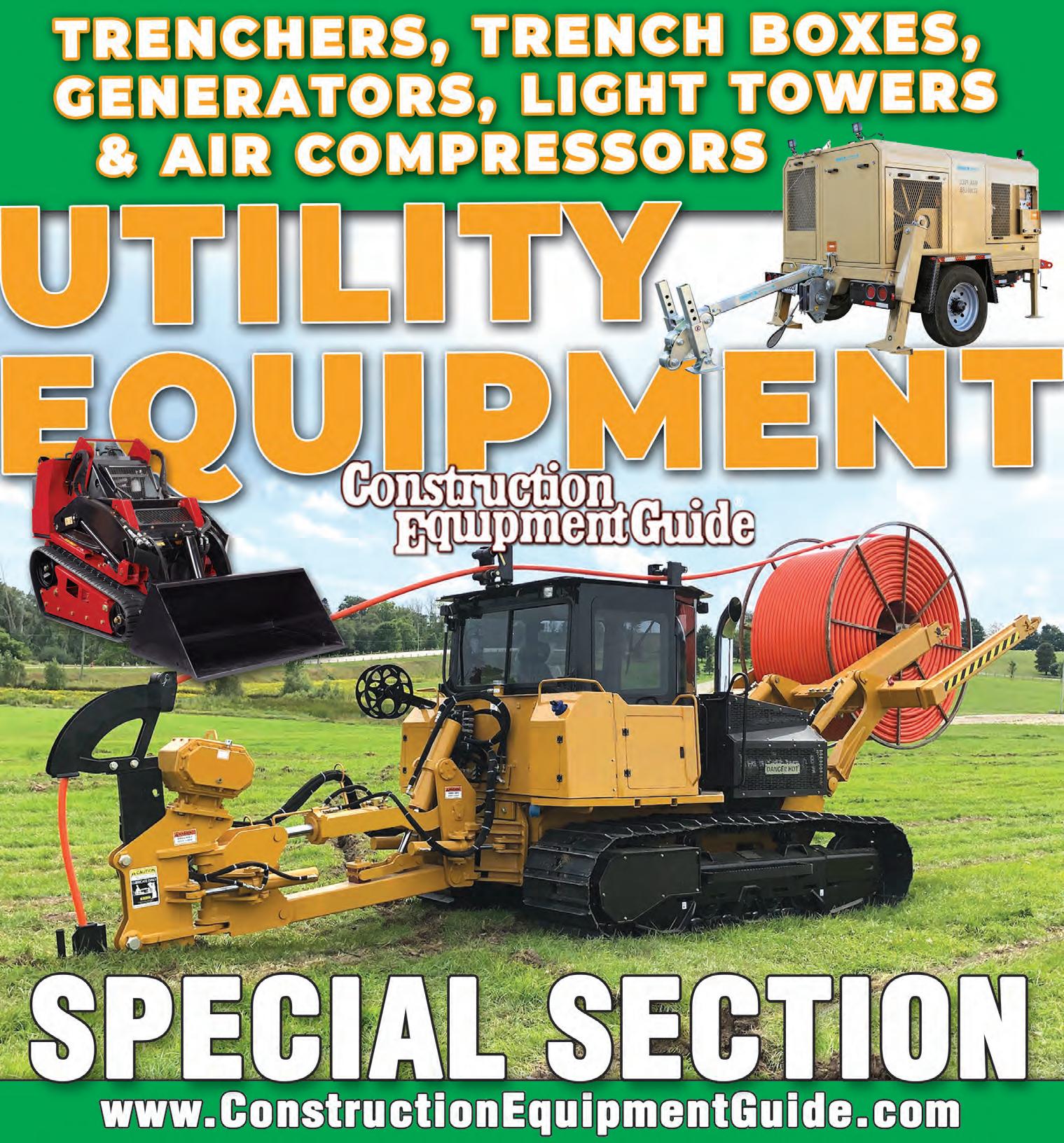

The Texas Department of Transportation (TxDOT) is taking steps to address anticipated highway congestion in rapidly growing Collin County in Texas by widening Spur 399/State Highway 5 from four to six lanes.

The $168 million project includes the construction of eight new bridges and the widening of two others.

The approximately 2-mi. stretch of roadway between Stewart Road and Eldorado Parkway is nearly 40 mi. north of Dallas.

The road widening is intended to make the

highway “easier and safer for the traveling public,” said Carlos Arocha, a senior project manager with Webber, a Ferrovial company, the project contractor.

As the spur reaches its northern endpoint, it will taper back to four lanes.

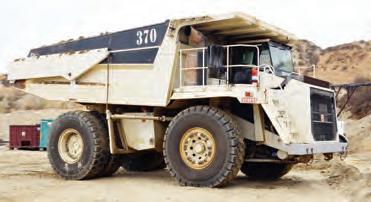

Arocha said there are anywhere from 40 to 60 workers on the site. Two crews are installing drainage, using excavators and rollers. Another two crews are setting up temporary detours to reroute traffic, using bulldozers, a motor grader, rollers and a water truck.

Workers use a 70ton rough-terrrain crane to help with the pouring of the first column of the project on the northbound ramp at Stewart Road Bridge.

By Lucy Perry CEG CORRESPONDENT

Uncertainty

“Go”

EQUIPMENT

PURCHASE or RENT

2019 John Deere 850K LT, Stk#: HR-1207, EROPS, A/C & Heat, Radio, 6 Way Blade, 6,728 hrs., 90% U/C, 24" Pads, Multi Shank Rear Ripper, 14 ft. Wide ..................$179,500

2018 Bell B30E, Stk#: 13464, EROPS, A/C & Heat, Radio, 5,453 hrs., 30 Ton Dump Cap., Auto Greaser, 23.5Rx25 Tubeless Tires $169,500

10' 4" Wide $79,500

2016 Cat 330FL, Stk#: 13598, EROPS, A/C & Heat, Radio, 7,301 hrs., 47" Bucket w/Manual Thumb, 31" Pads, Quick Connect. $139,500

2021

145X

2020 John Deere 750L LGP, Stk#: HR-1427, EROPS, A/C & Heat, Radio, 6 Way

$89,500

2020 Linkbelt 210X4EX, Stk#: HR-1322, EROPS, A/C & Heat, 5,445 hrs., 35" Bucket w/Hyd. Thumb, 31% Pads $99,500

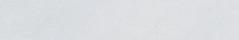

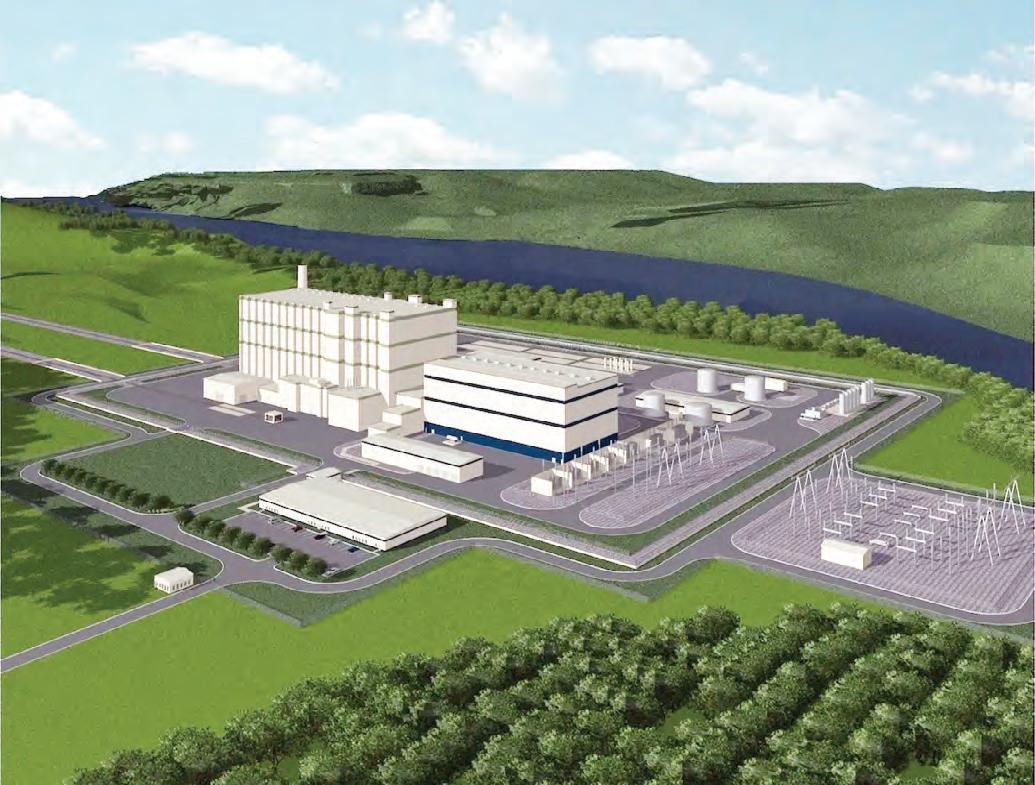

TerraPower, a nuclear innovation company, announced on Aug. 18, 2025, the start of construction on the Kemmerer Training Center (KTC) at the site of the Natrium project in Kemmerer, Wyo.

Associated Equipment Distributors (AED) successfully hosted its 2025 Leadership Conference Aug. 5–7 in Las Vegas, Nev., bringing together dealer professionals from across North America.

The DoD announced that the U.S. Army Corps of Engineers awarded ASRC Builders-Caddell a $290.3 million contract to build the Joint Integrated Test and Training Center at Alaska’s Joint Base Elmendorf-Richardson.

Apex Abatement and Demolition LLC announced the release of an AI-powered instant demolition budget calculator which provides free and fas, rough cost estimates for commercial and residential demolition projects.

In the dynamic world of road construction, Liebherr debuted a new free modeling assistance system, a technology, the company believes, is designed to improve efficiency in construction site management.

PIRTEK USA continued its growth in the second quarter of 2025, marking another milestone in its franchise development journey, spurred by the company opening nine new locations.

Associated Equipment Distributors announced the addition of Kurt Coffey, vice president of Case IH North America at CNH Industrial America LLC, to the lineup for the OEM panel discussion at the 2026 AED Summit in Dallas, Texas.

