By Irwin Rapoport

Whiting-Turner Construction Co. is just months away from delivering the $645.44 million new state hospital in Dallas — the Dallas State Hospital (DSH), a project initiated by the Texas Health and Human Services Commission (HHSC).

The plan is to open the adult facility first, followed by the pediatric section.

The groundbreaking ceremony occurred on Dec. 5, 2022. Construction on the adult wing is estimated to be complete this July, and the pediatric wing is expected to be ready in spring 2026. The psychiatric hospital will have 200 adult and 92 pediatric beds.

The project is part of the state’s comprehensive plan to expand inpatient psychiatric beds.

“Texas is making an unprecedented investment in helping people with serious mental illness,” HHS Executive Commissioner Cecile Erwin Young said in a news release. “When complete, this much-needed hospital will offer hope, healing and recovery for the most vulnerable Texans living in the surrounding Metroplex.”

The project’s financing stems from $384.44 million approved by the Texas Legislature. An additional $261 million contribution provided by Children’s Health financed the construction of the pediatric wing.

Planning for the hospital began about 10 years ago.

“The Dallas State Hospital will bring a modern inpatient psychiatric center to the Dallas-Fort Worth area,” said Emily Hummel, HHSC spokesperson. “It will also help increase overall state hospital capacity significantly.”

Designed by HKS Inc., the hospital is being constructed on 15 acres of land. It will have activity rooms for arts and crafts, gardening and more secure outdoor areas, and areas to support clinical programs and patient health. The new buildings include private rooms, common areas, outdoor courtyards and the use of natural light to promote recovery and healing. A parking garage is being built for staff and visitors.

“One of the biggest considerations is our regulatory compliance, which has more than 2,000 standards that must be met as well as best practices for psychiatric treatment and a therapeutic environment for patients,” Hummel said. “We expect the new Dallas State Hospital to serve Texans for many decades to come. The building will not be certified, but some LEED-type features will be incorporated into the building.”

In the adult wing, construction is estimated at 88 percent complete.

“Permanent power has been activated by Oncor,” said Hummel. “Boilers have been started up, and warm air is blowing in the building. Installation of building finishes including flooring, millwork, doors and interior glass and is progressing at various stages in the patient towers. A mockup patient room is complete, and courtyard paving and site paving are progressing.”

Construction of the pediatric wing is estimated at 55 percent complete:

ASHING EQ WA W S CRUSHING, QUIPMENT CREENING, DRILLING & – Plus Expert Installation & Repair Services. AR MO RAILC

VY CONS HEAAV VERS UCTION EQUIPM TR ENT & for Built – Driven Performance, by Excellence.

SOLUTIONS W MOBILE PO CT E A ER & COMP QUIPMENT

– Power & Reliability in Every Job.

CONCRETE & AVVING T P LTASPHAL A G

EQUIPMENT

– Built for Precision and Performance.

Agricultural Tractors

2022 JOHN DEERE 6R 155..............$189,500

2015 JOHN DEERE 6215R..............$120,000

2020 JOHN DEERE 6130M..............$115,000 (5) 2018-2024 JOHN DEERE 6120M.............. ........................................From $67,500

2018 JOHN DEERE 5125R................$98,500

2022 JOHN DEERE 5125M ............$125,000

2023 JOHN DEERE 5115M................$98,500 (3) 2021-2023 JOHN DEERE 5100M.............. ........................................From $81,000

Artic Trucks

(2) 2019 CATERPILLAR 740GC..From $369,500 (3) 2022-2025 CATERPILLAR 725................ ......................................From $395,000 (9) 2023-2024 ROKBAK RA30..............$CALL (5) 2023 ROKBAK RA40....................$CALL

Attachments

293-5556....................................$2,000

(3) CATERPILLAR LIFTS..............$2,500 Ea. CATERPILLAR D6 ANGLE BLADE........$5,000 CATERPILLAR D8T ANGLE BLADE........$7,500 CATERPILLAR D10T SS RIPPER..........$CALL CATERPILLAR ANGLE BLADE..............$7,500 CATERPILLAR WINCH......................$CALL

NPK GH15 HAMMER..................$CALL

NPK GH18 HAMMER..................$CALL PACCAR PA140-316V WINCH ............$CALL

CATERPILLAR CS11GC..............$CALL

CATERPILLAR CS66B............$102,500

(3) 2018-2022 CATERPILLAR CP56B............

$139,500 (7) 2017-2022 CATERPILLAR CS56B............

Crawler Carriers

$119,500

(2) 2019-2020 MOROOKA MST4000VD............ ........................................From $219,500

(2) 2018 MOROOKA MST3000VD................ ......................................From $159,500

(3) 2018-2019 MOROOKA MST2200VD............ ..........................................From $119,500

Dozers - Crawler

(2) 2023 CATERPILLAR D10T2From $1,695,000 2023 CATERPILLAR D9..............$1,375,000

(4) 2019-2023 CATERPILLAR D8From $675,000 2023 CATERPILLAR D7....................$CALL

(2) 2020 CATERPILLAR D6......From $275,000 (10) 2019-2024 CATERPILLAR D6 LGP............ ..........................................From $229,500 2020 CATERPILLAR D6 XL..............$255,000

CATERPILLAR D6N XL............$239,500 (2) 2023-2025 CATERPILLAR D5From $399,500

2019 CATERPILLAR D5K2XL..........$134,500 2023 CATERPILLAR D4..................$249,500

(2) 2022-2023 CATERPILLAR D3From $165,000 2022 CATERPILLAR D2....................$CALL

2022 CATERPILLAR 395................$955,000 (3) 2019-2022 CATERPILLAR 374FL.............. ......................................From $545,000 (4) 2021-2023 CATERPILLAR 352................ ......................................From $427,500

2019 CATERPILLAR 349FL..............$395,000 (4) 2021-2022 CATERPILLAR 349................ ......................................From $289,500

2022 CATERPILLAR 340................$389,500 (2) 2019-2024 CAT 336..........From $139,500

2018 CATERPILLAR 336FL..............$169,500 (2) 2023 CATERPILLAR 330-07..$309,500 Ea.

2020 CATERPILLAR 326-07............$289,500

2020 CATERPILLAR 320................$189,500

2017 CATERPILLAR 316FL..............$139,500

2023 CATERPILLAR 310................$149,500 (2) 2023 CATERPILLAR 306CR............$CALL

2021 CATERPILLAR 305E2..............$74,500

Motor Graders

(2) 2022 CATERPILLAR 16......From $995,000

2024 CATERPILLAR 14..................$765,000

2019 CATERPILLAR 14M3..............$329,500 (2) 2023-2024 CATERPILLAR 150........$CALL

Rigid Frame Truck

(2) 2017 CATERPILLAR 772G......$309,500 Ea.

