By Irwin Rapoport

Lott Brothers Construction Co. Ltd. began work on the Texas Health and Human Services Commission’s (HHSC) new Panhandle State Hospital in Amarillo on June 10, 2025.

Crews are now engaged in earthwork and site prep operations for the three-story facility with a 139,700-sq.-ft. footprint. The 75-bed hospital at 6610 Amarillo Blvd., which should be completed in spring 2027, will provide inpatient psychiatric services to adults.

The hospital was designed by the architecture, engineer-

ing and design firm Page. The exterior materials include granite, limestone and brick, with sections of corrugated metal paneling. The main entrance features a large limestone wall leading to the glass atrium lobby. The hospital will have parking for residents, visitors and staff.

“The building’s floor levels were integrated into the land’s contours to accommodate the site’s space limitations,” said Emily Hummel, an HHSC spokesperson. “We hope the Panhandle State Hospital will serve the people of Texas for over 100 years, as some of our other state hospitals have. The building will not be LEED certified, but some LEED-type

features will be incorporated into the building.”

The construction site contained one derelict building that was demolished.

Lott Brothers is experiencing some initial hurdles, Hummel said

“Space constraints restrict access for anything other than actual work on the building,” she said. “In addition, this spring/summer has had unusually high rainfall levels. Even with recent weather delays, the project is still within the current schedule timeline.”

ASHING EQ WA W S CRUSHING, QUIPMENT CREENING, DRILLING & – Plus Expert Installation & Repair Services. AR MO RAILC

VY CONS HEAAV VERS UCTION EQUIPM TR ENT & for Built – Driven Performance, by Excellence.

SOLUTIONS W MOBILE PO CT E A ER & COMP QUIPMENT

– Power & Reliability in Every Job.

CONCRETE & AVVING T P LTASPHAL A G

EQUIPMENT

– Built for Precision and Performance.

2022 JOHN DEERE 6R 155....................$189,500

2015 JOHN DEERE 6215R......................$120,000

2020 JOHN DEERE 6130M....................$115,000

(5) 2018-2024 JOHN DEERE 6120M....From $67,500

2018 JOHN DEERE 5125R......................$98,500

2022 JOHN DEERE 5125M ....................$125,000

2023 JOHN DEERE 5115M......................$98,500 (3) 2021-2023 JOHN DEERE 5100M....From $81,000

Artic Trucks

(2) 2019 CATERPILLAR 740GC........From $369,500 (3) 2022-2025 CATERPILLAR 725....From $395,000 (9) 2023-2024 ROKBAK RA30....................$CALL (5) 2023 ROKBAK RA40............................$CALL

Attachments

(3) CATERPILLAR 293-5556 LIFTS..........$2,000 Ea.

CATERPILLAR D6 ANGLE BLADE................$5,000

CATERPILLAR D8T ANGLE BLADE..............$7,500

CATERPILLAR D10T SS RIPPER..................$CALL

CATERPILLAR ANGLE BLADE....................$7,500

CATERPILLAR WINCH..............................$CALL 2018 NPK GH15 HAMMER........................$CALL 2022 NPK GH18 HAMMER........................$CALL PACCAR PA140-316V WINCH ....................$CALL

Crawler Loaders

(5) 2021-2024 CATERPILLAR 963....From $319,500 (2) 2024 CAT 953 LGP..............................$CALL

(4) 2022-2023 CATERPILLAR 815....From $635,000 2022 CATERPILLAR CS11GC......................$CALL (3) 2018-2022 CATERPILLAR CP56B..From $139,500 (7) 2017-2022 CATERPILLAR CS56B..From $119,500

Crawler Carriers

(2) 2019-2020 MOROOKA MST4000VDFrom $219,500

(2) 2018 MOROOKA MST3000VD......From $159,500 (3) 2018-2019 MOROOKA MST2200VD..From $119,500

Dozers - Crawler

(2) 2023 CATERPILLAR D10T2........From $1,695,000

2023 CATERPILLAR D9......................$1,375,000

(4) 2019-2023 CATERPILLAR D8........From $675,000 (2) 2020 CATERPILLAR D6..............From $275,000

(10) 2020-2024 CATERPILLAR D6 LGP..From $239,500

2020 CATERPILLAR D6 XL....................$255,000

2018 CATERPILLAR D6N XL..................$239,500

(3) 2023-2025 CATERPILLAR D5......From $399,500

2019 CATERPILLAR D5K2XL..................$134,500

2023 CATERPILLAR D4........................$249,500

(2) 2022-2023 CATERPILLAR D3......From $165,000

2022 CATERPILLAR D2............................$CALL 2017 KOMATSU D61EXi-24....................$162,500

(3) 2023 KOMATSU D71PXi-24........From $389,500

Dozers - Wheel 2015 CATERPILLAR 834K......................$285,000 Rigid Frame Truck (2) 2017 CATERPILLAR 772G............$309,500 Ea. Water Equipment - Tower/Tanks (2) 2024-2025 KLEIN KPT-120 WATER TOWERS.......... ......................................................$75,000 Ea.