The Volvo L120 electric wheel loader won over an international judging panel to scoop a Red Dot Product Design award at the annual ceremony in Essen, Germany.

Choosing the right generator size is essential to ensure reliability, protect your equipment and avoid unnecessary costs whether your genset will be used for continuous, prime or standby power.

RB Global Inc. announced

The U.S. Army Corps of Engineers (USACE) — Alaska District awarded a construction contract on Aug. 15, 2025, for the first portion of the Port of Nome Modification Project in Nome, Alaska.

BOMAG Americas, a Fayat Company, announced additions to its light equipment team, strengthening the level of support to the rental sales channel, naming four executives.

The Wyoming Transportation Commission awarded $22.7 million in contracts for seven Wyoming Department of Transportation construction projects during its August regular business meeting.

Earlier this year, the Iowa Department of Transportation (Iowa DOT) purchased the state’s first self-contained pothole filling truck — a more efficient and safer option for fixing potholes on state roadways.

At

Re-powering a mobile machine with a Tier 4 Final engine is a cost effective way to achieve a second life for your equipment while meeting CARB emissions standards.

At Smith Power Products, Inc. we understand the rigors of off-highway diesel engines and mobile machinery. Which is why our industrial products are designed to meet these tough everyday standards. We emphasize performance and reliability to provide you with a product that maximizes your production and profitability.

Our re-power capabilities cover a vast range of mobile machinery and our years of experience has taught us that proper installation is a key component in the second life of a machine.

➡ Less costly than buying a new machine

➡ Maintain or improve machine performance

➡ Makes good business sense All of these re-powers were completed using FPT and MTU Tier 4 Engines which DO NOT USE DPF technology!

4 Final solutions featuring:

•

Over 400 machines successfully re-powered by the most skilled shop in the Western US!

TerraPower, a nuclear innovation company, announced on Aug. 18, 2025, the start of construction on the Kemmerer Training Center (KTC) at the site of the Natrium project in Kemmerer, Wyo.

This is the second facility to reach the construction milestone of this next generation, advanced nuclear project.

The 30,000-sq.-ft. center will be integral to building the future workforce for the advanced nuclear industry as it will host all Natrium plant operation training activities and support all operator-accredited programs. The KTC will house the Natrium Training Simulator, laboratories for electrical and Instrumentation & Control (I&C), mechanical and scientific laboratories, training classrooms, an auditorium and more.

Cost totals and contractor names weren’t released.

“The future of energy will only come to fruition if we have a skilled, dedicated and robust workforce,” said Chris Levesque, TerraPower president and CEO. “The Kemmerer Training Center will serve as the central hub for future Natrium operators who will deliver the reliable and flexible power communities need. We are proud to be building this facility on the site of our first Natrium plant. The proximity between the plant and the training center, along with the ongoing support of the Kemmerer community, are invaluable as we continue to advance America’s next nuclear power plant.”

“Wyoming is leading the way in establishing the next gen-

eration nuclear sector,” said Wyoming Gov. Mark Gordon. “With today’s announcement at the Natrium site on the beginning of construction on the training center, southwest Wyoming has much to celebrate — from workforce opportunities to state-of-the-art energy production.”

TerraPower, which was founded by Bill Gates, broke ground on the Natrium project in 2024 and immediately began construction efforts.

The Natrium project is the only advanced nuclear developer to begin construction on a commercial-scale project in the United States.

The Natrium design features a 345 MW sodium-cooled fast reactor with a patented molten salt-based energy storage system. The storage technology can boost the system’s output to 500 MW of power when needed as it is designed to keep base output steady, ensuring constant reliability and can quickly ramp up when demand peaks.

The decoupled design separates major structures into two independent islands — nuclear and energy — which significantly reduces the quantity of specialized materials, cutting plant costs and accelerating construction timelines.

The first Natrium plant is being developed through the U.S. Department of Energy’s Advanced Reactor Demonstration Program (ARDP), a public-private partnership.

The project is expected to be completed in 2030 and will be the first utility-scale advanced nuclear power plant in the United States.

Associated Equipment Distributors (AED) successfully hosted its 2025 Leadership Conference Aug. 5–7 in Las Vegas, Nev., bringing together dealer professionals from across North America for three days of leadership development and high-impact networking.

Designed to strengthen leadership skills at all levels of the dealership, the conference delivered engaging, real-world sessions led by nationally recognized speakers and industry experts. From leadership strategies to practical tools for team management, attendees walked away equipped to lead with confidence, clarity and accountability.

“The future of our industry depends on strong, forwardthinking leaders,” said Brian P. McGuire, AED president and CEO. “The 2025 Leadership Conference was about more than training — it was about investing in people. By equipping our members with the tools to develop talent and inspire high-performing teams, we’re helping dealerships thrive today and preparing the next generation of leaders for tomorrow.”

Among the highlights of the conference was AI Mini Hackathon: Rapid Innovation in Real Time, a hands-on session led by Susan Frew that challenged participants to solve real business problems using AI tools, promoting innovation and collaboration.

In Leading Unbeatable Teams, former Navy SEAL Curt Cronin shared compelling lessons in alignment, trust and leadership drawn from his elite combat experience. In addition, Amy Parrish led an interactive session on The 4 Personality Styles, helping attendees improve communication by identifying and adapting to different personality traits within their teams. Attendees praised the conference for its engaging content and meaningful connections.

“I brought the team here because I believe in AED and what they are doing,” said attendee Joe Grady, vice president, Buck & Knobby Equipment Co. “A lot of my managers are new — so to hear different perspectives and be able to network with other dealers, I just think it’s a great growth opportunity for them. I think AED has a non-biased attitude where they bring the industry together, across all groups, and show how we can work collaboratively. AED hears the voice of its members — which is us — and tailors conferences to address the challenges we face.”

For more information, visit aednet.org.

The United States Department of Defense (DoD) announced in July that the U.S. Army Corps of Engineers (USACE) awarded ASRC BuildersCaddell a $290.3 million contract to build the Joint Integrated Test and Training Center at Alaska’s Joint Base Elmendorf-Richardson (JBER), govconwire.com reported.

The center will offer both synthetic and live-fly training and will be the first facility able to hold both joint and multinational force training.

The 149,913-sq-ft., two-story flight simulator training facility project will be designed to withstand the state’s cold weather conditions in Alaska, govconwire.com reported.

The project includes site improvements such as earthwork, landscaping, exterior lighting, parking, sidewalks and roadways; a structural steel frame and reinforced concrete foundations; insulated steel panel and masonry walls; a seam metal and membrane roof; interior raised access floor systems; utility space for chiller equipment; self-contained HVAC systems; enclosures for standby generators; a service substation; both nonsecure spaces and secure spaces; briefing

rooms and simulator rooms; mission operation centers; a central server room; and administrative areas, an auditorium, administrative areas, break rooms and security office.

The USACE said construction is expected to be finished by June 2029, govconwire.com reported.

The USACE obligated $110.9 million of fiscal 2025 military construction funds for the project at the time of the award.

When the Department of the Air Force first announced the selection of Joint Base Elmendorf-Richardson for the project, the department said its decision came “after assessing the area's ability to facilitate the mission and infrastructure capacity, while accounting for community support, environmental factors and cost,” govconwire.com reported.

“From our position in Alaska, Joint Base Elmendorf Richardson is uniquely situated to protect the homeland and project joint forces,” said Col. David Wilson, 673rd Air Base Wing and JBER commander. “This investment powers us to deliver on those missions, increase readiness and build the next generation of agile combat warfighters and support teams.”

Apex Abatement and Demolition LLC announced the release of an AI-powered instant demolition budget calculator.

The free online tool provides fast, rough cost estimates for commercial and residential demolition projects, helping contractors, property owners and developers plan more efficiently.

The calculator uses artificial intelligence to generate a budget based on pictures, project size, structure type and other basic inputs. While the tool does not replace a formal estimate, it offers valuable insight into project costs at the planning stage, saving time and reducing guesswork.

“We built this tool because clients often ask us for quick ballpark numbers,” said Robert Sullivan, owner of Apex Abatement and Demolition LLC. “With this calculator, they don’t have to wait for a call back — they can explore costs right away, then follow up for a formal quote.”

The Instant Demolition Budget Calculator is accessible now at apexabatement.com/instant-demolition-budget-calculator.

The tool is designed for ease of use on desktop and mobile devices, and no login or personal information is required to get started.

In the dynamic world of road construction, Liebherr debuted a new free modeling assistance system, a technology, the company believes, is designed to improve efficiency in construction site management.

This solution allows machine operators to create and modify simple 3D site models directly from their Liebherr crawler cabins. By integrating a GNSS machine control system with sensors and real-time data visualization, free modeling empowers operators to make informed decisions based on current site conditions.

The construction industry increasingly recognizes the importance of technology in enhancing efficiency and productivity. As projects become more complex and the demand for faster completion times grows, the need for solutions like free modeling becomes critical. This technology streamlines operations and enhances the overall quality of work, making it a valuable tool for contractors and operators alike, according to Liebherr.

One of the advantages of free modeling is its ability to facilitate real-time 3D site modeling. Operators can visualize projects in three dimensions, which streamlines the construction process and allows for immediate feedback on site conditions. This capability fosters a proactive approach to site management, ensuring that projects remain on track and within budget. By reducing reliance on dedicated site surveyors, free modeling saves time and reduces labor costs, increases job satisfaction and contributes to the overall success of construction projects by reducing the need for site surveyors, according to Liebherr.

The ability to create and modify 3D models on the fly enables operators to quickly adapt to changing site conditions.

For instance, if unexpected obstacles arise, operators can adjust their plans in real-time, minimizing delays and ensuring that the project stays on schedule. This flexibility is particularly valuable in road construction, where conditions can change rapidly due to weather, traffic or other unforeseen factors.

Integrating free modeling into road construction operations significantly accelerates project completion times, according to

Liebherr.

By minimizing the time spent on planning and surveying, projects can move forward more quickly. The ability to create and modify site models directly from the machinery allows for rapid adjustments, ensuring that any changes in site conditions are addressed promptly. This increased efficiency translates to shorter project timelines, enabling contractors to take on more projects and improve their overall productivity.

