New York Gov. Kathy Hochul, the NFL’s Buffalo Bills and Erie County celebrated the topping out of the new $2.1 billion Highmark Stadium at the construction site in Orchard Park, a suburb of Buffalo, on April 4, 2025.

A major building milestone, the topping out celebrates the lifting and placing of the last roof module for the arena’s structure. The ultramodern stadium design includes technology, art and an array of amenities designed to enhance the fan

experience — making it a world-class entertainment venue that will likely boost the Western New York economy for decades to come. The project is now approximately 50 percent

see STADIUM page 36

By Lucy Perry CEG CORRESPONDENT

Outback Parts is linked nationwide with three used parts networks, so finding dependable parts fast and conveniently is never a problem.

Outback Parts also supplies replacement parts for Non-Cat® machines. So when you’re needing parts, call or visit us on-line.

M&T Bank Stadium in Baltimore, home to the Baltimore Ravens, is undergoing significant work to upgrade the stadium, including adding concierge rooms and expanding walkways to enhance the fan experience.

Four Silos Land Management is carving out more than just earth. Based in Ancram, N.Y., this boutique excavation and land management company has steadily built a name for itself in Columbia and northern Dutchess Counties.

14 SKANSKA NEARS FINISH OF CIRCULATION IMPROVEMENT

Skanska has announced the substantial completion of the $74.2 million circulation improvement project at the Grand Central 42nd Street Station in New York, N.Y.

18 N.Y.’S NEW ADVANCED CLEAN TRUCK RULE FACES STIFF OPPOSITION

At the beginning of 2025, the New York State government began requiring truck dealerships to sell a percentage of zero-emission vehicles, or ZEVs, for trucks weighing 8,500 lbs. or more.

24 TIGER EXPANDS INTO MD., VA. WITH STEPHENSON EQUIPMENT

Tiger Mowers announced that Stephenson Equipment is expanding into Maryland and Virginia. Tiger looks forward to a lasting partnership that will support both its existing customers and new clients in these regions.

24 EQUIP EXPO NAMES SAVANNAH BANANAS’ JESSE COLE AS KEYNOTE

Marketing challenges face every business owner, and Equip Exposition attendees will learn from one of the most well-known marketers and entrepreneurs in the United States: Savannah Bananas founder Jesse Cole.

26 NEW $26.5M NEIGHBORHOOD HOSPITAL TO BE BUILT IN W.VA.

West Virginia’s Mon Health System has begun construction on its latest small-format hospital in Bridgeport, similar to the Mon Marion Neighborhood Hospital to the north in the Marion County town of White Hall.

40

Officials in Hoboken, N.J. announced that the city’s new waterfront reconstruction project got under way April 7, 2025 to ensure the long-term safety, resilience and functionality of the critical infrastructure.

42

The survey found 27.2 million Americans planning digging projects in the next year will not contact 811, putting themselves and communities at risk of utility service disruptions, costly fines and repairs and even serious injury or death.

48 NTSB ISSUES REPORT ON FATAL EXPLOSION IN PA.

The National Transportation Safety Board (NTSB) released its final report on the 2023 explosion at the Palmer Chocolate factory. The incident claimed seven lives at the Pennsylvania facility.

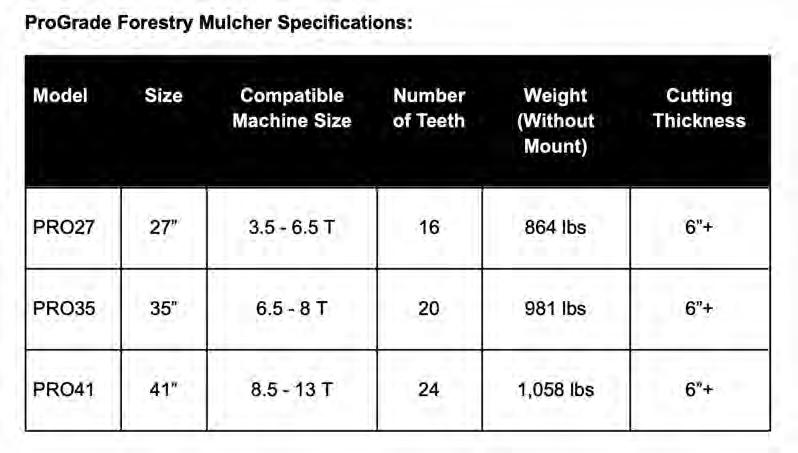

75 PREPARING YOUR ATTACHMENTS FOR SEASONAL USE

As winter fades and spring begins, construction and land-clearing professionals must ensure equipment is primed for peak performance. Rockland Manufacturing offers tips to prepare attachments for efficient and effective site preparation.

91 DESIGN-BUILD INSTITUTE OF AMERICA NAMES BRENNAN NEW COO

The Design-Build Institute of America (DBIA) announced the appointment of Carolyn Brennan as its new chief operating officer. In this role, Brennan will oversee DBIA’s revenue-generating departments.

92 JCB PLANS TO DOUBLE SIZE OF NEW U.S. PLANT IN WAKE OF TARIFFS

JCB is set to double the size of a new factory currently under construction in Texas as the company confirmed that newly announced tariffs will impact its business in the short-term.

GLOBAL PARTNERS WITH

508) 3799810

BACKHOES:

2019 NEW HOLLAND B110SPC, 747 HRS, CAB HVAC, QUICK TACH FRONT BKT, EXTENDAHOE, FRONT HYDRAULICS........................................$88,995

2008 NEW HOLLAND B95B, 5805 HRS, CAB, HVAC, 4WD, EXTENDAHOE, TOOL CARRIER..................................................................................$32,995

2008 NEW HOLLAND B95B, 5805 HRS, CAB, HVAC, 4WD, EXT HOE, TOOL CARRIER, TURF TIRES, BHOT SET TO CAT......................................$29,995

2021 NEW HOLLAND B95C TLB, 139 HRS, CAB, HVAC, 4 IN 1, EXT HOE.... $99,995

CHIPPERS:

2013 BANDIT 1390XP CHIPPER, 15” CAPACITY, 142 HP PERKINS DIESEL ENGINE, 2511 HRS, AUTOFEED, WINCH..........................................$29,995

2017 BANDIT 250XP 12” CHIPPER, CAT 120HP DIESEL ENGINE, 2305 HRS, AUTO FEED, WINCH..........................................................................$41,995

2022 BANDIT 250XP CHIPPER, 400 HRS, WINCH, 12" CAPACITY, CAT 120 HP......................................................................................................$64,995

SCREENERS:

EXCAVATORS:

2017 HITACHI ZX135-6, 3900 HRS, HYD THUMB, FRONT BLADE, COUPLER, PATTERN CHANGER......................................................

SKID STEER LOADERS:

2021

SCM40 $79,995 2021 VIBROSCREEN SCM27 $62,995 NEW VIBROSCREEN SCM75C BOX SCREEN W/CONVEYOR, TIER 3 ENGINE................................................................................

$195,000

NEW VIBROSCREEN SCM115T TROMMEL, NO DPF, NO DEF........$179,995

$105,000 2023 KOBELCO SK130LC-11, 516 HRS, CAB, HVAC, HYD THUMB, COUPLER........................................................................................

2021 KUBOTA SVL97-2 TRACK SKID STEER, CAB, HVAC, 905 HRS, STD FLOW HYD, HYD COUPLER, 78” BKT, BACKUP CAMERA................$69,000

$149,995

2019 KOBELCO SK140RLC, 2192 HRS, CAB, HVAC, HYD THUMB, FRONT BLADE, RUBBER TRACK PADS......................................................

$109,995

2023 KOBELCO SK140RLC-7, 288 HRS, CAB, HVAC, BLADE, THUMB, COUPLER........................................................................................

$169,995

2022 KOBELCO SK170LC-11, 256 HRS, CAB, HVAC, HYD THUMB $169,995

2023 KOBELCO SK350LC-11, 397 HRS, CAB, HVAC, 54” BUCKET, PLUMBED........................................................................................

$295,000

2003 TEREX HR16 MINI EXCAVATOR, CAB, HEAT, 3253 HRS, HYD THUMB, RUBBER TRACKS, 4 TON..................................................................$19,995

2018 YANMAR VI080-1A, CAB, HVAC, 1351 HRS, THUMB, RUBBER TRACKS............................................................................................$59,995

WHEEL LOADERS:

2022 AVANT 528LX, 40 HRS, CAB W/HEAT, 51” BUCKET, 43” ROTARY BROOM, LIKE NEW CONDITION........................................................$46,995

2002 DAEWOO MEGA200V, 2YD 4IN1 BKT, 2283 HRS, HYD COUPLER........ $39,995

2012 KUBOTA SVL90-2 TRACK SKID STEER, 1446 HRS, CAB HVAC, HIGH FLOW, LEXAN DOOR, COMES W/BKT, FORKS..................................$45,000

TRACTORS:

2012 CASE MAX110, CAB, HVAC, 6380 HRS, 4WD, LOADER, 3PT HITCH, 3 SETS REAR REMOTS, AG TIRES......................................................$42,000

MISCELLANEOUS:

ROTARY FORESTRY HEAD, SKID STEER MOUNT $17,995

96” SNOW BUCKET, SKID STEER MOUNT, 47.3 CU. FT. HEAPED$3000 KUBOTA KX080

By Craig Mongeau CEG EDITOR IN CHIEF

M&T Bank Stadium in Baltimore, home to the Baltimore Ravens, is undergoing significant work to upgrade the stadium, including adding concierge rooms and expanding walkways to enhance the fan experience.

However, along with these additions comes the need for infrastructure that can support the stadium’s new capacity and environmental goals. One of the major aspects of these upgrades is the implementation of a storm pod system, which is designed to help manage stormwater runoff in a sustainable and efficient manner.

Stormwater runoff can be a major issue in urban areas, as it overwhelms existing sewer systems and can cause flooding. The storm pod system being installed at M&T Bank Stadium is designed to capture stormwater and slow its release into the city’s sewer system, preventing it from being overwhelmed during heavy rains. These storm pods, precast concrete structures, are essentially large collection basins that store stormwater and allow it to dissipate gradually, preventing the city’s infrastructure from being overwhelmed. The storm pod system, which consists of approximately 60 pods, plays a crucial role in controlling the flow of stormwater and protecting the surrounding environment.

