By Jay Nachman CEG CORRESPONDENT

The ribbon cutting for the Butte City Bridge and Viaduct on State Route 162 in Butte City was June 3, 2025, but 3,100 vehicles, including 400 trucks, have traversed the structure since the winter, following a bridge replacement project.

The contractor, Golden State Bridge Inc., replaced the existing steel bridge built in 1948 with the new 4,686-ft. span, which has standard 12-ft. traffic lanes and 8-ft. shoulders.

The bridge, whose official name is the Sacramento River Bridge, opened before the ribbon cutting because there was movement in the pillars on the old bridge from debris in the river.

The old bridge had reached its lifespan, according to Megan Reese, a California Department of Transportation (Caltrans) spokesperson, and it wasn’t up to standards. The old bridge had sustained damage, there were misaligned piles and the bridge needed to be widened.

see BRIDGE page

Arizona Gov. Katie Hobbs signed into law on May 13, 2025, legislation that allows construction to start at 5 a.m. on weekends and 7 a.m. on Saturdays from May 1 to Oct. 15 to help workers cope with the state’s high temperatures, constructionconnect.com reported.

And concrete pouring can begin as early as 4 a.m. on weekdays.

The new law overrides local ordinances, enabling contractors to better schedule projects, construction connect.com reported.

hours are still controlled by local govern-

2019 John Deere 850K LT, Stk#: HR-1207, EROPS, A/C & Heat, Radio, 6 Way Blade, 6,728 hrs., 90% U/C, 24" Pads, Multi Shank Rear Ripper, 14 ft. Wide ..................$179,500

2008 JLG 1250AJP, Stk#: HR-1579, 1,000 lbs., 125 ft., 2,551 hrs. Since Certified, Refurb. 2015., 4WD, IN445/50D710 Tires $69,500

2018 Bell B30E, Stk#: 13464, EROPS, A/C & Heat, Radio, 5,453 hrs., 30 Ton Dump Cap., Auto Greaser, 23.5Rx25 Tubeless Tires $169,500

2020 John Deere 650K LGP, Stk#: HR-1182, OROPS, 6 Way Blade, 2,385 hrs., 24" Pads, 100% U/C, 10' 4" Wide $79,500

2021 John Deere 450K LGP, Stk#: HR-1232, OROPS, 6 Way Blade, 2,278 hrs., 24" Pads, 9' 7"

2016 Cat 330FL, Stk#: 13598, EROPS, A/C & Heat, Radio, 7,301 hrs., 47" Bucket w/Manual Thumb, 31" Pads, Quick Connect. $139,500

2021 Linkbelt 145X LC, Stk#: HR-1275, EROPS, A/C & Heat, 3,582 hrs., Radio, 100% U/C, 38" Bucket, 24" Pads, Aux. Hyd. $89,500

2020 John Deere 750L LGP, Stk#: HR-1427, EROPS, A/C & Heat, Radio, 6 Way Blade, 7,194 hrs., 33" Pads, 13' 5"

A fan and longtime customer of Bobcat Co., Josh Duhamel has used a range of Bobcat equipment to shape his land, creating a place of solace for him and his family to disconnect and get back to what matters most.

This strategic collaboration combines Volvo Penta’s industrial power systems portfolio with Central Power’s regional expertise and service infrastructure, providing a broad range of services for OEMs and operators in the region.

The Wyoming Transportation Commission awarded $18.5 million in contracts for 11 Wyoming Department of Transportation construction projects during its May 15 regular business meeting.

Members of the American Society of Civil Engineers (ASCE) have elected Carol Ellinger Haddock as president of the Society for the 2026-2027 term after a month-long election that closed on June 1, 2025.

The Mecalac Group has joined Fayat Road Equipment division, a world leader in road-building equipment, and will strengthen this division’s offerings, particularly for urban projects.

Herc Holdings Inc. announced that it has completed its acquisition of H&E Equipment Services Inc. With the completion of the transaction, shares of H&E common stock have ceased trading and will no longer be listed on the NASDAQ.

USACE was established on June 16, 1775, when the Continental Congress authorized the first chief engineer to oversee the construction of fortifications and other military infrastructure.

The University of Alaska Fairbanks (UAF) has begun building a planetarium as an addition to its University of Alaska Museum of the North, according to webcenterfairbanks.com.

38

Mammoet is helping the industry to decarbonize by providing safe and efficient solutions for moving and installing heavy objects. This was the case for the construction of the first large-scale Carbon Capture and Utilisation (CCU) plant.

39

Bob Thomas, president and CEO of CMHA announced two in-house promotions: Erin Hobson has been named vice president of education and events and Clare Ramminger as vice president of member engagement.

41 THUNDER CREEK HELPS LARGEST U.S. COMPOSTER SAVE TIME

Now the largest composting company in the United States, with 174 locations, Magic Valley Compost (MVC) started business with a dozen employees and just a few pieces of equipment.

Felling Trailers Inc. announced strategic changes to its sales leadership team, appointing Nathan Uphus as director of sales and promoting Jake Meyer to sales manager.

and Perris),

1090 W 2181 N

Salt Lake City, UT 84116 801-322-1300

atlasmachinery.us

6565 Smith Avenue Newark, CA 94560 510-400-5024

1535 SE 25th Street Oklahoma City, OK 73129 405-310-8700

2035 W Mountain View Road Phoenix, AZ 85021 480-463-4999

Equipmentshare.com

NEW 2024 CAT 725

5,000 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

NEW 2024 CAT 730 6,000 gallon water truck 0 hr machine with warranty, fully loaded New HEC tank and spray system

(2) New 2024 Hydrema 922G 4x4 4,250 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

Equipment for Builds/Order

Rigid Water Tanks up to 18,000+ Gallons 4,500-6,000 Gallon Water for Tandem/6x6 Chassis, Heavy Duty Off-Road Construction

Complete NEW CAT Articulated & Rigid Builds (any size) available with HEC tanks/bodies

New Articulated and Rigid Water Tanks for all Sizes and Brands installation at our place or yours Current stock for CAT 725, CAT 730, CAT 740, CAT 773/775, Bell B30, Bell B40

Fuel, Fuel/Lube Builds available. Articulated or Rigid. Open for warm weather or Up to Arctic Level enclosed for extreme cold operation

Just as his “Ransom Canyon” character is one with the land and intent on protecting his family’s legacy on a Texas ranch, director and actor Josh Duhamel has built a life off screen that somewhat mirrors his Netflix character, overhauling a cabin and remote property in Minnesota for an off-grid lifestyle that can become a legacy for his family.

A fan and longtime customer of Bobcat Co., Duhamel has used a range of Bobcat equipment to shape his land, creating a place of solace for him and his family to disconnect and get back to what matters most.

His connection with Bobcat equipment started with replacing back-breaking pickaxe and shovel work with a Bobcat Toolcat utility work machine. It was so much fun to operate, and progress was so improved that he decided to add a Bobcat compact tractor and then a compact track loader. With the help of this arsenal of equipment and attachments, his place has grown by warp speed over the past couple of years.

Even when he’s in Los Angeles, his heart is at this place he’s managed to carve out with the help of Bobcat equipment. He hopes this family getaway he’s built will live on for generations to come.

Here’s a closer look at some of the equipment that Duhamel uses on his property that operators may consider for their projects:

Compact track loaders are the ultimate multi-tool for your work. These powerful and adaptable machines are true game changers in construction, agriculture or landscaping job sites. Its tracks, low ground pressure and superior traction make these loaders ideal for challenging terrains where minimized ground disturbance is required.

The T86 is the most powerful compact track loader in Bobcat’s lineup and offers three hydraulic flow options (standard, high and super flow). This machine also offers superior cooling capabilities for running hydraulic attachments during long workdays. Many small and medium-sized

machines are used for clearing smaller areas that have narrower access points or tight surroundings.

Ideal for agriculture, landscaping and acreage management, compact tractors are dependable machines for feeding livestock, clearing snow, handling materials, grading, backfilling and a multitude of other tasks.

Bobcat recently expanded its compact tractor lineup with the introduction of the CT4545 and CT4558. Their enclosed cabs

are designed to make a hard day’s work as comfortable as possible and, like all of Bobcat’s models, offer the power, maneuverability and versatility that operators rely on.

Toolcat utility work machines combine the best features of a compact tractor, pickup truck, compact loader and utility vehicle into the ultimate, all-in-one toolkit for grounds maintenance, chores around your farm,

ranch or acreage. Perfect for spring cleanup, summer projects, fall preparation or winter snow clearing, operators find that a Bobcat Toolcat is ready for every season. These machines allow operators to lift, haul, tow and much more in a familiar cockpit.

Duhamel has accomplished what many strive for — to hurry up so he can slow down. Here’s to many more generations of moving dirt, catching frogs and making memories at the lake.

Watch Duhamel’s

(All photos

Volvo Penta is partnering with Central Power Systems & Services to deliver support for industrial customers across Kansas, Missouri and Oklahoma.

This strategic collaboration combines Volvo Penta’s industrial power systems portfolio with Central Power’s regional expertise and service infrastructure, providing a broad range of services for OEMs and operators in the region.

“Central Power brings unmatched local expertise, a strong service network and a customer-first culture that aligns perfectly with our own,” said Daren Tasker, vice president of industrial sales and services of Volvo Penta North America.

“With Central Power as our industrial distribution partner for these three states, we’re enhancing our ability to provide products and aftermarket support in this key area.”

With 20 locations and a growing team of more than 600 employees, Central Power is strategically positioned to serve industrial customers throughout the Midwest. The company employs more than 270 trained technicians and operates a fleet upwards of 125 fully equipped service trucks. Locations in Kansas, Missouri and Oklahoma will serve as regional hubs for Volvo Penta’s power solutions, services and technical support.

