ALABAMA STATE EDITION A

Demolition of the 83-year-old bridge that carried Alabama Highway over Town Creek, north of the DeKalb County community of Geraldine, began July 30, 2025, after a more modern span across the deep ravine opened earlier in the month.

The newly-built structure provides motorists with a longer, wider and taller bridge that includes shoulders and corrects the steep vertical curves on both approaches to improve safety, the Alabama Department of Transportation (ALDOT) noted in a news release.

Once it was completed, crews shifted vehicle traffic to the new bridge, built by Miller and Miller General Contractors in Huntsville at a cost of $13.7 million.

When the work began in October 2023 to build the new structure, included among the contractor’s first tasks were boring and casting eight drilled shafts to form a stable foundation and installing 32 massive steel girders to support the bridge deck.

Phase I includes the new

courtyard areas that will connect the

engineering space to the

as well as

The final structural beam was placed on the University of North Alabama’s new football stadium at roughly the halfway point of its construction, the school announced July 31, 2025.

Representatives of HPM, a Birminghambased construction program management firm, joined university officials at the ceremony to top out Bank Independent Stadium, a $65 million multipurpose facility on UNA’s campus in the northwest Alabama town of Florence.

The project, which will be the university’s first dedicated stadium in its history, broke ground in June 2024 for an anticipated opening in the fall of 2026.

Bobby Wallace Field at Bank Independent Stadium will feature a three-level press tower with concessions, restrooms, suites, a club level and a “home tunnel” connecting the home locker room to the school’s adjacent CB&S Bank Arena.

The venue will redevelop the athletic complex that previously included the UNA turf practice surface, Mike D. Lane Field and a band practice field that incorporates the school’s football, baseball and soccer programs and marching band into the reimagined design.

In addition to athletic practices and sporting events, Bank Independent Stadium is designed to enrich Florence with concerts, live performances and other community events.

In a news release, the university noted that HPM is working closely with UNA to provide specialized services from pre-construction through completion, including oversight of budgeting, scheduling, design management, bidding and construction oversight.

The building project is split into multiple packages, which the school said required careful sequencing to ensure the practice field was completed before the stadium work began.

In addition, a mass excavation package included recessing the football field approximately 15 ft. below the existing grade. The excavated dirt was then used as fill material across the site for the future baseball field.

This design will provide 360-degree concourse access, allowing fans to circulate around the facility without the sta-

dium structure blocking their view, according to UNA.

As part of a separate package, HPM also will oversee the addition of a 2,760-sq.-ft. video board for the stadium to use during games and community events. It will soon be erected at the northeast end of the stadium, UNA said.

In its news release, the school said, “Today’s topping out is one of many milestones in the construction of Bank Independent Stadium that UNA and North Alabama Athletics will be celebrating. We continue to work closely with our partners at HPM to ensure [the project’s] timelines and [see that] each phase [is] on schedule. Our student-athletes, coaches and staff are eager to use this great facility to enjoy football, soccer and baseball games.”

The stadium construction represents the first partnership

between HPM and the UNA. Additional project partners include the general contractor, Decatur, Ala.-based Fite Building Co.; Davis Architects in Birmingham; and Ampere, a Missouri design firm specializing in sports venues.

“Bank Independent Stadium is a long-awaited project that the community has been excited about since its announcement, and HPM is proud to help bring the school’s dynamic vision to life along with our numerous design and construction partners,” said Matt Ernst, a senior project manager of HPM.

With a presence throughout the United States and a total management portfolio value of more than $1 billion annually, HPM has established itself as one of the industry’s leading program managers and owner’s representative companies.

The firm’s other notable projects at higher education institutions include several facilities at the University of Alabama in Tuscaloosa, including Bryant Denny Stadium, Sewell Thomas Stadium, Rhoades Softball Stadium, the Hank Crisp Indoor Practice Facility, Coleman Coliseum and the Mal M. Moore Athletic Facility.

Among its other projects in the state was the construction of the University of Alabama at Birmingham’s Protective Life Stadium. It also provided program management expertise for building Regions Field and renovating Legacy Arena, both of which are located in Birmingham.

The University of North Alabama is an accredited, comprehensive regional state university offering undergraduate, graduate and doctoral degree programs.

The school is nestled on a 130-acre campus in a residential section of Florence, situated not far from the north bank of the Tennessee River. UNA is located within a four-city area that also includes Muscle Shoals, Sheffield and Tuscumbia.