Installing this large-scale system was no small task, and it required careful planning, expertise and innovative solutions—particularly in the shoring and excavation stages of the project.

The contractor responsible for installing the storm pod system at M&T Bank Stadium is DSM Contracting, a utility contractor based in Randallstown, Md. DSM is a minority-owned company that specializes in installing unique utility systems, making them an ideal choice for this complex and non-traditional stormwater management system.

TrenchTech, a leader in shoring solutions, also is playing a pivotal role in this project, utilizing its innovative slide rail system to ensure the safety and efficiency of the construction.

The installation of the storm pod system required deep excavations in a confined area next to the stadium, with a large volume of earth needing to be moved. To ensure the safety of workers during this phase of the project, Trenchtech’s slide rail system was selected as the optimal solution. The slide rail system is a positive shoring system, as opposed to traditional trench boxes or sheeting and bracing methods, offering several key advantages.

An elaborate multi-bay slide rail solution is being used to install pre-cast storm pods approximately 30 ft. from the main M&T gates.

The main advantage of TrenchTech’s slide rail system is its modularity. It’s specifically designed to be adaptable to various excavation sizes and configurations, making it ideal for complex projects with tight spaces, such as the storm pod

installation at M&T Bank Stadium. The slide rail system can be installed in stages, allowing workers to safely excavate and install the storm pods without exposing them to potential hazards.

This was crucial on the M&T Bank Stadium project, as the excavation area was not only large but also congested

with other ongoing construction work and existing utilities that could not be relocated or disturbed.

Carl Lamb, the sales manager of Trenchtech, based in Baltimore, said that the slide rail system was the perfect fit for this project.

“The excavation for the storm pods was a significant undertaking, measuring 146 feet long, 47 feet wide, and 12 feet deep,” he said. “Additionally, the excavation area was adjacent to a busy street with live traffic, requiring the shoring system to provide support not only to the workers but also to protect the surrounding infrastructure and ensure the safety of pedestrians and drivers.”

TrenchTech and DSM have worked together on several projects, and when DSM was tasked with installing the storm pods, the company reached out to Trenchtech for assistance in providing a shoring solution. DSM recognized that traditional shoring methods would not be feasible for this project, given the tight timeline, complex logistics and the need to manage the excavation in

New Model TAG25, 24’ or 26' deck with 6' Tail, Safety Lighting Pkg., Bucket Pocket' in Deck & Tail, Black Paint In Stock!

Rogers 55 Ton CobraNeck, Severe Service Design. 2-position pin, ratchet ride height, adjustable width bi-fold steel ramps, 26' clear deck, deep well pocket, chain bins, tool boxes, 275's, alum. outers, side reinforcing, extra lights, strobes, night light pkg. Air Lift 3rd Air Lift 4th axle, Black Paint..IN STOCK!

Rogers 40 ton Tandem, No-Foot Neck, 24' deck, adjustable width ramps, bucket pocket, 275's, aluminum outers, night lights, work lights, strobes. Rogers Black............ IN STOCK!

Rogers TAG25-32, 26' deck, 6' tail, 8' air ramps, dual gear, side steps, broom/ shovel chutes, Safety Lighting package, 235's on aluminum outers, Viper Red Paint........ IN STOCK

Rogers TAG21XL, 22’ + 6’ Tail & TAG21XXL, 24’ + 6’ tail, 235's on Aluminum, Air Ramps, Safety Lighting Pkg. with Strobes. Black Paint.. IN STOCK!

on Aluminum Outers...... ........JUST TRADED!

Rogers TAG25XXL, 25 Ton Capacity, Premium Specs, Superior Quality, 235’s Aluminum, 7-Year Warranty, Black Paint, 24’ deck + 6’ tail, 8’ Air Ramps IN STOCK!

In the rolling hills of New York’s Hudson Valley — between Poughkeepsie and Hudson — Four Silos Land Management is carving out more than just earth.

Based in Ancram, N.Y., this boutique excavation and land management company has steadily built a name for itself in Columbia and northern Dutchess Counties, focusing on specialized services that blend excavation, forestry and natural landscape design.

At the helm is owner Mason Berlinghoff, who grew up on a family farm, where early exposure to landscaping and equipment sparked a lifelong fascination.

“My mom had a landscaping business since she was 18,” he said. “We had tractors and small machines around — I always loved getting on the equipment.”

Today, Four Silos Land Management offers services in excavation, trenching, selective forestry work and landscape construction. Its approach is deeply hands-on, with one employee and occasional help from a business partner.

“We’re not your typical contractor,” Berlinghoff said. “Ninety-five percent of our work is directly with residential customers — no home builders or big developments. It’s all custom, site-specific work.”

The company’s projects often include trenching for utilities, woodland thinning, invasive species removal and natural hardscaping using bluestone and native boulders.

Over the years, the company has grown and prospered. A nice assortment of equip-

ment was acquired as the need arose.

A breakthrough for Four Silos came in the form of a Rotastar portable screening bucket, purchased through A&D Equipment. Mounted to the Mecalac 8MCR, the Rotastar uses durable polyurethane stars to aerate and screen material efficiently — without the need for an expensive screening plant.

“I had been eyeing something for screening material, but small screening plants were going for at least 30,000,” Berlinghoff said. “The Rotastar was significantly less expensive, had no engine to maintain and was way easier to transport and operate on tight job sites. You do not need to transport the materials, to the screening point — that saves a ton of money — you are only handling the materials once.”

A&D Equipment loaned a demo unit, letting Four Silos test it out (this is done through the Rotastar Tour America Program, which A&D Equipment will ship the bucket to a potential customer at no cost to use for a couple of weeks. The company also provides virtual training and best operating practices.)

“Once I used it, I was sold,” he said. “We were able to screen sod, garden soil, even chunky concrete-laced material. It handled everything. I haven’t had a single star wear out or break yet — and I’ve put 50 to 70 hours on it.”

The company opted for one of the midsize Rotastar buckets, the RS4-9, which features four shafts of stars, improving output and letting the company screen approximately 30 yds. of material per hour.

“It’s been a major time-saver.,” he said. “In trenching jobs, we screen right next to the trench, place the screened material back in as bedding and dump the excess rock farther down the line.”

The Rotastar also has been great for creating high grade topsoil from sod and other difficult to manage soil types.

“It does a great job breaking and aerating material,” he said. ““I am very glad we purchased the RS4-9 with four shafts versus a smaller unit with less shafts. I believe it greatly increased our production volume. When we are trenching, we use all of the materials that the screener produces. Oversized stone is used toward the top of the trench and the screened material gives us great bedding.”

“A&D Equipment’s support also has been phenomenal,” he said. “I didn’t even have them install the bucket, but they were ready to walk me through anything I needed including the installation. They’re quick to respond and really care about their customers. It’s rare to find that level of personal attention.”

see LANDSCAPING page 44

Skanska has announced the substantial completion of the $74.2 million circulation improvement project at the Grand Central 42nd Street Station in New York, N.Y.

The newly unveiled passageway creates a direct connection between the Flushing, Queens, 7 train and the 4, 5 and 6 subway lines. Awarded to Skanska by The Metropolitan Transportation Authority (MTA), the project included upgrades to the station’s structures and systems, such as building a new passageway and staircase for the Flushing Line platform and widening existing staircases by 25 percent to improve commuter flow between transfers.

“As one of Manhattan’s busiest transit hubs, ensuring uninterrupted train service for nearly 500,000 daily commuters at Grand Central Station was a top priority,”

said John Sullivan, senior vice president, operations of Skanska’s Northeast Civil operations. “We are proud to celebrate the successful completion of the project alongside the MTA and STV and to have played a pivotal role in enhancing the commuting experience for the thousands of travelers who transfer between lines daily.”