In addition, free modeling enhances

accuracy by providing operators with realtime data, which reduces the likelihood of errors that can arise from miscommunication or outdated plans. This access to current site information ensures that operators are always working with the most accurate data, allowing them to make informed decisions that improve the quality of their work, according to Liebherr. In road construction, where even minor discrepancies can lead to significant issues, this level of precision is crucial.

The technology also promotes better collaboration among team members. With real-time data accessible to all stakeholders, including project managers, engineers and operators, everyone is on the same page. This transparency fosters a collaborative environment where issues can be addressed quickly and solutions can be implemented efficiently.

The cost-effectiveness of free modeling is another advantage. By reducing the need for dedicated site surveyors and minimizing instances of rework, construction companies can lower overall project expenses. This technology optimizes resource allocation and minimizes waste, ultimately enhancing the profitability of projects, according to Liebherr.

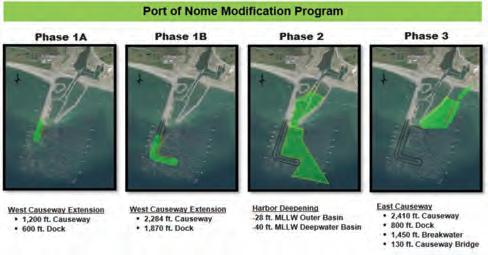

The U.S. Army Corps of Engineers (USACE) — Alaska District awarded a construction contract on Aug. 15, 2025, for the first portion of the Port of Nome Modification Project in Nome, Alaska.

Kiewit Infrastructure West Co. of Vancouver, Wash., will construct Phase 1A of the Port of Nome Modification project. Funded by the Infrastructure Investment and Jobs Act, formerly known as the Bipartisan Infrastructure Law, this construction contract award is valued at about $399.4 million.

“A robust and efficient transportation hub at Nome is foundational to the long-term viability of surrounding communities in the region,” said Col. Jeffrey Palazzini, commander of the USACE — Alaska District. “We are committed to assisting the city of Nome by providing a reliable solution that improves the port’s navigation efficiency.”

Phase 1A is the first of four phases of the required construction to build the Port of Nome project. The first phase of the project will construct a 1,200-ft. causeway extension with approximately 600 ft. of dock face. Following this portion of the project, the Phase 2 dredging of the deep and outer basins up to minus 40 ft. is next scheduled for construction.

The city of Nome is the non-federal sponsor for the project.

The entirety of the harbor expansion project aims to provide larger vessels with improved access to Nome’s existing harbor and creating a new deep-water basin at a depth of minus 40 ft. Dredging is required to deepen and maintain

both basins and associated navigation channels. Currently, ship transportation is limited by existing depths in the outer basin of minus 22 ft. This depth is inadequate to safely accommodate vessels of drafts greater than approximately 18 ft.

The new port project will serve research and public safety purposes as well as an important pivot point for the nation’s military presence above the Arctic Circle.

The Port of Nome is a regional hub located on the Seward Peninsula and adjacent to Norton Sound, which is centrally located along the western coast of Alaska. Nome has no access to major road systems and is approximately 545 mi. northwest of Anchorage.

USACE’s history in Nome dates to the construction of the original harbor in 1917.

The Wyoming Transportation Commission awarded $22.7 million in contracts for seven Wyoming Department of Transportation construction projects during its August regular business meeting.

The commission awarded an $8.29 million bid to Idaho-based H-K Contractors Inc., for combined projects involving asphalt paving, fencing, grading, traffic control and chip seal work on approximately 34 mi. on U.S. 30 at various locations in Lincoln County. The contract completion date is Oct. 31, 2026.

The commission awarded a $3.05 million bid to Worland, Wyo.-based McGarvin-Moberly Construction Co., for combined projects involving asphalt paving, fencing, chip seal, traffic control, milling and grading work on approximately 12 mi. on U.S. 26/287 at various locations in Fremont County. The contract completion date is June 30, 2027.

Concrete Works of Colorado Inc.

LLC was awarded a $2.08 million bid for intersection reconstruction and slab replacement projects involving concrete paving, traffic control and aggregate surfacing work at various locations on Wyoming Highway 59 & U.S. 14/16 in the city of Gillette in Campbell County. The contract completion date is July 31, 2026.

W.W. Clyde & Co. of Utah was awarded a $1.4 million bid for a bridge replacement project involving structure, grading, traffic control, aggregate surfacing and seeding/erosion control work on approximately 0.15 mi. of County Road 3 at the bridge over Third Sand Creek in Carbon County. The contract completion date is Oct. 31, 2026.

TCA Group Inc. of Montana was awarded a $854,836 contract for a bridge replacement project involving structure, seeding/erosion control, grading, traffic control, guardrail and clearing/grubbing work on approximately 0.10 mi. of Four Mile Creek

(County Road 603) in Carbon County. The contract completion date for this project is July 31, 2026.

King Enterprises of Mills, Wyo., was awarded a $1.18 million contract for a right-of-way project involving fencing and clearing/grubbing work on approximately 3.7 mi. on U.S. 189/191 between Daniel Junction and Bondurant Road in Sublette County. The contract completion date is Sept. 30, 2026.

All the above projects are funded primarily with federal dollars.

Funded primarily with state dollars, a $5.83 million bid was awarded to Lovell, Wyo.-based Mountain Construction Co. for a project involving asphalt paving, chip seal, traffic control, aggregate surfacing and stormwater drainage work on approximately 10 mi. of U.S. 14/16/20 between Yellowstone National Park and Cody in Park County. The contract completion date is Oct. 31.

Stockton, CA • 209-948-5401 Tulare, CA • 559-686-0054 Ukiah, CA • 707-468-5880 Woodland, CA • 530-615-2828 Madera, CA • 559-674-2496 Fresno, CA • 559-485-9090

Associated Equipment Distributors (AED) announced the addition of Kurt Coffey, vice president of Case IH North America at CNH Industrial America LLC, to the lineup of esteemed panelists for the OEM panel discussion at the 2026 AED Summit, taking place Jan. 19–21 in Dallas, Texas.

Coffey joins a group of top equipment executives for what promises to be one of the most impactful sessions of the summit. The panel will provide attendees with invaluable insights into the future of equipment manufacturing, distribution, and innovation across the industry.

“With his deep roots in agriculture and his commitment to customer-focused innovation, Kurt brings a valuable perspective to this panel,” said Brian P. McGuire, AED president and CEO. “His leadership at Case IH and experience across multiple sectors of the equipment industry will enrich the conversation and benefit all in attendance.”

Coffey has spent his career supporting farmers and equipment users through strategic leadership and product innovation. Raised on a family farm, he understands firsthand the challenges and opportunities facing today’s equipment customers. Before taking on his current role, he led marketing for Case IH globally and held executive positions in parts and service at CNH Industrial.

He also brings experience from past roles in both the finance and agriculture sectors, including time at Country Financial and Monsanto. Coffey holds a degree in agricultur-

al business from Illinois State University and serves on both the Association of Equipment Manufacturers (AEM) board of directors as well as the AEM Ag sector board.

Moderated by Marc Johnson, principal of Pinion, the panel will now feature six industry leaders:

• Rod Bull, CEO, Komatsu North America Corp.

• Scott Young, president / head of region North America, Volvo Construction Equipment

• Michael Ballweber, president, Doosan Bobcat North America

• Andrew Ryan, president, LiuGong North America

• Todd Stucke, executive officer, Kubota Corp.

• Kurt Coffey, vice president, Case IH North America, CNH Industrial America LLC

The OEM Panel will take place during a summit that includes a keynote interview with Ambassador Nikki Haley, and presentations by First Sergeant Matt Eversmann (Ret.) of Black Hawk Down fame and Lauren Saidel-Baker, economist of ITR Economics.

The 2026 AED Summit remains the equipment industry’s most comprehensive event, bringing together dealers, manufacturers and service providers for networking, education and strategic insights. With more than 40 expert-led sessions and over 200 exhibitors, this is a must-attend event for industry leaders focused on growth and innovation.

For more information, visit aedsummit.com.

PIRTEK USA continued its growth in the second quarter of 2025, marking another milestone in its franchise development journey.

The company announced the opening of nine new locations and the signing of 10 new units, further expanding its footprint to meet the rising demand for premium hydraulic and industrial hose services across the United States.

This quarter, PIRTEK’s nine new locations saw the company expand its presence in Colorado, Georgia, Louisiana, Maryland, North Carolina, Texas and South Carolina, as well as its first-ever location in Delaware. The franchise agreements for 10 units bring eight new owners to its growing franchisee network. This expansion includes three new units in Ohio, underscoring the brand’s commitment to strategic growth in high-potential regions.

“Our Q2 performance reflects the strength of our brand and the unwavering demand for fast, reliable hydraulic and industrial hose solu-

tions,” said Kim Gubera, CEO of PIRTEK USA. “We are proud to welcome new franchisees and expand into new markets, including our first location in Delaware. Our commitment to exceptional service and franchisee support remains at the heart of our continued success.”

In addition to its franchise growth, the company continues to champion military veterans. One of the new franchisees signed this quarter is a Navy veteran, Allen Wix, who will own and operate PIRTEK North Charleston in Charleston, S.C. This reinforces PIRTEK’s dedication to supporting veterans in entrepreneurship.

“As a Navy veteran, I’ve always been drawn to structured systems and mission-focused work, and PIRTEK immediately stood out as a natural fit,” said Wix. “With my background in B2B marketing and leadership, I recognized the essential value this service brings to the industries that keep our country running. I’m proud to bring PIRTEK to Charleston and join a fran-

chise system that truly supports its owners and the communities they serve.”

PIRTEK prides itself on quickly and efficiently filling customers’ hose service needs, having the widest variety of superior products and parts to keep essential projects running. Their quick turnaround time also is credited to the one hour ETA on-site emergency hose service offered 24/7/365. This service enables customers to be up and running again quickly, minimizing equipment downtime due to a hose failure.

PIRTEK onboards potential franchisees who prioritize customer service, and welcomes driven individuals from all industries, regardless of technical experience. The initial investment ranges from $235,137 to $666,638. Franchisees can expect extensive in-person and online training, ongoing support and exclusive territories.

For more information, visit pirtekusafranchise.com.

TX

915-541-0066

Loved for the features. Trusted for the performance.