Skid Steers - Track

(2) 2021 JOHN DEERE 333G....From $149,500 (3) 2021-2024 CATERPILLAR 299D3 XE........

Backed by nearly two decades of local industry experience, TexPro Equipment continues to support construction crews across the Dallas-Fort Worth market.

Following the acquisition of EQUIPRO, a service business originally established in 2006, TexPro Equipment provides repair, parts and light construction equipment support to contractors across DFW metro.

Operating from a 7,500-sq.-ft. facility with three service bays and a six-person team, the company supports a range of customers, including general contractors, rental companies and those in the construction and utility sectors.

TexPro Equipment emphasizes responsive service and instock inventory, aiming to meet the day-to-day needs of field operations with minimal delays.

“Our strength is service, and we intend to stay focused on that,” said Shawn Ramanathan, owner of TexPro Equipment. “We’re building on core values, experienced personnel, consistent turnaround times, and strong relationships with our customers.”

TexPro Equipment specializes in light construction equipment repairs, including trench rollers, compactors, generators, compressors and gasand diesel-powered engines. The company services equipment from a wide range of manufacturers and employs technicians who hold certifications from various OEMs. These qualifications allow TexPro Equipment to process warranty claims and meet requirements for authorized service status.

In addition to repair work, the company maintains an in-house inventory of both new and used equipment.

Parts frequently kept in stock include engines, carburetors, starters, diamond blades, filters, rings, seals and other commonly requested components. TexPro also offers compactors, rammers, vibratory plates, ride-on rollers, generators and concrete saws.

“We stock the items our customers need most often,” Ramanathan said. “Having the right parts available helps reduce downtime and keeps projects moving.”

TexPro Equipment reports that it maintains authorized

dealer relationships with more than 50 manufacturers. These include companies such as Wacker Neuson, Bomag, Generac, Chicago Pneumatic, Tsurumi Pumps, Husqvarna, Honda, Stihl and others.

The business continues to emphasize a customer-focused

(L-R) are TexPro Equipment staffers Sergio Gallardo, service tech; Steve Nichols, service manager; Marcie Crew, executive administration; Bobby Thomason, service technician; Rodney Kaderka, operations manager; Shawn Ramanathan, president; and Phillip Butler, parts and equipment supervisor.

approach, with in-person service and direct phone support. Many returning customers are greeted by name, and the small team structure operates by a more individualized experience.

“We’re not a large chain, and that allows us to be flexible,” said Ramanathan. “Our customers know they can call or stop in and get personal service.”

Looking ahead, TexPro Equipment is investing in system improvements, customer outreach and digital transformation. The company’s stated goal is to expand its customer base across North Texas while maintaining the operational practices that have defined its approach since the transition.

“We’re focused on becoming a dependable resource for construction crews who rely on light construction equipment,” said Ramanathan. “Our job is to help keep their projects on track and their equipment in working order.”

For more information, call 817/834-5800. (All photos courtesy of TexPro Equipment.)

The city of Dallas selected Trinity Alliance, a joint venture led by AECOM Hunt and Turner Construction Co., to serve as construction manager of Component 1 of the Kay Bailey Hutchison Convention Center master plan project.

Serving as construction manager at risk, Trinity Alliance will oversee the full scope of preconstruction, construction and related

demolition services for the first component of the project, the convention center expansion.

The contract is for $7.5 million, according to wfaa.com. The entire convention center project will be in the $1.9 billion to $2.5 billion range.

Construction on the convention center rebuild project will expand the exhibition halls by 76,000 sq. ft., nearly triple its meet-

ing and double ballroom space and feature seven total components. The new facility is slated to open in 2029, wfaa.com reported.

Trinity Alliance includes equity joint venture partners and associate partners, who are all part of the fabric of this community and will provide instrumental roles in successful project delivery.

Equity partners include: BOWA

Construction, CORE CMCI, EJ Smith Construction, GCC Enterprises, Pienado Construction and Source Building.

Additional teaming partners include Acari Management Group, BYRNE Construction Services, Copeland Contracting Company Inc., LeVis Consulting Group, Mahuya Industries, Othon Inc., RM Chin & see TRINITY page 18

Bobcat of Abilene 325-673-7361

Bobcat of Amarillo

806-622-9593

Bobcat of Austin 512-251-3415

Bobcat of Buda 512-884-5533

Bobcat of Corpus Christi 361-884-3959

Bobcat of Corsicana 902-483-6000

Bobcat of Lubbock 806-745-1322

Bobcat of Marble Falls 830-220-6070

Bobcat of Marion 830-420-9020

Bobcat of Midland–Odessa 432-685-9298

Bobcat of Pleasanton 830-580-4020

Bobcat of the Rio Grande Valley 956-425-4300

Bobcat of San Antonio 210-337-6136

Bobcat of Temple 254-523-4900

Bobcat of Victoria 361-579-0922

Bobcat of Waco 254-488-7004

Bobcat of Wichita Falls 940-285-7777

Ranchers ATV and Tractor Kerrville 830-315-2330

July 16th

By Shannon McIntire TEXAS DEPARTMENT OF TRANSPORTATION

Stunning discoveries sometimes lie just below the surface. A recent archeological excavation in the Lubbock area unearthed some colossal creatures. And the discoveries are just beginning.