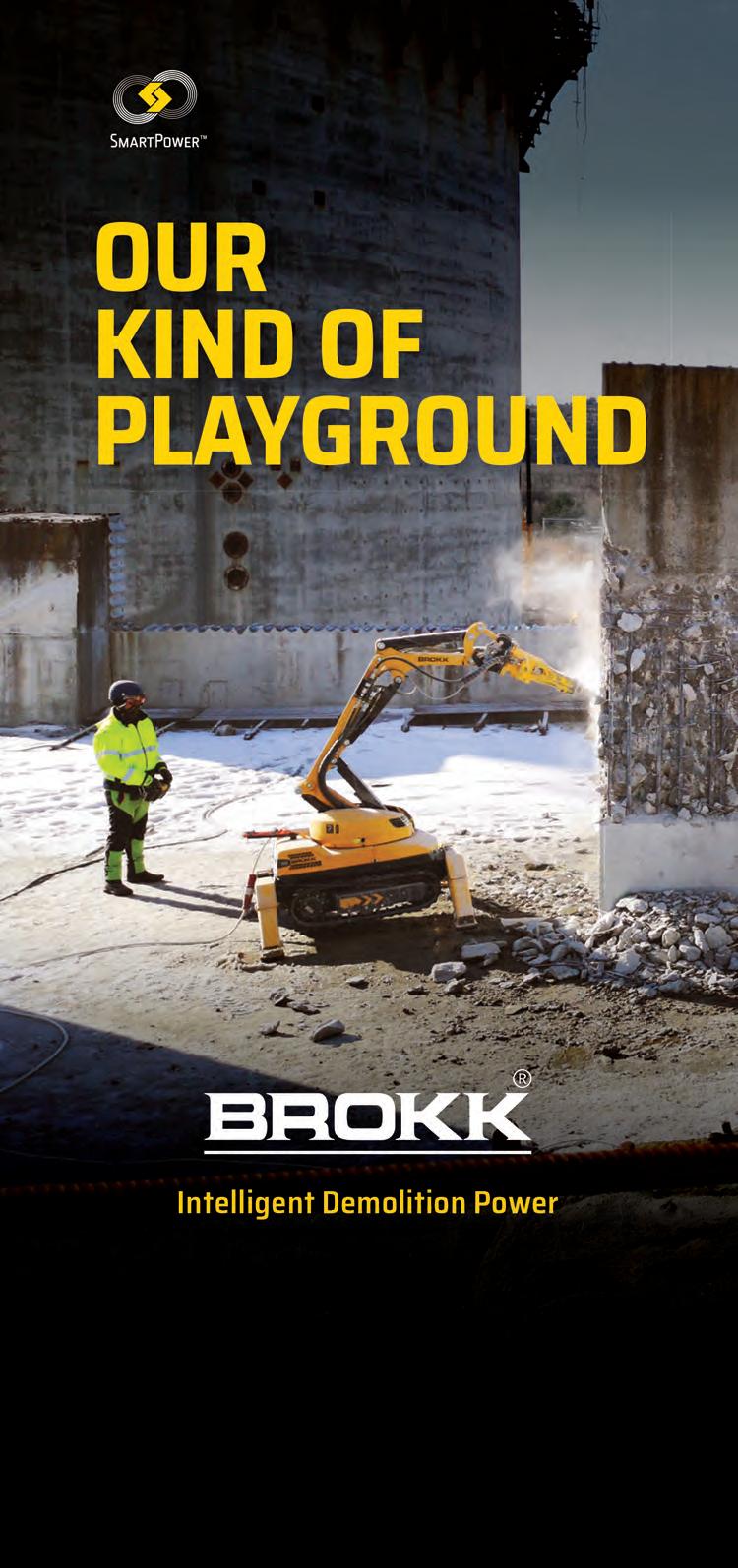

The 26-month project involved extensive rock excavation beneath East 42nd Street and Lexington Avenue under challenging conditions while utilizing Sequential Excavation Methods (SEM). Rock was removed using a combination of mechanical methods — using Brokk machines with hydraulic hammers — and low-power explosives, specifically NX Burst. This approach allowed for precise excavation in a highly sensitive area, just 6 ft. from the

active #7 Line at Grand Central Station.

Remarkably, due to a strategically located shaft, the access and excavation was handled from street leveling, allowing all work to be completed without any disruption to customer service.

This project marked the first time NX Burst had been used for rock excavation in New York City, demonstrating a groundbreaking advancement in controlled blasting techniques. In addition, the team implemented shotcrete for the structural walls and arch of the new passageway, further enhancing the project’s efficiency and safety — another significant innovation for the industry.

Construction on the project began in January of 2023 and the team achieved substantial completion in February 2025.

The project included upgrades to the station’s structures and systems, such as building a new passageway and staircase for the Flushing Line platform and widening existing staircases by 25 percent to improve commuter flow between transfers.

Four locations serve Maryland, Delaware,

and parts

Elliott & Frantz can show you the latest Gradall models, including Series IV excavators with highway speed travel capability. Featuring AutoDrive™, these models integrate a 6-speed automatic transmission and a new transfer case for efficient, simplified travel as well as convenient jobsite repositioning from the upper cab.

Gradall excavators also feature the job-proven telescoping, tilting boom that enables you to do more different jobs with just one machine – even under bridges and trees.

By Eric Olson PROFILE CORRESPONDENT

At the beginning of 2025, the New York State government began requiring truck dealerships to sell a percentage of zero-emission vehicles, or ZEVs, for trucks weighing 8,500 lbs. or more, with those percentages required to grow at a steady rate for the next decade.

Among the various types of ZEVs currently registered in a handful of states across the country are battery-electric vehicles (BEVs), more commonly referred to as EVs.

The high-minded intention of the New York Advanced Clean Truck (ACT) rule is, of course, to reduce harmful greenhouse gases and air pollution, while also promoting the green transportation industry, improving air quality and lowering the operating expenses of businesses that use trucks.

So far, only five other states have enacted rules similar to New York’s ACT: Massachusetts, New Jersey, Washington State, Oregon and California, the latter of which was the basis for New York’s initiative, adopted in 2021.

The Empire State’s trucking industry was given until this past New Year’s Day to comply with the mandate.

However, as a result of the ACT rule, the Trucking Association of New York (TANY), a lobbying group made up of dealers, trucking companies and industry supporters, has been working furiously to get Gov. Kathy Hochul and other leaders in Albany to hit the pause button on what it considers to be a piece of legislation that is both onerous and erroneously reasoned.

“Supporters of the ACT rule argue that delaying implementation will slow emissions reductions, harm public health and worsen environmental injustice,” TANY said in a recent e-mail to its members. “They point to transportation as the largest source of greenhouse gas emissions in New York and claim that reducing diesel truck usage will lower pollution levels, particularly in disadvantaged communities that bear the brunt of transportation-related emissions.”

“Even if zero-emission vehicle technology were fully developed, New York does not have the infrastructure to support widespread adoption.”

Trucking Association of New York

He added that the zero-emissions technology primarily supports light-duty vehicles and last-mile logistics, such as delivery services. However, for operations beyond a 75mi. radius or those requiring heavy loads, current ZEV capabilities are not yet viable. ACT’s requirement that a certain percentage of new trucks must be zero-emission vehicles, to be increased each year through model year 2035, along with the ratio of ZEV to diesel truck sales, Gallivan admits, will be “extremely difficult” to achieve under present conditions.

have the infrastructure to support widespread adoption,” the group reminded its members.

Among the key issues concerning TANY are:

• New York State currently has no heavyduty public charging stations.

• The state’s “unrealistic” sales requirements.

• The exorbitant costs of class 8 electric vehicles.

• Electric grid capacity problems.

• Worries that the charging process itself takes too long.

As a result, since last year, TANY and its supporters have been calling for the state “to delay their own compliance — in the form

Sean Gallivan is the owner, president and CEO of S.M. Gallivan, a trucking and construction firm based in Cohoes, N.Y., just north of Albany. He also is a well-respected business professional and has an influential voice within TANY.

His diversified company specializes in truck transportation, the manufacturing of landscape supplies, wood waste recycling, concrete and asphalt crushing and the commerce of agricultural commodities.

When asked March 6 where things stood on the clean trucks rule following continuing talks between TANY and state officials, he said a delay in enforcing ACT’s provisions is under discussion.

“To comply with the regulations, we would need multiple charging stations by 2026, adding to the financial and logistical challenges.”

The trucking association, though, said that the reality is the state has done almost nothing to make ACT compliance workable for most truck OEMs, dealers or vehicle owners.

While TANY supports reducing emissions and advancing clean transportation, it explained that the ACT rule, as written, is “unrealistic and counterproductive.”

“Even if zero-emission vehicle technology were fully developed, New York does not

Sean Gallivan S.M. Gallivan

of an enforcement exemption for municipal vehicles — because the ACT requirements are unattainable.”

Pushing ACT forward prematurely will not only fail to reduce emissions, New York’s trucking advocates believe, but it also will drive costs higher, limit truck availability, disrupt the supply chain and put jobs at risk.

TANY said it is more than willing to work with the state to set more practical objectives for implementing ACT.

“Dealerships are required to purchase a zero-emission vehicle within the same class before selling a truck to end users like us,” he said. “However, the New York State Senate and Assembly have just proposed legislation to postpone implementation and enforcement, and this has not passed yet.”

Gallivan believes the timeline for putting the ACT into effect should align with infrastructure development and technological advancements. While reducing emissions is an important goal, he said, “widespread adoption of ZEV trucks will likely require at least 10-15 years for infrastructure improvements and vehicle advancements to make them a viable option for heavy-hauling businesses.”

He also noted that his firm and the logistics companies it works with support the responsible adoption of ZEVs, “provided the technology and infrastructure can adequately support our businesses.”

But Gallivan added that at present, ZEVs “remain cost-prohibitive, have range and hauling limitations and lack the necessary charging infrastructure.”

“Our utility provider, National Grid, estimated that installing just one charging station would cost around $750,000, with a possible three-year timeline for providing power,” he said. “To comply with the regulations, we would need multiple charging stations by 2026, adding to the financial and logistical challenges.”

In addition, while a reduction in harmful emissions is the end goal, the current approach may unintentionally prevent the adoption of newer, cleaner-burning diesel trucks and keep older, higher-emission vehicles on New York’s roadways, according to Gallivan.

The economic and implementation effects of the ACT rule also deeply concern David Holzwarth, director of truck sales of Syracuse-based Tracey Road Equipment. A company employee for 35 years, the past 18 in his current position, he is highly respected by other trucking professionals for his knowledge of the industry.

Tracey Road is one of the state’s largest distributors of trucks and construction equipment, including the Daimler-owned Freightliner and Western Star lineup of commercial trucks. The dealership supplies vehicles across the United States, with a focus on the Northeast, and is known for its top-notch sales, service and parts operations.

From his position on the front line of selling trucks while under pressure to adhere to the ACT rules, Holzwarth said that its supporters — made up of state and political leaders, as well as environmental groups — did not seem to grasp the ramifications of the mandate on the trucking industry when the regulations were passed four years ago.

In fact, he said the planned rollout “did not make anybody’s radar until sometime late in 2023 when we at the dealership started telling our customers about [ACT] and they all looked at us like we were crazy. They thought, ‘This is stupid, it’s never going to happen.’

“Fast forward to today, and here we are more than two months into it and I’m $67.5 see ACT page 20

from page 18

million behind in truck sales from where I would have been in a normal year,” he said. “That’s 450 trucks at an average price of $150,000 per. These are retail dollars, not necessarily cost or profitability, but if it keeps going, we could have to cut somewhere in the vicinity of 30 percent of [Tracey Road’s] sales force. The dealership will survive with service and parts for quite some time, but the sales process is going to take a hit.”

He added that the ACT’s backers have likely figured if it is possible to easily charge electric cars, the same should be true for powering EV trucks that haul freight long distances.

“I believe they really didn’t understand, number one, that the power required for a truck charger is significantly more than what is needed for a car — we’re talking about a 60-kilowatt charger for a really small truck, up to a 150 kW or 240 kW unit, depending on how many trucks you are trying to charge.”

Most electric cars that require a complete recharge, by contrast, need only about 10 kW to reach full power.

Then there is the problem of the time it takes to charge an electric truck.

According to Gallivan, current “fast” charging stations need approximately five hours to power a truck to 80 percent capacity and up to 10 hours for a full charge. But, in cold weather, such as you would find in New York State, an electric vehicle’s range decreases significantly. Indeed, a recent test showed an electric truck running out of power after traveling just 80 mi., he said.