“At Central Power, we’ve built our reputation on treating customers like family, and our partnership with Volvo Penta strengthens our ability to deliver on that promise,” said Robin Roberts, CEO and chairman of Central Power. “From driving high-quality service to delivering engineering support, this collaboration empowers us to go the extra mile to improve efficiency and help customers maximize uptime.”

As a Volvo Penta industrial distributor, Central Power will offer a full suite of services, including engineering consultation and application integration, maintenance and repair capabilities, parts availability and inventory management and certified technicians. This support package is

designed to reduce downtime and lower the total cost of ownership for customers operating across a range of highdemand industries.

Volvo Penta’s partnership with Central Power is part of its broader strategy to expand its North American industrial support network by aligning with trusted, regionally established distribution partners. These collaborations reinforce Volvo Penta’s commitment to delivering more than just engines and offering full-system, customer-centric solutions that support long-term success.

“Working with Central Power helps us strengthen our service footprint and increases the scope of available services that our customers can expect from our distribution network,” said Tasker. “The team’s ongoing investment in engineering, infrastructure and technician training aligns well with the commitment we aim to make in the region. We will work as true partners to provide industry leading products and support.”

Central Power recently opened a new manufacturing and service facility in Kansas City, underscoring its ongoing investment in workforce development and operational

scalability.

“Our goal is to build a flexible network that adapts to our customers’ needs,” said Tasker. “Central Power is helping us do exactly that — positioning us for continued growth and innovation in a rapidly changing industrial landscape.”

The Wyoming Transportation Commission awarded $18.5 million in contracts for 11 Wyoming Department of Transportation construction projects during its May 15 regular business meeting.

The commission awarded a $13.69 million bid to Cheyenne, Wyo.-based Simon Contractors for a bridge replacement project involving structure work, asphalt paving, aggregate surfacing, traffic control and grading work at various locations within Platte County. The contract completion date is Nov. 30, 2027.

Cheyenne-based Reiman Corp. was awarded a $1.48 million bid for a bridge replacement project involving structure work, grading, seeding/erosion control, aggregate surfacing and traffic control work on approximately 0.10 mi. of County Road 702, the bridge over Muddy Creek in Carbon County. The contract completion date is July 31, 2026.

Keyhole Technologies LLC of Caspar,

Wyo., was awarded a $491,410 bid for a sign replacement project involving signing and traffic control work at various locations within Big Horn, Crook, Johnson, Sheridan and Washakie counties. The contract completion date is Oct. 31, 2025.

The commission awarded a $587,900 bid to Rock Springs, Wyo.-based DeBernardi Construction Co. Inc. for a slab replacement project involving concrete paving work, traffic control, sidewalk work, aggregate surfacing and curb and gutter work in various locations within Lincoln and Sweetwater counties, totaling approximately 0.20 mi. The contract completion date is Oct. 31, 2025.

Cheyenne-based Traffic Safety Services Inc. was awarded a $391,150 bid for a pavement markings project involving pavement striping and traffic control at various locations within Carbon and Laramie counties. The contract completion date is Oct. 31, 2025.

Superior Sign & Supply LLC of Caspar was awarded a $323,441 bid for a pavement marking project involving pavement striping and traffic control work at various locations within Converse, Goshen, Natrona and Platte counties. The contract completion date is Oct. 31, 2025.

The commission awarded Cowley, Wyo.-based S & L Industrial a $281,020 bid for a pavement markings project involving pavement striping and traffic control work at various locations within Campbell, Crook, Sheridan and Weston counties. The contract completion date is Oct. 31, 2025.

S&L Industrial also was awarded a $225,469 bid for a pavement markings project involving pavement striping and traffic control at various locations within Fremont, Park and Washakie counties. The contract completion date is Oct. 31, 2025.

Montana-based Streamline Markings Inc. was awarded a $330,600 bid for a

pavement markings project involving pavement striping and traffic control at various locations within Lincoln, Sublette, Sweetwater and Teton counties. The contract completion date is Oct. 31, 2025.

All the above projects are funded primarily with federal dollars.

Funded primarily with state dollars, S & L Industrial was awarded a $445,503 bid for a logo sign upgrade project involving signing and traffic control within Albany, Carbon, Laramie and Sweetwater counties. The contract completion date is Oct. 31, 2025.

Also funded primarily with state dollars, Gillett Wyo.-based Wescom Inc. was awarded a $258,579 bid for a pedestrian crossing lighting project involving electrical work and traffic control at the pedestrian crossings over Interstate 25 at mile marker 13.23 and over Interstate 80 at mile marker 361.04 in Cheyenne. The contract completion date is Oct. 31, 2025.

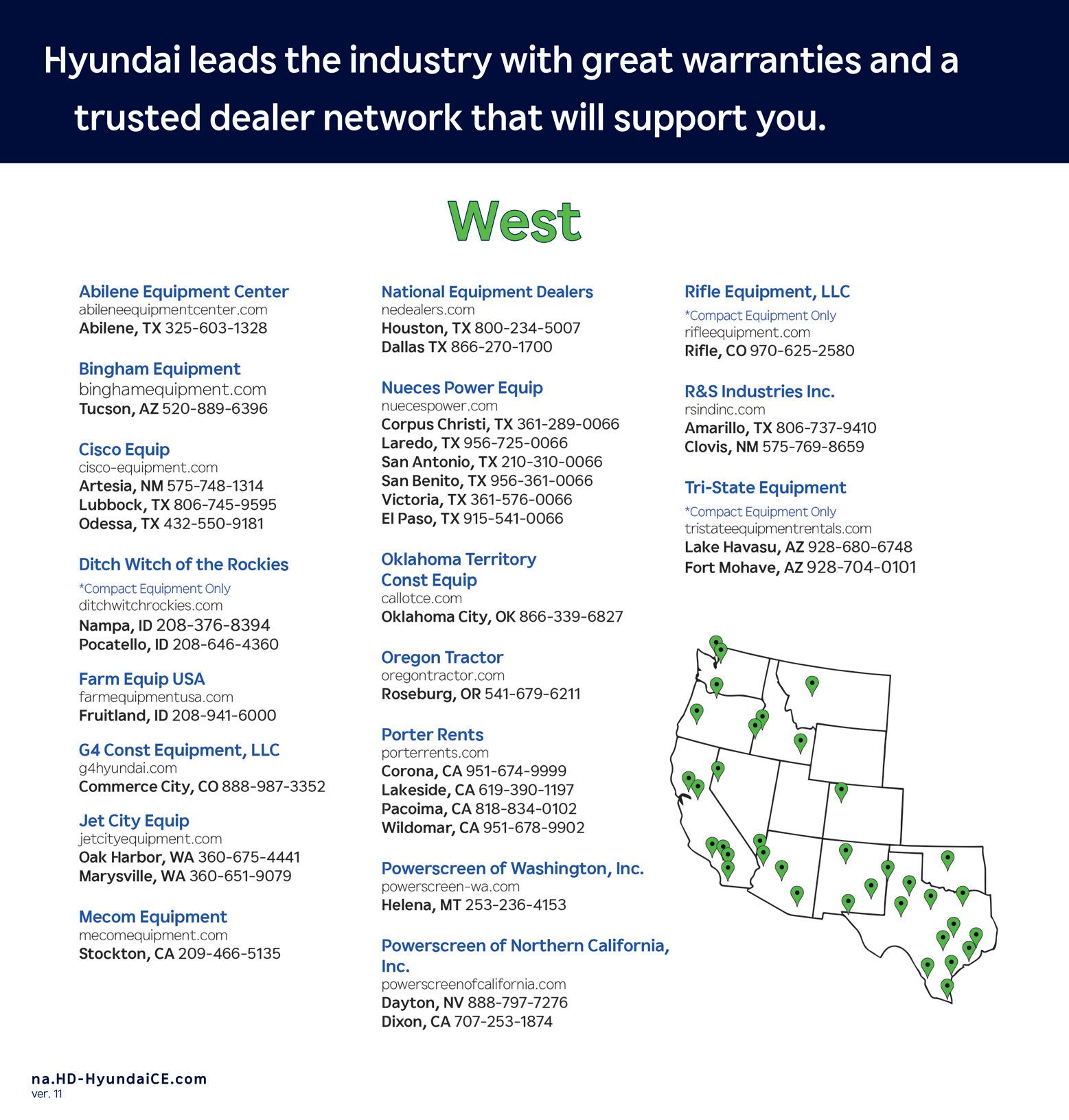

Loved for the features. Trusted for the performance.

Do more without feeling like it in Hyundai’s easy to own, easy to operate, skid steer and compact track loader.

Standard features include:

• LED front and rear work lights

• Auto leveling bucket

• Ride control

• Review camera

• Two speed travel

• AM/FM bluetooth radio

• Free Hi MATE telematics access for 5 years

No wonder so many first-time Hyundai users become longtime fans. See the Hyundai difference yourself at your local dealer, or na.hd-hyundaice.com.

Members of the American Society of Civil Engineers (ASCE) have elected Carol Ellinger Haddock as president of the Society for the 2026-2027 term after a month-long election that closed on June 1, 2025.

Haddock is the vice-chair of ASCE’s Committee on America’s Infrastructure, which released the 2025 Report Card for America’s Infrastructure in March. She previously served on ASCE’s board of direction from 2016-2019 and has served in a variety of leadership roles in ASCE’s Environmental and Water Resources Institute (EWRI). Haddock has been a licensed professional engineer in Texas since 1997. She is a professor-in-thepractice of Rice University and a senior program adviser of Black and Veatch. She previously served as director of Houston’s Department of Public Works from 2017 to 2024.

The Society president serves as the chief representative and spokesperson for the Society, working with ASCE’s executive director. The president chairs

the board of direction and the executive committee and assists in educating and motivating members and potential members by promoting the Society’s principles, policies and goals. The president has a one-year term but will spend three years advancing Society

initiatives in the roles of presidentelect, president and past-president.

“It takes everyone within ASCE providing their unique contribution while working together for us to achieve our mission and deliver our vision — engineered and natural systems work in harmony for the benefit of humanity,” said Haddock. “Not only do we have a mission that is people based, but we also have a commitment to our members and the general public to their wellbeing and future growth.”