“During the environmental review for Loop 88, TxDOT contracted an archeological survey,” said Chris Ringstaff, project planner of the Texas Department of Transportation’s environmental affairs division. “They found the bones of some large, prehistoric animals called megafauna, which is not unusual in the region.”

The Panhandle area is home to many playas — remnants of lakes from the Ice Age. In prehistoric times, animals and humans used playas as water sources and these sites can sometimes contain evidence of human activity.

“If the site involves humans, we have to address road construction impacts under state and federal law,” Ringstaff said. “If the site has no artifacts and dates to a time well before humans, TxDOT will recommend no further work, and the project can proceed to construction.”

Given that Texas has other sites that show human activity with megafauna, TxDOT staff decided to take a closer look at the Loop 88 location. They opted for a process called staged mitigation that involves archeological excavation to look for human artifacts like chipped stone or spear points.

“Excavation is one of many steps TxDOT can take prior to road construction to ensure that Texas history is preserved,” said Rebekah Dobrasko, cultural resources section director.

Earlier this year, TxDOT staff and consulting archeologists excavated bones and took geologic and sediment samples for fine screening. TxDOT also is collaborating with the Museum of Texas Tech University for assistance with preparation, identification and housing of the bones.

“We know we’ve found a giant ground sloth by its distinctive tooth,” Ringstaff said. “Whether all the bones are giant ground sloth or there are different animals such as mammoth or mastodon, we’re not sure. Paleontologists will give us positive identification.”

Experts are examining the dirt collected around the bones for micro-artifacts and using geologic dating techniques to get a better idea of the chronology of the objects.

Should the site reveal human activity with megafauna from the Ice Age, it would be the first of its kind for a TxDOT project.

Fortunately, even if further excavation is needed, the work is still well ahead of any project construction. TxDOT receives design plans far in advance to ensure reviews don’t affect a project’s timeline.

“We’re here to get the road built,” Ringstaff said. “But who doesn’t love digging up big ol’ animals?”

(All photos courtesy of Texas Department of Transportation.)

By Cynthia Vaquera TEXAS DEPARTMENT OF TRANSPORTATION

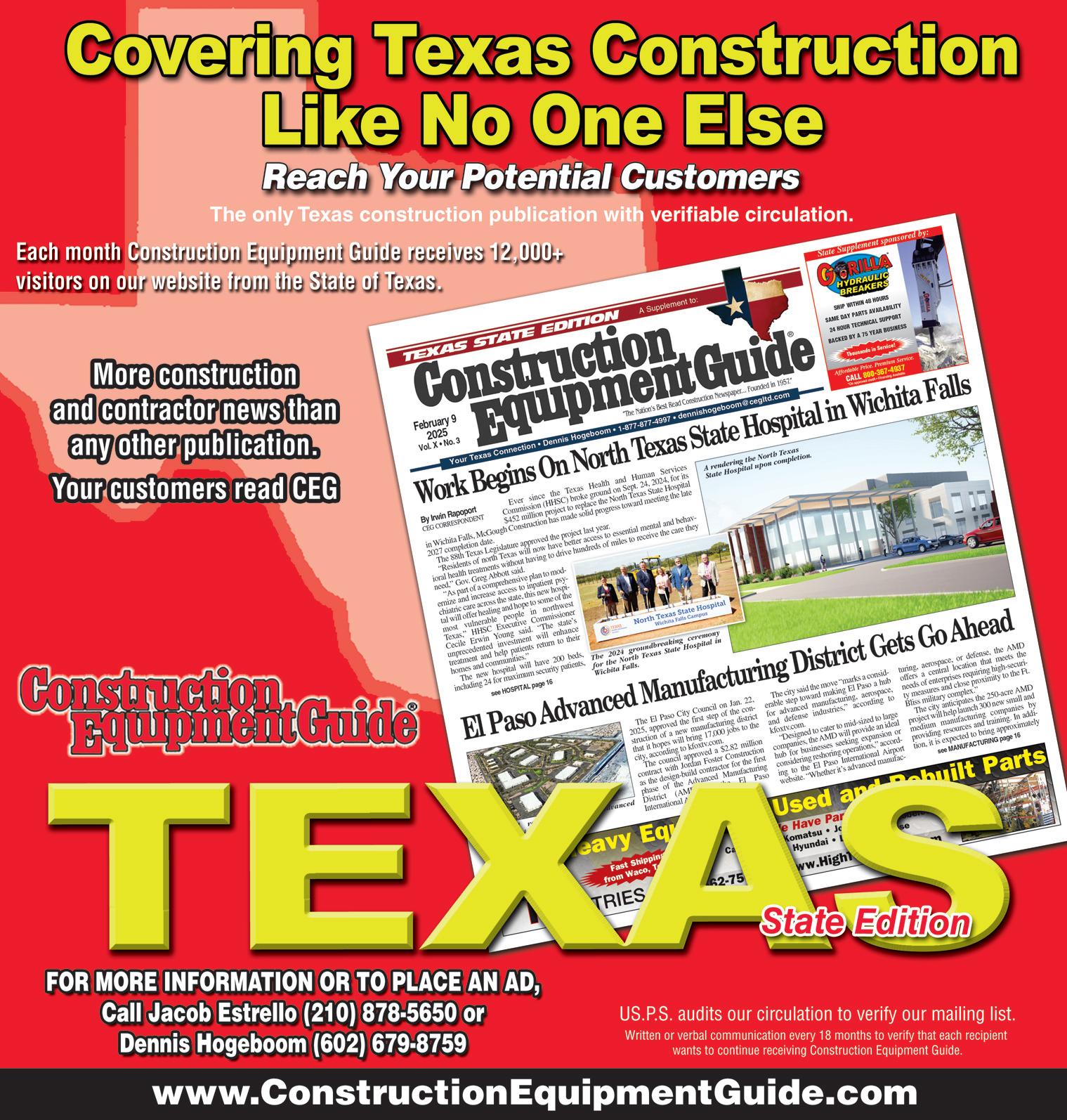

When we drive on Texas roads, the last thing we think about is what our tires are rolling on. But behind every mile of every

road, science is at work. At the Texas Department of Transportation’s (TxDOT) Materials and Tests division lab, even the smallest detail is studied to get you safely to your destination.