When Tracey Road’s truck customers began asking their utilities if they could get the needed electric power delivered to their location, according to Holzwarth, they learned that the amount of kilowatts was so massive that most small towns do not require as much energy as many chargers can provide.

“If the power companies can’t deliver the power, we can’t get the chargers and the customers can’t charge the trucks, so why should they buy an electric truck,” he said. “It’s simply unworkable.”

Now, with the ACT program in full swing, he admitted that this winter Daimler has not been accepting orders for any trucks other than snowplows, street sweepers, catch basin cleaners or dump trucks used for snowplow removal by municipalities.

“For a commercial account, if a customer wanted to come to us and order a truck for next year, I would first need to have had credits from selling an electric vehicle,” Holzwarth said. “At this point, though, I have no prospects for selling any electric vehicles and I have none on order.”

He added that Tracey Road sold one ZEV to National Grid, which registered it in Massachusetts, but the ACT rules say that when a company buys a truck from his dealership and registers it in a state other than New York, the credits go to the customer, not the dealership. After the deal was concluded, National Grid ended up with six credits, while Tracey Road gained none.

“As far as I am aware, nobody in the state is able to order trucks any differently than us,” Holzwarth said.

At this point, the process by which Tracey Road and other New York truck dealers must navigate their way to full ACT compliance is — to say the least — a study in bureaucracy.

He said that if he wants to order a truck for a municipality, for example, he must first get the customer to send a letter to the New York State Department of Environmental Conservation (DEC).

$60,000 to $100,000, have it installed, and all that must be done before we can order you a new truck,’” he said.

Gallivan added that the transitioning costs for trucking firms switching from diesel to electric vehicles are also substantial, noting that “while a diesel truck costs around

some of them are actually considering buying an EV simply to get the credits to buy the diesel vehicles, and then taking the price of that one electric machine and diluting it with the other six or eight that they would end up buying, which is not a good business practice because they are just inflating their acquisition costs,” he said.

“From what I understand, we have gotten some really good face time with key people in government and helped them to better understand the problems that the trucking industry faces.”

David Holzwarth

The function of that one EV, he added, would be for it to just sit unused on the lot of a freight hauler or construction company.

“Let’s say someone orders an electric Freightliner eM2, which is a six-wheel straight delivery truck, or maybe a tractor,” Holzwarth said.

“The tractor is going to get you eight credits, the eM2 is going to get you six credits. The people that contemplate doing this will buy the truck, register it — which is required — and then just park it.”

“The DEC takes a look at the letter and then either approves or disapproves it,” said Holzwarth. “When I get an approval letter back from DEC, and the customer e-mails me the letter they originally submitted to the DEC to get the OK, with those two things I can place my order with the OEM. Without them both, I have nothing. And that is for trucks that are going to be registered in New York State.”

Holzwarth also called out the state for its short sightedness in pouring hundreds of millions of dollars into building car-charging stations at all 27 service plazas on the New York Thruway — but not one for trucks.

Gallivan admitted that the lack of planning for heavy-duty charging infrastructure remains a significant issue.

“Effective policy implementation requires coordination between the state, utility companies, and industry stakeholders,” he added. “Currently, there are only three public charging stations in New York, and none within range of our company in Albany. This lack of infrastructure could create substantial operational inefficiencies, particularly for long-haul trucking.”

As a result, Holzwarth said that when Tracey Road pitches ZEVs to its customers, “we tell them that they are not going to be able to rely on the state for putting in the needed infrastructure,” and that, instead, they will need to have the funds necessary to purchase their own chargers.

“Now we ask them, ‘What do you have for power? Can you get 60-150 kW through your facility? If so, then you need to buy a charger, which [costs] in the vicinity of

$200,000 and can travel 500-650 miles per day, an electric truck costs between $550,000 and $700,000, with an additional $200,000 to $750,000 needed for charging infrastructure.”

With the current technology only allowing for a ZEV, carrying a full 80,000-lb. load, to travel with a maximum range of about 150 mi. from its base, he explained, “multiple electric trucks would be required to perform the same workload as a single clean diesel truck, leading to increased operational costs.”

For those New York trucking firms that rely on hauling freight to or doing business in other parts of the United States, most of which also have little to no EV infrastructure, using electric trucks is almost unthinkable, particularly for smaller companies.

Gallivan said that this, too, is a major concern for his construction and landscaping outfit, as well as for most other TANY members.

“Our operations extend throughout the Northeast,” he said. “Additionally, in recent hurricane relief efforts in North Carolina and Florida, our diesel trucks played a vital role in emergency response. The current electric truck technology does not yet support the heavy loads and long distances required for such critical missions.”

Truck customers are understandably frustrated and upset over New York State’s ACT regulations, according to Holzwarth.

“They simply want to be able to buy trucks at reasonable prices and, as a result,

Another option, he said, is for a company to go out of state to find older trucks that are likely to have dirtier engines than newer vehicles, which only serves to worsen New York’s air quality and do the opposite of what the ACT’s supporters intended.

Despite everything, though, both Gallivan and Holzwarth remain optimistic that TANY’s lobbying efforts to Hochul, state legislators, and other ACT backers will end with an agreement that is acceptable to all parties.

Gallivan noted that there has been significant bipartisan discussion on addressing TANY’s concerns and possibly adjusting ACT’s timeline.

“Earlier this year, S.M. Gallivan participated in a special investigatory hearing held by the New York Assembly where lawmakers on both sides of the aisle expressed concerns about the feasibility of these regulations. However, there is still a need for more direct engagement between state officials and the industry.”

Gallivan added that he hopes the ongoing discussions will lead to practical solutions that balance environmental goals with economic and operational realities.

“From what I understand, we have gotten some really good face time with key people in government and helped them to better understand the problems that the trucking industry faces,” said Holzwarth, who has himself been a part of TANY’s lobbying efforts. “We are making some headway, but I don’t know how long it will take.

“We need the issues ironed out now, though, not six months or a year from now.”

Hamm 3412P, 2012, 84” vibratory padfoot compactor, EROPS w/ heat & A/C, 1,200HMR .

$82,500

Cat 815F, 2006, EROPS cab, 12’4” S-Blade w/ tilt, new paint job, very good condition, 9,400 HMR . .$195,000

Hamm GRW-5 Pneumatic Roller, 1994, Deutz Diesel, ROPS Canopy, (9) Ea. 7.50-15C1 Tires

$15,500

(4) Cat 825C’s, 1981-1990, EROPS, S-blade w/tilt, all work ready

From $79,500

Rammax Walk Behind Rollers, over 25 in stock, lever & remote

$4,000 to $10,000 (8) Sheepsfoot, 48" and 60", double drum & single drum, tow type

$4,000 - $6,500

Volvo A40, 1998, 40 tons, 10991 hrs, 395 hp, 8WD, 29.5R25, A/C, 29 cy cap. sideboards, tailgate (currently off work), work ready

$127,500

Volvo A40, 1996, 40 tons, 395 hp, 6WD, A/C, 29.5R25, working everyday

$145,000

Volvo A40, 1996, 40 tons, 11,000 hrs, 6WD, 20.5R25, A/C, P/S trans, 29 cy cap., 6/06 hitch rebuilt .$115,000

Volvo A40, 1995, 40 tons, 395 hp, 8WD, 29.5R25, A/C, P/S trans, tailgate, work ready

$115,000

Volvo A35C, 1998, 35 tons, 6WD, 26.5R25 tires, approx 7,000 hrs, good condition

$147,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5x25, A/C, P/S trans, working everyday on jobsites

$87,500

Broderson IC80-2E, 1997, 8.5 ton, 24’ boom, dual fuel, 10.00R15 tires, 3,400 hrs .

$21,500

Grove RT58C, 1981, down cab, 18 ton r.t., 70' boom anti-two block, GM dsl, clean

185’s, JD diesels

CALL

(12) Allmand Light Plants, 2008-2010, diesel, s/a towtype, (4) MH lights, excellent

Cat 336EL, 2012, 33.5” TBG pads, Q/C, aux hyd, 6,700 HMR, work ready

$162,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5R25, A/C, P/S trans, 26 cy, working everyday on jobsites

$89,000

$224,500

Cat 336FL, 2015, 33.5” TBG Pads, Q/C, aux hyd, 4,300 HMR, work ready

Komatsu PC220LC-8 Longreach, 2011, Young Boom/Stick 60’ reach, 3,500 HMR

Volvo A30C, 1996, 30 tons, 11,000 hrs, 296 hp, 6WD, 23.5R25, 21 cy cap, A/C, P/S trans, works everyday

$179,000

$122,500

$72,500

Kobelco SK210LC, 2007, Q/C, aux hyd, 31.5” TBG Pads, 3,900 HMR

Cat D5NXL, 2006, 10’ PAT Blade, Paccar PA55 winch, 22” Pads, 4,100 HMR

$82,000

$49,500

Cat 613C Water Wagon, 1994, 5000 gal drop tank, ROPS, spray heads

Cat 621F, 1996, Scraper, OROPS, 33.25x2, very good condition

CALL

Cat 621E, 1989, Scraper, OROPS, 33.25x29, very nice CALL

CALL

Cat D6NLGP, 2008, VPAT Blade, Drawbar, 33” Pads, 9,900 HMR

$87,500

Cat D6NLGP, 2014, Foldable VPAT Blade, Paccar PA55 winch, 7,200 HMR

$142,500

100 Excavator, Loader, Specialized & Grapple Buckets in Stock -Call For Your Needs FORKS (8) IT28F/G Forks, Balderson qc, 48"-60" pallet style, excellent

$229,500

Komatsu D155AX-6, 2007, Sigma S-U Blade, 4-bbl Single Shank Ripper, 8,400 HMR

Cat D6TXW, 2013, 13’6” VPAT Blade, Carco 70APS winch, 28” pads, 7,300 HMR

Tiger Mowers announced that Stephenson Equipment is expanding into Maryland and Virginia. With its strong track record, Tiger looks forward to a lasting partnership that will support both its existing

customers and new clients in these regions.