Haddock has been an active member of ASCE for more than 30 years. In addition to her service on ASCE’s board of direction, she served on the Society’s public policy committee, flood safety policies and practices task committee and in a variety of leadership roles with the ASCE Texas Section and was elected as president of ASCE’s Houston Branch in 2010.

Haddock will be inducted as president-elect at the annual business meeting in October 2025 in Seattle during the ASCE Convention.

www.wpi.com

12320 S. Main Street Houston, TX 77035 713-723-1050 Buffalo, TX 903-322-7150 Bryan, TX 979-314-1191 Corpus Christi, TX 361-884-8275

Edinburg, TX 956-386-0107 Kilgore, TX 903-984-2011

Lufkin TX 936-243-6056

Pflugerville, TX 512-251-0013 Port Arthur, TX 409-721-5305 San Antonio, TX 210-648-4444 Tomball, TX 281-351-9016

Corporate Office 5000 Vasquez Blvd., Denver, CO 80216 303-355-5900 Colorado Springs, CO 719-576-5541 Grand Junction, CO 970-241-1550 Milliken, CO 970-587-1188

www.powermotivecorp.com

Cheyenne, WY 307-634-5149 Durango, CO 970-259-0455 Albuquerque, NM 505-345-8383 Bloomfield, NM 505-324-8601 Carlsbad, NM 505-485-1700 El Paso, TX 915-872-1001 Chandler, AZ 602-986-3003 Phoenix, AZ 602-463-3772 Tucson, AZ 520-649-2858

www.geehm.com

5461 S. Nikita Avenue Fresno, CA 93725 559-834-3149 1164 Prestige Way Redding, CA 96003

5400 Raley Blvd. Sacramento, CA 95838 916-375-3540 45051 Industrial Drive Fremont, CA 94538 510-955-1170

Abilene, TX 325-692-6334 Amarillo, TX 806-373-2826

Chico, TX 940-678-5046 Dallas, TX 214-371-7777 Ft. Worth, TX 817-378-0600

Hewitt, TX 254-261-1370 Lubbock, TX 806-745-2112

Odessa, TX 432-333-7000 www.clairemontequipment.com

858-278-8338

Fayat Group has acquired a 100 percent stake in the Mecalac Group.

The Mecalac Group has joined Fayat Road Equipment division, a world leader in road-building equipment, and will strengthen this division’s offerings, particularly for urban projects, by providing innovative and sustainable solutions worldwide. The division now has 29 production sites in Europe, Asia and the Americas.

Fayat Group has acquired a 100 percent stake in the Mecalac Group, which offers a wide range of compact and construction equipment for urban work sites: excavators, loaders, dumpers and backhoe loaders, with production units in France, Germany, the U.K. and Turkey.

Fayat Group — a family business with many years of experience in the civil works construction equip-

ment sector — can offer the Mecalac Group the support it needs to remain a stable and reliable partner for its clients worldwide now and in the long term. Within the group, Mecalac will retain its autonomy, like the division’s other brands, offering its clients technological solutions marketed under the Mecalac brand. Mecalac will collaborate with other Fayat Group entities to develop technologies of the future and its distribution network, so that it can keep offering clients the best solutions and enable them to meet tomorrow’s challenges.

“Mecalac will play a strategic role in our group and we are committed to ensuring the development of its product range.”

Jean-Claude Fayat Fayat Group

“This acquisition is a fantastic opportunity for Fayat Group and its customers. Mecalac is a highly recognized brand and an innovative player in the urban construction equipment market,” said Jean-Claude Fayat, president of Fayat Group. “Mecalac will play a strategic role in our group and we are committed to ensuring the development of its product range. We will be using its expertise and technologies to complement our existing ranges, so as to keep developing equipment that meets our clients’ specific needs, particularly on urban work sites.”

For more information, visit fayat.com/en

“The acquisition of H&E accelerates Herc’s proven strategy and strengthens our position as a premier rental company in North America.”

Herc Holdings Inc. announced that it has completed its acquisition of H&E Equipment Services Inc.

“The acquisition of H&E accelerates Herc’s proven strategy and strengthens our position as a premier rental company in North America,” said Larry Silber, Herc Rentals’ president and CEO. “The addition of H&E’s network and capabilities provides Herc with a leading presence in 11 of the top 20 rental regions, a larger fleet that provides our customers with a range of specialty and general rental products and a talented team who shares our focus on excellence in customer service and safety. We are excited to realize the substantial upside ahead for industry leading growth and superior value creation.”

Under the terms of the merger agreement, Herc Rentals acquired all of the issued and outstanding shares of H&E’s common stock for, on a per share basis, $78.75 in cash and 0.1287 shares of Herc Rentals common stock. With the completion of the transaction, shares of H&E common stock have ceased trading and will no longer be listed on the NASDAQ.

For more information, visit HercRentals.com

The U.S. Army Corps of Engineers (USACE) is highlighting 250 years of service to the nation by celebrating its birthday throughout 2025.

USACE was established on June 16, 1775, when the Continental Congress authorized the first chief engineer to oversee the construction of fortifications and other military infrastructure.

Over the centuries, USACE has been at the forefront of engineering excellence, responding to the nation’s most complex challenges with expertise and dedication.

From constructing fortifications during the Revolutionary War to building the infrastructure that saw America grow as a military and economic powerhouse, USACE’s mission has always been clear: deliver engineering solutions for the nation’s toughest challenges.

For the past 250 years, as the nation expanded, USACE’s

missions expanded as well to meet the needs of the country. Flood risk mitigation, navigation, water supply, environmental restoration, providing facilities for the nation’s warfighters and emergency response were all areas added to USACE’s responsibilities.

Today, USACE continues to be the nation’s leader in engineering, environmental and water resources management.

USACE is responsible for:

• Operating and maintaining more than 700 dams and reservoirs, which provide flood control, water supply and hydroelectric power to millions of Americans;

• Maintaining more than 12,000 miles of inland waterways, which facilitate the transportation of goods and commerce;

• Managing more than 150 million acres of public lands, which provide habitat for wildlife and recreational opportu-

nities for the public;

• Providing emergency response and recovery support to communities affected by natural disasters; and

• Conducting research and development to help solve the nation’s most challenging problems in civil and military engineering, geospatial sciences, water resources and environmental sciences for the Army, Department of Defense, civilian agencies and the nation’s public good.

“For 250 years, the Corps of Engineers has been working to safely deliver quality projects on schedule and within budget,” said Lt. Gen. William H. “Butch” Graham, 56th chief of engineers and commanding general of the U.S. Army Corps of Engineers. “I am proud to be a part of this elite organization and I’m extremely proud of the 40,000 committed USACE teammates who wake up every day to solve some of the nation’s toughest challenges.”

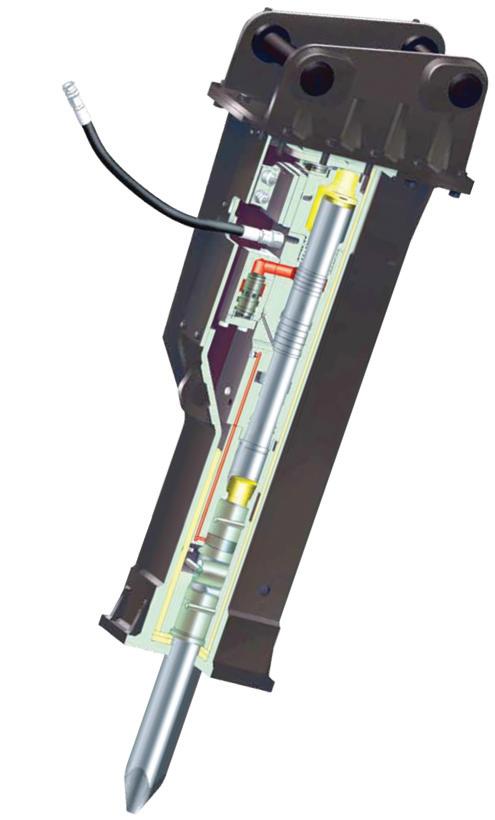

Many quarry companies still use drill-and-blast for large rock extraction.

Legal zoning regulations, or the proximity of houses or other buildings, may mean explosive blasting is not possible in some quarries. Using explosives also requires various stages and long downtimes — such as preparation of the rounds, distancing of personnel and cessation of activities. As a result, many operations are seeking alternative solutions that can reduce costs while increasing safety, production and lessening the impact on the environment, according to Toku America.

While drill-and-blast continues to prove problematic in a quarry setting, a large-sized excavator equipped with a heavy, powerful breaker can provide an alternative. Heavyduty hydraulic breakers represent an economic solution as they also provide high productivity and continuous production — without the risk of excessive vibrations, noise or potentially harmful flying debris.

In response to meeting this blasting dilemma head-on, Toku America Inc. has recently advanced its Striker TNB large quarry breakers line with a range of options that allows quarry operations to choose the right breaker specifically designed to their material size, hardness and other jobsite condition variables.

Consisting of five TNB models (TNB-151, 90, 30K, 40K, 400), the large hydraulic quarry breakers are engineered for

maintenance, according to Toku.

Ultimately, this configuration delivers impact energy, long life and low operating costs — while providing performance to overcome blasting safety, downtime and zoning limitations.

Paired to a carrier or pedestal boom system, with proper sizing based on material hardness and size, Toku’s large TNB quarry breakers all feature the following:

• short, fully enclosed tie rods;

• long-stroke piston: the most efficient design for energy transfer and recoil reduction;

• control valve: “flow through” design reduces hydraulic surge and efficiently controls the breaker operating cycle;

• 50/50 piston to tool weight ratio: efficiently transfers the blow energy into the material and reduces recoil;

• dual retainer pins: correct tool alignment and evens tool wear for longer tool and bushing life; and

• cushion chamber: each blow is isolated from the carrier and operator — energy recycled and used for the next blow.