A team of experts analyzes every crack,

every concrete mix and every microscopic particle they receive from all over the state to check if they meet safety standards. This testing is known as petrographic analysis.

“Petrographic analysis is essentially the use of microscopy, mineralogy, geology and chemistry to look at different failures in the roads and do forensic analysis,” said Maria Hruska, technical project manager at TxDOT’s Petrographic Lab.

This lab uses advanced technology to study the materials that make up our roads, such as the scanning of electron microscopes.

“They are extremely useful in doing very, very fine, detailed work and helping us see stuff that even normal microscopes wouldn't be able to see,” said Hruska.

This equipment studies the road in depth almost as if it were a medical exam, using technology that is also used in hospitals, to detect any damage that is invisible to the human eye.

“Something that starts off really small, once it starts spreading it can cause some really large-scale cracking. And it’s actually known as concrete cancer,” said Hruska.

In one of the most recent cases, the lab was sent samples of concrete that was failing strength tests. At first glance, it seemed like

nothing was wrong with it, but the analysis revealed a surprise.

“We found out that actually air had been mixed into that concrete, so much that it weakened it by about 30 percent. And that concrete actually had to be removed,” Hruska said.

In addition to advanced microscopes, the team also uses technology used in space, known as Laser-Induced Blast Spectroscopy (LIBS) scope.

“It’s actually the technology that's used on the Mars rover. A laser will essentially hit the surface and do an elemental analysis,” Hruska said.

Beyond the technology, the team adapts each analysis to the unique climate conditions of every corner of Texas. But despite all this advanced technology and effort, safety on the road is up to all of us.

“We put so much time and energy and effort into making sure these roadways as safe as possible, but at the end of the day, you still have to drive like a Texan: kind, courteous and safe,” Hruska said.

TxDOT works hard to improve safety in every nook and cranny on Texas roads, but it takes a team effort of engineers, law enforcement and drivers working together to save lives and prevent crashes.

Niece 8,000 gallon water tanks

installed on 40 ton Articulated Off Highway chassis. This combination is the workhorse of the dust control and water needs for quarries and large construction sites

The NWT9500 9500 Gallon water tank mounted on articulated truck. Pictured: Deere 460E with 9,500 gallon tank. Tanks come with 6X5 pumps. The

Off Road, Fuel and Lube Bed offers 3,000

of diesel fuel. The NFL10000 Fuel & Lube Can be mounted on any 100,000 lb rigid frame truck. Holds 10,000 gallons of diesel. 5 additional fluid tanks. Holds up to 3,000 gallons of oil.

of a button. The DewEze wireless remote gives you untethered control within a twenty foot radius of your bed.

Linde, a global supplier of industrial gases, began construction of a new air separation plant in Brownsville, Texas, to supply liquid oxygen (LOX) and liquid nitrogen (LN₂) to SpaceX’s Starbase operations in Boca Chica according to Texas Border Business.

The gases are critical to SpaceX’s Starship development and launch activities. Once it’s operational, the facility will likely reduce delivery times, trimming the distance between production and the launch site from more than 500 mi. to less than 50.

The location is within the North Brownsville Industrial Park, which is a 72acre development managed by the Greater Brownsville Incentives Corp. (GBIC), according to Texas Border Business.

Linde will spend approximately $100 million and could create approximately 90 local jobs.

Linde is based in Dublin, Ireland, and its United States headquarters is in Connecticut, according to myRGV.com.

The company bought 9 acres within the industrial park to develop the site. Construction signs and early infrastructure work are visible, Texas Border Business reported.

The city of Brownsville issued Linde a commercial new construction permit on March 29, myRGV.com reported.

The social media platforms within the SpaceX and Starship enthusiast community, have posted site visuals and observations.

Starship Gazer Facebook group posts include, “First look at the new Linde Air Separation Plant under construction in Brownsville to supply Starbase and Starship with Liquid Oxygen, Liquid…” Another said, “Linde will be setting up an Air Separation Unit in Brownsville to supply Starbase.”

Brownsville Mayor John Cowen acknowledged the project on Facebook, stating, “I am very glad to welcome the arrival of our newest industrial company, Linde, to Brownsville at GBIC’s North Brownsville Industrial Park. As I mentioned in the article, I appreciate their significant investment in our community, which will create well-paying jobs for our residents.”

Cowen said the GBIC will provide $1.3 million in job training incentives and grants so the company will have a properly trained workforce, myRGV.com reported.

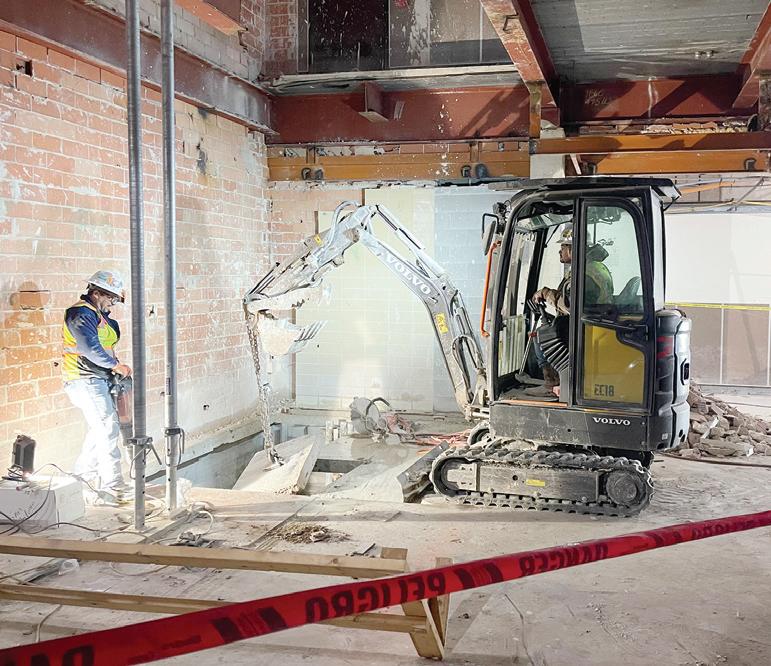

Tough demolition is the heart and soul of Robles1, a family-owned business in Texas with offices in San Antonio, Austin and El Paso.