2022 CATERPILLAR 395........................$955,000

(3) 2019-2022 CATERPILLAR 374FL..From $545,000 (4) 2021-2023 CATERPILLAR 352....From $427,500

2019 CATERPILLAR 349FL....................$395,000 (4) 2021-2022 CATERPILLAR 349....From $289,500

2022 CATERPILLAR 340........................$389,500 (2) 2019-2024 CAT 336..................From $139,500

2018 CATERPILLAR 336FL....................$169,500 (2) 2023 CATERPILLAR 330-07..........$309,500 Ea.

2020 CATERPILLAR 326-07....................$289,500

2020 CATERPILLAR 320........................$189,500

2017 CATERPILLAR 316FL....................$139,500

2023 CATERPILLAR 310........................$149,500 (2) 2023 CATERPILLAR 306CR....................$CALL

2021 CATERPILLAR 305E2......................$74,500

(2) 2022 CATERPILLAR 16..............From $995,000

2024 CATERPILLAR 14........................$765,000

2019 CATERPILLAR 14M3......................$329,500

(2) 2023-2024 CATERPILLAR 150................$CALL

(3) 2021-2024 CATERPILLAR 299D3 XEFrom $62,500

2022 CATERPILLAR 299D3 XPS................$92,500 (2) 2025 CATERPILLAR 275 XE..................$CALL

(3) 2025 CATERPILLAR 275 XPS................$CALL (2) 2021-2022 CATERPILLAR 299D3....From $59,500

(4) 2022-2024 CATERPILLAR 740GC......From $650,000

FREIGHTLINER M2............................$79,500 2024 KENWORTH T480 ................................$CALL (15)

KENWORTH T370..........From $89,500 (3) 2023-2026 INTERNATIONAL HV507..From $169,500 (6) 2022-2025 INTERNATIONAL HV607..............$CALL (7)

Loaders

Miscelleneous Equipment

When catastrophic flooding struck the Texas Hill Country in early July 2025, the response from the heavy equipment community was immediate and deeply personal.

Among those to act were TNT Crane & Rigging and Kerr County Search and Rescue. The latter’s Central and South Texas team quickly organized a relief effort to support residents in one of the hardest-hit areas: Hunt.

For John Johnson, southern district manager of TNT Cranes, the call to action was personal.

“I live near the Guadalupe River. I have family in Kerrville. Once we saw the devastation, the death toll, the missing people, it was clear we had to do something,” Johnson said.

The Monday after the storm, during a companywide safety and wellness meeting, an employee shared a heartfelt account of what local first responders were witnessing on the ground. That moment, Johnson said, made the decision easy.

“I left the meeting and immediately called our COO, Kevin Schultz, and our president, Kevin Lawson. I asked, ‘Can I do something for Kerrville and the flooding?’ Without hesitation, they said yes. No restrictions, no limits.”

From there, TNT’s response was swift

and organized. The company deployed staff and supplies from its Corpus Christi, San Antonio and Austin branches. The goal: to support locals with meals, tools, hydration and safety equipment.

TNT brought out its BBQ trailer and cooked for roughly 500 people. Employees and administrators brought food, water and other supplies. Teams gathered nine pallets of water and loaded them onto an 18-wheeler using Gehl and Manitou forklifts supplied by Anderson Machinery.

“Anderson Machinery Co. is proud to stand with the people of Texas during this time and remains committed to supporting local communities however possible,” the company said. “This effort is a reminder that when disaster strikes, Texans show up for one another, and we are honored to play a small part in that greater mission.”

Hand tools like shovels, machetes, brooms and PPE also were gathered and dispatched, including more than 200 dozen leather gloves, safety vests and hard hats.

“I called Albert Castillo, our HSE manager in Corpus. He’s also a volunteer assistant fire chief,” Johnson said. “He helped us get

in touch with the Hunt Volunteer Fire Department. Kerrville told us they were covered, but Hunt needed help badly.”

The team staged just a few hundred ft. from the river. What they found was a surreal scene of devastation and urgency.

“There were helicopters flying low overhead. Swift water rescue teams, ATVs, fire crews, volunteers. It looked like a war zone,” Johnson said.

More than a dozen TNT employees were on site throughout the day, distributing food, water and equipment. Johnson recalled seeing license plates from Oklahoma, other states and even a rescue crew from Mexico.

“One of the guys we fed came up from Mexico to help. We didn’t share a language, but you could feel the gratitude. There was mutual respect. Nobody asked where you were from or who you voted for. Everyone just wanted to help.”