• Box housing isolators help eliminate recoil shock to the carrier;

• Box housing with sound suppression for more quiet operation; and

• Box housing key slot anti-vibration design in front head.

• Blunt: Used for boulder and oversize breaking; tool impact delivers the stress wave generated by the hammer causing the material to fracture; excellent wear resistance.

• Chisel: suitable for slabby, angular material; tool provides wedge effect impact and good penetration.

• Moil: ideal for softer, abrasive material where high penetration is needed; similar to the blunt it results in less torque in the front head.

• Auto lube options for increased hammer life.

• Positive pressure air check valve keeps dust and dirt out of the tool area.

• Lower rebuild costs via simple design-only two moving parts.

• Low sensitivity to back pressure means the breaker can be used on virtually any carrier.

• No rubber diaphragm accumulators.

According to Toku America President, Matt Gruden, “Toku’s Striker TNB large quarry breakers are uniquely

While drill-and-blast continues to prove problematic in a quarry setting, a large-sized excavator equipped with a heavy, powerful breaker can provide an alternative.

engineered for extremely big demolition or construction projects. Whether mounted on an excavator, or integrated into a fixed system, they provide maximum productivity in quarry operations to minimize operator fatigue and operational costs — while improving safety and environmental impact.”

Toku also has an engineering team available with more than 40 years of experience to provide guidance and technical support in choosing the Rock Breaker System specific to customers’ needs. The company’s service profile also offers hydraulic breaker rebuild options including — master seal kit, front tool bushing, spring pins/stopper pins, retainer pins, labor and return freight. Additional parts and labor will be quoted as needed prior to repairs.

For more information, visit toku-america.com

astecindustries.com

806-364-5687

613 S. 4th Ave Mansfield, TX 76063 817-473-2110

3871 IH - 10 W. Freeway Exit 693 Columbus, TX 78934 979-732-6902

www.texasbearing.com

TOMRA Recycling has launched its latest generation X-TRACT unit.

The new X-TRACT harnesses the power of X-Ray Transmission (XRT) technology to detect and separate wood waste from impurities like inert materials, metals, heavy plastic and glass based on atomic density.

The sorting system is capable of processing up to 33.6 tons of wood chips per hour, depending on material conditions like moisture content and grain size. It delivers speed and accuracy in removing contaminants, thereby producing high purity recycled wood content to meet industrial production standards, according to TOMRA. The unit comes with a 16,000-hour warranty on critical components like the X-Ray source and sensor, demonstrating TOMRA’s confidence in the robustness and longevity of the X-TRACT.

TOMRA’s continuous investment in the global wood segment, combined with the expertise of its skilled in-house engineers and wood processing specialists, has resulted in the latest generation X-TRACT boasting numerous value-add features and capa-

bilities. Many of these are as a direct result of the field-proven and unrivalled success of the X-TRACT in the global mining and metals recycling markets, according to TOMRA.

Innovative features of the new XTRACT include:

• Up to 25 percent reduction in air consumption: X-TRACT now comes with a new standard ejection module which not only delivers greater precision but also reduces the amount of compressed air needed by up to 25 percent, depending on application and infeed material, according to TOMRA. As a result, customers can benefit from significant energy cost savings without compromising throughput rates.

• Sorting accuracy: TOMRA's latest innovation delivers high ejection rates, consistently exceeding 98 percent for metals (excluding foil), 98 percent for inert contaminants and 97 percent for heavy plastics.

This superior performance is the result of robust mechanical hardware, the new standard ejection module, carefully selected XRay components and TOMRA’s core technologies, ensuring consistently high throughput and exceptional sorting results, according to TOMRA.

• Enhanced reliability and stability: Engineered for high sorting accuracy and

minimal downtime, the new X-TRACT delivers long-term sorting stability, improved machine reliability and lower operational costs, according to TOMRA. For improved safety, a dust-resistant design prevents blockages and dust build-up.

The unit’s sensor also comes with a reinforced design that enables the extended component warranty of 16,000 hours. A redesigned catcher hood enables safer and faster maintenance, minimizing disruptions and maximizing uptime.

While X-TRACT effectively separates contaminants from waste wood, GAINnext — TOMRA’s deep learning-based technology for sorting wood by material type — takes sorting granularity to the next level by identifying objects by their shape, size and visual characteristics, enabling the differentiation between various types of wood or wood composites, according to TOMRA.

TOMRA introduced deep learning sorting technology for waste wood recycling in 2021, initially with a high-throughput application for sorting woodchips by type. Since then, its GAINnext technology, trained by TOMRA’s experts using thousands of photos, has evolved to meet the

market's growing demand for advanced wood sorting solutions. GAINnext now enables a wide range of wood recycling applications, including the precision sorting of different wood types and composites. It can distinguish between nonprocessed wood (Wood A) and processed wood (Wood B) such as OSB, chipboard and coated materials, according to TOMRA. It also can recover high purity MDF for MDF-to-MDF processing. The purity of recycled wood from complex construction and demolition waste also can be enhanced by identifying and removing large objects of up to 15.7 in.

Jose Matas, head of waste emerging segments at TOMRA Recycling, said: “We understand the critical importance of uninterrupted 24/7 operations for our customers, and with the latest advancements in our XTRACT, we are now even better equipped to support the industry. Furthermore, the combination of X-TRACT and GAINnext delivers an unprecedented level of purity, resulting in recycled waste wood of nearvirgin quality and, ultimately, opening new profitable revenue streams for our valued customers.”

For more information, visit tomra.com/waste-metal-recycling/applications/waste-recycling/wood.

systemcontrolthatreducestheriskofoperatinge variety of applications. The coarse screening plant locations and new operating conditions - making i range of screen linings, the MSS 802 EVO can eas

Thanks to its robust IMPRE SS IVE FR O M A T O Z . MSS802EVO error.Andallrelevant features an intuitive t ideal for a wide ily adapt to changing design and extensive solution in natural stone safetyTheMOBISCREE functions can be operat safety The MOBISCREE system control that redu

And all

ed from a safe distance for EN MSS 802 EVO - the heav

TX 817-378-0600

www uces the risk of operating

and recycling.