The team of Robles1 works hard to tackle a wide range of projects, including complete, structural, selective and interior demolition.

This commitment to hard work and quality service began in the 1960s when Jesús Robles started a demolition company. He taught several of his sons the business as they were growing up.

In 2008, his son Saul started his own demolition company and now Saul Robles’ son, Adam, is the director of operations, managing the south/central Texas team out of San Antonio.

As a third-generation demolition expert working alongside his parents, Adam Robles carries on his family’s tradition of finding smart ways to make safe, efficient work of tough projects. That’s what led him to the company’s first-ever electric compact excavator — a Volvo EC18 Electric.

“Our bread and butter is interior demolition work,” Adam Robles said. “That’s what we specialize in. We do the stuff nobody else wants to do. The hard plaster, the concrete openings, the shoring of structural openings — work that can be very dangerous. Most of the other interior demo guys aren’t equipped with a fleet of electric machines that keep emissions down. We are, and that sets us apart.”

In the interior demolition world, safety inspectors are putting more focus on dust control and emissions in the workplace. That means proper airflow and ventilation are essential.

“A lot of times, we don’t have that luxury because we’re the first ones in,” hes said. “By the time we get there, we’re dealing with dust, moldy grounds, dampness and things like that. It’s our job to contain it, so that’s why we bring in machines like the EC18 Electric to do the work.”

By going electric, Robles1 has cut emissions so they can continue working more efficiently throughout the day.

In the past, the team used diesel machines with scrubbers to filter the air. Everyone inside wore carbon monoxide testers, and when the testers went off, the machines had to stop and everyone had to go outside for 30 to 45 minutes while the air inside refreshed. Only then could the team get back to work; but once the carbon monoxide levels spiked again, another break was in order.

“We weren’t being as efficient as we could be,” Adam Robles said. “This Volvo electric excavator — paired with the other electric support equipment we use — helps get us out of that pinch.”

Electric machines are giving Adam Robles and his San Antonio team more ways to keep their projects moving and on time.

“We also use sherpas, which are electric stand-on skid steers, to haul out the material,” he said. “Volvo included an amazing demolition guarding package on our electric excavator so we can safely clear out the trash chutes where we funnel and sort the material we’re tearing out. It also helps prevent damage to our new machine. And with an enclosed cab, the air quality for our operators is better so they can be in that environment much longer.”

The Volvo EC18 Electric moves plaster blocks, steel and other materials that come down the trash chute and separates the piles for recycling.

“We’re working it hard,” Adam Robles said. “Everything it lifts is heavy and bulky.” So how does the battery of the EC18 Electric hold up in tough conditions like these?

“Even on our hardest days, the battery lasts about four-and-a-half hours,” he said.

That can leave them with half a day to go, but in those situations, they give it a quick 45-minute charge over the lunch break with a DC fast charger. The team also has built a case for the charger and a hook to easily pick it up and move it around. When the day is done, they recharge the excavator on a standard 120-volt outlet overnight to bring it back to full for the next day’s work.

“One thing I’ve been most impressed by with our EC18 Electric is that it still has the same power as the diesel version,” Adam Robles said. “Some electric machines feel slower, but this one has the speed and strength for the duration of the battery charge. It can be at 30 percent charge or less and still have full power the whole time — it never struggles.”

In lieu of purchasing the EC18 Electric outright, Robles1 chose to lease the new excavator for three years through Volvo Financial Services with the assistance of their local Volvo dealer, ROMCO.

Adam Robles said the agreement allows him and his crew to try out the capabilities of the electric machine before potentially committing to purchasing one. So far, he feels confident that once the lease is up, they’ll be in the market for another Volvo EC18 Electric, or a newer model if it’s the right fit.

With electric machines now in their arsenal, Robles1 is equipped to take on more jobs that will help them move their business forward — a new generation of demolition equipment adam Robles’ grandfather would be proud of.

Gathering at the future site of the new Texas A&M Engineering Extension Service (TEEX) Public Service Training Complex (PSTC), approximately 100 TEEX employees and A&M System leaders were among those on May 14, 2025, who celebrated the groundbreaking of the facility on the south side of Texas A&M-RELLIS.

With a scheduled completion date of May 2026, the $25.3 million, 86-acre facility will provide training for front-line and public safety professionals who provide essential services to protect the lives and property of Texans, maintain critical infrastructure, such as electric power and water and wastewater systems, and ensure the economic viability of Texas communities.

“The Public Service Training Complex will serve future generations of students, improve emergency response around the state and strengthen the core of our Texas communities,” TEEX Agency Director David Coatney told attendees. “This groundbreaking is symbolic of TEEX’s continued commitment to safety, innovation and a highly skilled workforce for Texas and the nation. We appreciate Chancellor Sharp and the Board of Regents for making this new facility a reality.”

TEEX training requires a wide range of infrastructure, facilities and equipment to simulate realistic situations. Included in the complex will be an urban grid that simulates a city environment, a drive track with a skills pad for police

and motorcycle training, various training props that can be used in any type of weather and an upgraded classroom and laboratory spaces.

The TEEX Lineworker Academy and the Central Texas Police Academy will relocate their training programs to the new complex, which will be TEEX’s primary training hub at Texas A&M-RELLIS.

“TEEX’s advanced technical training programs are the gold standard for preparing a skilled, ready workforce in Texas,” said John Sharp, chancellor of The Texas A&M University System. “This new complex is just the latest example of how the Texas A&M System is building the future at the RELLIS Campus—providing world-class training that improves the lives of Texans, strengthens our communities, and powers the state’s economy.”

Some of the training courses that will be offered at the complex include electric power training; commercial driver training; emergency vehicle operations; unmanned aerial systems (UAS) flight training; heavy equipment training; truck and trailer safety training; all-terrain vehicle (ATV) operations; cell tower rescue operations; police patrol tactics; crime scene investigation and processing; and unexploded ordnance identification and safe handling, among others.