UNA Athletics, a renowned collegiate athletics program with seven Division II National Championships, is currently a member of NCAA Division I sports as part of the Atlantic Sun and United Athletic conferences.

BRIDGE from page 1

At 715-ft.-long, 38-ft.-6-in.-wide and 75ft.-high, the new bridge is substantially longer, wider and taller than the original span, first constructed in 1942.

On the first day of the older structure’s demolition, a concrete removal subcontractor began the process by cutting into the roadway bridge. It will be removed piece by piece so as to limit disturbing the creek below, according to ALDOT.

The state agency anticipates that its razing of the older structure and removal of the old bits of roadway on either side of it will be completed this fall, bringing an end to the Ala. 75 bridge replacement.

By Cindy Riley CEG CORRESPONDENT

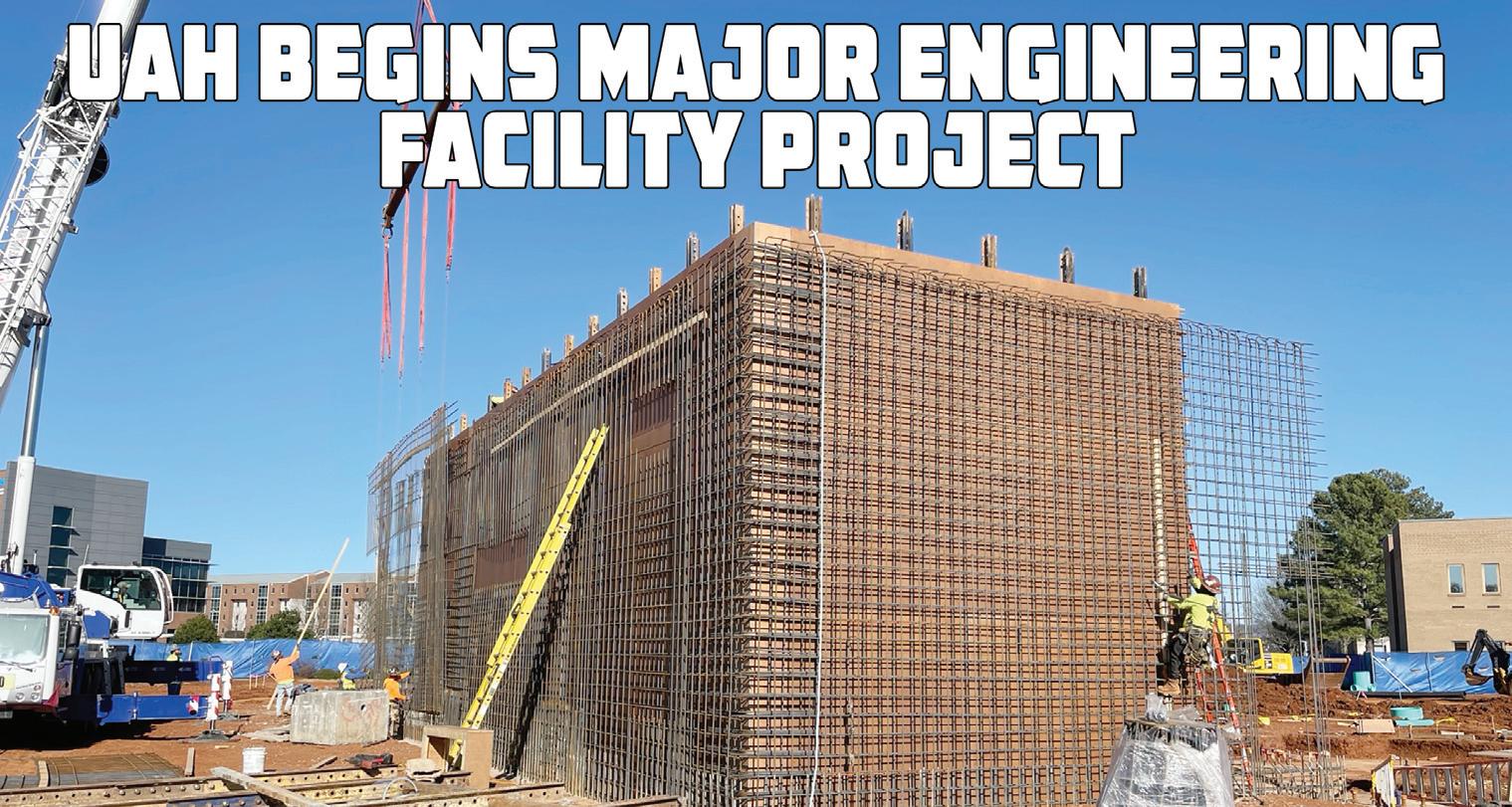

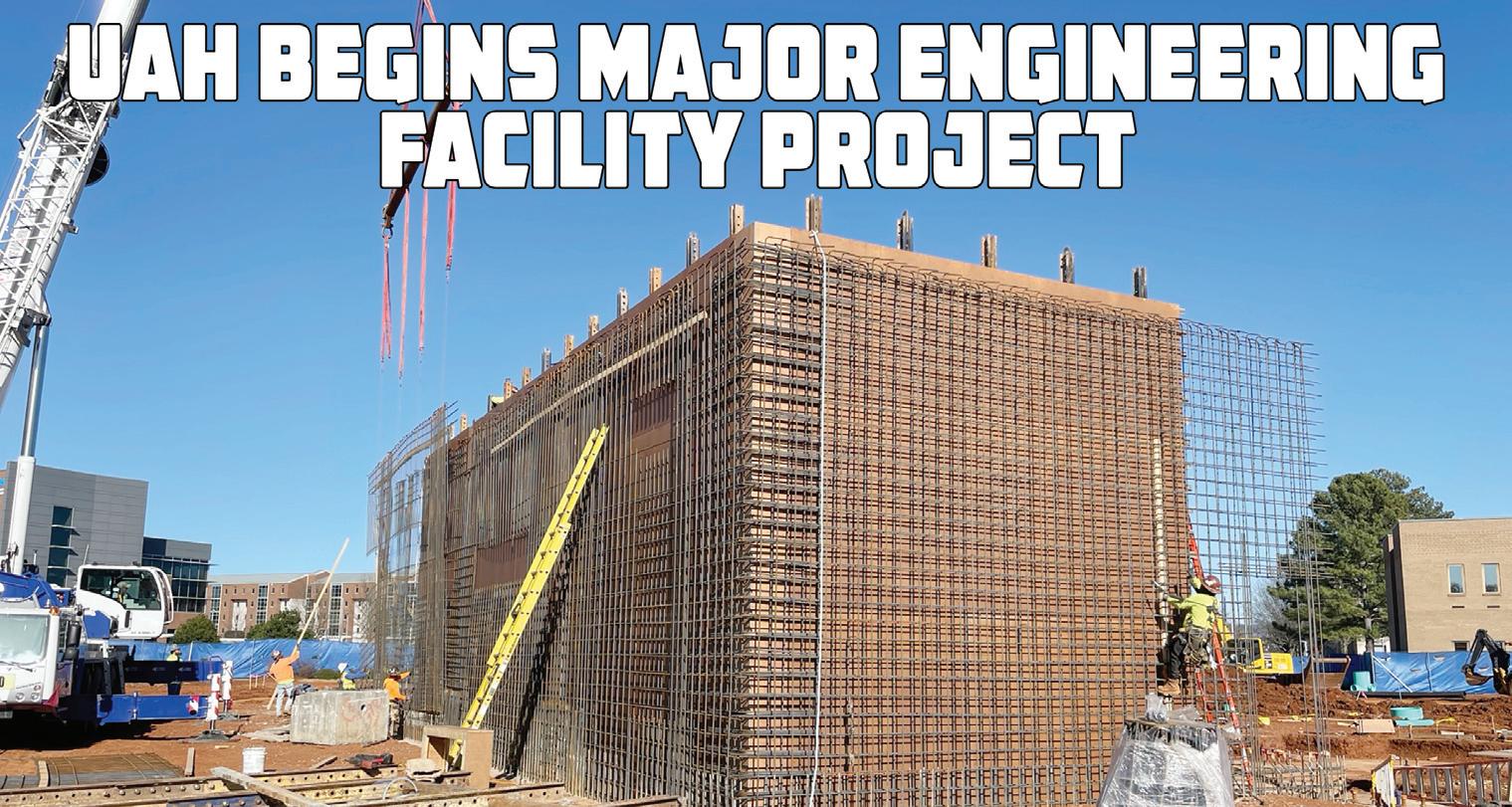

Although construction was delayed more than a year after the 2023 groundbreaking, a new facility at the University of Alabama in Huntsville (UAH) is finally rising from the ground.

When completed, the Raymond B. Jones Engineering Building will feature three levels of research labs, collaborative teaching spaces and flexible classrooms designed to promote innovation and experiential learning.