The experience left a lasting impression on Johnson and his team.

“We didn’t do it for attention. We didn’t send salesmen. There was no financial benefit. What

we did was purely from the heart,” he said.

Their high-visibility safety vests and hard hats, stamped with the TNT logo, were later spotted in news coverage of the flood response. For Johnson, it was a proud but sobering reminder of their efforts.

Though the immediate rescue phase has passed, the rebuilding process continues. TNT has maintained contact with local officials in case additional help is needed.

“We haven’t been asked to go back yet, and we didn’t want to turn this into a business opportunity,” Johnson said. “We’re standing by if they need us again.”

For now, Johnson said the biggest takeaway is the reminder that unity still exists, especially in times of crisis.

“We see so much division in the news and on social media. But out there, nobody cared about politics. Everyone came together. It reminded me that we live in the greatest country in the world, and that we have some really good neighbors, too.”

(All photos courtesy of Anderson Machinery Co.)

Bobcat of Abilene 325-673-7361

Bobcat of Amarillo

806-622-9593

Bobcat of Austin 512-251-3415

Bobcat of Buda 512-884-5533

Bobcat of Corpus Christi 361-884-3959

Bobcat of Corsicana 902-483-6000

Bobcat of Lubbock 806-745-1322

Bobcat of Marble Falls 830-220-6070

Bobcat of Marion 830-420-9020

Bobcat of Midland–Odessa 432-685-9298

Bobcat of Pleasanton 830-580-4020

Bobcat of the Rio Grande Valley 956-425-4300

Bobcat of San Antonio 210-337-6136

Bobcat of Temple 254-523-4900

Bobcat of Victoria 361-579-0922

Bobcat of Waco 254-488-7004

Bobcat of Wichita Falls 940-285-7777

Ranchers ATV and Tractor Kerrville 830-315-2330

Vermeer Texas-Louisiana’s Cypress branch welcomed customers on Aug. 1, 2025, for its annual customer appreciation event. Guests enjoyed a freshly grilled burger lunch while catching up with the Cypress team and exploring equipment on display.

Branch Manager David Behrens said the event is about more than just showing equipment.

“Our customers are our family,” he said. “This is a small way we can say thank you for trusting us and allowing us to be part of their success.”

The appreciation day gave attendees the chance to connect with staff, see the latest Vermeer machinery and enjoy a relaxed afternoon among fellow industry professionals. CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

Niece 8,000 gallon water tanks

installed on 40 ton Articulated Off Highway chassis. This combination is the workhorse of the dust control and water needs for quarries and large construction sites

The NWT9500 9500 Gallon water tank mounted on articulated truck. Pictured: Deere 460E with 9,500 gallon tank. Tanks come with 6X5 pumps. The NFL3000 Off Road, Fuel and Lube Bed offers 3,000

of diesel fuel. The NFL10000 Fuel & Lube Can be mounted on any 100,000 lb rigid frame truck. Holds 10,000 gallons of diesel. 5 additional fluid tanks. Holds up to 3,000 gallons of oil.

The future of Dallas Fort Worth International Airport (DFW) continues to take shape with the completion of its latest construction milestone — the historic move of six prefabricated module structures that have come together to create the framework for the first phase of the airport’s new Terminal F.

On Aug. 8, 2025, the airport completed the last of six module moves that make up the structure for Terminal F. The modules, some nearly as large as a football field, were moved overnight during a two-week period using self-propelled modular transporters along one of DFW’s airside taxiways.

The structures were then placed onto the foundations constructed at the Terminal F site, where the facility will now proceed to the next stage of construction.

This is DFW’s third project to deploy the innovative module-based method to reconstruct or expand its terminal facilities, with the most recent moves being the largest modules for a terminal expansion at any airport.

The modules for Terminal F are approximately four times larger than the structures moved earlier this year for the ongoing expansion of Terminal C. The largest of the six modules measured 278 ft. long by 136 ft.

wide and weighed 3,320 tons — about as heavy as 12 Boeing 787-9 Dreamliner widebody aircraft.

“This milestone reflects the dedication and vision of the many teams who are building the future of our airport,” said DFW’s CEO Chris McLaughlin. “Together with our partners, we are delivering infrastructure through innovation and collaboration that will serve the growing needs of north Texas while setting the stage for the next era of DFW’s development. By embracing modular construction, we are finding smarter ways to deliver results faster, with less impact on travelers.”

The airport completed the last of six module moves that make up the structure for Terminal F.

The milestone serves as another example of how DFW has used modular construction for the development of terminal facilities and further showcases the benefits it brings to airports.