(All photos courtesy of the Texas A&M Engineering Extension Service.)

The San Antonio City Council on June 12, 2025, awarded a $110 million designbuild contract for the construction of the San Antonio International Airport's third parking garage –- a six-story structure that will add more than 2,000 parking spaces and is slated for a fall 2027 opening, San Antonio Express-News reported.

To be called the Ground Transportation Center, it will include lanes for VIA Metropolitan Transit buses, hotel shuttles, taxis and ride-hailing services. The center’s goal is to clear the frequently clogged pickup and drop-off lanes outside Terminals A and B.

The council awarded the contract to Kansas City-based J.E. Dunn Construction, San Antonio’s Marmon Mok Architecture

and the Houston-based PGAL design firm.

The project’s overall cost is expected to approach $125 million, San Antonio Express-News reported.

All three firms have worked on San Antonio projects in the past. For example, J.E. Dunn and Marmon Mok built a 900space parking garage at University Health System’s Women’s and Children’s Hospital.

Airport Director Jesus Saenz said the garage and new surface lots surrounding it will add up to 2,500 parking spaces.

Construction will begin later this summer, San Antonio Express-News reported.

The Ground Transportation Center will sit outside the loop that drivers circle when dropping off or picking up airport travelers.

Open parking spaces at the airport are scarce, particularly since the demand for air travel has increased since the pandemic. The airport’s two existing garages often are full, which forces to people to surface lots requiring shuttles to get to the airport.

The airport’s two parking garages, two surface lots and five small overflow lots provide about 10,000 parking spaces, San Antonio Express-News reported.

The new garage will be the airport’s second largest, behind the 4,000-space longterm parking garage.

The project is one of the pricier parts of the airport’s 20-year, $2.5 billion expansion plan. The largest is a $1.7 billion terminal under construction since December.

The garage was first expected to open in

2028 with just 500 spots.

Also on June 12, the council approved a $90 million contract with Coppell, Texasbased Austin Bridge and Road for airfield improvements. Those include drainage work and pavement rehabilitation on one of the three runways, San Antonio ExpressNews reported.

The runway supports most of the airport’s air travel, but Saenz said the revamp isn’t likely to slow down travel. Work on the runway will begin in January 2026 and is scheduled to be completed in eight months.

Austin Bridge and Road has worked on airfield projects at 25 airports nationwide, including Dallas Fort Worth International Airport.

PIRTEK Denton

2126 Hamilton Rd Ste 350-360 Argyle, TX 76226 (940) 241-0082

PIRTEK Riverside

15301 N Interstate Hwy 35 Unit G Pflugerville, TX 78660 (512) 448-0800

PIRTEK Waco

125 Topeka Dr, Suite D Woodway, TX 76712 (254) 294-8508

PIRTEK Brushy Creek

Mobile Service Only

Brushy Creek, TX 78681 (512) 363-5973

PIRTEK Liberty Hill Mobile Service Only Liberty Hill, TX (512) 737-4673

PIRTEK College Station Mobile Service Only (979) 789-4673

PIRTEK Tomball

26010 State Hwy 249 Suite B Tomball, TX 77375 (281) 741-8090

PIRTEK Baytown

4308 Garth Rd. Suite A Baytown, TX 77521 (281) 837-7203

PIRTEK Beltway North 1920 Rankin Rd. Suite 170 Houston, TX 77073 (713) 649-3801

PIRTEK Conroe 1775 N Loop 336 E, STE13 Conroe, TX 77301 (346) 406-4122

PIRTEK Gulfgate 6205 Brookhill Dr. Suite 1 Houston, TX (713) 649-3800

PIRTEK Katy

1920 Primewest Pkwy. Suite 500 Katy, TX 77449 (832) 737-4673

PIRTEK Northwest Crossing 13230 Hempstead Rd. Suite 306 Houston, TX 77040 (281) 741-2979

PIRTEK Pearland

2201 Hwy. 35 Bypass N Suite D Alvin, TX 77511 (713) 572-5439

PIRTEK Rosenberg

Mobile Service Only Rosenberg, TX 77471 (346) 576-4673

PIRTEK Stafford

Mobile Service Only Stafford, TX 77477 (281) 982-5246

PIRTEK Plano South 811 E Plano Parkway, Suite 121, Plano, TX 75074 (972) 423-1111

PIRTEK Sherman Mobile Service Only Sherman, TX 75090 (903) 487-4750

PIRTEK Temple

Mobile Service Only Temple, TX 76501 (254) 299-5751

TRINITY from page 4

Associates and STL Engineers.

The Kay Bailey Hutchison Convention Center master plan project is poised to be a once-in-a-generation investment in the future of downtown Dallas. Under Trinity Alliance’s leadership, Component 1 of the project will not only reimagine the convention center but also help drive local economic activity, create new jobs and bring broad opportunities to firms and workers throughout the region.

The team’s past expertise includes:

• more than 70 convention projects nationwide, including the Fort Worth and San Antonio convention centers;

• $15 billion in convention center projects, generating more than 150,000 jobs; and

• the completion of SoFi Stadium, Intuit Dome and other high-profile entertainment venues.

Trinity Alliance’s commitment to delivering projects with integrity and collaboration is central to its approach. In the past 18 months alone, the team has contributed more than 1,000 volunteer service hours to the North Texas region.

AECOM Hunt of Dallas has delivered major infrastructure projects across the Metroplex since 1979.

“Our company is proud to call Dallas home, and even more proud to contribute to our city’s growth and momentum,” said Corissa Smith, co-principal of AECOM Hunt. “We share the community’s excitement about this project and are honored to be part of the team bringing it to life.”

Turner Construction Co., now celebrating its 100th year in Texas, has played a leading role in shaping the Dallas-Fort Worth skyline through the delivery of numerous landmark civic and commercial buildings.

“Dallas is a city with vision — and this project helps build toward that next chapter,” said Dewey Newton, co-principal of Turner Construction Co.

The 89th Texas House Legislature honored Karla Garza of VMK Concrete with a House Resolution for “distinguishing herself through her professional achievements.”

