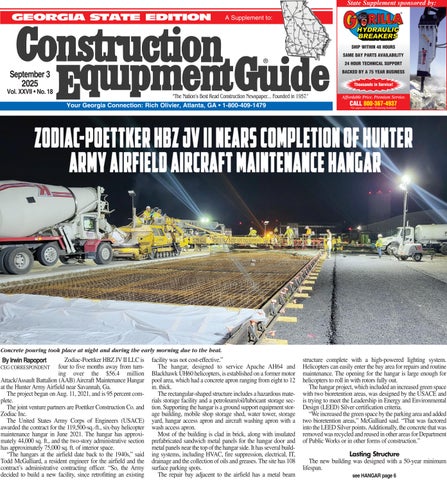

Zodiac-Poettker HBZ JV II LLC is four to five months away from turning over the $56.4 million Attack/Assault Battalion (AAB) Aircraft Maintenance Hangar at the Hunter Army Airfield near Savannah, Ga.

The project began on Aug. 11, 2021, and is 95 percent complete.

The joint venture partners are Poettker Construction Co. and Zodiac Inc.

The United States Army Corps of Engineers (USACE) awarded the contract for the 119,500-sq.-ft., six-bay helicopter maintenance hangar in June 2021. The hangar has approximately 44,000 sq. ft., and the two-story administrative section has approximately 75,000 sq. ft. of interior space.

“The hangars at the airfield date back to the 1940s,” said Todd McGalliard, a resident engineer for the airfield and the contract’s administrative contracting officer. “So, the Army decided to build a new facility, since retrofitting an existing

facility was not cost-effective.”

The hangar, designed to service Apache AH64 and Blackhawk UH60 helicopters, is established on a former motor pool area, which had a concrete apron ranging from eight to 12 in. thick.

The rectangular-shaped structure includes a hazardous materials storage facility and a petroleum/oil/lubricant storage section. Supporting the hangar is a ground support equipment storage building, mobile shop storage shed, water tower, storage yard, hangar access apron and aircraft washing apron with a wash access apron.

Most of the building is clad in brick, along with insulated prefabricated sandwich metal panels for the hangar door and metal panels near the top of the hangar side. It has several building systems, including HVAC, fire suppression, electrical, IT, drainage and the collection of oils and greases. The site has 108 surface parking spots.

The repair bay adjacent to the airfield has a metal beam

structure complete with a high-powered lighting system. Helicopters can easily enter the bay area for repairs and routine maintenance. The opening for the hangar is large enough for helicopters to roll in with rotors fully out.

The hangar project, which included an increased green space with two bioretention areas, was designed by the USACE and is trying to meet the Leadership in Energy and Environmental Design (LEED) Silver certification criteria.

“We increased the green space by the parking area and added two bioretention areas,” McGalliard said. “That was factored into the LEED Silver points. Additionally, the concrete that was removed was recycled and reused in other areas for Department of Public Works or in other forms of construction.”

Lasting Structure

Y COMFORT & EASE O ATTION

Your choice of a sealed or pressurized cab is equipped with system, adjustable wrist rests and a suspension seat to help comfortably all day long. Controls are easy to use, and the i monitor provides customizable machine operator preferenc information.

EXCLUSIVE STICK STEER TRAVEL MODE

Maneuvering on the jobsite is even easier with the Cat Stick traditional travel controls with levers and pedal to joystick c button.

BIG PERFORMANCE IN A MINI DESIGN

an improved air conditioning p keep you working ntuitive Next Generation es and easy to read machine

Increased lifting, swinging and travel and multi-functional pe k Steer option. Switch from controls with a push of a erformance help you get the

are just a few of the safety feature

SIMPLE SERVICE

Maintenance is quick and easy on access at ground level with group

OPERA

ATTING COSTS

with a variable displacement pum es built into the

the Cat 306 CR. Routine check poi ped service points and robust servic &

mp, the Cat 306 CR was designed to ints are easy to ce panels. reduce operating

blade, angle blade or Extra Tool C

Contact our dealership today t excavator in the market. arrier (XTC). to learn more about the newest 6-t

USACE’s Aircraft Maintenance Hangar Nears Completion

HANGAR from page 1

“We have seismic activity in this area,” said McGalliard, “but there was nothing out of the normal design and construction practices for this area. There were a lot of concrete blocks and a 48-in. concrete drainage structure that had to be rerouted around the building. The design challenges were more upfront, and it was planned for with the JV’s construction techniques and sequencing in mind.”