Do more without feeling like it in Hyundai’s easy to own, easy to operate, skid steer and compact track loader.

Standard features include:

• LED front and rear work lights

• Auto leveling bucket

• Ride control

• Review camera

• Two speed travel

• AM/FM bluetooth radio

• Free Hi MATE telematics access for 5 years

No wonder so many first-time Hyundai users become longtime fans. See the Hyundai difference yourself at your local dealer, or na.hd-hyundaice.com.

equipment rental and staging to subcontractor assignments and jobsite security. Here’s how to ease the headaches when supply-chain issues crop up.

“What once seemed like temporary disruptions have become a persistent reality,” said attorney William Blasses about today’s construction logistics process. “Meticulous planning can be undone overnight by a single supplier’s inability to deliver.”

In this environment, said Blasses, with Kerr, Russell and Weber PLC, the standard contract is either a safeguard or a liability.

In a post on the website of the National Association of Surety Bond Producers (NASBP), he talked about logistics strategies.

“Proactively embedding resilience into these agreements is no longer just a legal formality but a core business strategy,” he said. “By tailoring key clauses to their needs, companies can better insulate themselves from costly volatility.”

Blasses urges clients to consider the foundation of any agreement — clarity — before examining specific clauses.

Contracts riddled with ambiguous terms, he said, are invitations for future disputes because each party will interpret subjective terms advantageously.

“A truly defensive contract systematically replaces such ambiguity with objective, measurable standards,” said Blasses. “This precision is the bedrock of an enforceable and reliable agreement.”

Setting boundaries and expectations for both parties, reinforces the business relationship and avoids the potential to deteriorate it over time, said Blasses.

Market volatility spells price fluctuations in key construction materials, cautions tax and accounting firm RSM.

Supply-chain digitalization and scenario planning are “no longer aspirational; they are essential,” said business advisors with the organization.

“Forward-thinking construction leaders are responding proactively,” said Mac Carroll, real estate industry analyst.

They ask the right questions and invest in strategies that build resilience.

RSM clients’ biggest question is how to prepare for potential cost increases.

A focus on forecasting, communication and relationships will get contractors through the challenges, believes Joe Barbalaco, a management consulting manager. He advises clients to run a sensitivity analysis on current and upcoming projects to assess how margin would shift with changes in key material prices.

Barbalaco gives clients a list of steps they can take now:

www.cpower.com

9200 Liberty Drive

Liberty, MO 64068

816-781-8070

Wichita, KS

316-943-1231

Great Bend, KS

620-792-1361

Liberal, KS

620-624-7274

Woodward, OK

580-256-6014

Salina, KS

785-825-8291

Colby, KS

785-462-8211

Springfield, MO

417-865-0505

Joplin, MO

417-726-5373

Riverside, MO 816-415-6787

Wichita, KS

316-789-7370

Yukon, OK 405-324-2330

Maryland Heights, MO 314-427-4911

Liberty, MO 806-415-6700

Tulsa, OK 918-984-6565

www.PacWestMachinery.com

8207 South 216th Street

Kent, WA 98032 206-762-5933

Mount Vernon, WA 360-588-3083

Portland, OR 503-252-5933

Eugene, OR 541-302-3762

Spokane Valley, WA 509-534-5933

Pasco, WA 509-547-5933

1519 W Belt Line Road Carrollton, TX 75006 214-819-4100

Austin, TX 512-388-2529

Carmine, TX 979-278-3570

Ft. Worth, TX 817-626-2288

Houston, TX

713-937-3005

Longview, TX 903-758-5576

Midland, TX 432-234-9409

San Antonio, TX 210-648-4600

Corpus Christi, TX 361-881-4891

Mercedes, TX 956-565-0100

Stephenville, TX 254-266-2871

12320 S. Main Street

Houston, TX 77035 713-723-1050

1720 Hicks Street Tomball, TX 77375 281-351-9016

2077 N. Craig Drive Buffalo, TX 75831 903-322-7150

8903 Memorial Blvd Port Arthur, TX 77640 409-721-5305

5732 S MacArthur Drive Alexandria, LA 71302 318-408-3099

7502 Pecue Lane Baton Rouge, LA 70809 888-973-9767

125 E Airline Hwy Kenner, LA 70062 888-974-0532

apcoequipment.com North Las Vegas, NV 702-871-7474

scottequip.com

Fontana, CA 800-316-0327

Santa Fe Springs, CA 562-777-0775

Temecula CA 951-355-3085

ttjequipment.com Jasper, TX 409-384-4611

Longview, TX 903-803-3365

Lufkin, TX 936-634-3365

cpower.com Midland, TX 432-248-8344

San Antonio, TX 210-591-6807

Corpus Christi, TX 361-737-0049

Oklahoma City, OK 405-324-2330

Tulsa, OK 918-984-6565

Woodward, OK 580-256-6014

stewartandstevenson.com Albuquerque, NM 505-881-3511

Denver, CO 303-287-7441 El Paso, TX 915-790-1848

Lubbock, TX 806-745-4224

Wichita Falls, TX 940-322-5227

are Jonas Fredberg, studio engineer; Peter Reuterberg, senior chief advanced designer; Jenny Arnell, group manager; and Nina Augustsson, design director, all of Volvo Group.

The Volvo L120 electric wheel loader won over an international judging panel to scoop a Red Dot Product Design award at the annual ceremony in Essen, Germany.

The Red Dot is one of the world’s largest and most respected design competitions and recognizes achievements in product and industrial design.

The machine’s modern look was the result of a year of bold thinking by technology and design teams from Jinan in China and Eskilstuna and Gothenburg in Sweden. This award achievement is therefore a testament to the power of global collaboration.

Peter Reuterberg, senior chief advanced designer of Volvo CE, said: “I’m happy we won this award but I’m especially happy that we won it for this machine. The change from diesel to electric gave us the opportunity to think differently and strive for big impact. Our hope is that this new silhouette will be instantly recognizable as electric.”

cab. As wheel loaders are designed to be driven both forward and backward in equal measure, all-round visibility is crucial to their safe and efficient operation.

Instead, engineers and designers worked together on a more thoughtful solution and agreed to integrate the batteries into the counterweight of the machine. The heavy weight of a battery is often seen as a problem in electric machine design, but in this case, the battery is being used to replace a concrete counterweight required for wheel loaders.

The result is a machine that not only looks great, but provides enhanced visibility, safety and sustainability compared to traditional diesel variants.

The streamlined frame of the electric loader is made possible due to the removal of a combustion engine. The result is a transformation from a boxy’ rear end common to diesel machines into a sleeker shape for the new era of electric.

If designers replaced the combustion engine with largerin-size batteries, this would have not only created a ‘bulkier’ shape but would have also reduced visibility from the

Annie Gao, product platform engineer of the Jinan Technology Center, Volvo CE China, said: “When we debuted the machine it marked a significant breakthrough, truly capturing the spirit of an electric vehicle. It is our relentless pursuit of innovation, close attention to detail and commitment to quality that made this possible.”

ARNOLD MACHINERY CO. www.arnoldmachinery.com

Salt Lake City, UT 801-972-4000

Idaho Falls, ID 208-523-0822 Meridian, ID 208-887-6000 Twin Falls, ID 208-733-1715

PACWEST MACHINERY www.PacWestMachinery.com

Sparks, NV 775-356-1511

Las Vegas, NV 702-642-9000 Phoenix, AZ 602-414-1900 Tucson, AZ 520-294-7677

Kent, WA 206-762-5933

Mount Vernon, WA 360-588-3083 Portland, OR 503-252-5933

Eugene, OR 541-343-6926

Spokane Valley, WA 509-534-5933 Pasco, WA 509-534-5933

Artesia, NM 575-746-6592 Austin, TX 512-388-2529 Carmine, TX 979-278-3570 Corpus Christi, TX 361-881-4891 Dallas (Carrollton), TX 214-819-4100

El Paso, TX 915-772-0613

Ft. Worth, TX 817-626-2288

Houston, TX 713-937-3005

Longview, TX 903-758-5576

Lubbock, TX 806-745-1511

Midland, TX 432-234-9409

Rio Grande Valley, TX 956-565-0100

San Antonio, TX 210-648-4600

Stephenville, TX 254-266-2871

Excavators - Crawlers

Choosing the right generator size is essential to ensure reliability, protect your equipment and avoid unnecessary costs. Whether your genset will be used for continuous, prime or standby power, careful planning can help you avoid common pitfalls.

Here are the key factors to consider:

1. Start with the Load

The first and most critical step in sizing a generator is understanding your power requirements. Identify the loads that are essential to your operation and determine their power demands when utility power is unavailable.

Create a list of all required loads, including their voltages, to size your generator correctly. Undersizing can lead to startup failures or even damage connected equipment. Conversely, oversizing can result in inefficient operation, increased maintenance and higher repair costs due to light loading.

As businesses grow, power demands often increase. It’s common to oversize a genset by a margin to accommodate future expansion but avoid going too far — expansion plans that take too long to materialize can lead to unnecessary expenses.

2. Understand the Type of Load

Not all loads behave the same. Loads can be broadly divided into resistive and reactive (non-linear):

• Resistive loads (such as incandescent lighting or heating elements) draw the same current to start as they do to run.

• Reactive loads (such as motors, pumps and HVAC systems) require significantly more power to start, making them the biggest factor in generator sizing.

Motors and similar equipment often list their NEMA code on data plates, which indicates their locked rotor current. Using this data helps achieve more accurate generator sizing.

To manage reactive loads effectively and avoid oversizing, consider:

• Load sequencing: Bringing loads online in stages — allowing one motor to reach full operation before starting the next — can significantly reduce the generator’s required capacity.

• Advanced starters: Using soft starters or Variable Frequency Drives (VFDs) can minimize the inrush current by controlling voltage and frequency during startup, allow-

ing for a smaller genset without sacrificing performance.

3. Match Site Requirements

Voltage and frequency stability, as well as

Total Harmonic Distortion (THD), must meet the needs of your specific application. Generators used for life safety, fire prevention or other critical systems have stricter regulations, often dictated by local, state and national codes. Always verify that the engine and generator are correctly sized to meet these performance standards.