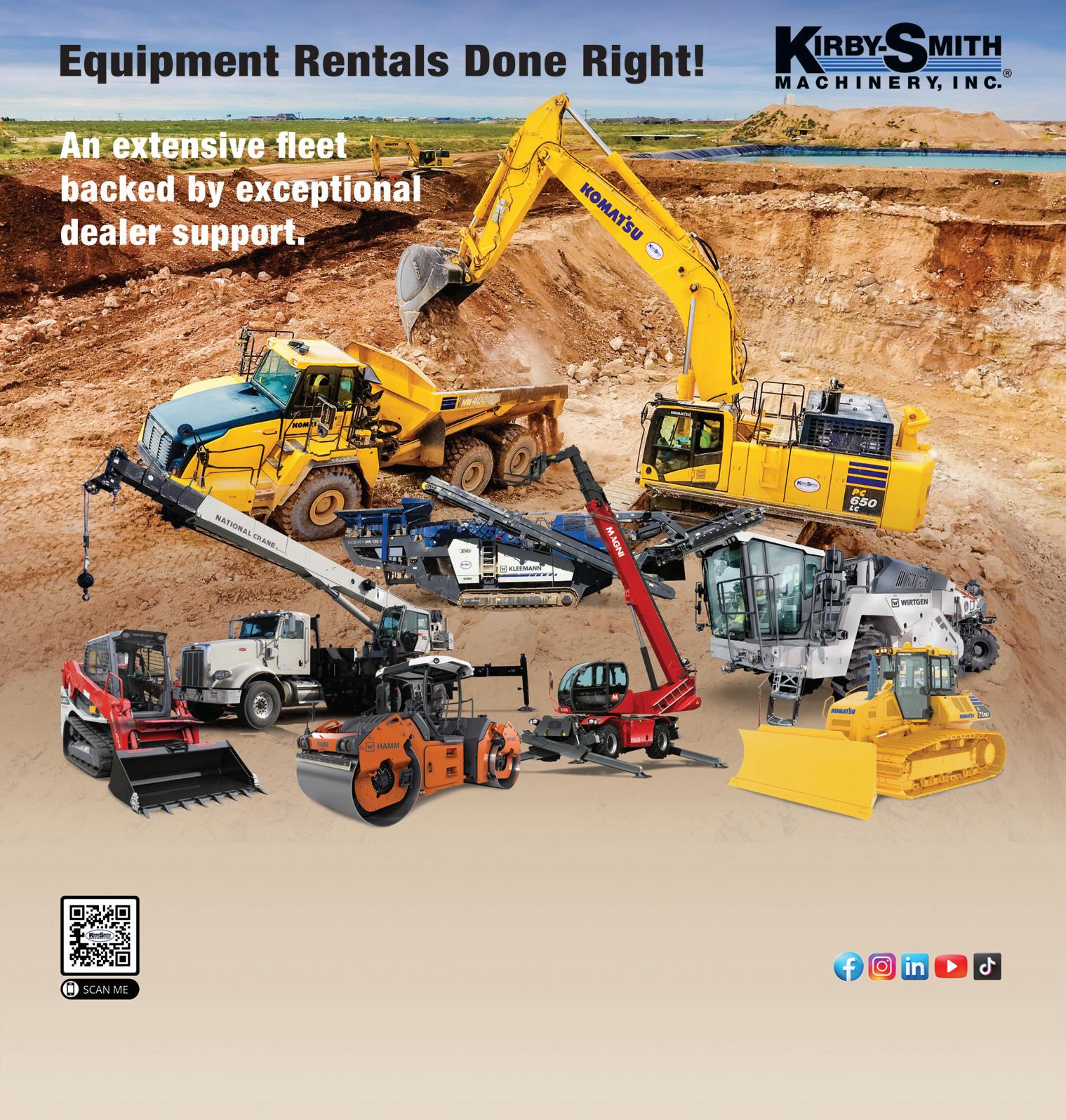

www.kirby-smith.com

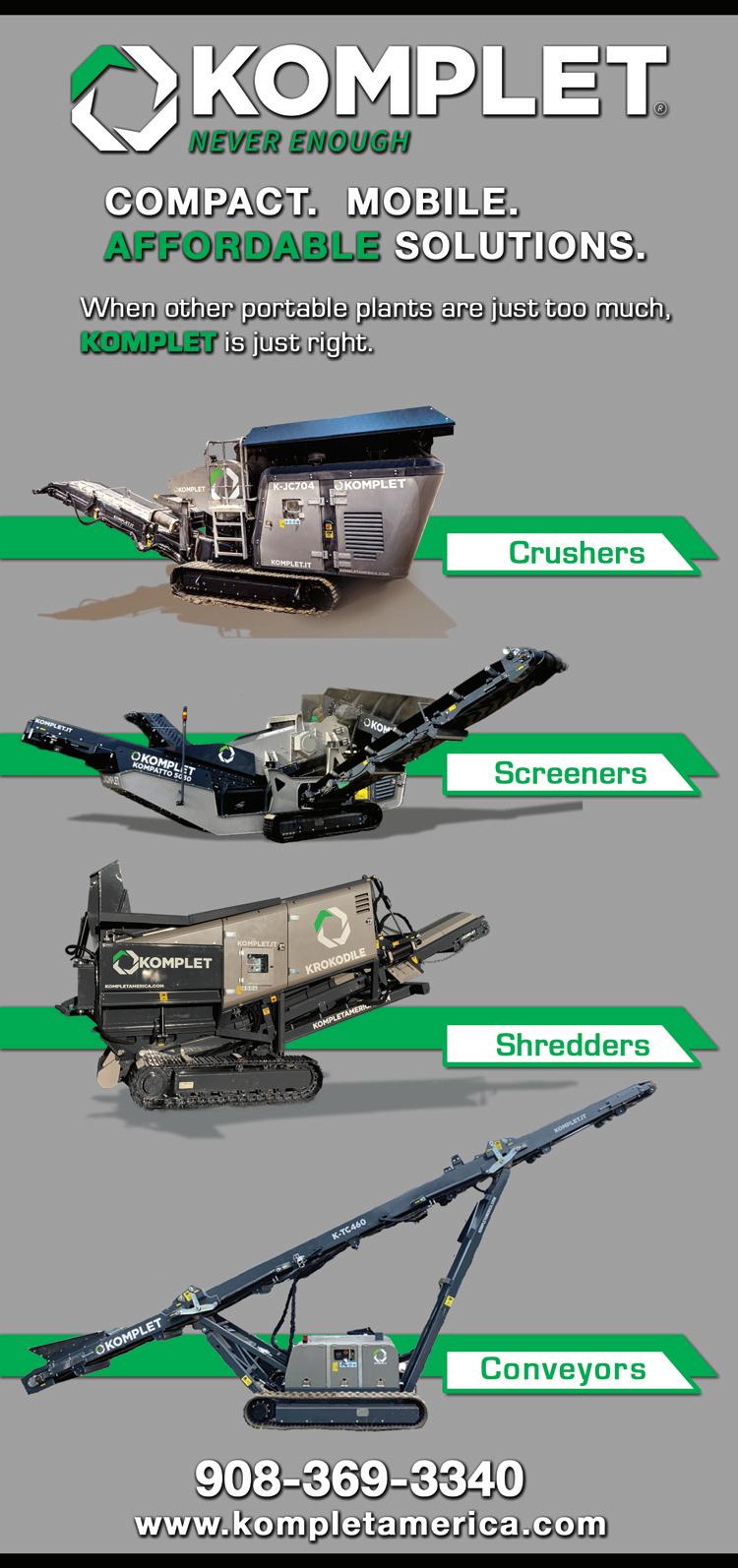

www.nuecespower.com

Case 580SR Backhoe/Loader, 1:50 scale ..............................................

Case 850B Angle/Tilt Dozer, 1:35 scale ................................................

Case DH4B Trencher, 1:35 scale

Case 9030B Excavator, 1:50 scale

Caterpillar AP-1000 Asphalt Paver, 1:50 scale ......................................

Caterpillar CB534 Double Drum Roller, 1:50 scale $40

Caterpillar D3 Track-Type Tractor, 1:50 scale $110

Caterpillar D4E Track-Type Tractor, new color, 1:50 scale ....................$75

Caterpillar D4E Track-Type Tractor, old color, 1:50 scale $75

Caterpillar D6H Track-Type Tractor, 1:50 scale

Caterpillar D7C Track-Type Tractor, 1:50 scale ....................................$110

Caterpillar D8L Track-Type Tractor, 1:50 scale

Caterpillar D8N Track-Type Tractor, 1:50 scale $110

Caterpillar D9N Track-Type Tractor w/black Tracks, 1:50 scale ..........$100

Caterpillar D9N Track-Type Tractor w/yellow Tracks, 1:50 scale ........

Caterpillar D10 Track-Type Tractor w/ ripper, 1:50 scale

Caterpillar D11R Track-Type Tractor, 1:50 scale

Caterpillar 225 Crane w/clamshell bucket, 1:50 scale

ALASKA NC MACHINERY

www.ncmachinery.com

800-478-7000

Anchorage, AK • 907-786-7500

Dutch Harbor, AK • 07-581-1367

Fairbanks, AK • 907-452-7251

Juneau, AK • 907-789-0181

Prudhoe Bay, AK • 907-659-6900

Wasilla, AK • 907-352-3400

ARIZONA

EMPIRE CAT

www.empire-cat.com

1725 S Country Club Mesa, AZ 85210

800-EMPIRE-1

CALIFORNIA

HOLT OF CALIFORNIA

www.holtca.com

Pleasant Grove • 916-921-8969

NEVADA

EMPIRE CAT

www.empire-cat.com

3300 St. Rose Parkway, Henderson, NV 89052

702-649-8777

Elko • 775-738-9871

Reno/Sparks • 775-358-5111

NORTH DAKOTA

TRACTOR AND EQUIPMENT

www.tractorandequipment.com

Williston • 701-572-8377

WYOMING

TRACTOR AND EQUIPMENT

www.tractorandequipment.com

Worland • 307-347-4747

MONTANA

TRACTOR AND EQUIPMENT

www.tractorandequipment.com

Billings, MT • 406-656-0202

Billings-Sgt. • 406-245-4426

Bozeman • 406-585-5800

Great Falls • 406-761-7900

Helena • 406-442-2990

TEXAS

MUSTANG CAT

mustangcat.com

Beaumont • 409-892-8412

Bryan • 979-775-0639

El Campo • 979-543-3389

Houston • 713-460-2000 Lufkin • 936-639-5551

WASHINGTON

NC MACHINERY

www.ncmachinery.com

800-562-4735

Seattle • 425-251-5800

Chehalis • 360-748-8845

Fife • 253-896-0878

Monroe • 360-805-6000

Mt. Vernon • 360-424-4292

Wenatchee • 509-886-5561

Yakima • 509-248-2371

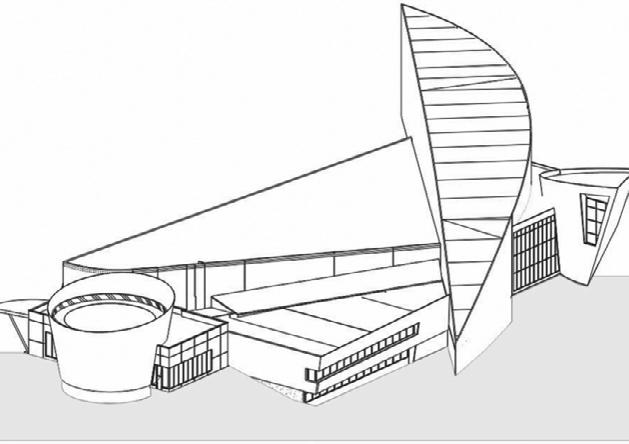

The University of Alaska Fairbanks (UAF) has begun building a planetarium as an addition to its University of Alaska Museum of the North, according to webcenterfairbanks.com.

The UAF Geophysical Institute has sought a planetarium for decades, said Bob McCoy, the director of the Geophysical Institute at UAF.

The project’s development was first announced in September 2024. That’s when UAF Chancellor Dan White mentioned at convocation the school’s intention to build the facility.

Davis Constructors & Engineers was named as the general contractor in 2024, according to UAF. Completion is expected in 2026.

When it opens, the 5,700-sq.-ft. addition to the west end of the museum will house a 65-seat planetarium under a 10-meter dome. A planetarium has been part of the vision for the museum since it opened in 1980 and also a longtime goal of the UAF Geophysical Institute.

Patrick Druckenmiller, the museum director, said the construction of the planetarium will cost about $9 million, according to webcenterfairbanks.com.

“The lion’s share of that comes from a sin-

gle private anonymous donor,” he said.

“This will be an amazing facility for talking about all the wonderful things that we do here at UAF, in terms of our research,” Druckenmiller added, noting that the plan is to use the facility for a variety of purposes, including but not lim ited to education and tourism.

McCoy discussed reasons for building the planetarium, including showcasing the research done at the university.

That’s something the National Science Foundation and NASA want their collaborators, which include UAF, to do, webcenter fairbanks.com reported.

He said the community has sought a planetarium for years, giving UAF another educational tool and means to attract tourists.

“As a classroom, I think it’s really a unique — very unique opportunity,” Druckenmiller said. “I mean, what more of a perfect way to talk about the solar system?”

He also expects the facility can be used to

teach topics such as studies, glaciers and wildlife, according to webcenterfairbanks.com.

“To explain planetary orbits on a chalkboard is one thing, but to show it on a dome, show the planets moving around, you can

speed it up,” McCoy said.