As an authorized Tiger dealer, Stephenson Equipment will play a key role in bringing Tiger Mowers’ products and services to a broader audience, strengthen-

Tiger Mowers photo Stephenson Equipment will play a key role in bringing Tiger Mowers’ products and services to a broader audience.

ing our presence in the Mid-Atlantic. Its expertise and dedication will be invaluable in driving success and growth in these markets.

Tiger Mowers photo Tiger Mowers announced that Stephenson Equipment is expanding into Maryland and Virginia.

With the expanded territory, customers in Maryland and Virginia can expect the same mowers and service that have made them a trusted name in the industry.

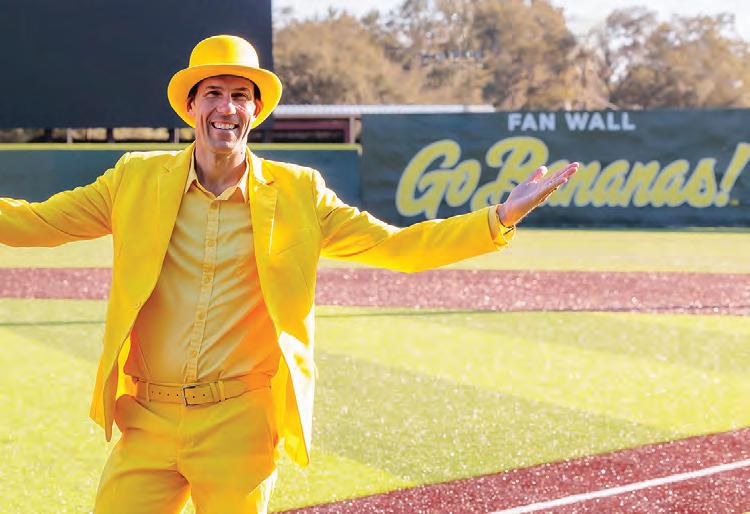

Marketing challenges face every business owner, and Equip Exposition attendees will learn from one of the most well-known marketers and entrepreneurs in the United States: Savannah Bananas founder Jesse Cole.

Founder of the popular baseball team, Cole will deliver the keynote address, sponsored by Kress, at the blockbuster trade show for landscapers, dealers, contractors, hardscape experts and outdoor power equipment manufacturers. The trade show drew 28,500 attendees last year.

Known for his banana yellow suit and marketing ideas, Cole will share what it takes to develop a great idea into a brand that people embrace and love. His story will delve into marketing brands and how to keep creativity flowing.

Those are lessons smart industry business owners are seeking to learn.

“There’s just so much to learn from being around a group of growth-minded people who are really, truly just trying to better themselves and their businesses,” said Mark Bradley of LMN and TBG Landscape, when asked what draws him to Equip Exposition.

Ideas from Cole will likely be hot discussion points for the trade show’s legendary networking opportunities, which span a wel-

come reception at Churchill Downs where a new signature bourbon will debut this year, two concerts, a women’s leadership reception sponsored by Belgard, Hunter Industries and SiteOne and more peer-to-peer activities.

exclusive concert for show attendees at the Kentucky International Convention Center

the Thursday night of the show. The concert is included with the registration to Equip Exposition.

“We offer a number of social opportunities at Equip but they’re created with purpose,” said Kris Kiser, president and CEO of the Outdoor Power Equipment Institute (OPEI), an international trade association representing manufacturers and suppliers of power equipment, small engines, battery power systems, portable generators, utility and personal transport vehicles and golf cars, which owns and manages the blockbuster show. “Unlike any other time of year, peers can talk with one another, get to know each other, at the show. It’s especially a great opportunity for team building.”

With more than 1.2 million sq. ft. of indoor and outdoor exhibit space, Equip Exposition is a “must see” for dozens of reasons, including the 30-acre Outdoor Demo Yard, networking events, education and technical training in English and Spanish.

“Anything that has anything to do with marketing, it’s here,” said Keith Kalfas, a leading lawncare podcaster. If you’ve never been to the [Equip] Expo, you have to come at least once. Be committed, because once you get here, you’re going to be like, whoa!”

You call Milton CAT when you need to rent a generator:

• Availability. Even when everyone else needs a generator, you’ll get yours.

• Product quality. All EPA-certified, clean, well-serviced gensets.

• Complete range. From 20 to 2,000 kW; Diesel and gas; portable and Tier IV models.

• All the ancillaries.

• Expert support; 7/24 service.

• Priced to fit your budget.

West Virginia’s Mon Health System, a member of the regional Vandalia Health network, has begun construction on its latest small-format hospital in Bridgeport, similar to the Mon Marion Neighborhood Hospital to the north in the Marion County town of White Hall.

David Goldberg, president of Mon Health and CEO and executive vice president of Vandalia Health, told West Virginia MetroNews that the long-awaited $26.4 million Mon Harrison Neighborhood Hospital within Bridgeport’s rapidly developing Charles Pointe Crossing is modeled after his company’s successful White Hall facility, which has been in operation for about three years.

The new northern West Virginia hospital will be on a parcel of land just past the Menards store in Bridgeport. It will be a two-story, 40,000-sq.-ft. small format hospital.

“There have been 15,000 emergency

room visits [to the White Hall facility] over the past year,” Goldberg said. “We just got a report that there have been more than 1,200 days since we’ve had any kind of hospitalacquired infection, and we’re in the top 10th

25E009 – 2012 CAT 321DLCR, EROPS W/AC, 9’.6” STICK, AUX. HYDRAULICS, HYD. Q/C, 31” SHOES................................................$89,000

24E041 – 2012 CAT 321DLCR, EROPS W/AC, 9’.6” STICK, AUX. HYDRAULICS, HYD. Q/C, 50” BUCKET, 31” SHOES............................$73,000

24E009 – 2018 CAT 320, EROPS W/AC, REVERSE/SIDE CAMERA, 9’.6” STICK, AUX. HYDS, QC, 48” BUCKET, GRADE CONTROL, 31” SHOES............. $109,000

22E056 – 2007 CAT M318D, EROPS W/AC, 9’.6” STICK, AUX. HYD, HYD Q/C, 36” BUCKET, FRONT AND REAR STABILIZERS, RIDE CONTROL, 10.00X20 TIRES..................................................................................$60,500

24E012 – 2017 CATERPILLAR 315FL, EROPS, W/AC, REVERSE CAMERA, 9’.10” STICK, AUX. HYDRAULICS, TWIST WRIST, 36” BUCKET, 20” SHOES W/RUBBER PADS................................................................................$95,000

25E010 – 2013 CAT 308ECR, EROPS W/AC, 7’.7” PUSH BLADE, 7’.4” STICK, AUX HYDRAULICS, 30” BUCKET, 18” SHOES W/RUBBER PAD INSERTS....... $60,000

24E028 – 2015 CAT 308E2CR, EROPS W/AC, REVERSE CAMERA, 7’.7” PUSH BLADE, 7’.3” STICK, AUX HYDRAULICS, Q/C, 36” BUCKET, RUBBER TRACKS..............................................................................................

percentile in the country related to patient experience.”

A combination of inflation and construction circumstances has pushed the cost of the Bridgeport-Harrison County hospital higher than the White Hall-Marion County facility, built for a little more than $20 million.

In White Hall, the project started in an existing structure, while the newest Bridgeport is starting from scratch, MetroNews reported April 5, 2025.

“We bought a building in [White Hall’s] Middletown Commons area that was already four-walls established,” said Goldberg. “We didn’t have to rebuild the outside structure there, so [the new Bridgeport hospital] will be a little more expensive.”

The recent filing of the facility’s building permit with the city of Bridgeport marked a key milestone in a process that began in July 2022, when Mon Health System filed for a certificate of need for the structure.

According to Mon Health, the path to construction included extensive collaboration with Charles Pointe’s developers, Genesis Partners, as well as the city of Bridgeport, the Harrison County Commission and stakeholders within the county’s tax increment financing (TIF) district.

The new hospital’s construction is anticipated to take just over a year, with architectural and engineering work already complete, Mon Health noted.

The first floor of the new Mon Harrison Neighborhood Hospital will include an

emergency room with eight beds, board-certified physicians and comprehensive inpatient care, including 10 private inpatient rooms. The second floor will be constructed as shell space reserved for future clinical or administrative expansion, designed to address future needs of the community.

“We have a lab on site, a pharmacy on site for patient use and we have full radiology — MRI, CT, X-ray, ultrasound and echocardiogram,” Goldberg said.

In addition, patients will have access to telehealth at the facility and all specialty care and services offered across the Mon Health System.

History has proven that the small-format model used at the older Mon Marion Neighborhood Hospital can offer the same type of care offered at larger hospitals..

“We now do infusions — not chemotherapy — for those who are on an infusion treatment … at the Mon Marion Neighborhood Hospital and that will come to the [new facility],” said Goldberg.

Available services always are being evaluated, he said, and changes are focused on improving convenience and the patient experience. Those evaluations are done across the entire system by studying actual patient experiences and input from staff.

“We look at the data on why people leave one community and come to Mon Health Medical Center,” Goldberg said. We see why they’re leaving and for what care and then we offer that in the community close to home. We’ve been doing that since I got here, and we’ll continue to do that.”

“Vandalia Health Mon Marion Neighborhood Hospital has become a model for delivering advanced medical services in a smaller, more accessible footprint,” said Christopher Edwards, DO and director of emergency services for both Vandalia Health and Mon Health. “We’ve exceeded expectations in patient satisfaction, speed of care and operational efficiency and [are] recognized as having one of the shortest emergency room visit times in the nation.

“Our hospital’s success has proven that neighborhood hospitals can offer the same quality of care as larger institutions — just closer to home,” he said. “We’re extremely excited to bring this quality, convenient care to the people of Harrison County and surrounding communities with the construction of Vandalia Health Mon Harrison Neighborhood Hospital.”

CAREERS from page 1

significant roles while creating a pipeline for the industry’s next generation of qualified technicians.

The Foundation believes this project will help close in on its mission to address professional education and workforce development. At the same time, Vision 2025 will bring more awareness to the benefits available for the equipment industry.

The Foundation is “challenging AED members to help create a strong and robust pipeline of skilled workers within the next four years.”