Garza is co-owner of ready-mix concrete supplier VMK Concrete of Mission, Texas, which has grown to encompass five separate business enterprises and more than 100 employees to become one of the largest concrete producers in South Texas.

An industry pioneer, Garza was elected to the Texas Aggregates & Concrete Association (TACA) board of directors, making history as the first Hispanic female to serve on the board since its inception in 1951. She also serves on the National Ready Mix Concrete Association board of directors, again making history as the first Hispanic female and the first female owner from Texas to hold a seat on the national board.

“What I once thought was simply my everyday work is actually helping to change an industry — for women, for Hispanics and for future generations. I am deeply honored by the recognition at the Capitol, and even more excited for the years ahead and the strides we will continue to make — not just for my daughter and children, but also for yours,” Garza said.

During her career, Garza has helped pave the way for more women — and more Hispanic women — to enter this growing and vital industry. Texas’ population surge — projected to increase from approximately 31 million residents in 2025 to 42 million by 2045 — has set the demand for substantial infrastructure development.

Garza is a strong advocate for community involvement, mentoring young women interested in the construction industry and supporting scholarships for students pursuing architecture, engineering and construction careers.

“We are incredibly proud to see one of our own recognized by the Texas Legislature for her outstanding achievements and leadership in the ready-mix concrete and construction industry,” said Rich Szecsy, incoming TACA chair. “As a trailblazing Hispanic woman in a traditionally underrepresented industry, she exemplifies the strength, grace and innovation that define the future for Texas infrastructure. Her success not only elevates our industry — it also inspires the next generation to dream bigger, build stronger and understand that there are no limits.”

TACA is the main resource for the aggregate, concrete, cement and other associated industries in Texas.

Infinium, a producer of commercially available eFuels, announced on May 19, 2025, that construction is under way on its second United States-based eFuels production site, known as Project Roadrunner.

The project is in Reeves County, Texas, near the city of Pecos.

The site is expected to become the world’s largest eFuels production facility when operational, producing 23,000 tons per year (7.6 million gal.) of sustainable aviation fuel (eSAF) and other eFuel products for customers including global aviation leaders American Airlines and IAG, owner of British Airways, Aer Lingus and other international airline brands.

“Infinium’s Project Roadrunner marks a huge achievement for the fuel industry,” said Infinium CEO Robert Schuetzle. “Not only will the project produce commercial eSAF for its customers, it will bring highly skilled jobs and economic growth to the Pecos community and state of Texas. This project demonstrates the ongoing

commitment of Infinium, its investors and partners to help ensure that the United States remains a global leader in energy security, resilience and innovation.”

eFuels are synthetic fuels, produced from waste carbon dioxide and renewable energy, that are chemically identical to conventional petroleum-based fuels. These drop-in fuels are used in the transportation and chemicals sectors, seamlessly integrating with existing engines, infrastructure and

manufacturing processes.

Infinium eFuels provide an opportunity for energy diversification while leveraging the global infrastructure that powers the transportation and chemicals industries today. In 2023, Infinium became the world’s first company to produce and ship commercial volumes of eFuels to customers in the U.S. and Europe from its production facility, Project Pathfinder, in Corpus Christi, Texas.

Infinium’s Project Roadrunner facility will convert waste carbon

dioxide and renewable energy to produce sustainable aviation fuel, leveraging new renewable power assets purpose-built for the project. The fuels produced by the Roadrunner project will be sold domestically in the U.S. and exported to international markets.

Under an agreement with airline group IAG, the eSAF will be shipped to the United Kingdom to satisfy compliance requirements under the recently enacted UK SAF Mandate which requires that at least 10 percent of all jet fuel in flights taking off from the U.K. is sourced from sustainable feedstocks by 2030.

“The construction of Project Roadrunner represents a real step forward in the production of sustainable aviation fuel at scale,” said Jonathon Counsell, IAG's group sustainability officer. “We’re proud to be an early customer of Infinium’s eSAF and working hard to procure and invest in SAF to deliver our 10 percent 2030 SAF goal. The aviation industry is making progress, but continued support

and stronger incentives are necessary to accelerate production at the scale and pace required to ensure a long-term, affordable supply.”

The Roadrunner project reached financial close with investments from Brookfield Asset Management and Breakthrough Energy Catalyst. It represents significant investment in the region and will support highly skilled direct labor jobs in construction, fabrication, operations and logistics locally and across Texas.

The facility is expected to reach commercial operations in 2027. Roadrunner has secured 150 MW of new wind generation capacity from a subsidiary of NextEra Energy Resources through a longterm power purchase agreement.

Infinium selected leading electrolyzer manufacturer Electric Hydrogen to supply its complete 100 MW HYPRPlant solution for the project, which will be integrated on site for green hydrogen production.

For more information, visit infiniumco.com.

A Link-Belt Cranes TCC-1200 and TCC1100 are working in Temple, Texas, as part of a $42,645,706 transportation infrastructure project.

Launched in February 2025, the initiative, named the Temple Outer Loop North project, seeks to meet growing transportation demands in the area with the construction of a new 9,500ft. four-lane roadway and a 1,135-ft. bridge over the BNSF Railway. Six mechanically stabilized earth (MSE) retaining walls and 12,910 ft. of storm drainage are incorporated into the build to provide structural support and prevent flooding.

Jordan Foster Construction Operations Manager Matt Gold said the Link-Belt telecrawlers have been vital to the operation, lifting and placing a total of 138 prestressed concrete beams at a combined weight of 110,000 lbs. Gold said the crawlers provided the most efficient and cost-effective way to set the beams.

“These are both very reliable cranes [TCC1200 and TCC-1100],” Gold said. “Their ability to work in tandem and operate within a compact job site fits our needs perfectly.”

With more than 40 years of crane operating experience, Jordan Foster Construction operator Rick Jackson said the Link-Belt telecrawlers are unmatched in terms of strength and workload capacity.

“It really is a beast of a crane,” Jackson said of the Link-Belt telecrawler product, referring to his recent operation of the TCC-1200.