“UAH is a nationally recognized research institution committed to discovery, innovation and preparing graduates for leadership in high-demand fields,” said Christian Reed, UAH’s chief facilities officer and campus architect. “With a strong emphasis on hands-on learning and workforce readiness, UAH plays a critical role in supporting Redstone Arsenal, the Huntsville region and the broader state economy. This building directly supports this mission by expanding the university’s capacity to deliver cutting-edge education and research in its flagship engineering program.

“The facility will replace a decades-old facility with a modern, world-class space designed to support UAH’s largest college,” Reed added. “Designed to foster collaboration and innovation, the facility will enhance UAH’s ability to prepare students for careers in fast-growing technical areas such as unmanned aerial systems, big data, hypersonics and artificial intelligence.”

The 80,000-sq.-ft. structure, which will serve as a centerpiece for UAH, is located west of the existing engineering building, adjacent to the campus lake along John Wright Drive. The project is named in memory of Jones, a civic leader and past chairman of the UAH Foundation.

At a cost of $64 million, Phase I of construction is well under way, with completion anticipated in June 2026.

“This project has been years in the making, and the visible progress affirms the university’s commitment to advancing education, research and workforce development,” said Reed. “We are committed to driving forward the frontiers of engineering through research, exceptional education and industry collaboration. Our current facilities have served us well for 40 years.”

The new space will play a key role in preparing students for the STEM labor force.

“With modern labs and advanced technology, the building will give students real-world, hands-on experience in engineering disciplines,” said Reed. “It will also support faculty-led research in areas aligned with North Alabama’s booming tech sector, helping graduates transition directly into the workforce. The response from students and faculty has been enthusiastic and optimistic. They recognize the potential of this facility to elevate the learning environment and attract top talent, reinforcing UAH’s reputation as a premier research institution.”

Phase I includes the new building, courtyard areas that will connect the existing engineering space to the new structure, as well as various site improvements. Phase II will include renovating the existing facility.

MJ Harris Construction Services LLC serves as the general contractor. As with any campus construction project, working in an active university environment has presented challenges for crews on site.

“Often, this includes site logistics, campus interrup-

tions and academic schedule,” said Reed. “In addition, the construction site is adjacent to an existing facility that will remain in operation for the duration of construction.”

Reed added that when erecting a building that’s focused on engineering needs, it’s critical to design a space that provides flexible classrooms and specialized lab spaces with appropriate utilities.

“Structural systems must support heavy equipment and vibration-sensitive instruments often used in labs. Collaboration areas and durable finishes must be considered to support long-term student and faculty use.”

Most recently, workers have been erecting steel, which should be completed in August. Concrete floors have been poured in areas of all floors and will be completed in the near future. In areas where concrete floors are finished, subcontractors are working on interior framing and MEP rough-in. On the exterior, the contractor is working to install exterior sheathing and begin the waterproofing process.

The building has been categorized into pieces A and B. Foundations in both areas are complete. In area A, the steel superstructure and slab-on-grade are finished. The slab-on-metal deck has been completed in both areas. In area B, crews have wrapped up work on the concrete structure of the storm shelter.

Key items remaining include installing the roof and drying in the building, which will allow for interior finishes to progress. Glazing and curtain wall need to be addressed by workers, who must condition the space and complete interior tasks.

Demolition also was required on the project. It was, however, limited to site demo involving existing parking lots, roadway, landscape and storm water.

Sitework entailed balanced cut-and-fill, as well as importing fill from off site. Cut occurred on the south end of the building, while the north end required 8-10 ft. of fill to build up the building pad. In addition, there were a lot of underground utilities issues, including a significant amount of stormwater system work, which required excavation.

Approximately 12,000 cu. yds. of material have been moved on the project. This involved 2,150 cu. yds. of topsoil that was stripped, stockpiled and respread, 9,350 cu. yds. of imported fill from off site and 370 cu. yds. of fill that was on site balanced cut-and-fill.

A crawler crane with a lattice boom has been required for steel erection. Concrete pump trucks are being used for slab on grade pours and elevated slab on metal deck pours. Other heavy equipment includes lifts, excavators and backhoes. Concrete and steel are being used for the main structure, along with metal wall panels and curtain wall for the exterior.

Reed added it’s a privilege to contribute to a project that will shape the learning environment for the next generation of engineers.

“Knowing that the spaces we help bring to life, such as labs, classrooms and collaborative areas, will support innovation, discovery and leadership for decades to come is humbling and motivating. Projects like this aren’t just buildings, they’re investments in the future, and being part of that legacy is one of the most meaningful aspects of our work.” CEG

(All photos courtesy of UAH.)