“DFW is at the forefront of innovation in terminal construction, continually redefining what’s possible,” said Mohamed Charkas, DFW’s executive vice president of infrastructure and development. “The time we

save using modular construction techniques is crucial for fostering the growth of our community and supporting our airline partners. We are steadfast in our commitment to being an economic engine for north Texas.”

In May 2025, DFW and American Airlines announced the decision to expand the scope and accelerate the phasing of the new Terminal F. With the first phase of construction already under way, DFW has been hard at work designing the subsequent phases while concurrently construction the modules off-site. The first phase of the Terminal

F expansion program is anticipated to open with 15 gates in 2027.

The estimated $4 billion Terminal F is planned to ultimately deliver a total of 31 gates to be serviced entirely by American Airlines, expand capacity for international operations and widebody aircraft and include areas to facilitate parking, ticketing, check-in, security screening and baggage operations. American will return some gates in other areas of the airport, which will help facilitate the growth of other airlines at DFW as well.

In addition to a new centralized Skylink Station, which is included with the first phase of construction, the final configuration will provide a walking connection with Terminal D.

The design-build team for the first phase of Terminal F is Innovation Next+, a joint venture comprised of Archer Western Construction, Turner Construction Co., Phillips May Corp., H. J. Russell & Co. and CARCON Industries, with PGAL, Gensler and Muller2 as design team members.

Chevron Corp., the U.S.-based oil and gas giant, plans to build a huge blue hydrogen and ammonia plant in Port Arthur, Texas, according to Yahoo! Finance.

The company has completed the needed filings for tax abatements to support the plant’s construction. There is an investment of nearly $5 billion associated with the largescale blue hydrogen and ammonia plant.

Aside from tax benefits, Chevron seeks project funding through the HyVelocity Hub initiative, Yahoo! Finance reported. That federally funded initiative is expected to reduce the total Chevron investment in the low-carbon energy project. Construction on the development, which is named Project Labrador, is expected to start in 2027, with commercial operations beginning in 2032, according to Yahoo! Finance.

The project could qualify for tax exemptions if the construction begins on schedule.

Yahoo! Finance reported that Chevron is targeting the 10year 45V clean hydrogen production tax credit, which has an expiration date of Jan. 1, 2028. If the project proceeds on time, it could meet the deadline to access that incentive. The 45V clean hydrogen production tax credit could provide up to $3 per kilogram of clean hydrogen produced for 10 years. Chevron already has significant operations in Port Arthur, according to cpechem.com.

Diesel delivery without the drama. That’s what customers can expect from Fuel Monkey — around the clock and year-round — for industries ranging from construction and agriculture to manufacturing, grocery and logistics, plus emergency services, according to the company.

It aims to keep partners in the Dallas and Houston metro areas, as well as the Texas Panhandle, operating smoothly and without delay, with options for on- and off-road diesel and diesel exhaust fluid (DEF).

“Typically, we're servicing generators, jobsite trailers, yellow iron equipment, small fleet, really anyone in need of diesel fuel — whether on a scheduled basis or in response to a same-day emergency,” said Ethan Dunlap, operations manager of Fuel Monkey. “Weekly, we’re running about 40,000 to 50,000 gallons a week in each market.”

Fuel Monkey accomplishes this with Thunder Creek No HAZMAT Fuel and Service Truck Upfits, or MTUs. These medium-duty trucks are an all-in-one solution for fueling that helps Fuel Monkey service customers, big and small.

For its fleet, Fuel Monkey chose the Ford F-550 model of MTU, which can carry 920 gal. of diesel, along with 100 gal. of DEF and options for grease and auxiliary oil. The MTU consists of eight 115-gal. tanks that connect via a common manifold and pumping system. When the manifold is closed, it mitigates the need for drivers to have a CDL or HAZMAT endorsement.

According to Dunlap, that fuel capacity, along with the maneuverability of the MTUs , is essential for supporting their customers. Unlike a truck and trailer, the MTUs all-inone configuration makes it easy to drive to hard-to-reach locations and makes quick work of fueling. That’s important because Fuel Monkey recognizes its services mean

more to their customers than just fuel. It’s a way for those customers to maintain their productivity, meet deadlines and generate a profit.

“The Thunder Creek trucks are freaking amazing. You can get into these job sites, and you can go around obstacles. There are no issues,” he said. “These trucks are very efficient, simply because you get in and get out fast. They’ve saved us tons of time compared to trailers simply because they're nimble. Plus, we can fuel more, smaller fleet jobs faster with the truck than we can with the trailer.”

That maneuverability of the MTUs also provides Fuel Monkey with a competitive advantage over fuel service companies with larger equipment.

“They’ve helped us as far as being able to service the accounts that the bigger companies can’t send a Bobtail fuel truck out on,” said Dunlap. “We can get to the job sites faster and service more accounts. Plus, we

can take on the small jobs they don’t want to get to. That's the value of Thunder Creek trucks. They get the job done when the big boys won't even touch it.”