While picking the beams, Jackson said the cranes needed to work in close, tight quarters at a 30-ft. radius. He said this was no issue for the telecrawlers on account of their exceptional mobility and capacity to pick and carry heavy loads as well as retract boom to travel under structures.

“If you can pick it, you can walk with it,” Jackson said.

Paired with this, he said the cranes are easy to transport and set up to work quickly. This maximized the crew’s workload potential on a daily basis, setting as many as 15 beams per day.

“For what we do, these are perfect cranes,” Jackson said. “Setup is easy, and they’re so versatile.”

He added that the cranes are easy to maintain, noting the TCC-1200 consolidates the majority of its grease fittings in one central location. This makes for less downtime on the job and ensures the cranes are always operating at full capacity.

Jackson concluded by saying both cranes were exceptional on the job, getting it done right and efficiently turning a profit

“These cranes made us money,” Jackson said. “That’s what it’s all about.”

Gov. Greg Abbott announced on June 10, 2025, that the Texas Health and Human Services Commission (HHSC) broke ground on the new Panhandle State Hospital in Amarillo.

Lott Brothers Construction of Round Rock, Texas, is the construction manager at risk, while Houston-based Page Southerland Page is the architect, according to theconstructionbroadsheet.com.

Abbott and the Texas Legislature approved $159 million in funding for the inpatient psychiatric hospital, which is expected to be completed in 2027.

“Texas is delivering on its promise to expand healthcare to rural communities across our great state,” Abbott said. “This Panhandle State Hospital — the first state-operated facility in the region — will provide Texans greater access to mental health professionals and high-quality care close to home. I thank the Texas Legislature and the Texas Health and Human Services Commission for their work to increase access to mental health care for Texans in every corner of our state.”

“Texans are better served when they have access to healthcare closer to home, and that is why state leaders and HHSC have invested in facilities like the Panhandle State Hospital,” said HHS Executive Commissioner Cecile Erwin Young. “When completed, this hospital will offer hope and healing to some of the most vulnerable people in the Panhandle.”

The 164,475-sq.-ft. 75-bed hospital will provide highquality inpatient psychiatric services to adults. The hospital is designed with the latest mental health care standards in mind to promote recovery and healing. Patients will have access to common activity areas and outdoor courtyards to encourage social interaction.

This is the first state-operated hospital in the 26-county area.

Since 2017, Abbott and the Texas Legislature have invested more than $2.5 billion to replace, renovate and build state hospitals across Texas. These projects are part of a comprehensive plan to modernize facilities and increase access to inpatient psychiatric care.

HHSC owns and operates nine state hospitals and one residential youth treatment center for people experiencing mental illness. The hospitals provide evidence-based treatment and 24-hour care to patients across the state who have been deemed to be unsafe to themselves or others, incompetent to stand trial, or found not guilty by reason of insanity.

For details, visit hhs.texas.gov.

(Photo courtesy of the Texas Health and Human Services Commission.)

from page 1

“Drywall work is progressing with the completion of the in-wall MEP work throughout the building,” said Hummel. “Installation of building finishes including flooring, millwork, doors and interior glass is progressing at various stages in the patient towers.”

Construction crews are using excavators, dozers, loaders, large crawler cranes, manlifts, telehandlers and other standard pieces of equipment.

The construction site provided large spaces to operate, store equipment and materials, set up field offices and establish a layout yard.

The ample space was crucial for the earthwork and site prep operations which house the multistory buildings. Before building construction, site prep including installing the underground services and preparing the areas for the foundations, which required multiple concrete pours.

funding from the 88th Texas Legislature in 2023.

The spaces will align with evidence-based treatment. The new building includes private rooms designed to balance privacy and security for patients, and common activity areas will encourage social interaction. Natural light throughout the facility will help pro-

mote recovery and healing.

The amounts for materials excavated and new materials brought in have not been finalized.

DHS isn’t the only hospital under construction in Texas: The HHSC also initiated the building of the $573 million Terrell State Hospital in August 2024.

Contractors Robins & Morton expect to achieve substantial completion there in 2027. The three-story, 415,000-sq.-ft. building is located on a 160-acre campus site in the city of Terrell.

“This groundbreaking ceremony for the new state hospital in Terrell is a step forward in Texas’ ongoing efforts to expand and modernize state facilities that offer behavioral health treatment to Texans,” said Gov. Greg Abbott in a news release. “Since 2017, Texas has provided more than $2.5 billion to build, renovate and improve our state hospitals.”

The new hospital will have 250 beds (165 non-maximum-security, 50 maximum-security, and 35 adolescent). Adult and adolescent patients will have separate living areas, and the maximum-security unit will include strict security measures to ensure the safety of patients, staff and the community.

The existing hospital serves 31 counties in North Texas.

Planning began when HHSC received

“The Terrell State Hospital’s cutting-edge approach to inpatient psychiatric care includes areas that will help teach practical life skills such as a teaching kitchen, gardens and a greenhouse, a library where patients can practice computer skills and more,” Hummel said. “Secure outdoor courtyards and terraces will allow patients to spend time outdoors while providing a private and secure environment for the patients and staff.”

The new hospital, designed by CannonDesign, is sited on the same campus as the existing hospital that opened in July 1885.

“The exterior design of the new hospital strikes a balance of creating a new image that elevates and complements the established historical context,” Hummel said. “The massing of the building balance transparency with privacy, and the material selected will create an image that is both familiar and inspiring. The use of red and grey ultra-high performance concrete panels connects the building to the existing campus. A wide and tall high-performance curtain wall glazing system and metal panel wall system give the building a modern look.”

This is the second large-scale hospital replacement project that Robins & Morton has led for HHSC in the last five years. The company delivered the Rusk State Hospital in 2023.

(All photos courtesy of Texas Health and Human Services Commission.)

Bane Machinery is a family owned and operated business that offers heavy machinery sales, rentals, parts, and service. We are proud to offer Liebherr equipment with full service including preventative maintenance and warranty up to OEM standards.

Liebherr machines are custom-engineered to perform efficiently. From material handling to waste management, these machines showcase a range of what’s possible.

Contact us today to find the right solution for your project application.