4. Choose the Right Fuel

Fuel type is another important consideration for commercial and industrial generators. The three most common options are

diesel, natural gas and propane, each with its own advantages:

• Diesel: On-site fuel storage, generally lower cost per kW (depending on emissions requirements), but higher fuel costs and emissions. Fuel must be delivered during extended outages.

• Natural Gas: Cleaner emissions, lower fuel costs and readily available if a gas line exists. Generators typically have a higher upfront cost, and new gas line installation may add expenses.

• Propane: On-site storage, relatively clean emissions and often lower fuel costs than diesel. Like diesel, fuel must be delivered during long outages and per kW costs tend to be higher.

Each site has unique needs, so weigh the pros and cons carefully before deciding.

The right generator sizing ensures optimal performance, protects your investment and supports future growth. For expert advice tailored to your specific application, reach out to your HIPOWER sales or support team.

Niece 8,000 gallon water tanks

installed on 40 ton Articulated Off Highway chassis. This combination is the workhorse of the dust control and water needs for quarries and large construction sites

The NWT9500 9500 Gallon water tank mounted on articulated truck. Pictured: Deere 460E with 9,500 gallon tank. Tanks come with 6X5 pumps.

The NFL3000 Off Road, Fuel and Lube Bed offers 3,000 gallons of diesel fuel.

The NFL10000 Fuel & Lube Can be mounted on any 100,000 lb rigid frame truck. Holds 10,000 gallons of diesel. 5 additional fluid tanks. Holds up to 3,000 gallons of oil.

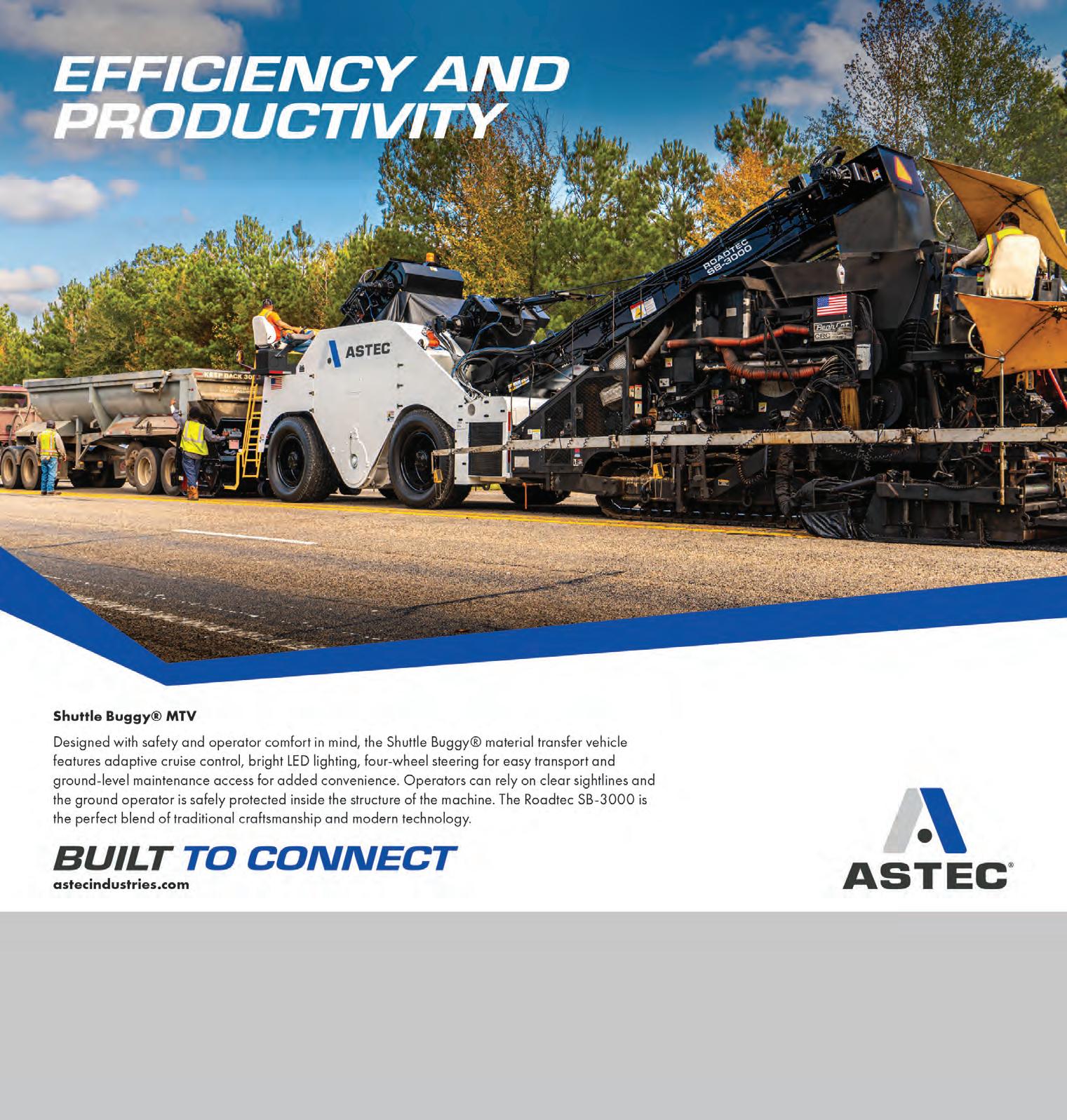

Due to its high daily output, the large milling machine from Wirtgen can handle a broad spectrum of applications, ranging from surface layer rehabilitation and fulldepth pavement removal to fine milling, according to Wirtgen.

The new large milling machine W 210 XF has been available and working on construction sites since January 2025. Currently, it is available in the United States, Europe, Australia, Japan and Taiwan. The large milling machine from Wirtgen can handle a broad spectrum of applications ranging from surface layer rehabilitation and full-depth pavement removal to fine milling.

Its Mill Assist machine control system ensures absolute efficiency on every construction site. In automatic mode, it always ensures the most favorable working balance between performance and costs, according to Wirtgen. It also allows the selection of three different working strategies that optimize the process with respect to cost, performance or quality, according to Wirtgen.

Powered by a John Deere engine with a maximum rated power output of 778 hp, the W 210 XF delivers powerful and efficient milling performance in every situation. Wirtgen and John Deere worked in close collaboration on fine-tuning the engine’s torque characteristic to meet the specific needs of cold milling applications, according to the companies.

The combination of the powerful engine and the Dual Shift two-speed powershift transmission enables an enormous range of milling drum speeds. The lower range of milling drum speeds enables significant reductions of fuel consumption, pick wear and noise emissions, according to Wirtgen.

The upper range of milling drum speeds makes it possible to achieve high area performance with a high-quality milling pattern, even at the maximum milling depth of 33 cm. This means that the W 210 XF is ideally equipped to

complete even the most demanding milling tasks with maximum sustainability, according to Wirtgen.

The requirements on construction sites often change from one day to the next. This means that outstanding flexibility is a must. An example of this in the case of the W 210 XF is that the milling drum can be exchanged for a Multiple Cutting System (MCS) drum within minutes.

The ability to rapidly change to application-specific milling drums with different tool spacings considerably increases machine productivity. At the same time, the choice of the ideal drum for a specific application also reduces wear-related costs, according to Wirtgen.

Wirtgen offers a range of milling drums for the W 210 XF to meet the requirements of any milling application.

closner.com

6532 East Highway 114 Rhome, TX 76078

817-708-9108

21910 FM 2252 Schertz, TX 78154 210-732-2131

13800 FM 973 N Manor, TX 78653 512-272-8200

18851 GH Circle Waller Industrial Park Waller, TX 936-525-9949

ascoeq.com

5980 S M L King Jr Pkwy Beaumont, TX 77705 409-746-5102

202 I-35 Frontage Road Belton, TX 76513 254-613-1500

2800 Hwy 290 E Brenham, TX 77833 979-836-6641

1875 N Earl Rudder Fwy Bryan, TX 77803 979-779-8942

1512 Neptune Dr. #9706 Clinton, OK 580-323-3422

2019 Airport Fwy Euless, TX 76040 817-283-2844

980 N Sam Houston Pkwy E Houston, TX 77032 281-987-1990

6203 Long Drive Houston, TX 77087 713-649-0940

27500 E University Drive Aubrey, TX 76227 972-441-2726

12805 US-290 E Manor, TX 78653 512-272-8922

7100 SW 3rd Street Oklahoma City, OK 73128 405-789-6812

902 SE 9th Avenue Perryton, TX 79070 806-435-7773

1920 S East Loop 410 San Antonio, TX 78220 210-333-8000

3600 US-82 Sherman, TX 75090 903-893-7586

401 FM 148 Terrell, TX 75160 972-563-2171

12210 E 1st Street Tulsa, OK 74128 918-437-5085

2602 E Front Street Tyler, TX 75702 903-593-0201

2900 Henry S Grace Fwy Wichita Falls, TX 76302 940-687-2726

nixonegli.com

2044 S. Vineyard Avenue Ontario, CA 91761 909-930-1822

800 E. Grant Line Road Tracy, CA 95304 209-830-8600

2750 Marion Drive Las Vegas, NV 89115 702-342-8100

2019 Weiler P385B track paver, 8-16 ft electric heated vibratory screed, All new screed plates, 9 ton hopper, Cat dsl eng, steel tracks- $84,000

New Marathon TPS250PT tack

distributor, Briggs gas eng, 18GPM pump, 250 gal, 6 ft spray bar, operator’s platform, spray wand & hose, propane burners, flushing system - $22,550

2022 Volvo PT125C pneumatic roller, 9 wheel rubber tire, Volvo dsl eng, water system, 365 hrs$62,000

2019 Volvo DD30B double drum 49” vibratory roller, Kubota dsl eng, double drum drive, water system, 3 tons- $26,000

New Marathon TPS500PT tack

distributor, Briggs gas eng, 18GPM pump, 500 gal, spray wand w/50 ft hose, hose reel, 6 ft spray bar, operator’s platform, propane burners, overnight heater, flushing system - $34,550

2020 Leeboy 8510E track paver, Kubota dsl eng, 8-15 ft vibratory electric heated screed, auger sensors, wash down hoses on reels, New screed plates on Extensions - $95,000

HIGHWAY from page 1

Another crew is setting up temporary barriers at night with excavators. And there ais a traffic control crew that directs traffic so the work can continue.