Dunlap and his team appreciate the versatility of their Ford F-550 MTUs in terms of carrying both diesel and DEF.

“These trucks are great because we’ve got a hundred gallons of DEF on them,” he said “You can carry clear or dyed diesel. So, that really helps for any system as far as fuel trucks go.”

The hose and pumping system on the MTUs also offer advantages for Fuel Monkey. Thunder Creek installs a hydraulicdriven centrifugal pump on each truck upfit, along with a retracting hose. Fifty ft. is the standard hose length, but Fuel Monkey opted for longer and is pleased with their decision.

“We’ve got that 100-foot hose and that has saved us several times,” Dunlap said. “Say you back up to a muddy job site, and

that generator is way over there in the mud. We can stretch out that long hose and go.”

Dunlap added, “The pumping speeds on our trucks are also pretty darn good. I mean, we're getting sometimes upwards of 15 to 18 gallons a minute with a long hose.”

When asked about the reliability of their MTUs and the service support Thunder Creek provides, Dunlap has nothing but a positive response.

“It’s so important to have good support equipment in the field. If you break down, you can have issues,” he said. “I’ve personally changed out valves and so forth on our trucks. Every time I've called Thunder Creek, I get answers to my questions, and the parts are shipped out right away. They have been wonderful to work with.”

Based on the amount of jobs Fuel Monkey has taken on since buying its Thunder Creek MTUs, it anticipates it will be close to even on the investment by the end of the year. Dunlap is optimistic.

“We need to make about 30 drops per driver, per week, to break even. Anything over 30 drops, that's money. And we have guys in the Dallas market doing 40 to 50 drops a week, easy,” he said. “If we can get one to two an hour, that’s even better. So, that’s our goal.”

According to Dunlop, the investment and hard work is well worth it and, once they reach the goal, they plan to add more Thunder Creek MTUs to the Fuel Monkey fleet.

“I've been around a lot of equipment over my lifetime, and I've seen a lot of okay stuff. This is like the Porsche of a fuel tank,” he said. “If I'm going to buy something that's going to make me money, I want it built tough. These are tough, and they go to work with us. I guarantee that as we grow, Thunder Creek will grow with us.” (All photos courtesy of Fuel Monkey.)

Next Issue Closes September 10th

Overspin

Landscaping isn’t static. It’s not poured in concrete or carved in stone. It’s alive — growing, changing, thriving. That’s what makes it both a challenge and an art.

For MasterScapes, a full-service landscaping company based in Abilene, Texas, working with living materials requires a long view — vision, craftsmanship and the tools to bring that vision to life.

“It’s not like a sculpture where the work ends once it’s done,” said Kevin Roberts, CEO of MasterScapes. “Landscapes evolve, they grow, they die. It takes both design and grit to get them in the ground and to keep them thriving.”

Founded in 1992 with little more than a lawnmower in the back of a pickup, MasterScapes has grown into a 120employee operation serving commercial and residential clients throughout the region. Today, the company designs, builds and maintains landscapes of all kinds, leaning heavily on equipment like Bobcat compact loaders and excavators to keep up with demand.

“What we learned early is that the right equipment pays for itself again and again,” Roberts said. “When we started working with Bobcat of Abilene, everything changed. Jobs we never could have done by hand: Those doors suddenly opened.”

One of the company’s recent projects, Storybook Garden, is a testament to that evolution. Located in Abilene, the Storybook Capital of the World, the garden is a vibrant public space designed to bring the community together. MasterScapes played a key role in its creation, installing irrigation and final touches that will help the garden flourish for years to come.

Throughout the build, Bobcat of Abilene was never far behind.

“Whether it's parts, service or rental sup-

port, we know we can pick up the phone and get what we need. That kind of partnership is rare, and it’s critical when you’re trying to grow.”

As MasterScapes looks to the future, it remains focused on efficiency, innovation and, above all, cultivating beauty in the spaces they touch.

“There’s no way we could accomplish what we do without Bobcat,” Roberts said. “It helps us show up every day ready to go.” (All photos courtesy of MasterScapes.)

Merlo America of Rock Hill, S.C., announced its newest partnership with Hendrix Timber Mulchers, welcoming the Texas-based dealership into its growing U.S. network.

Hendrix Timber Mulchers now offers Merlo’s complete line of Italian-engineered telehandlers to customers across East Texas and the broader United States.

Built from a background in the timber industry, Hendrix Timber Mulchers has grown into a trusted source for forestry equipment. It specializes in timber mulchers, brush cutters, grapples and hydraulic solutions tailored to the demands of land clearing, vegetation management and forestry operations. Based in Livingston, Texas, Hendrix offers sales, rentals, parts and service for leading equipment brands.