Launched in 2020, Vision has three areas of focus: schools with equipment technology programs, students within these programs and AED dealer members. The goal by 2027: 120 accredited college programs, 200 recognized high schools, 10,000 skilled technicians and 5,000 Foundation-certified technicians.

The initiative was conceived in 2019 after a Foundation study showed the industry would need to recruit 73,000 technicians over five years to meet demand.

“We had done a study with the college of William and Mary,” said Brian P. McGuire, Foundation president.

Job vacancies already were open twice the average length of time because the industry couldn’t draw people who were qualified, he said.

So, the Foundation board decided to call attention to the current situation and estab-

lish the tools to solve the problem for the future.

“The situation didn’t happen overnight, and it wouldn’t solve itself overnight,” said McGuire.

The Foundation determined the best course of action would be to start at the highschool level, to get younger students exposed to tech careers early.

“We have to let them see there’s a viable career path,” said McGuire.

Many of AED’s member dealerships are

owned by people who came up as technicians, he added. Several CEOs of dealerships stated off as techs.

“Some go into sales from training as technicians. You can have a great career as a technician, but it’s also an on ramp to other areas of the business.”

The Foundation saw the need to help high-school students and their parents understand that these have the potential to be “sixfigure careers,” he said.

It required conveying to parents, students and educators that ‘you can go into this career path and your employer will pay for your training, so you have no debt.’

Tim Watters, president of Hoffman Equipment, based in Piscataway, N.J., also sees a career in equipment technology can be a draw. He said the need for qualified technicians is huge.

“And it’s going to get exponentially worse,” said Watters, AED Foundation chair. “I walk around our shop — we have 50 techs. So many of them are 50 years old plus, and a significant chunk are 60 years plus. Try to find a 30-year-old.”

There are a few, he said. “But there are so few it’s like gold to find someone who wants to work with their hands and be a technician.”

The industry, he said, needs to create a steady flow of kids interested in equipment technology careers.

“We need to implement learning opportunities in schools for students to come into the industry with a basic level of skills and confidence.”

The original goal back for the initiative in

2020 was to pledge $5 million by 2025. By 2022, it hit that number.

“So, our chair said let’s go to $10 million and go to 2027 with the overall goal to increase the number of accredited collages,” said McGuire.

At the same time, the Foundation would restart its high-school recognition program, which had gone dormant from its height of activity in the 1990s.

The initiative also set out to certify 5,000 technicians through the Foundation’s certification program.

“And to have 10,000 folks we could point to and say, ‘they’ve come into the workforce because of this initiative,’” said McGuire. see CAREERS page 32

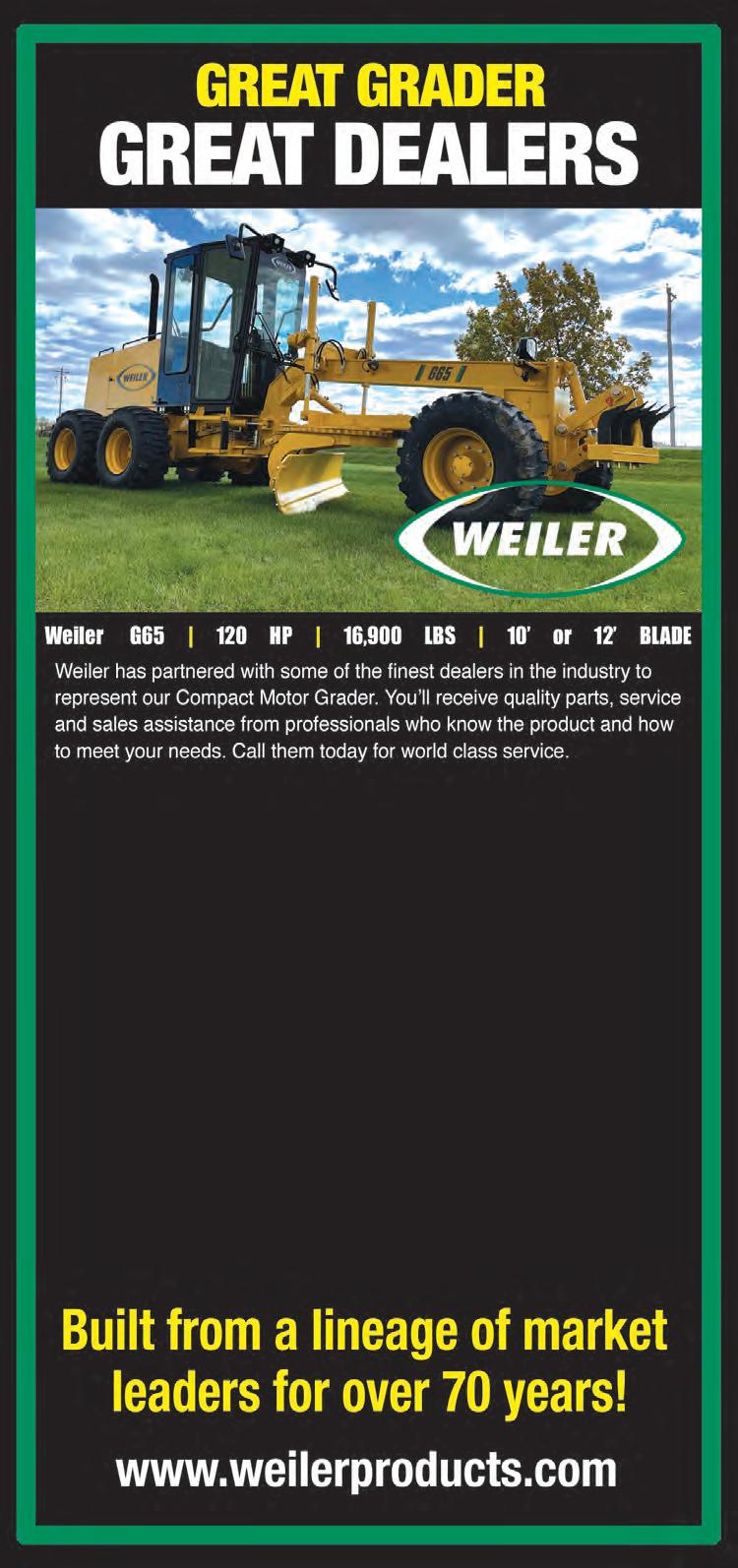

Ahearn Equipment

ahearnequipment.com

Hudson, NH 603-324-1164

A. Montano amontanoco.com

Saugerties, NY 845-247-0206

All Island Equip Corp allislandequipment.com

West Babylon, NY 631-643-2605

Butler Equip butlerequip.com

West Hartford, CT 860-233-5439

George & Swede georgeandswede.co

Pavillion, NY 585-584-3425

Heavy Equip Loaders and Parts heavyequipmentloaders.com Lebanon, PA 717-277-7686

Kahn Tractor & Equip Inc. kahntractor.com N Franklin, CT 860-642-7596

Lorusso Heavy Equip, LLC lhequip.com Walpole, MA 508-660-7600

Modern Group Ltd.

moderngroup.com

Allentown, PA 800-459-4659

Bristol, PA 800-866-3376

Edison, NJ 800-866-3376

Hasbrouck Heights, NJ 201-288-1441

Newlons International newlonsinternational.com Elkins, WV 304-636-4561

Pete’s Equip Sales & Rentals Inc. petesequipmentvt.com Morrisville, VT 802-888-5138

Pro Power Equipment, Inc. *Compact Equipment Only propowerequipinc.com Mount Pleasant, PA 724-542-7368

Quality Fleet Service, Inc. qualityfleetservice.com South Hadley, MA 413-213-0632

Seaview Equipment seaviewequipment.com

Bridgeport, CT 203-330-0130

TB Equip & Rental tbequipment.net

Bangor, ME 207-262-0014

Tracey Road Equip, Inc. traceyroad.com

Albany, NY 518-438-1100

Binghamton, NY 607-775-5010

Marcy (Utica), NY 315-765-8746

Queensbury, NY 518-793-9688

Syracuse, NY 315-437-1471

Watertown, NY 315-788-0200

Dubois, PA 814-371-3600

Erie, PA 800-872-2390

Wilkes-Barre, PA 570-410-2123

Zelienople (Pittsburgh), PA 800-872-2390

Whited Equipment whitedtruck.com

Auburn, ME 207-786-3673

Presque Isle, ME 207-764-7300

Saco, ME 207-391-6250

MAKE YOUR MOVE

Push

... more material with the new Hyundai HD100 crawler dozer's best-inclass power-to-weight ratio.

See ...more than ever with the unobstructed view to the blade.

Engage

...more accurately and more productively with standard 2D or optional 3D machine guidance.

Doze

...with confidence, knowing your new 115 hp Hyundai crawler dozer delivers the quality and value you expect from Hyundai, with the peace of mind that comes with our industry-leading warranty.

No wonder so many first-time Hyundai users become longtime fans. See the Hyundai difference yourself at your local dealer, na.hd-hyundaice.com.

CAREERS from page 28

The Foundation currently recognizes 94 accredited colleges, which puts the initiative at 78 percent of its goal. There are 102 recognized high-school programs.

“Our goal was to build a high-school feeder program into accredited colleges,” said McGuire. “We’re at 52 percent of our goal with high-schools and 88 percent of our goal of certified technicians with just under 4,500. So, we will exceed that goal.”

Just under 6,000 technicians have entered the workforce because of the effort, he said.

“The exciting thing is — and the figures change weekly — we’re at just over $8.5 million pledged and we’ve collected $6 million,” he said.

Vision 2025 is “a little different” from most campaigns in that this money is being collected to spend.

“We are putting $5 million in a Foundation endowment to continue these efforts after pledging,” said McGuire. “We have brought on five staff to make sure we’re hitting what we need to keep donors satisfied.”

A workforce coordinator connects the dots between dealers, OEMs and educational institutions.

“They make stuff happen,” said McGuire. “We’d go and have a workforce meeting with a couple dealers, a community college and a local politician to talk about the needs of our industry. Everybody would say ‘we should start a program.’ We’d get back on the plane and nothing would happen short of the politician issuing a press release.”

“The workforce development position is geared to make sure things happen,” added McGuire. “We have dealers on school advisory committees.”

Dealer internship programs are in place as well. And the Foundation has arranged career days where students learn about careers in the equipment industry.