Concurrently, work has begun on the first new bridge out of the project’s 10. The two bridges now on the road will be widened.

During the first week of August, the contractor started drilling shafts on one of the 10 bridges. For the work, which will continue for all the new bridges, the crew is using a drill rig, a 12k forklift and a skid steer loader. Another two crews are working on the substructure of the first bridge and its retaining walls. For this work, Webber is using forklifts, manlifts and rough-terrain cranes.

This task requires a drill rig, which drills a hole in the ground. With the same rig, a crew sets up the reinforcing steel and pours concrete into the hole. After the shafts are drilled, crews will begin working on the bridge columns.

The diameter of the drilled shafts for the project varies from 18 in. to 108 in. On the first bridge, they vary from 18 in. to 42 in. The length of the shafts varies from 20 to 70 ft. For the first bridge, the lengths vary from 25 to 40 ft.

see HIGHWAY page 54

ARNOLD MACHINERY COMPANY

www.arnoldmachinery.com

Las Vegas, NV

702-642-9000 Phoenix, AZ

602-414-1900 Tucson, AZ

520-294-7677

Albuquerque, NM

505-895-1565

www.ascoeq.com

Beaumont, TX 409-212-8100

Brenham, TX 979-836-6641 (North) Houston, TX 281-987-1990 (South) Houston, TX 713-649-0940

CLOSNER

www.closner.com

Schertz, TX 210-732-2131

Rhome, TX 817-708-9108 Manor, TX 512-272-8200

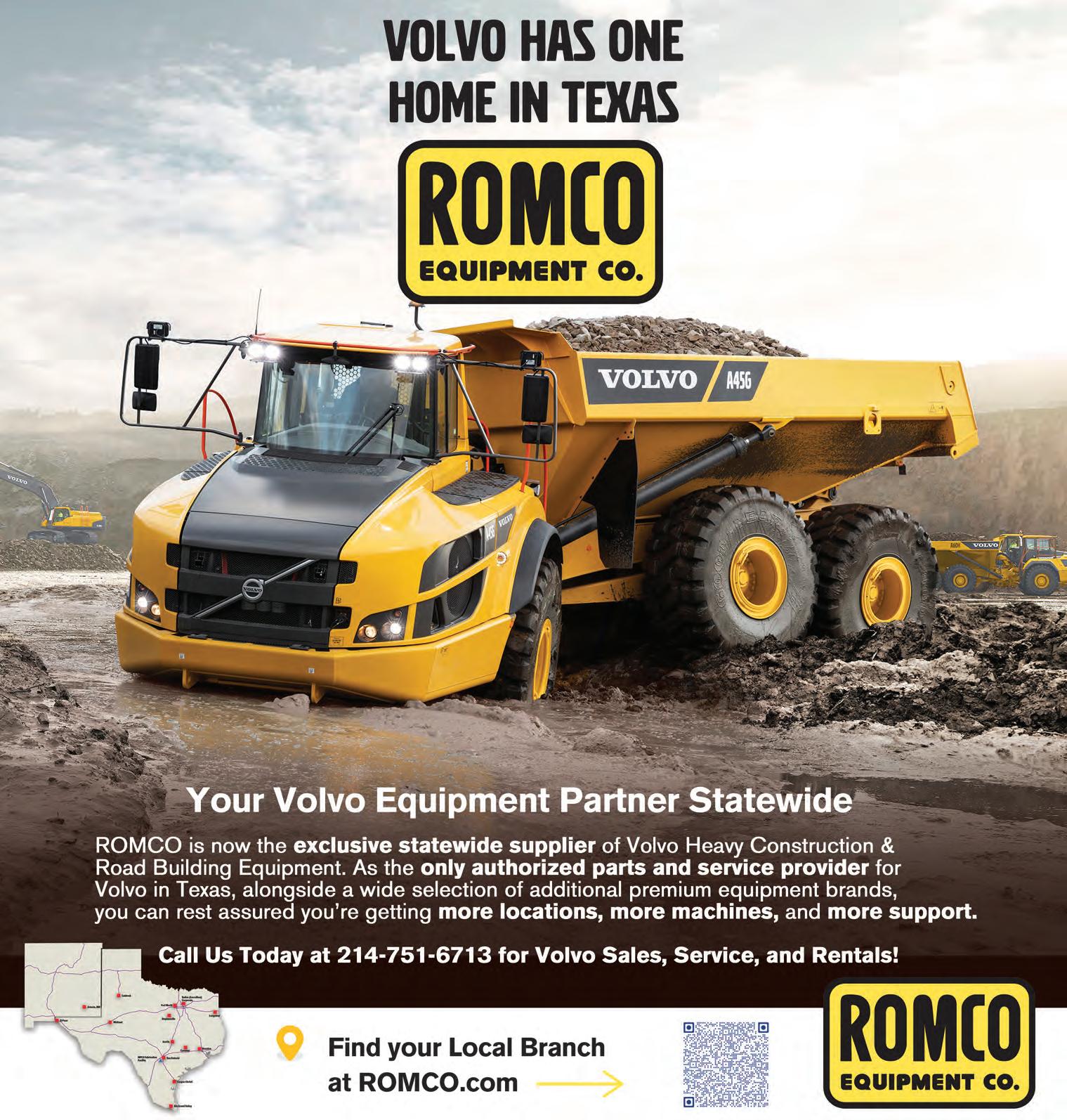

www.romco.com

Artesia, NM 575-746-6592

Austin, TX 512-388-2529

Carmine, TX 979-278-3570

Waller, TX 936-525-9949 NIXON-EGLI EQUIPMENT CO.

Corpus Christi, TX 361-881-4891

Dallas (Carrollton), TX 214-819-4100

El Paso, TX 915-772-0613

Ft. Worth, TX 817-626-2288

Houston, TX 713-937-3005

Longview, TX 903-758-5576

Lubbock, TX 806-745-1511

Midland, TX 432-234-9409

Rio Grande Valley, TX 956-565-0100

San Antonio, TX 210-648-4600

Stephenville, TX 254-266-2871

www.nixonegli.com

Ontario, CA 91761

909-930-1822

Tracy, CA 95304 209-830-8600

WIRTGEN from page 33

Exchanging the milling drum assembly enables the completion of milling widths of 6.5 ft., 7.2 ft. or 8.2 ft.. With the aid of the quick-change system, the entire milling drum housing can be exchanged in less than an hour, according to Wirtgen.

Wirtgen Group Performance Tracker Milling, or WPT Milling for short, is available for the automated documentation of milling tasks. The operator is kept constantly informed about the current machine and job parameters, and when the work has been completed, the data is transmitted to the machine owner, who can then use them for fast and precise billing.

In addition to displaying construction site and machine data, the automated documentation also shows the CO₂ emissions for the entire construction site. The John Deere Operations Center presents all information in real time.

The Level Pro Active leveling system was developed by Wirtgen specifically for cold milling machines. Clearly readable control panels provide information and measured values from all currently connected sensors and ease the machine operator’s workload, according to Wirtgen.

The system is fully integrated into the control system of the cold milling machines and, as essential machine functions are directly interconnected, enables a high level of automation and precise milling results. The system also offers numerous automatic and additional functions that make the operator’s job easier, for instance, automatic lifting for driving over manhole covers.

For more information, visit wirtgen-group.com.

BOMAG Americas, a Fayat Company, announced additions to its light equipment team, strengthening the level of support to the rental sales channel.

Jim Davis was recently appointed to the new position of director of national accounts, light equipment, to address the unique needs of the larger rental customers with multiple locations throughout North America.

The recent appointments of three regional sales managers help to further reduce sales territory size and increase the level of support BOMAG provides to all its light equipment rental and preferred customers. These include:

• Cody Nichols as the regional sales manager northeast;

• Alex Schmantowsky as the regional sales manager midwest; and

• Jacob Salinas as the regional sales manager pacific southwest.

“BOMAG continues to add experience and talent to the sales team to match our superior equipment quality and performance with a premium level of sales and support for our light equipment channel,” said Tom Watson, director of sales, light equipment. “In turn, this enables the rental companies to help their customers get the most from the entire rugged and dependable BOMAG light equipment line.”

Jim Davis brings more than 40 years of industry and sales experience to the BOMAG team. As director of national accounts, Davis is charged with formalizing and implementing the program designed to support large national rental chains such as United Rentals, Sunbelt, Sunstate and HERC.

This includes managing contracts, pricing, warranty and rebate programs and service and equipment training to help rental outlets select the right equipment for the market’s needs and keep it well maintained.

Davis’s work history includes more than two decades of national rental account management, sales direction and management of key roles in the light equipment and fuel storage markets.

“Once you get in the industry, it gets in your blood,” said Davis. “BOMAG has a well-earned reputation for equipment quality that consistently delivers a high return on investment to reduce total cost of ownership. We are putting

in place a formalized structure to better support our national program.”

As the regional sales manager, northeast for BOMAG, Cody Nichols supports rental partners across Maine, Vermont, New Hampshire, Massachusetts, Rhode Island, Connecticut, New York, New Jersey, Pennsylvania and Delaware. Nichols brings more than a decade of experience in equipment sales and business development, with a focus on the construction industry and other sectors where uptime, quality and dependable service are critical.

“BOMAG has the reputation for manufacturing reliable equipment that’s engineered for durability, simplified maintenance and operator comfort,” said Nichols. “I’ll ensure our partners get the right machines for the job, backed by the responsiveness and expertise they need to keep their customers productive and projects moving.”

Alex Schmantowsky is the new Midwest regional sales manager, supporting rental customers in North and South Dakota, Minnesota, Wisconsin, Iowa, Nebraska, Kansas, Missouri and Illinois. He brings a diverse range of experience to BOMAG from working in product and technical sales management for Western Global — where he assisted contractors in optimizing their energy consumption and safety operations — to working for the NFL and owning a classic car restoration company.

Working with independent rental companies and assisting with national rental accounts, Schmantowsky plans to support customers by helping them to optimize their operations and prof-

itability with the use of BOMAG light rental equipment.

“I plan to use a mastery of the BOMAG product portfolio to fully support our customers from all angles and cover a lot of ground in the territory,” Schmantowsky said. “BOMAG’s equipment and technology innovations are amazing, from safe operation offered by the remote trench compactor to the simplicity of our single direction plate compactors to the wellbalanced tamper series.”