With years of hands-on experience and a reputation for top-tier customer service, Hendrix Timber Mulchers is a respected name in the region’s forestry and land management sector, according to the company. Their deep understanding of the terrain, timber life cycle and contractor needs makes them an ideal partner for Merlo America. The dealership’s dedication to providing dependable, operator-focused solutions aligns with Merlo’s mission to build

machines that work as hard as those who run them.

“Adding Merlo to our equipment offerings is a strategic move we’re confident will add more value for our customers. Their broad range of machines and attachments, coupled with their innovative technology, ensures our forestry customers will clearly see the operational advantages and the robust return this partnership provides their businesses,” owner Trent Hendrix said.

The partnership continues introducing Merlo’s versatile forestry machines to the U.S. market, bringing Italian-made machinery further into the Southeast. For Hendrix customers, it introduces a new class of machinery with versatile capabilities that complement forestry and land-clearing operations, especially when equipped with Merlo’s wide array of attachments.

Merlo telehandlers and forestry machines are engineered to perform in demanding environments where operator comfort, safety and machine agility matter most. Standard features like the enclosed 360-degree visibility cab, adaptive stability control system and intuitive capacitive joystick controls create a responsive experience with built-in safety features, giving operators better control, even in rough or remote terrain.

Merlo offers machines that excel in forestry work, including equipment loading, brush handling, vegetation clearing and work site logistics. With patented automatic attachment recognition and a design that prioritizes versatility and operator comfort, each machine is adaptable to evolving forestry and land management needs. Hendrix Timber Mulchers will provide customers access to these machines, parts, service and product support.

“When we look for dealer partners across the country, we prioritize deep local knowledge and a proven record of customer care,” said Cole Renken, general manager for Merlo America.

“Hendrix Timber Mulchers brings both to the table — with a boots-on-the-ground understanding of forestry work and a team that truly supports its customers.”

As a Merlo America dealer partner, Hendrix Timber Mulchers will now offer full-service sales, rentals,

parts and support for Merlo’s complete U.S. lineup. Customers can expect the same reliable service Hendrix is known for, now with access to Merlo’s equipment. Visit hendrixtimbermulchers.com for details.

The AEM Manufacturing Express kicked off its month-long tour of Texas on Aug. 1, 2025, visiting association member companies across the Lone Star State and encouraging equipment manufacturers to make their voices heard on the policies made at the state and federal levels.

Throughout August, the AEM Manufacturing Express will visit 22 manufacturers at their facilities across the state. The visits serve as opportunities to engage lawmakers, provide them with chances to tour the facilities, as well as meet workers and see the impact of pro-manufacturing policies firsthand.

“Since we announced this year’s tour, I have often been asked: ‘Why Texas? Why now?’” said Kip Eideberg, AEM senior vice president of government and industry relations, in a byline in the AEM Industry Advisor.

“The simple answer is that Texas leads by example. The Lone Star State is the equipment manufacturing capital of America, supporting 345,000 jobs and adding $49.5 billion to the state's economy — more than any other state equipment manufacturing industry,” Eideberg said.

The Texas tour opened with a visit to NXG Truck Bodies’ grand opening in Mount Pleasant on Aug. 1, followed by stops at Anderson UnderBridge, Epiroc, DY Concrete Pumps, C&W DustTech and Cummins. To close out a busy first week, the AEM Manufacturing Express stopped by Kubota in Grapevine.

AEM also is offering member company employees the opportunity to take the “Manufacturing Challenge,” an interactive game that tests players’ knowledge about the innovative technologies, processes, people and products powering equipment manufacturing across America. AEM also will continue to recruit I Make America supporters,

who help AEM and its industry peers advocate for pro-manufacturing policies.

The ribbon-cutting event at NXG Truck Bodies for the company’s Mount Pleasant grand opening proved to be the perfect way to kick off the AEM Manufacturing Express Summer 2025 tour. Industry leaders, local officials and community members joined together with friends and family to celebrate the new facility, which is expected to create about 100 jobs in Mount Pleasant by year’s end.

According to a post on Manufacturingexpress.org, “NXG’s brand-new 110,000 square-foot manufacturing facility specializes in building premium steel and aluminum truck bodies with precision, durability and next-generation features. From flatbeds and haulers to contractor and crane bodies, every product reflects a commitment to excellence for hardworking professionals and the industries it serves.”

Three days later, the AEM Manufacturing

Express arrived in Greenville to visit Anderson UnderBridge, manufacturer of the Anderson Hydra Platform, an under bridge work platform built for heavy-duty inspections, utility installs and safe access. The company welcomed AEM and the Greenville Chamber of Commerce for a grand opening and ribbon-cutting ceremony to celebrate Anderson UnderBridge’s new training center.