The dome can also be used to help people understand the changes in daylight and sunrises in the Arctic, while allowing for aurora viewing when the summer sun doesn’t permit visibility, webcenterfairbanks.com reported.

Both Druckenmiller and McCoy said that being able to show those aspects of Alaska will be a tourist draw.

“One of the things that would be nice, with all the tourists coming in the summer, is if we had a planetarium movie,” McCoy said. “So, we’re buying cameras. We’re giving them to our researchers when they go in the field. These are planetarium cameras, so they can make movies of whatever research they’re doing.”

While construction is under way, Druckenmiller said disruptions to the rest of the museum have been negligible, as the rest of the building is fully open, webcenterfairbanks.com reported.

“It is a benefit for the construction workers to make sure that their health and safety is being taken into account, while also expediting the development of new housing, which is another piece of this bigger puzzle of the affordable housing crisis,” state Sen. Analise Ortiz, who sponsored the legislation, told kjzz.org.

During a bill hearing, Spencer Kamps of the Home Builders Association of Central Arizona said some of the risks construction workers face during Arizona’s extreme summers are preventable.

“You can do a lot of mitigation measures — water, rest and shade — but quite honestly the best mitigation measure to prevent heat stroke or heat injury is the schedule,” Kamps said, according to kjzz.org.

Hobbs also signed an executive order on May 22 that directs the Industrial Commission of Arizona’s Arizona Division of Occupational Safety and Health (ADOSH) to form a Workplace Heat Safety Task Force. Composed of industry leaders, worker representatives, and occupational safety and health experts, the task force will be responsible for drafting and recommending heat guidelines for employers before the end of the year.

This work will build on the ICA’s Heat Stress State Emphasis Program (SEP) launched in July 2023, which was created to reduce heat-related illnesses and injuries in the workplace through inspections, training, and compliance assistance.

“We are taking action to protect Arizonans from heat risk in the workplace,” Hobbs said. “Whether building our homes, growing our produce or manufacturing the next advanced technology, Arizonans deserve to be safe at work. Through this executive order, we are partnering with employers to ensure the health and safety of all Arizona workers.”

As temperatures rise in Arizona, approximately one in five workers is in a heat hazard industry, and every year the ICA receives hundreds of workers’ compensation claims for heat-related illnesses.

“Prioritizing occupational heat safety is not merely a matter of adhering to legal statutes and upholding ethical responsibilities; it is also a demonstrably sound business practice,” said ICA Director Gaetano Testini.

“As ironworkers we know the dangers of working in the Arizona heat, and over the years we have worked to implement best practices on our jobsites to make sure our members return home safely to their family after a hard day’s work,” said Jason Sangster, business manager of Ironworkers Local 75 and member of the Workplace Heat Safety Task Force. “We look forward to working with Gov. Hobbs to ensure all Arizonans can receive the training necessary to identify and prevent heat illness starting with having access to cool clean water, shade, and a place to rest.”

(All photos courtesy of Arizona Department of Transportation.)

Waratah Forestry Equipment has launched an all-new HX line with its 624HX and 626HX harvester heads and purposebuilt LPX loader-processor head. Building on generations of Waratah HTH attachments, the new extra-large harvester and loader-processor heads have been redesigned for extreme applications.

“All part of our new HX [harvester extreme] line, the 624HX, 626HX and new loader-processor LPX are more durable and higher performing than previous models,” said Brent Fisher, product marketing manager of Waratah.

“We understand the challenges loggers face to produce more wood each day, and we listen and evolve our products to meet their needs. These heads are designed to deliver tremendous performance so our customers can confidently take on extreme applications and experience measurable results.”

Weighing in at 8,796 lb., the redesigned 624HX harvester head delivers impressive log picking, feeding and handling with unmatched uptime, according to the manufacturer. This efficient 600-Series head provides the durability, reliability and speed loggers need to maximize every minute of work.

The new 626HX harvester head redefines Waratah’s legendary Bigwood head with even more performance. Weighing in at 10,141 lb., this 600-Series head takes feeding and delimbing to the next level. Its large 37.4 in. sawing capacity helps boost productivity day in and day out.

In addition, the 624HX and the 626HX boast a slew of beneficial HX-line features. The main frame and tilt frame provide improved durability and are optimized for weight and strength. The heads feature stronger clamping force to provide better log grip at the deck and holding power.

With HD-swept profile delimb arms, the 624HX and 626HX feature improved log picking due to larger delimb openings. Feeding is improved by new diameter sensor technology, while arm design helps log transport. Larger saw capacities, improved saw control plus larger saw motors con-

tribute more efficiency and power to the cut.

A new main control valve provides better flow, cooler operation and higher working pressures. It also allows an improved layout and better feed-motor synchronization. The valve cover is stronger and sleeker with tough hinges and a quick latching system.

Features like the new auto-tension top saw, an improved measuring arm design, a hinged and removeable oil tank and feed arm hose bulkheads contribute to accessible and simplified servicing. Easy-access grease points and grease banks enable the greasing of the entire head in less than 15 minutes.

Loggers can tailor the heads to their oper-

ation with options like higher-torque feed motors, a variety of feed wheels, dual rotate motors, LED and SED color-marking systems and more.

The all-new LPX is a purpose-built loader-processor head that includes many of the new HX line features. With a weight of 8,973 lb., this durable head is built to work in tight spaces, with balanced grapple and processing capabilities to improve daily productivity.

The LPX makes no compromises on log

processing quality. Its wide grapple opening and two delimb/grapple arms provide optimum delimbing, deck processing and log handling to keep timber moving.

The new auto-tension top saw on the LPX has even more capacity, allowing for sawing large-diameter or multiple logs, and greater rotate torque and power improve log placement capability. Additionally, the high, wide saw box improves log picking over the side of a landing. The LPX’s sleek, short-tilt frame tilts for feeding and decking logs on slopes and reduces swinging for smoother operation in and out of the log deck. It also provides better servicing and valve accessibility than previous LP models. The LPX, 624HX and 626HX heads all utilize the TimberRite H-16 control system for optimum head performance, productivity and measuring accuracy.

All Waratah heads come with easily accessible support for dealers and products, and genuine Waratah parts with an industryleading warranty.

These heads are now available to customers in the United States, Canada, Europe, Australia, New Zealand, Asia Pacific, Brazil and Latin America.

For more information, visit Waratah.com.

(All photos courtesy of Waratah.)

The new Cat tiltrotator line helps to deliver cost savings by reducing the number of machines and ground staff at the site.

The tilt rotate system allows the attachment to simultaneously rotate 360 degrees and tilt up to 40 degrees, allowing tracked excavators to perform a range of tasks — digging, grading and compacting — with more precise movements without repositioning the machine. Less machine repositioning helps to reduce undercarriage wear and lower costs, according to Caterpillar.

“Our fully integrated new TRS12, TRS17, TRS20 and TRS26 models reduce installation time and show up automatically on the machine’s monitor, allowing it to be easily controlled by the joystick,” said Scott Rosengaard, senior product consultant, Caterpillar. “Our tiltrotators can be used with a wide range of attachments like buckets, grapples, compactors and more, allowing for higher machine utilization and improved productivity. Plus, the new standard tilt sensor delivers precise tilt and rotation angles to the grading system.”

These new models feature a standard high flow swivel, providing up to 200 l/min flow at 250 bar for use with high-flow work tools. Pairing the tiltrotator with a next generation Cat excavator that has a second hydraulic line boosts hydraulic flow and pressure to 250 l/min at 350 bar. New pressure compensated hydraulic valves manufactured with spools provide

even better control of the hydraulic flow than previous designs, allowing the tiltrotator to maintain stable rotation speed regardless of tilt speed. A quick-connect interface provides fast hydraulic attachment changes. SecureLock uses sensor technology inside

the locking cylinder to verify the tool is correctly connected and securely locked to reduce the risk of swinging or dropping tools, according to Caterpillar.

Cat TRS models feature a single grease point connection with the excavator’s autogrease system and the simple-to-use innovative lubrication system is developed to quickly distribute the right amount of grease to the appropriate points. Double-acting tilt cylinders fitted with a load holding valve ensure the load is securely in position, even in the event of the hydraulic system losing pressure. Providing maximum heat distribution, the worm gearbox is filled with oil for optimum lubrication.

With the new tiltrotator models, operators can change tools without leaving the cab when equipped with the full hydraulic coupler, enhancing safety, productivity, performance and efficiency.

A plastic cover with built-in electrical harness provides easy connection to the hydraulic valves and simplifies servicing. Frame modification on the new series reduces dirt exposure for the grading sensor, which is further protected by a metal cover. For more information, visit cat.com.

Furukawa Rock Drill (FRD) USA, a manufacturer of blast hole drills, hydraulic breakers and various other attachments for skid steers, mini-excavators, backhoes and excavators, introduced a new large-series breaker with the Fx800 Qtv.

It replaces the Fx770 12,000-ft-lb. class breaker, offering numerous advancements, including increased breaking performance and reduced energy loss during operation.

Like its predecessor, the Fx800 runs on a broad range of excavators (48.5-ton to 83-ton). The Fx800 still requires the same pressure and flow as the Fx770, but reengineered internal hydraulic routing delivers improved efficiency, improving

breaking performance and reducing energy loss during operation, according to the company.

Other updates to the Fx800 include modified thru bolts with a larger thread diameter to increase thru-bolt longevity and improve operating life, a more robust front-head ideal for abrasive applications and an anti-blow feature for increased performance, extending breaker life. Large diameter working steel at 7.48 ft. maximizes rock breaking and a redesigned soundproof cover provides easier maintenance access.

“The new Fx800 breaker is a great choice for breaking hard rock, working in quarries and large-scale demolition jobs,” said Ted Crane, FRD USA’s national sales manager of the breaker attachment division. “The Fx770 has always been a dependable, powerful breaker. The Fx800 builds on that foundation with multiple updates and advancements to make it even more powerful and efficient, while also reducing downtime and maintenance.”