In some cases, hundreds of students attend a single day event.

“In Ohio, just under 500 students came through,” said McGuire. “In Illinois last fall, over 500 kids were there. Some rode the bus for an hour to get there.”

The events include mock interviews as well as equipment demonstrations where the students “get to do a little digging,” he said.

Watters said the biggest challenge for Vision 2025 is getting more of the industry to pledge to help reach the initiative’s goals.

“There are 1,000 member dealers, another 200 member manufacturers, another 200 associate dealers,” he said. “We’ve reached $8 million, but if you count the number of donors that’s about 15 percent of our membership.”

Overall, said McGuire, Vision 2025 has been very embraced by AED Foundation membership.

“These dollar numbers come from 95 unique contributors. They are a mix of service providers, dealers and OEMs that have come to support Vision 2025.

The Foundation is not seeking deeper pockets, but broader participation from membership, Watters said. “And it doesn’t have to be a lot.”

He admits all these efforts are a drop in the bucket of workforce needs in the equipment technology sector. But it’s a place to start, he said.

“The Foundation board knows that 5,000 techs and 10,000 workforce entries doesn’t add up to what’s needed,” he said. “But it’s getting accrediting programs online and filling them as a start to address the problem.”

And though a lot of people in the industry recognized the problem and were working before, it was not the coordinated effort Vision 2025 is shaping up to be.

“The Foundation board was direct in saying ‘Vision 2025 is not a replacement for all the things you should be doing,’” said McGuire. “You should be recruiting locally. You have to continue doing the things you’ve been doing. But this is an overlay.”

Both McGuire and Watters believe this effort is valuable not just for distributors, but for the entire heavy equipment industry.

“Manufacturers need distributors to have a solid gold, youthful workforce for technicians into the future to repair their machines,” said Watters. “The skills needed today are different than they were 20 years ago. Today, technicians must be digitally and software confident.”

The industry needs to change the image of what a mechanic looks like, he added, comparing the machine technician’s job to that of a lab technician.

“You’re dealing with software codes and [and understanding of] what the computer is telling you,” said Watters.

He believes young people need permission to bypass college for a trade career, and preferably one in equipment technology.

“We — all distributors and manufacturers — need to change the perception of what a mechanic does in our industry and the need for college in general.”

Both Watters and McGuire believe the initiative’s goal is achievable in the time period the Foundation set.

“We sailed through our original goal,” said Watters. “Now, we’re so close, we’re in that final lap. We just need to get more support.”

McGuire said the need never stops. “When we’re no longer begging for techs to join the workforce, it’ll be mission accomplished.”

So, McGuire’s question is simple: “If you’re in the equipment industry and you haven’t supported the program, why not?

He stressed there’s only one foundation working on this issue specifically for the equipment technology industry.

“You can give money to a lot of causes. But one that’s actually working for the benefit of your industry — I’ve got to believe there’s room for that.” CEG

Caterpillar 528 Log Skidder, 1:50 scale - $110 Caterpillar D8N Track-Type Tractor, 1:50 scale - $110

Allis Chalmers Forty-Five Motor Grader,1:50 scale................................$80

Allis Chalmers TS300 Motor Scraper, 1:50 scale..................................$80

Bantam Lattice Truck Crane on White WC Carrier,1:50 scale..............$160

Bucyrus Erie 22B Dragline,1:50 scale....................................................$295

Bucyrus Erie 22B Cable Shovel,1:50 scale............................................$215

Bucyrus Erie 22B Cable Backhoe,1:50 scale..........................................$215

Case 580D Backhoe/Loader, 1:35 scale................................................$100

Case 580E Backhoe/Loader,1:35 scale....................................................$65

Case 580SR Backhoe/Loader,1:50 scale................................................$150

Case 850B Angle/Tilt Dozer,1:35 scale..................................................$100

Case 1845B Uni-Loader,1:35 scale..........................................................$35

Case DH4B Trencher,1:35 scale..............................................................$75

Case 9030B Excavator,1:50 scale............................................................$50

Caterpillar AP-1000 Asphalt Paver,1:50 scale......................................$100

Caterpillar C-591 Pipelayer,1:70 scale....................................................$70

Caterpillar CB534 Double Drum Roller, 1:50 scale................................$40

Caterpillar D3 Track-Type Tractor,1:50 scale........................................$110

Caterpillar D4E Track-Type Tractor, new color,1:50 scale......................$60

Caterpillar D4E Track-Type Tractor, old color,1:50 scale......................$60

Caterpillar D6H Track-Type Tractor,1:50 scale........................................$90

Caterpillar D9N Track-Type Tractor w/black Tracks,1:50 scale............$100

Caterpillar D9N Track-Type Tractor w/yellow Tracks,1:50 scale..........$100

Caterpillar D8L Track-Type Tractor,1:50 scale......................................$100

Caterpillar D7C Track-Type Tractor,1:50 scale......................................$110

Caterpillar D10 Track-Type Tractor w/ ripper,1:50 scale......................$100

Caterpillar D10N Track-Type Tractor,1:50 scale......................................$40

Caterpillar D11R Track-Type Tractor,1:50 scale......................................$75

Caterpillar 225 Excavator,1;70 scale........................................................$45

Caterpillar 225 Crane w/clamshell

Caterpillar 555D Log Skidder,1:50 scale..............................................

Caterpillar 631 Tilting Dumper,1:70

Caterpillar 773B Off-Highway Truck, 1:70 scale

825B

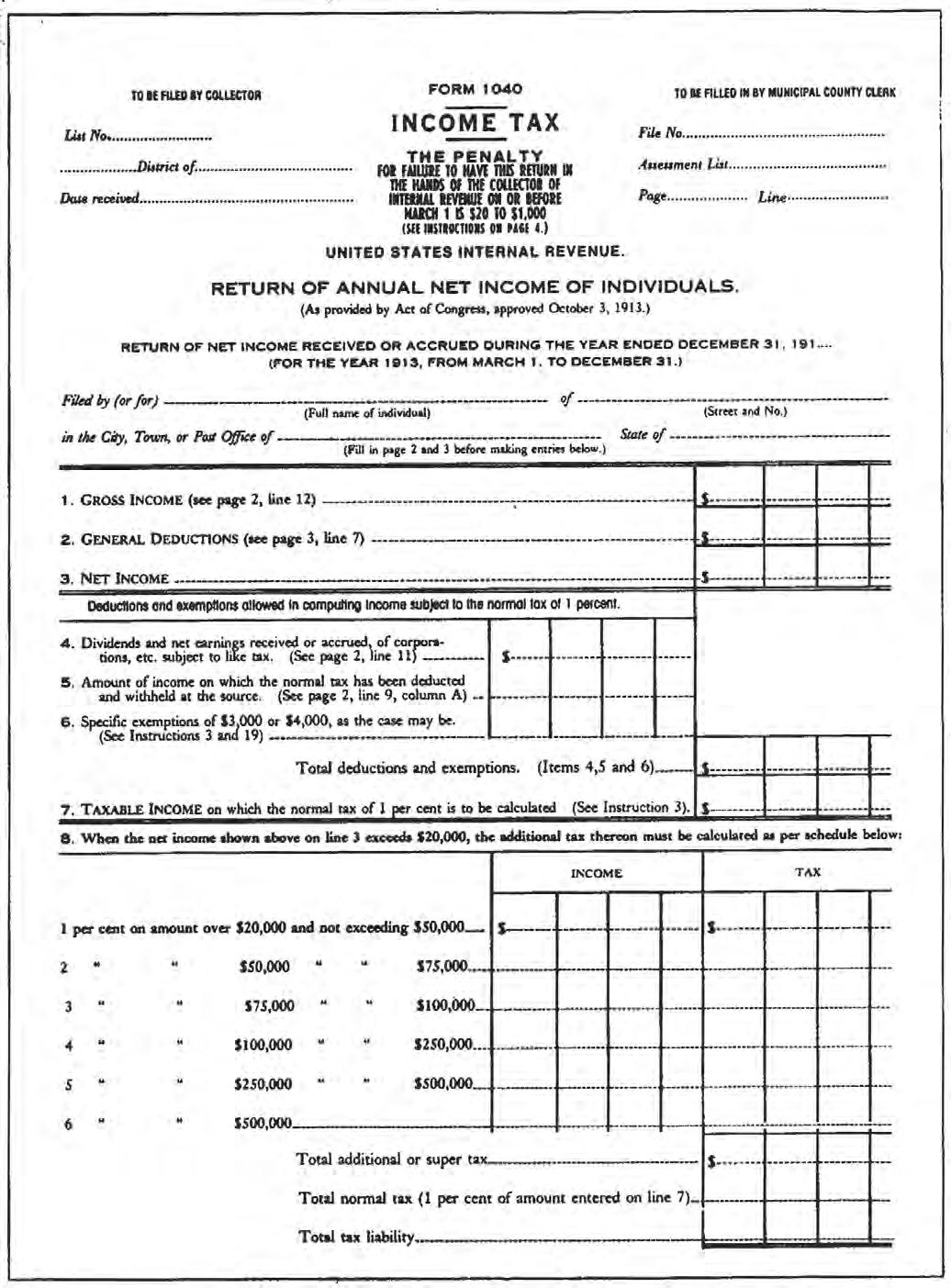

Many of you may have already filed your federal taxes while some of you may have requested an extension. Either way, we thought we’d share with you a federal tax form from 1913. A lot of things were certainly harder more than 100 years ago, but not taxes.

complete and is slated to be finished before the 2026 NFL season.

The joint venture team of Gilbane | Turner, along with 34 Group and Arc Building Partners, was chosen by Bills officials to provide construction management services for the new stadium. The full project team also includes Legends Project Development, the site management firm and Populous, the designer.

As envisioned, the completed project will include a 1.35-million-sq.-ft. open-air football stadium, an 18,750-sq.-ft. ancillary building, demolition of the current stadium just across the street and related site development.

The new venue’s capacity will have a minimum of 60,000 seats with an expandable capacity to hold special events. Premium areas will include suites, ledge seats, clubs and other choice seating options.