The USACE has Centers of Standardization to ensure installations meet common expectations in terms of capabilities, capacities and throughput.

“We incorporate lessons learned from past designs and ensure they are site adapted,” McGalliard said.

“This hangar was designed locally at the Savannah District Engineering Division. We incorporated some enhancements, such as the workstations, which have the ability to power the helicopters; a compressed air system; data cabling that allows for computer connectivity; the mechanical shops that incorporated a lot of ventilation and safety measures; as well as the installation of overhead cranes.”

Construction at an active airfield is never easy.

This has primarily been a daytime operation, with only concrete placement taking place at night and during the early morning, due to the usual heat.

Project Challenges

The concrete placement was challenging at times, since utility installation was a consideration.

“Concrete placement could be challenging, depending on where we were placing it,” said McGalliard. “Sometimes utilities were encased by concrete, and sometimes they were below the concrete footers. If the utilities are within the building, they could be under the slabs or through the footers and walls. Outside of the building, we try to avoid placing concrete over the utilities, but with concrete paving, utilities will sometimes be underneath, so we place clean outs where needed for access along with other measures.

“[The project] has some special requirements in paving, and the process was very technical and meticulous in its placement,” she said. “It is very different compared to a normal concrete footer or slab. … We have very high standards and detailed specifications that contractors must meet for testing, thickness, elevation and strength characteristics above and beyond normal foundation and slab concrete.”

Standard construction methods were followed.

“We had footers that had to be placed below grade,” said McGalliard, “and then we have the stem walls, slab, bearing walls, second-floor concrete deck and the load-bearing walls that are going up with the concrete tie-beams at the top of the masonry walls.”

For the concrete placement, Milestone Webber and AB Construction used a telebelt — a truck with a large boom that has a hopper where concrete mix trucks empty their load. From there, a conveyer fed from the hopper is placed in front of the triple-tube screed machine.

Following the motor pool removal, the JV focused on constructing the hangar building.

“All the utilities within the building are new,” said

McGalliard. “We tied into the water mains and then extended them. For power, there was a major feed line that had to be relocated from underneath the new building footprint. We also included a new transformer and a new natural gas line.”

Inside the building are water, sewer, a fire suppression system and a 200,000-gal. fire suppression holding tank, plus a foam fire suppression system.

The hangar bay is composed of a structural steel frame, while the administrative section is concrete masonry framed with a composite steel and concrete deck. The roof is a structural steel system.

The first step was to remove the concrete surface for the motor pool.

“The concrete removal went very well,” said McGalliard. “They used a guillotine-type concrete buster attached to the back of a large utility truck. It helped that the concrete had limited reinforcement, making it easier to break up. They set up a sorting/crushing plant to crush the concrete and graded it for different gradations and purposes. Any reinforcing material was separated and recycled.”

Excavation operations were minimal, as only footers and holding tanks were placed below grade.

Cranes were crucial for the building construction, particularly for the steel-setting elements.

“The highest point of the steel is 50 feet,” said McGalliard. “We had very large structural steel girders that spanned over 130 feet, and we used two cranes to set it.”

The cranes worked in tandem, with each lifting an end and setting it on the columns.

“This was done three times,” McGalliard said. “After that, another crane was used for setting the rest of the structural steel in the hangar. There wasn’t a lot of need for cranes on the administrative side.”

Punch List Phase

Aside from some minor construction work, the focus is on a long and detailed commissioning process to ensure the internal systems are working properly.

“For the hangar side, we’re finishing up the floors, and the doors still need some finish work,” McGalliard said. “We are down to the fine-tuning part of the project, making sure everything works the way it’s designed to, and the construction meets all the requirements.”

Construction materials include approximately 2,600 cu. yds. of structural concrete in the building footprint and 3,000 cu. yds. for airfield paving.

Typical days have 60-70 workers on site with high points of up to 120.

Subcontractors include Milestone Webber for concrete paving, AB Construction for concrete placements and Pyramid for the masonry, along with dozens of other subcontractors.

Equipment operators used several pieces, including a triple-tube roller screed, a telebelt, a rubber track placer, a motorized paving bridge for airfield paving and paving train, telehandlers, dozers and excavators.

The Attack/Assault

The hangar, designed to service Apache AH64 and Blackhawk UH60 helicopters, is established on a former motor pool area, which had a concrete apron ranging from 8- to 12-in. thick.

Construction crews are now tackling punch list items as the project nears completion. The hangar project dates to 2021.

Battalion (AAB) Aircraft Maintenance Hangar begins taking shape.