Wirtgen’s compact SP 33 is the manufacturer’s latest slipform paver model for the construction of monolithic concrete profiles.

Because of its modular construction concept and a wide range of setting options, the machine can be configured for use in almost all situations encountered on construction sites, according to Wirtgen.

Two track units with parallelogram swing legs at the front and a laterally adjustable single-track unit at the rear enable zero-clearance paving and maximum flexibility. In offset mode, it can pave curb and gutter profiles, rectangular profiles and concrete barriers up to 1.3 m in height as well as sewer and drainage channel profiles.

Concrete slabs with a paving width of up to 2.2 m also can be realized without any problems, or up to a width of 2.4 m in combination with a Trimmer, said the company.

In Crosspave mode, the track units are turned by 90 degrees and the machine then paves transverse to the direction of travel. The slipform mold is centrally mounted under the machine, which enables the paving of concrete slabs with widths of up to 3.0 m. The quick and easy conversion from one paving mode to the other makes the machine particularly versatile, according to Wirtgen.

The new operating concept with event-driven graphic visualization assists operators in their work with both paving modes. The machine control panel provides separate zones for clear and simple visualization of the currently relevant machine information for each of the three main working phases: transport, set-up and concrete paving.

For instance, in set-up, it visualizes the set-up process on the construction site in a logical sequence that guides operating personnel through the successive set-up of individual systems, such as the crawler units, the mold, the vibrators, the sensors, etc., intuitively, efficiently and without errors, according to Wirtgen.

The load-dependent engine management system identifies every working situation and the power it requires and automatically adjusts the speed of the diesel engine accordingly without intervention on the part of the operator.

This ensures that the diesel engine runs within the envelope of optimal efficiency as often as possible. This leads to low diesel fuel consumption and simultaneous reductions of CO₂ and noise emissions, said Wirtgen.

The operator also is assisted by the AutoPilot 2.0 control system. In concrete paving, pavers are traditionally controlled by the scanning of a physical stringline.

As an alternative, Wirtgen offers its AutoPilot 2.0 stringless paving system for all offset pavers and placer/spreaders. This completely eliminates the need for control by a physical stringline, which leads to considerable savings in terms of time and effort and increases the safety of the personnel on the construction site, according to Wirtgen.

The system controls both the height adjustment and steering of the machine. AutoPilot 2.0 also enables fast and precise paving of tight radii and complex geometries. A GNSS signal and, depending on the configuration, various local sensors, such as an ultrasonic sensor on the machine, act as a reference.

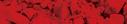

Every year, industrialized nations lose approximately 3 percent of GDP due to issues associated with material corrosion and degradation.

In particular, damage to concrete structures and infrastructure, ranging from small cracks to complete failure, can lead to severe disruptions and repairs can incur significant expense. But what if damaged concrete had the ability to self-heal microcracks before they could propagate into larger-scale issues?

In IDTechEx’s report, “Self-Healing Materials 2025-2035: Technologies, Applications and Players,” a detailed overview of the market is given, including insights into technical challenges and progress, key sectors for market growth and commercial readiness levels. A thirdparty, independent assessment of the market is provided throughout, including an unbiased outlook for the covered materials and industry sectors.

Concrete typically fails due to the development of microcracks, which gradually expand into larger cracks. Freeze-thaw action can be a major issue, where water fills cracks before freezing and expanding, causing further damage in a repetitive cycle. Selfhealing concrete is designed to repair these microcracks efficiently. Many technologies exist, but IDTechEx research finds that biological approaches lead the way for the successful commercialization of self-healing concrete.

Rome wasn’t built in a day, but many of its most beautiful buildings and structures have stood the test of time, remaining standing more than two millennia after their construction. Roman concrete is composed of quicklime (calcium oxide), volcanic ash and water, and was produced at high tempera-

IDTechEx graphic

Concrete typically fails due to the development of microcracks, which gradually expand into larger cracks. Freeze-thaw action can be a major issue, where water fills cracks before freezing and expanding, causing further damage in a repetitive cycle.

tures using a technique called “hot mixing.”

Studies have revealed the presence of lime clasts (calcium-rich mineral deposits) visible in Roman architecture as small, distinct white features measuring a few millimeters in size.

When a crack forms, water infiltrates and a calcium-enriched solution is created. Despite detailed research, two proposed healing mechanisms exist. In the most straightforward scenario, the solution heals the crack itself. The second and more complex mechanism is known as the Pozzolanic reaction and involves the formation of several intermediates at the interface between the volcanic aggregate and the surrounding matrix.

A promising approach, from players such

as Basilisk, involves embedding mineralproducing bacteria into concrete for selfhealing purposes. These acid-producing bacteria can remain dormant for more than 200 years and serve as catalysts in the crackrepair process. When cracks develop, the bacteria becomes active, consuming calcium lactate and generating limestone to seal the damage. Bacterial strains used in construction include Bacillus pasteurii, B. sphaericus, B. subtilis, B. cohnii, B. halodurans and B. pseudofirmus, according to IDTechEx.

The healing process occurs through a biological reaction between unreacted limestone and a calcium-based nutrient. When bacterial spores encounter water, they begin to feed on the calcium lactate, a process that consumes oxygen and helps reduce the risk of steel corrosion. The soluble calcium lactate is converted into insoluble limestone,

which hardens and fills the crack. Alternative approaches to self-healing construction materials also are discussed in the IDTechEx report. Geopolymer concrete is produced from waste materials such as fly ash and self-healing mechanisms have been proposed, while there also is a compelling method using bacteria-coated fibers. The major benefit is that the core of the fiber acts like a stitch and holds the crack closed, restricting the propagation of the crack and minimizing the extent of self-healing that is required.

Concrete offers a high-volume route to market for self-healing materials, allowing confidence and trust to be built in the novel approach to increasing the lifespan of structures. Initial risks can be lowered by considering only slabs, with vertical pours for walls delayed until phase two of adoption.

From an economic perspective, IDTechEx’s assessment of the market reports a 30 percent increase in material costs when adding self-healing properties; however, these can be accounted for in a number of ways. Saving on the aforementioned GDP loss, reduced need for replacements, minimized maintenance and limited downtime can all be summed up in the lifecycle costs that are reduced in total when considering self-healing concrete.

The “Self-Healing Materials 2025-2035: Technologies, Applications, and Players” report provides an in-depth analysis of this emerging market. Leveraging its expertise in advanced materials, IDTechEx delivers an independent evaluation, covering technology comparisons, industry trends and key player assessments, offering valuable insights into this promising but still-developing sector.

For more information, visit IDTechEx.com/selfhealingmats.

The American Concrete Institute (ACI) announced the return of its global event, 24 Hours of Concrete Knowledge.

Now in its fifth year, this free, virtual conference will take place July 8-9, 2025, bringing together experts, professionals and students worldwide for 24 continuous hours of learning, collaboration and innovation.

Hosted in cooperation with more than 20 ACI International Chapters and industry partners across multiple time zones, 24 Hours of Concrete Knowledge provides a platform for the global concrete community to exchange knowledge on the latest advancements, research and trends in concrete technology and construction. Each event hour features presentations from a different region of the world, offering diverse perspectives and realworld case studies.

“ACI envisions a future where our stakeholders possess the knowledge and skills necessary to use concrete effectively in

today’s ever-changing world,” said Frederick H. Grubbe, ACI executive vice president. “As participation in 24 Hours of Concrete Knowledge continues to grow, presenters and participants may disseminate and absorb educational and technical expertise throughout these critical global markets.”

Highlights of the 2025 event include:

• presentations from ACI Chapters and international partners in 24 countries;

• real-time Q&A sessions with global experts;

• insight into sustainable concrete practices, innovations in materials, structural design and more; and

• opportunities to connect with peers and thought leaders from around the world.

Participation is free and open to anyone interested in concrete. Registration details and the program schedule are available at concrete.org/newsandevents/24hoursofconcreteknowledge.aspx.

The American Concrete Institute (ACI), in collaboration with the Post-Tensioning Institute (PTI), announced the joint release of ACI/PTI CODE-320-25: Post-Tensioned structural concrete — code requirements and commentary in PDF format.

This new code provides minimum requirements and guidance for the materials, design and detailing of post-tensioned concrete buildings and, when applicable, nonbuilding structures.

document more widely accessible before the upcoming printed version.

ACI/PTI CODE-320-25 was developed through a consensus process and outlines minimum requirements for post-tensioned structural concrete systems, including members with bonded and unbonded tendons.

The PTI technical advisory board code task group played a key role in developing the provisions and commentary, and ACI acknowledges their expertise and dedication.

While the code was initially made available to ACI 320 PLUS subscribers, the release of the PDF edition now makes the

The ACI PLUS platform continues to evolve, giving industry professionals digital access to several essential codes. In addition to ACI 320 PLUS, available subscriptions include ACI 318 PLUS, ACI 319 PLUS, ACI 323 PLUS, and the ACI 562 PLUS repair subscription — all offering interactive features such as 3D graphics, advanced search tools, in-document cross-referencing and multi-set digital notetaking.

ACI/PTI CODE-320-25 is now available in PDF format through the ACI store.

For more information, visit concrete.org.

Heidelberg Materials North America announced that it has acquired certain assets of Concrete Crushers Inc. (CCI), the largest concrete recycler in Calgary, Alberta.

The transaction includes a recycled aggregates yard in southeast Calgary and a contract crushing business with four mobile plants.

“The acquisition of the CCI assets further strengthens our existing footprint in the Calgary market and accelerates our focus on recycled concrete aggregates and circular solutions,” said Oliver Patsch, president of the northwest region of Heidelberg Materials North America.

This recent acquisition is aligned with the company’s strategic focus on optimizing its portfolio in core markets and strengthening its existing businesses through bolt-on acquisitions while advancing its focus on sustainable and circular products.

“We are excited about increasing our recycled concrete offerings in this growing market and pleased to welcome the CCI employees to our team,” said Patsch.