“When a lot of you drove here, you probably went over a lot of bridges along the way,” Anderson UnderBridge CEO Jamie Roush said in The Herald Banner in Greenville. “And while you may not think much about what’s under the bridge, there is a lot going on under there … and those bridges have to be inspected at least once every two years.

“There are about 6,000 bridges in the U.S., and about half of them are considered to be substandard,” Roush told the Herald

Banner. “What we specialize in is getting inspectors under those bridges quickly, safely and much more easily [than with scaffolding or similar methods].”

After a trip to Garland to spend a day with Epiroc and showcase the company’s commitment to being at the forefront of the future of mining, the AEM Manufacturing Express visited Alvarado for a pair of stops at DY Concrete Pumps and C&W DustTech.

Then it was off to Cummins, where the tour celebrated an organization that has made its name by putting sustainability and community at the forefront of its business.

“When you hear our CEO Jennifer Rumsey talk about Destination Zero, it’s apparent that our business strategy is deeply tied with our value system and who we are as a company — and we’ve stuck to these values for decades,” said Brian Mormino, Cummins executive director of technical and environmental systems.

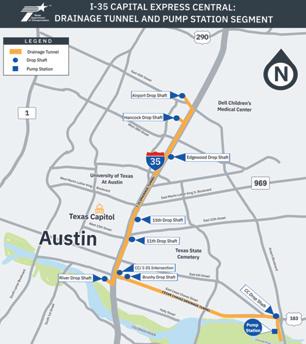

The Texas Department of Transportation (TxDOT) is reconstructing and lowering Interstate 35 as part of its I-35 Capital Express Central project.

Work on the $1.1 billion project began in May 2025, with completion anticipated in 2029.

The planned improvements will require effective flood and stormwater management.

This segment will construct 6.5 mi. of 22-ft.-diameter drainage tunnels between Airport Boulevard and Holly Street; and along Cesar Chavez

Street, from I-35 to U.S. 183.

Access shafts will be added along I-35 to ensure proper maintenance and operational access to the new infrastructure.

The segment also includes the construction of a pump station to improve stormwater management along the corridor.

The contractor for the drainage tunnel is SAK/Shea JV, and the pump station contractor is Webber LLC.

Work on the project is taking place in four phases:

• Utility relocation and site

work at Airport Boulevard, 15th Street, Brushy Street and River Street drop shafts and the Cesar Chavez/I-35 intersection; excavate at the Airport Boulevard and 11th Street drop shafts and CC/I-35 intersection; install geotechnical monitoring equipment.

• Excavate 15th Street, Cesar Chavez Street and River Street drop shafts.

• Relocate utilities at Hancock Center, Edgewood Avenue and 11th Street drop shafts; launch tunnel boring

machines; excavate the Hancock Center, Edgewood Avenue and Brushy Street drop shafts.

• Establish tunnel connections from drop shafts; restore drop shaft sites; install final tunnel lining.

Construction is funded by TxDOT and the Capital Area Metropolitan Planning Organization (CAMPO).

(All images courtesy of the Texas Department of Transportation.)

Construction Partners Inc., a civil infrastructure company specializing in the construction and maintenance of roadways in local markets across the Sunbelt, announced on Aug. 4, 2025, that it has acquired Durwood Greene Construction Co. and G&S Asphalt Inc. (doing business as American Materials, Inc.), an asphalt manufacturing and construction business in Stafford, Texas.

From its three hot-mix asphalt plants and owned rail-serviced aggregates terminal, Durwood Greene provides construction and paving services for a variety of public and private projects throughout the Houston metro area.

“We are pleased to welcome Durwood Greene and its nearly 200 employees to Construction Partners,” said Fred J. (Jule) Smith, III, the company’s president and CEO. “As a third-generation family business, Durwood Greene has earned its reputation as a well-respected market leader in Houston, the fifth largest and one of the fastest-growing metro areas in the nation.

“Under the continuing leadership of Brad, Jonathan and Daniel Greene, all of whom

are knowledgeable and experienced industry veterans, we expect Durwood Greene to continue its legacy of operational excellence and to benefit from vertical integration opportunities as part of our family of companies, including the ability to purchase liquid asphalt cement from Lone Star Paving's existing terminal in nearby Channelview and drive additional throughput at this facility.”

Construction Partners operates in local markets throughout the Sunbelt in Alabama, Florida, Georgia, North Carolina, Oklahoma, South Carolina, Tennessee and Texas. Supported by its hot-mix asphalt plants, aggregate facilities and liquid asphalt terminals, CPI focuses on the construction, repair and maintenance of surface infrastructure.

Publicly funded projects make up most of its business and include local and state roadways, interstate highways, airport runways and bridges. The company also performs private sector projects that include paving and sitework for office and industrial parks, shopping centers, local businesses and residential developments. For details, visit constructionpartners.net.