A second-generation industry professional, Jacob Salinas is charged with supporting rental companies operating in California, Nevada and Arizona as the pacific southwest regional sales manager. With his father working for compaction and paving equipment manufacturers, Salinas grew up around the industry and most recently sold equipment for an industrial manufacturer representative in the Rocky Mountain region. As regional sales manager, Salinas sees much opportunity to build the BOMAG brand and offer consistent representation to rental outlets in the territory.

“BOMAG offers a wide range of light compaction equipment — from tampers and plate compactors to trench compactors and ride-on rollers — so we can flexibly serve the independent rental outlet’s needs,” said Salinas “And BOMAG’s low-emission electric construction ePerformance machines offer an opportunity for rental companies to serve customers working in regions that are requiring the removal of gas and diesel equipment.”

For more information, visit bomag.com/us-en.

Hamm photo

The new HC 100i – HC 130i G-Tier models from Hamm are being launched in North America, with other markets to follow.

Roller manufacturer Hamm presents new models for compaction in earthworks.

The new models are available now with operating weights between 11 and 13 metric tons (25,832–29,745 lbs.) and can be supplied with a smooth drum or a padfoot drum. They meet the EU Stage V and EPA Tier IVf exhaust emission standards and are initially being launched in North America, with other markets to follow.

The new compactors with a drum width of 84.3 in. deliver high centrifugal forces and linear loads. ECO mode allows users to drastically reduce their diesel consumption without compromising on compaction power, according to Hamm.

With this mode engaged, the frequency and compaction forces remain consistently high even at a reduced engine speed, which not only saves fuel but also cuts CO2 emissions. The machines achieves gradability with the 3-point articulation that guarantees the high level of maneuverability, stability against overturning and exceptional traction. The new compactors are driven by a John Deere engine delivering 114 hp.

Various options are available for the new models, including compaction measurement with the Hamm compaction meter, a process data interface, padfoot shells, a powerful lighting package or even the automatic vibration system.

The working environment of the new compactors is characterized by ergonomic design and offers numerous equipment options. Examples include the ROPS cabin with heating and air conditioning functions, a tilting steering column or different types of seats to best meet the varying needs of operators. The easily accessible maintenance points make servicing the machines simple, which keeps downtimes brief and ensures smooth operation.

For more information, visit wirtgen-group.com.

Closner Equipment

www.closner.com

Rhome, TX 817-708-9108

Schertz, TX 210-732-2131

Manor, TX 512-272-8200

www.pacwestmachinery.com

Seattle, WA 206-762-5933

Spokane, WA 509-534-5933

Pasco, WA 509-547-5933

Mt Vernon, WA 360-588-3083

Waller, TX 936-525-9949 PacWest Machinery

Portland, OR 503-252-5933

www.power-equip.com

Farmington, NM 505-326-1413

Durango, CO 970-247-8830

Denver, CO 303-288-6801

Eugene, OR – Branch 541-302-3762 Power Equipment Company

Colorado Springs, CO 719-392-1155

Grand Junction, CO 970-243-0722

Greeley, CO 970-353-1224

www.tristatetruckandequip.com

Belgrade, MT 406-388-5818

Billings, MT 406-245-3188

Casper, WY 307-472-1818

Great Falls, MT 406-452-9551

Albuquerque, NM 505-345-7811 Tri-State Truck and Equipment

Rock Springs, WY 307-362-4000 Shafer Equipment

wwwshaferequipmentco.com

Sparks, NV 208-801-7772 Boxcer Equipment

www.boxcerequipment.com

Tulsa, OK 918-272-7237

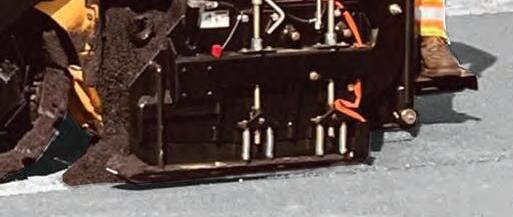

Earlier this year, the Iowa Department of Transportation (Iowa DOT) purchased the state’s first self-contained pothole filling truck — a more efficient and safer option for fixing potholes on state roadways.

Operated by a single individual, the Cimline Durapatcher — currently deployed in Iowa DOT’s District 4, based in

Council Bluffs and in District 1, based in Ames — this selfcontained vehicle mixes and applies emulsion in a fraction of the time with a fraction of the labor.

More importantly, it is safer than the current pothole-filling method, which requires a dump truck and a trailermounted hopper to be followed by two or three staff to spread the material with shovels and compaction tools by hand — all while exposed to traffic.

After a tragic I-80 work zone crash that killed Matt Dickerson, an Iowa DOT District 4 staff member, near Council Bluffs in 2024, the agency’s field staff and leadership have sought out safer ways to accomplish routine work like pothole patching.

“The ability to remove staff from the operation takes more employees off the road … to do different tasks for the day. It also increases safety by putting one operator in a protected truck cab that protects them,” said Cory Kirkpatrick, maintenance supervisor for Iowa DOT’s DeSoto/Perry garage, in a blog post.

“With no staff on the roadway and faster filling, this truck also reduces the disruption to the public, so we’re able to provide a higher level of service to our customers.”

The agency said the Cimline Durapatcher pothole patching machine preps and installs a patch in minutes without the need for compaction. The truck chassis houses a hopper to hold the supply of rock chips and a 300-gal. heated oil tank that together produce enough product to apply approximately 10 tons of patch material.

Inside the cab, the operator uses a joystick to control mixing and pump the oil — known as emulsion — and rock material forward to a hydraulic arm and nozzle in the front of the unit. When the Durapatcher approaches a pothole, the operator can activate a compressor to clear debris and water.

The next step is to spray the emulsion to fully coat the inside of the pothole, followed by the application of a rock and emulsion mixture.

“We’re looking for a salt and pepper look with the black emulsion oil and the light-colored rock,” said Matt Conaway of the DeSoto Maintenance garage. “Then we’re adding another layer of clean rock over the top to protect the public’s vehicles from the oil.”

As Iowa DOT’s maintenance shops continue to learn more about operating the new system, the agency said reviews of the new pothole filling machine are positive as staff find the new technology to be more streamlined than the conventional dump truck and trailer method.

Iowa DOT added that staff report that the system is “instinctive” to new operators and allows them to get closer to the pothole to see where levelling is needed to provide a better seal and more comfortable ride for the public.

The Carlson CP100 II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100hp engine, an array of configurations and the class-leading EZCSS single slide screed, it’s time to see why the CP100 II has fast become the contractor’s choice for heavy-duty commercial paver platforms.

The CP100II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100 horsepower engine, an array of configurations and the class-leading Carlson EZCSS single slide screed, it’s easy to see why the CP100II is the ideal choice for heavy-duty commercial paving.

HDD contractors can now more efficiently complete fiber and other underground utility jobs with the new JT21 directional drill from Ditch Witch.

An upgraded replacement for the JT20, the JT21 delivers up to 40 percent more downhole horsepower than its predecessor and 35 percent faster carriage speed than any drill in its class, empowering crews to work more effectively, increasing ROI.

The JT21 features 21,000 lbs. of pullback, 20,000 lbs. of thrust and 2,250 ft.-lbs. of torque, allowing crews to complete installations at a faster pace in a variety of soil conditions. Also, a new design and lower center of gravity increases stability, according to the manufacturer.

“Any operator who puts the JT21 drill to work will quickly see why it’s the most powerful drill in its class,”

said Britton Yunker, HDD product manager of Ditch Witch. “But it’s not sheer power alone that sets the JT21 drill apart from other drills in its class. It also incorporates several productivity-boosting enhancements, making it an ideal choice for contractors whether they’re looking to replace an aging drill or make crews more effective.”

Among the JT21 features that help boost productivity and ease operations are:

• Improved hydraulic efficiencies and a direct-drive rotation motor delivering more downhole horsepower.

• Virtually Assisted Make-up (VAM) technology provides software-driven make-up and breakout of pipe to simplify operators’ jobs and help prevent pipe-thread damage to extend pipe longevity.

• A proven pipe-loading system provides the horizon-

tal-style pipe loading customers asked for and helps optimize efficiency and uptime on job sites.

• An enhanced operator station provides a common display with other HDD platforms and multi-mode joysticks that allow operators choose their preferred control style, minimizing training needs across multiple platforms.

• Advanced telematics give operators access to a wide range of drill health and operating parameters, helping them make quick, informed decisions while improving overall jobsite management and reducing maintenance.

• A larger displacement pump, generating 35 gpm and running at a lower rpm, increases the life of the pump and wearables.

For more information, visit ditchwitch.com.

Sullair, a Hitachi Global Air Power US LLC brand, reached a major milestone — 60 years of manufacturing air compressors in Michigan City, Ind. — with a company picnic that brought together employees, their families and distinguished guests to honor the company’s legacy, people and deep roots in the community.

“This anniversary isn’t just about honoring our past — it’s a celebration of the progress we’ve made and the future we are building together,” said Hideki Fujimoto, president and CEO of Hitachi Global Air Power. “For 60 years, our air compressors — proudly assembled in Michigan City, Indiana — have earned a global reputation for reliability and durability. This legacy and milestone are a tribute to the generations of dedicated employees whose hard work, passion and commitment shaped who we are today. Our future is full of opportunity, and I’m excited for what the next 60 years will bring.”

The picnic took place at the company’s Michigan City campus and featured food, games, music and entertainment for employees and their families. The celebration wel-

comed special guests including Masashi Mizobuchi, consul-general of Japan in Chicago, and Tetsuro Mitani, executive director of the Japan Chamber of Commerce

and Industry of Chicago.

Since the company’s founding in 1965, the Sullair brand and Hitachi Global Air Power continues to grow, enjoying more than $45 million in investments from Hitachi — mostly in the company’s Michigan City manufacturing facility that employs more than 500 staff regionally.

In addition to the company picnic and in honor of the company’s 60th anniversary, Hitachi Global Air Power is gifting the city of Michigan City a mural, painted by renowned artist Felix Maldonado, Jr., and organized by the Lubeznik Center for the Arts. The mural will depict imagery reflective of the region’s industrial heritage and will be painted on several cityowned retaining walls along Michigan Boulevard. The mural is expected to be completed in September 2025.