“The acquisition of the CCI assets further strengthens our existing footprint in the Calgary market and accelerates our focus on recycled concrete aggregates and circular solutions.”

Oliver Patsch

Heidelberg Materials North America

Mammoet is helping the industry to decarbonize by providing safe and efficient solutions for moving and installing heavy objects.

This was the case for the construction of the first largescale Carbon Capture and Utilisation (CCU) plant for the cement plant at the Lengfurt site of Heidelberg Materials — one of the world’s largest manufacturers of building materials.

Due to its engineering expertise and many years of experience, Mammoet was requested by Linde Engineering to develop a lifting and installation concept for various large components.

The confined space and many different contractors required precise planning of workflows, interfaces and construction progress. A feasibility study was conducted a year before the start of the execution, in which various solution options were analyzed and examined in detail.

Using a 3D model of the existing cement plant, Mammoet’s team was able to leverage its own engineering platform, Move3D, to visualize the complex processes, space requirements and potential interfering edges at the confined construction site. This visualization provided all parties involved with a better understanding of the planned moves and made coordination easier.

The use of a 826.7 ton crawler crane proved to be the most flexible and efficient method of lifting and installing large components safely and on time at the confined construction site. Due to three-dimensional planning, the crawler track for the crane could be kept as small as possible, minimizing the impact of lifting operations.

Mammoet’s concept included the delivery of the large components to the construction site, the planning of areas for pre-dressing within the swing radius of the crawler crane, as well as the crane setup and heavy lifts.

Through early involvement, Mammoet’s team was able to provide valuable recommendations for adapting the layout of the CCU plant to the requirements of the installation. In addition, the space requirements were integrated into the overall construction site logistics. This later enabled a safe, efficient and smooth execution, saving the customer time and costs.

First, the 110.2 ton absorber column was erected on the pre-dressing area using a tandem lift. The load was swung almost 180 degrees on the hook of the crawler crane and moved approximately 65.6 ft. to the installation position. There, the column had to be carefully guided behind a building before it could be positioned, aligned and bolted onto the foundation in the steel structure.

Due to the 180.4 ft. length of the absorber column and the high complexity of the lifting process, this was the most challenging heavy lift.

Following this, the 73.9 ton stripper column, four tanks each weighing 79.3 ton and finally, the 196.2 ton heat exchanger were installed.

Mammoet’s crawler crane solution offered several crucial advantages. The crawler crane was flexible enough to safely lift loads of varying sizes and weights over long distances. So, intermediate transport on the construction site could be avoided. To allow for the pre-installation and parallel construction of the steel structure, the configuration of the crawler crane was changed shortly before the project began. This adjustment saved additional time.

The early involvement of Mammoet, 3D engineering, close supervision of the execution by the planning engineers

The use of a 826.7 ton crawler crane proved to be the most flexible and efficient method of lifting and installing large components safely and on time at the confined construction site.

on-site, as well as the open, solution-oriented and trustful collaboration significantly contributed to a successful project.

More information on Cap2U: Under the name ‘Capture-to-Use’ (Cap2U), Heidelberg Materials and Linde have established a joint venture for the construction and operation of a carbon dioxide capture and liquefaction plant, which is currently being built on the site of the Lengfurt cement plant. The plant is being planned and built by Linde Engineering.

For more information, visit mammoet.com.

Concrete Masonry & Hardscapes Association (CMHA) President and CEO Bob Thomas announced two in-house promotions: Erin Hobson was named vice president of education and events and Clare Ramminger was named vice president of member engagement.

Both have served the association for more than a decade and the promotions represent an expansion of their responsibilities.

Ramminger has long been recognized as an industry connector, perfectly suited for her role as director of membership. “If you know anyone at CMHA, you know Clare,” said Starling Johnson, CMHA’s vice chair of the board and vice president of sales of Johnson Concrete Products. “She really helps to bring us all together to be a more cohesive industry.”

Thomas stressed that the promotion is a reflection of the experience and leadership that Ramminger brings to the organization, noting that her tenure actually extends even further back than his own before taking time off to raise her family. In her new role, she will have oversight over both the membership as well as the marketing operations of the association, areas which Thomas believes needs to be intimately linked.

Hobson has earned accolades for her management of Hardscape North America (HNA), the annual trade show conducted by CMHA in Louisville every year attracting more than 5,000 hardscape contractors, and in conjunction with Equip Expo attracting more than 30,000 total attendees. HNA is CMHA’s top non-dues revenue program and has inspired many hardscape careers.

In her new role, she brings that management experience to the association’s second leading program area: education and certification. In addition to educating its own members, the association has had a long, dedicated focus to growing markets by supporting the professional development of contractor installers of concrete pavers, manufactured stone veneer and segmental retaining walls.

CMHA Chair of the Board David Pitre, vice president, commercial and architectural of Quickrete’s hardscape and masonry group, has had the opportunity to work with Hobson since her start with the association.

“Erin has taken advantage of her opportunities to manage complex projects and to support the overall management of the association. This is an obvious next step in her continuing development.”

from page 1

“Instead of throwing all of our money into an older bridge, it was cost effective in the long run to build a new bridge,” Reese said.

“This project will preserve and extend the useful life of the existing roadway throughout the project limits and replace the existing Sacramento River Bridge and viaduct to meet current design standards,” she said.

Primary subcontractors on the project, which began in March 2022, included the rebar replacement company, Commercial Metals Co., also known as CMC, based in Texas, and the California-based earthworks subcontractor, Teichert Construction.

As with any structure, the project began with the foundation, said Matt Crete, a Caltrans transportation engineer. That was followed by excavation and reinforced concrete placement. After the foundations were complete, he said the columns were built on piers; each pier had two columns.

After the columns were built, the bridge’s superstructure was built with reinforced concrete girders and bent caps, which transmit loads from the superstructure into the columns and foundations.

The last section to be completed was the bridge’s deck. For the last few years, Caltrans has used micro and macro fibers in the concrete as well as shrinkage-reducing admixture.

The fibers, Crete said, offer greater tensile capacity in the concrete and help prevent the concrete from cracking when it dries out and, in general, improves the quality of the concrete. The admixture gets mixed into every yard of deck concrete and helps prevent the concrete from shrinking and reducing in volume as it dries.

Caltrans has used shrinkage-reducing admixtures on statewide projects consistently for six or seven years, Crete said.

“It extends the life and improves the quality of the bridge and reduces the overall lifecycle maintenance cost of the bridge,” he said.

The approach and departure roadway sections were built and graded intermittently, especially toward the end of the project. The final paving will be during the summer or fall.

“The demands from the traffic design require a depth of

asphalt to be put down that is unmanageable and ends up being an inferior product if you put it down in a single lift,” Crete said. “There has to be multiple applications of asphalt put down.”

The project required two 300-ton cranes and one 250-ton crane; excavators, arial manlifts, diesel impact hammers, hydraulic rams, mobile forklifts and welders — both personnel and equipment.

For much of the project, there were three dozen workers on the site daily, Crete said.

The project faced environmental and weather challenges.

“For three successive winters, for the life of the project, we’ve had some pretty significant rains and we’ve had job sites flooding, either localized or across the entire flood plain, and that’s caused pretty significant damage to our temporary access trestles and some of the temporary structures that have supported the bridge while the concrete was curing before it was actually able to support itself,” Crete said. “Those impacts and those damages had to be repaired.”

This meant that the contractor had to build “much more robust driven pile foundations for the temporary structures for the new bridge over the river.” Because of the storm damage and the limited access, for the last few months of the project the contractor used barges for more efficient access to the portions of the structure over the river, Crete said.

“Overall, that hasn’t really had significant impact on the schedule, but that’s been a huge reflection on the efforts and the commitment by Caltrans and the contractor to really work things out and resolve issues quickly and in the best interests of everyone involved,” he said.

Additionally, the project had limited work windows in the river due to restrictions placed by the Environmental Access Permits.

Some of the native species that inhabit that part of the river are on the endangered species list, while others are threatened and others are protected.

“Based on their reproductive cycles, we’re only allowed certain months of the year that we can actually work in the water to try to limit the threat we pose to those species,” Crete said.

One advantage that the project had was that the old bridge was in operation during construction.

Steel casings at piles in the Sacramento River extend to within a few inches of the superstructure to improve the longevity of the new bridge by minimizing the risk of future storm damage.

“We didn’t have the inefficacies that normally come with maintaining public traffic when you’re under construction,” Crete said.

The project cost was $114 million and was funded by federal and state sources.

Specifically, it was funded under the 20.XX.201.113 State Highway Operation and Protection Program (SHOPP), which is eligible for federal aid. SHOPP funding is a combination of state fuel taxes, federal funding, and SB 1’s Road Maintenance and Rehabilitation Account (RMRA).

In addition, the project received federal funding through the Highway Bridge Replacement and Rehabilitation (HBRR-S) program, which is supported by the Federal Highway Trust Fund. The Trust Fund itself is primarily financed through federal excise taxes on motor fuel.

Crete said Golden State Bridge Inc. plans to reuse as much as possible the materials they used to build the temporary structures.

The entire project will not be completed until 2026 with the demolition of the old bridge. CEG

(All photos courtesy of Caltrans.)

Now the largest composting company in the United States, with 174 locations, Magic Valley Compost (MVC) started business with a dozen employees and just a few pieces of equipment.

Today, the company provides soil amendment solutions to dairymen and farmers across Utah, Idaho and Nevada to enrich their land, support healthy plant growth and increase water retention. The aim is to improve the quality and nutrition of crops to, in turn, improve nutrition for individuals and the community.

“We work with smaller farms with a hundred acres, and we work with more corporate farms with 10,000 to 30,000 acres,” said Ray Silene, owner/general manager at MVC. “But more and more now, we’re dealing with the large dairy farms. And with that, everything’s on scale and we need bigger equipment, which means more fuel and more labor.”