HOSPITAL from page 1

Excavation operations are ongoing.

“The site elevation changes, and heavy rain can cause water to collect within the current excavation areas,” Hummel said.

The nearly square-shaped construction site is bounded by a highway, a road, a parking lot and a field. Scrubbing crews first cleared the property.

Thus far, this is a day-shift operation with more than 10 pieces of iron on site, along with additional personnel involved in excavation and site prep activities essential for the construction of the building and parking areas.

Excavation crews using dozers, motor graders, loaders and water trucks have made serious progress in preparing the site, Hummel said. Equipment operators have plenty of space to conduct multiple operations as they remove the sandy soil, which is placed into piles, then later removed.

At this point, the site has a variety of elevations. Underground infrastructure, such as water and sewer mains, is yet to be installed.

Once the current operations are completed, which will include drilling, the pouring of the foundation for the hospital can begin, to be followed by the steel framing and pouring of the concrete floorplate. The slab on grade foundation will run between 5 and 10 in. thick, Hummel said.

There are approximately 20 Lott Brothers and subcontractor personnel onsite each day. Local and regional subcontracting will be involved in the construction process.

Everyday equipment wear and tear issues are repaired promptly. Lott Brothers buys and rents equipment from a variety of dealerships.

The $159 million project is state funded. Since 2017, Gov. Greg Abbott and the Texas Legislature have invested more than $2.5 billion to replace, renovate and build state hospitals across Texas. These projects are part of a comprehensive plan to modernize facilities and increase access to inpatient psychiatric care.

“Texans are better served when they have access to healthcare closer to home, and that is why state leaders and HHSC have invested in facilities like the Panhandle State Hospital,” said Cecile Erwin Young, HHSC executive commissioner. “When completed, this hospital will offer hope and healing to some of the most vulnerable people in the Panhandle.”

This will be the first state-operated hospital in the 26county area. Planning and design for the Panhandle State Hospital began in December 2023.

The hospital has common activity areas and outdoor courtyards designed to encourage healthy social interactions, while the use of natural light throughout each space promotes recovery and healing, Hummel said.

“The state’s modern approach to inpatient psychiatric care includes areas that will help develop practical life skills such as a teaching kitchen, gardens, a greenhouse and a library where patients can practice computer skills,” she said. CEG

(All photos courtesy of the Texas Health and Human Services Commission.)

PIRTEK Denton

2126 Hamilton Rd Ste 350-360 Argyle, TX 76226 (940) 241-0082

PIRTEK Riverside

15301 N Interstate Hwy 35 Unit G Pflugerville, TX 78660 (512) 448-0800

PIRTEK Waco

125 Topeka Dr, Suite D

Woodway, TX 76712 (254) 294-8508

PIRTEK Brushy Creek

Mobile Service Only

Brushy Creek, TX 78681 (512) 363-5973

PIRTEK College Station Mobile Service Only (979) 789-4673

PIRTEK Tomball

26010 State Hwy 249 Suite B Tomball, TX 77375 (281) 741-8090

PIRTEK Baytown

4308 Garth Rd. Suite A Baytown, TX 77521 (281) 837-7203

PIRTEK Beltway North

1920 Rankin Rd. Suite 170 Houston, TX 77073 (713) 649-3801

PIRTEK Conroe 1775 N Loop 336 E, STE13 Conroe, TX 77301 (346) 406-4122

PIRTEK Gulfgate 6205 Brookhill Dr. Suite 1 Houston, TX (713) 649-3800

PIRTEK Katy

1920 Primewest Pkwy. Suite 500 Katy, TX 77449 (832) 737-4673

PIRTEK Northwest Crossing 13230 Hempstead Rd. Suite 306 Houston, TX 77040 (281) 741-2979

PIRTEK Pearland

2201 Hwy. 35 Bypass N Suite D Alvin, TX 77511 (713) 572-5439

PIRTEK Rosenberg

Mobile Service Only Rosenberg, TX 77471 (346) 576-4673

PIRTEK Stafford

Mobile Service Only Stafford, TX 77477 (281) 982-5246

PIRTEK Plano South 811 E Plano Parkway, Suite 121, Plano, TX 75074 (972) 423-1111

PIRTEK Sherman Mobile Service Only Sherman, TX 75090 (903) 487-4750

PIRTEK Temple Mobile Service Only Temple, TX 76501 (254) 299-5751

Bane Machinery is a family owned and operated business that offers heavy machinery sales, rentals, parts, and service. We are proud to offer Liebherr equipment with full service including preventative maintenance and warranty up to OEM standards.

Liebherr machines are custom-engineered to perform efficiently. From material handling to waste management, these machines showcase a range of what’s possible.

Contact us today to find the right solution for your project application.