For more information, visit hitachi globalairpower.com.

Webber is using a CZM EK200 drilling rig.

Because birds like to nest close to bridges and waterways, the contract with TxDOT only allows Webber to demolish bridges as long as no nesting is observed during their migration season, which takes place from Feb. 15 to Sept. 30. During this period, the bridges will be monitored and Webber will be in constant communication with TxDOT to make sure the bridges are free of nests before any work takes place.

The largest scope of work on the project is the retaining walls that will be constructed, followed by the concrete paving. Work on these walls has started by the new Stewart Road bridges. There are more than 40 retaining walls in this project, which will be built throughout the job. Work is projected to start on the retaining walls in late August.

The project calls for the installation of 33 streetlights. These will be put in place throughout the project.

Fernandez said that as much as possible, the company is recycling the concrete that is being demolished and incorporating it into the subgrade of the pavement.

Arocha estimated that at the project’s peak, with work being done on paving, structures, roadway and drainage simultaneously, there will be more than 100 people working on the site.

“The volume of traffic is pretty high. We have some big challenges with lane closures and coordination of trucking and so on,” Arocha said.

TxDOT awarded the project in December. According to TxDOT, the segment is expected to take about 3 1/2 years to complete, with a projected finish date in early 2029.

Officials broke ground on the project in June.

Subcontractors include Choctaw Erectors, which is furnishing and installing steel girders for a flyover bridge; CND Contracting, which is demolishing existing bridges; FGA Construction, which is managing the flatworks; and Mica Corp., which is overseeing the electrical work.

“We’re really excited because this is the first of many projects for the Spur 399 extension,” said Madison Schein of TxDOT Dallas. “This is something that's really important to

the Collin County area, as there’s so much growth in this area. And the purpose of this project is to really help improve mobility in the eastern part of the county.”

Over the coming years, TxDOT will invest $8 billion into projects along Spur 399 and U.S. 380 in Collin County.

(All photos courtesy of Webber, a Ferrovial company.)

A crew pours the first column of the project on northbound ramp at Stewart Road Bridge, while a drill shaft crew works on the next shafts.

www.wpi.com

12320 S. Main Street Houston, TX 77035 713-723-1050 Buffalo, TX 903-322-7150 Bryan, TX 979-314-1191 Corpus Christi, TX 361-884-8275 Edinburg, TX 956-386-0107 Kilgore, TX 903-984-2011

Lufkin TX 936-243-6056

Pflugerville, TX 512-251-0013

Port Arthur, TX 409-721-5305 San Antonio, TX 210-648-4444 Tomball, TX 281-351-9016

Corporate Office 5000 Vasquez Blvd., Denver, CO 80216 303-355-5900 Colorado Springs, CO 719-576-5541 Grand Junction, CO 970-241-1550 Milliken, CO 970-587-1188

www.powermotivecorp.com

Cheyenne, WY 307-634-5149 Durango, CO 970-259-0455 Albuquerque, NM 505-345-8383 Bloomfield, NM 505-324-8601

Carlsbad, NM 505-485-1700

El Paso, TX 915-872-1001 Chandler, AZ 602-986-3003 Phoenix, AZ 602-463-3772 Tucson, AZ 520-649-2858

Oklahoma City, OK 405-495-7820 McAlester, OK 918-310-1550 Tulsa, OK 918-438-1700

Abilene, TX 325-692-6334 Amarillo, TX 806-373-2826

Hewitt, TX 254-261-1370

Lubbock, TX 806-745-2112

Odessa, TX 432-333-7000

Chico, TX 940-678-5046 Dallas, TX 214-371-7777 Ft. Worth, TX 817-378-0600

858-278-8338

In addition to improving operational efficiency, free modeling significantly enhances comfort on construction sites. By providing operators with a clear understanding of site conditions, the system allows for betterinformed decisions, which can lead to a more relaxed and confident working environment, said Liebherr.

Comfort is further enhanced by the ergonomic design of the machinery and the user-friendly interface of free modeling. Operators can work for extended periods without experiencing fatigue, as the controls are designed to be intuitive and responsive. This focus on operator comfort not only improves productivity but also contributes to job satisfaction, as operators feel more in control and less stressed while managing complex tasks, according to Liebherr.

In addition, the reduction in labor costs associated with free modeling can be substantial. With operators able to perform tasks that would typically require additional personnel, companies can allocate their resources more effectively. This not only leads to cost savings but also allows for a more streamlined workforce, reducing the complexity of project management, according to Liebherr.

Liebherr has prioritized creating an interface that allows operators to navigate the system with ease, the company said. This focus on user experience ensures that operators can quickly adapt to the technology without extensive training, making it accessible to a broader range of users.

The interface is designed to be straightforward, featuring clear visualizations and controls. Operators can switch between different views, zoom in on specific areas and manipulate the 3D models with simple gestures. This ease of use is particularly beneficial in highpressure environments like road construction, where time is of the essence, and quick decisions are often required, according to Liebherr. Training programs are designed to familiarize operators with the system, emphasizing hands-on experience and practical applications.

Sustainability also is a key focus of free modeling. The ability to optimize site operations in real-time contributes to more environmentally friendly practices. By improv-

ing resource management and reducing waste, free modeling allows for better planning and execution, minimizing the environmental impact of road construction projects. This commitment to sustainability not only meets regulatory requirements but also enhances the reputation of construction companies in the industry, according to Liebherr. In addition, the ability to visualize projects in 3D allows for better planning of resource use. Operators can identify potential issues before they arise, leading to more efficient use of materials and reducing the likelihood of costly mistakes. This proactive approach not only benefits the environment but also enhances the overall efficiency of construction projects.

The versatility of free modeling is evident in its adaptability to various types of construction projects, from residential buildings to large infrastructure developments. Whether working on a small road repair or a major highway construction project, free modeling provides the flexibility needed to meet the unique demands of each job. This adaptability ensures that construction companies can leverage the benefits of free modeling across a wide range of applications, maximizing

their investment in this innovative technology, according to Liebherr.

For instance, in urban environments where space is limited, the ability to create accurate 3D models can help operators navigate complex site conditions more effectively. This capability is invaluable in ensuring that projects are completed on time and within budget, even in challenging environments.

In conclusion, free modeling represents a significant advancement in road construction management, offering a host of benefits that enhance efficiency, accuracy and cost-effectiveness. By empowering operators with realtime 3D modeling capabilities and providing a user-friendly interface, Liebherr has created a solution that transforms the way construction projects are managed, according to Liebherr.

As the construction landscape continues to evolve, innovations like free modeling will play a crucial role in shaping the future of the industry. Embracing these advancements allows construction companies to improve their operations, enhance their competitiveness and ultimately deliver better results for their clients.

RB Global Inc. announced leadership changes and senior management appointments, effective Sep. 1, 2025, to position the company for accelerated and consistent growth.

“Since becoming CEO, I’ve been laserfocused on setting the right foundation for our growth for another 50-plus years,” said Jim Kessler, CEO of RB Global. “With this go-forward structure, our teams are set up to focus on big-picture strategy and efficiency, while also strengthening how we can deliver on our commitments to each marketplace’s unique needs. We’re making it even easier for our partners to do business with us, helping them succeed and setting ourselves up for strong, sustainable growth.”

RB Global’s senior leadership teams will provide strategic oversight, efficient scaling and promote best practice with functional support teams at the enterprise level, while two specialized, high-performing marketplace execution teams spearhead the go-tomarket level. Keeping its go-to-market leadership close to customers and the verticals they operate in helps to maximize the speed and efficiency with which buyers and sellers can do business on the company’s platforms, add value for its partners and position the company for a strong future, according to

Carmen Thiede, chief transformation officer and chief of staff to the CEO, will begin her transition into retirement, following two years of focus on critical integration work to help unlock the full value of the Ritchie Bros. and IAA businesses under RB Global. During this transition, Thiede will serve as a coach and advisor to the go-to-market leaders, using her expertise to help ensure a smooth handoff and continued momentum. Under the new operating model, each marketplace will leverage the unified executive leadership team to set enterprise-wide vision, growth strategy and operational discipline, while empowering brand-specific go-to-market teams to drive execution tailored to their unique marketplaces. The go-

Bucyrus - Erie 22-B C, Serial# 121937, Running Condition, Includes Detroit Diesel Engine, 45’ of Boom w/Rud’A’Matic Tagline, Claim Bkt, Dragline w/Rotating Fairlead, Hoe Attachment $17,500 or best reasonable offer. FOB Corona, CA Info@Malloyco.com 17-18

• Supply us with a photo of a machine (one machine per Bargain Ad) and a maximum 17 word description, plus contact and phone number.

• Either email your copy & photo to: production@cegltd.com, or mail to: Construction Equipment Guide, 470 Maryland Drive, Ft Washington, PA 19034.

• Cost is $140 per ad, $65 additional for color.

• Your ad will run for two consecutive issues in 1 region.

to-market sales leaders — both of whom have been instrumental in driving performance alongside prior leadership — are already deeply embedded in their teams, strategies and relationships.

Their proven expertise and continuity of leadership will help to ensure a smooth transition and position the business for growth in this next chapter, as Jeff Jeter, chief revenue officer, begins his transition toward retirement and serves as a strategic advisor for the go-to-market leaders.

The Ritchie Bros. go-to-market teams will be led by Jake Lawson, president and head of Ritchie Bros. North America sales, and Shiv Dutt, who has joined RB Global as executive vice president and head of Ritchie Bros. Marketplace. As leaders of the Ritchie Bros. business, Lawson and Dutt will work closely with Steve Steinberg, senior vice president and head of strategic management and decision support, to drive gross transaction value growth within the Ritchie Bros. marketplace. Doug Rusch, executive vice president and head of strategic accounts and rouse in North America will continue in his current role, reporting to Lawson.

of overseeing IAA’s operations in addition to his current responsibilities. As part of RB Global’s commitment to operational excellence, the technology team, led by Nancy King, chief technology officer, also will now report to Lewis in his expanded role, helping to ensure platform enhancements are tied directly to operational priorities. Karl Werner, chief business development officer, will continue in his role leading the IAA International businesses, reporting to Lewis.