It also will have state-of-the-art video and scoreboards, a modern sound system, administrative and event staff offices and lockers, broadcast facilities, a Bills team store, locker rooms, food service kitchens and concessions, signage, sports lighting and maintenance, in addition to storage areas, a plaza, parking and site landscaping.

The April 4 event commemorated what Hochul called “the tremendous efforts of construction professionals” — both men and women of organized labor — to maintain safe and on-time construction.

“Today marks a major milestone for the future home of the Buffalo Bills and one of the largest construction projects ever in Western New York,” she said. “This worldclass stadium would not be possible without our skilled union workers and partners and I look forward to cheering along with them at the first Bills game being played here in the 2026 season.”

Terry Pegula, the pro football team’s owner, echoed the governor’s comments when he said, “Today is about you hard workers. We’re going to put this piece of steel up. We’re calling this the topping-off ceremony; I call it the first piece of building the rest of the stadium.”

With more than 1,400 guests and hundreds of members of organized labor in attendance, one of the super cranes on site was used to erect the highest beam 156 ft. in the air.

The final beam was adorned with an American flag and an evergreen tree, standing as a talisman for good luck and prosperity for the future occupants of the building. It bears the signature of hundreds of partners,

contributed more than 1.7 million crafthours to construction, with that number expected to double by completion.

“We’re incredibly proud to reach this major milestone in the construction of the new Highmark Stadium,” noted John LaRow, the principal-in-charge of Gilbane | Turner. “This achievement is testament to the hard work of our skilled trade partners who have worked over 1.8 million hours to date building this state-of-the-art facility.”

Gary LaBarbera, president of the New York State Building and Construction Trades Council, also was among those who spoke at the stadium’s ceremonial topping out.

He characterized the stadium’s latest milestone “as a testament to the positive impacts development done under project labor agreements and with prevailing wage measures can have on our local communities and collective state economy.”

“The construction of this new home for the Buffalo Bills is generating thousands of family-sustaining careers, adding economic stimulus to our neighborhood and providing hard-working people in the Western New York region accessible pathways to the middle class,” said LaBarbera.

With the topping out ceremony now complete, construction is continuing on the interior of the building, as well as the roof and exterior enclosure. Gilbane/Turner is putting the canopy structure on the stadium’s highest level, which tops out at 116 ft. above grade — nearly double the height of the current Highmark Stadium.

In addition, the joint venture is installing precast materials, which will make up the exoskeleton of the building.

In spring 2025, the skin of the building will be installed using precast architectural, perforated metal and glass panels on the upper decks that capture outside views of Lake Erie and downtown Buffalo.

employees and stakeholders who are contributing to the development of the new stadium.

“When you stand next to this future home of the Buffalo Bills, you realize how big this stadium is, not just in size, but in the economic impact to the community,” said Erie County Executive Mark Poloncarz. “With more than 1,000 highly paid construction workers building this stadium each day, this project is the biggest one in Erie County history and it is improving the lives of many.”

The topping out came just 20 months after the groundbreaking for the new, 60,000-seat facility.

To date, the construction team has put in place more than 22,000 individual pieces of

steel weighing more than 25,000 tons, Hochul’s office noted in a news release. The scope of work necessitated the participation of 16 fabrication companies, with 60 percent of the steel being produced in New York, and almost all of it manufactured in the United States.

In addition to the erection of its structural steel, the building project has included the removal of 742,000 cu. yds. of dirt and the installation of more than 46,000 cu. yds. of foundation concrete, as well as miles of piping.

Up to 1,500 workers will be on the site at the peak of construction — including those working on masonry, electrical and plumbing at the building site. Crews have already

The future world-class home of the Bills will host a variety of other sporting and nonsporting events and will feature an array of premium amenities every level of the building, including:

• A 360-degree canopy covering 65 percent of the seats;

• A heated concourse and seating areas in several areas;

• The world’s largest snow melt system, which uses roof sensors to monitor and liquify snow piles;

• An inviting welcome plaza highlighted by a sculpture of a family of American bison; and

• Accessibility for people with disabilities.

Officials in Hoboken, N.J. announced that the city’s new waterfront reconstruction project got under way April 7, 2025 to ensure the long-term safety, resilience and functionality of the critical infrastructure, while also laying the foundation for its planned redesign of Frank Sinatra Drive and the first phase of its new Maritime Park.

Hoboken’s initial first phase of the Hudson River Waterfront Reconstruction effort aims to rebuild and stabilize the eroding concrete seawall beneath portions of Sinatra Drive as well as the walkway stretching from the gazebo near Seventh Street to the skate park near Ninth Street.

The construction follows a thorough investigation triggered by a sinkhole near Sybil’s Cave in June 2024, according to the city of Hoboken.

Conducted by Holmdel, N.J.-based Colliers Engineering & Design, the study involved marine engineers, scuba divers, ground-penetrating radar and geotechnical borings to assess the seawall’s integrity.

The investigation revealed that the void beneath the seawall, measuring 11 ft. long, 20 in. high, and 48 in. deep, was caused by the loss of historic fill beneath the wall, which dates to the 1950s.

Designed to serve as the foundational first step for the broader Sinatra Drive Redesign Project, the reconstruction will incorporate Vision Zero upgrades, a two-way protected bikeway from Fourth Street to Sinatra Drive North, safer pedestrian crossings, the planting of 164 trees, lighting upgrades and additional onstreet parking.

N.J. photo

The 2024 sinkhole led to the discovery of significant erosion of the concrete seawall beneath portions of Sinatra Drive and the waterfront walkway.

The new seawall also will allow Phase I of Maritime Park to be built at the former Union Dry Dock site, which includes a new skatepark with both street and transition/bowl style features, a public plaza inspired by the nearby palisade cliffs overlooking the Hudson, a living shoreline to promote educational opportunities and restore natural habitats and a temporary learning nursery and tree staging area.

Hoboken’s Waterfront Reconstruction Project began with initial mobilization activities, which included staging equipment and removing surface features like benches and garbage cans.

Simpson & Brown Inc., a marine and civil construction company in Cranford, N.J., is the contractor on the waterfront project in Hoboken, located directly across the Hudson River from midtown Manhattan.

The firm started by demolishing the existing surface infrastructure, including the skate park, pavement, sidewalks, curbs, pavers and railings, to reveal the existing concrete seawall planks.

Over the next several months, the seawall will be reinforced with a combined pipe pile and steel sheet pile wall in critical areas, followed by the installation of new planking.

Simpson & Brown plans to use barges and tugboats to transport large equipment and materials to the site via the river to reduce traffic impacts and conduct in-water work related to the installation of the new seawall.

The work is scheduled to occur weekdays between 8 a.m. and 4 p.m., according to a city press release. To expedite construction, municipal officials plan to seek future Hoboken City Council approval for a waiver from the noise ordinance to extend those hours from 8 a.m. to 8 p.m., allow for work on Saturdays between the hours of 8 a.m. and 4 p.m., in addition to select federal holidays.

The rebuilding will further narrow the street, creating overcrowded conditions on the sidewalk during the summer months, which experience the highest volumes of pedestrian traffic. Vibrations from ongoing construction will also increase the risk of rocks falling from the adjacent cliffside. As a result, pedestrians will be directed to use Hudson Street as an alternative route.

This portion of the work is expected to be completed this fall, the city noted.

Additional project phases will include the waterfront near the former Monarch site at 15th Street and Shipyard Lane, the southern portion of Sinatra Park at the boat launch, and the walkway near the southern entrance to Pier C Park.

ROBERT H. FINKE AND SONS, INC.

Selkirk, NY 518-767-9331

Colchester, VT 802-316-3805

www.finkeequipment.com

TRACEY ROAD EQUIPMENT

East Syracuse, NY 315-437-1471

Kirkwood, NY 607-775-5010

Henrietta, NY 585-334-5120

Adams Center, NY 315-788-0200

Utica, NY 315-765-8746 • 800-872-2390 DuBois, PA 814-371-3600 Erie (McKean), PA 800-872-2390 COMING SOON! Pittsburgh (Zelienople), PA 800-872-2390

www.traceyroad.com

MARSHALL MACHINERY, INC. South Abington Twp., PA 570-489-3642 Tannersville, PA 570-895-4884

marshall-machinery.com

Milford, MA

508-634-3400

North Reading, MA

978-276-2400

Stoughton, MA

781-399-8580

In observance of National Safe Digging Month in April, Common Ground Alliance announced results from a recent national survey.

The survey found that 27.2 million Americans planning digging projects in the next year will not contact 811, putting themselves and their communities at risk of utility service disruptions, costly fines and repairs and even serious injury or death.

“As we work to unleash American energy, the Department of Transportation will continue to educate the public on free resources they can use to enhance safety,” said U.S. Secretary of Transportation Sean Duffy. “Whether you’re a homeowner planting a garden or a contractor breaking ground on a major project, we encourage you to contact 811 prior to any excavation activity to ensure a safe dig every time.”

everyone must contact 811 before every digging project — whether it’s installing a patio or major construction.”

Even common do-it-yourself projects — such as planting a garden, installing a mailbox or setting up a fence — can pose risks, as the depth of buried utilities can vary.

To keep homeowners, families and communities safe, a few days before breaking ground, make a free request to have the approximate location of underground lines marked with flags or paint by calling 811 or visit 811beforeyoudig.com. This National Safe Digging Month and all year long, take the following steps when planning a digging project:

• Always contact 811 a few days before digging, regardless of the depth or familiarity with the property;

MILTON CAT • www.miltoncat.com

Wareham, MA 508-291-1200

Brewer, ME 207-989-1890

Scarborough, ME

207-883-9586

Londonderry, NH 603-665-4500

Batavia, NY 585-815-6200

Binghamton, NY 607-772-6500

Clifton Park, NY 518-877-8000 N. Syracuse, NY 315-703-7000

Syracuse, NY 315-476-9981

Tonawanda, NY 716-799-1320

Cranston, RI 401-946-6350

Richmond, VT 802-434-4228

Digging without knowing the location of underground utilities can lead to serious injuries, service outages and expensive repairs. Accidentally striking gas, electric, communications, water or sewer lines can cause significant disruptions to homes and businesses. A free 811 request is available by calling 811 or submitting a ticket online. Your dig request ensures that underground utility lines are properly marked before digging, preventing accidents and keeping communities safe.